Sensor Data Fusion in Multi-Sensor Weigh-In-Motion Systems

Abstract

1. Introduction

- competitive fusion, where different types of sensors are used to measure the same physical quantity. This may lead to information redundancy

- complementary fusion, where each sensor is used to measure a different property of the studied object

- cooperative fusion, where the correct operation of a single sensor is dependent on the results of some other sensor. Without cooperation, the operation of the first sensor would be impossible or undesirable.

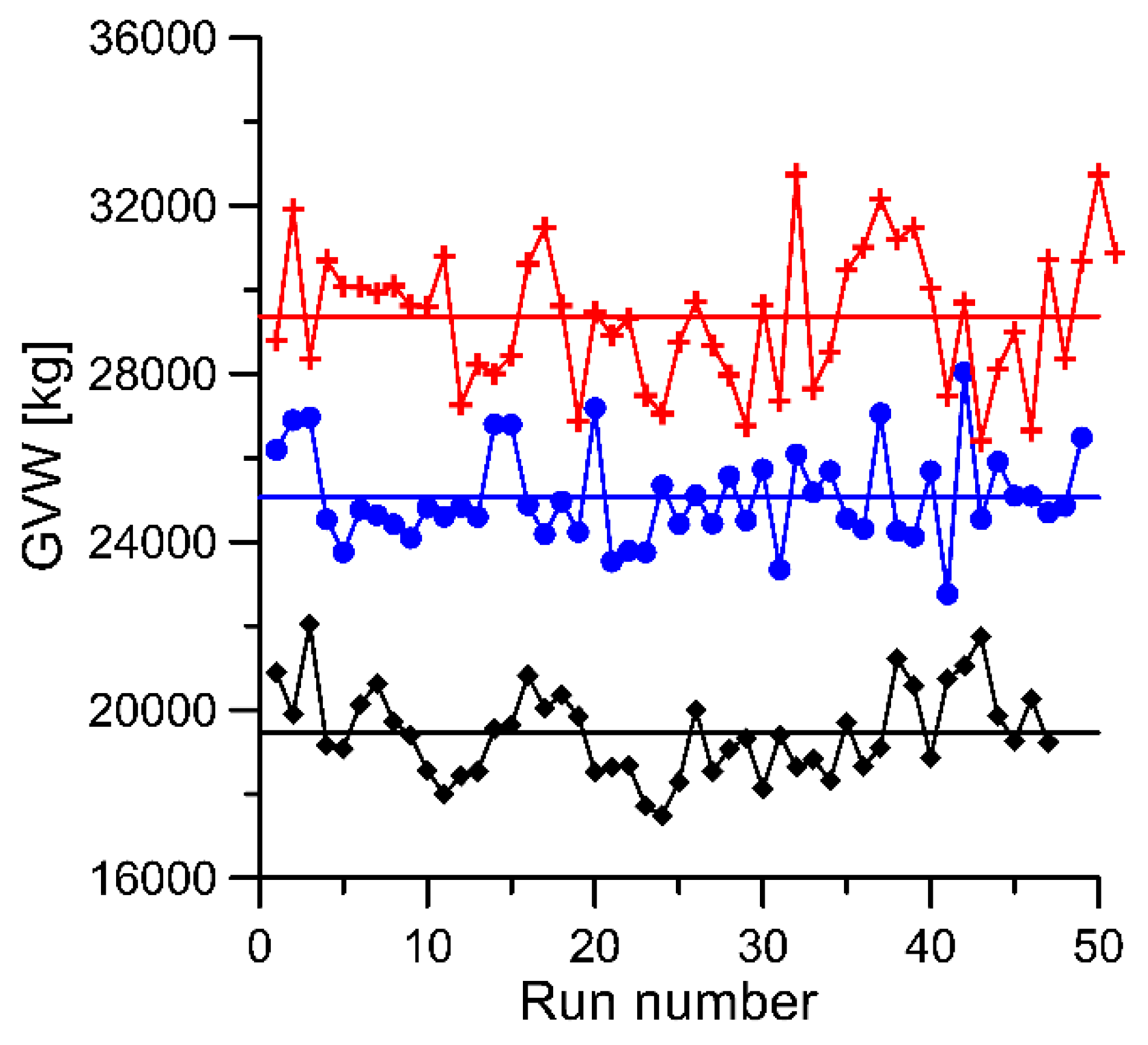

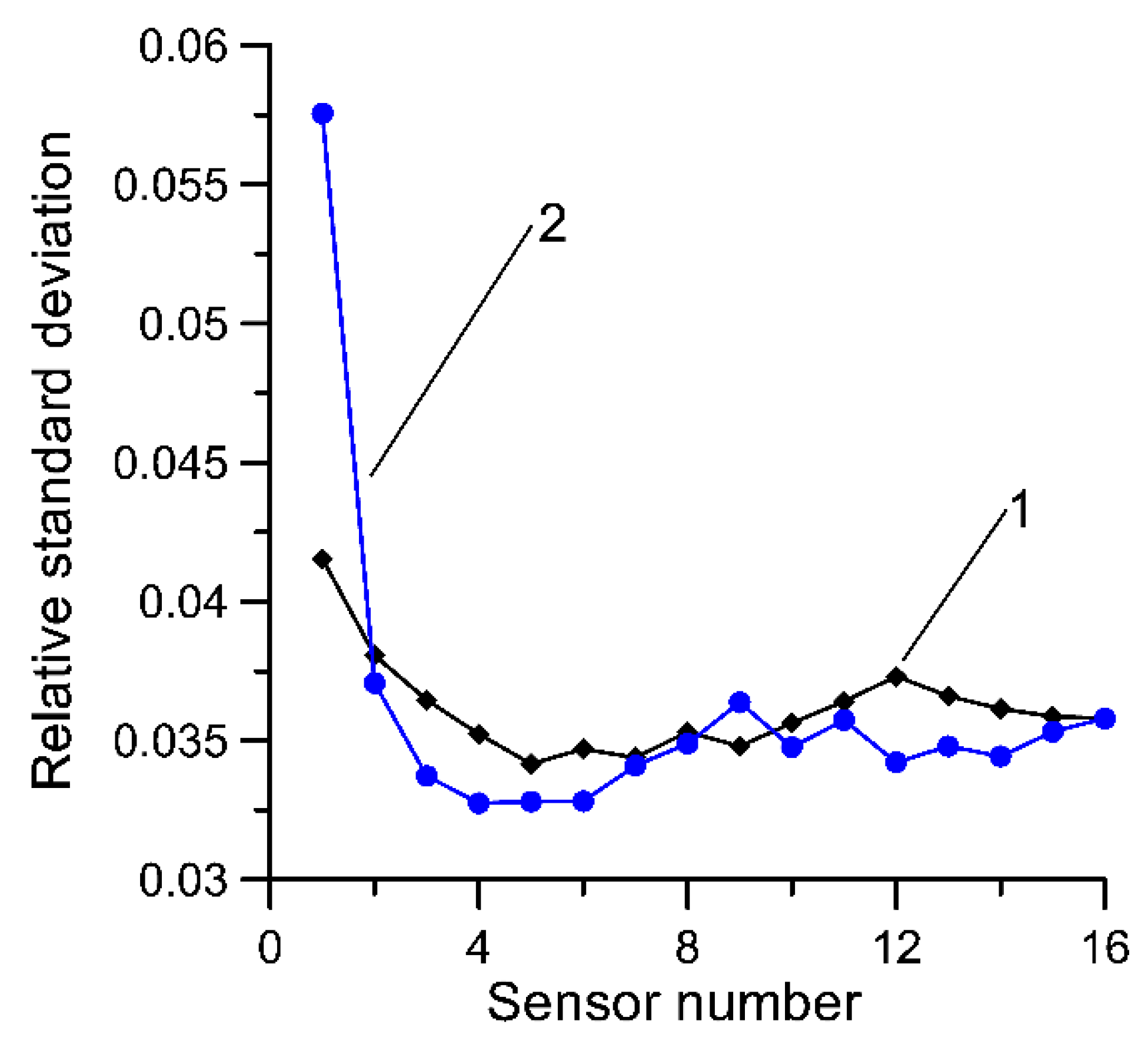

2. Mean Value as an Estimator of Static Axle Load and GVW

