Analysis of Modern Optical Inspection Systems for Parts Manufactured by Selective Laser Melting

Abstract

1. Introduction

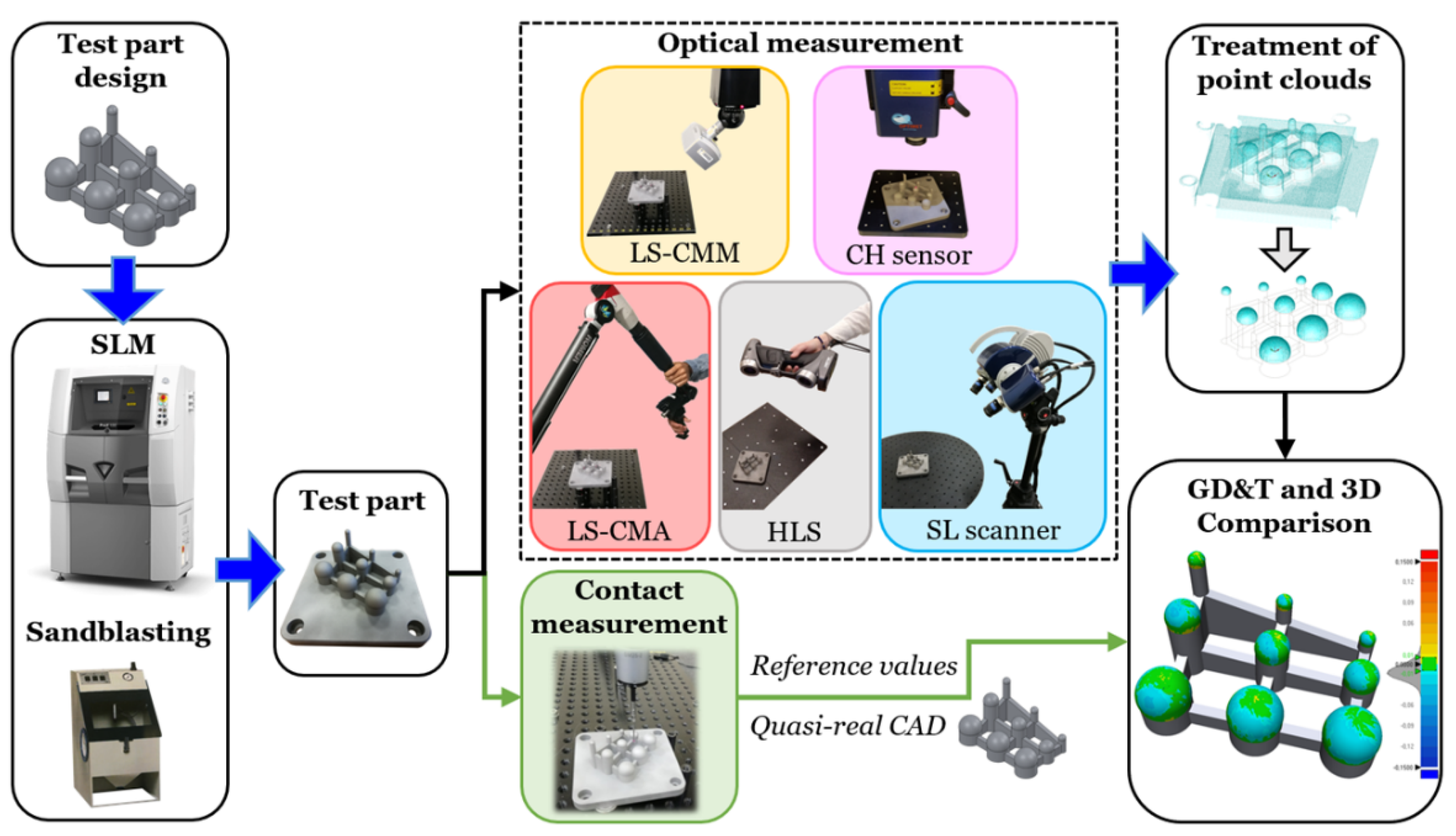

2. Materials and Methods

- Test part design: A test part was designed considering the restrictions of the AM machine and process (allowing the characterization of its limits) and the requirement for measuring with contact and optical systems.

- SLM manufacturing process and sandblasting post-process: Once the CAD design was exported in *.stl format, the test part was manufactured in 17-4PH stainless steel using SLM. The part was post-processed by sandblasting to improve the surface finish and facilitate the acquisition of the point clouds with several OMSs.

