Low-Cost, High-Frequency, Data Acquisition System for Condition Monitoring of Rotating Machinery through Vibration Analysis-Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Acquisition System Design

2.1.1. Raspberry Pi Specifications

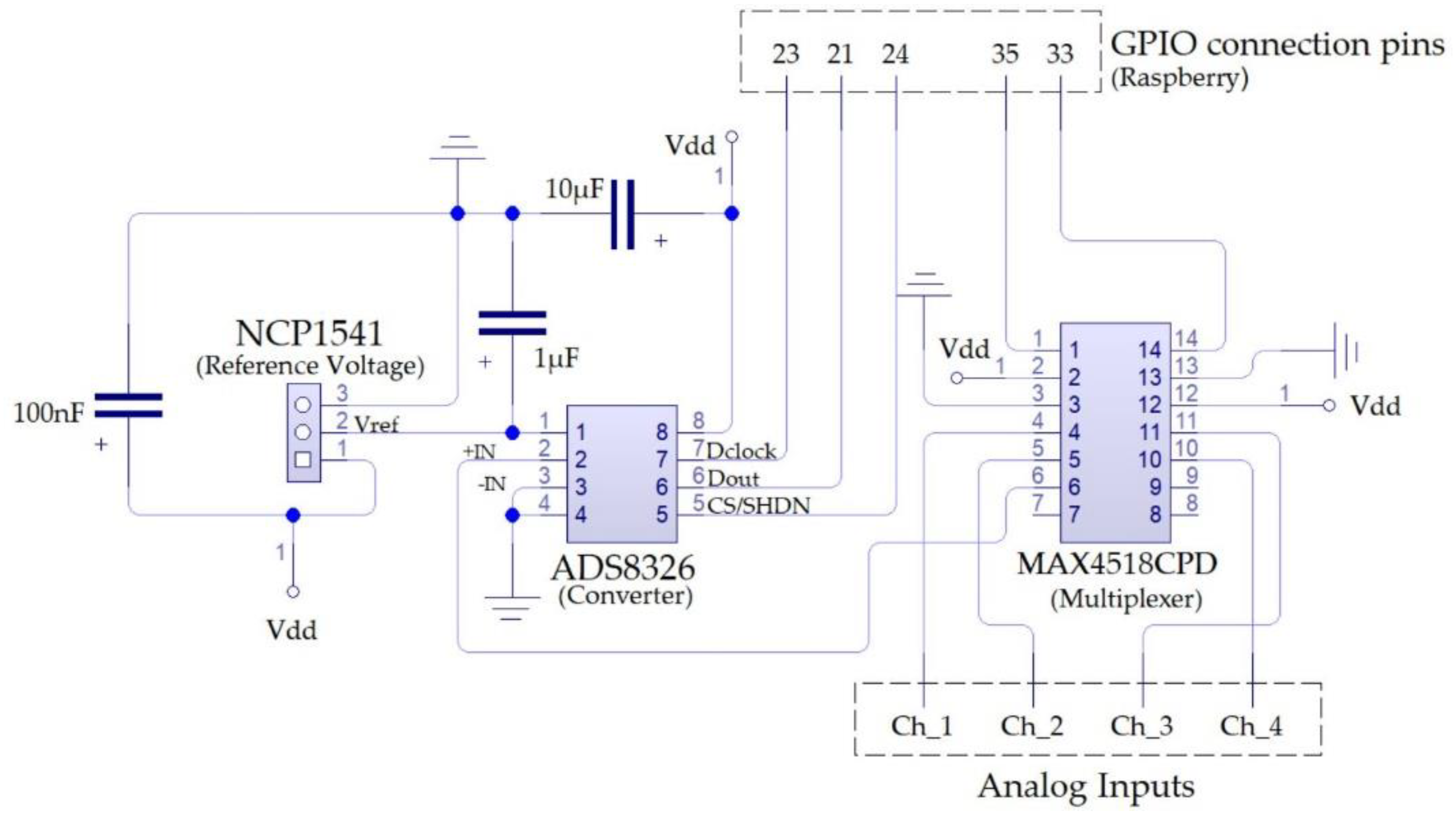

2.1.2. Analogue/Digital Converter (ADC)

