1. Introduction

Sensors are devices that measure a certain value and convert them into electrical signals. The main working principle of sensors is to convert physical changes into electrical quantities, and match mechanical systems with electrical systems. Thus, they ensure that a physical change in a system can be detected, measured and transferred to the environment, where it will be evaluated by the observer. As a result, they work as a source of information about a system. In machining, the aim is to obtain a stable and reliable production using various sensors. It is desired to prevent unexpected losses by monitoring the manufacturing process with high sensitivity sensors. Various breakdowns and accidents cause the halting of the production, leading to increased costs and lower efficiency [

1]. Such accidents lead to idle time and increased waste material. The sustainability of a production chain becomes very important in mass production, especially in today’s competitive manufacturing industry [

2]. For this reason, there is a need for a TCMS (Tool Condition Monitoring System) that works as a source of information related to machine tools and processes [

3,

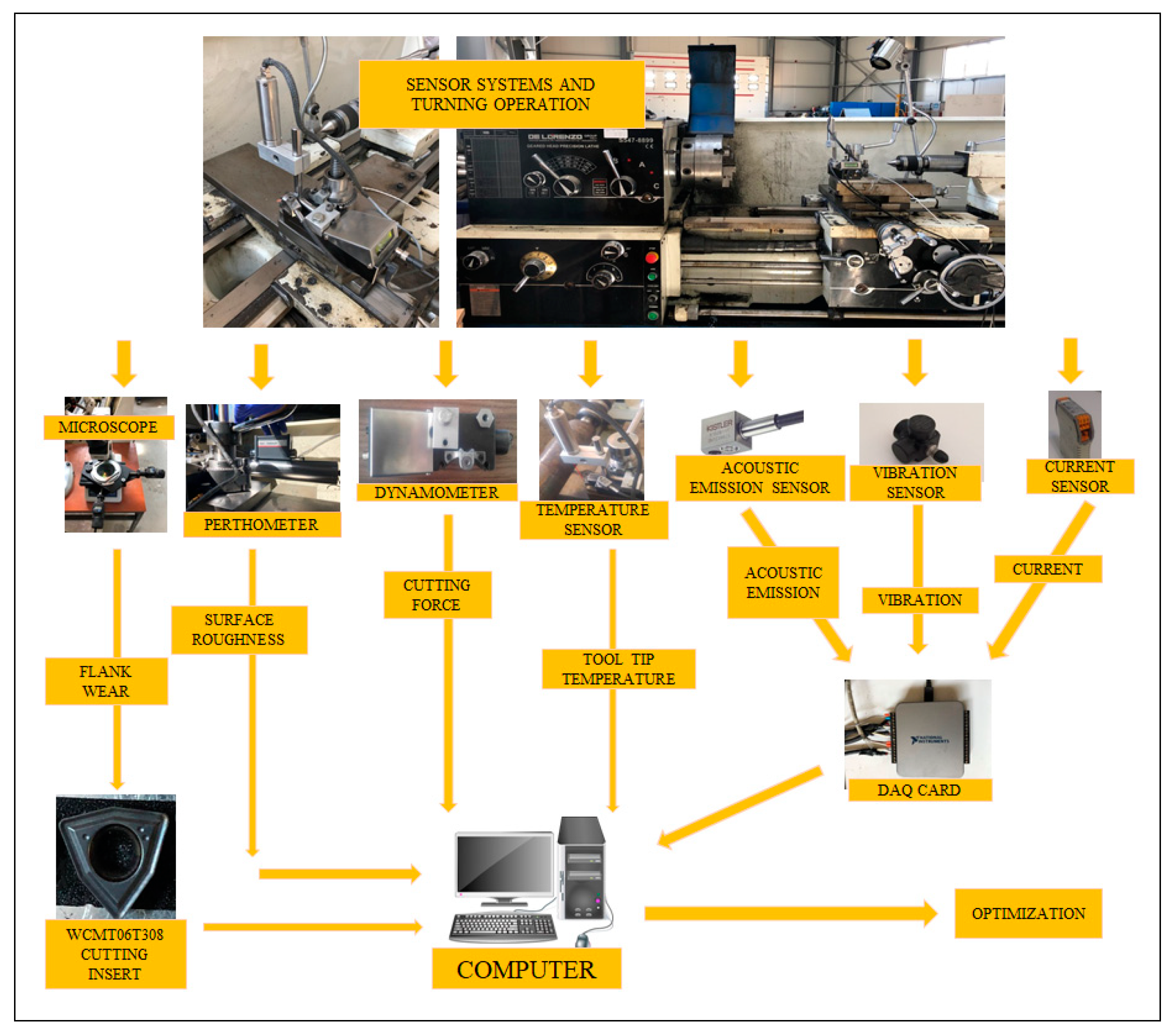

4]. Therefore, the integration of various types of sensors into machine tools is essential for them to provide their analysis and optimal values under different conditions of product manufacturing.