3. Maximum Likelihood Estimator

4. Results

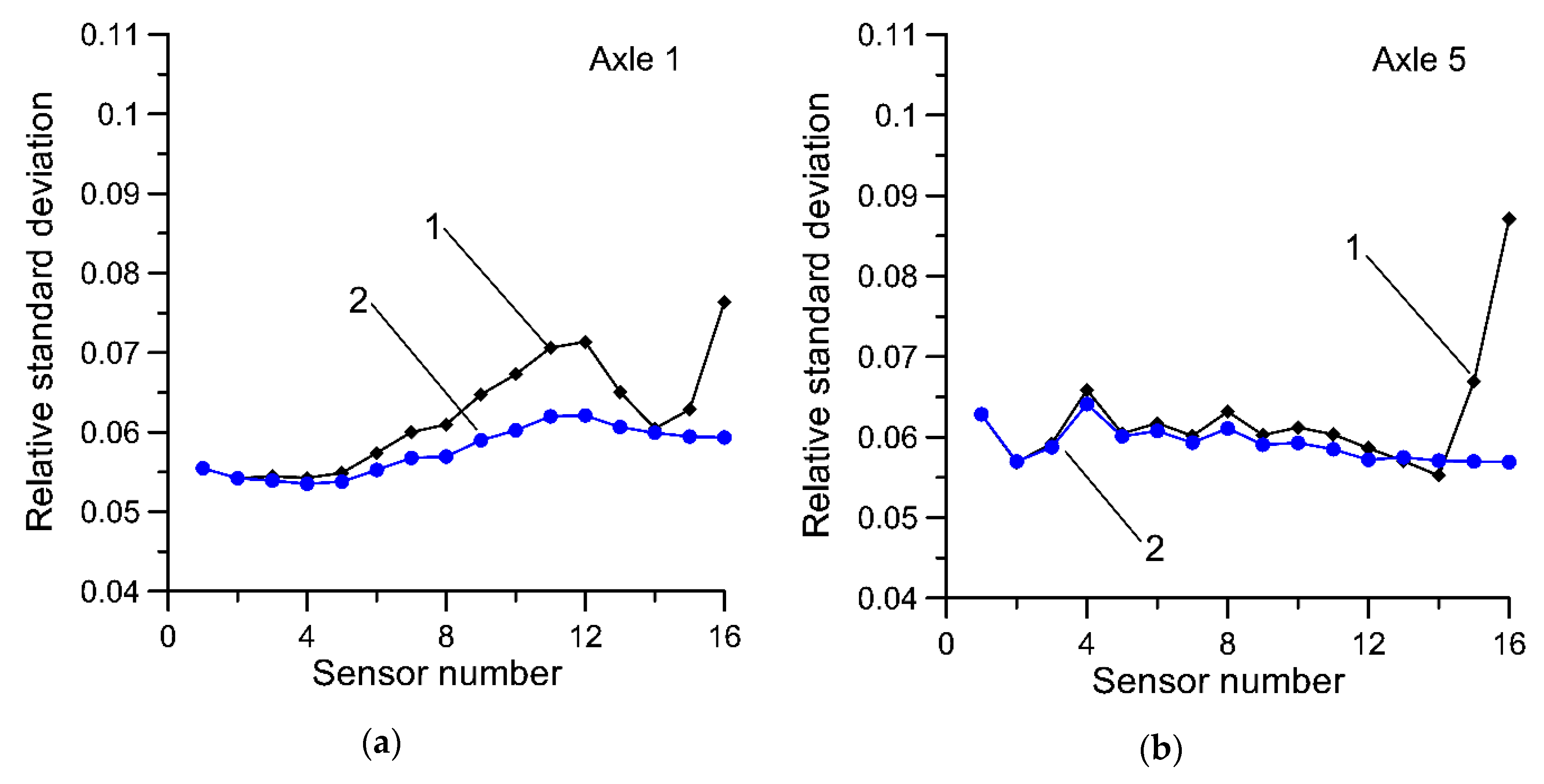

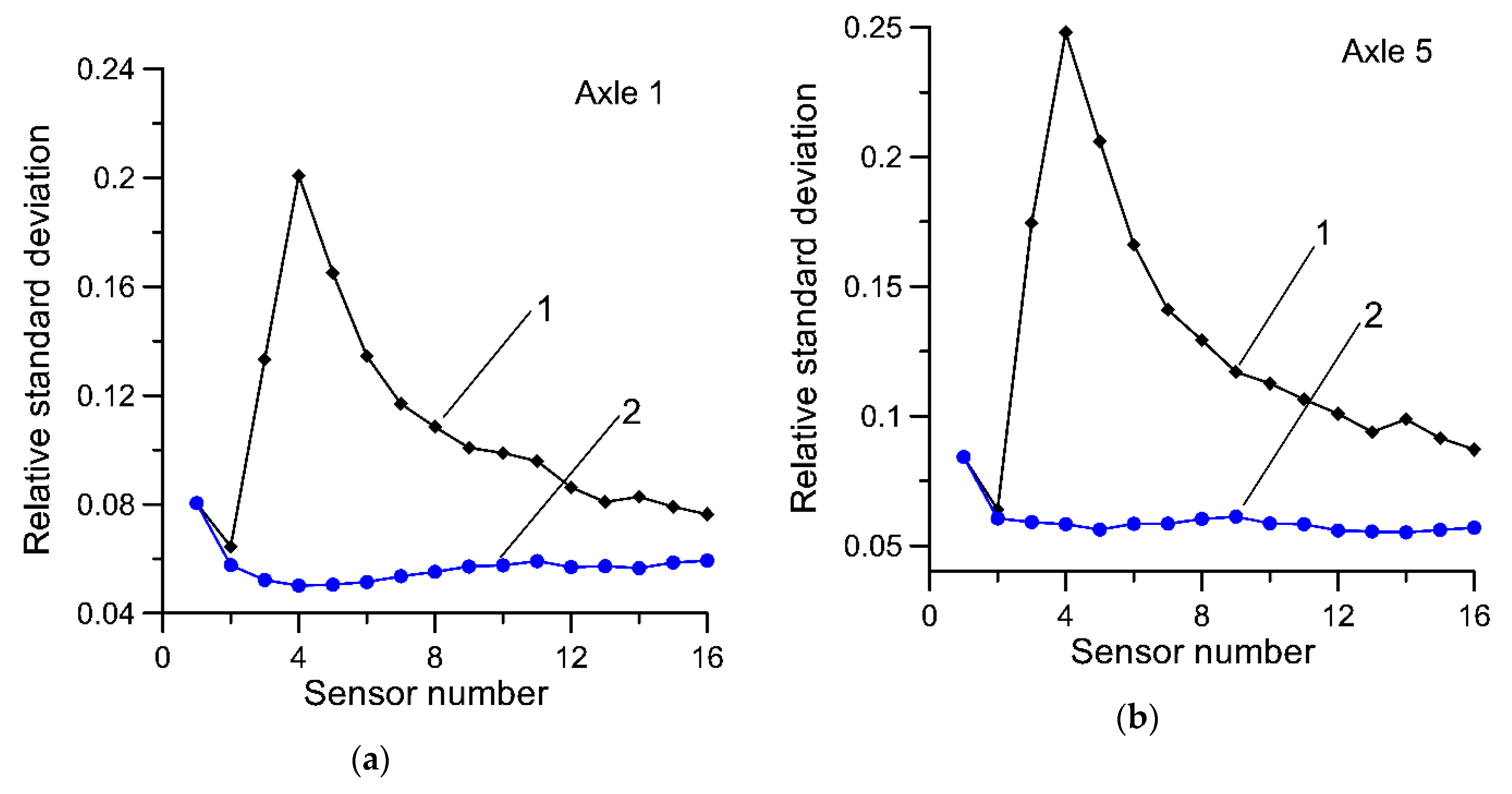

4.1. Simulation Results

4.2. Experimental Results

5. Discussion

- MLE Equation (7) allows an estimate of GVW to be obtained with an uncertainty that is no greater than the uncertainty of estimate determined using Equation (1),

- the benefit derived from the use of Equation (7) depends on the number of sensors installed in the MS-WIM system and on the range of their standard deviations,

- the properties of Equation (1) depend on the order of averaging of results obtained from successive load sensors,

