Iterative Learning Control for a Soft Exoskeleton with Hip and Knee Joint Assistance

Abstract

1. Introduction

- A novel assistance scheme is proposed for assisting one-leg hip joint flexion and extension as well as knee joint extension through a single actuator, which is obtained by actuating the Knee Board and the wraps of the front side of the hip with one motor. It is beneficial to decrease the system’s weight and increase the convenience of wearing. The muscle fatigue of wearers can be reduced significantly through this scheme on different terrains.

- We employ an iterative learning control approach, based on parameter optimization, to improve the performance of assistance by compensating the error generated from the wearing position and terrain change. The approach makes the exoskeleton suitable for different pilots.

- The assistance strategy is built based on the biological moment of human walking on different slopes, and the resulting effectiveness is verified through experiment.

2. System Overview

2.1. Design of The Proposed Soft Lower Limb Exoskeleton

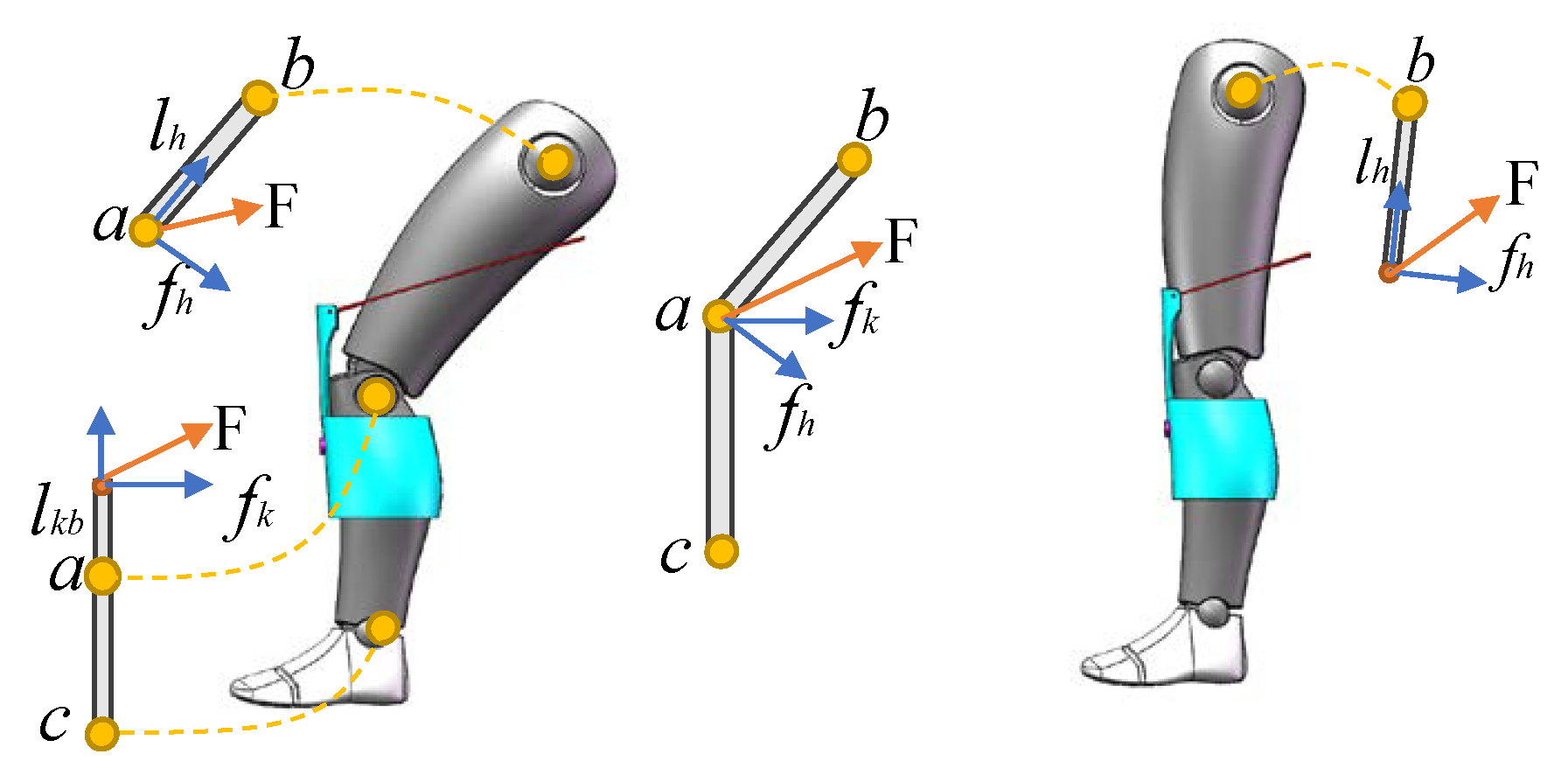

2.2. Movement Character

2.3. Modeling

3. Control

3.1. Assistance Strategy

3.2. Gait Event Estimation Using IMU

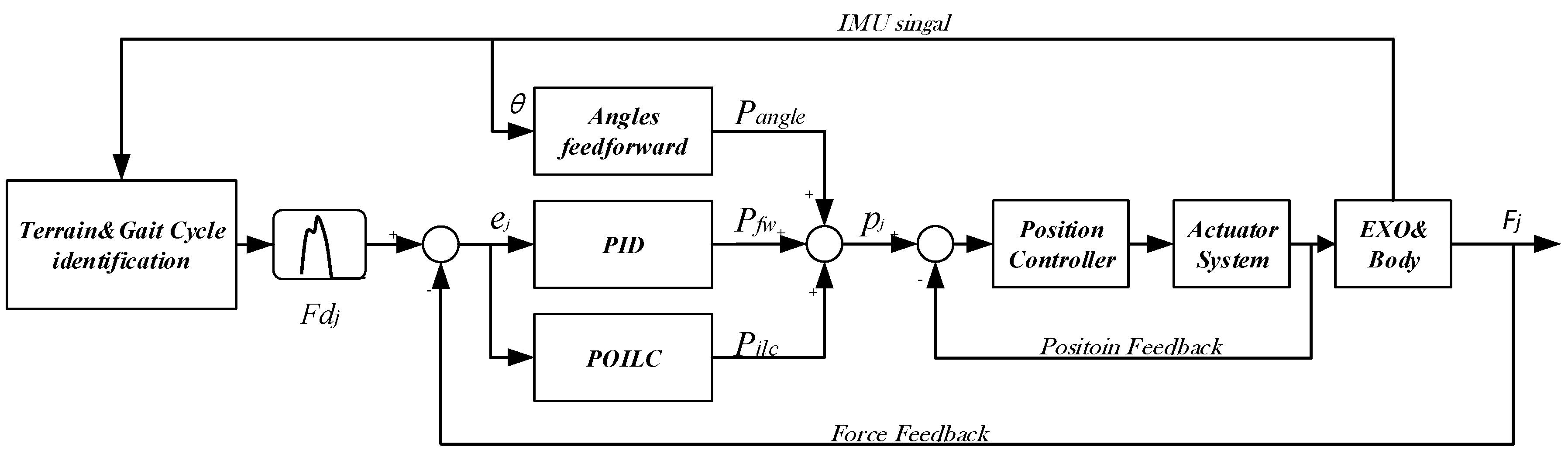

3.3. Controller Design

4. Experimentation

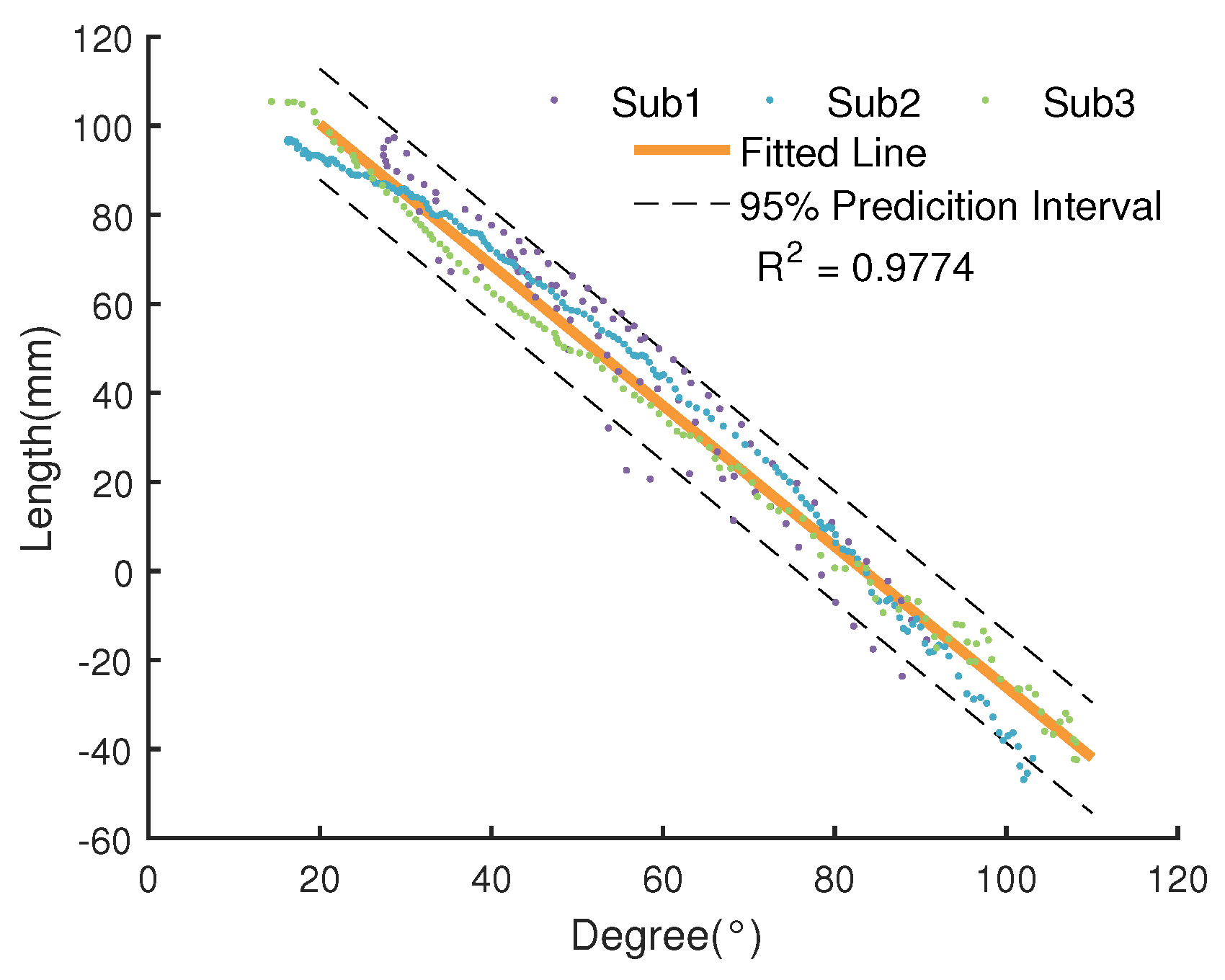

4.1. Model Validation

4.2. The Force Tracking Performance Evaluation

4.3. Metabolic Cost Test

4.3.1. Experimental Setup and Protocol

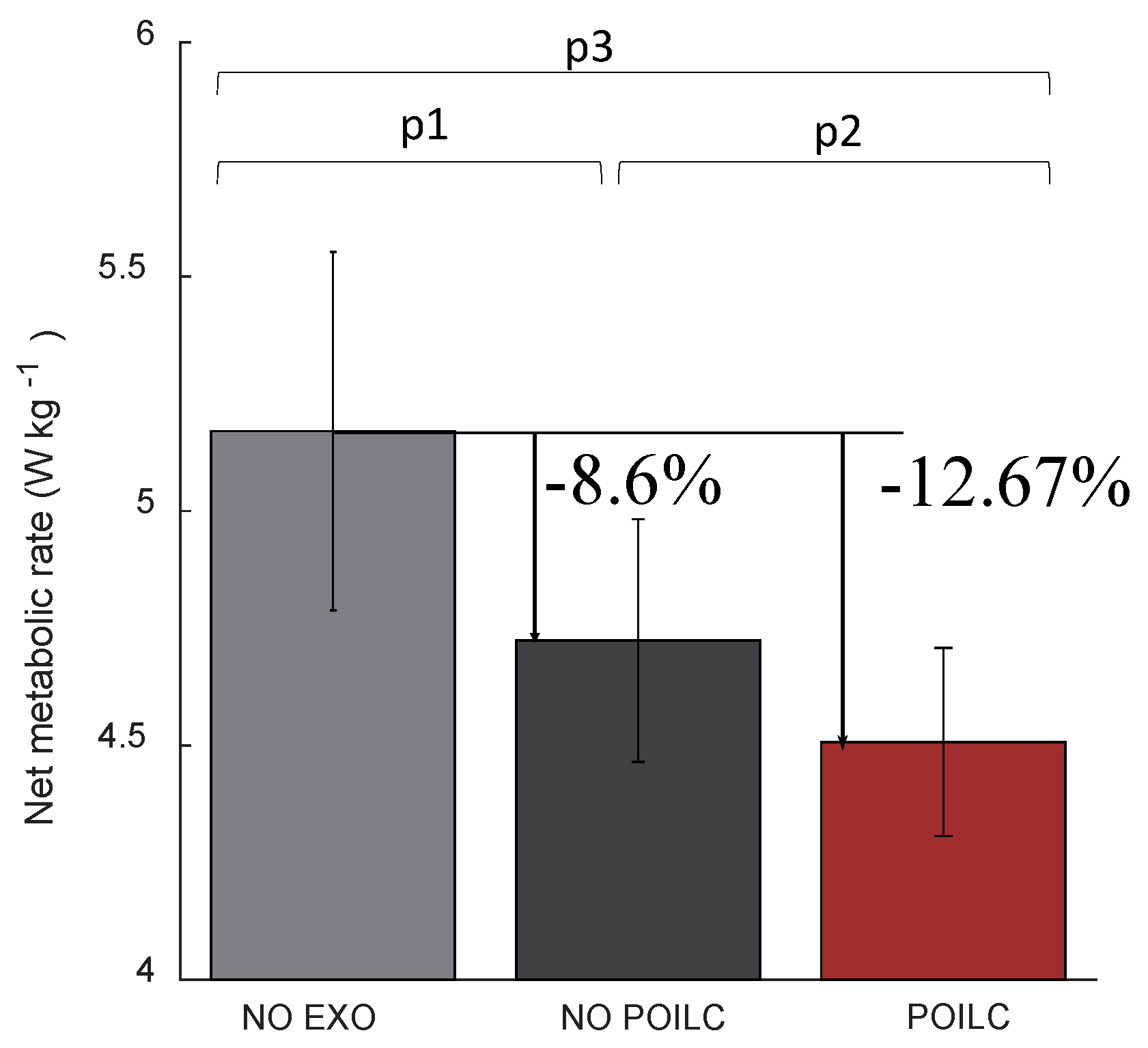

4.3.2. Metabolic Reduction by POILC

4.3.3. Metabolic Reduction in Three Slopes

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| GC | Gait Cycle |

| IMU | Inertial measurement unit |

| ILC | Iterative learning control |

| POILC | Parameter optimal iterative learning control |

References

- Winter, D.A.; Patla, A.E.; Frank, J.S.; Walt, S.E. Biomechanical Walking Pattern Changes in the Fit and Healthy Elderly. Phys. Ther. 1990, 70, 340–347. [Google Scholar] [CrossRef] [PubMed]