2.1.3. Sensors

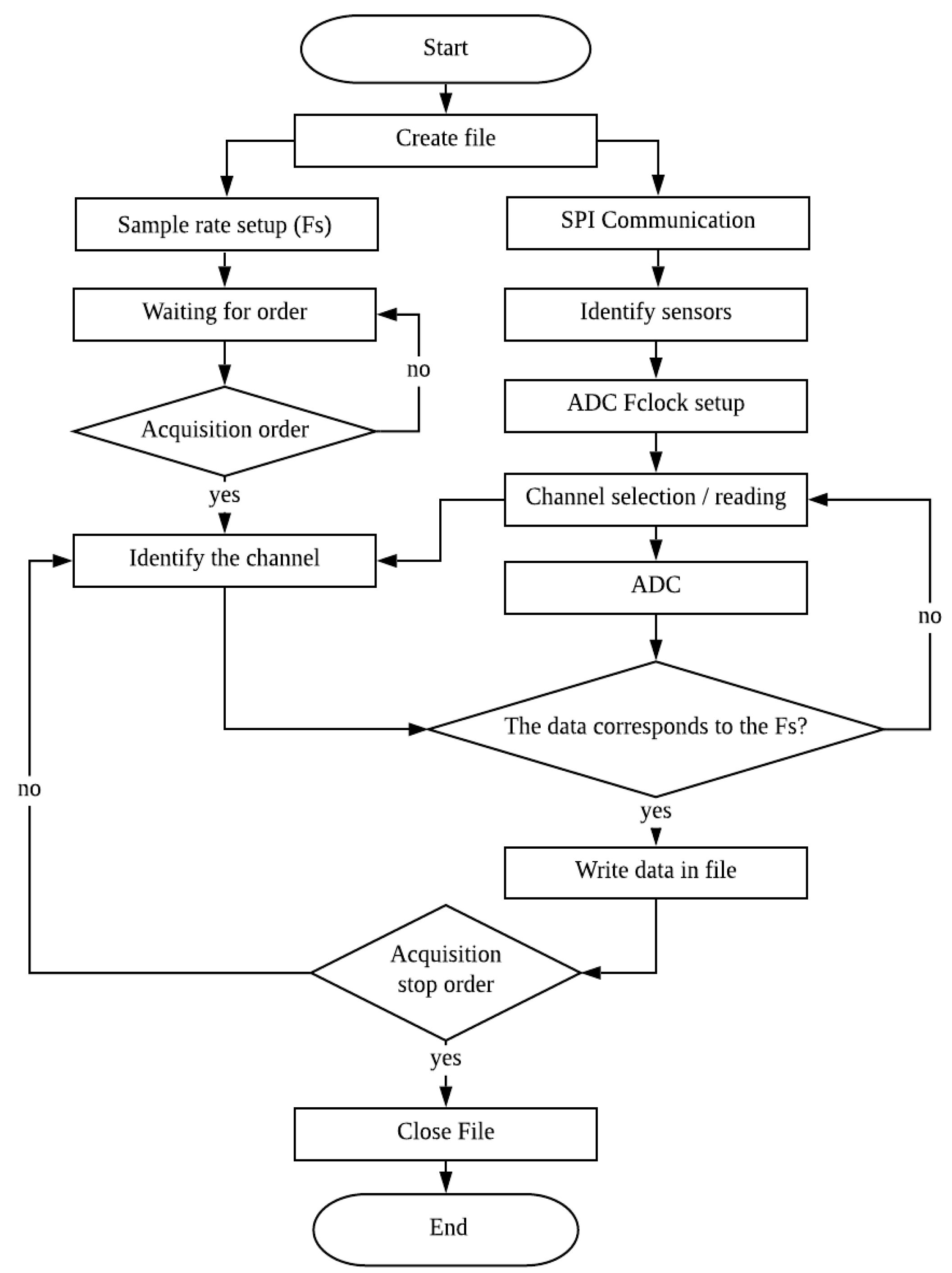

2.1.4. Programming the Raspberry Software

2.1.5. Connecting the Data Acquisition System

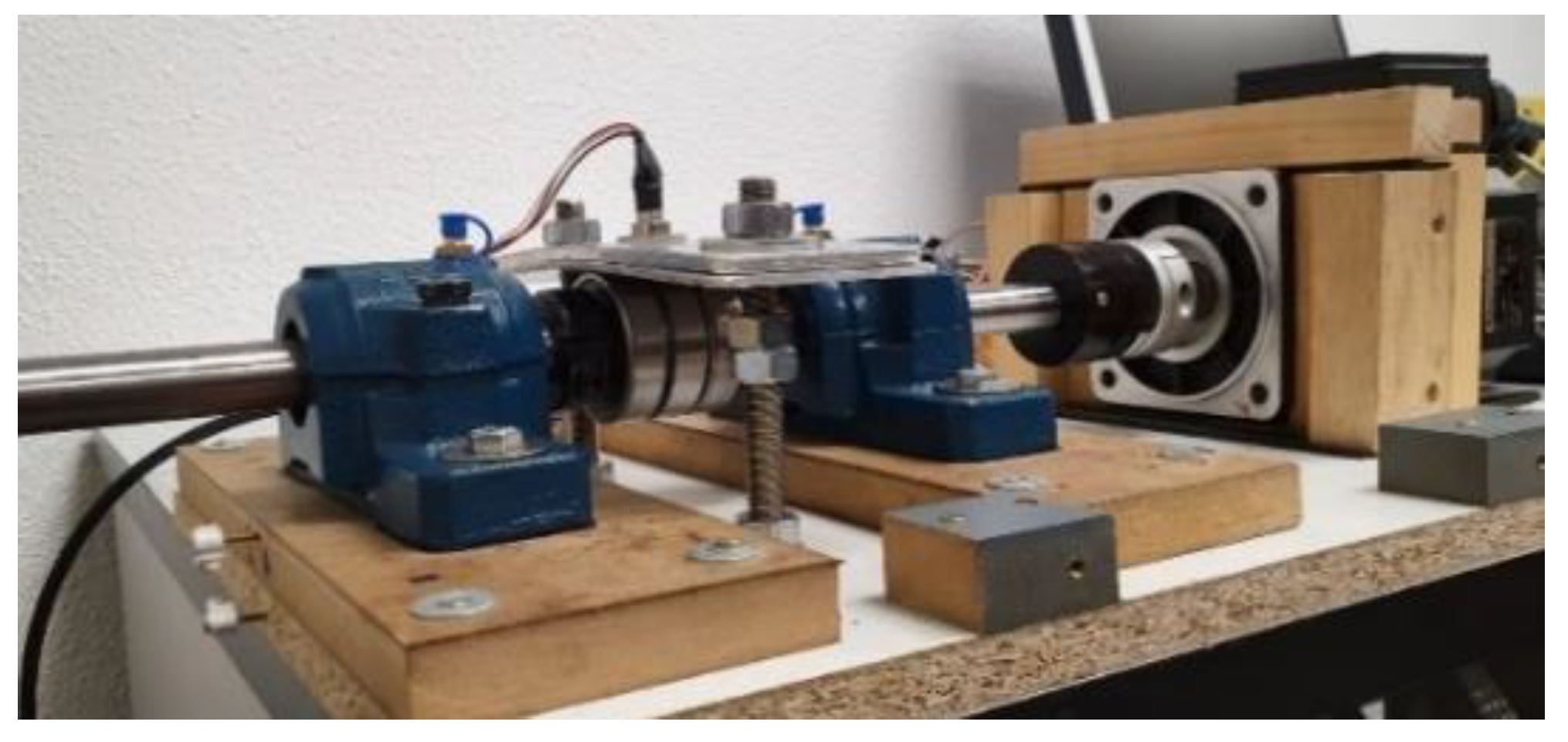

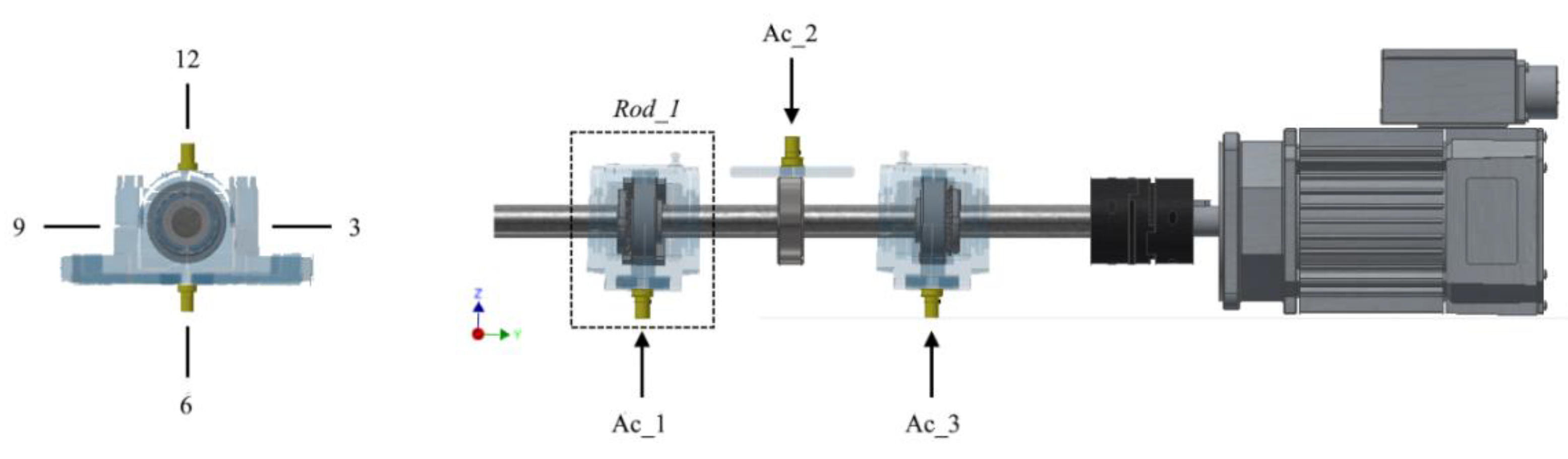

2.2. Bearing Test Bench

2.2.1. Traction Unit

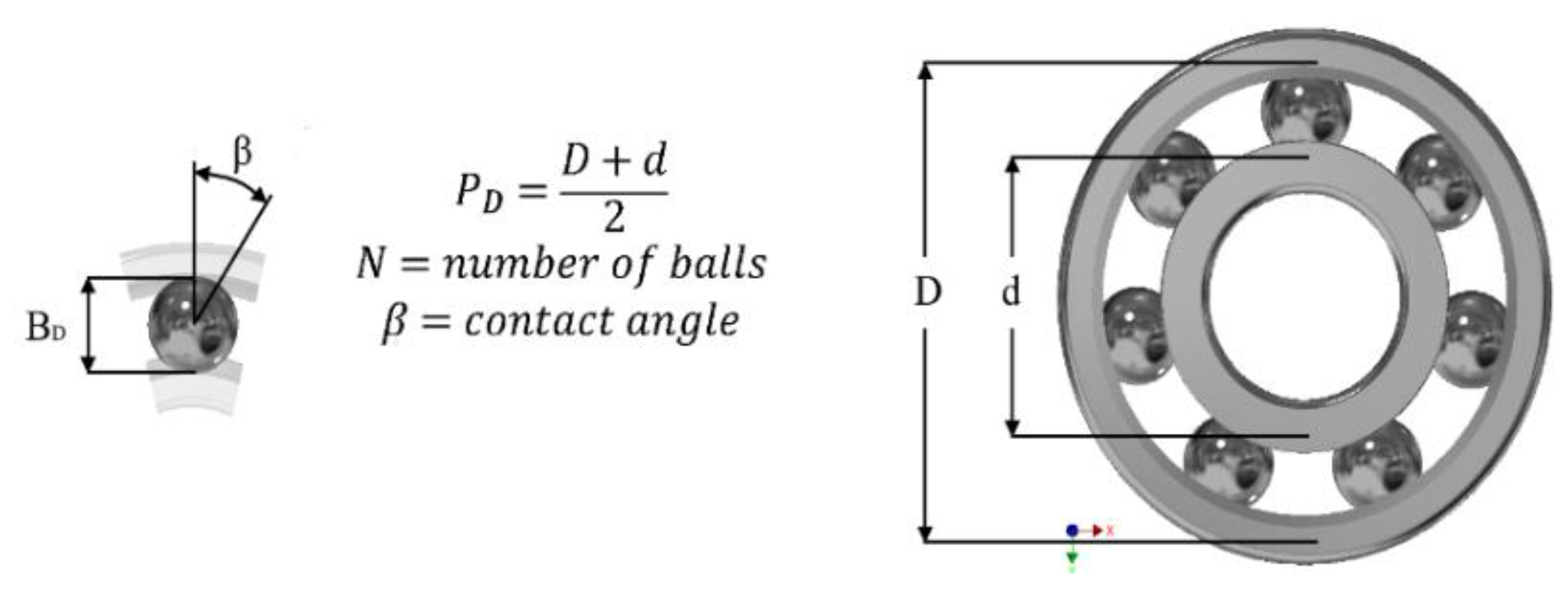

