A Novel Order Analysis and Stacked Sparse Auto-Encoder Feature Learning Method for Milling Tool Wear Condition Monitoring

Abstract

1. Introduction

2. Basic Theory

2.1. Order Analysis

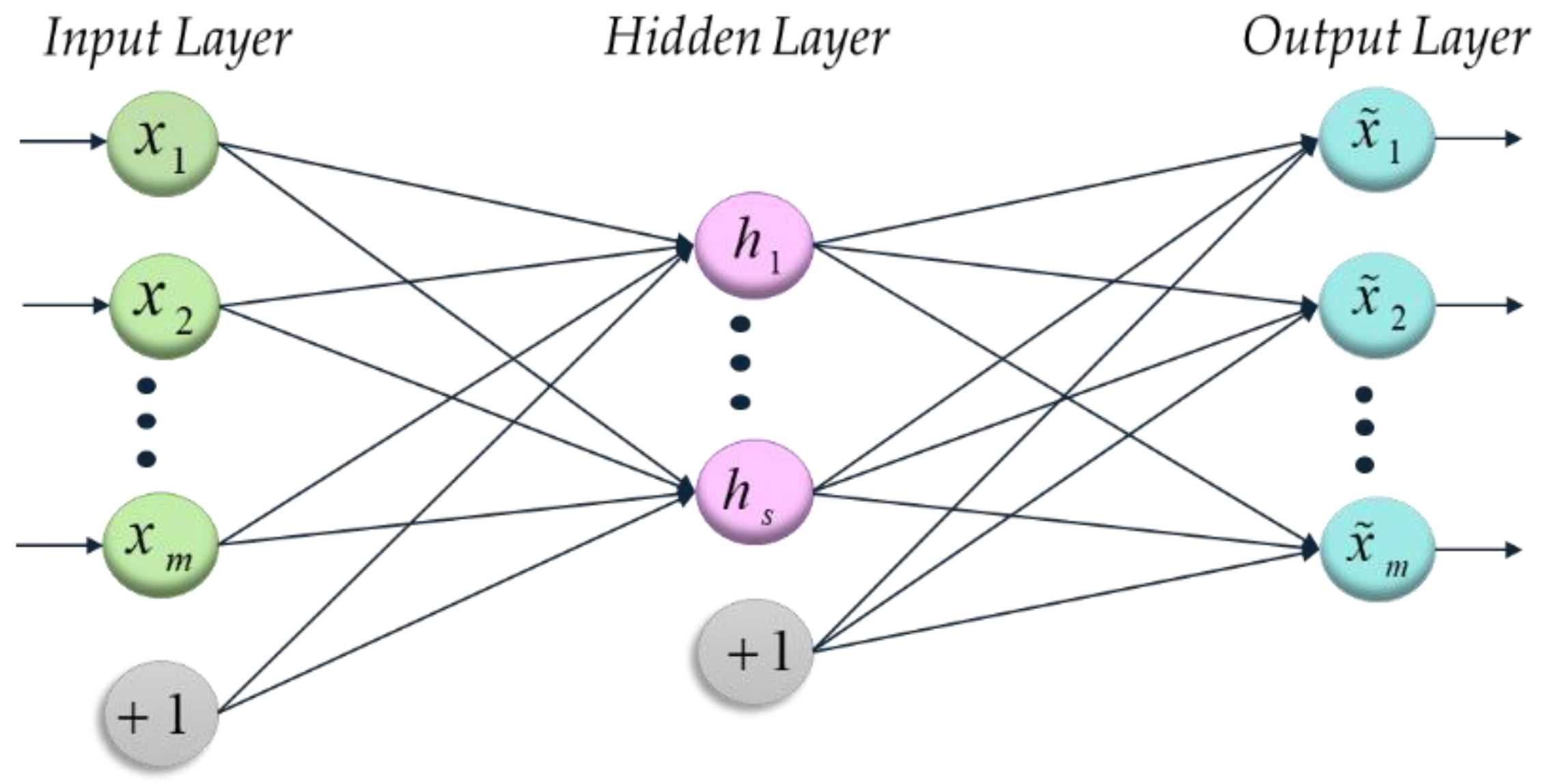

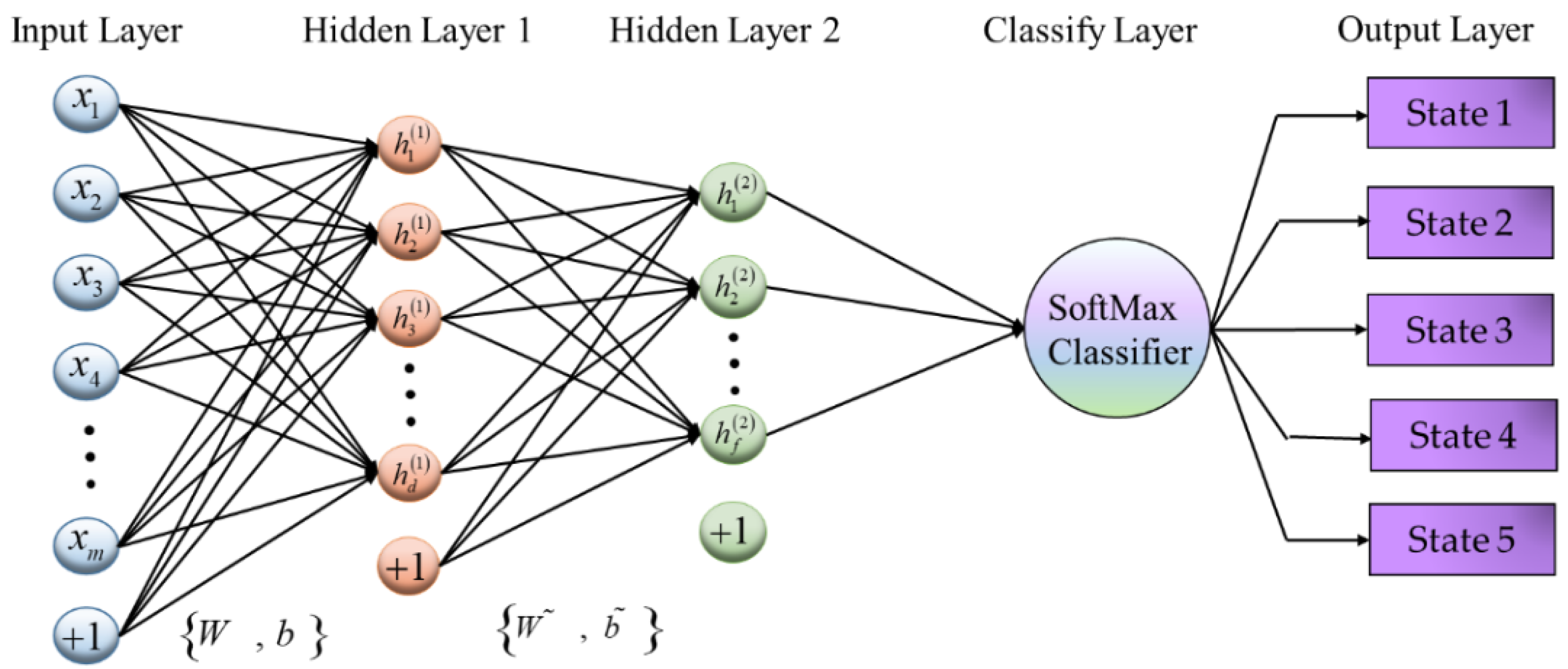

2.2. Stacked Sparse Autoencoder

3. General Procedure

4. Experimental Verification

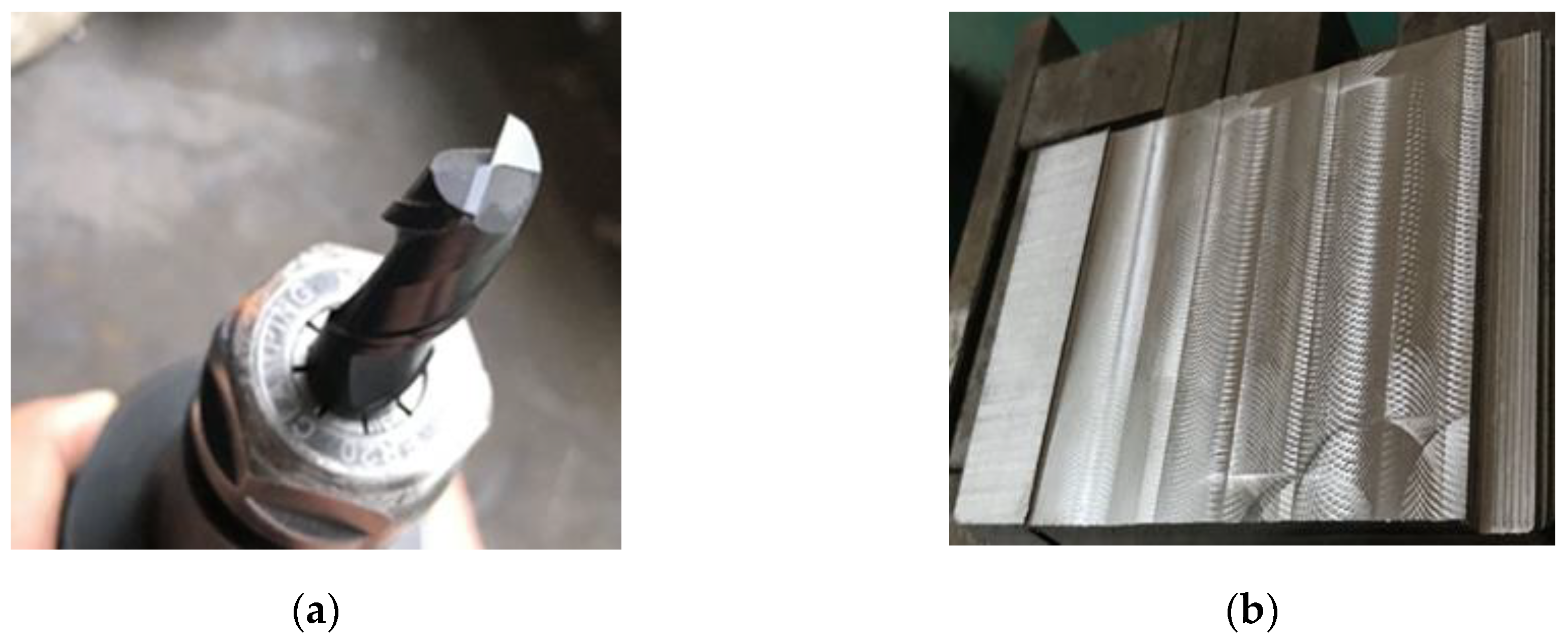