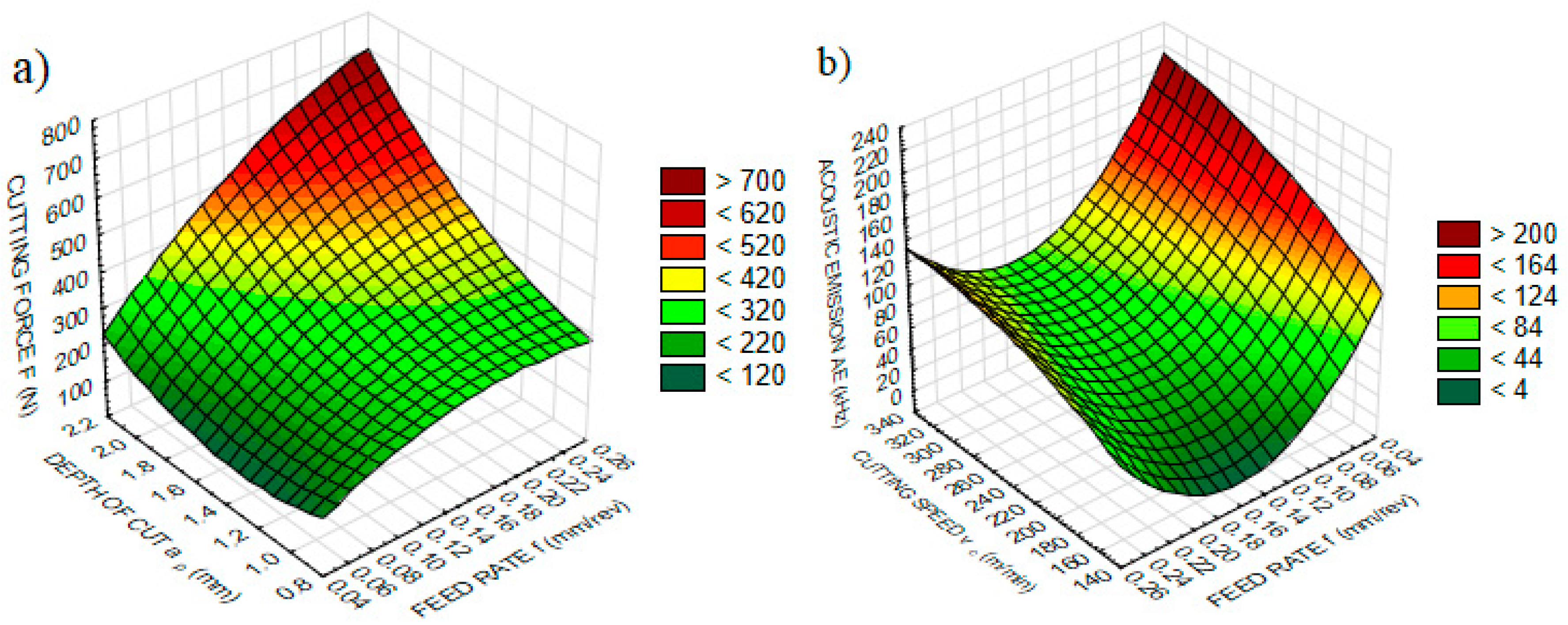

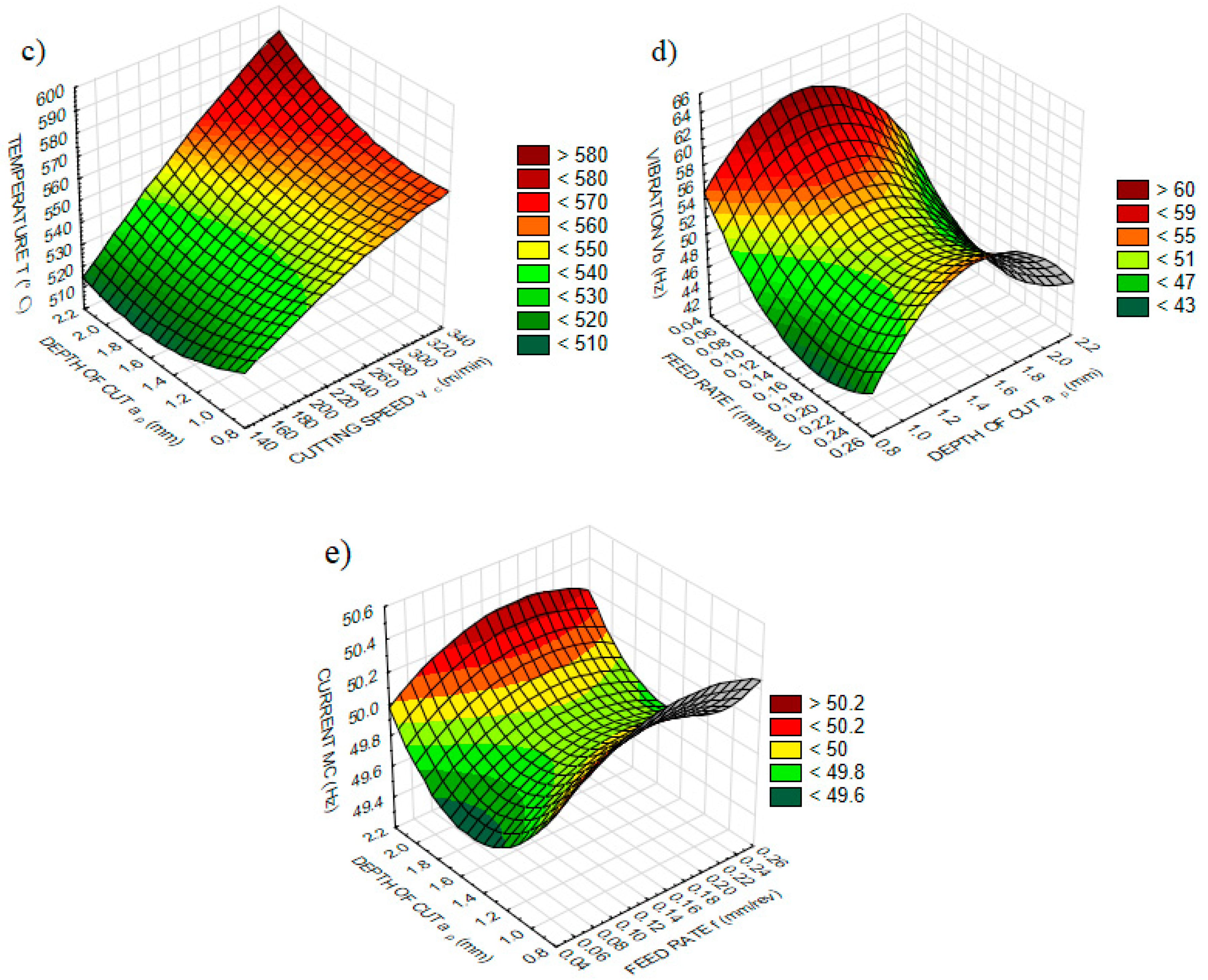

Machining processes create various physical effects caused by high speeds. During the cutting process, chip formation occurs in the metal, which undergoes high plastic deformation. There is also noise and vibration in the tool and the machine, and temperature and pressure changes at the tool–workpiece chip interface. The sudden increase or decrease of the mentioned variables indicates that the steady state of the machining can change. It may not be sufficient to use a single sensor in the processing environment, where many parameters are constantly changing. Therefore, there is a need for reliable and sensitive sensors that will provide instant data about the process, and verify each other in predicting variables [

5,

6].