2.2.2. Bearing under Study

Bearing Vibration Mode

2.2.3. Load

2.3. Sensing

2.4. Design of Experiment (DoE)

2.5. Data Processing

3. Results and Discussion

3.1. Validation of the Recording Equipment

3.2. Determining the Analysis Band

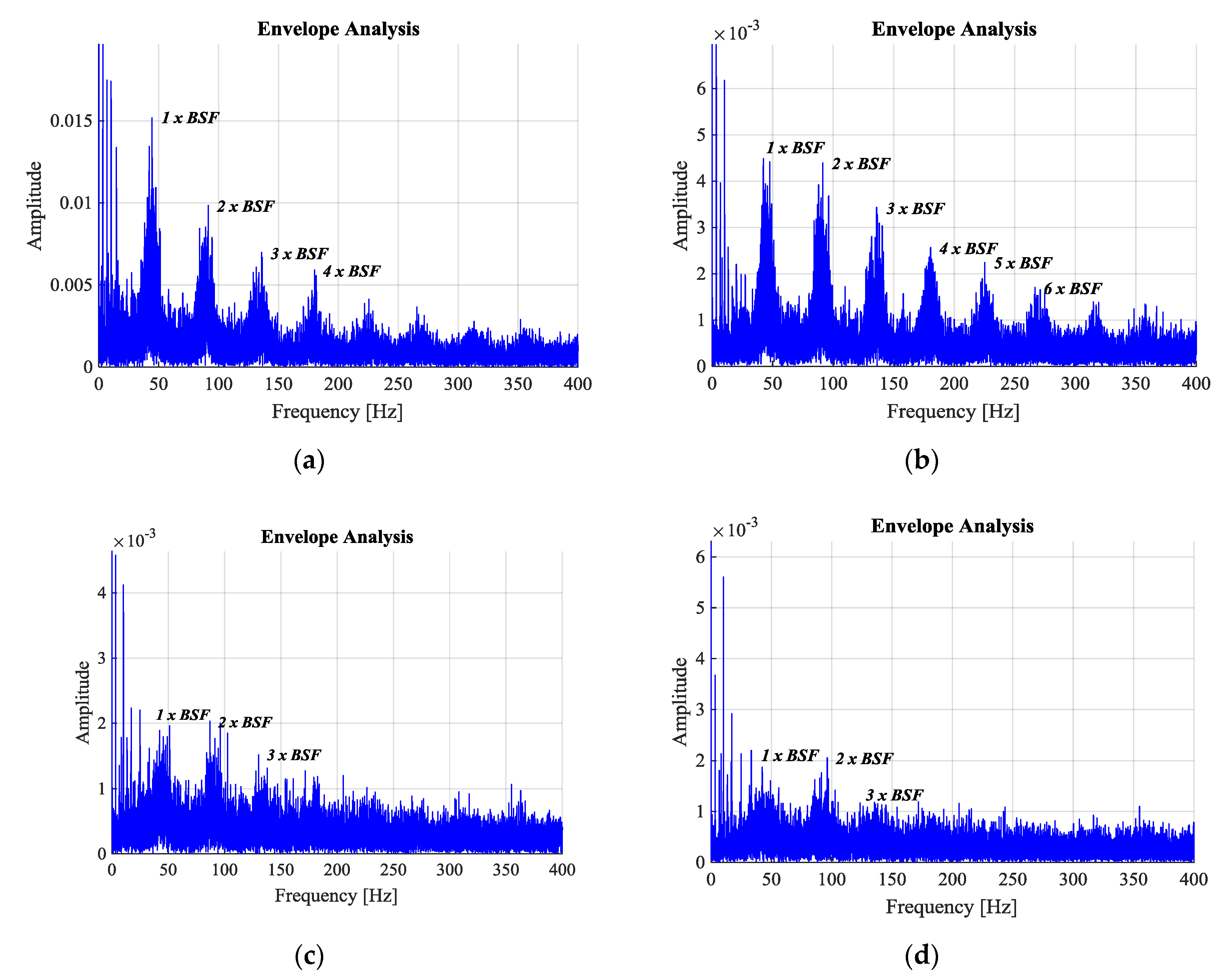

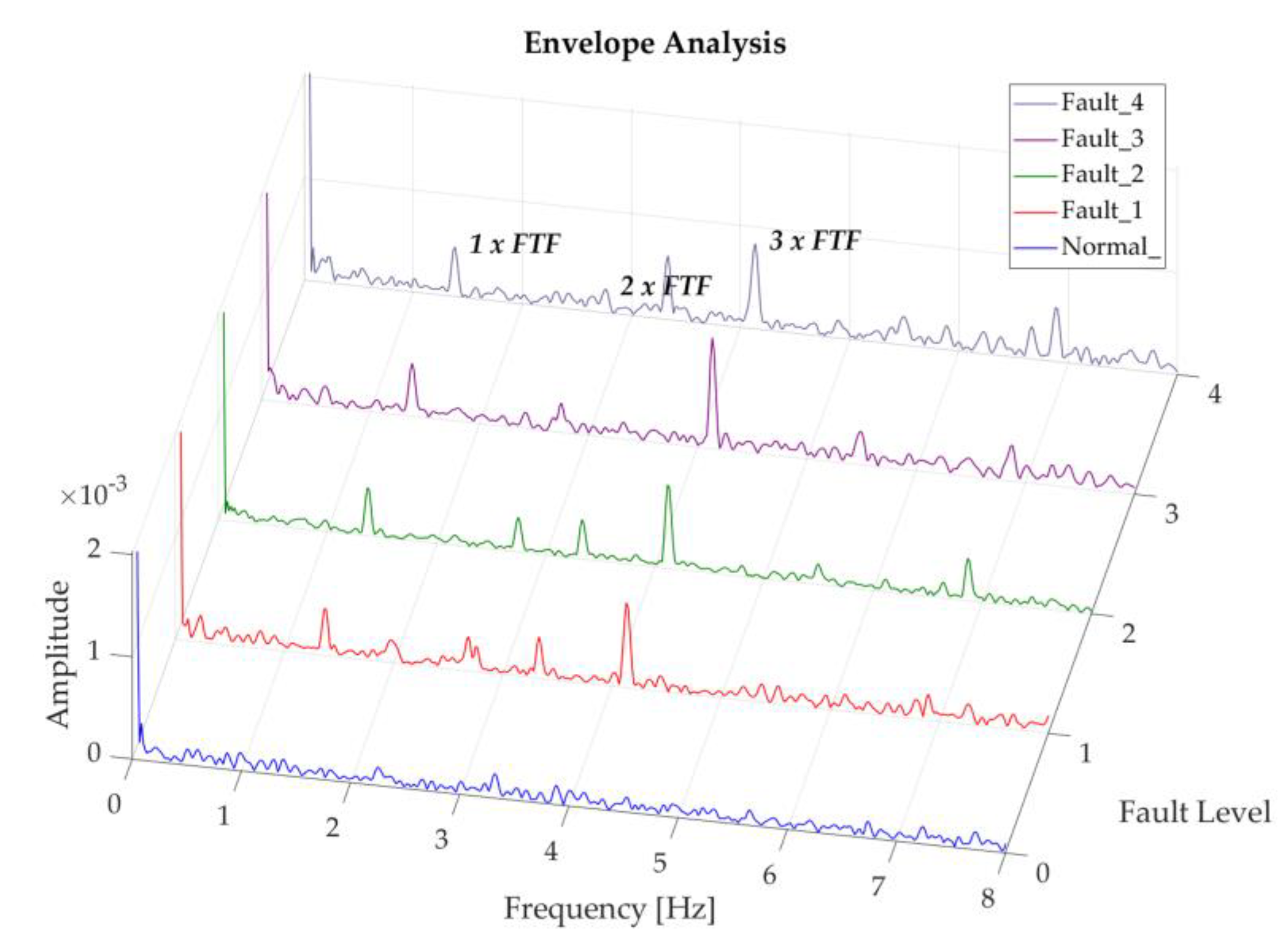