4.1. Tool Wear State Test Rig

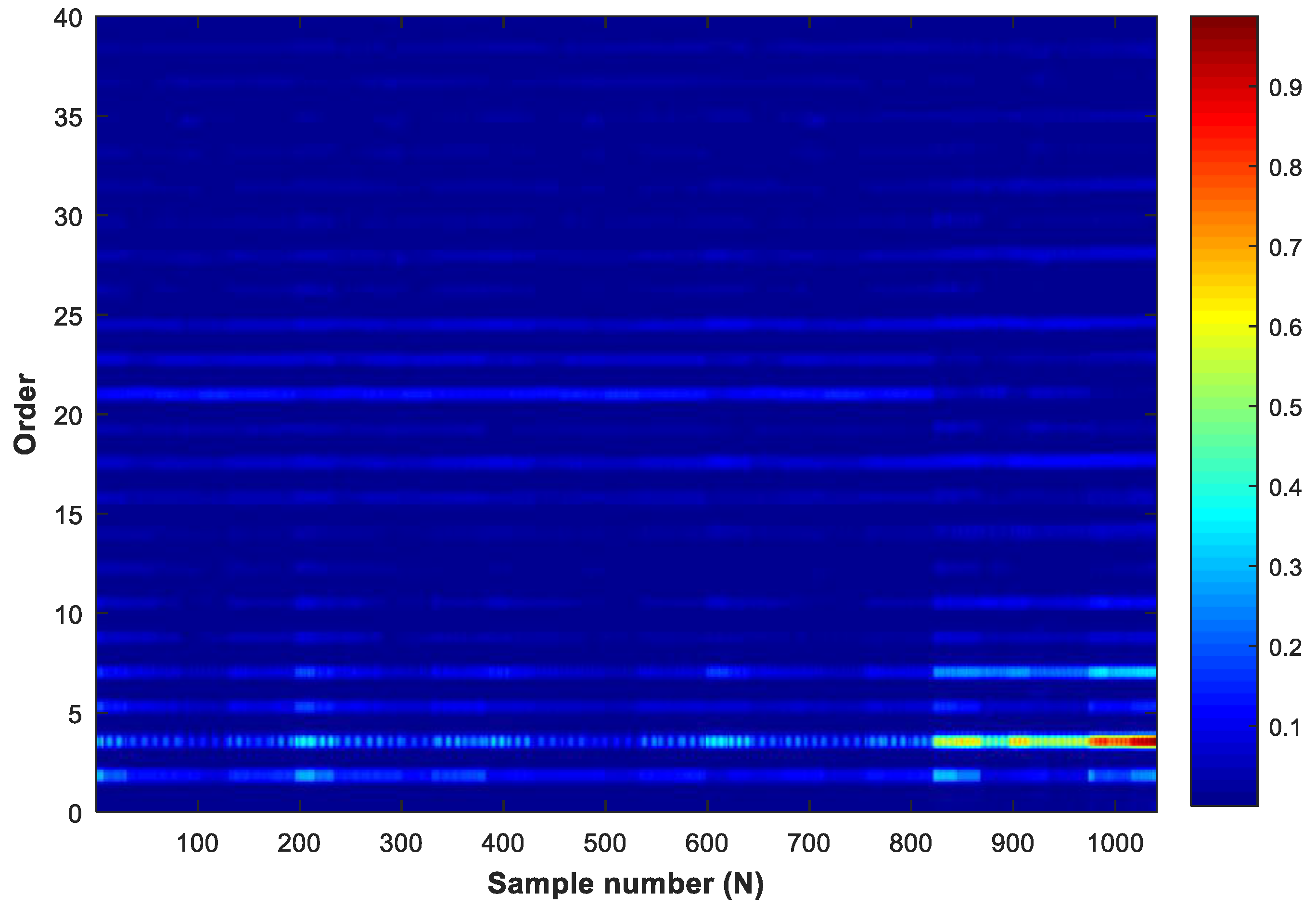

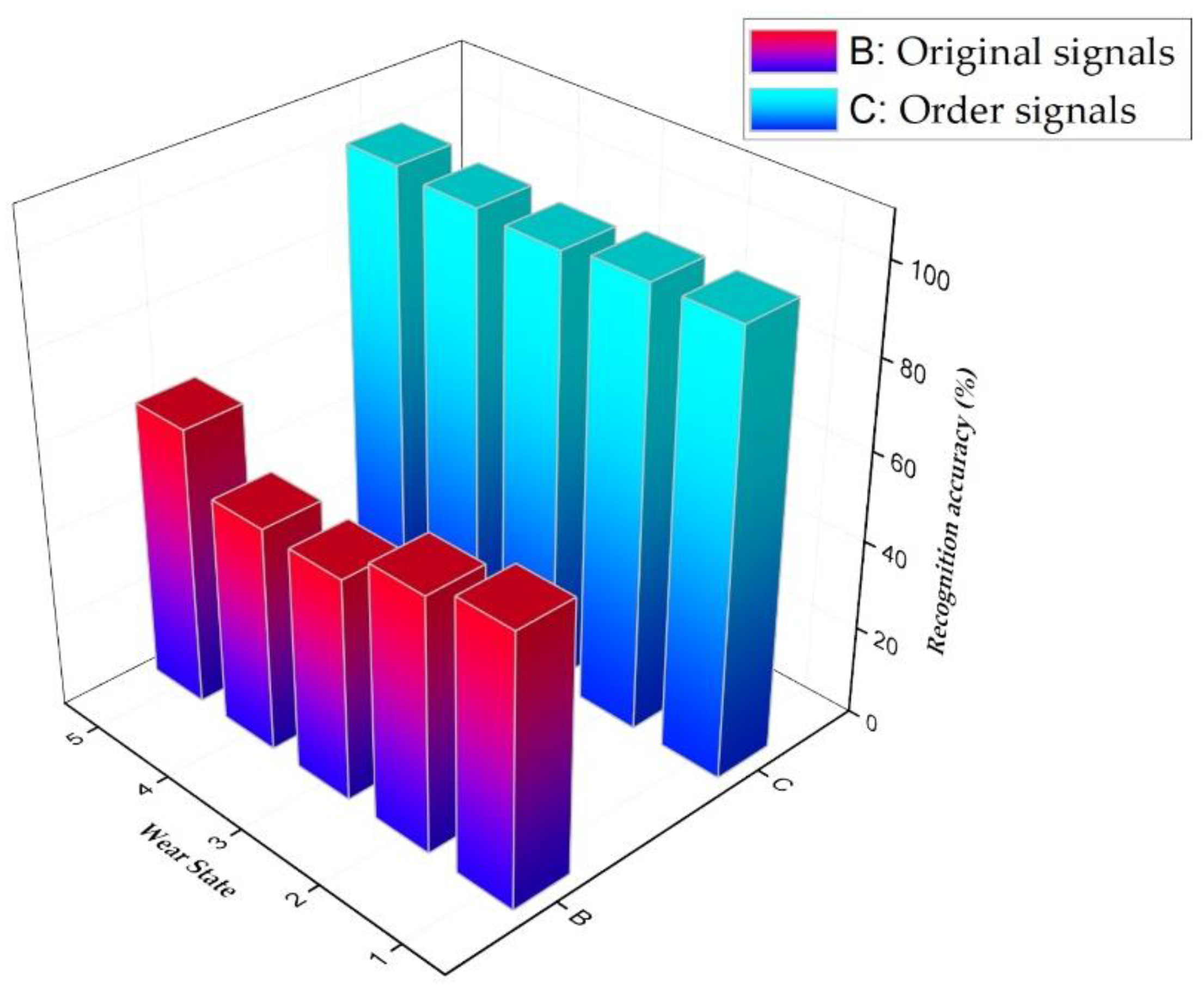

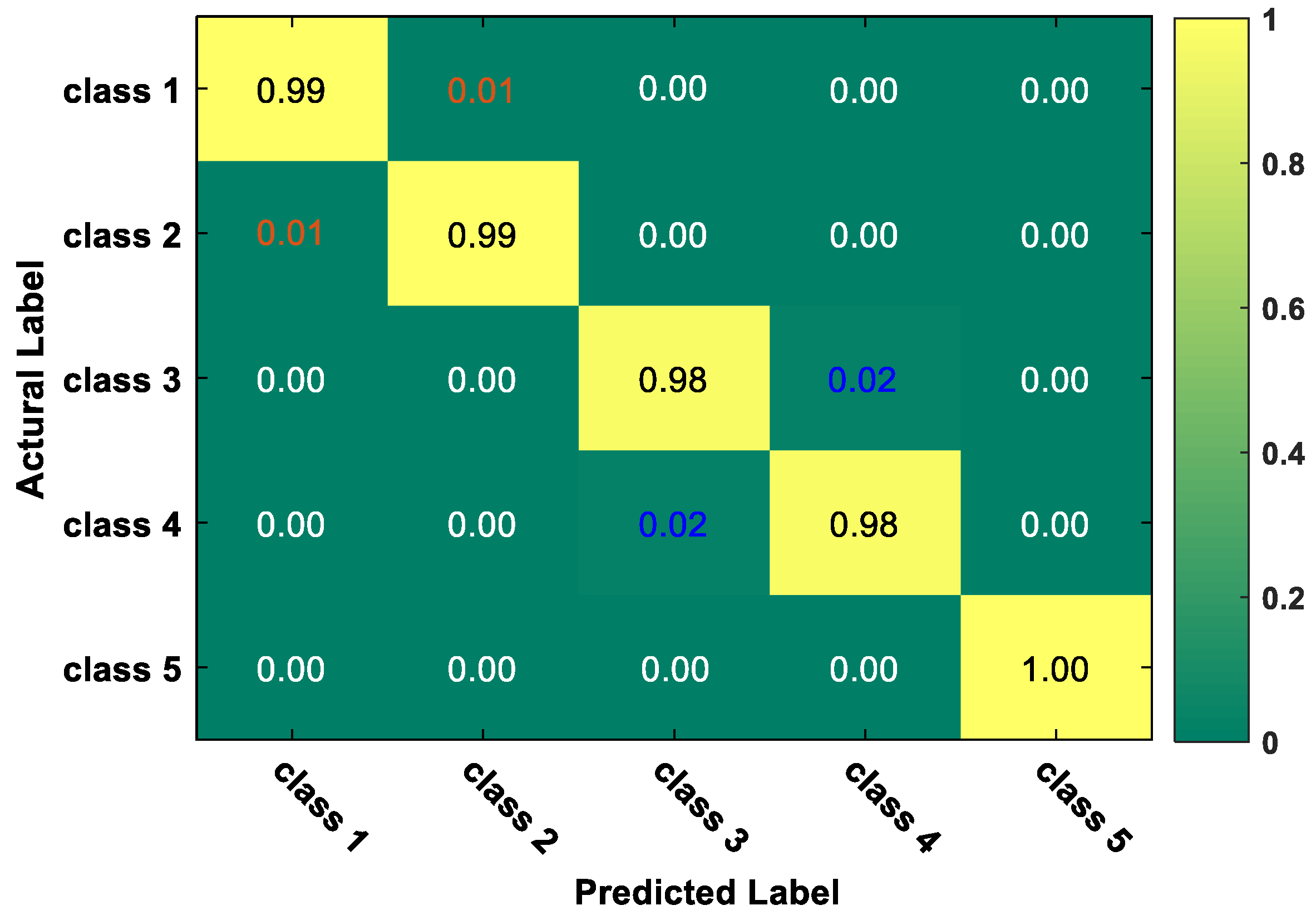

4.2. Result and Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yu, X.; Lin, X.; Dai, Y.; Zhu, K. Image edge detection based tool condition monitoring with morphological component analysis. ISA Trans. 2017, 69, 315–322. [Google Scholar] [CrossRef] [PubMed]