- Duschau-Wicke, A.; Zitzewitz, J.V.; Caprez, A.; Lunenburger, L.; Riener, R. Path control: A method for patient-cooperative robot-aided gait rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2010, 18, 38–48. [Google Scholar] [CrossRef] [PubMed]

- Wehner, M.; Quinlivan, B.; Aubin, P.M.; Martinez-Villalpando, E.; Baumann, M.; Stirling, L.; Holt, K.; Wood, R.; Walsh, C. A lightweight soft exosuit for gait assistance. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 3362–3369. [Google Scholar] [CrossRef]

- Caldwell, D.G.; Tsagarakis, N.G.; Kousidou, S.; Costa, N.; Sarakoglou, I. “SOFT” Exoskeletons for upper and lower body rehabilitation—Design, control and testing. Int. J. Humanoid Robot. 2007, 4, 549–573. [Google Scholar] [CrossRef]

- Schmidt, K.; Duarte, J.E.; Grimmer, M.; Sancho-Puchades, A.; Wei, H.; Easthope, C.S.; Riener, R. The myosuit: Bi-articular anti-gravity exosuit that reduces hip extensor activity in sitting transfers. Front. Neurorobotics 2017, 11, 57. [Google Scholar] [CrossRef] [PubMed]

- Asbeck, A.T.; Schmidt, K.; Walsh, C.J. Soft exosuit for hip assistance. Robot. Auton. Syst. 2015, 73, 102–110. [Google Scholar] [CrossRef]

- Asbeck, A.T.; Rossi, S.M.M.D.; Holt, K.G.; Walsh, C.J. A biologically inspired soft exosuit for walking assistance. Int. J. Robot. Res. 2015, 34, 744–762. [Google Scholar] [CrossRef]

- Lee, S.; Karavas, N.; Quinlivan, B.T.; LouiseRyan, D.; Perry, D.; Eckert-Erdheim, A.; Murphy, P.; Goldy, T.G.; Menard, N.; Athanassiu, M.; et al. Autonomous multi-joint soft exosuit for assistance with walking Overground. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; pp. 2812–2819. [Google Scholar]

- Ortiz, J.; Rocon, E.; Power, V.; de Eyto, A.; O’Sullivan, L.; Wirz, M.; Bauer, C.; Schülein, S.; Stadler, K.S.; Mazzolai, B.; et al. Xosoft-a vision for a soft modular lower limb exoskeleton. In Wearable Robotics: Challenges and Trends; Springer: Berlin, Germany, 2017; pp. 83–88. [Google Scholar]

- Ortiz, J.; Di Natali, C.; Caldwell, D.G. XoSoft-iterative design of a modular soft lower limb exoskeleton. In Proceedings of the International Symposium on Wearable Robotics, Pisa, Italy, 16–20 October 2018; Springer: Berlin, Germany, 2018; pp. 351–355. [Google Scholar]

- Park, Y.L.; Santos, J.; Galloway, K.G.; Goldfield, E.C.; Wood, R.J. A soft wearable robotic device for active knee motions using flat pneumatic artificial muscles. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 4805–4810. [Google Scholar]

- Collins, S.H.; Kim, M.; Chen, T.; Chen, T. An ankle-foot prosthesis emulator with control of plantarflexion and inversion-eversion torque. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 1210–1216. [Google Scholar]

- Sasaki, D.; Noritsugu, T.; Takaiwa, M. Development of pneumatic lower limb power assist wear driven with wearable air supply system. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 4440–4445. [Google Scholar]

- Di Natali, C.; Sadeghi, A.; Mondini, A.; Bottenberg, E.; Hartigan, B.; De Eyto, A.; O’Sullivan, L.; Rocon, E.; Stadler, K.; Mazzolai, B.; et al. Pneumatic Quasi-Passive Actuation for Soft Assistive Lower Limbs Exoskeleton. Front. Neurorobotics 2020. [Google Scholar] [CrossRef]