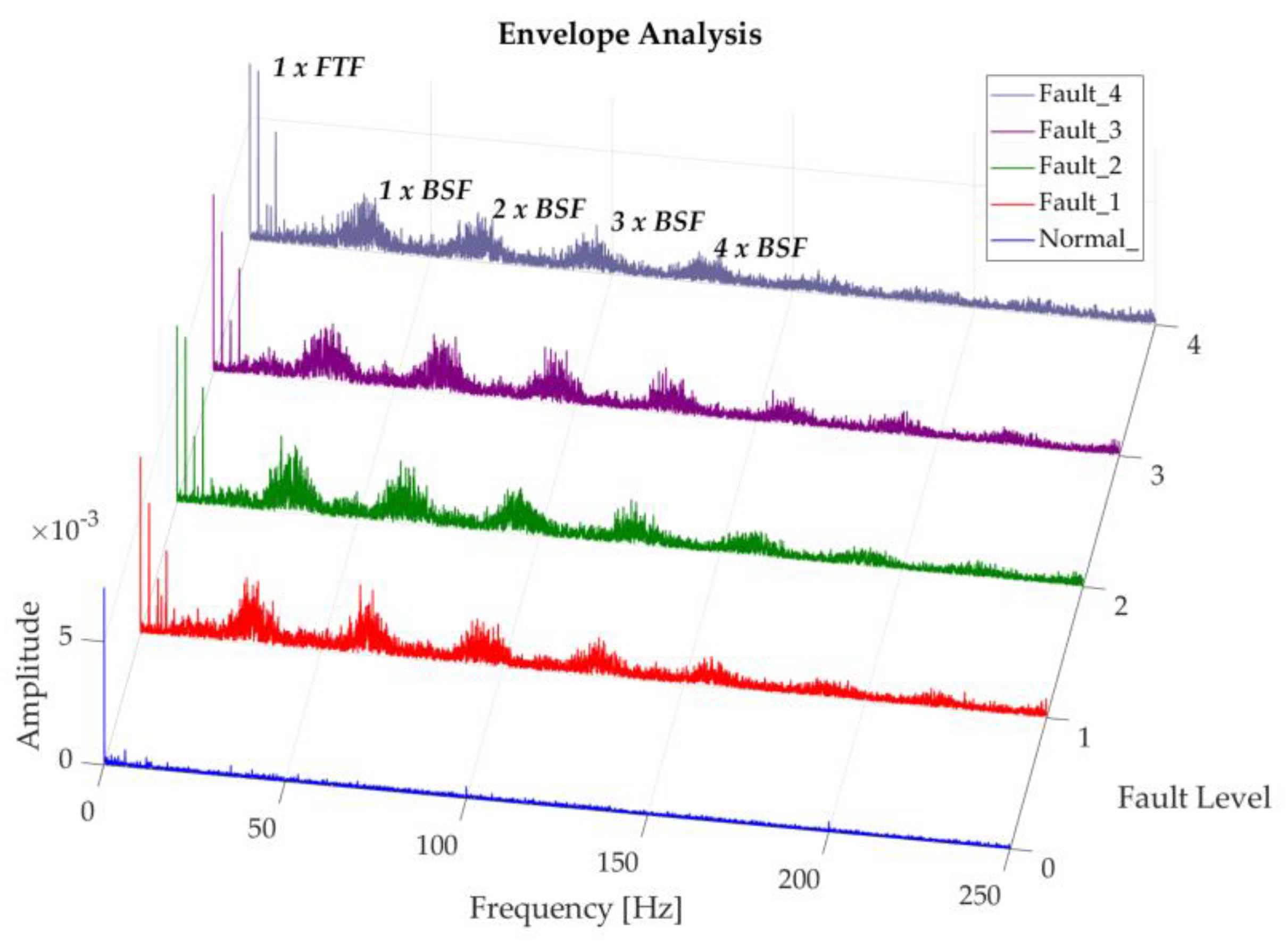

3.3. Detection of Faults in “Rolling Elements”

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Heng, A.; Zhang, S.; Tan, A.C.C.; Mathew, J. Rotating machinery prognostics: State of the art, challenges and opportunities. Mech. Syst. Signal Process. 2009, 23, 724–739. [Google Scholar] [CrossRef]

- Qiu, H.; Lee, J.; Lin, J.; Yu, G. Robust performance degradation assessment methods for enhanced rolling element bearing prognostics. Adv. Eng. Inform. 2003, 17, 127–140. [Google Scholar] [CrossRef]

- Austerlitz, H. Data Acquisition Techniques Using PCs; Academic Press: San Diego, CA, USA, 2002. [Google Scholar]

- Liu, S.; Wang, S. Machine Health Monitoring and Prognostication Via Vibration Information. In Proceedings of the Sixth International Conference on Intelligent Systems Design and Applications, Jinan, China, 16–18 October 2006; Volume 1, pp. 879–886. [Google Scholar] [CrossRef]

