1. Introduction

During the last decade, implantable electronics have become increasingly popular for the treatment of drug-resistant diseases and as an alternative to traditional therapies using pharmaceuticals. A large number of implantable electronics, such as the retinal implants Argus II (Second Sight Medical Products Inc., Sylmar, CA, USA), IRIS II (Pixium Vision S.A., Paris, France), Alpha AMS and IMS (Retina Implant AG, Reutlingen, Germany) [

1,

2], the vagus nerve stimulators AspireSR and SenTivaTM (LivaNova PLC, London, UK) [

3], or the hypoglossal nerve stimulator from Inspire Medical Systems [

4], are nowadays used to treat diseases such as retinitis pigmentosa, age-related macular degeneration, epilepsy, depression, pain, tinnitus and obstructive sleep apnea.

The extension of the field of application of implantable electronics is associated with increased requirements in terms of functionality and miniaturization without impairing reliability. Most of the implantable electronic devices with application in functional electrostimulation comprise a large number of active electronic components, sensors and a bulky battery unit. As a consequence, the degree of miniaturization is restricted, whereby the implantable electronics cannot be placed at the location where the stimulation pulses need to be applied. The electrical stimulation pulses are delivered through wire-bound electrodes, which are susceptible to migration and fracture over time [

5]. Examples include the Argus II epiretinal implantable system [

1,

6] and the Alpha IMS subretinal implantable system [

1,

7] where a wire connection through the eye is required to connect the stimulation electrodes to the implantable electronics. Such connections are exposed to mechanical stress, require a more complex surgical procedure and increase the risk of infections. The latter can lead to complications and prevent long-term use [

8]. From this point of view, highly miniaturized implantable systems would be more suitable [

9].

A considerable advantage of advanced implantable electronics is the implementation of a wide range of functionalities. This is at the expense of high circuit complexity and the need of a battery unit, which may lead to malfunctions and age-related battery replacement [

10]. One solution concept is to use only passive electronic components to increase the degree of miniaturization and to use the intrinsic nonlinear properties of these electronic components to realize certain functionalities.

By applying this principle of frugal engineering, the stimulation current in implantable electronics could be determined by using the nonlinear junction capacitance of a rectifier diode without having to use sensors or other active electronic components [

11]. This principle was also used in the so-called “Neural Dust” sensors to wirelessly acquire neural signals using the intrinsic properties of a piezo-element [

12]. Due to the considerable reduction in the overall number of electrical components, a high degree of miniaturization was achieved. As a result, an implantable sensor with a length of 3 mm and a cross-section of 1 mm

2 was produced. The implantable electronics considered in this paper contain neither batteries nor sensors or active electronic components and are therefore not suitable for autonomous operation. Power is supplied by induction at a frequency below 1 MHz using an extracorporeal wearable device. The amount of inductively transferred power directly impacts the induced voltage.

In recent years, the suitability of ferroelectric ceramic capacitors, as control elements of resonant half-bridge converters and as tuning elements of resonant circuits for wireless power transmission, has been investigated [

13,

14,

15,

16,

17,

18]. In these applications, the intrinsic nonlinear properties of ferroelectric ceramic capacitors were used in resonant circuits. The use of ferroelectric ceramic capacitors as a control element and tuning element was realized by setting a DC bias voltage. In contrast, our strategy is to drive the nonlinear capacitors with an AC voltage.

In a previously published conference paper, we have introduced a simulation model for modeling the nonlinear properties of ferroelectric materials in ceramic capacitors [

19]. Exemplary calculations of two serially connected nonlinear capacitors were carried out in Mathcad Prime 3.1 and ANSYS 2019 R2 Simplorer and were subsequently validated by measurements. As a result, it was found that the Adams, Bulirsch–Stoer, Backward Differentiation Formula, Radau5 and the fourth-order Runge–Kutta method with adaptive step size and a resolution of 50 k points (Mathcad) and the Adaptive Trapezoid-Euler method with constant step size and a resolution of 500 k points and with an adaptive step size and a resolution between 50 k and 5 M points (ANSYS) are most suitable. Using these calculation methods, the modeling in ANSYS and Mathcad showed small and equal deviation from the measurements [

19].

Despite the high agreement between the calculations and the measurements, discrepancies in amplitude and time constants have been observed. In this paper, the cause of these discrepancies is investigated with the aim of improving the simulation model in terms of consistency, computing time and memory consumption.