- averaging in order from the most accurate sensor to the least accurate allows the uncertainty of results obtained using Equation (1) to be significantly decreased. It also allows the optimum number of sensors to be determined. It is possible to monitor the state of individual load sensors, but this, however, requires further technical operations,

- MLE Equation (7) is in practical terms not sensitive to the order of averaging. This is due to the fact that an algorithm for eliminating inaccurate sensors is “built-in” to its structure.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fourati, H. Multisensor Data Fusion: From Algorithms and Architectural Design to Applications; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Hall, D. Mathematical Techniques in Multisensor Data Fusion; Artech House: London, UK, 1992. [Google Scholar]

- Wald, L. Data Fusion, Definition and Architectures; Les Presses de l’Ecole des Mines: Paris, France, 2002. [Google Scholar]

- Kelly, G. Data Fusion: From Primary Metrology to Process Measurement. In Proceedings of the 16th IEEE IMTC, Venice, Italy, 24–26 May 1999; Volume 3, pp. 1325–1329. [Google Scholar]

- Sroka, R.; Gajda, J.; Burnos, P.; Piwowar, P. Information fusion in weigh in motion systems. In Proceedings of the IEEE Sensors Applications Symposium, Zadar, Croatia, 13–15 April 2015; pp. 395–400. [Google Scholar]