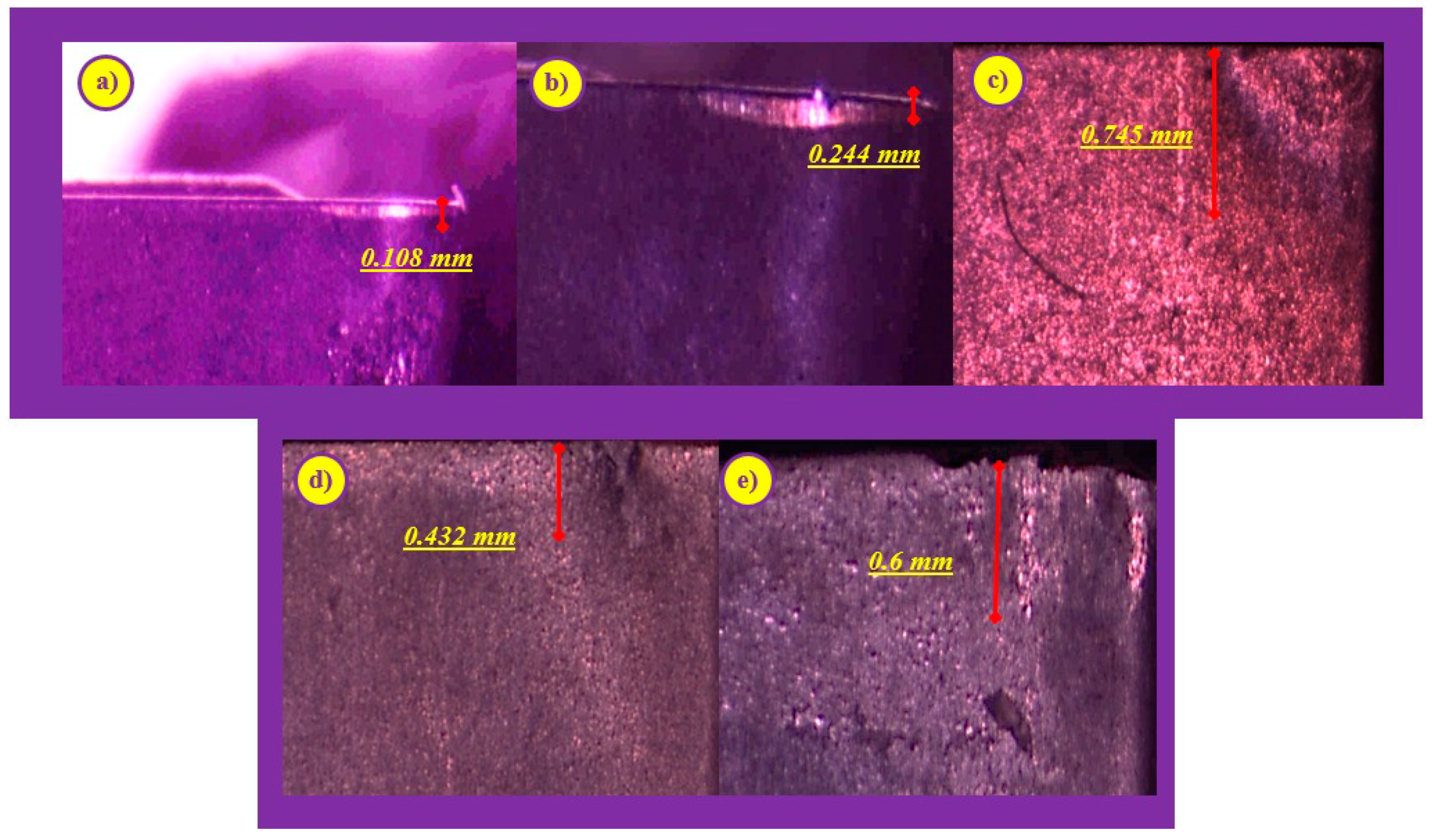

The changes that occur during the manufacture of a component are derived from the complex structure of the process and the dynamic processing conditions. Considering the inhomogeneity in the material structure and the lack of rigidity in the system, unexpected developments occur inevitably. The repetitive loads on the tool during metal cutting lead to the deprivation of material and the change of tool geometry over time [