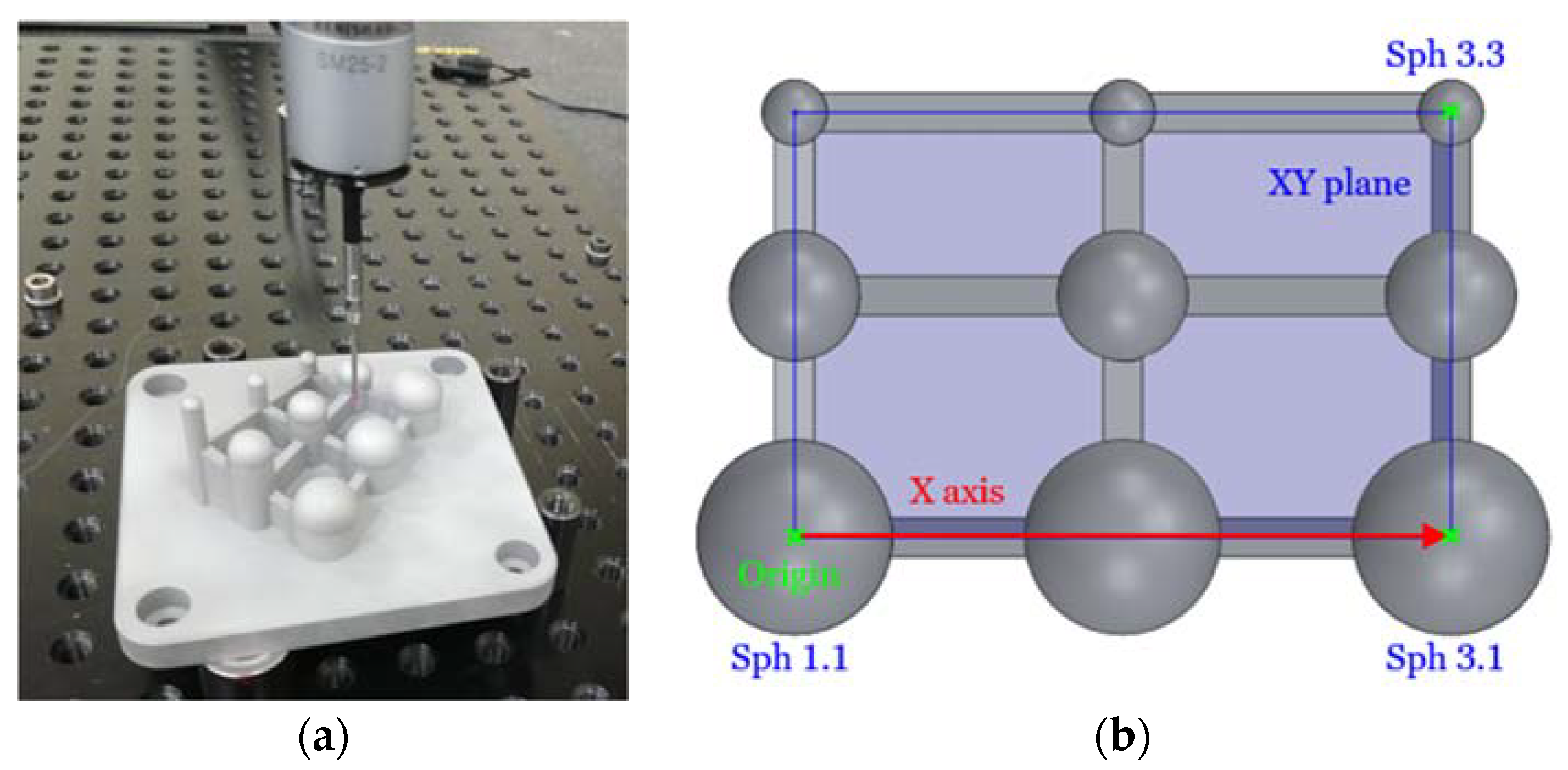

- Contact measurement: The test part was measured with high precision using a CMM, obtaining the geometric dimensioning and tolerancing (GD&T) model. These contact measurements were taken as reference or quasi-real CAD values.

- Optical measurement: The sphere-based test part was digitized using different OMSs (laser triangulation, CH, and SL sensors).

- Treatment of point clouds and GD&T measurements: The point clouds were cleaned by removing all scanned points not belonging to the part spheres. Subsequently, the GD&T measurements and 3D comparisons were performed between the quasi-real CAD and the point clouds obtained by the different non-contact systems.

