An Adaptive Sliding-Mode Iterative Constant-force Control Method for Robotic Belt Grinding Based on a One-Dimensional Force Sensor

Abstract

1. Introduction

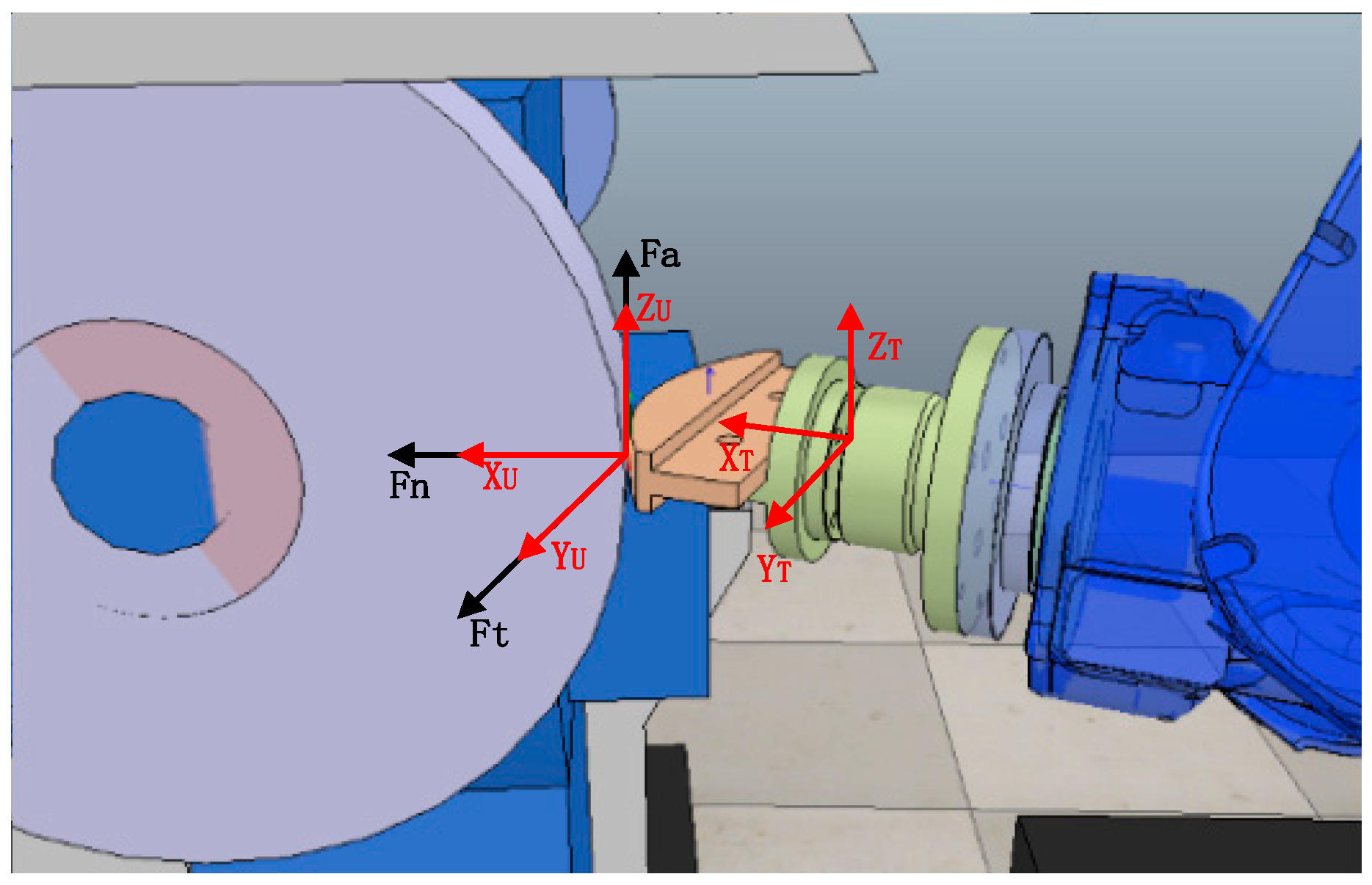

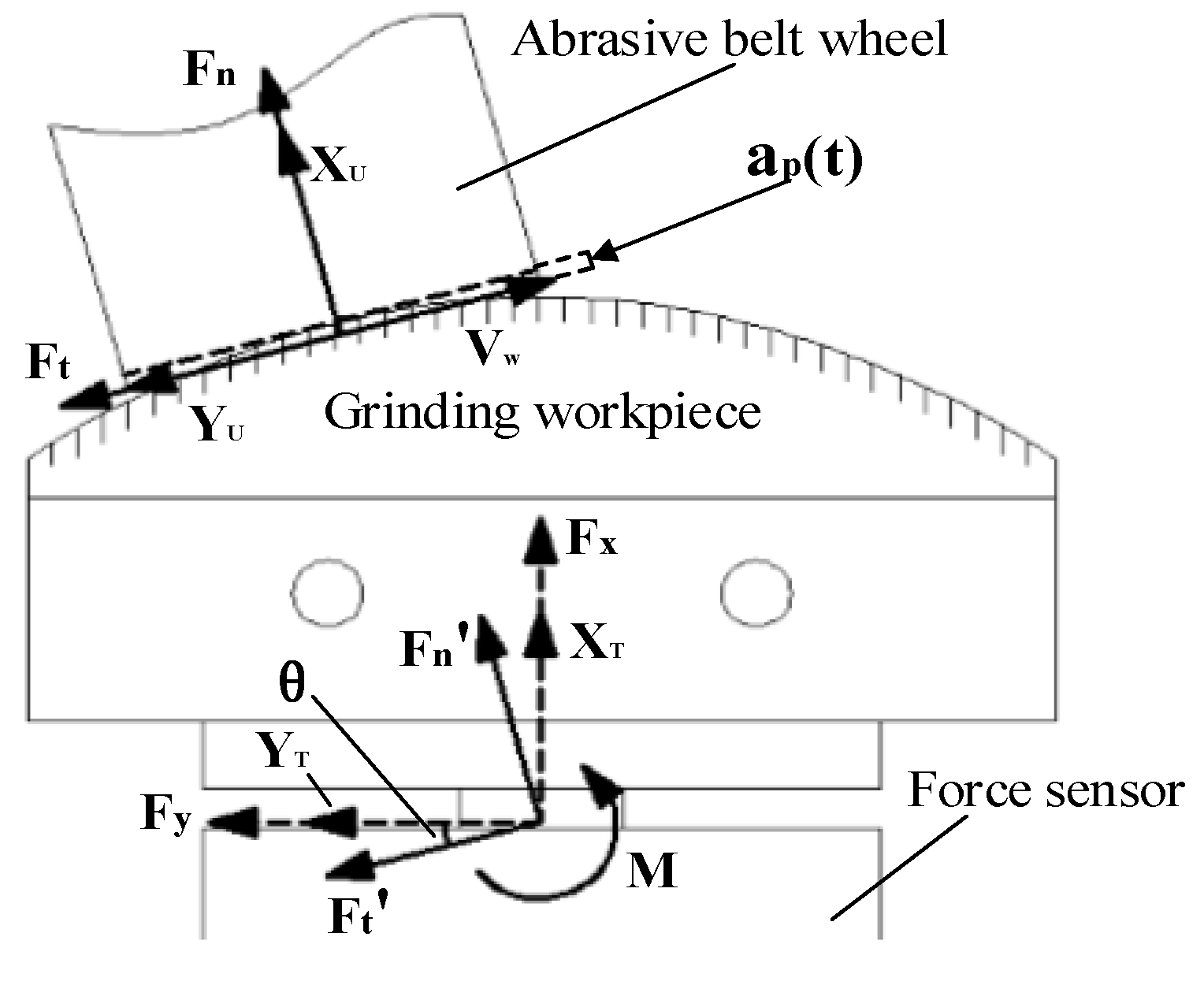

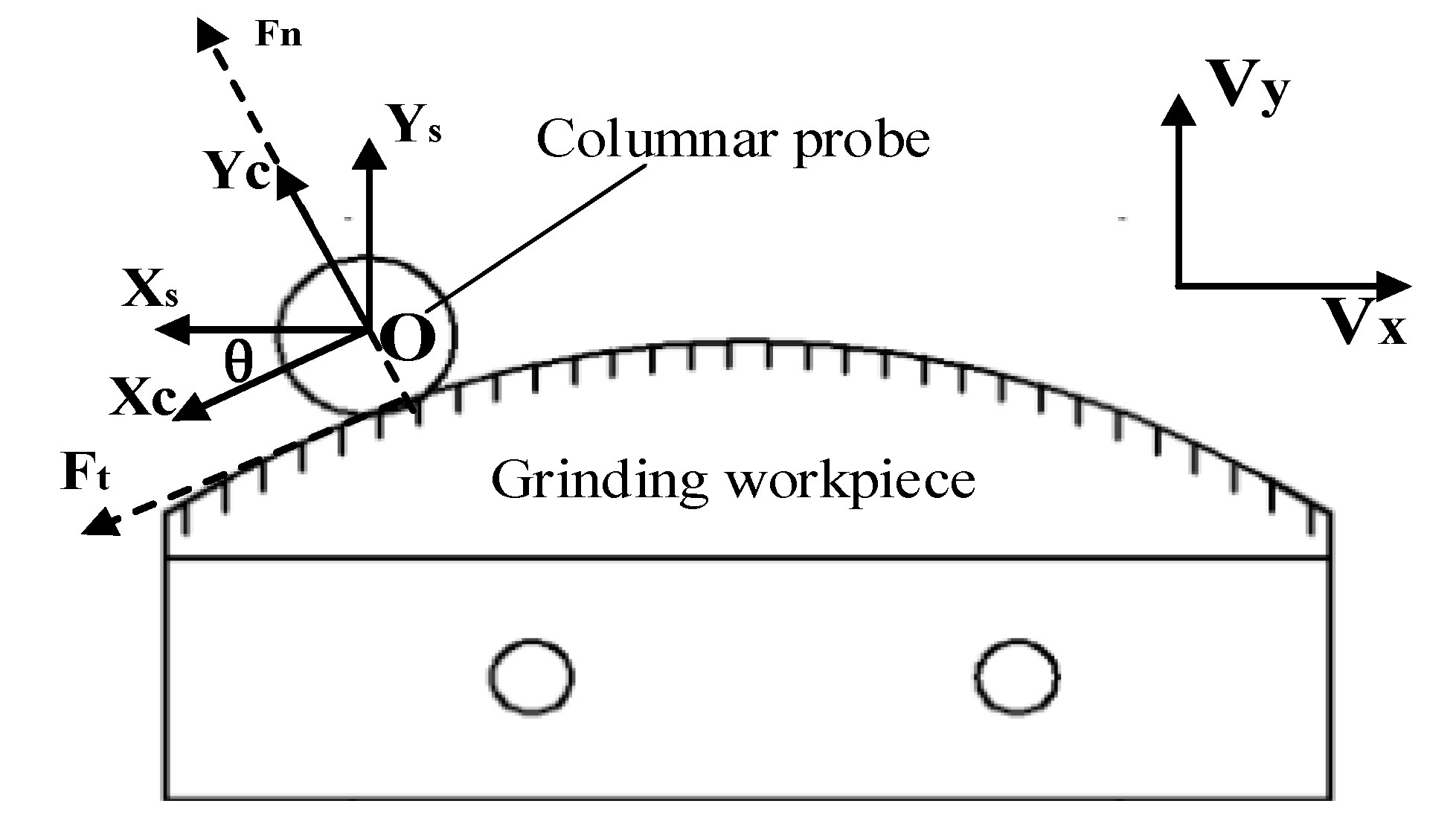

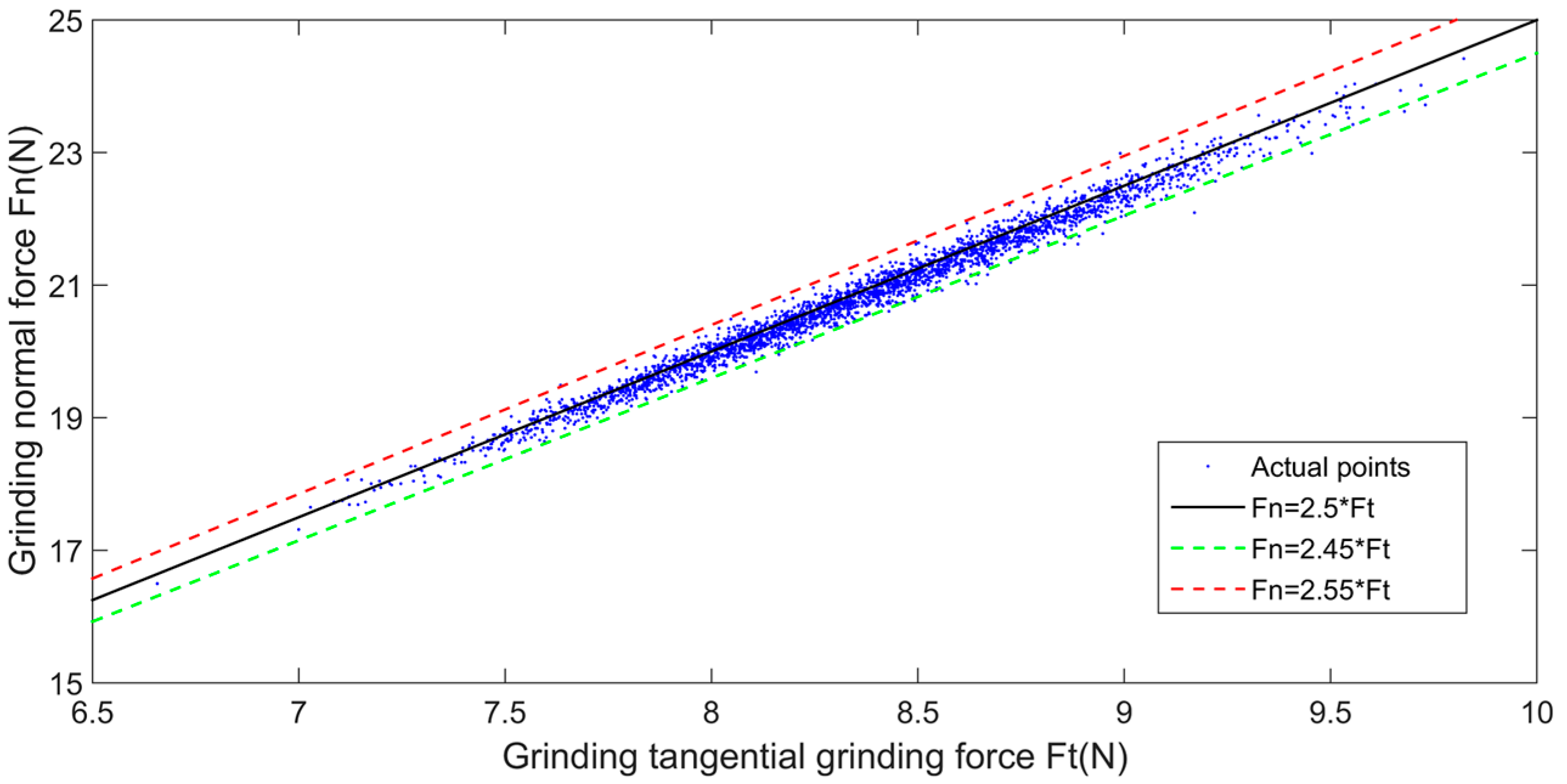

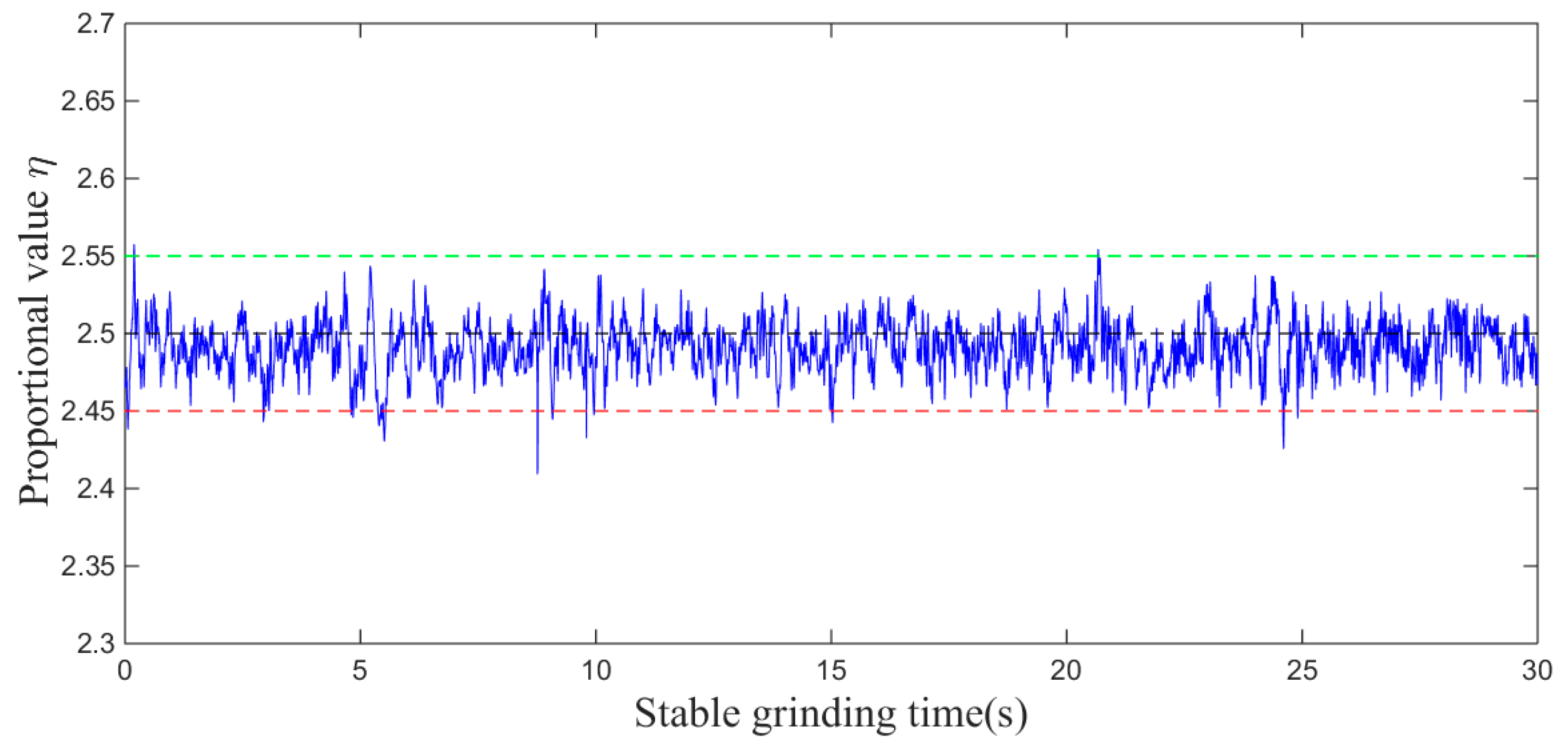

2. Abrasive Belt Grinding Force Analysis

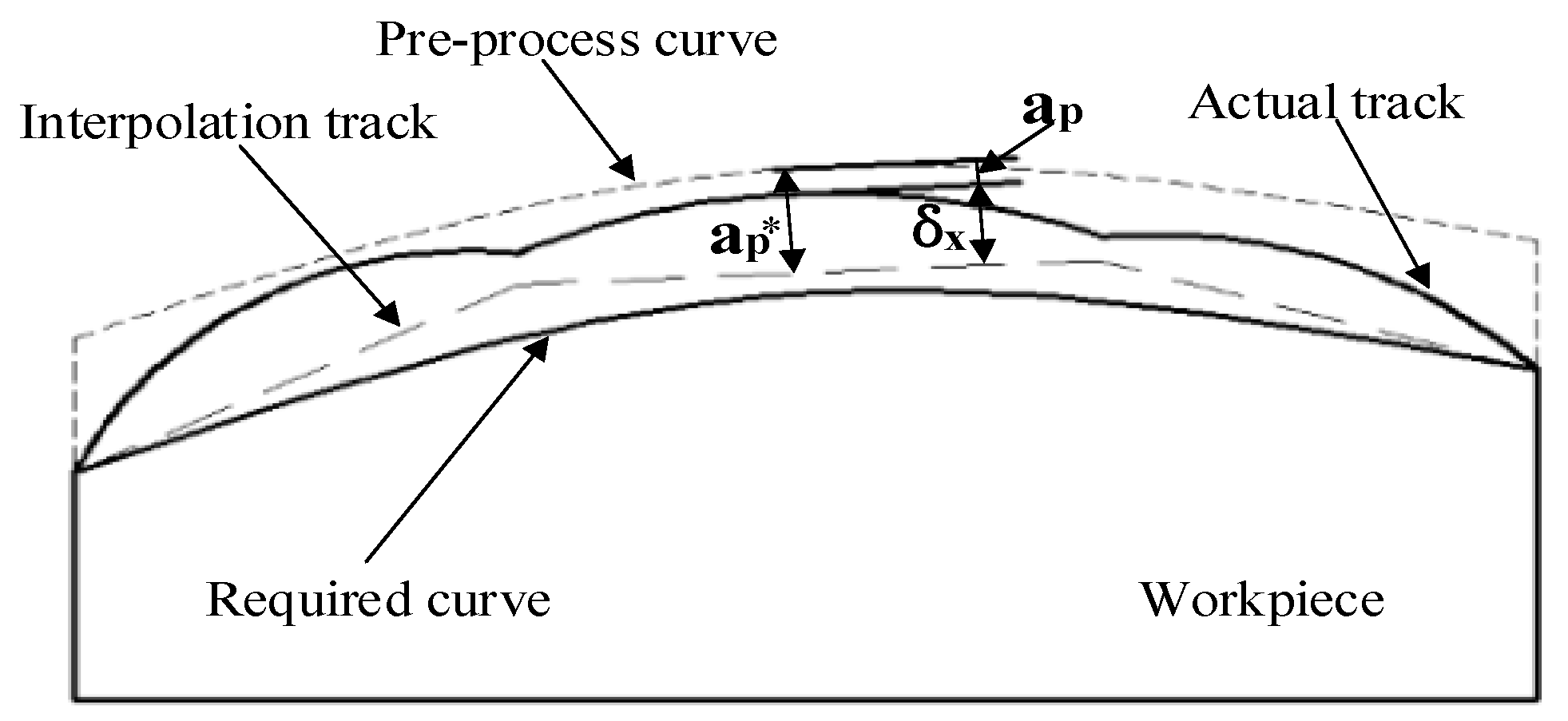

3. Grinding Dynamics Model

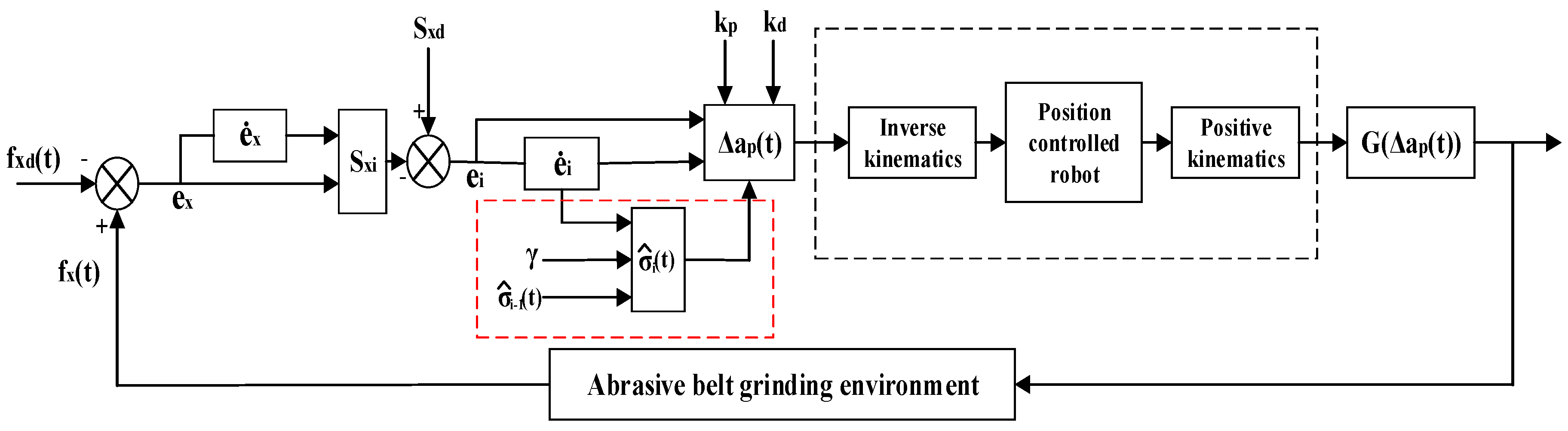

4. Adaptive Sliding-mode Iterative Force Control

4.1. Design of Control Law

4.2. Analysis of Algorithm Stability

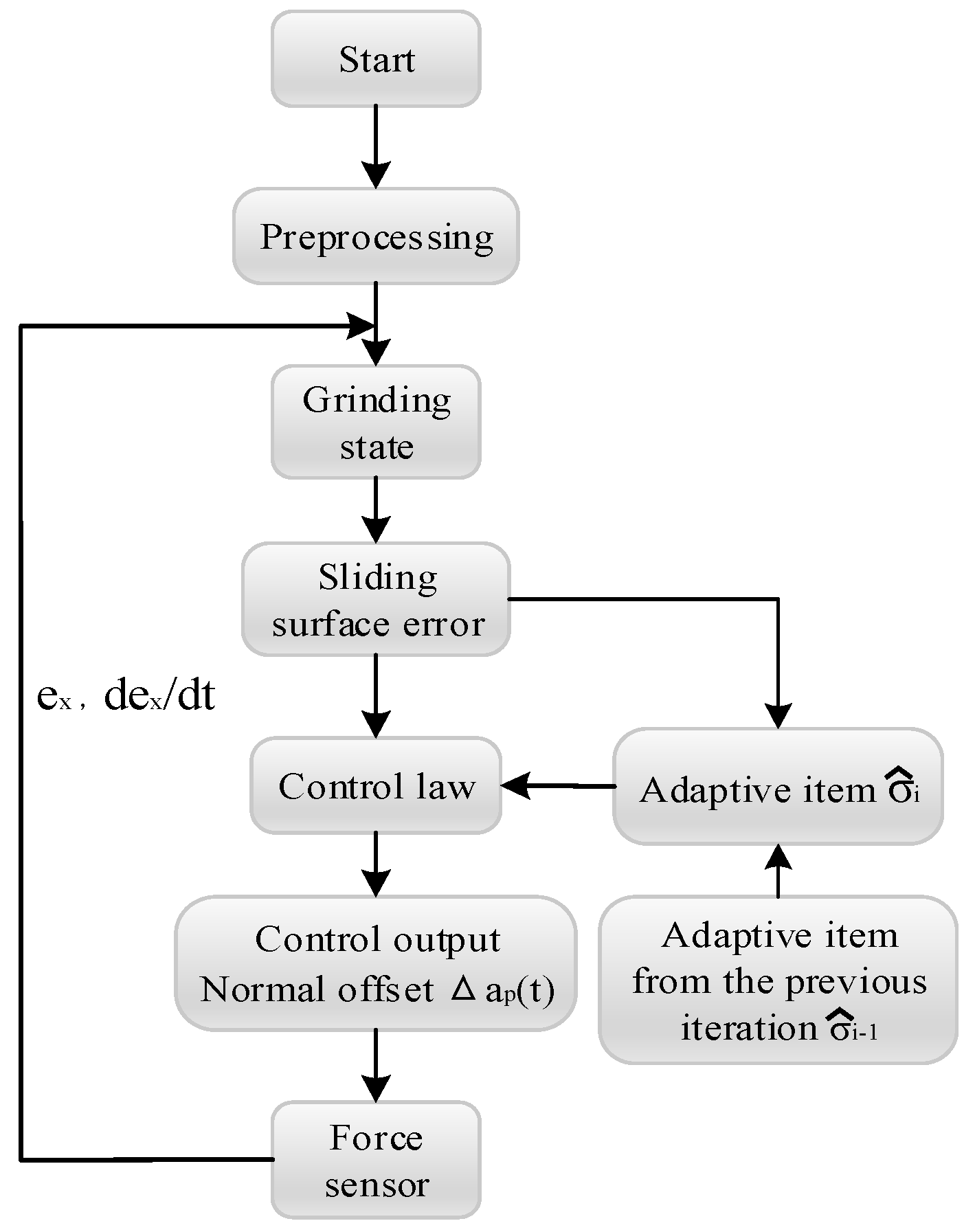

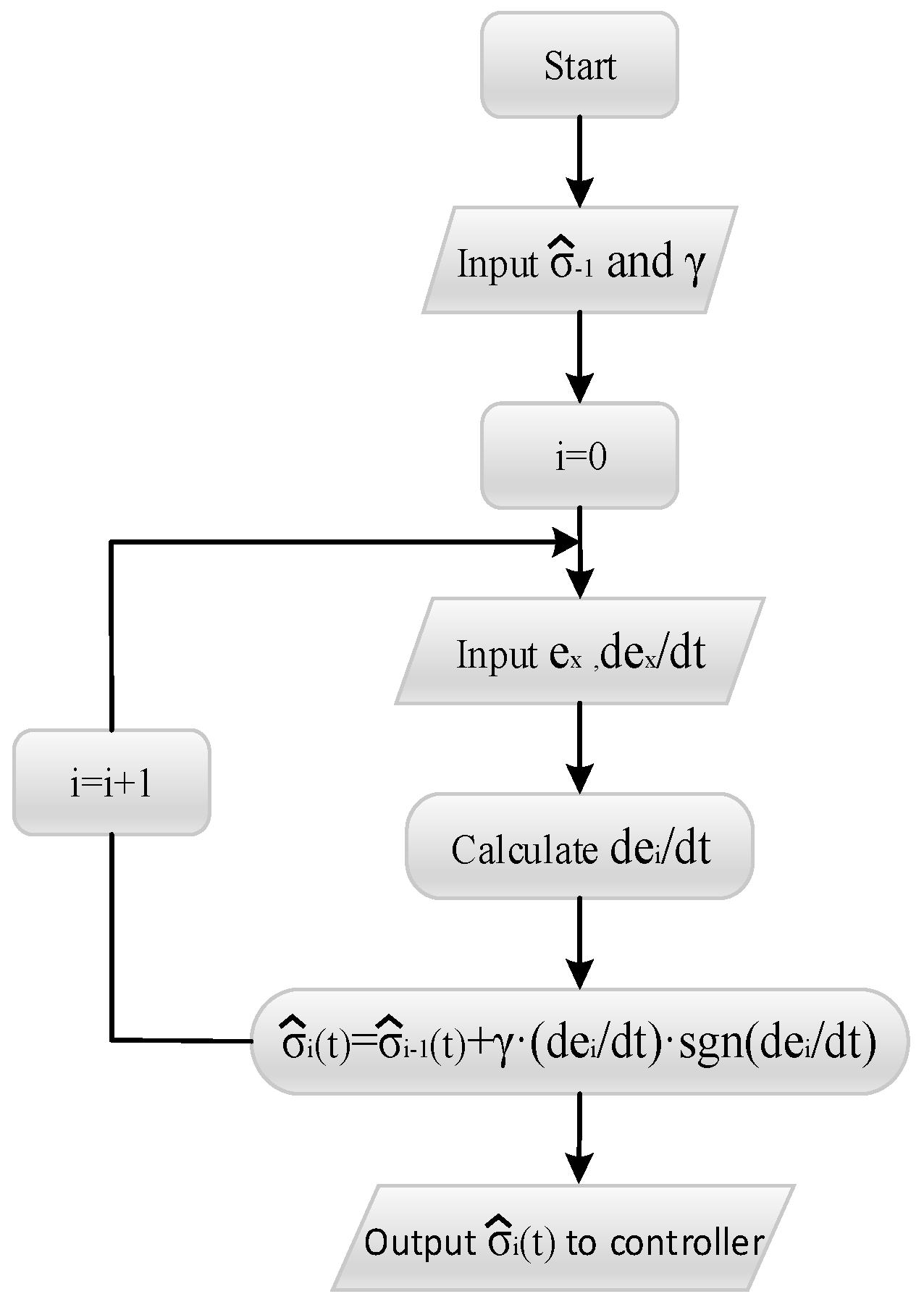

4.3. Design of Control Process