- Kostrzewski, M.; Gnap, J.; Varjan, P.; Likos, M. Application of simulation methods for study on availability of one-aisle machine order picking process. Communications 2020, 22, 107–114. [Google Scholar] [CrossRef]

- Mali, R.; Telsang, M.T.; Gupta, T.V.K. Real time tool wear condition monitoring in hard turning of inconel 718 using sensor fusion system. Mater. Today Proc. 2017, 4, 8605–8612. [Google Scholar] [CrossRef]

- Pandiyan, V.; Caesarendra, W.; Tjahjowidodo, T.; Tan, H.H. In-process tool condition monitoring in compliant abrasive belt grinding process using support vector machine and genetic algorithm. J. Manuf. Process. 2018, 31, 199–213. [Google Scholar] [CrossRef]

- Kannatey-Asibu, E.; Yum, J.; Kim, T.H. Monitoring tool wear using classifier fusion. Mech. Syst. Signal Proc. 2017, 85, 651–661. [Google Scholar] [CrossRef]

- Kong, D.; Chen, Y.; Li, N.; Duan, C.; Lu, L.; Chen, D. Relevance vector machine for tool wear prediction. Mech. Syst. Signal Pr. 2019, 127, 573–594. [Google Scholar] [CrossRef]

- Ong, P.; Lee, W.K.; Lau, R.J.H. Tool condition monitoring in CNC end milling using wavelet neural network based on machine vision. Int. J. Adv. Manuf. Tech. 2019, 104, 1369–1379. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Zhao, K.; Wei, D.; Li, X. A novel tracking deep wavelet auto-encoder method for intelligent fault diagnosis of electric locomotive bearings. Mech. Syst. Signal Proc. 2018, 110, 193–209. [Google Scholar]

