Mask Gradient Response-Based Threshold Segmentation for Surface Defect Detection of Milled Aluminum Ingot

Abstract

1. Introduction

- In terms of ROI extraction in an aluminum ingot image, we design a novel mask gradient response-based threshold segmentation algorithm to iteratively separate out defects of varying significance. In addition, the combination of the mask gradient response-based threshold segmentation (MGRTS) and Difference of Gaussian (DoG) can effectively improve the detection rate of the above defects.

- In the classification stage, we use the inception-v3 network structure with focal loss in the training process and data augmentation technologies to overcome the class imbalance problem and realize the accurate identification of various defects.

- Our method can make full use of central processing unit (CPU) and graphics processing unit (GPU) resources in a workstation or server. Even if the server used in the production line is not configured with GPU, the algorithm can still ensure the realization of rapid defect detection.

- At the beginning of the project, even without a large number of labeled samples, the algorithm can still deploy and detect the suspicious regions quickly owing to the improved ROI detection algorithm.

2. Materials and Methods

2.1. ROI Extraction

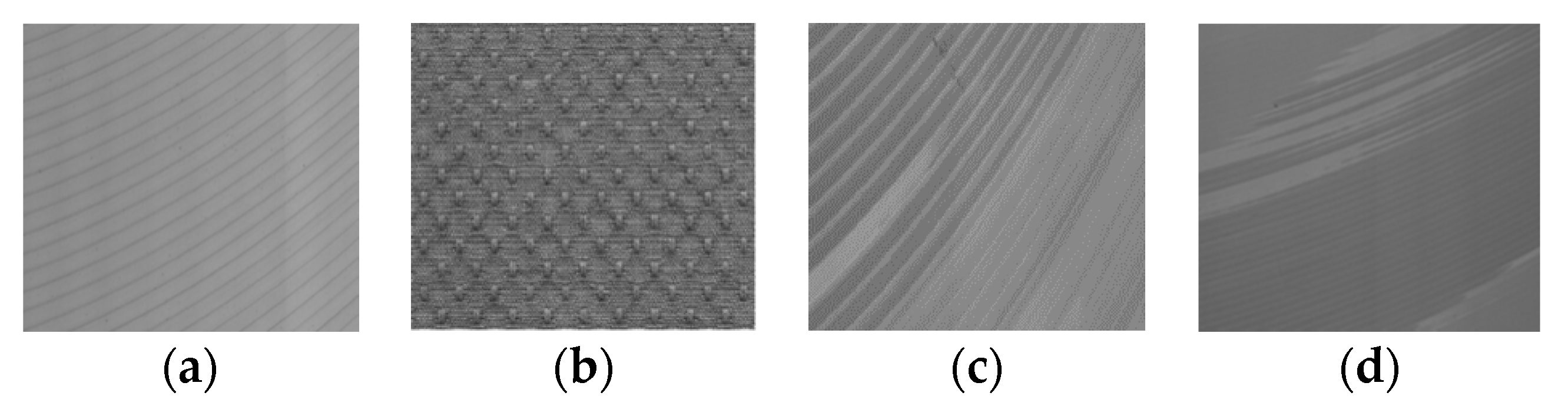

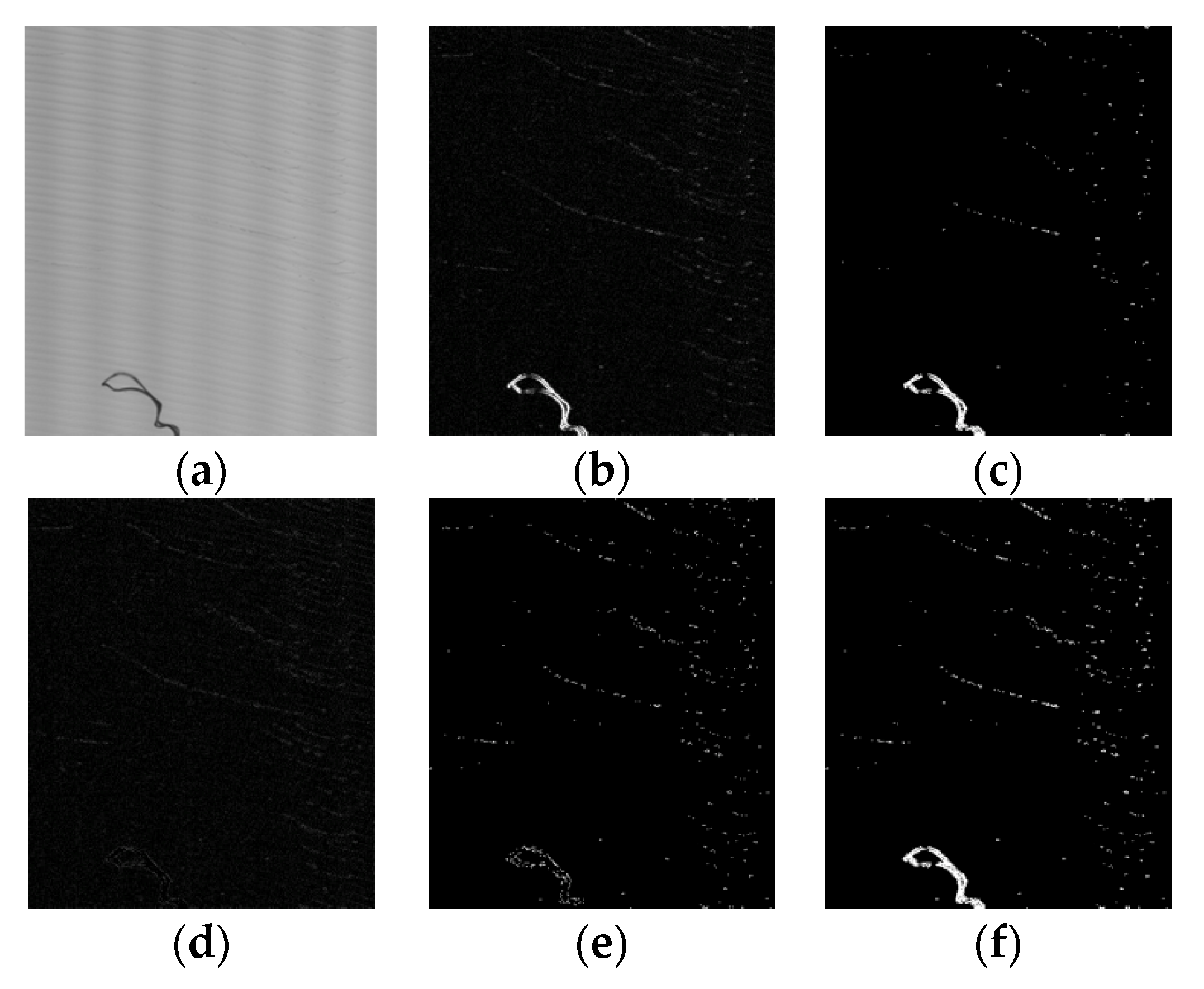

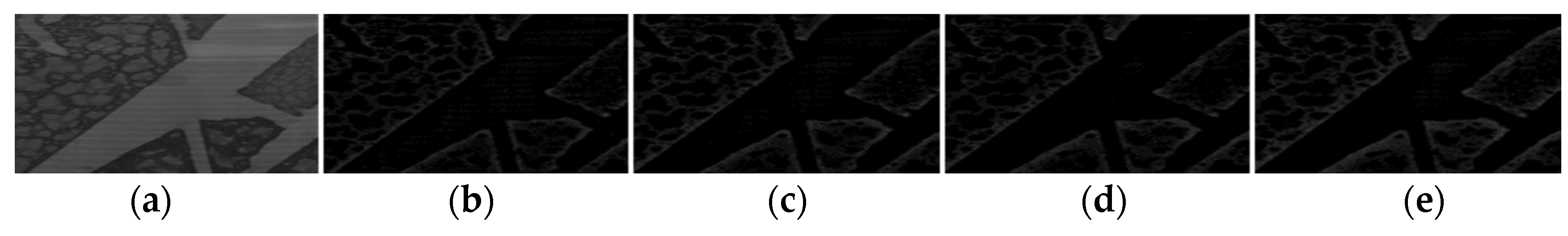

2.1.1. MGRT-Based Iterative Threshold Segmentation

2.1.2. Difference of Gaussians

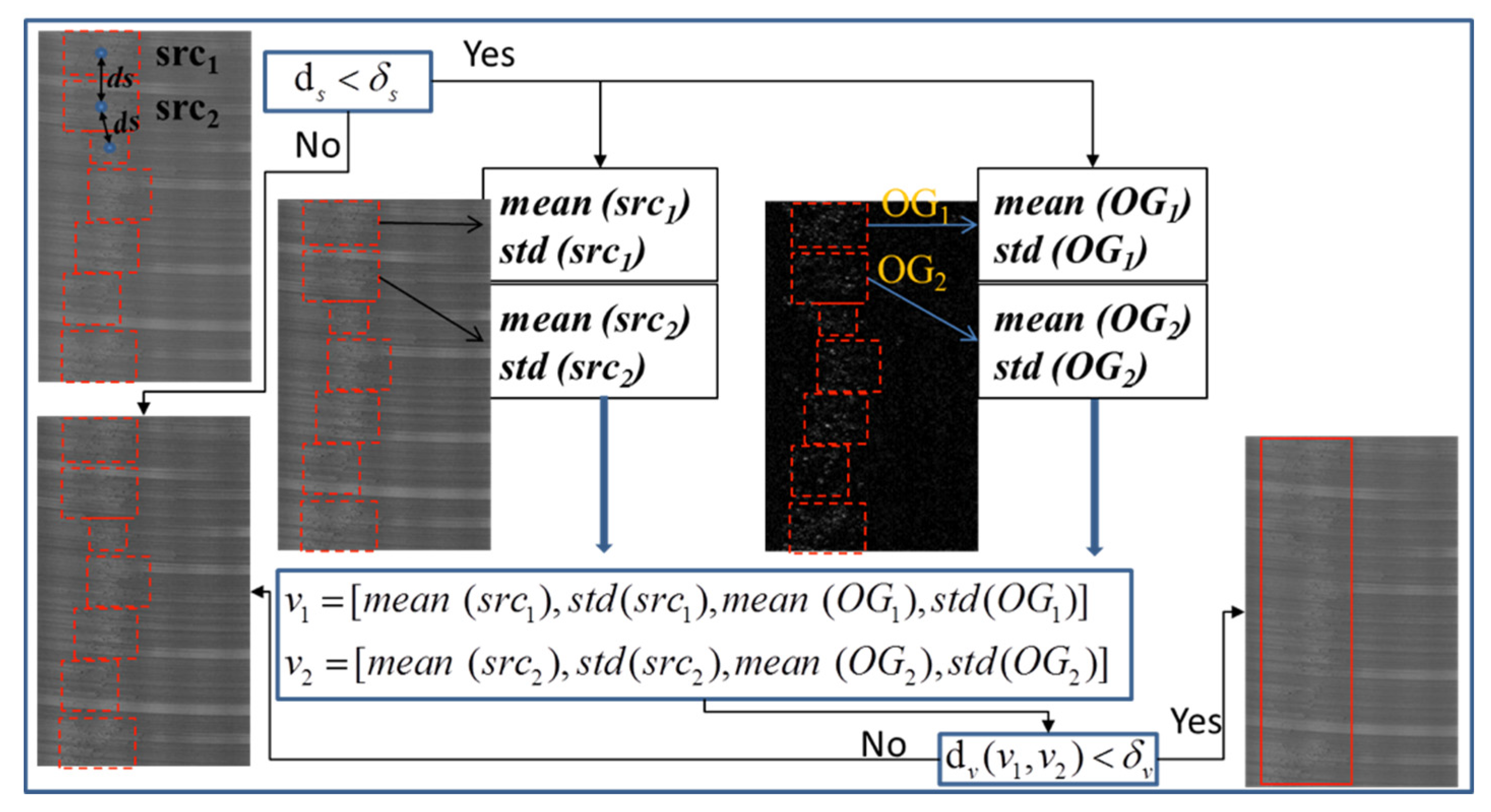

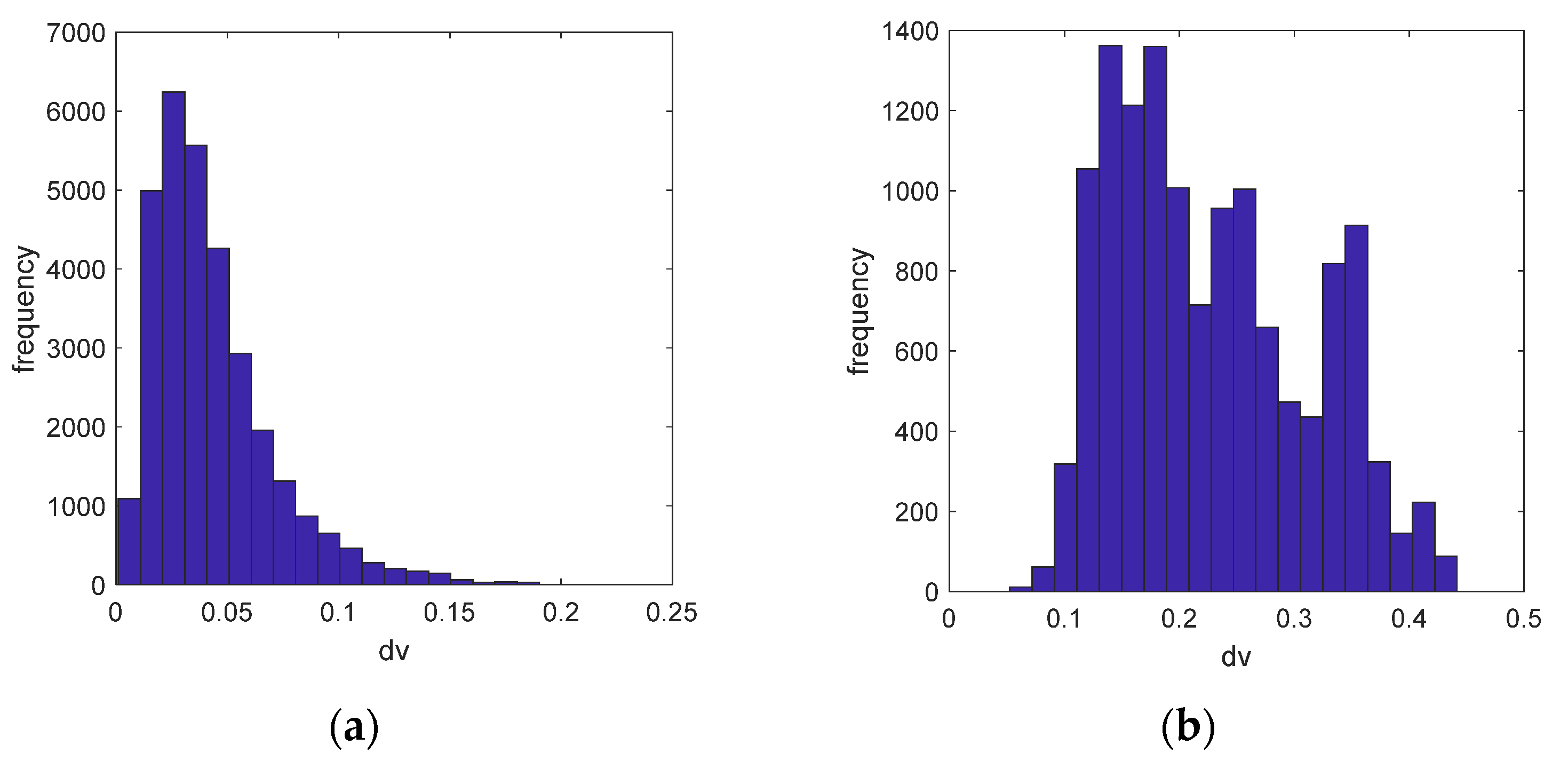

2.1.3. Similar Areas Merge

2.2. Defect ROI Classification

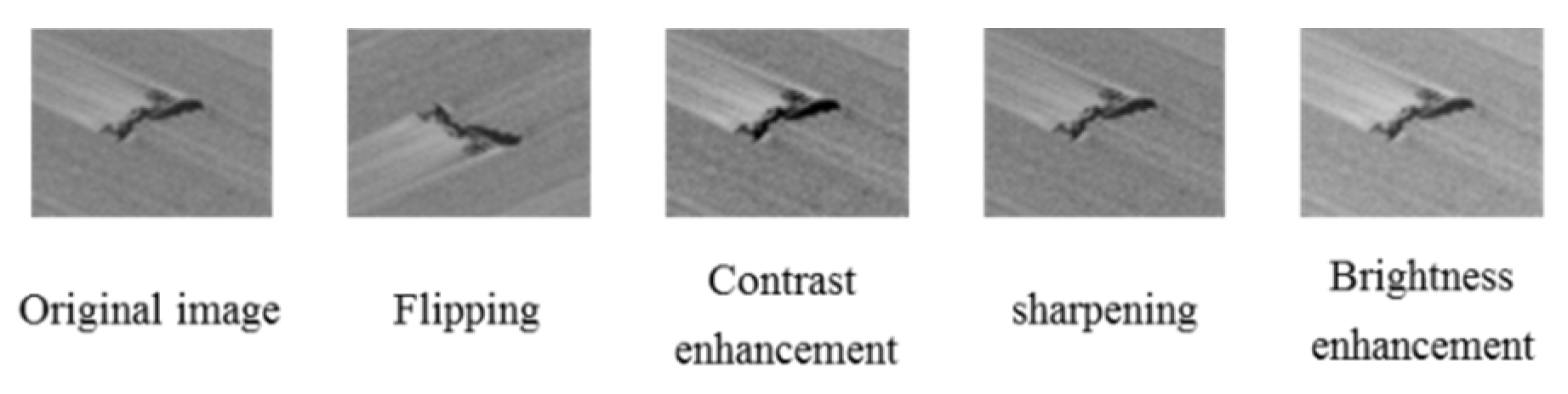

2.2.1. Data Augmentation

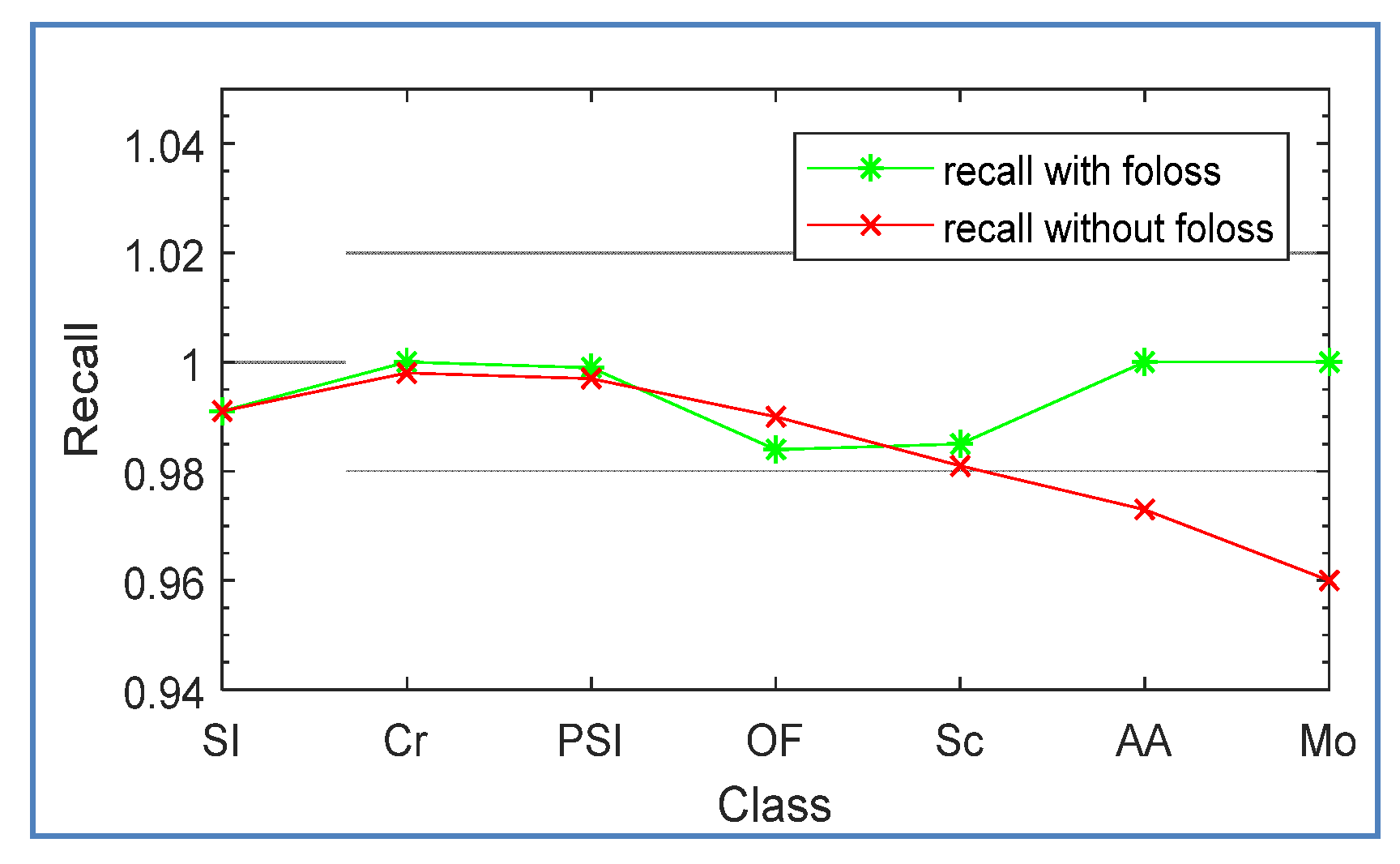