5. Robotic Belt Grinding Experiments

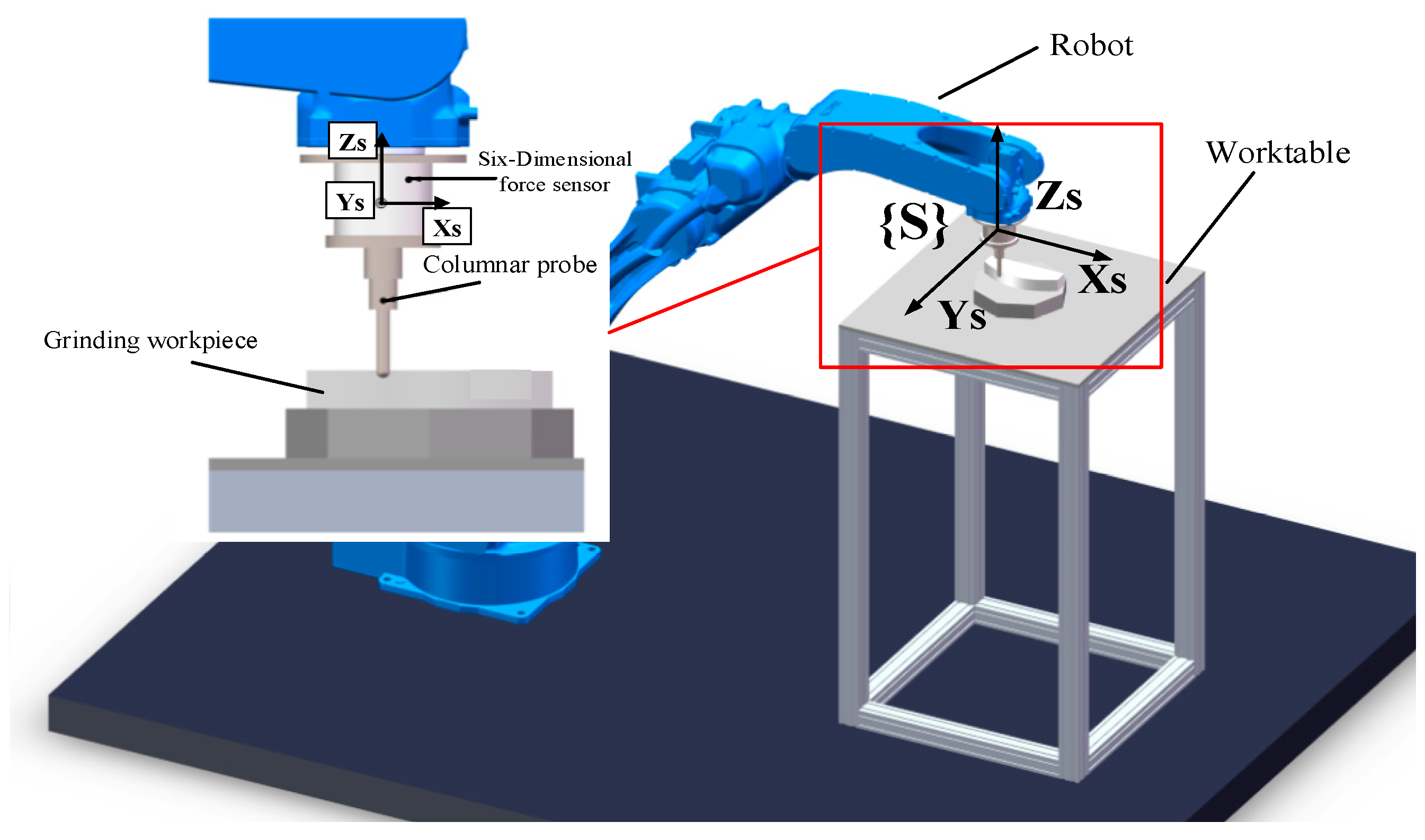

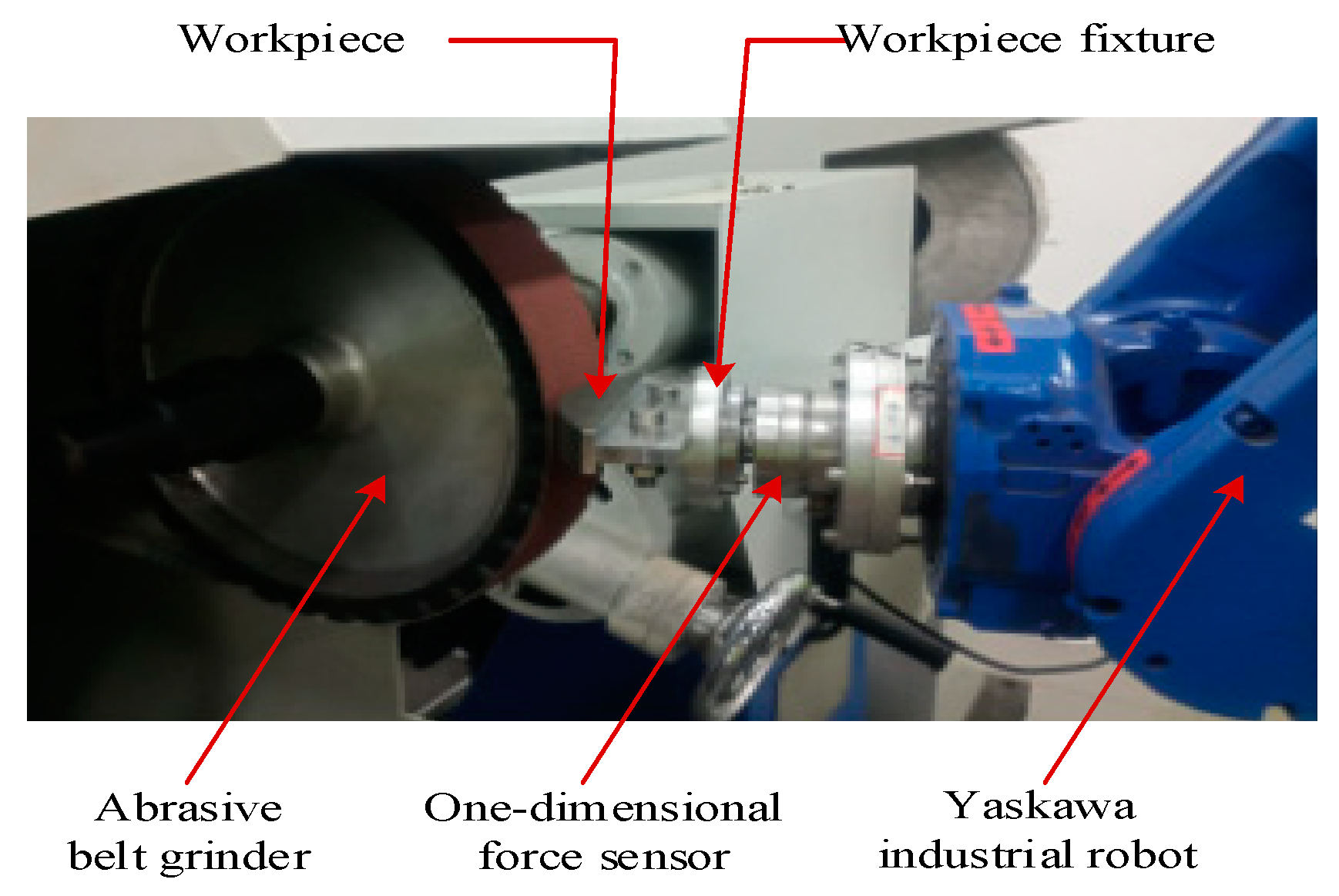

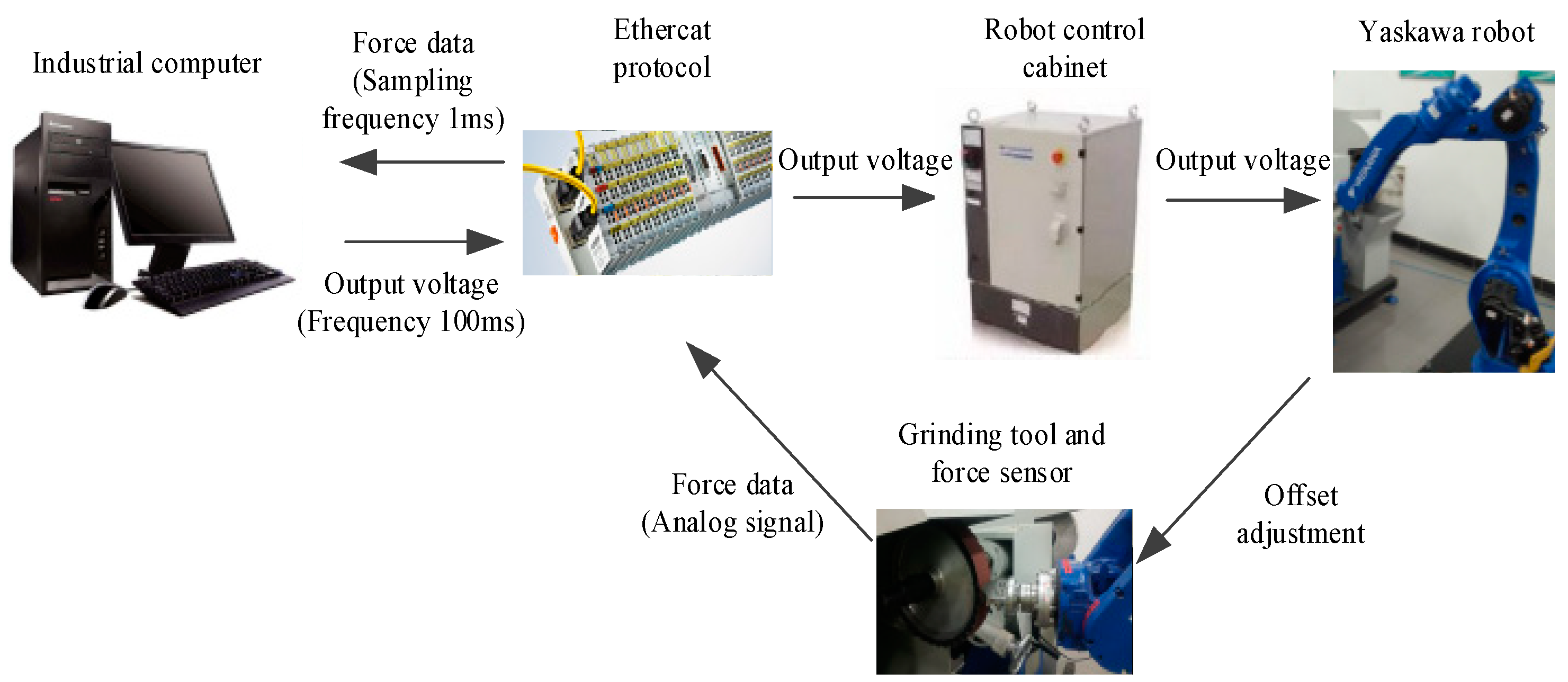

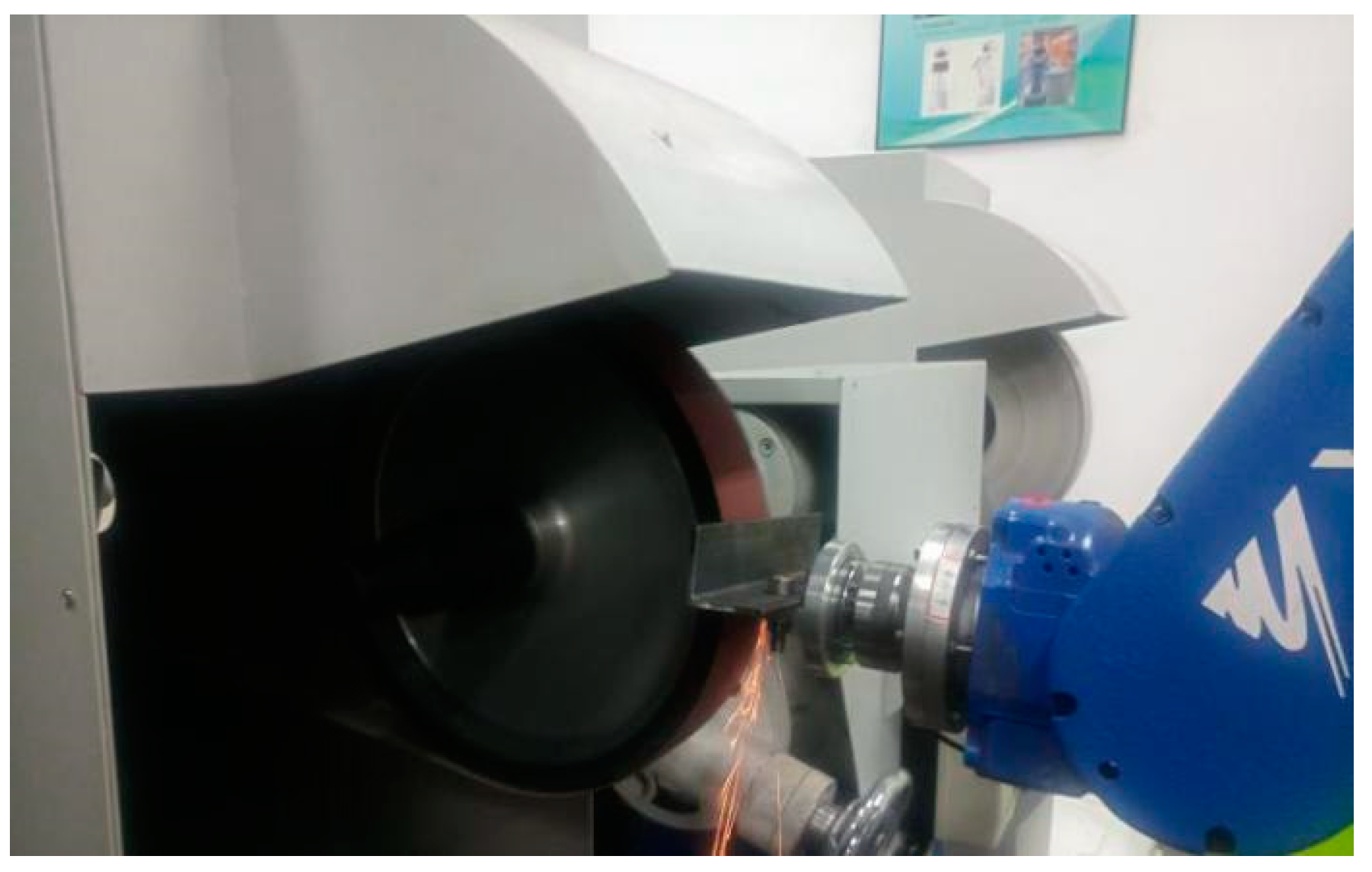

5.1. Robotic Belt Grinding System

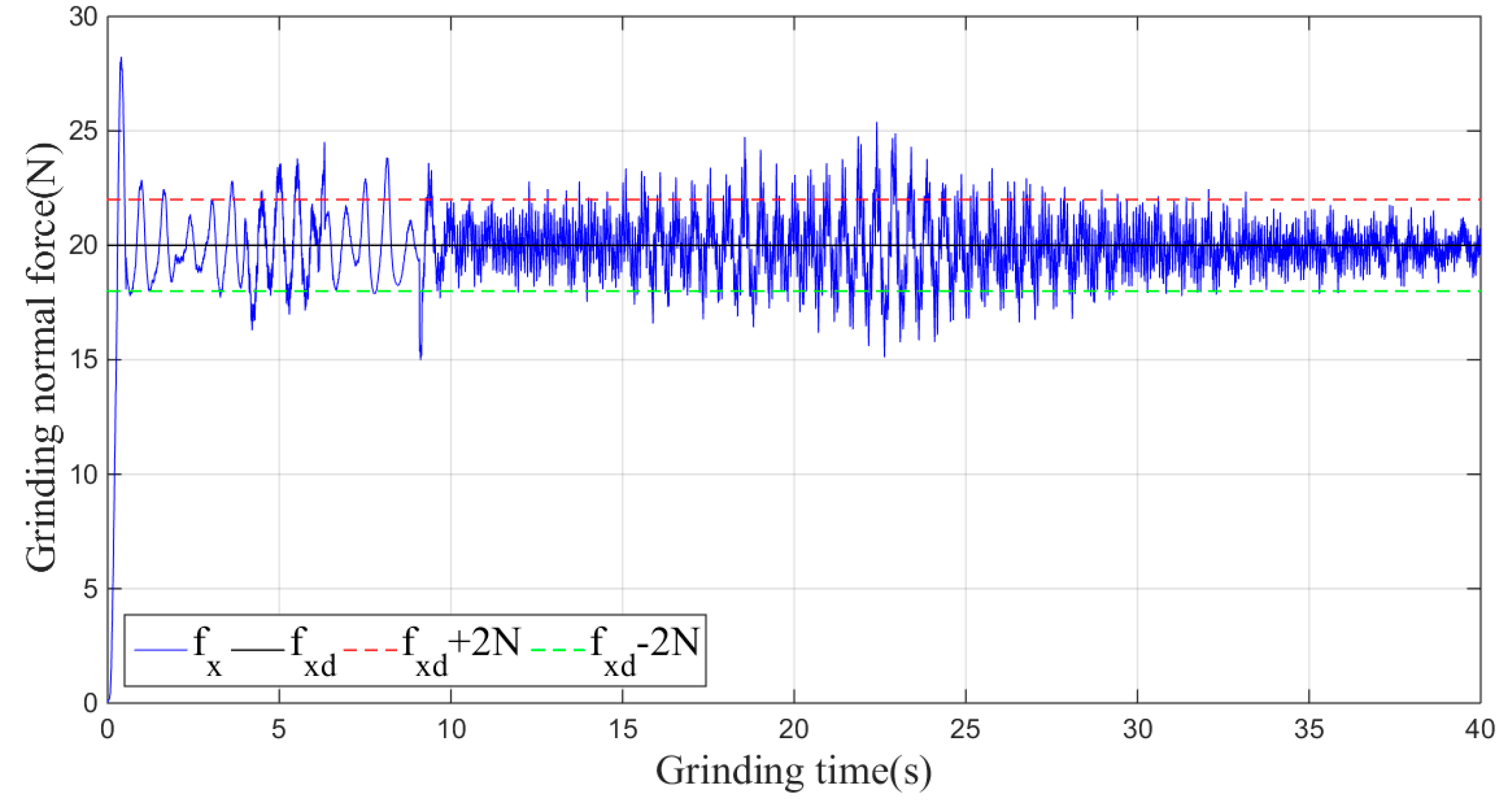

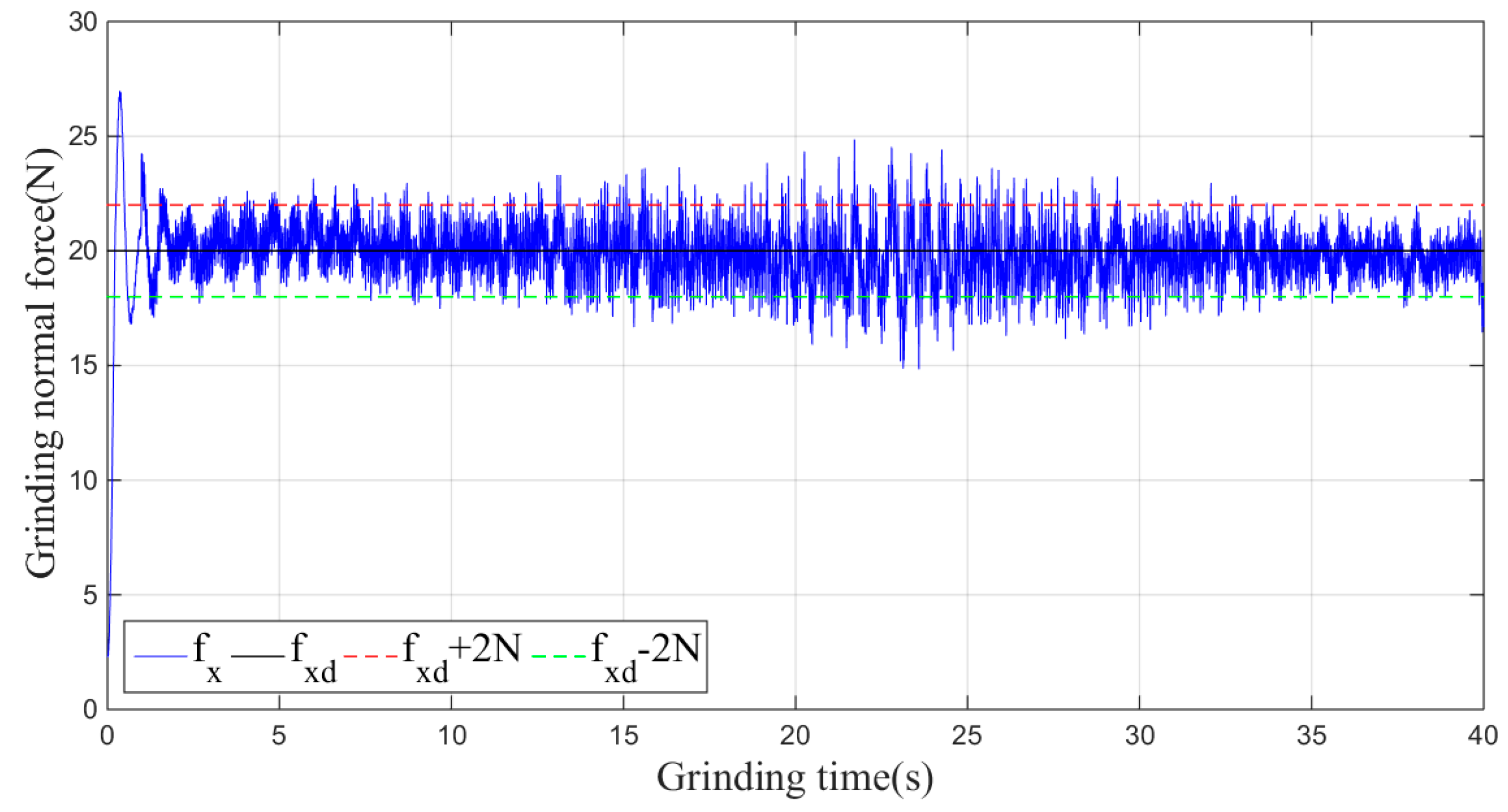

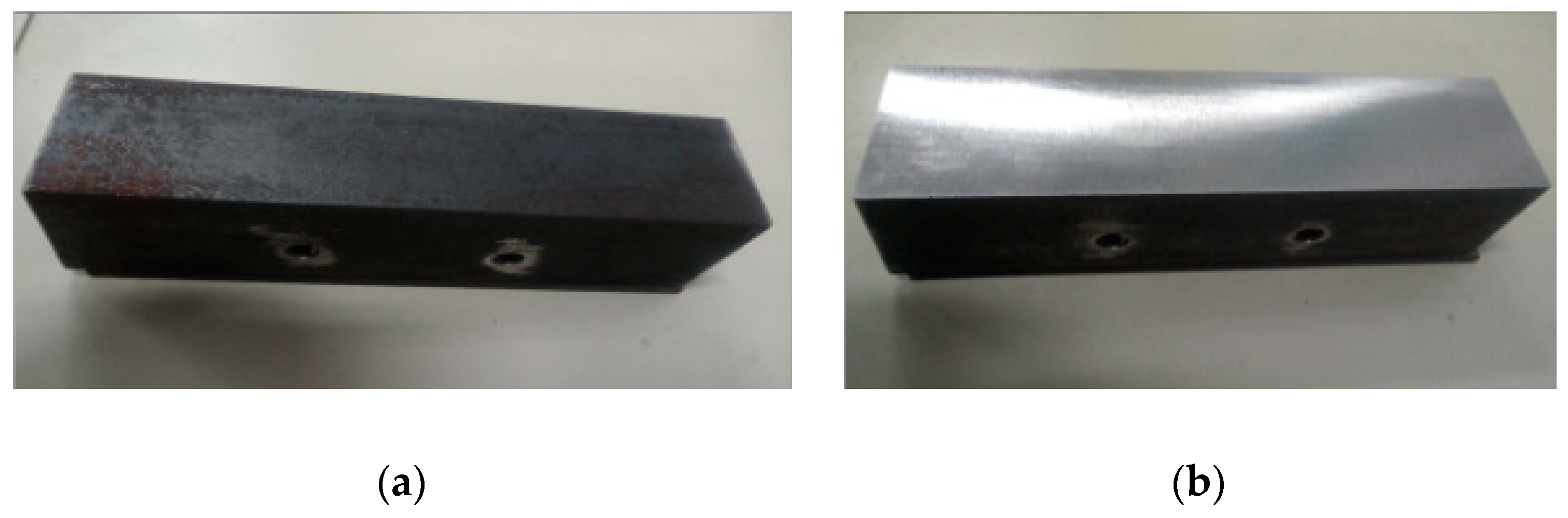

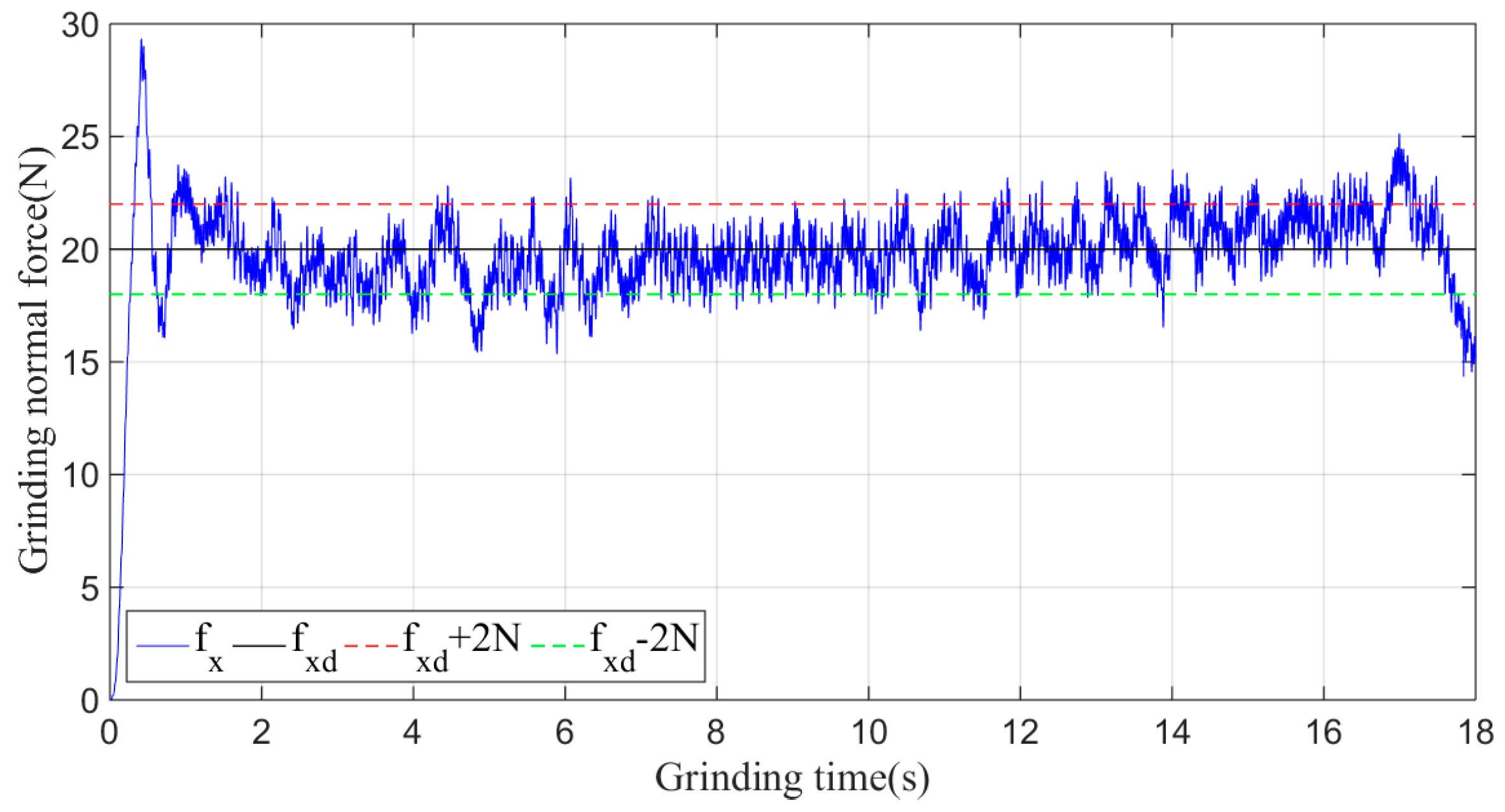

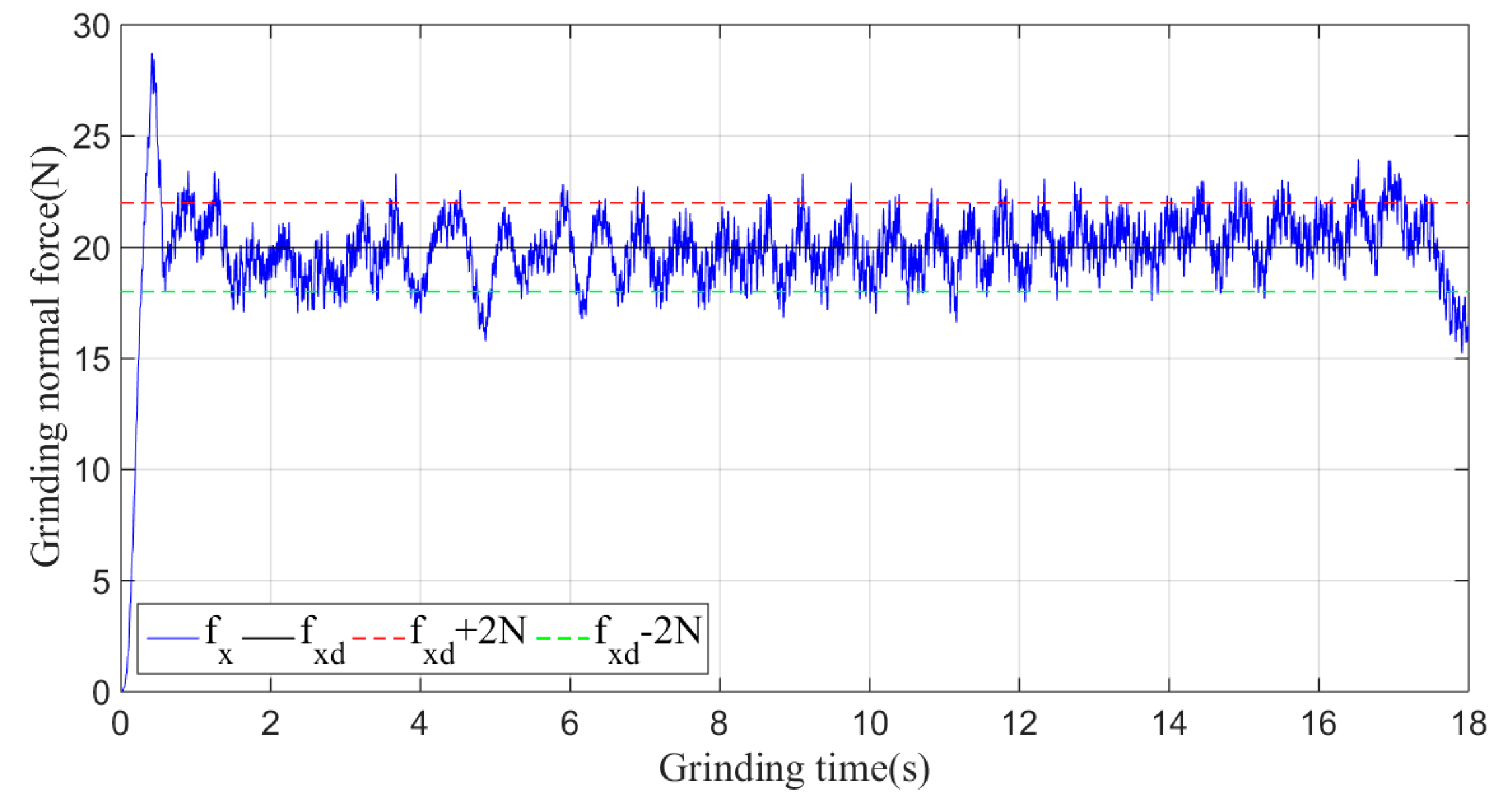

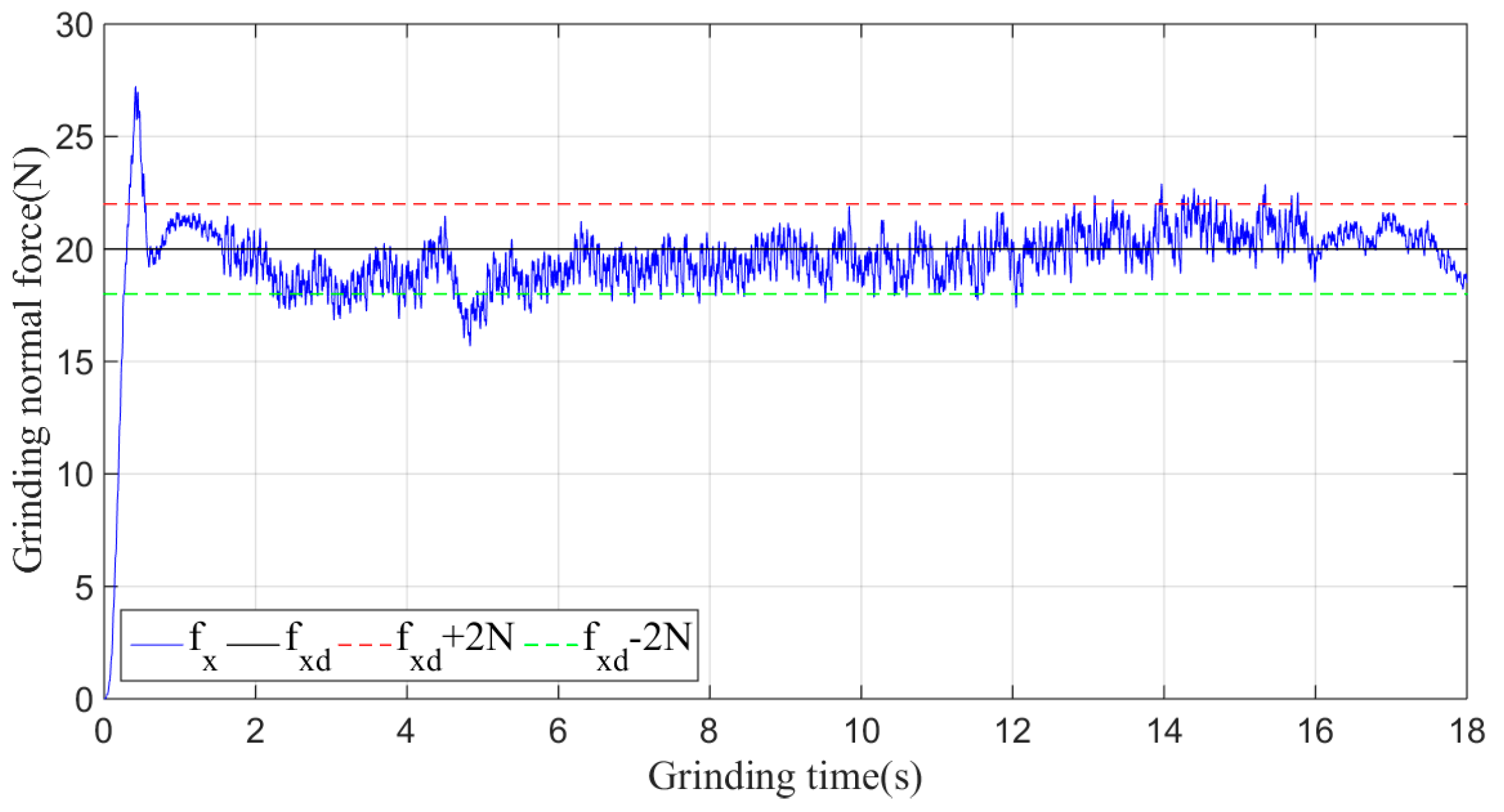

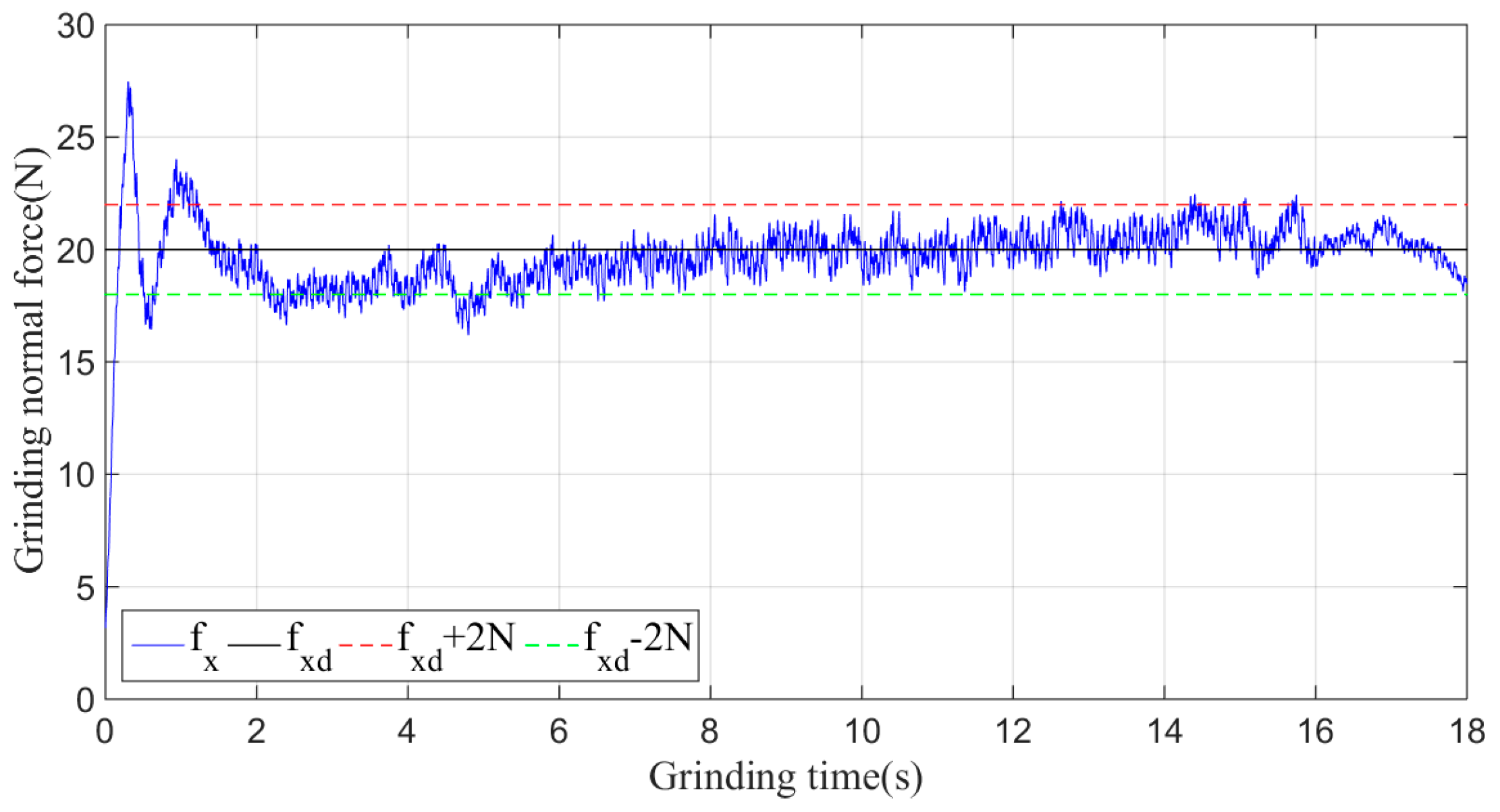

5.2. Angle Steel Grinding Experiment

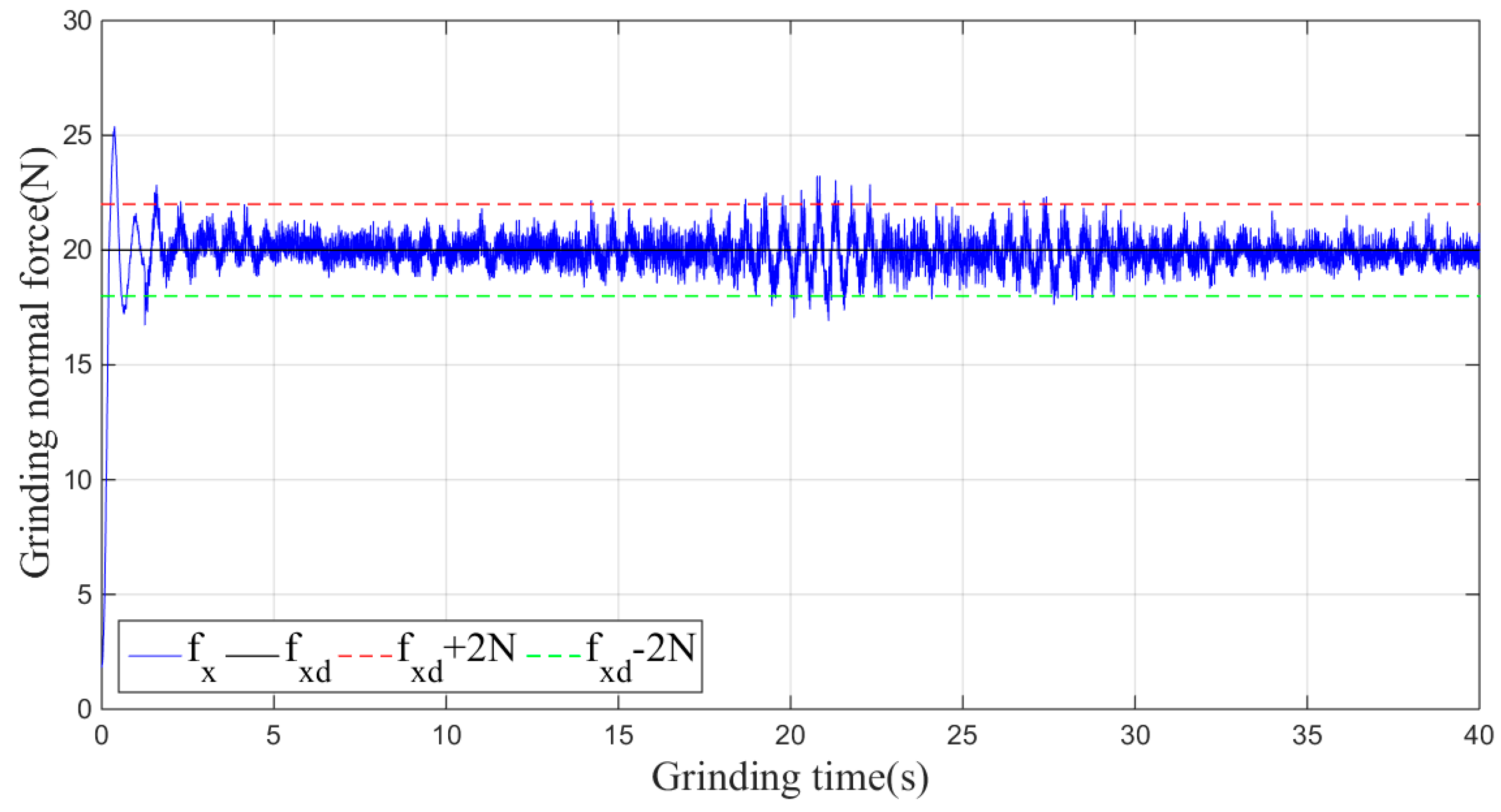

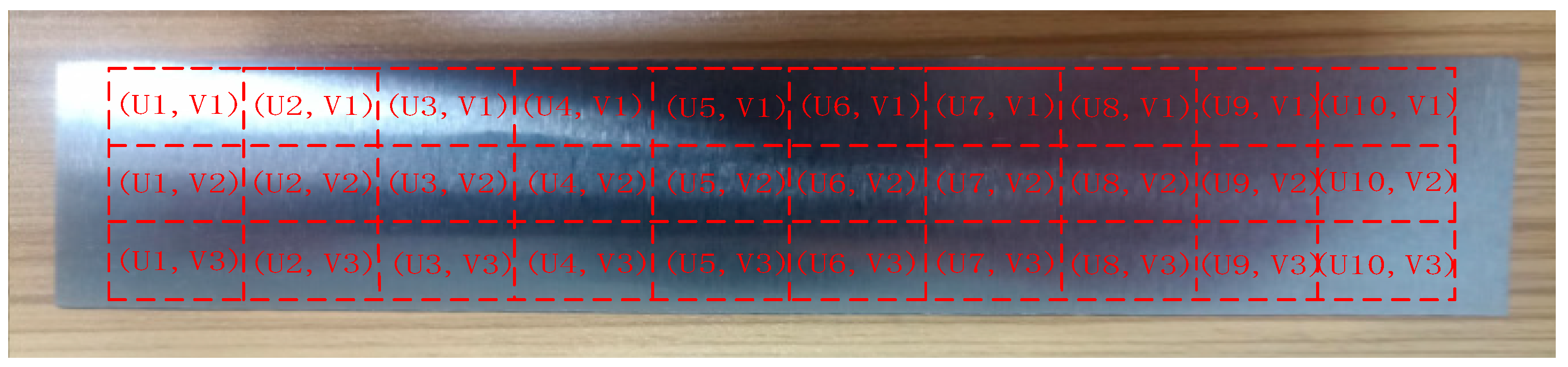

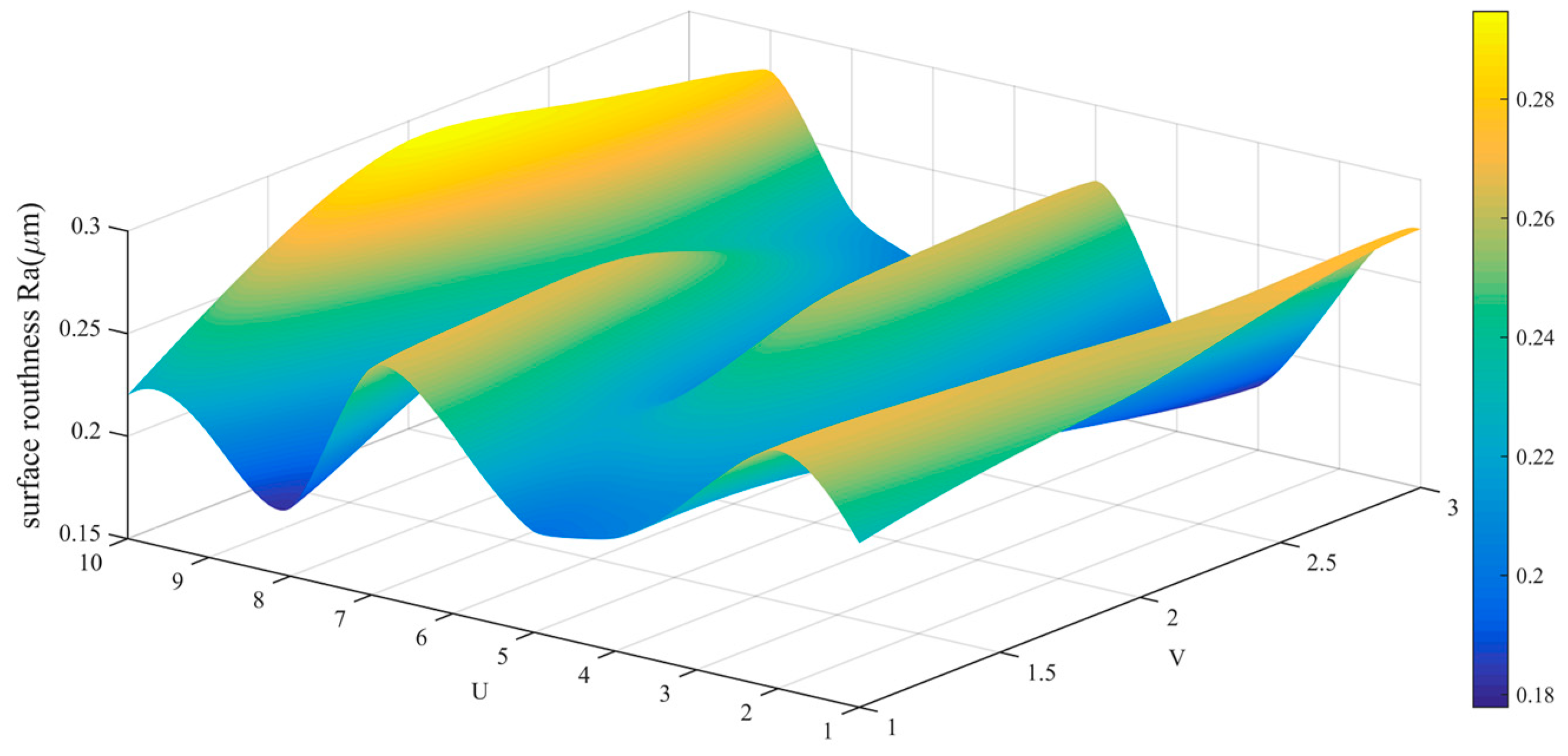

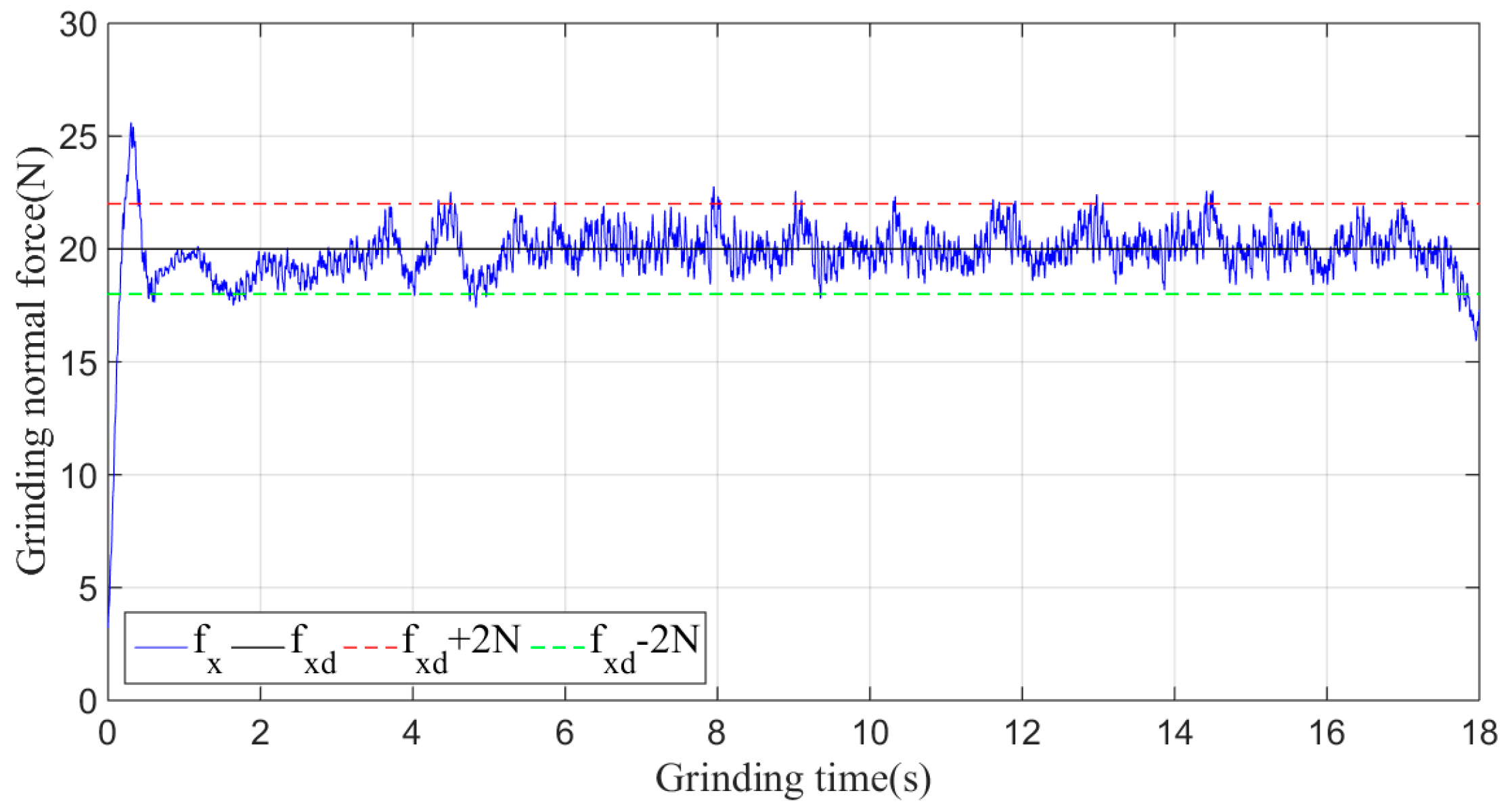

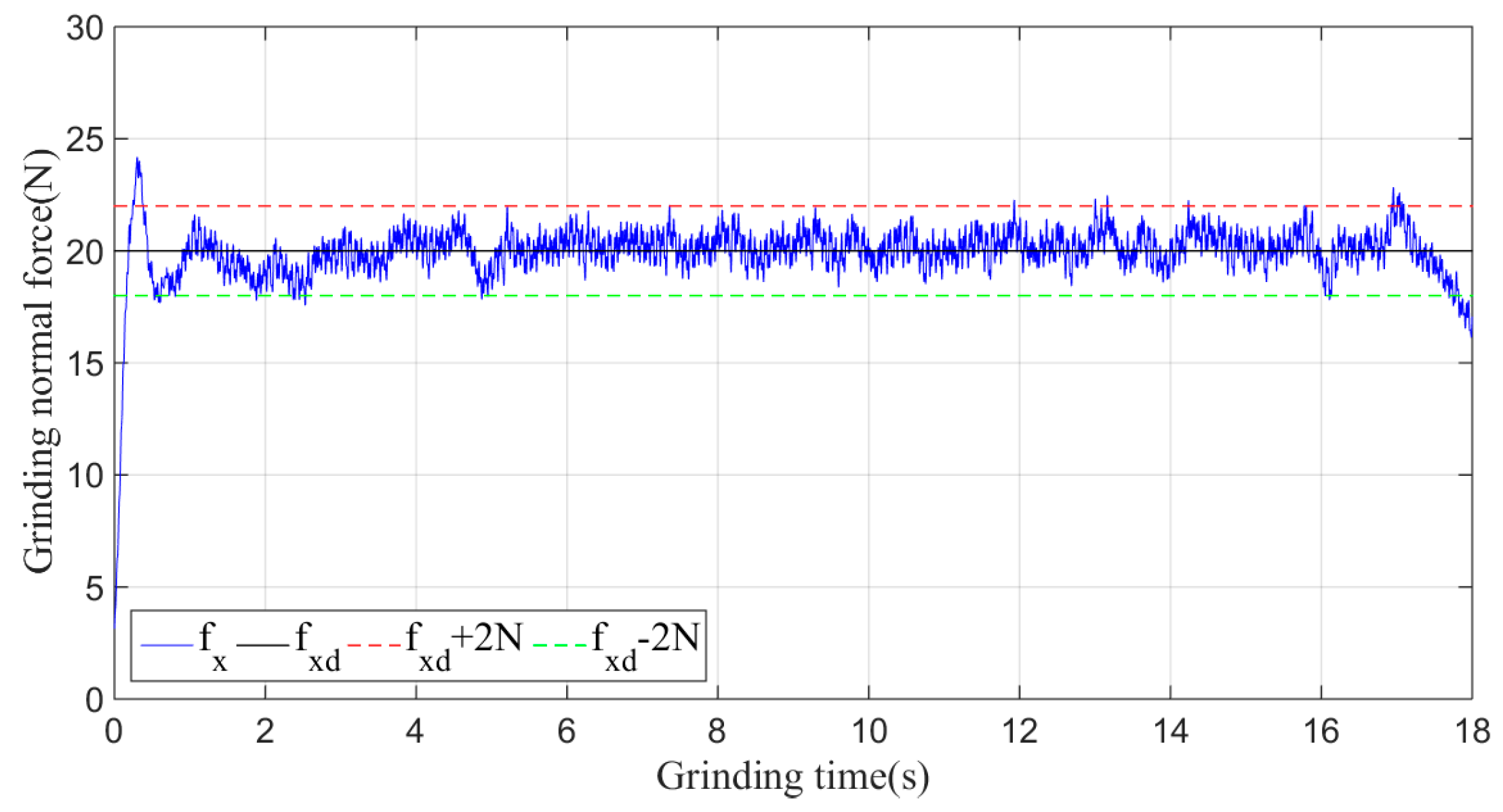