- Zhu, K.; Yu, X.L. The monitoring of micro milling tool wear conditions by wear area estimation. Mech. Syst. Signal Proc. 2017, 93, 80–91. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Lu, X.; Wang, S.; Wang, W.; Li, W.D. A multi-sensor based online tool condition monitoring system for milling process. Procedia CIRP 2018, 72, 1136–1141. [Google Scholar] [CrossRef]

- Uekita, M.; Takaya, Y. Tool condition monitoring technique for deep-hole drilling of large components based on chatter identification in time–frequency domain. Measurement 2017, 103, 199–207. [Google Scholar] [CrossRef]

- Diaz-Rozo, J.; Bielza, C.; Larrañaga, P. Machine-tool condition monitoring with Gaussian mixture models-based dynamic probabilistic clustering. Eng. Appl. Artif. Intell. 2020, 89, 103434. [Google Scholar] [CrossRef]

- Kothuru, A.; Nooka, S.P.; Liu, R. Application of deep visualization in CNN-based tool condition monitoring for end milling. Procedia Manuf. 2019, 34, 995–1004. [Google Scholar] [CrossRef]

- Sun, W.; Shao, S.; Zhao, R.; Yan, R.; Zhang, X.; Chen, X. A sparse auto-encoder-based deep neural network approach for induction motor faults classification. Measurement 2016, 89, 171–178. [Google Scholar] [CrossRef]

- Cao, X.; Chen, B.; Yao, B.; He, W. Combining translation-invariant wavelet frames and convolutional neural network for intelligent tool wear state identification. Comput. Ind. 2019, 106, 71–84. [Google Scholar] [CrossRef]

- Cheng, C.; Li, J.; Liu, Y.; Nie, M.; Wang, W. Deep convolutional neural network-based in-process tool condition monitoring in abrasive belt grinding. Comput. Ind. 2019, 106, 1–13. [Google Scholar] [CrossRef]

- Patra, K.; Jha, A.K.; Szalay, T.; Ranjan, J.; Monostori, L. Artificial neural network based tool condition monitoring in micro mechanical peck drilling using thrust force signals. Precis. Eng. 2017, 48, 279–291. [Google Scholar] [CrossRef]

- Escajeda Ochoa, L.E.; Ruiz Quinde, I.B.; Chuya Sumba, J.P.; Guevara, A.V.; Morales-Menendez, R. New approach based on autoencoders to monitor the tool wear condition in HSM. IFAC-Pap. 2019, 52, 206–211. [Google Scholar] [CrossRef]

- Jungblut, J.; Ploeger, D.F.; Zech, P.; Rinderknecht, S. Order tracking based least mean squares algorithm. IFAC Pap. 2019, 52, 465–470. [Google Scholar] [CrossRef]

- Wu, J.; Zi, Y.; Chen, J.; Zhou, Z. Fault diagnosis in speed variation conditions via improved tacholess order tracking technique. Measurement 2019, 137, 604–616. [Google Scholar] [CrossRef]

- Fyfe, K.R.; Munck, E.D.S. Analysis of computed order tracking. Mech. Syst. Signal Proc. 1997, 11, 187–205. [Google Scholar] [CrossRef]

- Schmidt, S.; Heyns, P.S.; de Villiers, J.P. A tacholess order tracking methodology based on a probabilistic approach to incorporate angular acceleration information into the maxima tracking process. Mech. Syst. Signal Proc. 2018, 100, 630–646. [Google Scholar] [CrossRef]

- Sun, C.; Ma, M.; Zhao, Z.; Tian, S.; Yan, R.; Chen, X. Deep transfer learning based on sparse autoencoder for remaining useful life prediction of tool in manufacturing. IEEE Trans. Ind. Inform. 2019, 15, 2416–2425. [Google Scholar] [CrossRef]

- Wen, L.; Gao, L.; Li, X. A new deep transfer learning based on sparse auto-encoder for fault diagnosis. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 136–144. [Google Scholar] [CrossRef]

- Dai, J.; Tang, J.; Shao, F.; Huang, S.; Wang, Y. Fault diagnosis of rolling bearing based on multiscale intrinsic mode function permutation entropy and a stacked sparse denoising autoencoder. Appl. Sci. 2019, 9, 2743. [Google Scholar] [CrossRef]