7,

8]. The resulting deformation causes a gradual breakdown of the tool, and deteriorates its cutting [

9]. The main goal is to give a warning before a certain level of tool wear is reached that could cause sudden tool failure [

10]. During the machining, many parameters that change with the increase of wear, such as cutting forces, cutting temperatures, vibrations in the tool, the sound, chip and current, can be used as information sources to determine the severity of tool wear. Therefore, factors affecting the machining economy and productivity, such as tool life, chip control, idle time of the machine, waste material, power and time, can be controlled at the desired level, especially the final targets (production of the workpiece at desired tolerances and surface quality) [

11,

12]. The main problem that should be solved here is to observe the behavior of different cutting variables simultaneously in the complex nature of machining operations.

Balazinski et al. [

13] used a system of sensors to monitor tool wear based on the cutting forces in turning, and various artificial intelligence approaches for predictive purposes. In addition to the artificial neural network and fuzzy logic approaches, an artificial neural network model based on fuzzy logic was also used, and the results were compared. Al-Habaibeh and Gindy [

14] examined the number and type of sensors in milling to investigate tool conditions. The aim of this study is to facilitate design optimization and development by reducing the cost and time of the turning process of AISI 5140 steel alloy. In the study, the Taguchi experimental design was used and

AE (Acoustic Emission), vibration, current and cutting force signals were collected and evaluated. Oraby and Hayhurst [

15] employed non-linear regression analysis to develop models that can estimate tool wear/life in terms of force ratios, instead of using absolute values of force. During the turning of stainless steel, a sensor system was established with the help of neural networks to determine formation using cutting forces and

AE signals [

16]. Tool wear values were measured offline, and AE and power signals were measured on-line. It was observed that the

AE signals were successful in tool wear monitoring, and the axial force increased with the increase of tool wear so that cutting forces could also be used. Zhang et al. [

17] presented a sensor system that can predict tool wear and tool life, defined as a low-cost and effective manufacturing optimization method. The system includes vibration, shear force and power sensors. The results showed that the multi-sensor system is an effective method.

Ratava et al. [

18] established a sensor system to examine the intermittent cutting situation that occurs during the turning of a flywheel, and to monitor the wear occurring in the cutting tool. The system is based on the use of acceleration sensors to estimate the tool deflection as a source of the actual cutting force. It was found that this method can be used to prevent catastrophic failure, and to prevent small breaks in the tool. Ambhore et al. [

19] observed tool wear using the vibrations that occurred during the turning of an AISI 52100 material. Multiple regression models were used to show the relationship between tool vibrations and tool wear. Ong et al. [

20] established a sensor system based on an artificial neural network and examined the effect of different levels of cutting speed, feed, depth of cut and machining time on surface roughness and tool wear.

VB estimation was made using an artificial neural network. In addition to cutting parameters and machining time, tool wear can be successfully estimated with the contribution of the image processing method. Panda et al. [

21] performed the monitoring of tool wear, surface roughness and vibration in the turning of AISI 52100 material. According to the results, cutting speed was the most effective parameter on

VB, surface roughness and vibration. Bhuiyan et al. [

22] introduced a method that separates the signal frequency that occurs during tool wear and plastic deformation using an

AE sensor. As a result, it was revealed that the two cases showed variation in their frequency ranges. While tool wear frequency fluctuates in different stages of wear,

AE signal amplitude increases with the increased tool wear and depth of cut. Based on the previous literature [

13,

14,

15,

16,

17,

18,

19,

20,

21,

22], it can be concluded that none of the previous studies utilized various sensors.

