ZnO ALD-Coated Microsphere-Based Sensors for Temperature Measurements

Abstract

1. Introduction

2. Materials and Methods

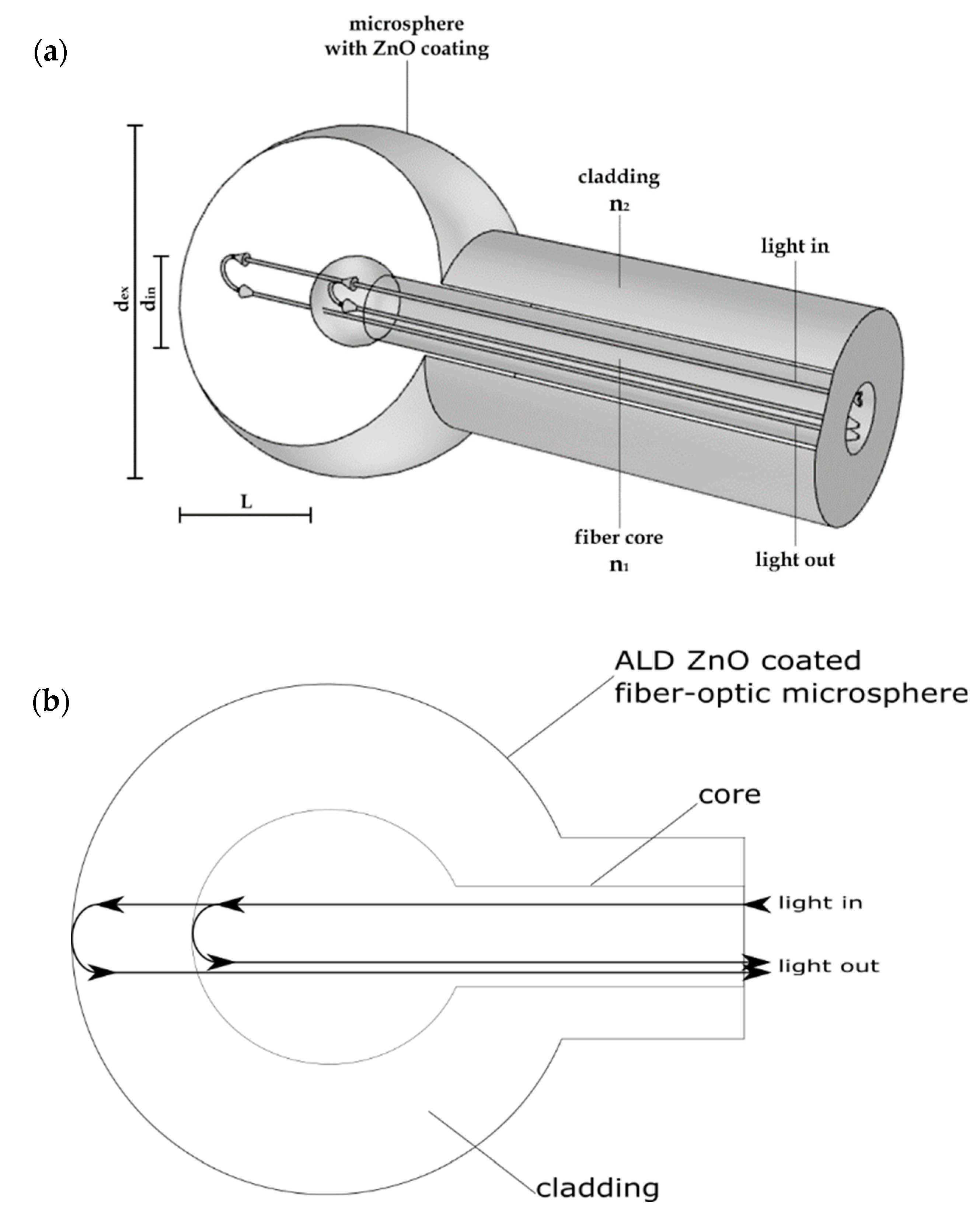

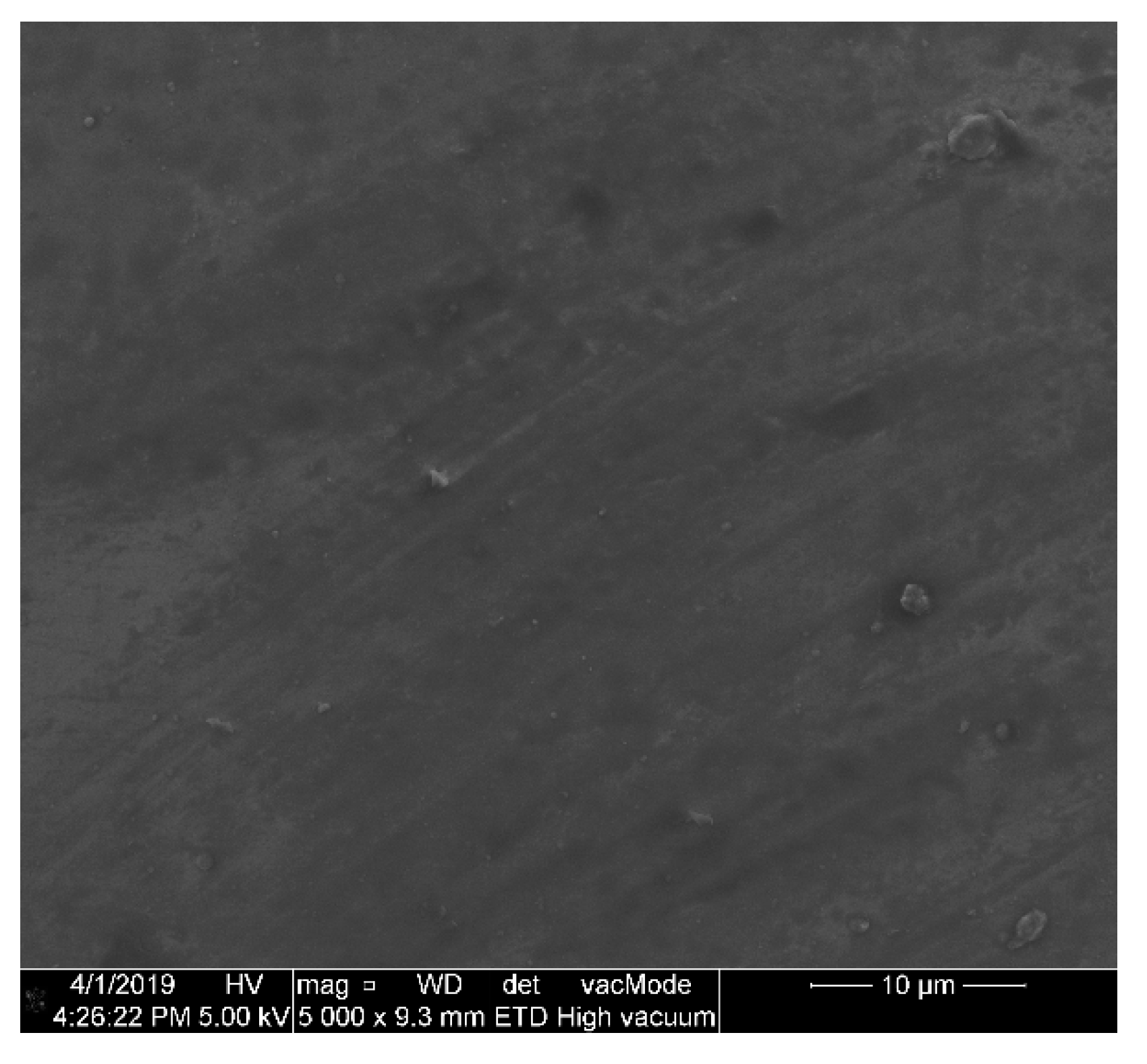

2.1. Microsphere Development

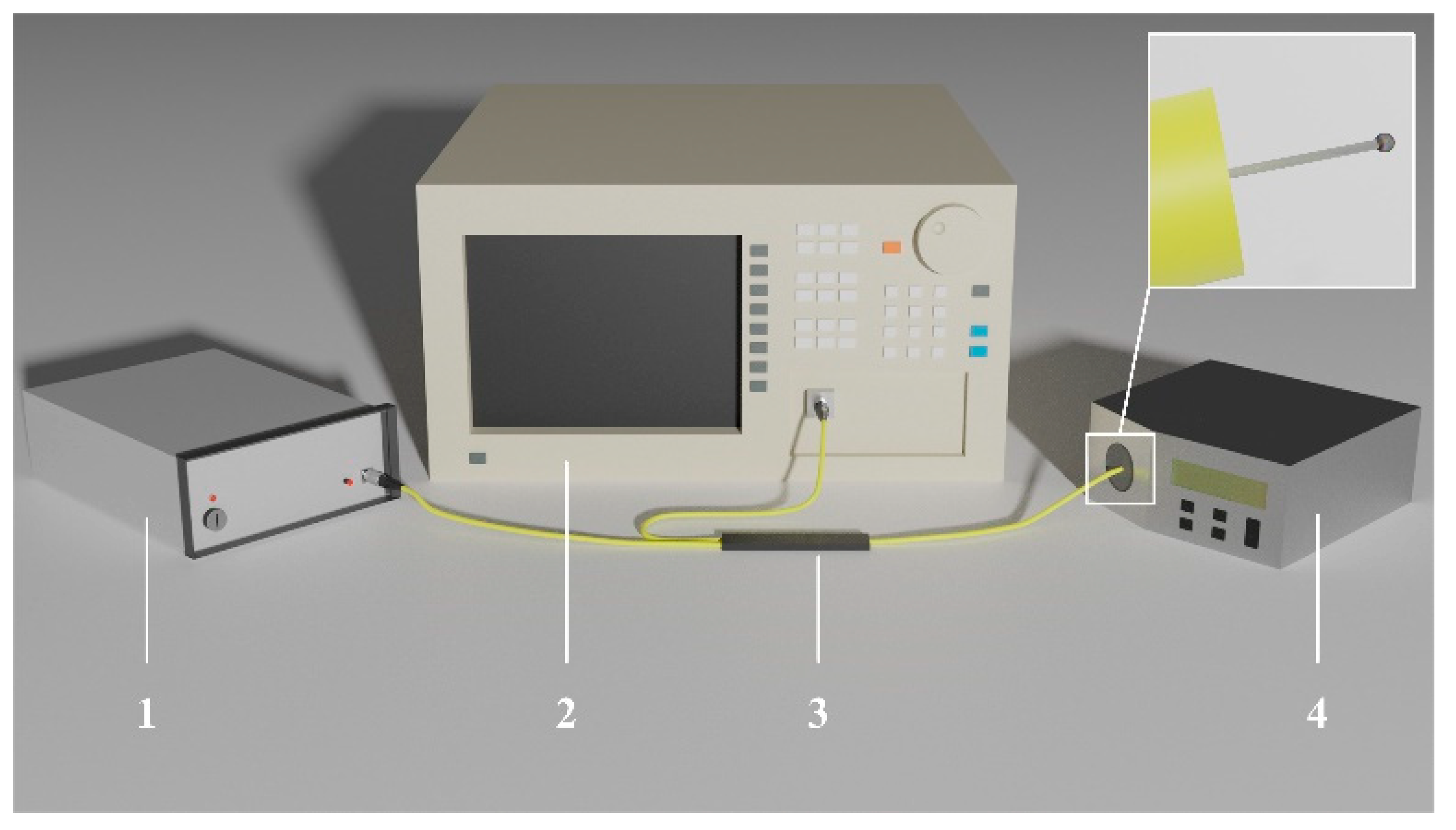

2.2. Experimental Setup