- Mahalungkar, S.; Ingram, M. Online and manual (offline) vibration monitoring of equipment for reliability centered maintenance. In Proceedings of the IEEE-IAS/PCA 2004 Cement Industry Technical Conference (IEEE Cat. No04CH37518), Chattanooga, TN, USA, 25–30 April 2004; pp. 245–261. [Google Scholar] [CrossRef]

- Graney, B.P.; Starry, K. Rolling Element Bearing Analysis. Mater. Eval. 2012, 70, 78. [Google Scholar]

- Yu, K.; Lin, T.R.; Tan, J.; Ma, H. An adaptive sensitive frequency band selection method for empirical wavelet transform and its application in bearing fault diagnosis. Measurement 2019, 134, 375–384. [Google Scholar] [CrossRef]

- Nguyen, P.; Kang, M.; Kim, J.-M.; Ahn, B.-H.; Ha, J.-M.; Choi, B.-K. Robust condition monitoring of rolling element bearings using de-noising and envelope analysis with signal decomposition techniques. Expert Syst. Appl. 2015, 42, 9024–9032. [Google Scholar] [CrossRef]

- Bernal, E.; Spiryagin, M.; Cole, C. Onboard Condition Monitoring Sensors, Systems and Techniques for Freight Railway Vehicles: A Review. IEEE Sens. J. 2019, 19, 4–24. [Google Scholar] [CrossRef]

- IS/ISO 13373-1. Condition Monitoring and Diagnostics of Machines—Vibration Condition Monitoring, Part 1: General Procedures; Bureau of Indian Standards: New Delhi, India, 2002; p. 57. Available online: https://archive.org/details/gov.in.is.iso.13373.1.2002/page/n49/mode/2up (accessed on 10 August 2019).

- IS/ISO 13373-2. Condition Monitoring and Diagnostics of Machines—Vibration Condition Monitoring, Part 2: Processing Analysis and Presentation of Vibration Data; Bureau of Indian Standards: New Delhi, India, 2005; p. 38. Available online: https://archive.org/details/gov.in.is.iso.13373.2.2005 (accessed on 10 August 2019).

- Gani, A.; Salami, M.J.E. A LabVIEW based data acquisition system for vibration monitoring and analysis. In Proceedings of the Student Conference on Research and Development, Shah Alam, Malaysia, 17 July 2002; pp. 62–65. [Google Scholar] [CrossRef]

- Had, A.; Sabri, K. A two-stage blind deconvolution strategy for bearing fault vibration signals. Mech. Syst. Signal Process. 2019, 134, 106307. [Google Scholar] [CrossRef]

- Bosso, N.; Gugliotta, A.; Zampieri, N. Design and testing of an innovative monitoring system for railway vehicles. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 445–460. [Google Scholar] [CrossRef]

- Moreno, C.; González, A.; Olazagoitia, J.L.; Vinolas, J. The Acquisition Rate and Soundness of a Low-Cost Data Acquisition System (LC-DAQ) for High Frequency Applications. Sensors 2020, 20, 524. [Google Scholar] [CrossRef] [PubMed]

- Vidal-Pardo, A.; Pindado, S. Design and Development of a 5-Channel Arduino-Based Data Acquisition System (ABDAS) for Experimental Aerodynamics Research. Sensors 2018, 18, 2382. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Yu, H.; Sun, C.; Zhang, Z.; Zheng, E. Continuous and Real-Time Vibration Data Acquisition and Analysis System Based on S3C6410 and Linux. In Proceedings of the 2013 Fifth International Conference on Measuring Technology and Mechatronics Automation, Hong Kong, China, 16–17 January 2013; pp. 389–392. [Google Scholar] [CrossRef]

- González, A.; Olazagoitia, J.; Vinolas, J. A Low-Cost Data Acquisition System for Automobile Dynamics Applications. Sensors 2018, 18, 366. [Google Scholar] [CrossRef] [PubMed]

- ISO 10816-7. Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Non-Rotating Parts—Part 7: Rotodynamic Pumps for Industrial Applications, Including Measurements on Rotating Shafts. 2009. Available online: https://www.iso.org/obp/ui/#iso:std:iso:10816:-7:ed-1:v1:en (accessed on 17 November 2019).

- Ghafari, S.H. A Fault Diagnosis System for Rotary Machinery Supported by Rolling Element Bearings. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2007. [Google Scholar]

- Gupta, P.; Pradhan, M.K. Fault detection analysis in rolling element bearing: A review. Mater. Today Proc. 2017, 4, 2085–2094. [Google Scholar] [CrossRef]

- Randall, R.B.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Smith, W.A.; Randall, R.B. Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mech. Syst. Signal Process. 2015, 64–65, 100–131. [Google Scholar] [CrossRef]

- IS 14883. Mechanical Vibration and Shock—Mechanical Mounting of Accelerometers; Bureau of Indian Standards: New Delhi, India, 2000; p. 18. Available online: https://archive.org/details/gov.in.is.14883.2000 (accessed on 10 August 2019).