2.2.2. Focal Loss for Multi-Class

3. Results

3.1. Evaluation Metric

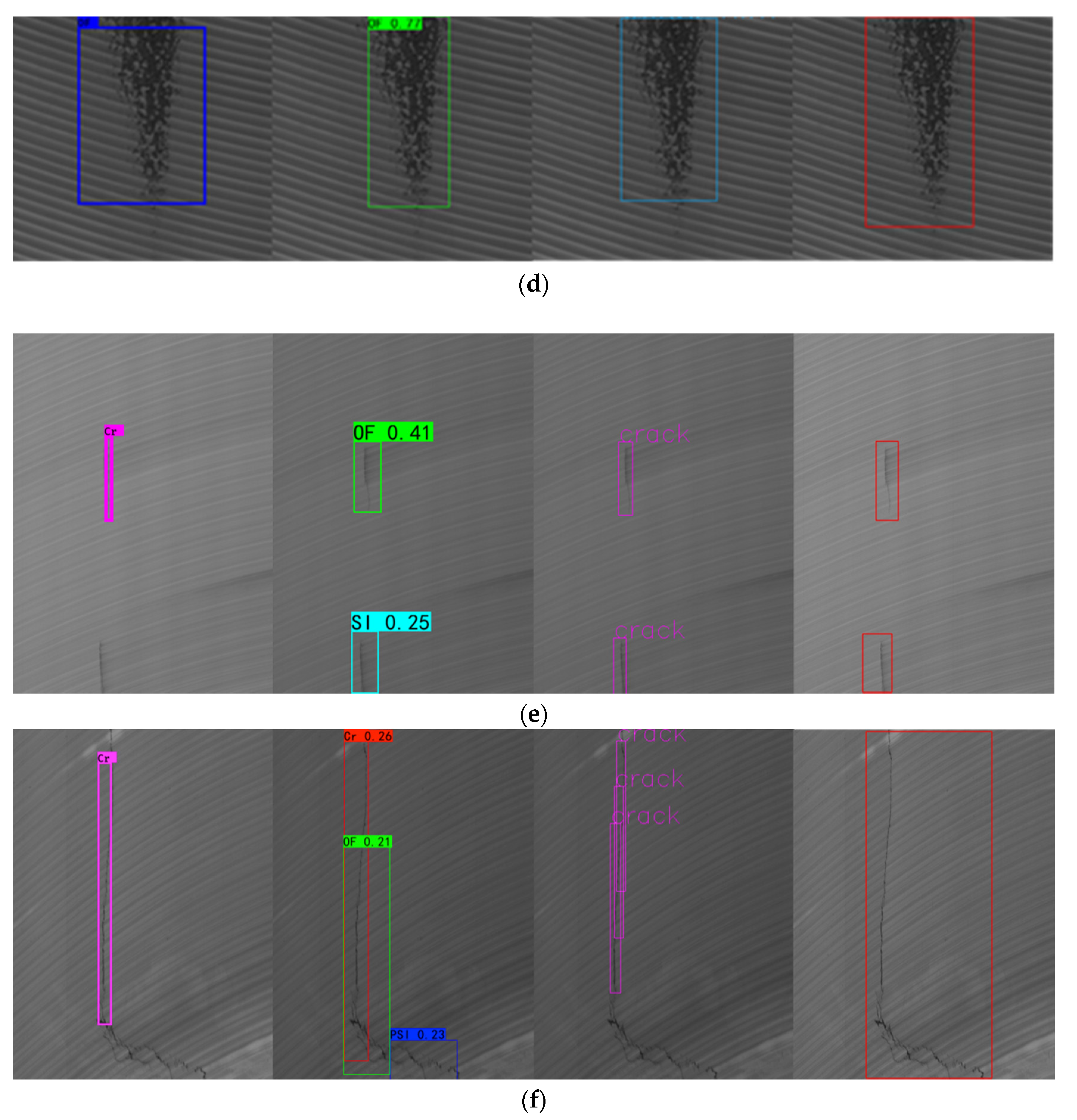

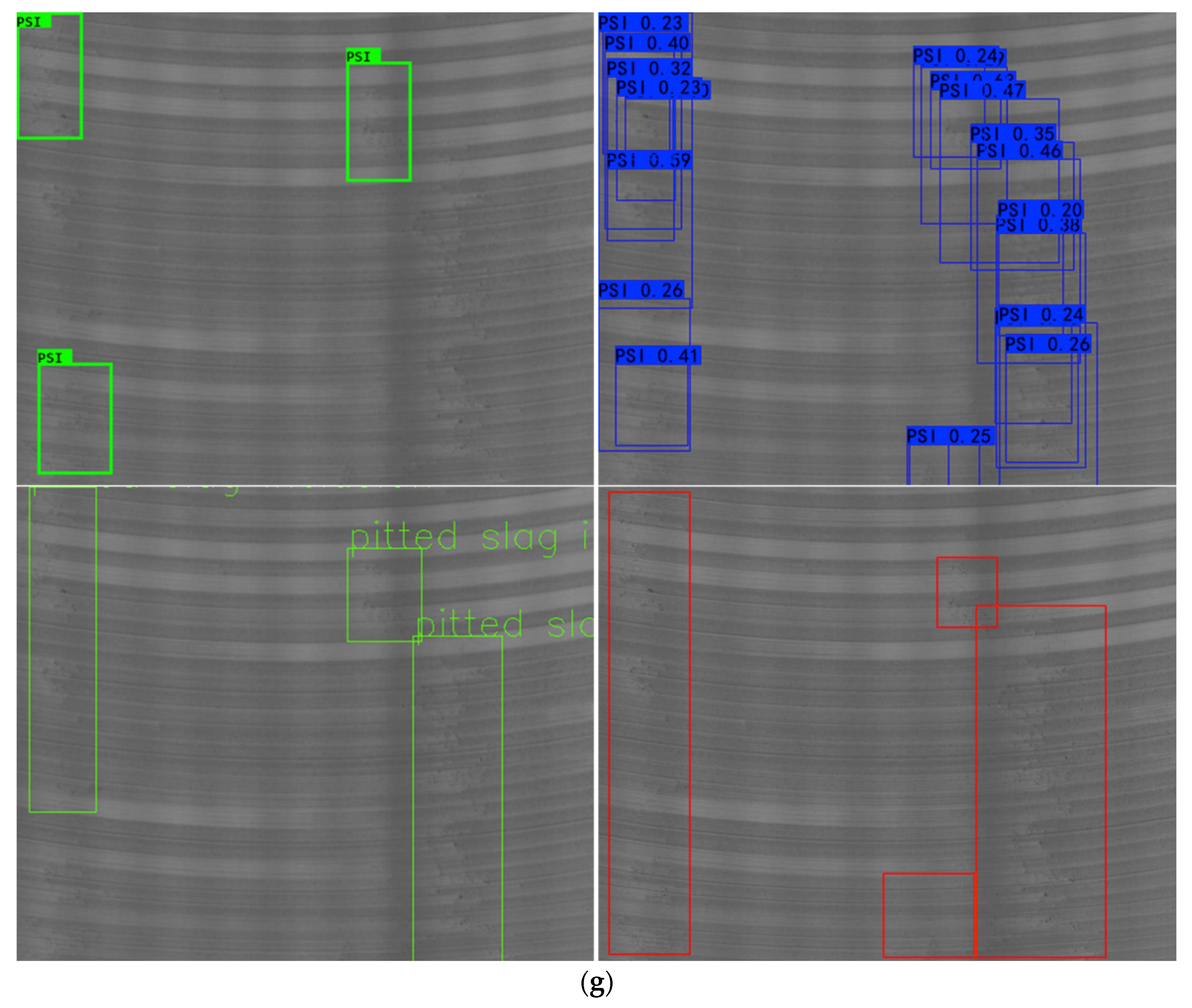

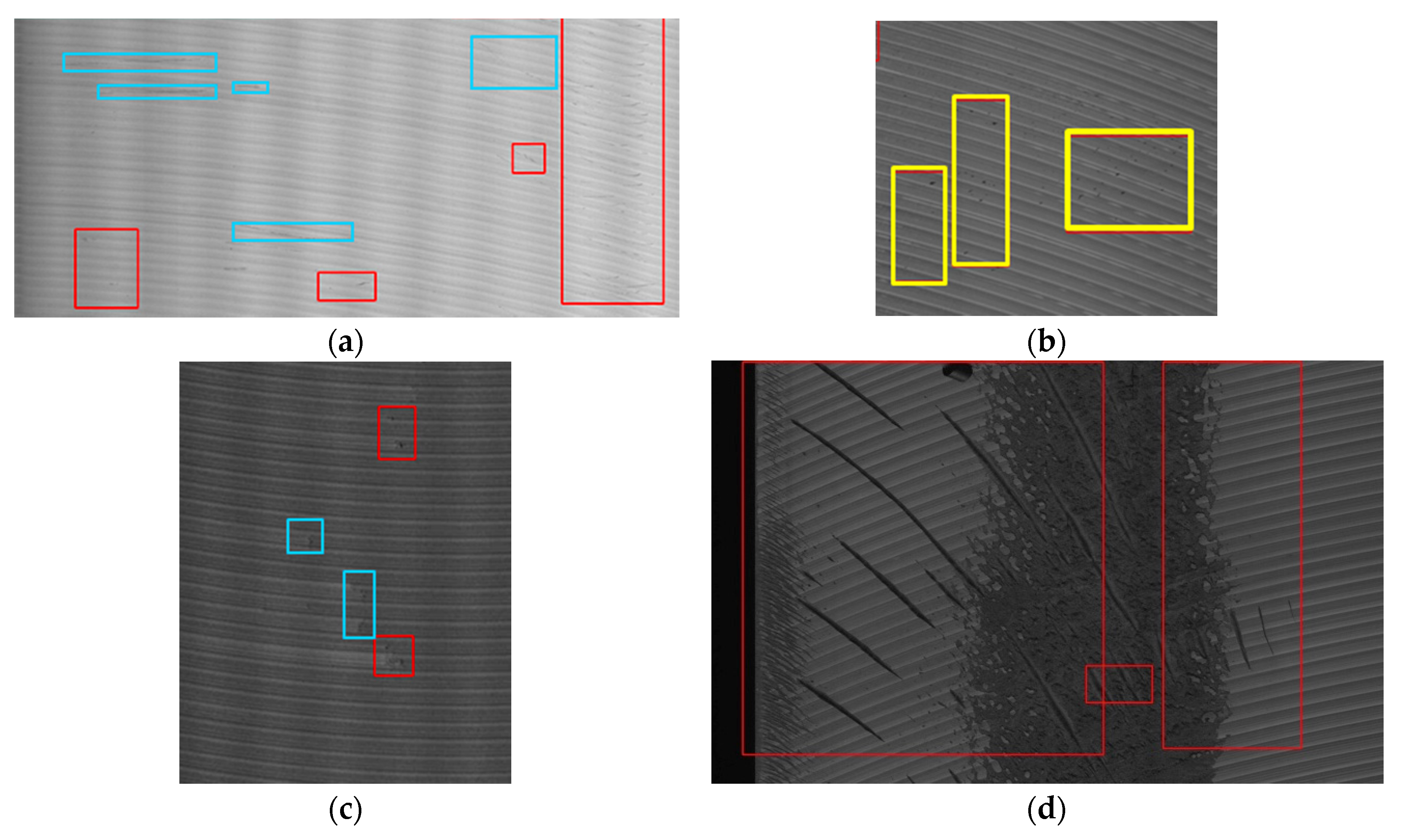

3.2. Experimental Analysis of ROI Extraction Algorithm

3.3. Experimental Analysis of Defect ROI Classification

3.4. Overall Performance Analysis of the Proposed Algorithm

4. Application in Actual Production Line

4.1. Image Acquisition Devices

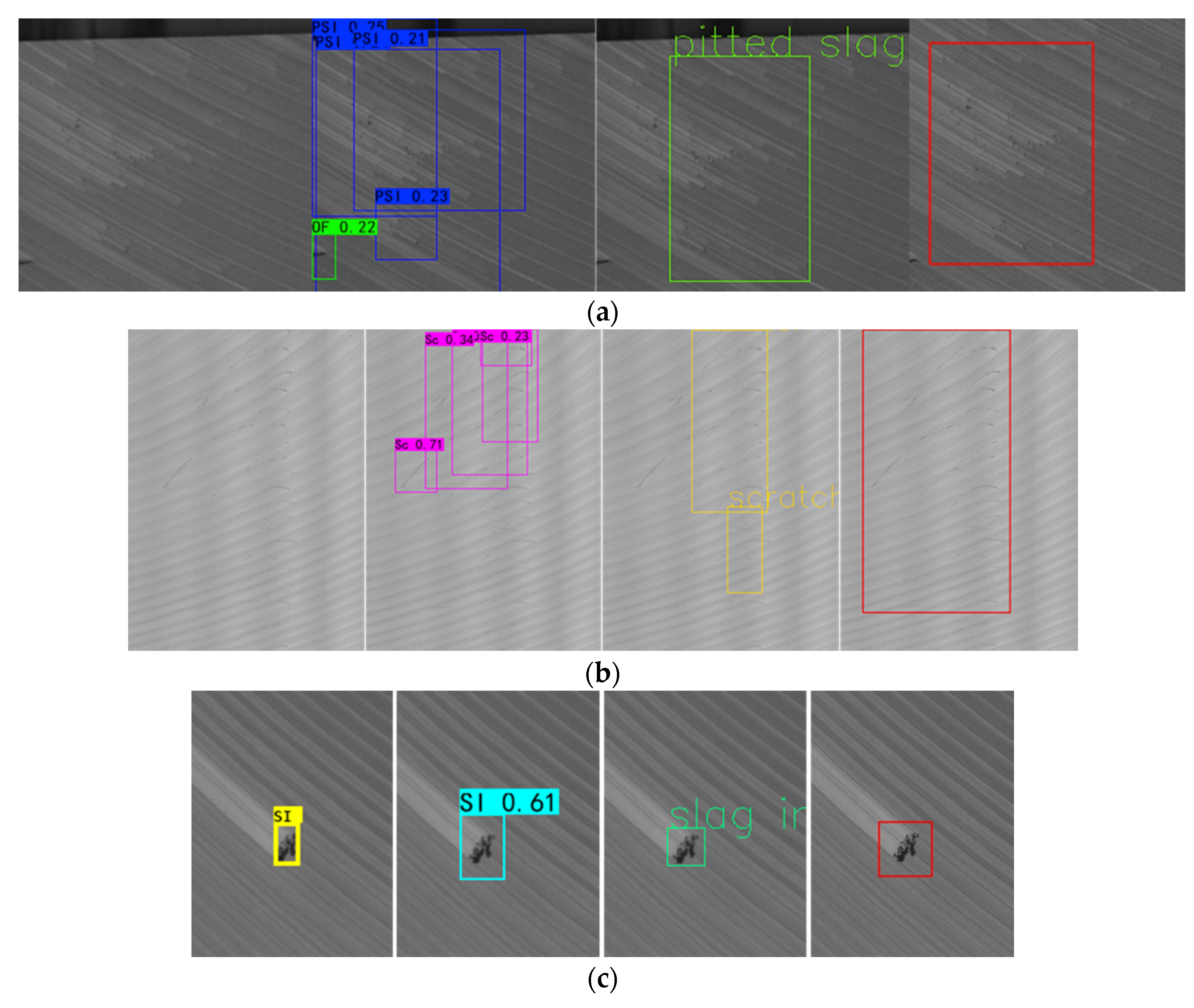

4.2. Effectiveness of Our Method

4.3. Time Efficiency

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Huke, P.; Klattenhoff, R.; von Kopylow, C.; Bergmann, R.B. Novel trends in optical non-destructive testing methods. J. Europ. Opt. Soc. Rap. Public. 2013, 8, 13043. [Google Scholar] [CrossRef]

- Zhu, Y.K.; Tian, G.Y.; Lu, R.S.; Zhang, H. A review of optical NDT technologies. Sensors 2011, 11, 7773–7798. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Farrell, G. Overview of fiber optic sensor technologies for strain/temperature sensing applications in composite materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Q.W.; Lau, D. A novel approach for near-surface defect detection in FRP-bonded concrete systems using laser reflection and acoustic-laser techniques. Constr. Build. Mater. 2017, 141, 553–564. [Google Scholar] [CrossRef]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent advances in active infrared thermography for non-destructive testing of aerospace components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef]

- Navarro, P.J.; Fernandezisla, C.; Alcover, P.M.; Suardíazet, J. Defect detection in textures through the use of entropy as a means for automatically selecting the wavelet decomposition level. Sensors 2016, 16, 1178. [Google Scholar] [CrossRef]