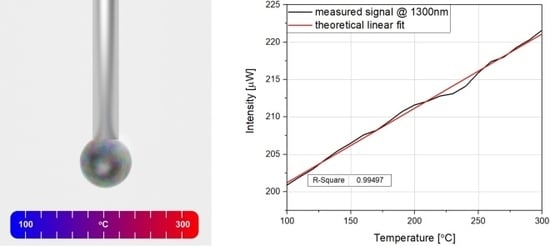

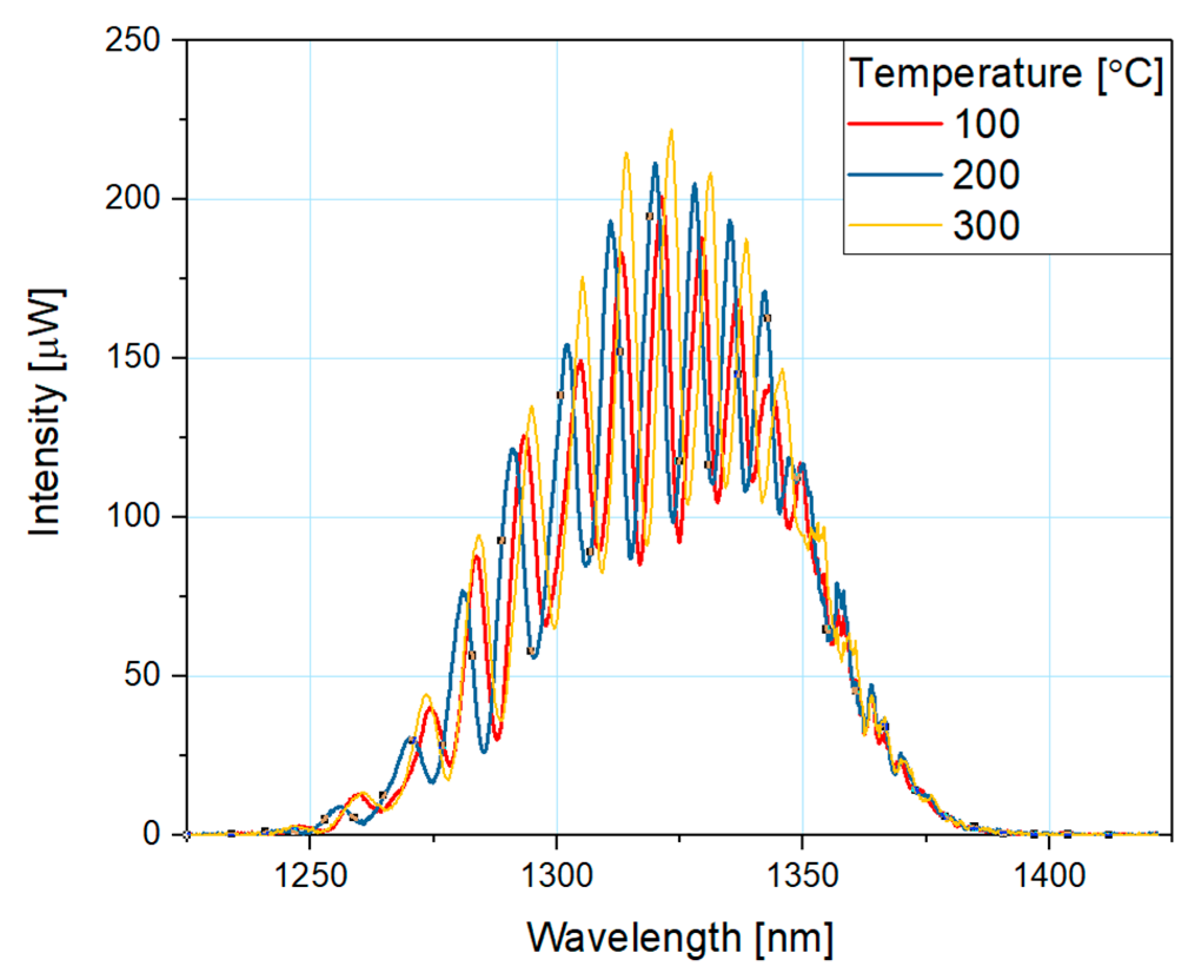

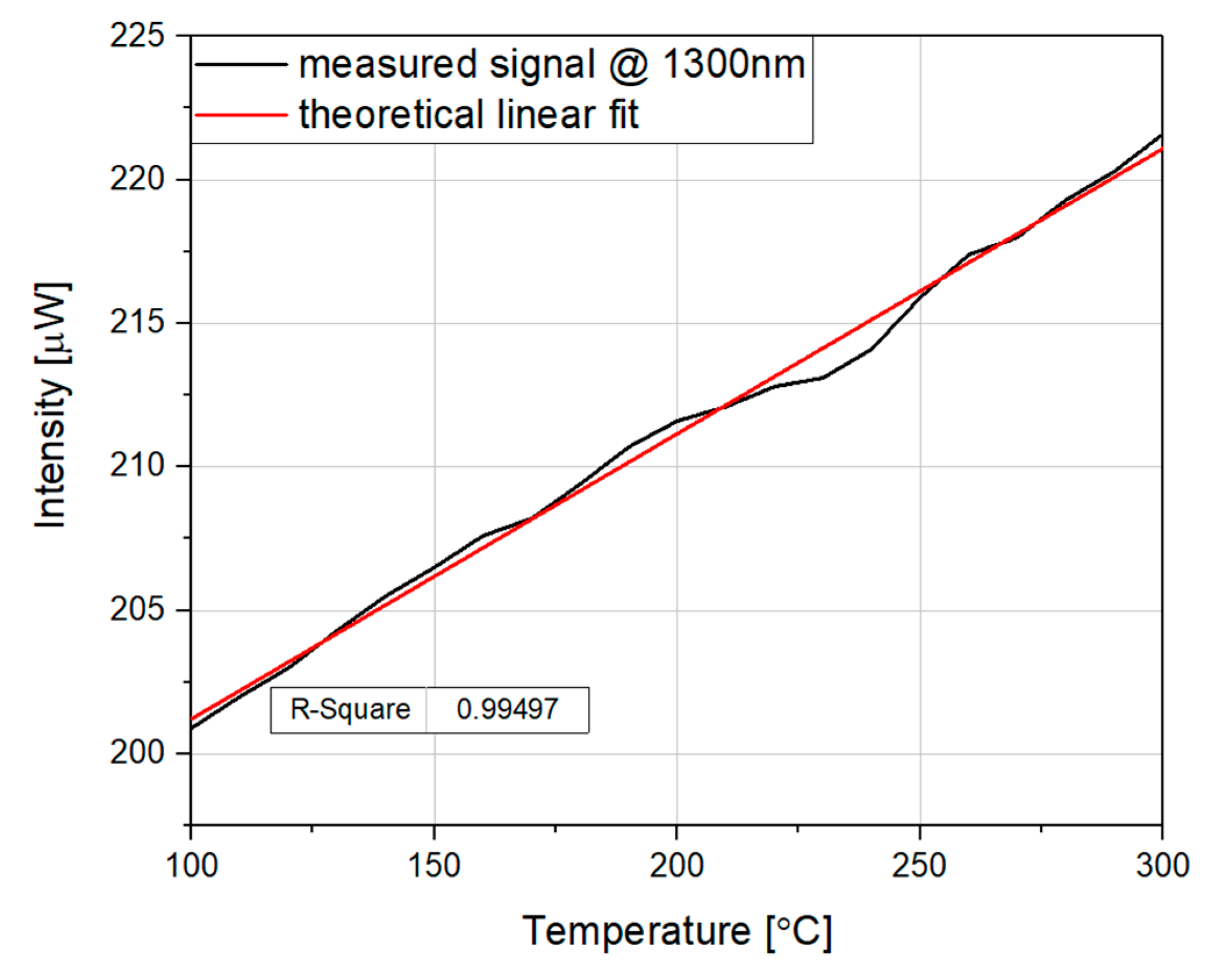

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sergeyev, D.; Solovjov, A.; Shunkeyev, K.; Zhanturina, N. Temperature dependences of the excess current and pseudogap in high-temperature superconductor Bi2Sr2CaCu2O9. In Proceedings of the 2017 International Siberian Conference on Control and Communications (SIBCON), Astana, Kazakhstan, 29–30 June 2017; pp. 1–6. [Google Scholar]

- Teunissen, L.P.J.; Klewer, J.; de Haan, A.; de Koning, J.J.; Daanen, H.A.M. Non-invasive continuous core temperature measurement by zero heat flux. Physiol. Meas. 2011, 32, 559–570. [Google Scholar] [CrossRef] [PubMed]

- D’Acquisto, L.; Scardulla, F.; Pasta, S. Steam sterilization processes affect the stability of clinical thermometers: Thermistor and prototypal FBG probe comparison. Opt. Fiber Technol. 2020, 55, 102156. [Google Scholar] [CrossRef]

- Kocjan, B.; Krawczyk, K.; Snopek, L.; Jasinski, R.; Dudek, E. Temperature chamber with precise temperature stability. In Proceedings of the 2018 Conference on Precision Electromagnetic Measurements (CPEM 2018), Paris, France, 8–13 July 2018; pp. 1–2. [Google Scholar]