- Jin, S.; Iwamoto, N.; Hashimoto, K.; Yamamoto, M. Experimental evaluation of energy efficiency for a soft wearable robotic suit. IEEE Trans. Neural Syst. Rehabil. Eng. 2016, 25, 1192–1201. [Google Scholar] [CrossRef]

- Di Natali, C.; Poliero, T.; Sposito, M.; Graf, E.; Bauer, C.; Pauli, C.; Bottenberg, E.; De Eyto, A.; O’Sullivan, L.; Hidalgo, A.F.; et al. Design and evaluation of a soft assistive lower limb exoskeleton. Robotica 2019, 37, 2014–2034. [Google Scholar] [CrossRef]

- Manti, M.; Cacucciolo, V.; Cianchetti, M. Stiffening in soft robotics: A review of the state of the art. IEEE Robot. Autom. Mag. 2016, 23, 93–106. [Google Scholar] [CrossRef]

- Lenzi, T.; Carrozza, M.C.; Agrawal, S.K. Powered hip exoskeletons can reduce the user’s hip and ankle muscle activations during walking. IEEE Trans. Neural Syst. Rehabil. Eng. 2013, 21, 938–948. [Google Scholar] [CrossRef] [PubMed]

- Asbeck, A.T.; Schmidt, K.; Galiana, I.; Wagner, D.; Walsh, C.J. Multi-joint soft exosuit for gait assistance. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 6197–6204. [Google Scholar]

- Ding, Y.; Galiana, I.; Asbeck, A.; Quinlivan, B.; De Rossi, S.M.M.; Walsh, C. Multi-joint actuation platform for lower extremity soft exosuits. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 1327–1334. [Google Scholar]

- Lee, G.; Ding, Y.; Bujanda, I.G.; Karavas, N.; Zhou, Y.M.; Walsh, C.J. Improved assistive profile tracking of soft exosuits for walking and jogging with off-board actuation. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 1699–1706. [Google Scholar]

- Bristow, D.A.; Tharayil, M.; Alleyne, A.G. A survey of iterative learning control. IEEE Control Syst. Mag. 2006, 26, 96–114. [Google Scholar]

- Angelini, F.; Della Santina, C.; Garabini, M.; Bianchi, M.; Gasparri, G.M.; Grioli, G.; Catalano, M.G.; Bicchi, A. Decentralized trajectory tracking control for soft robots interacting with the environment. IEEE Trans. Robot. 2018, 34, 924–935. [Google Scholar] [CrossRef]

- Marchese, A.D.; Tedrake, R.; Rus, D. Dynamics and trajectory optimization for a soft spatial fluidic elastomer manipulator. Int. J. Robot. Res. 2016, 35, 1000–1019. [Google Scholar] [CrossRef]

- Hofer, M.; Spannagl, L.; D’Andrea, R. Iterative Learning Control for Fast and Accurate Position Tracking with a Soft Robotic Arm. arXiv 2019, arXiv:1901.10187. [Google Scholar]

- Ding, Y.; Galiana, I.; Siviy, C.; Panizzolo, F.A.; Walsh, C. IMU-based iterative control for hip extension assistance with a soft exosuit. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 3501–3508. [Google Scholar]

- Huang, R.; Cheng, H.; Guo, H.; Chen, Q.; Lin, X. Hierarchical interactive learning for a human-powered augmentation lower exoskeleton. In Proceedings of the 2016 IEEE international conference on robotics and automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 257–263. [Google Scholar]

- Li, J.A.; Dong, D.; Wei, Z.; Liu, Y.; Pan, Y.; Nori, F.; Zhang, X. Quantum reinforcement learning during human decision-making. Nat. Hum. Behav. 2020, 4, 294–307. [Google Scholar] [CrossRef]

- Perry, J.; Davids, J.R.; Jon, R. Gait analysis: Normal and pathological function. J. Pediatr. Orthop. 1992, 12, 815. [Google Scholar] [CrossRef]

- McIntosh, A.S.; Beatty, K.T.; Dwan, L.N.; Vickers, D.R. Gait dynamics on an inclined walkway. J. Biomech. 2006, 39, 2491–2502. [Google Scholar] [CrossRef]