- Prasanna, P.; Dana, K.J.; Gucunski, N.; Basily, B.B.; La, H.M.; Lim, R.S.; Parvardeh, H. Automated crack detection on concrete bridges. IEEE Trans. Autom. Sci. Eng. 2016, 13, 591–599. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, H.; Han, D.; Liu, W.; Chen, P.; Liu, K. Structure-aware-based crack defect detection for multicrystalline solar cells. Measurement 2020, 151, 107170. [Google Scholar] [CrossRef]

- Chun, P.J.; Izumi, S.; Yamane, T. Automatic detection method of cracks from concrete surface imagery using two-step light gradient boosting machine. Comput. Aided Civ. Inf. 2020, 1–12. [Google Scholar] [CrossRef]

- Zhang, C.; Chang, C.; Jamshidi, M. Concrete bridge surface damage detection using a single-stage detector. Comput. Aided Civ. Inf. 2020, 35, 389–409. [Google Scholar] [CrossRef]

- Dung, C.V.; Anh, L.D. Autonomous concrete crack detection using deep fully convolutional neural network. Autom. Constr. 2018, 99, 52–58. [Google Scholar] [CrossRef]

- Fernandez, C.; Campoy, P.; Platero, C.; Sebastian, J.M.; Aracil, R. On-Line Surface Inspection for Continuous Cast Aluminum Strip. In Computer Vision for Industry; Electronic Imaging Device Engineering: Munich, Germany, 1993; pp. 26–37. [Google Scholar] [CrossRef]

- Huang, X.Q.; Luo, X.B. A real-time algorithm for aluminum surface defect extraction on non-uniform image from CCD camera. In Proceedings of the International Conference on Machine Learning and Cybernetics(ICMLC), Lanzhou, China, 13–16 July 2014; pp. 556–561. [Google Scholar] [CrossRef]

- Xu, K.; Liu, S.H.; Ai, Y.H. Application of shearlet transform to classification of surface defects for metals. Image Vis. Comput. 2015, 35, 23–30. [Google Scholar] [CrossRef]

- Zhai, M.; Shan, F. Applying target maneuver onset detection algorithms to defects detection in aluminum foil. Signal Process 2010, 90, 2319–2326. [Google Scholar] [CrossRef]

- Wei, R.F.; Bi, Y.B. Research on recognition technology of aluminum profile surface defects based on deep learning. Materials 2019, 12, 1681. [Google Scholar] [CrossRef] [PubMed]

- Neuhauser, F.M.; Bachmann, G.; Hora, P. Surface defect classification and detection on extruded aluminum profiles using convolutional neural networks. Int. J. Mater. Form. 2019, 3, 1–13. [Google Scholar] [CrossRef]

- Zhang, D.F.; Song, K.C.; Xu, J.; He, Y.; Yan, Y.H. Unified detection method of aluminium profile surface defects: Common and rare defect categories. Opt. Lasers Eng. 2020, 126, 105936. [Google Scholar] [CrossRef]

- Ai, Y.H.; Xu, K. Feature extraction based on contourlet transform and its application to surface inspection of metals. Opt. Eng. 2012, 51, 113605. [Google Scholar] [CrossRef]

- Ai, Y.H.; Xu, K. Surface detection of continuous casting slabs based on curvelet transform and kernel locality preserving projections. J. Iron Steel Res. 2013, 20, 83–89. [Google Scholar] [CrossRef]

- Ghorai, S.; Mukherjee, A.; Gangadaran, M.; Dutta, P.K. Automatic defect detection on hot-rolled flat steel products. IEEE Trans. Instrum. Meas. 2013, 62, 612–621. [Google Scholar] [CrossRef]

- Tian, S.Y.; Ke, X. An algorithm for surface defect identification of steel plates based on genetic algorithm and extreme learning machine. Metals 2017, 7, 311. [Google Scholar] [CrossRef]

- He, D.; Xu, K.; Zhou, P. Defect detection of hot rolled steels with a new object detection framework called classification priority network. Comput. Ind. Eng. 2019, 128, 290–297. [Google Scholar] [CrossRef]

- Song, K.C.; Yan, Y. A noise robust method based on completed local binary patterns for hot-rolled steel strip surface defects. Appl. Surf. Sci. 2013, 285, 858–864. [Google Scholar] [CrossRef]

- Liu, M.F.; Liu, Y.; Hu, H.J.; Nie, L.Q. Genetic algorithm and mathematical morphology based binarization method for strip steel defect image with non-uniform illumination. J. Vis. Commun. Image Represent. 2016, 37, 70–77. [Google Scholar] [CrossRef]

- Youkachen, S.; Ruchanurucks, M.; Phatrapomnant, T.; Kaneko, H. Defect Segmentation of Hot-rolled Steel Strip Surface by using Convolutional Auto-Encoder and Conventional Image processing. In Proceedings of the International Conference of Information and Communication Technology for Embedded Systems(IC-ICTES), Bangkok, Thailand, 25–27 March 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Liu, W.W.; Yan, Y.H. Automated surface defect detection for cold-rolled steel strip based on wavelet anisotropic diffusion method. Int. J. Ind. Syst. Eng. 2014, 17, 224–239. [Google Scholar] [CrossRef]

- Li, Y.; Li, G.Y.; Jiang, M.M. An end-to-end steel strip surface defects recognition system based on convolutional neural networks. Steel Res. Int. 2016, 88, 176–187. [Google Scholar] [CrossRef]

- Liu, K.; Wang, H.Y.; Chen, H.Y.; Qu, E.Q.; Tian, Y.; Sun, H.X. Steel surface defect detection using a new haar-weibull-variance model in unsupervised manner. IEEE Trans. Instrum. Meas. 2017, 66, 1–12. [Google Scholar] [CrossRef]

- Luo, Q.; Fang, X.; Liu, L.; Yang, C.; Sun, Y. Automated visual defect detection for flat steel surface: A survey. IEEE Trans. Instrum. Meas. 2020, 69, 626–644. [Google Scholar] [CrossRef]

- Sun, X.H.; Gun, J.N.; Tang, S.X.; Li, J. Research progress of visual inspection technology of steel products—A review. Appl. Sci. 2018, 8, 2195. [Google Scholar] [CrossRef]

- Kumar, A. Computer-vision-based fabric defect detection: A survey. IEEE Trans. Ind. Electron. 2008, 55, 348–363. [Google Scholar] [CrossRef]

- Tsai, D.; Hsieh, C.Y. Automated surface inspection for directional textures. Image Vis. Comput. 1999, 18, 49–62. [Google Scholar] [CrossRef]

- Asha, V.; Bhajantri, N.U.; Nagabhushan, P. Automatic detection of texture defects using texture-periodicity and Gabor wavelets. Comput. Netw. Intell. Comput. 2011, 548–553. [Google Scholar] [CrossRef]