- Jia, R.; Xiong, Q.; Liang, S.; Shi, W.; Wang, L. The study of temperature distribution reconstruction based on the singular value decomposition and the griddata interpolation algorithm in industry microwave heating. In Proceedings of the 27th Chinese Control and Decision Conference (2015 CCDC), Qingdao, China, 16–18 July 2015; pp. 4015–4020. [Google Scholar]

- Chen, P.-K.; Chen, C.-H.; Lin, S.-C.; Kuan, Y.-T.; Lin, H.-L.; Chen, J.-W. Study of the Water Temperature and Quality Change with Hot and Cold Springs. In Proceedings of the 2017 International Conference on Information, Communication and Engineering (ICICE), Xiamen, China, 17–20 November 2017; pp. 193–196. [Google Scholar]

- Wang, W.; Ma, Z.; Wang, X.; Li, C.; Ma, J.; Long, K.; Hao, Z.; Liu, S.; Wu, Y. Distribution of moisture in oil immersed pressboard under transient temperature condition. In Proceedings of the 2012 IEEE International Conference on Condition Monitoring and Diagnosis, Bali, Indonesia, 23–27 September 2012; pp. 897–900. [Google Scholar]

- Vadivambal, R.; Jayas, D.S. Applications of thermal imaging in agriculture and food industry—A review. Food Bioprocess Technol. 2011, 4, 186–199. [Google Scholar] [CrossRef]

- Raghunathan, N.; Xiaofan, J.; Peroulis, D.; Ganguly, A. Wireless low-power temperature probes for food/pharmaceutical process monitoring. In Proceedings of the 2015 IEEE SENSORS, Busan, Korea, 1–4 November 2015; pp. 1–4. [Google Scholar]

- Patel, H.; Sheth, S.; Farhad, S.M. Cloud based temperature and humidity alert system to prevent food poisoning. In Proceedings of the 2019 Cybersecurity and Cyberforensics Conference (CCC), Melbourne, Australia, 8–9 May 2019; pp. 1–5. [Google Scholar]

- Bansal, B.; Chen, X.D. Effect of temperature and power frequency on milk fouling in an ohmic heater. Food Bioprod. Process. 2006, 84, 286–291. [Google Scholar] [CrossRef]

- Mutyala, M.S.K.; Zhao, J.; Li, J.; Pan, H.; Yuan, C.; Li, X. In-situ temperature measurement in lithium ion battery by transferable flexible thin film thermocouples. J. Power Sources 2014, 260, 43–49. [Google Scholar] [CrossRef]

- Novais, S.; Nascimento, M.; Grande, L.; Domingues, M.F.; Antunes, P.; Alberto, N.; Leitão, C.; Oliveira, R.; Koch, S.; Kim, G.T.; et al. Internal and external temperature monitoring of a Li-Ion battery with fiber bragg grating sensors. Sensors 2016, 16, 1394. [Google Scholar] [CrossRef]

- Utada, S.; Rame, J.; Hamadi, S.; Delautre, J.; Villechaise, P.; Cormier, J. Kinetics of creep damage accumulation induced by a room-temperature plastic deformation introduced during processing of AM1 Ni-based single crystal superalloy. Mater. Sci. Eng. A 2020, 789, 139571. [Google Scholar] [CrossRef]

- Jung, J.G.; Lee, K.; Lee, B.; Lee, H.S. Effect of rapid thermal annealing on bulk micro-defects and plastic deformation in silicon during high temperature processing. Mater. Sci. Semicond. Process. 2018, 85, 83–89. [Google Scholar] [CrossRef]

- Dubois, A.; Dubar, M.; Dubar, L. Warm and hot upsetting sliding test: Tribology of metal processes at high temperature. Procedia Eng. 2014, 81, 1964–1969. [Google Scholar] [CrossRef]

- Debey, D.; Bluhm, R.; Habets, N.; Kurz, H. Fabrication of planar thermocouples for real-time measurements of temperature profiles in polymer melts. Sens. Actuators A Phys. 1997, 58, 179–184. [Google Scholar] [CrossRef]

- Souza, E.L.d.J.; Santos, T.L.M. Transient compensation for thermistor-based sensors in constant temperature configuration. Sens. Actuators A Phys. 2020, 305, 111920. [Google Scholar] [CrossRef]