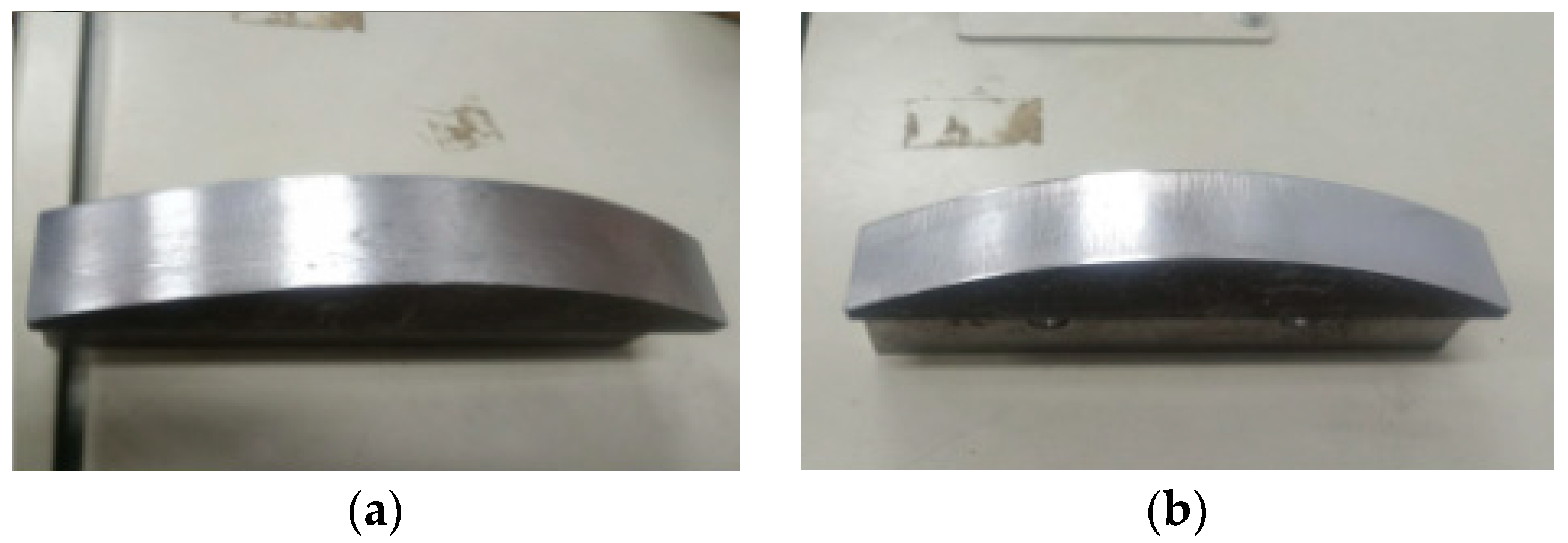

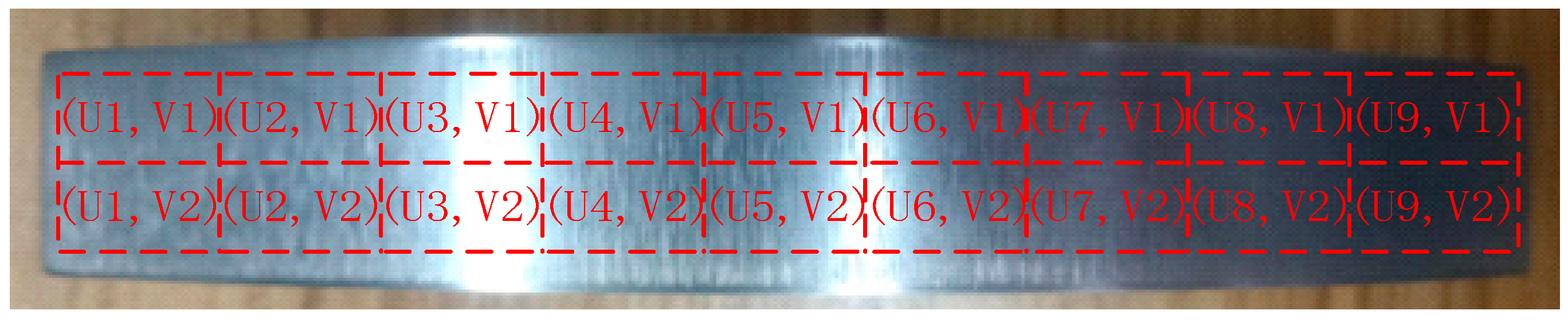

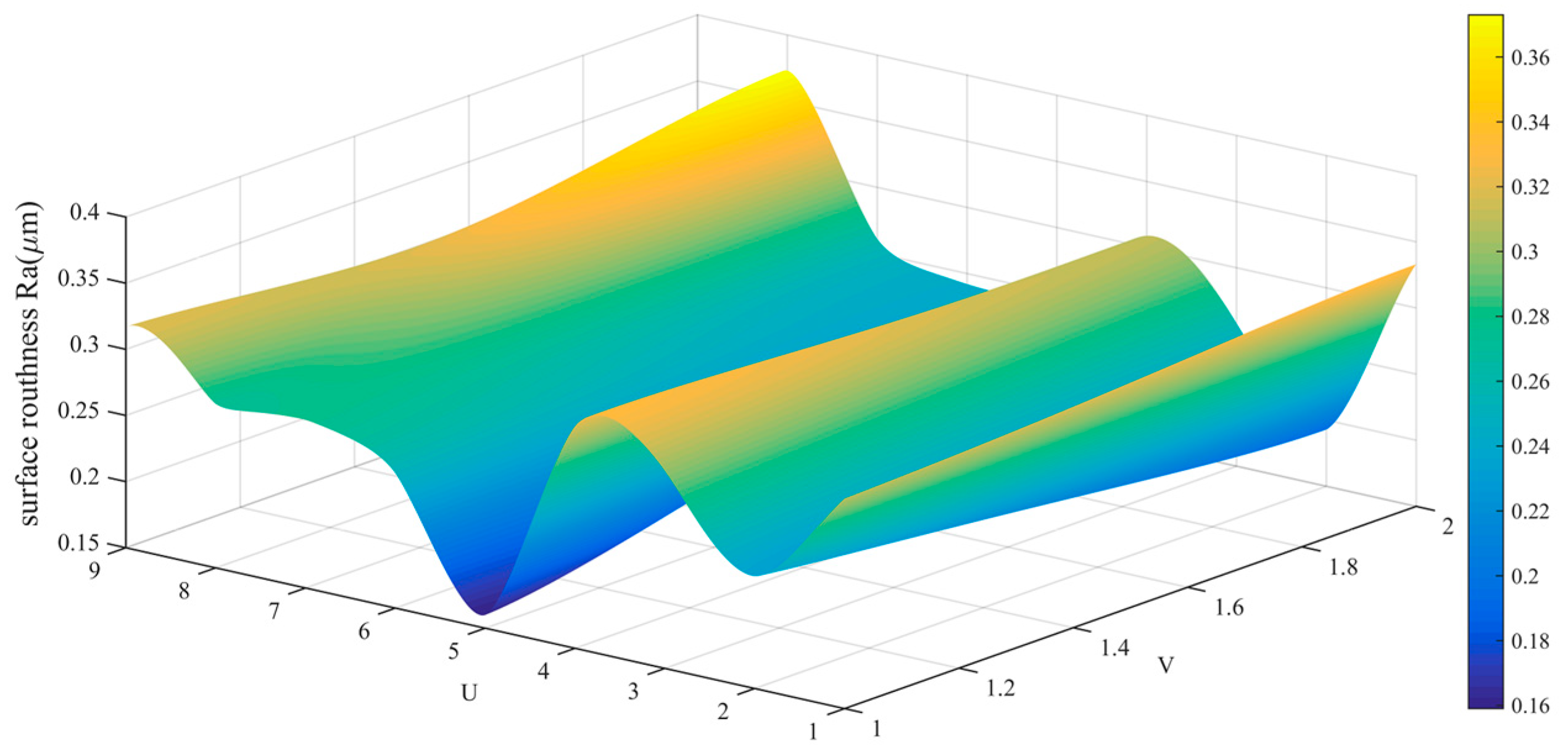

5.3. Curved-surface Workpiece Grinding Experiment

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pandiyan, V.; Caesarendra, W.; Tjahjowidodo, T.; Tan, H.H. In-process tool condition monitoring in compliant abrasive belt grinding process using support vector machine and genetic algorithm. J. Manuf. Process. 2018, 31, 199–213. [Google Scholar] [CrossRef]

- Ren, X.; Cabaravdic, M.; Zhang, X.; Kuhlenkötter, B. A local process model for simulation of robotic belt grinding. Int. J. Mach. Tools Manuf. 2007, 47, 962–970. [Google Scholar] [CrossRef]