Azouzi and Guillot [

23] have designed a system based on a sensor system and an artificial neural network, using force, vibration and temperature sensors. Successful predictions were carried out with an acceptable error rate in the study, wherein the dimensional deviation and surface finish were successfully estimated. Chen and Jen [

24] developed a sensor system model based on cutting force and vibration measurements in milling. A sensor system based on an artificial neural network measurement was established, tool wear estimation was also performed, and network training and test performance were evaluated. Mali et al. [

25] developed a sensor system based on force and vibration measurement in turning the Inconel 718 material. With this system, tool wear was monitored in real-time and the results were evaluated with variance analysis based on the Taguchi method. It has been observed that tool wear estimation with sensor systems can be obtained with higher accuracy. Duro et al. [

26] conducted a study to understand the most accurate sensor region for monitoring the cutting process, and which sensor signal defines the process most accurately. They aimed to use different signal features related to the cutting process, and make an estimate by using a sensor system. Wu et al. [

27] designed an information and prediction system based on a fuzzy logic extraction system using a sensor system. In this way, the amount of wear was estimated by a method based on multiple sensor systems, and

AE, vibration and current sensors were used. Looking back at the summarized literature, it can be concluded that none of the previous studies monitored tool wear and surface roughness during the turning of AISI 5140 steel.

It is important to obtain desired surface roughness in machining operations, as it is the final process in the production of a part. In this manner, a variety of methods for measuring the surface roughness in order to minimize flatness, model surface topography and monitor with sensors exist. Pimenov et al. [

28] reported a study on modeling flatness deviation while compensating for the torsional angle of the milling face. Quinsat and Tournier [

29] proposed an in-situ measurement system for surface roughness to solve the problem of removing the workpiece material from the machine tool. Nieslony et al. [

30] performed a study based on solving the turning of mould parts precisely for topographic inspection and surface roughness. Wojciechowski [

31] carried out a study on the relationship between tool displacements and surface quality at the end milling process. Krolczyk [

32] demonstrated the description of surface topography in dry and lubricated cutting conditions, and found that the roughness of the surface can be reduced by using lubrication. Li et al. [

33,

34] presented studies of on-machine surface measurement to increase accuracy and efficiency during machining operations. Shahabi and Ratnam [

35] utilized machine vision for the monitoring of tool wear and surface roughness, and the effect of nose wear on surface quality was investigated as well. Rao et al. [

36] presented a TCMS for a boring operation measuring surface roughness in addition to vibration and material removal rate, and an empirical relation was obtained for tool life and surface roughness. Bustillo et al. [

37] used different artificial intelligence methods, namely multilayer perceptron, radial basis networks and random forest, for the prediction of surface wear during electro discharge machining, turning and grinding operations. Pimenov et al. [

38] proposed an artificial intelligence-based prediction using teeth wear in a face milling operation. They compared different methods, namely random forest, multilayer perceptron, regression trees and radial-based functions, and random forest was found as the most accurate model. Kassim et al. [

39] used tool conditions for the identification of surface texture, and they reported that TCMS can be accurately implemented in analyzing surface texture.

Maruda et al. [

40] presented an analytical approach for the different lubrication conditions after a turning operation. They intended to find the minimum surface roughness value, and reported that oil retention leads to an increase in surface roughness. Sivaiah et al. [

41] compared the effect of cryogenic coolant conditions with a minimum quantity of lubrication, wet machining and dry machining. According to the results, cryogenic machining seems the best option for surface integrity and tool wear. Priarone et al. [

42] tested the performance of Cubic Boron Nitride (CBN) and Polycrystalline Diamond (PCD) cutting tools for tool life and surface integrity under cryogenic cooling and conventional cooling. Cryogenic cutting with PCD provided the best solution. Da Silva et al. [

43] focused on surface integrity and tool life under different cooling conditions, and high-pressure coolant provided the best tool life. Said et al. [

44] investigated the studies on using nano-cutting fluids comprehensively. Sarıkaya et al. [

45] studied the effects of dry, conventional cooling and minimum quantity lubrication methods on tool wear and surface roughness. They obtained the optimum cutting conditions for the cutting parameters and lubrication conditions of the turning of Haynes 25. Sartori et al. [

46] purpose to test the different minimum quantity lubrication strategies for better tool life and surface integrity using a solid lubricant. They found that new strategies gave increased tool life and surface integrity. Mia et al. [

47] developed an approach to hard turning under different cooling conditions, and found that the minimum quantity of lubrication provided desirable machining conditions.