2. Methods

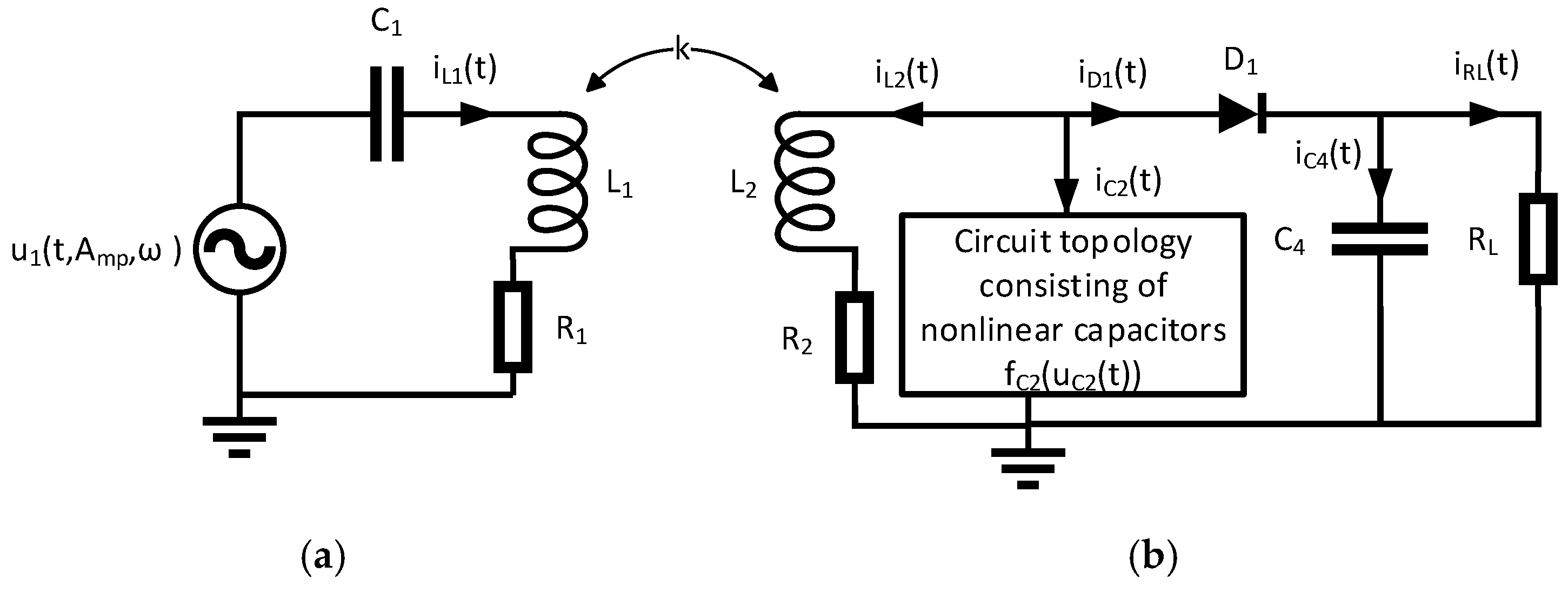

The designed circuit consists of an “extracorporeal” primary side that represents the inductive power supply (

Figure 1a) and an “implantable” secondary side that converts the inductively received power into stimulation pulses (

Figure 1b). The concept of the circuit in

Figure 1b is based on the design of the first visual prosthetic implant from Brindley [

20,

21,

22,

23]. Both resonant circuits are tuned to the same frequency. Power is transmitted on this frequency for a defined pulse duration and at a defined interval between successive pulses. The stimulation pulses are generated by rectification of the individual power pulses with diode D

1 and capacitor C

4. The duration and interval between the individual power pulses corresponds to the stimulation duration and frequency at the electrode impedance R

L.

The inductively coupled system for power transfer represented in

Figure 1 was described by the first-order differential Equations (1)–(9) [

24]:

where:

: inductive coupling factor between the inductances L1 and L2

: amplitude of the sinusoidal voltage

: angular frequency of the sinusoidal voltage

: electrical current across the primary resonant circuit

: electrical voltage across the capacitor C1

: electrical current across inductance L2 and its loss resistance R2

: electrical current across the circuit topology consisting of nonlinear capacitors

: electrical voltage across the circuit topology consisting of nonlinear capacitors