- Zhao, B.; Feng, F.; Tian, B.; Yu, Z.; Li, X. Micro thermal conductivity detector based on SOI substrate with low detection limit. Sens. Actuators B Chem. 2020, 308, 127682. [Google Scholar] [CrossRef]

- Bhadra, S.; Tan, D.S.Y.; Thomson, D.J.; Freund, M.S.; Bridges, G.E. A wireless passive sensor for temperature compensated remote pH monitoring. IEEE Sens. J. 2013, 13, 2428–2436. [Google Scholar] [CrossRef]

- Guo, Y.; Xiong, L.; Liu, H. Research on the durability of metal-packaged fiber bragg grating sensors. IEEE Photon. Technol. Lett. 2019, 31, 525–528. [Google Scholar] [CrossRef]

- Wen, J.; Liu, W.; Huang, Y.; Liu, Y.; Luo, Y.; Peng, G.-D.; Pang, F.; Chen, Z.; Wang, T. Spun-related effects on optical properties of spun silica optical fibers. J. Lightwave Technol. 2015, 33, 2674–2678. [Google Scholar] [CrossRef]

- Chen, K.; Zhou, X.; Yang, B.; Peng, W.; Yu, Q. A hybrid fiber-optic sensing system for down-hole pressure and distributed temperature measurements. Optics Laser Technol. 2015, 73, 82–87. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, P.; Li, M.; Zhang, P.; Ding, L. Complex of hydrogel with magnetic immobilized GOD for temperature controlling fiber optic glucose sensor. Biochem. Eng. J. 2016, 114, 262–267. [Google Scholar] [CrossRef]

- Bremer, K.; Reinsch, T.; Leen, G.; Roth, B.; Lochmann, S.; Lewis, E. Pressure, temperature and refractive index determination of fluids using a single fibre optic point sensor. Sens. Actuators A Phys. 2017, 256, 84–88. [Google Scholar] [CrossRef]

- Velázquez-González, J.S.; Monzón-Hernández, D.; Moreno-Hernández, D.; Martínez-Piñón, F.; Hernández-Romano, I. Simultaneous measurement of refractive index and temperature using a SPR-based fiber optic sensor. Sens. Actuators B Chem. 2017, 242, 912–920. [Google Scholar] [CrossRef]

- Guermat, A.; Guessoum, A.; Demagh, N.-E.; Zaboub, M.; Bouhafs, Z. Fibre-optic temperature and pressure sensor based on a deformable concave micro-mirror. Sens. Actuators A Phys. 2018, 270, 205–213. [Google Scholar] [CrossRef]

- Gao, S.; Ji, C.; Ning, Q.; Chen, W.; Li, J. High-sensitive Mach-Zehnder interferometric temperature fiber-optic sensor based on core-offset splicing technique. Opt. Fiber Technol. 2020, 56, 102202. [Google Scholar] [CrossRef]

- Tregubov, A.V.; Svetukhin, V.V.; Novikov, S.G.; Berintsev, A.V.; Prikhodko, V.V. A novel fiber optic distributed temperature and strain sensor for building applications. Results Phys. 2016, 6, 131–132. [Google Scholar] [CrossRef]

- Kesavan, K.; Ravisankar, K.; Parivallal, S.; Sreeshylam, P.; Sridhar, S. Experimental studies on fiber optic sensors embedded in concrete. Measurement 2010, 43, 157–163. [Google Scholar] [CrossRef]

- Mirzaei, A.; Bahrampour, A.R.; Taraz, M.; Bahrampour, A.; Bahrampour, M.J.; Ahmadi Foroushani, S.M. Transient response of buried oil pipelines fiber optic leak detector based on the distributed temperature measurement. Int. J. Heat Mass Transf. 2013, 65, 110–122. [Google Scholar] [CrossRef]

- Fuhr, P.L.; Huston, D.R. Corrosion detection in reinforced concrete roadways and bridges via embedded fiber optic sensors. Smart Mater. Struct. 1998, 7, 217–228. [Google Scholar] [CrossRef]

- Du, C.; Dutta, S.; Kurup, P.; Yu, T.; Wang, X. A review of railway infrastructure monitoring using fiber optic sensors. Sens. Actuators A Phys. 2020, 303, 111728. [Google Scholar] [CrossRef]