- Guo, W.; Li, B.; Shen, S.; Zhou, Q. An intelligent grinding burn detection system based on two-stage feature selection and stacked sparse autoencoder. Int. J. Adv. Manuf. Tech. 2019, 103, 2837–2847. [Google Scholar] [CrossRef]

- Luo, X.; Xu, Y.; Wang, W.; Yuan, M.; Ban, X.; Zhu, Y.; Zhao, W. Towards enhancing stacked extreme learning machine with sparse autoencoder by correntropy. J. Frankl. Inst. 2018, 355, 1945–1966. [Google Scholar] [CrossRef]

- Sun, M.; Wang, H.; Liu, P.; Huang, S.; Fan, P. A sparse stacked denoising autoencoder with optimized transfer learning applied to the fault diagnosis of rolling bearings. Measurement 2019, 146, 305–314. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Gao, L.; Chen, W.; Li, P. Intelligent fault diagnosis of rotating machinery using a new ensemble deep auto-encoder method. Measurement 2020, 151, 107232. [Google Scholar] [CrossRef]

- Saufi, S.R.; Bin Ahmad, Z.A.; Leong, M.S.; Lim, M.H. Differential evolution optimization for resilient stacked sparse autoencoder and its applications on bearing fault diagnosis. Meas. Sci. Technol. 2018, 29, 12500212. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, M.; Bao, Z.; Zhang, S. Stacked sparse autoencoder with PCA and SVM for data-based line trip fault diagnosis in power systems. Neural Comput. Appl. 2019, 31, 6719–6731. [Google Scholar] [CrossRef]

- Zhang, L.; Jiao, L.; Ma, W.; Duan, Y.; Zhang, D. PolSAR image classification based on multi-scale stacked sparse autoencoder. Neurocomputing 2019, 351, 167–179. [Google Scholar] [CrossRef]

| Item | Parameter |

|---|---|

| Induced current type | AC or DC or Pulse current |

| Band width | 100 kHz |

| Response time | <1 |

| Nominal output | 50 mA |

| Di/dt tracing accurate | Better than 100 A/us |

| linearity | <0.1% |

| Tool Wear State Sample | Initial Wear | Intermediate Wear I | Intermediate Wear II | Intermediate Wear IIII | Severe Wear |

|---|---|---|---|---|---|

| Training | 157 | 147 | 176 | 183 | 177 |

| Testing | 40 | 40 | 40 | 40 | 40 |

| Labels | 1 | 2 | 3 | 4 | 5 |

| Method | Training Accuracy (%) | Testing Accuracy (%) | Computation Time(s) |

|---|---|---|---|

| SSAE-Softmax | 96.411 | 98.788 | 16.934 |

| ELM | 73.268 | 79.176 | 6.189 |

| BPnn | 80.379 | 81.654 | 1.180 |

| SVM | 89.873 | 91.831 | 8.329 |

| RF | 90.421 | 94.364 | 15.436 |

| KNN | 84.142 | 84.182 | 5.317 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ou, J.; Li, H.; Huang, G.; Zhou, Q. A Novel Order Analysis and Stacked Sparse Auto-Encoder Feature Learning Method for Milling Tool Wear Condition Monitoring. Sensors 2020, 20, 2878. https://doi.org/10.3390/s20102878

Ou J, Li H, Huang G, Zhou Q. A Novel Order Analysis and Stacked Sparse Auto-Encoder Feature Learning Method for Milling Tool Wear Condition Monitoring. Sensors. 2020; 20(10):2878. https://doi.org/10.3390/s20102878

Chicago/Turabian StyleOu, Jiayu, Hongkun Li, Gangjin Huang, and Qiang Zhou. 2020. "A Novel Order Analysis and Stacked Sparse Auto-Encoder Feature Learning Method for Milling Tool Wear Condition Monitoring" Sensors 20, no. 10: 2878. https://doi.org/10.3390/s20102878

APA StyleOu, J., Li, H., Huang, G., & Zhou, Q. (2020). A Novel Order Analysis and Stacked Sparse Auto-Encoder Feature Learning Method for Milling Tool Wear Condition Monitoring. Sensors, 20(10), 2878. https://doi.org/10.3390/s20102878