: electrical voltage across diode D1

: electrical current flowing through the diode D1 as a function of the voltage

: electrical voltage across the capacitor C4

: electrical current across the capacitor C4

: electrical current across the resistive load RL

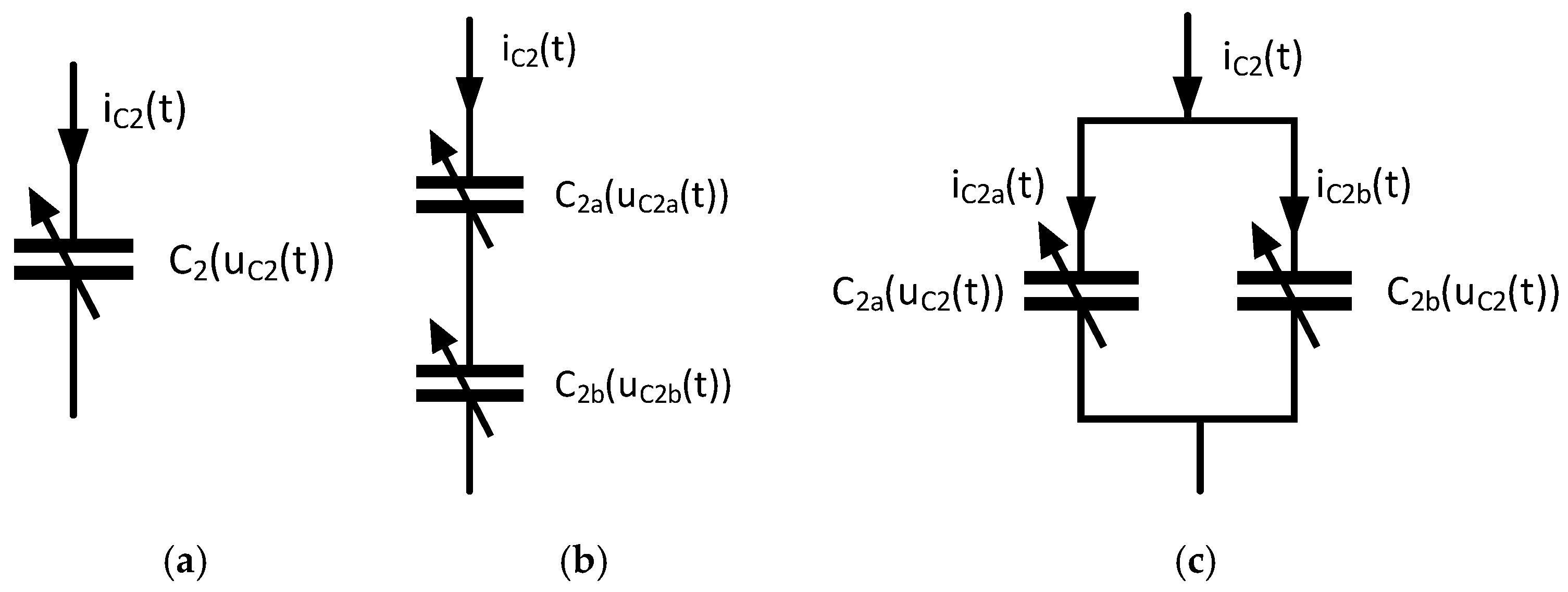

We investigated the following structures of nonlinear capacitors shown in

Figure 2. Depending on the structure under investigation, Equations (1)–(9) must be adapted.

Using the structure shown in

Figure 2a, Equation (4) must be changed to Equation (10).

By using the structure shown in

Figure 2b, Equation (4) must be changed to Equations (11) and (12) and the voltage

must be replaced by

.