In machining, TCMS, which comprises sensors, data acquisition equipment, data processing software and measuring devices adapted to machine tools, is required for determining machinability. Sensors can monitor a mechanical system to detect the changes and transmit the information for further evaluation with computer software. From this point of view, it is seen that it has relevance to sensor system [

3,

13,

14] and wear-roughness inspection [

48,

49] studies. Investigating the effects of cutting parameters via ANOVA provides information on the availability of each sensor’s data in the monitoring of response parameters, i.e., flank wear and SR. Beyond following a quality indicator, TCMS can make decisions with an artificial intelligence supporting system by making on-line deductions about the condition of the process.

The workpiece material AISI 5140 was chosen because of its wide range of utilizations in the automotive and energy industries. The alloy has a high-strength and -hardness structure that leads to excessive cutting forces and cutting vibrations, and finally make it difficult for machining. This situation arises from the high chrome content and resultant hard carbides. The studies on machining AISI 5140 steel in the open literature are limited. Furthermore, the use of multi sensor systems simultaneously to monitor machining outputs such as tool wear and surface roughness is not reported. On the machinability of AISI 5140, Grzesik [

50] explored wear development in hard turning, and found abrasive, adhesive and fracture generation on ceramic tools. Ebrahimi and Moshksar [

51,

52] investigated the effect of cutting speed, feed rate and cutting force on flank wear during boring, and the influence of cutting speed, feed rate and hardness on tool life in the turning operation. Li et al. [

53] performed a study based on different coating conditions, and found that TiN-coated tools demonstrated abrasive and adhesive wear, while TiAlN-coated tools showed adhesive, diffusive and oxidation wear. Zhang et al. [

54] examined an experimental study for sintered tools to obtain wear mechanisms and optimum cutting conditions during turning. According to the results, cermet tools offered a better performance than cemented carbide tools. Bican et al. [

55] researched the influence of boriding, quenching and tempering after boriding on the wear development of AISI 5140, and they found that quenching and tempering after boriding reduces tool life. The investigation of the machining of AISI 5140 only concerned grinding; for example, Huang et al. [

56] examined the effect of lubrication, Köklü [

57] researched the effect of different-angled grooved grinding wheels on AISI 5140, and Grzesik and Wanat investigated the surface roughness under different feed rates. For the optimal cutting conditions of AISI 5140, Kahraman [

58] performed an optimization approach in the turning of AISI 5140 steel for better surface roughness. Aslan [

59] also proposed an optimization and analysis for minimum flank wear, cutting forces and vibration. As can be seen, limited research exists in the open literature about AISI 5140 carbon steel, and none of it handles the turning of this material based on a multi-sensor system. One of the main objectives of this study is to fill this gap.

ANOVA is a widely used statistical technique in many fields of research. It determines and quantifies the effective experimental factors (i.e., cutting parameters) affecting the measured outcome of an experiment (i.e., machining quality characteristics). Accordingly, the levels of effectiveness of the parameters with various statistical values are expressed numerically. A large number of researchers employed statistical analysis to study the various machining parameters of a wide range of materials under different cutting conditions, which reflects the success of this approach [

3,

60,

61,

62,

63,

64].

Having more parameters and variables, turning is applied in industrial studies as the most common manufacturing method. To eliminate failures and maximize productivity, sensor-based systems have been used in the past, as was mentioned before. Only one or a group of these sensors were compared and evaluated, but the success of all in the detection of several results cannot be seen in the literature. The summarized review indicates that no previous study seems to pursue an investigation of the influence of cutting speed, feed rate and depth of cut on VB and Ra, based on multi-sensorial data, namely cutting force, vibration, AE, temperature and motor current. The investigation of cutting parameters for all the cutting variables provides a comprehensive guideline for scientists and manufacturers to obtain high quality products, and makes it easy to evaluate the resultant cutting variables during turning of AISI 5140.