- ISO 10816-3. Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Non-Rotating Parts—Part 3: Industrial Machines with Nominal Power Above 15 kW and Nominal Speeds between 120 r/min and 15 000 r/min When Measured In Situ. ISO: 2009. Available online: http://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/05/05/50528.html (accessed on 17 November 2019).

- Yang, H.; Mathew, J.; Ma, L. Fault diagnosis of rolling element bearings using basis pursuit. Mech. Syst. Signal Process. 2005, 19, 341–356. [Google Scholar] [CrossRef]

- Samanta, B.; Al-Balushi, K.R. Artificial neural network based fault diagnostics of rolling element bearings using time-domain features. Mech. Syst. Signal Process. 2003, 17, 317–328. [Google Scholar] [CrossRef]

- Feng, G.-J.; Gu, J.; Zhen, D.; Aliwan, M.; Gu, F.-S.; Ball, A.D. Implementation of envelope analysis on a wireless condition monitoring system for bearing fault diagnosis. Int. J. Autom. Comput. 2015, 12, 14–24. [Google Scholar] [CrossRef]

- McInerny, S.A.; Dai, Y. Basic vibration signal processing for bearing fault detection. IEEE Trans. Educ. 2003, 46, 149–156. [Google Scholar] [CrossRef]

- Carter, D.L. Rolling element bearing condition testing method and apparatus. U.S. Patent 5,477,730, 26 December 1995. [Google Scholar]

- Amini, A.; Entezami, M.; Papaelias, M. Onboard detection of railway axle bearing defects using envelope analysis of high frequency acoustic emission signals. Case Stud. Nondestruct. Test. Eval. 2016, 6, 8–16. [Google Scholar] [CrossRef]

| 22205E1KC3 | Frequency | Regime (rpm) | |||

|---|---|---|---|---|---|

| 200 | 350 | 500 | |||

| BPFO | 6.1852 | × f | 20.62 | 36.08 | 51.54 |

| BPFI | 8.8148 | × f | 29.38 | 51.42 | 73.46 |

| BSF | 5.4030 | × f | 18.01 | 31.52 | 45.03 |

| FTF | 0.4123 | × f | 1.37 | 2.41 | 3.44 |

| 6304-2R | Frequency | Regime (rpm) | |||

|---|---|---|---|---|---|

| 200 | 350 | 500 | |||

| BPFO | 2.5783 | × f | 8.59 | 15.04 | 21.49 |

| BPFI | 4.4398 | × f | 14.80 | 25.90 | 37.00 |

| BSF | 3.5241 | × f | 11.75 | 20.56 | 29.37 |

| FTF | 0.3687 | × f | 1.23 | 2.15 | 3.07 |

| Study Factor | Levels | Units | |||||

| F1 | F2 | F3 | F4 | F5 | |||

| RE | Area | 0 | 11.05 | 11.57 | 11.7 | 13 | mm2 |

| Depth | 0 | 0.006 | 0.014 | 0.019 | 0.027 | mm | |

| Control Factor | Levels | Units | |||||

| R1 | R2 | R3 | |||||

| Regime | 200 | 350 | 500 | rpm | |||

| Uncontrolled Factors | Value | Units |

|---|---|---|

| Ambient Temperature | 20 to 24 | °C |

| Operating temperature of casing | 35 to 45 | °C |

| Relative humidity | 40 to 52 | % |

| Atmospheric Pressure | 1010 to 1016 | hPa |

| No. of Channels | Sampling Frequency [kHz] | Standard Deviation [Hz] |

|---|---|---|

| 1 | 110 | 16,280 |

| 2 | 65 | 7085 |

| 3 | 45 | 4403 |

| 4 | 35 | 3057 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soto-Ocampo, C.R.; Mera, J.M.; Cano-Moreno, J.D.; Garcia-Bernardo, J.L. Low-Cost, High-Frequency, Data Acquisition System for Condition Monitoring of Rotating Machinery through Vibration Analysis-Case Study. Sensors 2020, 20, 3493. https://doi.org/10.3390/s20123493

Soto-Ocampo CR, Mera JM, Cano-Moreno JD, Garcia-Bernardo JL. Low-Cost, High-Frequency, Data Acquisition System for Condition Monitoring of Rotating Machinery through Vibration Analysis-Case Study. Sensors. 2020; 20(12):3493. https://doi.org/10.3390/s20123493

Chicago/Turabian StyleSoto-Ocampo, César Ricardo, José Manuel Mera, Juan David Cano-Moreno, and José Luis Garcia-Bernardo. 2020. "Low-Cost, High-Frequency, Data Acquisition System for Condition Monitoring of Rotating Machinery through Vibration Analysis-Case Study" Sensors 20, no. 12: 3493. https://doi.org/10.3390/s20123493

APA StyleSoto-Ocampo, C. R., Mera, J. M., Cano-Moreno, J. D., & Garcia-Bernardo, J. L. (2020). Low-Cost, High-Frequency, Data Acquisition System for Condition Monitoring of Rotating Machinery through Vibration Analysis-Case Study. Sensors, 20(12), 3493. https://doi.org/10.3390/s20123493