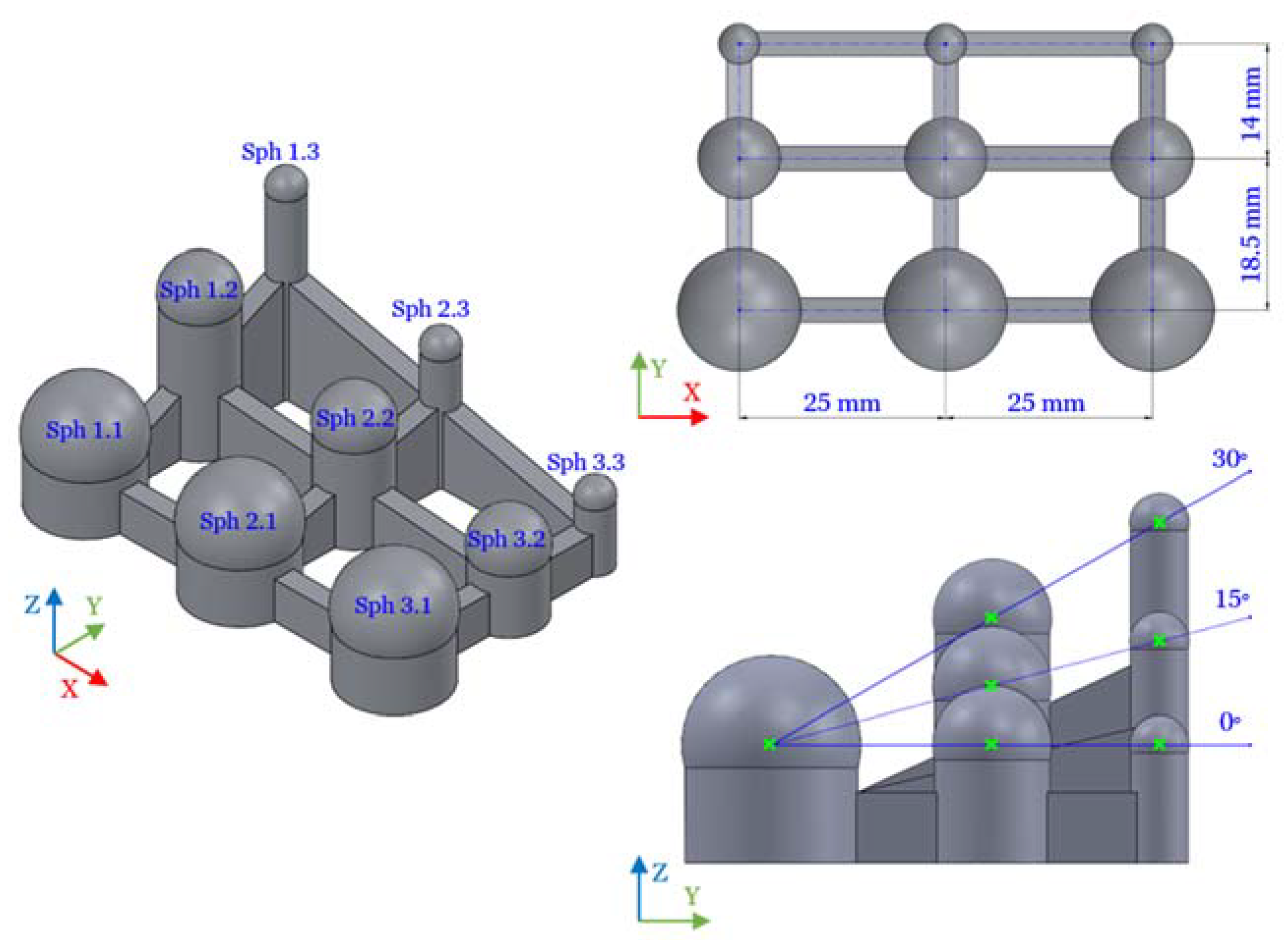

2.1. Test Part Design

2.2. SLM Manufacturing Process and Sandblasting Post-Process

2.3. Contact Measurement

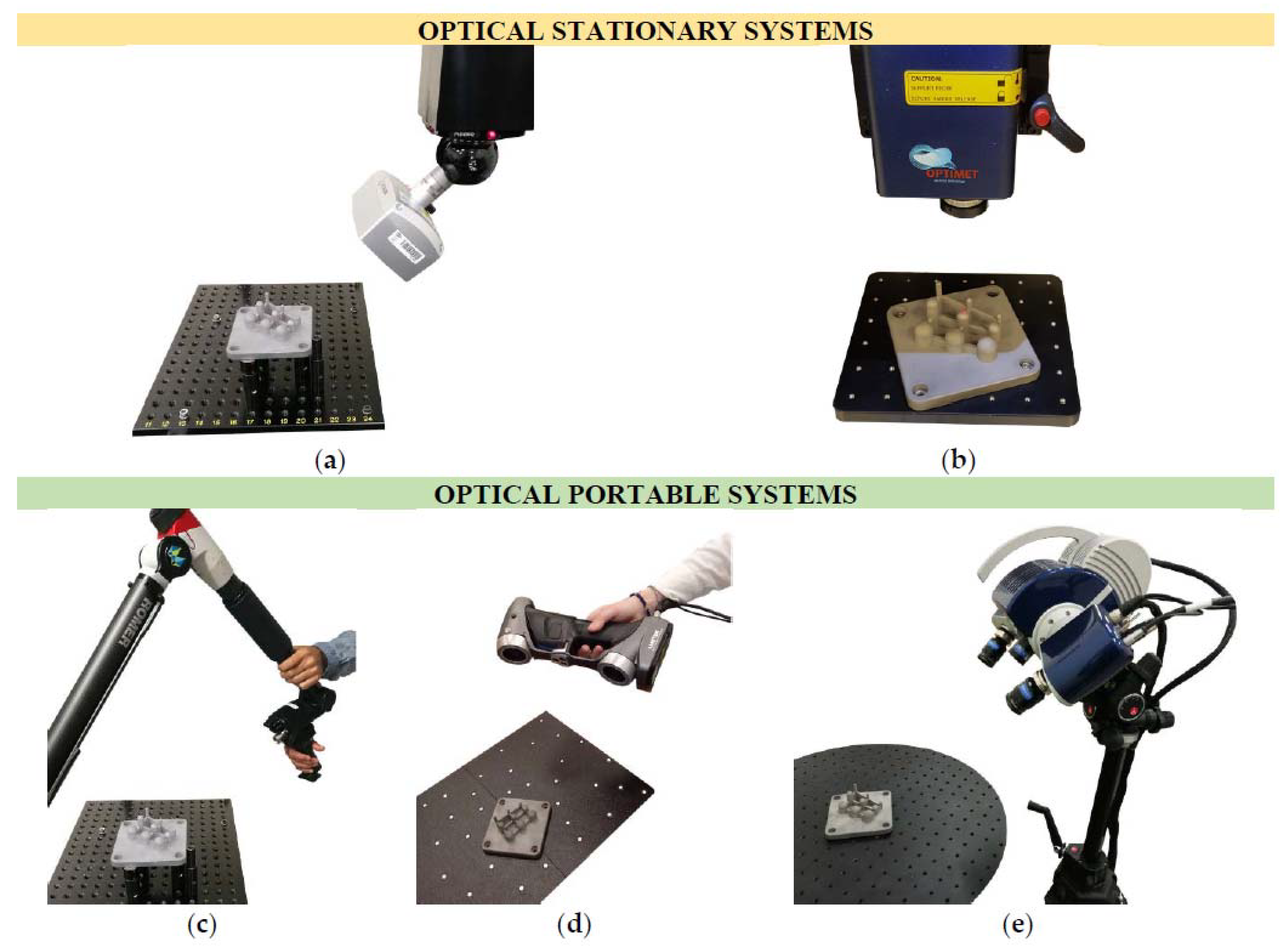

2.4. Optical Measurement

2.4.1. Laser Scanner on CMM (LS-CMM)

2.4.2. Conoscopic Holography Sensor (CH)

2.4.3. CMA with Integrated Laser Scanner (LS-CMA)

2.4.4. Portable and Handheld Laser Scanner (HLS)

2.4.5. Structured Blue-Light Scanner (SL)

2.5. Treatment of Point Clouds and GD&T Measurements

3. Results and Discussion

3.1. GD&T Comparison among the Evaluated OMS