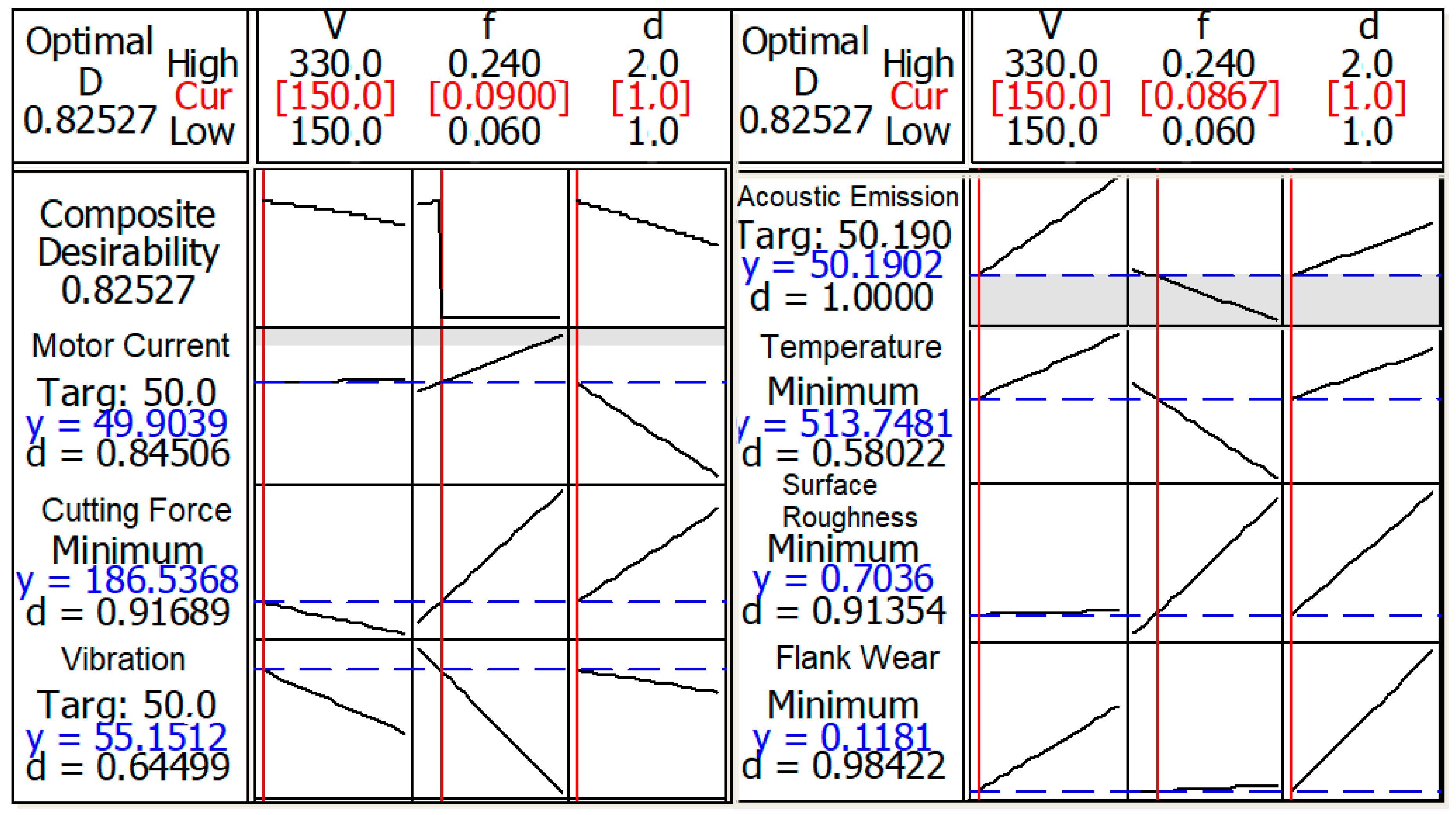

To fill this gap, this paper deals with five different sensors and vital quality characteristics; specifically, VB and Ra were evaluated with ANOVA. The experimental plan involved using the Taguchi method. Besides, RSM-based optimization was applied to VB and Ra and sensorial data. Three levels of cutting speed, feed rate and depth of cut were used to compose the experimental study during the dry turning of an AISI 5140 material. Cutting force, vibration, AE, temperature and motor current measurements were performed as on-line during machining, while VB and Ra were measured as off-line when the tool machine was stopped. A statistical, and subsequently an optimization, approach with various measurement devices provides broad perspectives, and provides practical recommendations for the turning of AISI 5140 steel.