- Ng, W.X.; Chan, H.K.; Teo, W.K.; Chen, I.M. Capturing the tacit knowledge of the skilled operator to program tool paths and tool orientations for robot belt grinding. Int. J. Adv. Manuf. Technol. 2017, 91, 1599–1618. [Google Scholar] [CrossRef]

- Huang, H.; Zhou, L.; Chen, X.Q.; Gong, Z.M. SMART robotic system for 3D profile turbine vane airfoil repair. Int. J. Adv. Manuf. Technol. 2003, 21, 275–283. [Google Scholar] [CrossRef]

- Slavkovic, N.; Milutinovic, D.; Glavonjic, M. A method for off-line compensation of cutting force-induced errors in robotic machining by tool path modification. Int. J. Adv. Manuf. Technol. 2013, 70, 2083–2096. [Google Scholar] [CrossRef]

- Pan, Z.; Polden, J.; Larkin, N.; VanDuin, S.; Norrish, J. Recent progress on programming methods for industrial robots. Robot. Comput. Integr. Manuf. 2012, 28, 87–94. [Google Scholar] [CrossRef]

- Zha, X.F.; Chen, X.Q. Trajectory coordination planning and control for robot manipulators in automated material handling and processing. Int. J. Adv. Manuf. Technol. 2004, 23, 831–845. [Google Scholar] [CrossRef]

- Zhao, P.; Shi, Y. Posture adaptive control of the flexible grinding head for blisk manufacturing. Int. J. Adv. Manuf. Technol. 2013, 9, 1989–2001. [Google Scholar]

- Diao, S.; Chen, X.; Luo, J. Development and Experimental Evaluation of a 3D Vision System for Grinding Robot. Sensors 2018, 18, 3078. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.; Xu, X.; Yang, Z.; Zhuang, K.; Yan, S.; Ding, H. Analysis and assessment of robotic belt grinding mechanisms by force modeling and force control experiments. Tribol. Int. 2018, 120, 93–98. [Google Scholar] [CrossRef]