- Ding, Y.; Kim, M.; Kuindersma, S.; Walsh, C.J. Human-in-the-loop optimization of hip assistance with a soft exosuit during walking. Sci. Robot. 2018, 3, eaar5438. [Google Scholar] [CrossRef]

- Voloshina, A.S.; Kuo, A.D.; Daley, M.A.; Ferris, D.P. Biomechanics and energetics of walking on uneven terrain. J. Exp. Biol. 2013, 216, 3963–3970. [Google Scholar] [CrossRef]

- Zhang, J.; Fiers, P.; Witte, K.A.; Jackson, R.W.; Poggensee, K.L.; Atkeson, C.G.; Collins, S.H. Human-in-the-loop optimization of exoskeleton assistance during walking. Science 2017, 356, 1280–1284. [Google Scholar] [CrossRef] [PubMed]

- Felt, W.; Selinger, J.C.; Donelan, J.M.; Remy, C.D. “Body-In-The-Loop”: Optimizing Device Parameters Using Measures of Instantaneous Energetic Cost. PLoS ONE 2015, 10, e0135342. [Google Scholar] [CrossRef]

- Haufe, F.L.; Wolf, P.; Riener, R. Human-in-the-loop optimization of a multi-joint wearable robot for movement assistance. Proc. Autom. Med Eng. 2020, 1, 023. [Google Scholar]

- Wu, X.; Fang, K.; Chen, C.; Zhang, Y. Development of a lower limb multi-joint assistance soft exosuit. Sci. China Inf. Sci. 2020, 63, 170207. [Google Scholar] [CrossRef]

- Knapik, J.J.; Reynolds, K.L.; Harman, E. Soldier load carriage: Historical, physiological, biomechanical, and medical aspects. Mil. Med. 2004, 169, 45–56. [Google Scholar] [CrossRef] [PubMed]

- Ordóñez, F.J.; Roggen, D. Deep convolutional and lstm recurrent neural networks for multimodal wearable activity recognition. Sensors 2016, 16, 115. [Google Scholar] [CrossRef]

- Zhang, K.; Xiong, C.; Zhang, W.; Liu, H.; Lai, D.; Rong, Y.; Fu, C. Environmental features recognition for lower limb prostheses toward predictive walking. IEEE Trans. Neural Syst. Rehabil. Eng. 2019, 27, 465–476. [Google Scholar] [CrossRef]

- Jang, J.; Kim, K.; Lee, J.; Lim, B.; Shim, Y. Online gait task recognition algorithm for hip exoskeleton. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 5327–5332. [Google Scholar]

- Owens, D.H.; Hätönen, J. Iterative learning control—An optimization paradigm. Annu. Rev. Control 2005, 29, 57–70. [Google Scholar] [CrossRef]

- Brockway, J. Derivation of formulae used to calculate energy expenditure in man. Hum. Nutr. Clin. Nutr. 1987, 41, 463–471. [Google Scholar]

- Kim, J.; Lee, G.; Heimgartner, R.; Revi, D.A.; Karavas, N.; Nathanson, D.; Galiana, I.; Eckert-Erdheim, A.; Murphy, P.; Perry, D.; et al. Reducing the metabolic rate of walking and running with a versatile, portable exosuit. Science 2019, 365, 668–672. [Google Scholar] [CrossRef]

- Ding, Y.; Panizzolo, F.A.; Siviy, C.; Malcolm, P.; Galiana, I.; Holt, K.G.; Walsh, C.J. Effect of timing of hip extension assistance during loaded walking with a soft exosuit. J. Neuroeng. Rehabil. 2016, 13, 87. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Seo, K.; Lim, B.; Jang, J.; Kim, K.; Choi, H. Effects of assistance timing on metabolic cost, assistance power, and gait parameters for a hip-type exoskeleton. In Proceedings of the 2017 International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 498–504. [Google Scholar]