By application of the structure shown in

Figure 2c, Equation (4) must be changed to Equations (13)–(14) and the current

must be replaced by

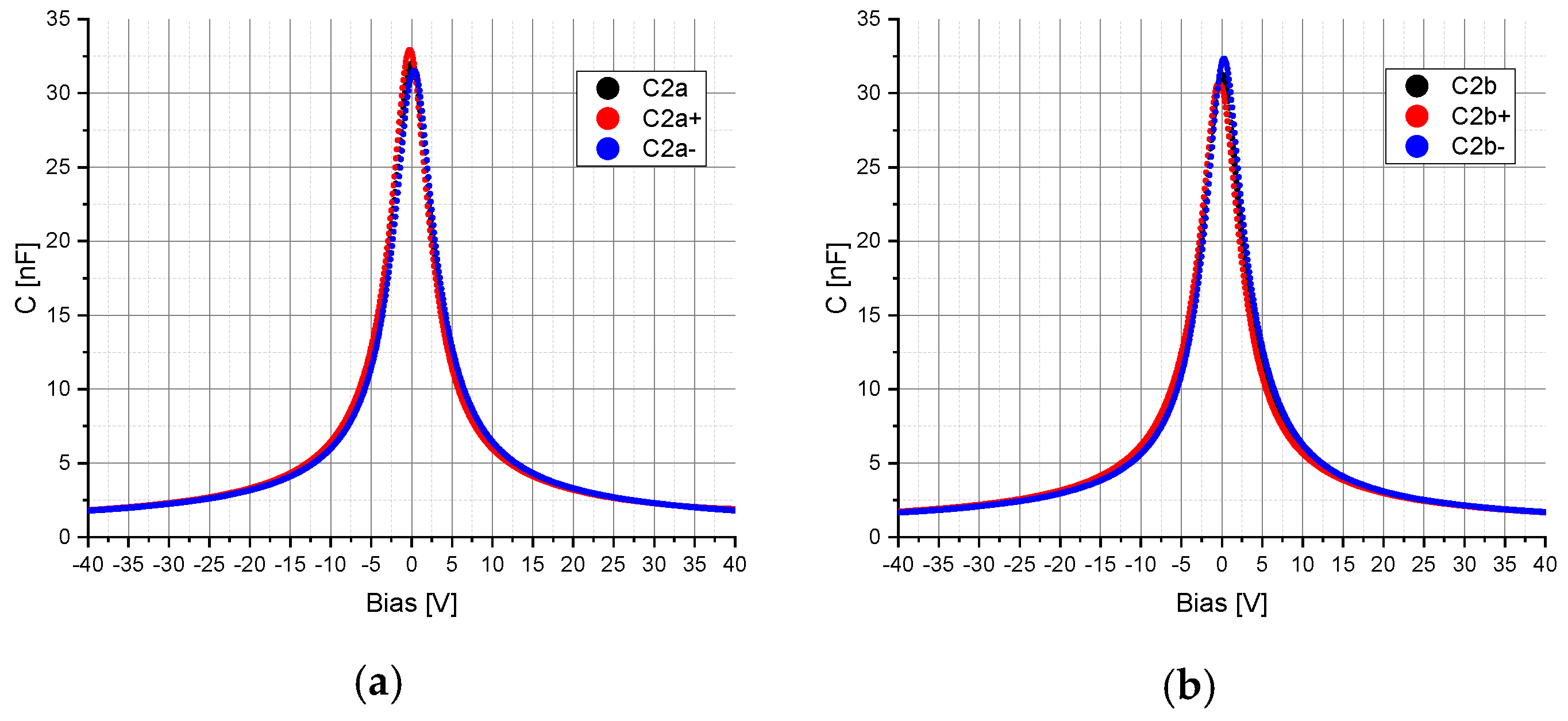

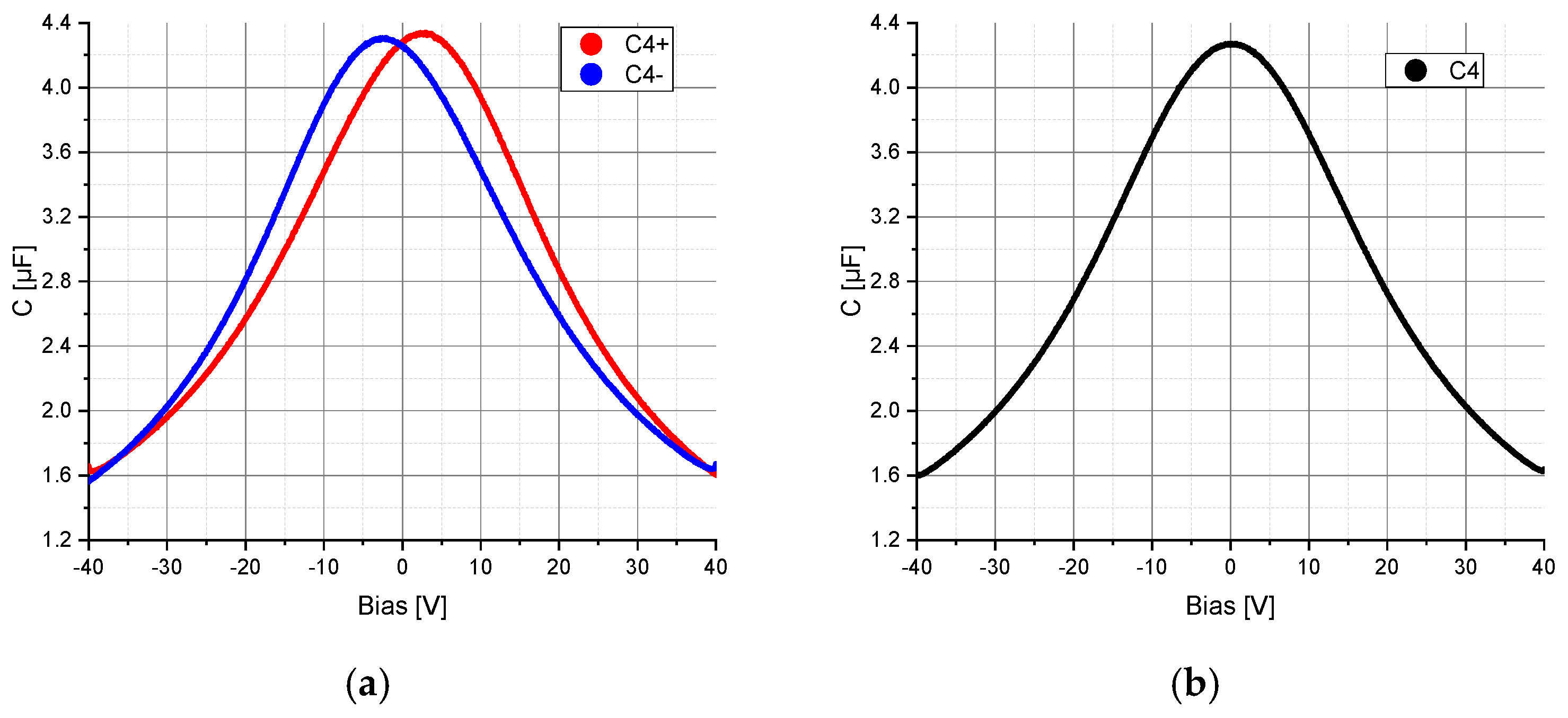

2.1. Characterization of the Voltage Dependency of Ceramic Capacitors

The voltage dependency of the capacitors C

2, C

2a, C

2b and C

4 was measured using the precision impedance analyzer Agilent 4294A (Agilent Technologies, Inc., Santa Clara, PA, USA, 4294A R1.11 Mar 25 2013) and the test fixture Agilent 16034E (Agilent Technologies, Inc., Santa Clara, PA, USA). The AC component was set to a frequency of 375 kHz for the capacitor C

2, C

2a and C

2b and to 40 Hz (lower limit of the impedance analyzer) for the voltage rectifier capacitor C

4. The amplitude was set to 5 mV and was superimposed with a DC bias voltage varying in the range from −40 V to +40 V with a resolution of 801 points. To determine the hysteresis, the electrical capacitance of C

2, C

2a, C

2b and C

4 was measured by varying the bias voltage from −40 V to +40 V and from +40 V to −40 V. The obtained characteristic curves of the capacitors C

2, C

2a, C

2b and C

4 were implemented in the simulation model in Mathcad (PTC, Boston, MA, USA) and ANSYS (ANSYS, Inc., Canonsburg, PA, USA) in order to include the voltage-dependent capacitance change in the calculations (

Figure 3 and

Figure 4). Additional specifications for the capacitors C

2, C

2a, C

2b and C

4 can be found in

Section 2.4.