3.1.1. Dimensional Errors: Diameter and Spheres Center Position

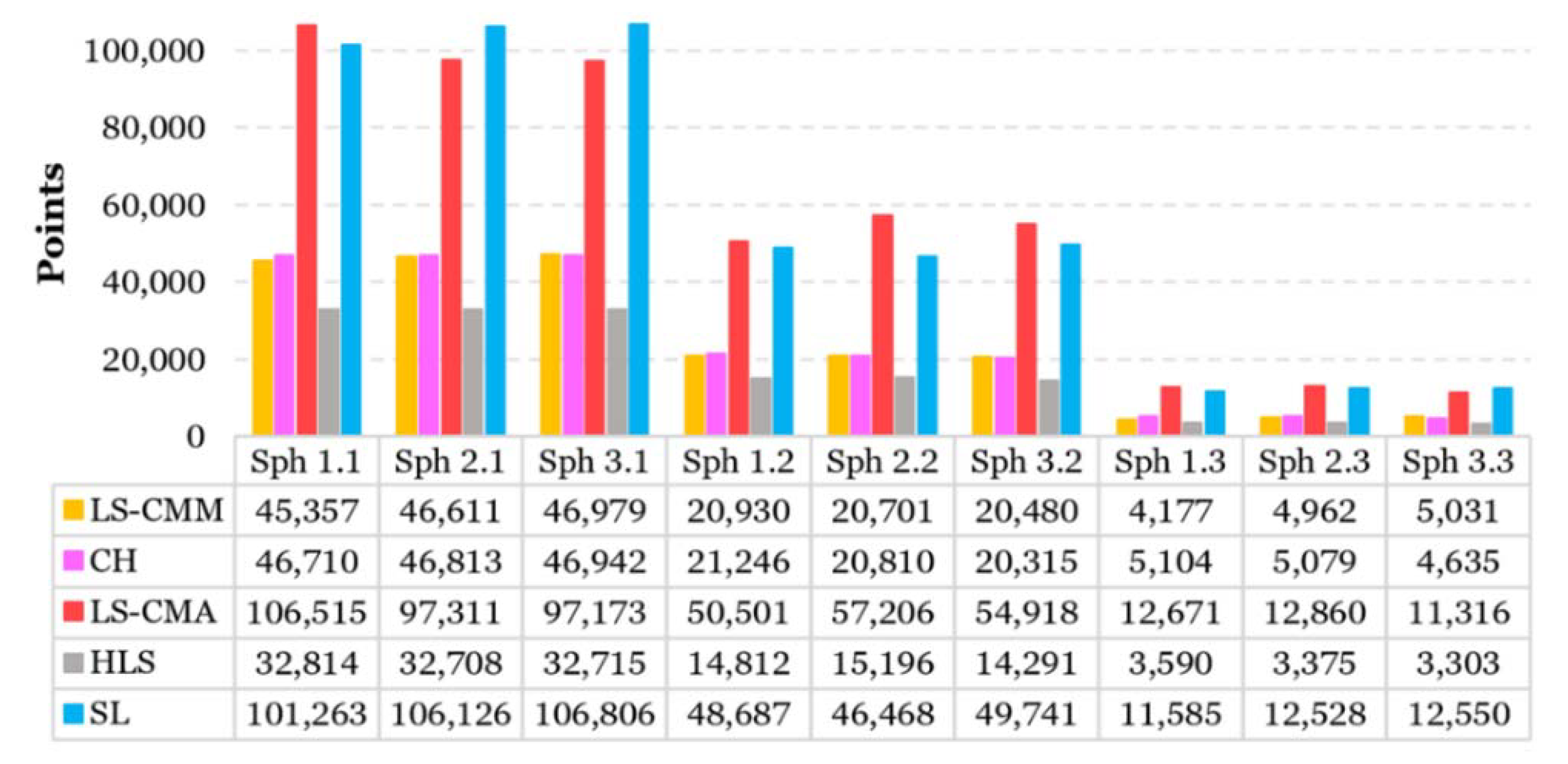

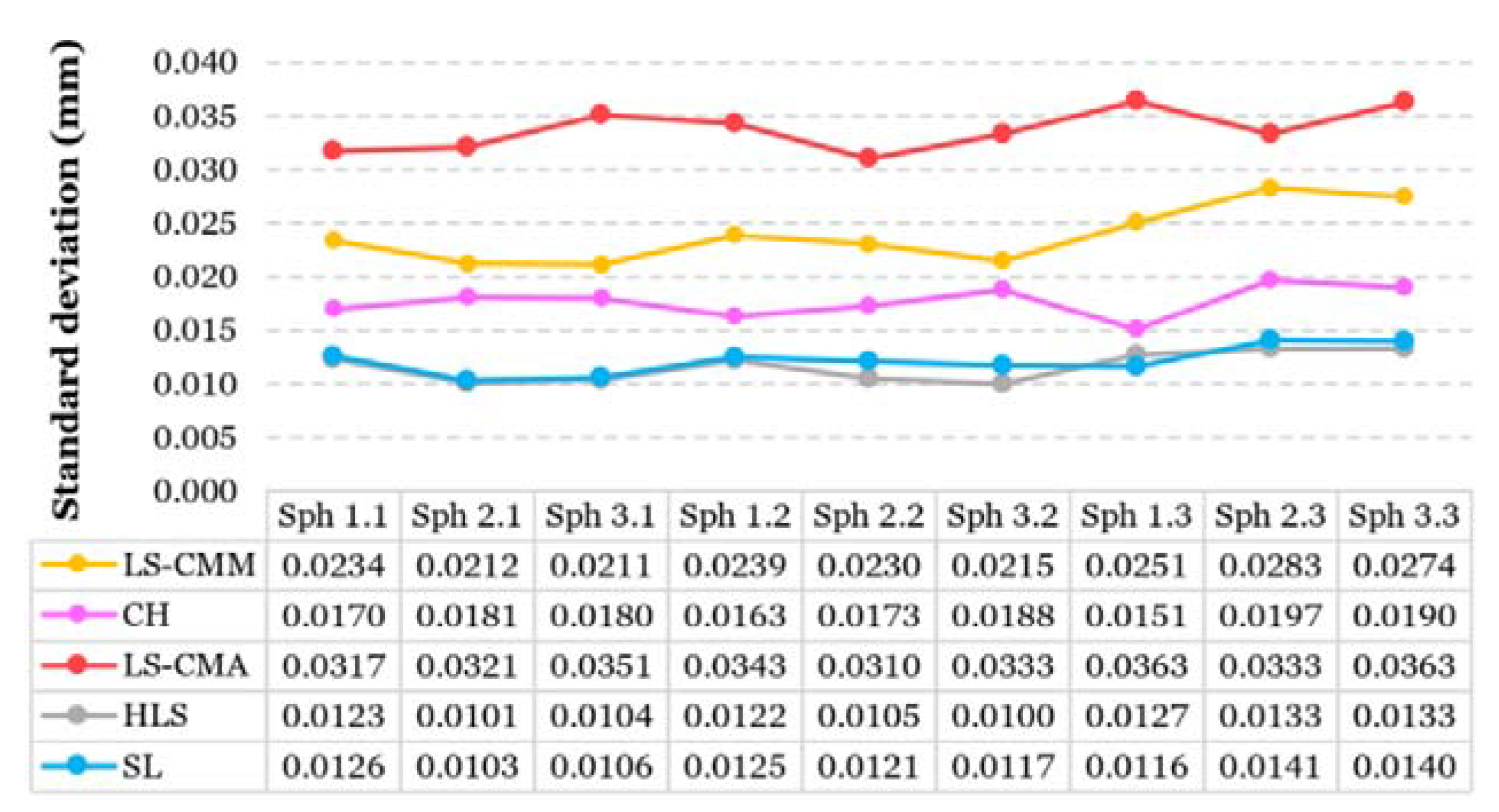

3.1.2. Geometrical Errors: Sphericity and Standard Deviation

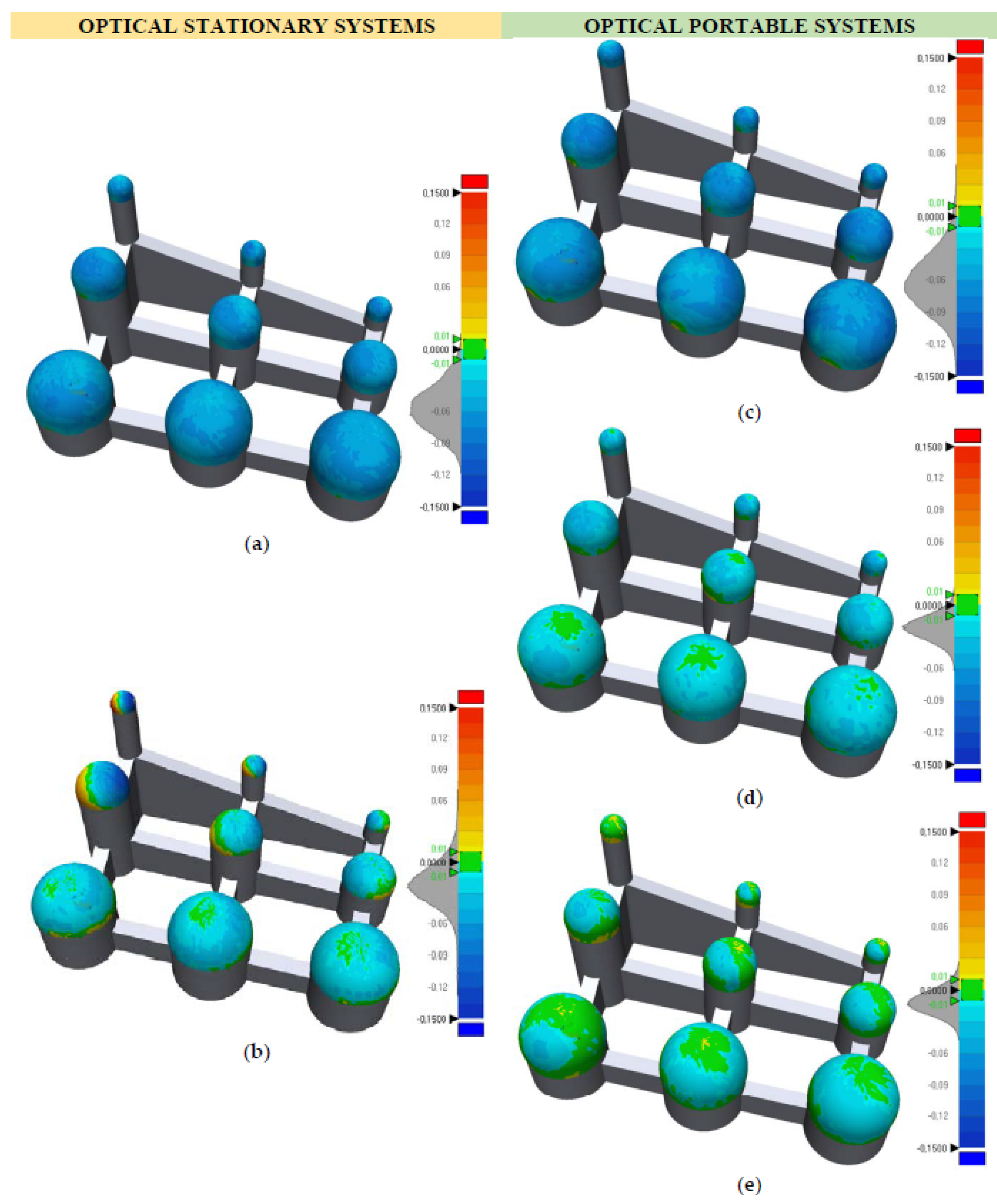

3.1.3. 3D Comparison between the Evaluated OMS and the Quasi-Real CAD

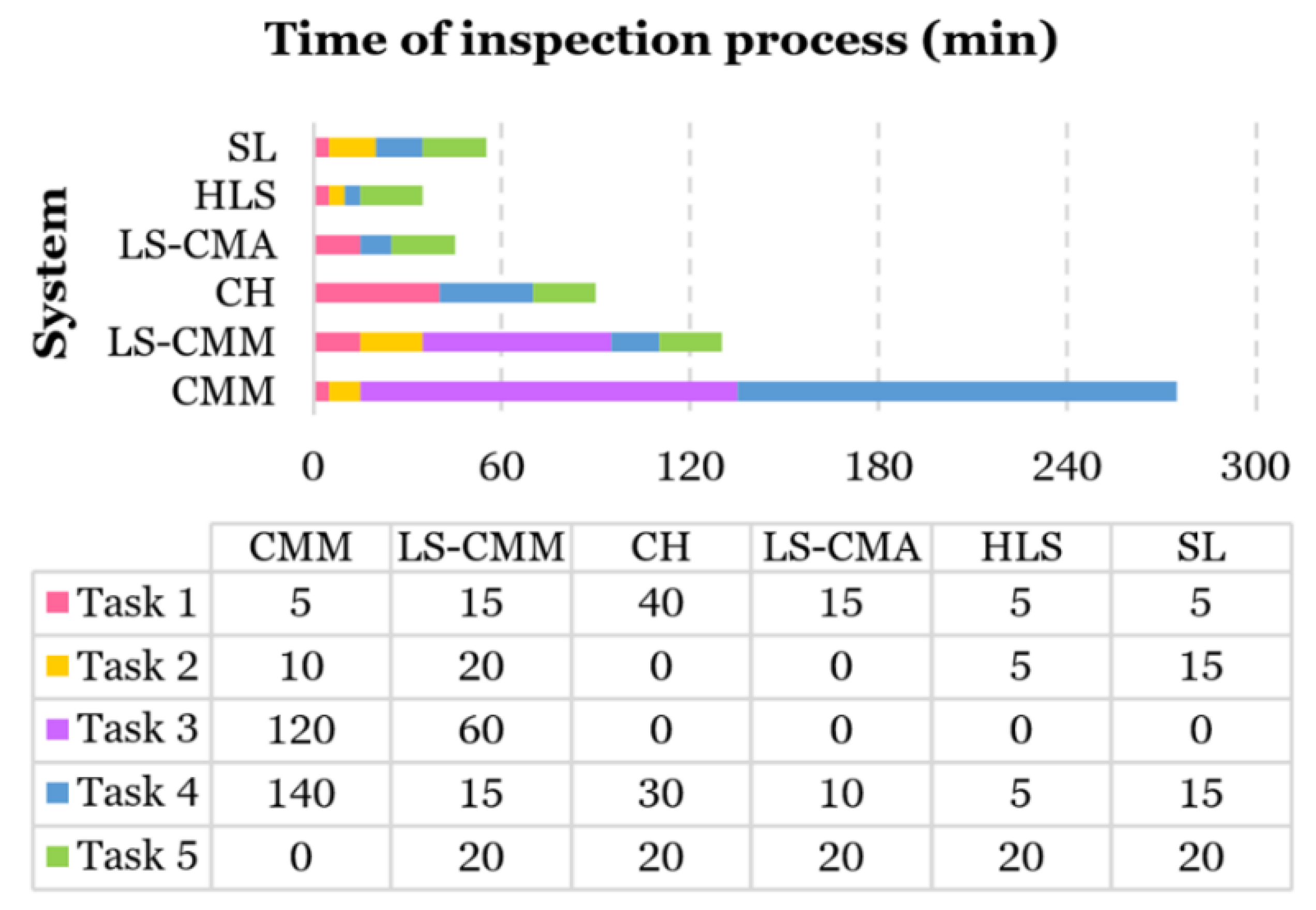

3.2. Comparison of the Complete Inspection Process Time

- Task 1—Setup: Setups consist of switching on both the measurement equipment and software. In the case of non-contact systems, this activity also includes optical sensor heating.

- Task 2—System calibration: The CMM was calibrated using a certified calibration sphere measured by contact. The LS-CMM was optically calibrated using a specific laser calibration sphere. The HLS and SL scanner calibrations were carried out by measuring a calibration plate (marked with circles). The rest of the systems do not have a specific calibration task; the calibration is integrated into the equipment setup once started.

- Task 3—Program preparation: This activity is only necessary when the measurement software is PC-DMIS. It consists of editing the measurement program, including the output variables that will compose the results report.

- Task 4—Execution of digitization: This task consists of acquiring data to obtain the dimensional and geometrical information of the test part. For the CMM, a manual pre-alignment is done first, then an automatic alignment and measurement are carried out. In the case of the LS-CMA and HLS systems, this task is done manually, whereas, for the rest of the OMSs, it is done in automatic mode. This activity also includes setting scanning parameters without requiring program preparation.