- Marszalek, Z.; Sroka, R. Signal fusion of changes in the inductive loop impedance components for vehicle axle detection. In Proceedings of the 21th International Conference on Methods and Models in Automation and Robotics, Międzyzdroje, Poland, 29 August–1 September 2016; pp. 25–29. [Google Scholar]

- Burnos, P.; Gajda, J.; Piwowar, P.; Sroka, R.; Stencel, M.; Zeglen, T. Accurate Weighing of Moving Vehicles. Metrol. Meas. Syst. 2007, 14, 507–516. [Google Scholar]

- Gajda, J.; Sroka, R.; Stencel, M.; Zeglen, T. Data Fusion Applications in the Traffic Parameters Measurement. Metrol. Meas. Syst. 2005, 12, 249–262. [Google Scholar]

- Burnos, P.; Gajda, J.; Sroka, R. Accuracy criteria for evaluation of weigh-in-motion systems. Metrol. Meas. Syst. 2018, 25, 743–754. [Google Scholar]

- Burnos, P.; Gajda, J.; Sroka, R. Accuracy requirements for weigh-in-motion systems for direct enforcement. In Proceedings of the ICWIM8-International Conference on Weigh-in-Motion, Prague, Czech Republic, 20–24 May 2019; pp. 93–106. [Google Scholar]

- Gajda, J.; Sroka, R.; Zeglen, T. Accuracy analysis of WIM systems calibrated using pre-weighed vehicles method. Metrol. Meas. Syst. 2007, 14, 517–527. [Google Scholar]

- Burnos, P.; Gajda, J. Thermal Property in Analysis of Axle Load Sensors for Weighing Vehicles in Weigh-in-Motion System. Sensors 2016, 16, 2143. [Google Scholar] [CrossRef]

- Gajda, J.; Burnos, P. Temperature Properties of Weigh-in-Motion Systems. In Proceedings of the 7th International Conference on Weigh-in-Motion & PIARC Workshop, Foz do Iguaçu, Brazil, 7–10 November 2016; pp. 46–55. [Google Scholar]

- Gajda, J.; Sroka, R.; Zeglen, T.; Burnos, P. The influence of temperature on errors of WIM systems employing piezoelectric sensors. Metrol. Meas. Syst. 2013, 20, 171–182. [Google Scholar] [CrossRef]

- Gajda, J.; Sroka, R.; Stencel, M.; Zeglen, T.; Piwowar, P.; Burnos, P. Analysis of the temperature influences on the metrological properties of polymer piezoelectric load sensors applied in weigh-in-motion systems. In Proceedings of the IEEE I2MTC, Graz, Austria, 13–16 May 2012; pp. 772–775. [Google Scholar]

- Vaziri, S.H.; Haas, C.; Rothenburg, L.; Haas, R.; Jiang, X. Investigation of the effects of air temperature and speed on performance of piezoelectric weigh-in-motion systems. Can. J. Civ. Eng. 2013, 40, 935–944. [Google Scholar] [CrossRef]

- Gajda, J.; Burnos, P.; Sroka, R. Accuracy Assessment of Weigh-in-Motion Systems for Vehicle’s Direct Enforcement. IEEE Intell. Transp. Syst. Mag. 2018, 10, 88–94. [Google Scholar] [CrossRef]

- Burnos, P.; Rys, D. The Effect of Flexible Pavement Mechanics on the Accuracy of Axle Load Sensors in Vehicle Weigh-in-Motion Systems. Sensors 2017, 17, 2053. [Google Scholar] [CrossRef] [PubMed]

- Czech Institute of Metrology. Metrological and Technical Requirements for Specified Measuring Devices, Including Test Methods for Verifying Specified Measuring Devices: High-Speed Weigh-in-Motion Road Vehicle Scales; Document of Czech Institute of Metrology; Czech Institute of Metrology: Brno, Czech, 2010. [Google Scholar]

- Doupal, E.; Adameova, Z.; Kriz, I. Start of Direct Enforcement in the Czech Republic. In Proceedings of the 7th International Conference on Weigh-in-Motion & PIARC Workshop, Foz do Iguaçu, Brasil, 7–10 November 2016; pp. 46–55. [Google Scholar]

- Vaziri, S.H. Investigation of Environmental Impacts on Piezoelectric Weigh-in-Motion Sensing System. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2011. [Google Scholar]