2.2. Calculations in Mathcad Prime 3.1

We used the first-order differential Equations (1)–(14) (

Section 2) in Mathcad Prime 3.1 to model the circuit shown in

Figure 1 with the circuit topologies of nonlinear capacitors shown in

Figure 2. To solve these differential equations, the Adams, Bulirsch–Stoer, and Runge–Kutta methods of fourth-order for non-stiff systems, and the Backward Differentiation Formula and Radau5 method for stiff systems, were applied. The tolerance of the calculations was set to 10

−7 and the number of points for a given solution interval was set to 50 k, 500 k and 5 M. The step size was constant or varying within a solution interval, depending on the solver used. Under consideration of the currents i

C2(t) or i

C2a(t) and i

C2b(t), the hysteresis losses can be incorporated into the model. The characteristic curves of the capacitors C

2, C

2a, C

2b and C

4 have been interpolated with third order B-spline functions. In order to achieve different modulations of the electrical capacitance resulting from each circuit topology, the amplitude of the sinusoidal excitation

was varied from 0.1 V to 10 V in 0.1 V steps at a coupling factor k of 1% and 10%

2.3. Calculations in ANSYS 2019 R3 Simplorer

The “extracorporeal” primary side and the “implantable” secondary side were modeled in ANSYS 2019 R3 Simplorer according to

Figure 1. The solvers based on the Euler, Adaptive Trapezoid-Euler and Trapezoid method were used. The number of points for a given solution interval was set to 50 k, 500 k and 5 M, with a constant and adaptive step size. For an adaptive step size, the number of points for the given solution interval is determined by the solver and can vary between 50 k and 5 M. In order to achieve different modulations of the electrical capacitance resulting from each circuit topology, the amplitude of the sinusoidal excitation

was varied from 0.1 V to 10 V in 0.1 V steps at a coupling factor k of 1% and 10%.

2.4. Model Validation by Means of a Measurement Setup

The simulation results were validated using a measurement setup. The components L

1 and R

1, C

1 as well as L

2 and R

2 and C

4 were measured with the precision impedance analyzer Agilent 4294A and the test fixture HP 1604D (Hewlett Packard, Palo Alto, CA, USA). For all circuit topologies in

Figure 2, L

1 and R

1 (14.53 µH, 0.4 Ω, Würth Elektronik), and C

1 (12.45 nF, WIMA, FKP1, 2 kV) remain constant.

A linear capacitor C

2 (47 nF, 200 V, C0G), a nonlinear capacitor C

2 (47 nF, ±20%, 4 V, X5R, 01005) and an inductance L

2 and loss resistance R

2 (3.76 µH, 0.3 Ω, Würth Elektronik) were used for the circuit topology shown in

Figure 2a. The capacitors C

2a and C

2b (47 nF, ±20%, 4 V, X5R, 01005) and the inductance L

2 and loss resistance R

2 (8.45 µH, 0.86 Ω, Würth Elektronik) were used for the circuit topology shown in

Figure 2b. Finally, the capacitors C

2a and C

2b (47 nF, ±20%, 4 V, X5R, 01005) and the inductance L

2 and loss resistance R

2 (1.75 µH, 0.28 Ω, Würth Elektronik) were used for the circuit topology in

Figure 2c.

The electrical properties of the components D

1 (MULTICOMP, 1N4148WS.) and R

L (1 kΩ, ±1%) were taken from the datasheets. The capacitors C

2 (47 nF, 200 V, C0G), C

2a and C

2b (47 nF, ±20%, 4 V, X5R, 01005) and C

4 (4.7 µF, 50 V) were determined according to

Section 2.1 (

Figure 3 and

Figure 4).

Different voltages across the capacitors C2, C2a, C2b and C4 were set by changing the distance between the inductances L1 and L2 on the primary and secondary sides. A loose coupling between the inductances L1 and L2 was ensured, so that the detuning of the resonant circuits on the primary and secondary sides was avoided in order to be able to compare the calculations and the measurements. The voltage Uc2RMS, resulting from the root mean square value over time of the voltage uc2(t) across the circuit topology consisting of nonlinear capacitors, and the voltage Uc4Mean, resulting from the mean value over time from the voltage uc4(t) at the load RL, were measured with the digital oscilloscope RIGOL MSO4054 (RIGOL Technologies, Inc., Suzhou, China). It should be noted that the measurement was performed on the internal memory and not on the graphical memory, otherwise the root mean square value would be wrong, due to insufficient resolution. The internal memory was accessed using the UltraSigma and UltraScope programs (RIGOL Technologies, Inc., Suzhou, China). The measured values refer to a time span of 14 ms, with a sampling rate of 4 GS/s. Furthermore, a pulsed inductive power transfer at a frequency of 375 kHz, a duration of 5 ms and a period of at least 1 s was performed, so that the thermal detuning of the capacitors C2, C2a, C2b and C4 can be neglected.