- Task 5—Generation of results report: The results report generation is automatic in the case of the CMM with PC-DMIS software. For the non-contact systems, this activity is performed with the Geomagic® Control X™ software, and it includes the tasks of point cloud cleaning, sphere reconstruction, and generating the results report.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal additive manufacturing in the commercial aviation industry: A review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2015. Additive Manufacturing—General principles—Terminology; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Kruth, J.P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Cabanettes, F.; Joubert, A.; Chardon, G.; Dumas, V.; Rech, J.; Grosjean, C.; Dimkovski, Z. Topography of as built surfaces generated in metal additive manufacturing: A multi scale analysis from form to roughness. Precis. Eng. 2018, 52, 249–265. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; MacDonald, E.; Wie, H.; Chen, X.; Jiang, L. The influence of process parameters on vertical surface roughness of the AlSi10Mg parts fabricated by selective laser melting. J. Mater. Process. Technol. 2019, 266, 26–36. [Google Scholar] [CrossRef]

- Bartlett, J.L.; Li, X. An overview of residual stresses in metal powder bed fusion. Addit. Manuf. 2019, 27, 131–149. [Google Scholar] [CrossRef]

- Cheng, B.; Shrestha, S.; Chou, K. Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit. Manuf. 2016, 12, 240–251. [Google Scholar]

- Van Elsen, M. Complexity of Selective Laser Melting: A New Optimisation Approach. PhD Thesis, Katholieke Universiteit, Leuven, Belgium, 2007. [Google Scholar]

- Leach, R.K.; Bourell, D.; Carmignato, S.; Donmez, A.; Senin, N.; Dewulf, W. Geometrical metrology for metal additive manufacturing. CIRP Ann. Manuf. Technol. 2019, 68, 677–700. [Google Scholar] [CrossRef]

- Kalms, M.; Narita, R.; Thomy, C.; Vollertsen, F.; Bergmann, R.B. New approach to evaluate 3D laser printed parts in powder bed fusion-based additive manufacturing in-line within closed space. Addit. Manuf. 2019, 26, 161–165. [Google Scholar] [CrossRef]

- He, W.; Shi, W.; Li, J.; Xie, H. In-situ monitoring and deformation characterization by optical techniques; part I: Laser-aided direct metal deposition for additive manufacturing. Opt. Lasers Eng. 2019, 122, 74–88. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Cordero, P.M.; Mireles, J.; Ridwan, S.; Wicker, R.B. Evaluation of monitoring methods for electron beam melting powder bed fusion additive manufacturing technology. Prog. Addit. Manuf. 2017, 2, 1–10. [Google Scholar] [CrossRef]

- Townsend, A.; Senin, N.; Blunt, L.; Leach, R.K.; Taylor, J.S. Surface texture metrology for metal additive manufacturing: A review. Precis. Eng. 2016, 46, 34–47. [Google Scholar] [CrossRef]

- Townsend, A.; Racasan, R.; Blunt, L. Surface-specific additive manufacturing test artefacts. Surf. Topogr. Metrol. Prop. 2018, 6, 024007. [Google Scholar] [CrossRef]

- Newton, L.; Senin, N.; Gomez, C.; Danzl, R.; Helmli, F.; Blunt, L.; Leach, R. Areal topography measurement of metal additive surfaces using focus variation microscopy. Addit. Manuf. 2019, 25, 365–389. [Google Scholar] [CrossRef]

- Stavroulakis, P.I.; Leach, R.K. Review of post-process optical form metrology for industrial-grade metal additive manufactured parts. Rev. Sci. Instrum. 2016, 87, 041101. [Google Scholar] [CrossRef]

- Imkamp, D.; Berthold, J.; Heizmann, M.; Kniel, K.; Manske, E.; Peterek, M.; Schmitt, R.; Seidler, J.; Sommer, K.D. Challenges and trends in manufacturing measurement technology—The “Industrie 4.0” concept. J. Sens. Sens. Syst. 2016, 5, 325–335. [Google Scholar]

- Gerbino, S.; Del Giudice, D.M.; Staiano, G.; Lanzotti, A.; Martorelli, M. On the influence of scanning factors on the laser scanner-based 3D inspection process. Int. J. Adv. Manuf. Technol. 2016, 84, 1787–1799. [Google Scholar] [CrossRef]

- Martínez-Pellitero, S.; Cuesta, E.; Giganto, S.; Barreiro, J. New procedure for qualification of structured light 3D scanners using an optical feature-based gauge. Opt. Lasers Eng. 2018, 110, 193–206. [Google Scholar] [CrossRef]

- Dury, M.R.; Woodward, S.D.; Brown, S.B.; McCarthy, M.B. Surface finish and 3D optical scanner measurement performance for precision engineering. In Proceedings of the 30th Annual Meeting of the American Society for Precision Engineering, Austin, TX, USA, 1–6 November 2015; pp. 419–423. [Google Scholar]

- Yue, H.; Dantanarayana, H.G.; Wu, Y.; Huntley, J.M. Reduction of systematic errors in structured light metrology at discontinuities in surface reflectivity. Opt. Lasers Eng. 2019, 112, 68–76. [Google Scholar] [CrossRef]

- Rico, J.C.; Valiño, G.; Fernández, P.; Zapico, P.; Blanco, D.; Mateos, S. Adjustment recommendations of a conoscopic holography sensor for a reliable scanning of surfaces with roughness grades obtained by different processes. Precis. Eng. 2015, 42, 335–345. [Google Scholar] [CrossRef]