- Wu, X.; Xu, K.; Xu, J. Application of undecimated wavelet transform to surface defect detection of hot rolled steel plates. In Proceedings of the International Congress on Image and Signal Processing, Sanya, Hainan, China, 27–30 May 2008; pp. 528–532. [Google Scholar] [CrossRef]

- Ngan, H.Y.; Pang, G.K.; Yung, S.P.; Michael, K.N. Wavelet based methods on patterned fabric defect detection. Pattern Recognit. 2005, 38, 559–576. [Google Scholar] [CrossRef]

- Lowe, D.G. Distinctive image features from scale-invariant keypoints. Int. J. Comput. Vis. 2004, 60, 91–110. [Google Scholar] [CrossRef]

- Szegedy, C.; Vanhoucke, V.; Ioffe, S.; Shlens, J.; Wojna, Z. Rethinking the inception architecture for computer vision. In Proceedings of the Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 2818–2826. [Google Scholar] [CrossRef]

- Szegedy, C.; Liu, W.; Jia, Y.Q.; Sermanet Reed, P.; Anguelov, S.D.; Erhan, D.; Vanhoucke, V.; Rabinovich, A. Going deeper with convolutions. In Proceedings of the Conference on Computer Vision and Pattern Recognition (CVPR), Boston, MA, USA, 7–12 June 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Deng, J.; Dong, W.; Socher, R.; Li, L.J.; Li, K.; Li, F.F. Imagenet: A large-scale hierarchical image database. In Proceedings of the Conference on Computer Vision and Pattern Recognition (CVPR), Miami, FL, USA, 20–25 June 2009; pp. 249–255. [Google Scholar] [CrossRef]

- Lin, T.Y.; Goyal, P.; Girshick, R.; He, K.M.; Dollár, P. Focal loss for dense object detection. IEEE Trans. Pattern Anal. Mach. Intell. 2020, 42, 318–327. [Google Scholar] [CrossRef]

- Yin, Y.; Tian, G.Y.; Yin, G.F.; Luo, A.M. Defect identification and classification for digital X-ray images. Appl. Mech. Mater. 2008, 10–12, 543–547. [Google Scholar] [CrossRef]

- Joseph, R.; Ali, F. Yolov3: An incremental improvement. arXiv 2018, arXiv:1804.02767. [Google Scholar]

- Bochkovskiy, A.; Wang, C.Y.; Liao, H.Y.M. Yolov4: Optimal speed and accuracy of object detection. arXiv 2004, arXiv:2004.10934v1. [Google Scholar]

| Method | Recall | Precision |

|---|---|---|

| MGRTS | 97.4% | 56.2% |

| DoG | 54.9% | 93.3% |

| MGRTS + DoG | 99.3% | 56.7% |

| Defects | SI | PSI | Cr | AA | Sc | OF | Mo | Tb | Total |

|---|---|---|---|---|---|---|---|---|---|

| Total | 3709 | 5413 | 5204 | 347 | 1932 | 6062 | 902 | 9096 | 32,665 |

| Train | 2969 | 4331 | 4164 | 249 | 1546 | 4850 | 722 | 7278 | 26,139 |

| Validation | 370 | 541 | 520 | 34 | 193 | 606 | 90 | 909 | 3263 |

| Test | 370 | 541 | 520 | 34 | 193 | 606 | 90 | 909 | 3263 |

| Defects | SI | PSI | Cr | AA | Sc | OF | Mo | Average |

|---|---|---|---|---|---|---|---|---|

| ANN | 83.0% | 89.0% | 84.0% | 0.0% | 59.0% | 42.0% | 0.0% | 51.0% |

| inceptions-v3 | 99.1% | 99.9% | 100.0% | 97.3% | 98.1% | 99.0% | 99.6% | 99.0% |

| inceptions-v3 with focal loss | 99.1% | 99.7% | 99.8% | 100.0% | 98.5% | 98.4% | 100.0% | 99.4% |

| Method | Our Method | YOLOv3 | Retina Net | YOLOv4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Metric | R | P | F1 | R | P | F1 | R | P | F1 | R | P | F1 |

| (%) | (%) | (%) | (%) | |||||||||

| Sc | 96.7 | 93.8 | 95.2 | 3.6 | 66.7 | 6.8 | 71.4 | 93.0 | 80.8 | 75.9 | 100.0 | 86.3 |

| OF | 95.7 | 98.2 | 96.9 | 90.5 | 93.5 | 92.0 | 87.4 | 86.5 | 87.0 | 88.4 | 97.9 | 92.9 |

| Cr | 98.6 | 98.6 | 98.6 | 88.9 | 92.3 | 90.6 | 15.9 | 81.3 | 26.5 | 100.0 | 98.8 | 99.4 |

| SI | 94.1 | 91.9 | 94.0 | 76.9 | 69.0 | 72.7 | 57.7 | 62.5 | 60.0 | 84.6 | 100.0 | 91.7 |

| PSI | 88.6 | 85.2 | 86.9 | 70.3 | 95.5 | 81.0 | 91.9 | 85.3 | 88.5 | 82.8 | 98.7 | 90.1 |

| Average | 94.7 | 93.5 | 94.3 | 66.1 | 83.4 | 68.6 | 64.8 | 81.7 | 68.5 | 86.3 | 99.1 | 92.1 |

| Time (ms) 512 × 512 | 103 | 233 | 304 | 167 | ||||||||

| Process Stage | Time Consumption (ms) |

|---|---|

| Aluminum ingot region detection + ROI extraction | 272 |

| Defect ROI Classification | 140 |

| Total | 412 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Xu, K.; Zhou, P. Mask Gradient Response-Based Threshold Segmentation for Surface Defect Detection of Milled Aluminum Ingot. Sensors 2020, 20, 4519. https://doi.org/10.3390/s20164519

Liang Y, Xu K, Zhou P. Mask Gradient Response-Based Threshold Segmentation for Surface Defect Detection of Milled Aluminum Ingot. Sensors. 2020; 20(16):4519. https://doi.org/10.3390/s20164519

Chicago/Turabian StyleLiang, Ying, Ke Xu, and Peng Zhou. 2020. "Mask Gradient Response-Based Threshold Segmentation for Surface Defect Detection of Milled Aluminum Ingot" Sensors 20, no. 16: 4519. https://doi.org/10.3390/s20164519

APA StyleLiang, Y., Xu, K., & Zhou, P. (2020). Mask Gradient Response-Based Threshold Segmentation for Surface Defect Detection of Milled Aluminum Ingot. Sensors, 20(16), 4519. https://doi.org/10.3390/s20164519