- Huang, J.; Liu, Y.; Zhang, P.; Li, Y.; Ding, L. A temperature-triggered fiber optic biosensor based on hydrogel-magnetic immobilized enzyme complex for sequential determination of cholesterol and glucose. Biochem. Eng. J. 2017, 125, 123–128. [Google Scholar] [CrossRef]

- Gomes, A.D.; Monteiro, C.S.; Silveira, B.; Frazão, O. A brief review of new fiber microsphere geometries. Fibers 2018, 6, 48. [Google Scholar] [CrossRef]

- Renganathan, B.; Sastikumar, D.; Gobi, G.; Rajeswari Yogamalar, N.; Chandra Bose, A. Nanocrystalline ZnO coated fiber optic sensor for ammonia gas detection. Optics Laser Technol. 2011, 43, 1398–1404. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, M.; Zhang, G.; Dai, J.; Zhang, Y.; Zhuang, Z.; Hu, W. Fiber optic hydrogen sensor based on fabry–perot interferometer coated with Sol-Gel Pt/WO 3 coating. J. Lightwave Technol. 2015, 33, 2530–2534. [Google Scholar] [CrossRef]

- Listewnik, P.; Hirsch, M.; Struk, P.; Weber, M.; Bechelany, M.; Jędrzejewska-Szczerska, M. Preparation and characterization of microsphere ZnO ALD coating dedicated for the fiber-optic refractive index sensor. Nanomaterials 2019, 9, 306. [Google Scholar] [CrossRef] [PubMed]

- Niedziałkowski, P.; Białobrzeska, W.; Burnat, D.; Sezemsky, P.; Stranak, V.; Wulff, H.; Ossowski, T.; Bogdanowicz, R.; Koba, M.; Śmietana, M. Electrochemical performance of indium-tin-oxide-coated lossy-mode resonance optical fiber sensor. Sens. Actuators B Chem. 2019, 301, 127043. [Google Scholar] [CrossRef]

- Wei, H.; Yunhui, D.; Lianqing, Z.; Mingli, D. Angular sensing system based on Y-type twin-core fiber and reflective varied-line spacing grating fabricated by electron beam lithography. Results Phys. 2020, 18, 103193. [Google Scholar] [CrossRef]

- Ma, Q.; Rossmann, T.; Guo, Z. Whispering-gallery mode silica microsensors for cryogenic to room temperature measurement. Meas. Sci. Technol. 2010, 21, 025310. [Google Scholar] [CrossRef]

- Vikas; Verma, R.K. Design considerations of a surface plasmon resonance (SPR) based tapered fiber optic bio-sensing probe with graphene-MoS2 over layers. Optik 2019, 180, 330–343. [Google Scholar] [CrossRef]

- Cai, L.; Wang, J.; Pan, J.; Liu, Q.; Chen, Y. A tunable fiber-optic Fabry–Perot cavity formed between a silica microsphere and a target. Opt. Commun. 2020, 459, 124996. [Google Scholar] [CrossRef]

- Hirsch, M.; Listewnik, P.; Struk, P.; Weber, M.; Bechelany, M.; Szczerska, M. ZnO coated fiber optic microsphere sensor for the enhanced refractive index sensing. Sens. Actuators A Phys. 2019, 298, 111594. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Listewnik, P.; Bechelany, M.; Jasinski, J.B.; Szczerska, M. ZnO ALD-Coated Microsphere-Based Sensors for Temperature Measurements. Sensors 2020, 20, 4689. https://doi.org/10.3390/s20174689

Listewnik P, Bechelany M, Jasinski JB, Szczerska M. ZnO ALD-Coated Microsphere-Based Sensors for Temperature Measurements. Sensors. 2020; 20(17):4689. https://doi.org/10.3390/s20174689

Chicago/Turabian StyleListewnik, Paulina, Mikhael Bechelany, Jacek B. Jasinski, and Małgorzata Szczerska. 2020. "ZnO ALD-Coated Microsphere-Based Sensors for Temperature Measurements" Sensors 20, no. 17: 4689. https://doi.org/10.3390/s20174689

APA StyleListewnik, P., Bechelany, M., Jasinski, J. B., & Szczerska, M. (2020). ZnO ALD-Coated Microsphere-Based Sensors for Temperature Measurements. Sensors, 20(17), 4689. https://doi.org/10.3390/s20174689