- Cuesta, E.; Álvarez, B.J.; Martínez-Pellitero, S.; Barreiro, J.; Patiño, H. Metrological evaluation of laser scanner integrated with measuring arm using optical feature-based gauge. Opt. Lasers Eng. 2019, 121, 120–132. [Google Scholar] [CrossRef]

- Mian, S.H.; Al-Ahmari, A.M. Comparative analysis of different digitization systems and selection of best alternative. J. Intell. Manuf. 2019, 30, 2039–2067. [Google Scholar] [CrossRef]

- Álvarez, I.; Enguita, J.M.; Frade, M.; Marina, J.; Ojea, G. On-Line Metrology with Conoscopic Holography: Beyond Triangulation. Sensors 2009, 9, 7021–7037. [Google Scholar] [CrossRef]

- Ramos Barbero, B.; Santos Ureta, E. Comparative study of different digitization techniques and their accuracy. Comput. Aided Des. 2011, 43, 188–206. [Google Scholar] [CrossRef]

- Ameen, W.; Al-Ahmari, A.M.; Mian, S.H. Evaluation of handheld scanners for automotive applications. Appl. Sci. 2018, 8, 217. [Google Scholar] [CrossRef]

- Tóth, T.; Živčák, J. A Comparison of the outputs of 3D scanners. Procedia Eng. 2014, 69, 393–401. [Google Scholar] [CrossRef]

- Iuliano, L.; Minetola, P. Rapid manufacturing of sculptures replicas: A comparison between 3D optical scanners. In international cooperation to save the world’s cultural heritage. In Proceedings of the CIPA 2005 XX International Symposium, Torino, Italy, 26 September–1 October 2005; ACTA Conferences and Events. pp. 384–389. [Google Scholar]

- Guerra, M.G.; De Chiffre, L.; Lavecchia, F.; Galantucci, L.M. Use of miniature step gauges to assess the performance of 3D optical scanners and to evaluate the accuracy of a novel additive manufacture process. Sensors 2020, 20, 738. [Google Scholar] [CrossRef] [PubMed]

- Rivas Santos, V.M.; Thompson, A.; Sims-Waterhouse, D.; Maskery, I.; Woolliams, P.; Leach, R. Design and characterisation of an additive manufacturing benchmarking artefact following a design-for-metrology approach. Addit. Manuf. 2020, 32, 100964. [Google Scholar] [CrossRef]

- 3DSystems. Direct Metal Printers. Metal Additive Manufacturing with the ProX DMP 3D Printers. 2017. Available online: https://www.3dsystems.com/3d-printers/metal (accessed on 4 June 2020).

- ISO 10360-2:2009. Geometrical product specifications (GPS)—Acceptance and Reverification Tests for Coordinate Measuring Machines (CMM)—Part. 2: CMMs Used for Measuring Linear Dimensions; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- ISO 10360-8:2013. Geometrical Product Specifications (GPS)—Acceptance and Reverification Tests for Coordinate Measuring Systems (CMS)—Part. 8: CMMs with Optical Distance Sensors; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- ISO 1101:2017. Geometrical Product Specifications (GPS)—Geometrical Tolerancing—Tolerances of Form, Orientation, Location and Run-Out; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

| Visualization | Spheres | Diameter (mm) | Semi-Sphere Area (mm2) | Contact Points | Density (Points/mm2) |

|---|---|---|---|---|---|

| Sph 1.1 Sph 2.1 Sph 3.1 | 15 | 353 | 900 | 2.55 |

| Sph 1.2 Sph 2.2 Sph 3.2 | 10 | 157 | 400 | 2.55 |

| Sph 1.3 Sph 2.3 Sph 3.3 | 5 | 39 | 100 | 2.55 |

| Parameter | LS-CMM | CH | LS-CMA | HLS | SL | |

|---|---|---|---|---|---|---|

| Deviation of sphere center position (mm) | X | 0.0011 | −0.0369 | −0.0028 | −0.0018 | −0.0011 |

| Y | 0.0042 | −0.0056 | 0.0039 | −0.0015 | −0.0020 | |

| Z | 0.0056 | −0.0049 | 0.0078 | 0.0062 | 0.0083 |

| Parameter | LS-CMM | CH | LS-CMA | HLS | SL |

|---|---|---|---|---|---|

| Average (mm) | −0.0561 | −0.0224 | −0.0611 | −0.0220 | −0.0116 |

| Standard Deviation (mm) | 0.0230 | 0.0279 | 0.0311 | 0.0125 | 0.0123 |

| RMS (mm) | 0.0607 | 0.0358 | 0.0686 | 0.0253 | 0.0169 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giganto, S.; Martínez-Pellitero, S.; Cuesta, E.; Meana, V.M.; Barreiro, J. Analysis of Modern Optical Inspection Systems for Parts Manufactured by Selective Laser Melting. Sensors 2020, 20, 3202. https://doi.org/10.3390/s20113202

Giganto S, Martínez-Pellitero S, Cuesta E, Meana VM, Barreiro J. Analysis of Modern Optical Inspection Systems for Parts Manufactured by Selective Laser Melting. Sensors. 2020; 20(11):3202. https://doi.org/10.3390/s20113202

Chicago/Turabian StyleGiganto, Sara, Susana Martínez-Pellitero, Eduardo Cuesta, Víctor M. Meana, and Joaquín Barreiro. 2020. "Analysis of Modern Optical Inspection Systems for Parts Manufactured by Selective Laser Melting" Sensors 20, no. 11: 3202. https://doi.org/10.3390/s20113202

APA StyleGiganto, S., Martínez-Pellitero, S., Cuesta, E., Meana, V. M., & Barreiro, J. (2020). Analysis of Modern Optical Inspection Systems for Parts Manufactured by Selective Laser Melting. Sensors, 20(11), 3202. https://doi.org/10.3390/s20113202