- Li, C.; Wang, Z.; Fan, C.; Chen, G.; Huang, T. Research on grinding and polishing force control of compliant flange. In Proceedings of the International Conference on Engineering Technology and Application (ICETA), Xiamen, China, 29–30 May 2015. [Google Scholar]

- Qi, L.; Gan, Z.; Yun, C.; Tang, Q.; Sun, Y. Working accuracy analysis and error compensation for robotic belt grinding system. Robot 2010, 32, 787–791. [Google Scholar]

- Wang, W.; Yun, C. Dexterity analysis and optimization of belt grinding robot. Robot 2010, 32, 48–54. [Google Scholar] [CrossRef]

- Miomir, V.; Dragoljub, S.; Yury, E.; Katic, D. Dynamics and Robust Control of Robot-Environment Interaction, 1st ed.; World Scientific Publishing: London, UK, 2009; pp. 77–253. [Google Scholar]

- Raibert, M.H.; Craig, J.J. Hybrid position/force control of manipulators. ASME J. Dyn. Syst. Meas. Control 1980, 103, 126–133. [Google Scholar] [CrossRef]

- Hogan, N. Impedance control: An approach to manipulator, part I-theory, part II-implementation, part III-application. ASME J. Dyn. Syst. Meas. Control 1985, 107, 1–24. [Google Scholar] [CrossRef]

- Zhang, Q.W.; Han, L.L.; Xu, F.; Jia, K. Research on velocity servo-based hybrid position/force control scheme for a grinding robot. Adv. Mater. Res. 2012, 490–495, 589–593. [Google Scholar] [CrossRef]

- Lahr, G.J.G.; Caurin, G.A.D.P.; Fortulan, C.A. The use of robot with force control in machining of green ceramics. Mater. Sci. Forum 2014, 805, 615–620. [Google Scholar] [CrossRef]