The deviation between the measurement and the simulation results was determined using Equation (15). B corresponds to the calculated and M to the measured voltage Uc4Mean at the load. The squared difference of M and B was summed over an equal range of the root mean square voltage Uc2RMS from 0.7 V to 21 V with a step size of 10 mV and subsequently divided by the number of steps, N. For this calculation, M and B were piecewise linearly interpolated.

3. Results and Discussion

First, we show the results for the circuit in

Figure 1 with the circuit topology in

Figure 2a having a linear capacitor C

2 (47 nF, 200 V, C0G) and C

4 (4.7 µF, 50 V). The capacitors C

2 and C

4 were defined as constant at 48 nF and 4.56 µF. The deviation S between the calculations with ANSYS/Mathcad and the measurements is shown in

Table 1.

All selected calculation methods in Mathcad, regardless of the applied resolution, show a small deviation. A high consistency between calculations and measurements can also be achieved in ANSYS, except for the Euler method with constant step size and a resolution of 50 k and 500 k points and an adaptive step size, and the Adaptive Trapezoid-Euler method with constant step size and a resolution of 50 k points.

Table 1 shows that in case of a linear capacitor C

2 and C

4, most calculation methods in ANSYS and all calculation methods in Mathcad lead to a high consistency between calculations and measurements. As an additional result, the memory consumption and computing time of the calculation methods used in

Table 1 are shown in

Table 2 and

Table 3, respectively. The calculations were performed on a workstation HP Z250 (L8T12AV, Intel Xeon E3-1280 v5 (8M Cache, 3.70 GHz), 32 GB DDR4, 256 GB SSD, Windows 10 Pro 64-bit).

Table 2 shows that the calculations with Mathcad generally require less memory than with ANSYS, because the results obtained with Mathcad can be stored in binary format. For calculations with Mathcad and ANSYS with equal resolution of 50 k, 500 k and 5 M points and with constant step size, the memory consumption for calculations with ANSYS is about 5 times higher than with Mathcad. The memory consumption for the Euler and Adaptive Trapezoid-Euler methods (ANSYS) with an adaptive step size is about the same as for the calculation methods used in Mathcad at a resolution of 500 k points. On the other hand, the memory consumption for the Trapezoid method with an adaptive step size is about 1.5 times higher than with the calculations in Mathcad with a resolution of 5 M points. In terms of consistency and memory consumption, the Adams, Bulirsch–Stoer, Backward Differentiation Formula, Radau5 and the fourth-order Runge–Kutta method with constant and adaptive step size and a resolution of 50 k points (Mathcad) and the Trapezoid method with constant step size and a resolution of 50 k points (ANSYS) are most suitable.

Table 3 shows that the calculations with a resolution of 50 k points show the lowest computing time. It should also be noted that the Bulirsch–Stoer method with a resolution of 50 k, 500 k and 5 M points shows the highest computing time. In addition, the computing time with the Adams, Backward Differentiation Formula and Radau5 method changes only slightly at the different resolutions. In terms of consistency, memory consumption and computing time, the Adams, Radau5 and fourth-order Runge–Kutta method with a constant and adaptive step size and a resolution of 50 k points are most suitable in Mathcad and the Trapezoid method with a constant step size and a resolution of 50 k points is most suitable in ANSYS.