- Collins, S.H.; Wiggin, M.B.; Sawicki, G.S. Reducing the energy cost of human walking using an unpowered exoskeleton. Nature 2015, 522, 212. [Google Scholar] [CrossRef] [PubMed]

| Device | Number | Mass (g) |

|---|---|---|

| motor | 2 | 662 |

| actuator | 2 | 320 |

| gearbox | 2 | 768 |

| pulley | 2 | 220 |

| battery | 1 | 700 |

| wraps | 2 | 630 |

| vest | 1 | 670 |

| IMU | 2 | 80 |

| load cell | 4 | 188 |

| other part | – | 621 |

| total | – | 4859 |

| Terrain | Reduction | ||

|---|---|---|---|

| 13.55 | 6.61 | 51.22% | |

| flat | 37.20 | 19.92 | 46.45% |

| 37.61 | 25.20 | 33.00% |

| Subject | Downhill (−10°) | Flat (0°) | Uphill (10°) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| NE | AO | Re | NE | AO | Re | NE | AO | Re | |

| (W/kg) | (W/kg) | (W/kg) | (W/kg) | (W/kg) | (W/kg) | ||||

| S1 | 2.88 | 2.67 | 7.42% | 4.69 | 4.20 | 10.61% | 7.48 | 5.79 | 22.54% |

| S2 | 2.60 | 2.36 | 9.11% | 5.42 | 4.72 | 12.83% | 7.54 | 5.93 | 21.41% |

| S3 | 2.67 | 2.37 | 11.57% | 5.90 | 5.08 | 13.90% | 9.53 | 7.27 | 21.51% |

| S4 | 2.73 | 2.48 | 9.30% | 6.44 | 5.58 | 13.34% | 6.50 | 5.05 | 22.35% |

| S5 | 2.98 | 2.62 | 11.84% | 5.89 | 5.29 | 10.20% | 6.42 | 5.37 | 16.47% |

| S6 | 3.20 | 2.88 | 9.91% | 6.19 | 5.32 | 14.00% | 5.85 | 4.33 | 25.99% |

| Research | Assistance | System Weight (Kg) | Application Scenarios | Maximum Energy Cost Reduction (%) |

|---|---|---|---|---|

| Kim [43] | Hip extension | 5.004 | Different slope | 9.3 |

| Sangjun [8] | Hip extension and flexion | 5.1 | Outdoors | 16.93 |

| & Ankle plantar flexion | ||||

| Ding [31] | Hip extension | N.A | Flat ground | 17.4 |

| Juanjuan Zhang [33] | Ankle plantar flexion | N.A | Flat ground | 24.2 |

| Collins [46] | Ankle plantar flexion | 1 | Flat ground | 7.2 |

| This work | Hip extension and flexion | 4.6 | Different slope | 22.08 |

| & Knee extension |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Zhang, Y.; Li, Y.; Wang, Z.; Liu, Y.; Cao, W.; Wu, X. Iterative Learning Control for a Soft Exoskeleton with Hip and Knee Joint Assistance. Sensors 2020, 20, 4333. https://doi.org/10.3390/s20154333

Chen C, Zhang Y, Li Y, Wang Z, Liu Y, Cao W, Wu X. Iterative Learning Control for a Soft Exoskeleton with Hip and Knee Joint Assistance. Sensors. 2020; 20(15):4333. https://doi.org/10.3390/s20154333

Chicago/Turabian StyleChen, Chunjie, Yu Zhang, Yanjie Li, Zhuo Wang, Yida Liu, Wujing Cao, and Xinyu Wu. 2020. "Iterative Learning Control for a Soft Exoskeleton with Hip and Knee Joint Assistance" Sensors 20, no. 15: 4333. https://doi.org/10.3390/s20154333

APA StyleChen, C., Zhang, Y., Li, Y., Wang, Z., Liu, Y., Cao, W., & Wu, X. (2020). Iterative Learning Control for a Soft Exoskeleton with Hip and Knee Joint Assistance. Sensors, 20(15), 4333. https://doi.org/10.3390/s20154333