- van Loo, H. Project WIM-hand. In Results of the Second Stage of the Project Weigh-in-Motion for Direct Enforcement in 2001 and 2002; 2nd Interim Report; Public Works and Water Management Department, Road and Hydraulic Engineering Institute: Hague, The Netherlands, 2004. [Google Scholar]

- Gajda, J.; Burnos, P.; Sroka, R. Weigh-in-Motion Systems for Direct Enforcement in Poland. In Proceedings of the 7th International Conference on Weigh-in-Motion & PIARC Workshop, Foz do Iguaçu, Brasil, 7–10 November 2016; pp. 302–311. [Google Scholar]

- Ronay-Tobel, B.; Mikulas, R.; Katkics, A.; Toldi, M. Weight Enforcement Network of Hungary. In Proceedings of the ICWIM8 8th International Conference on Weigh-in-Motion, Hotel Olšanka, Prague, 19–23 May 2019. [Google Scholar]

- Antofie, A.; Boreux, J.; Corbaye, D.; Geroudet, B.; Liautaud, F.; Bancel, A. Approach of the Walloon Legal Metrology (Belgium) for Weigh in Motion (WIM) Free-Flow Direct Enforcement. In Proceedings of the ICWIM8 8th International Conference on Weigh-in-Motion, Hotel Olšanka, Prague, 19–23 May 2019. [Google Scholar]

- Pintelon, R.; Schoukens, J. System Identification: A Frequency Domain Approach; IEEE Press: Piscataway, NJ, USA, 2001. [Google Scholar]

- Gajda, J.; Sroka, R.; Stencel, M.; Zeglen, T.; Piwowar, P.; Burnos, P.; Marszalek, Z. Design and accuracy assessment of the multi-sensor weigh-in-motion system. In Proceedings of the IEEE International Instrumentation and Measurement Technology Conference, Pisa, Italy, 11–14 May 2015; pp. 1036–1041. [Google Scholar]

- Sroka, R.; Burnos, P.; Gajda, J. Vehicle’s Axle Load Sensors in Weigh-in-motion Systems. In Physical and Chemical Sensors: Design, Application & Networks; Yurish, S.Y., Ed.; International Frequency Sensor Association (IFSA) Publishing, Advances in Sensors: Barcelona, Spain, 2019; Volume 7. [Google Scholar]

- Cheng, L.; Zhang, H.; Li, Q. Design of a capacitive flexible weighing sensor for vehicle WIM system. Sensors 2007, 7, 1530–1544. [Google Scholar] [CrossRef]

- Xiang, T.; Huang, K.; Zhang, H.; Zhang, Y.; Zhang, Y.; Zhou, Y. Detection of moving load on pavement using piezoelectric sensors. Sensors 2020, 20, 2366. [Google Scholar] [CrossRef] [PubMed]

- Yuksel, K.; Kinet, D.; Chah, K.; Caucheteur, C. Implementation of a mobile platform based on fiber bragg grating sensors for automotive traffic monitoring. Sensors 2020, 20, 1567. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Wang, L.; Zhao, K.; Yang, H. Development of a novel piezoelectric sensing system for pavement dynamic load identification. Sensors 2019, 19, 4668. [Google Scholar] [CrossRef] [PubMed]

| Vehicle No. | GVW [kg] | Axle Load [kg] | No. of Runs | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |||

| 1 | 19,460 | 6044 | 5505 | 2604 | 2604 | 2703 | 47 |

| 2 | 25,060 | 6645 | 7229 | 3526 | 3805 | 3855 | 49 |

| 3 | 29,360 | 6436 | 7328 | 5149 | 5248 | 5199 | 51 |

| Total | 147 | ||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gajda, J.; Sroka, R.; Burnos, P. Sensor Data Fusion in Multi-Sensor Weigh-In-Motion Systems. Sensors 2020, 20, 3357. https://doi.org/10.3390/s20123357

Gajda J, Sroka R, Burnos P. Sensor Data Fusion in Multi-Sensor Weigh-In-Motion Systems. Sensors. 2020; 20(12):3357. https://doi.org/10.3390/s20123357

Chicago/Turabian StyleGajda, Janusz, Ryszard Sroka, and Piotr Burnos. 2020. "Sensor Data Fusion in Multi-Sensor Weigh-In-Motion Systems" Sensors 20, no. 12: 3357. https://doi.org/10.3390/s20123357

APA StyleGajda, J., Sroka, R., & Burnos, P. (2020). Sensor Data Fusion in Multi-Sensor Weigh-In-Motion Systems. Sensors, 20(12), 3357. https://doi.org/10.3390/s20123357