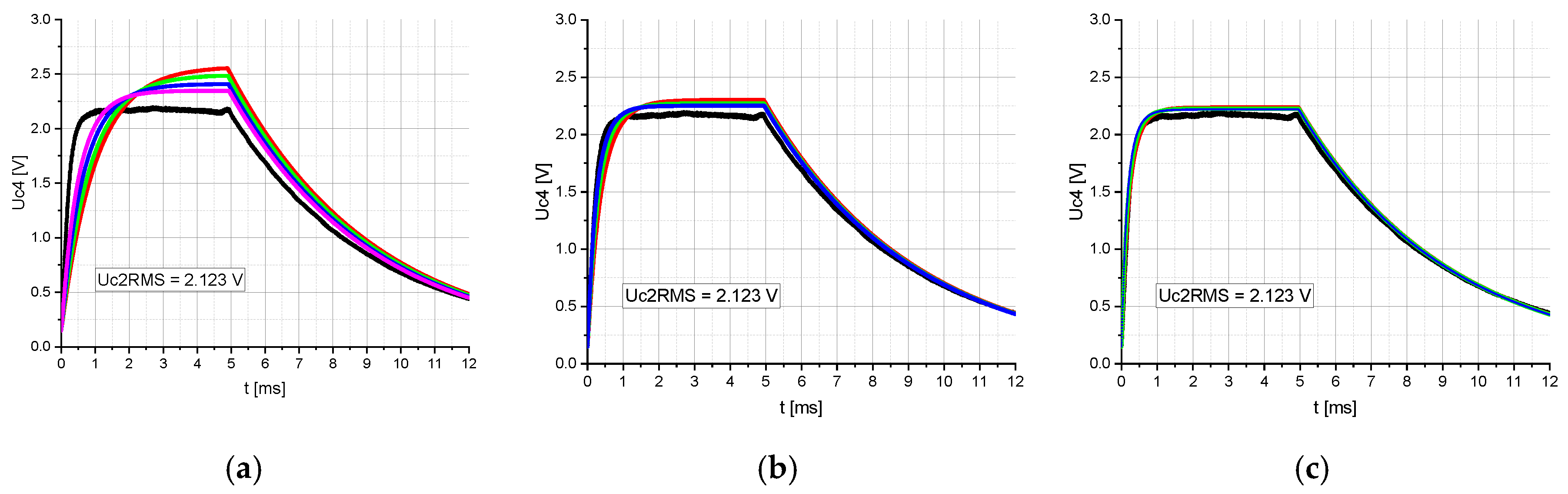

However, despite the small deviation, discrepancies in amplitude and time constants between the calculated and measured time-related voltage Uc4 were observed (

Figure 5a). The same discrepancies have been observed in the previously published conference paper [

19], although it was not clear whether they were due to the modeling of the two serially connected nonlinear capacitors, C

2a and C

2b, or to another cause. Since these discrepancies occur in the case of both, a linear capacitor C

2 and two serially connected nonlinear capacitors, C

2a and C

2b, they cannot be assigned to the modeling of the nonlinear capacitors.

To find the root cause, the impact of the coupling factor k on the above-mentioned discrepancies was investigated. For this purpose, the calculations were performed with the circuit shown in

Figure 1 having a linear capacitor C

2 (

Figure 2a) and C

4. The coupling factor was varied from 1% to 10% in 1% steps and the amplitude of the sinusoidal voltage source was adjusted so that the voltage Uc2RMS was equal to 2.123 V.

Figure 5 shows that an increasing coupling factor directly impacts the amplitude and time constant of the voltage Uc4. By changing the coupling factor between 1% and 4% (

Figure 5a), the amplitude and time constant of voltage Uc4 change significantly. For coupling factors above 4%, the impact of the coupling factor on the amplitude and time constant becomes less significant (

Figure 5b,c). At a coupling factor between 7% and 10%, the consistency between the calculated and measured time-related voltage curves Uc4 is highest (

Figure 5c). Consequently, it should be ensured that the coupling factor is sufficiently high to achieve more accurate results even in the case of loose coupling.

Finally, the impact of the nonlinear properties of the capacitor C

4 on the model consistency was determined. The calculations were performed with the circuit in

Figure 1 having a linear capacitor C

2 (

Figure 2a), a nonlinear capacitor C

4 (

Figure 4) and a coupling factor of 10%. According to

Figure 6, the nonlinearity of the voltage rectifier capacitor C

4 has no significant impact on the consistency of the model.

Based on these results, the calculations from

Table 1 were repeated with a coupling factor k of 10%.

Table 4 shows that increasing the coupling factor from 1% to 10% reduces the overall deviation, except for the Euler method with a resolution of 50 k points and a constant and adaptive step size. The reduction in deviation is especially noticeable in the Euler and Adaptive Trapezoid-Euler method. The deviation was reduced from 14.8 V to 0.3 V for the Euler method with constant step size and a resolution of 500 k points, and from 10.7 V to 0.3 V for the Adaptive Trapezoid-Euler method with constant step size and a resolution of 50 k points.

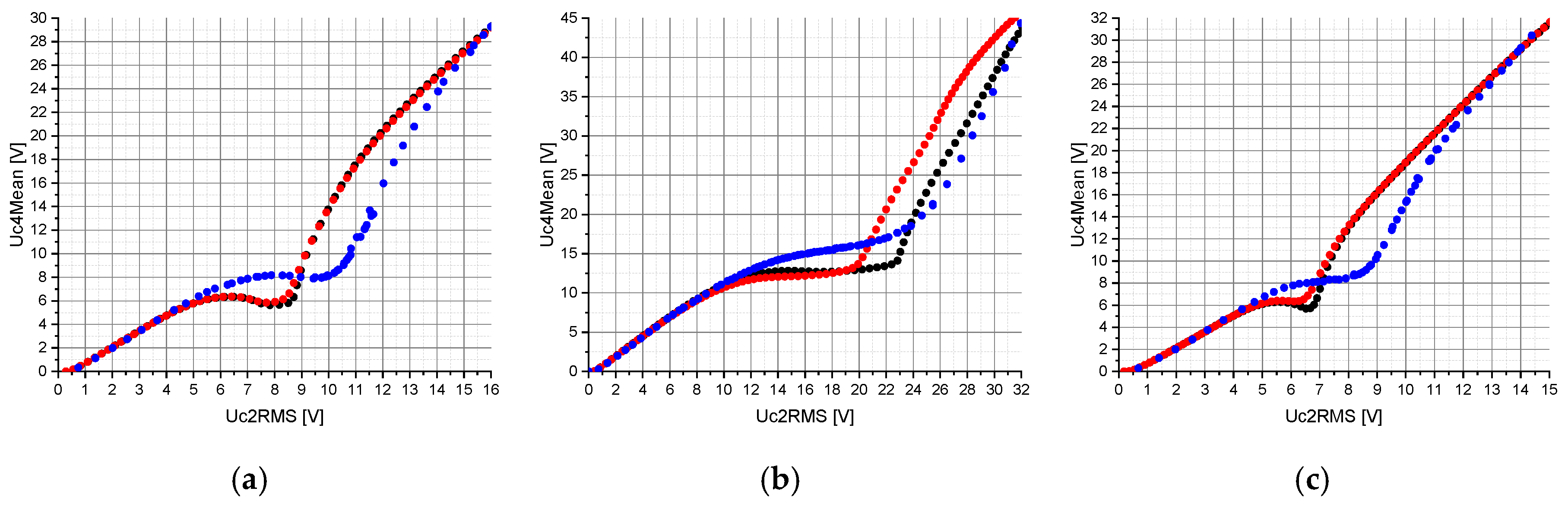

The measurements and calculations in

Figure 7 can be split into two parts. A part in which the relationship between Uc4Mean and Uc2RMS is linear and a part in which the nonlinear properties of the circuit topologies shown in

Figure 2 are effective. Within the linear range, the consistency between calculations and measurements is high. However,

Figure 7 shows that the threshold values to be reached by Uc2RMS for triggering the nonlinear behavior on Uc4Mean are lower in the calculations than in the measurements. The same observation was also made in the previous conference paper [

19]. The impact of the hysteresis losses on the calculations is particularly noticeable in the circuit topology consisting of two serially connected nonlinear capacitors, C

2a and C

2b (

Figure 7b). The value of Uc2RMS at which the voltage Uc4Mean increases changes from about 23 V to 20 V due to the hysteresis losses. The same behavior can also be observed with a nonlinear capacitor, C

2, and two nonlinear capacitors, C

2a and C

2b, connected in parallel (

Figure 7a,c), in a range of Uc2RMS between about 6 V and 9 V. An interesting point in

Figure 7 is that depending on the circuit topology used, an approximately constant range of Uc4Mean is achieved within a specific range of Uc2RMS. The range of Uc2RMS in which Uc4Mean is approximately constant and the slope of Uc4Mean within this range are defined by the circuit topology of nonlinear capacitors.

Despite the increase in the coupling factor k from 1% to 10% and the implementation of hysteresis losses, the calculations deviate from the measurements for higher values of Uc2RMS. A possible explanation would be that the measurement of the nonlinear capacitors used in this work, according to

Section 2.1, is no longer valid for higher AC voltages [

25,

26,

27].

4. Conclusions

This paper describes the optimization steps for modeling the nonlinear properties of ferroelectric materials in ceramic capacitors in terms of consistency, memory consumption and computing time. It turned out that the coupling factor k directly impacts the consistency between simulation and measurement. Particular attention should be paid to ensure a sufficiently high coupling factor k even in the case of loose coupling. A coupling factor between 7% and 10% should be adequate to properly model the time constant of the inductive power transmission system.

In addition, it was found that the consideration of the nonlinear properties of the capacitor C4 does not significantly improve the model, but increases the computing time. Therefore, with regard to consistency and computing time, we recommend neglecting the nonlinear properties of the capacitor C4 for further modeling purposes.

Based on the results of the previously published conference paper, it was concluded that the Trapezoid method with a constant step size and a resolution of 500 k points and with an adaptive step size is most suitable in ANSYS [

19]. Considering the computing time and memory consumption in

Table 2 and

Table 3, the Trapezoid method with a constant step size and a resolution of 500 k points should be preferred.

A high consistency between calculations and measurements was achieved in Mathcad using the Adams, Bulirsch–Stoer, Backward Differentiation Formula, Radau5, and fourth-order Runge–Kutta method with an adaptive step size and a resolution of 50 k points. The calculations in Mathcad with a resolution of 50 k points show the lowest memory consumption (

Table 2). With regard to the computing time, we recommend using the Adams method in the first place and the Backward Differentiation Formula and Radau5 method as an alternative (

Table 3).

Based on these results, a simulation model for modeling ferroelectric materials in ceramic capacitors is now available that exhibits high consistency and efficiency in terms of computing time and memory consumption. Nevertheless, the simulation model is limited to lower AC voltages across the circuit topology of nonlinear capacitors. In order to expand the application of the model to higher AC voltages, it is necessary in the next step to characterize the voltage dependence of ceramic capacitors for large signals. Furthermore, the impact of the manufacturing tolerances of ferroelectric capacitors on the robustness of the collective nonlinear dynamics of the proposed meaningful circuit topology should be investigated [

28].

We plan to use this simulation model in combination with various optimization algorithms to establish a frugal circuit topology with nonlinear components for the realization of a closed-loop current control. This will increase the degree of miniaturization in electronic implants because there will be no need to use dedicated sensors or other active electronic components. Electronic implants with inductive power supply, such as retinal implants [

1,

6,

7,

9], cochlear implants [

29,

30], and the hypoglossal nerve stimulator GenioTM (Nyxoah SA, Mont-Saint-Guibert, Belgium) [

31] would be particularly suitable for this purpose.