- Zhang, J.F.; Liu, G.F.; Zang, X.Z.; Li, L.Y. A Hybrid passive/active force control scheme for robotic belt grinding system. In Proceedings of the IEEE International Conference on Mechatronics and Automation, Harbin, China, 7–10 August 2016; pp. 737–742. [Google Scholar]

- Lu, Z.; Kawamura, S.; Goldenberg, A.A. Sliding mode impedance control and its application to grinding tasks. In Proceedings of the IEEE/RSJ International Workshop on Intelligent Robots and Systems, Osaka, Japan, 3–5 November 1991; pp. 350–355. [Google Scholar]

- Song, Y.; Yang, H.; Lv, H. Intelligent control for a robot belt grinding system. IEEE Trans. Control Syst. Technol. 2013, 21, 716–724. [Google Scholar]

- Seraji, H.; Colbaugh, R. Force tracking in impedance control. Int. J. Robot. Res. 1993, 16, 97–117. [Google Scholar] [CrossRef]

- Jung, S.; Hsia, T.C.; Bonitz, R.G. Force tracking impedance control of robot manipulators under unknown environment. IEEE Trans. Control Syst. Technol. 2004, 12, 474–483. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Z.; Xia, G.; Xie, X.; Zhu, Q. Efficient Force Control Learning System for Industrial Robots Based on Variable Impedance Control. Sensors 2018, 18, 2539. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Su, J. Collision-free planning algorithm of motion path for the robot belt grinding system. Int. J. Adv. Robot. Syst. 2018, 15, 1–13. [Google Scholar] [CrossRef]

- Su, J. Path Planning and Optimization of Robotic Belt Grinding System. Master’s Thesis, South China University of Technology, Guang Zhou, China, 2017. [Google Scholar]

- Zhang, T.; Hu, G. Nonlinear dual-loop force controller of contour following. Electr. Mach. Control 2017, 21, 99–106. [Google Scholar]

- Nuno, M.; Pedro, N. Indirect adaptive fuzzy control for industrial robots: A solution for contact applications. Expert Syst. Appl. 2015, 42, 8929–8935. [Google Scholar]

- Ye, B.S.; Song, B.; Li, Z.Y.; Xiong, S.; Tang, X.Q. A study of force and position tracking control for robot contact with an arbitrarily inclined plane. Int. J. Adv. Robot. Syst. 2013, 10, 1–7. [Google Scholar]

- Tayebi, A. Adaptive iterative learning control for robot manipulators. Automatica 2004, 40, 1195–1203. [Google Scholar] [CrossRef]

- Lyapunov, A.M. The general problem of the stability of motion. Int. J. Control 1992, 55, 531–534. [Google Scholar] [CrossRef]

- Graig, J.J. Introduction to Robotics: Mechanics and Control, 3rd ed.; Pearson Education International: London, UK, 2006; pp. 317–339. [Google Scholar]

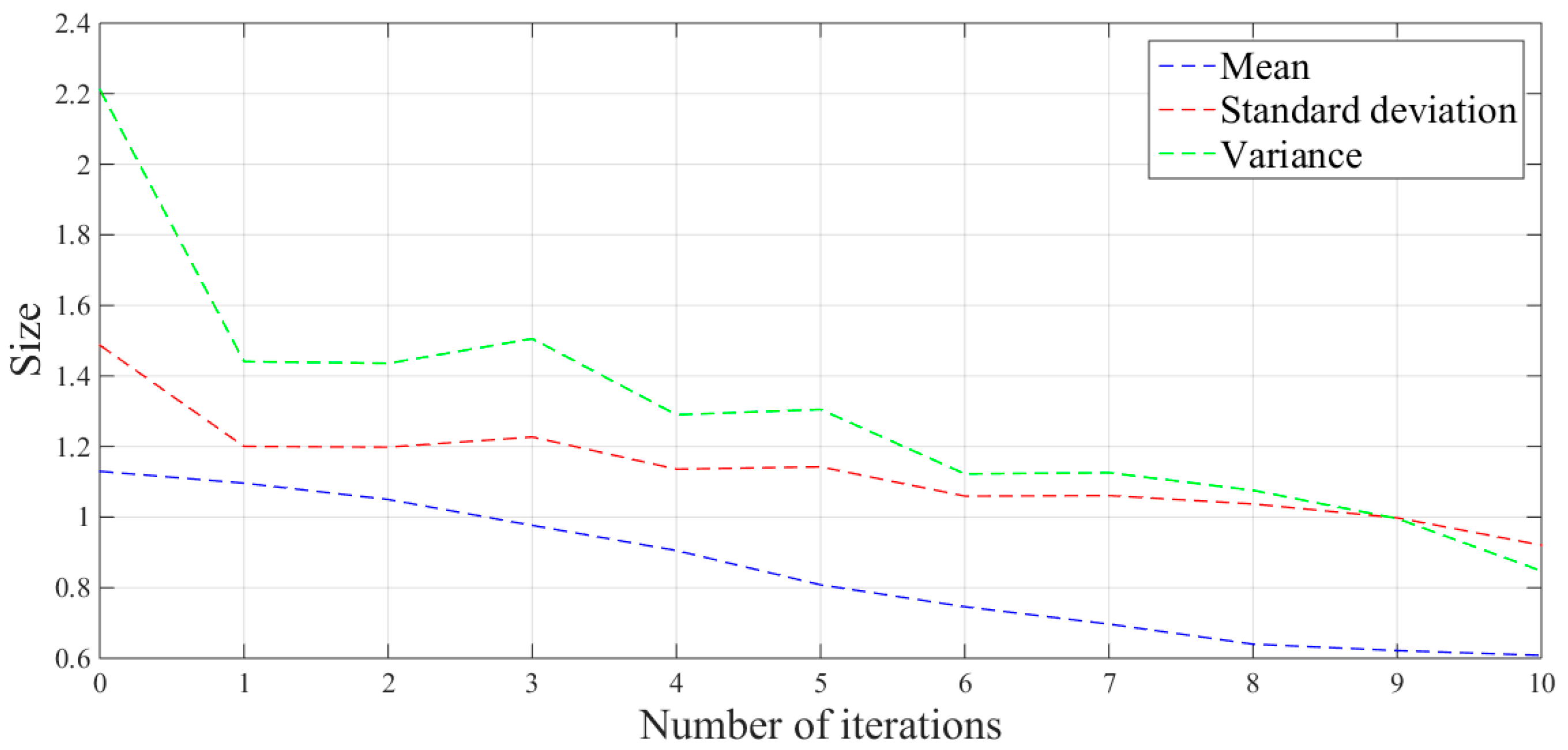

| Iteration Number | Mean | Standard Deviation | Variance |

|---|---|---|---|

| 0 | 1.1297 | 1.4872 | 2.2118 |

| 1 | 1.0962 | 1.2004 | 1.4410 |

| 2 | 1.0500 | 1.1982 | 1.4359 |

| 3 | 0.9765 | 1.2270 | 1.5055 |

| 4 | 0.9052 | 1.1358 | 1.2900 |

| 5 | 0.8080 | 1.1424 | 1.3051 |

| 6 | 0.7459 | 1.0595 | 1.1225 |

| 7 | 0.6968 | 1.0610 | 1.1257 |

| 8 | 0.6399 | 1.0372 | 1.0758 |

| 9 | 0.6217 | 0.9979 | 0.9958 |

| 10 | 0.6082 | 0.9205 | 0.8473 |

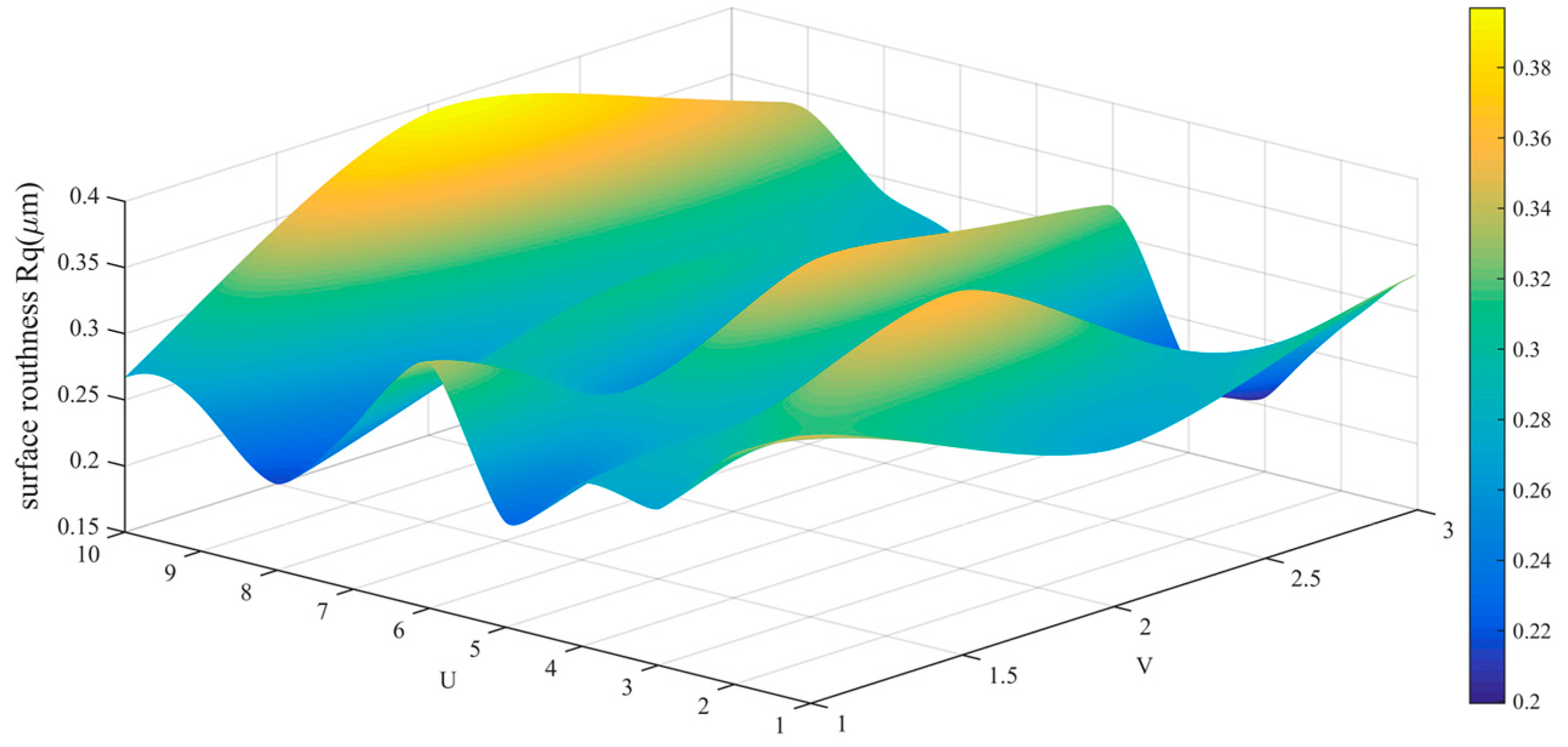

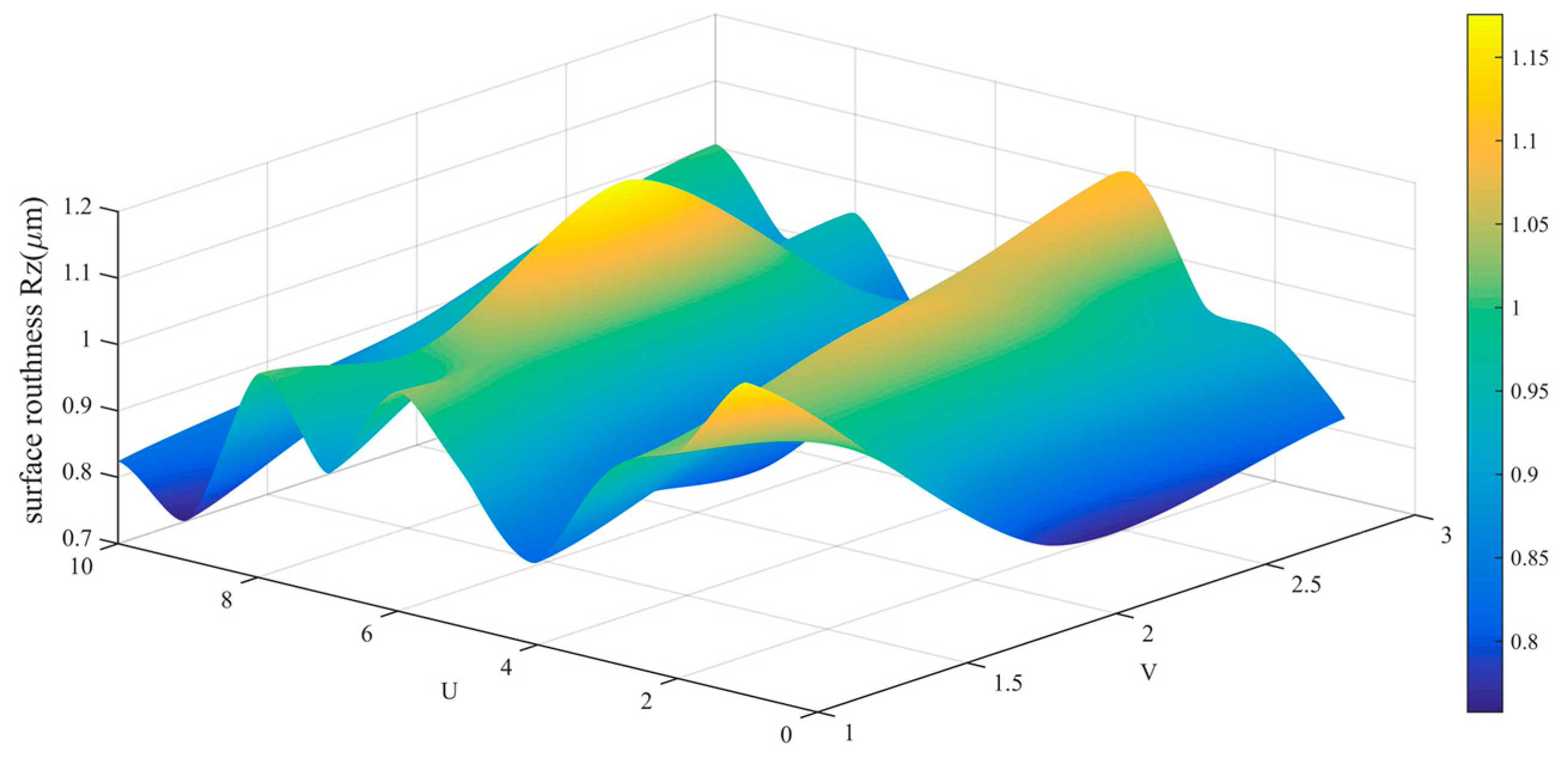

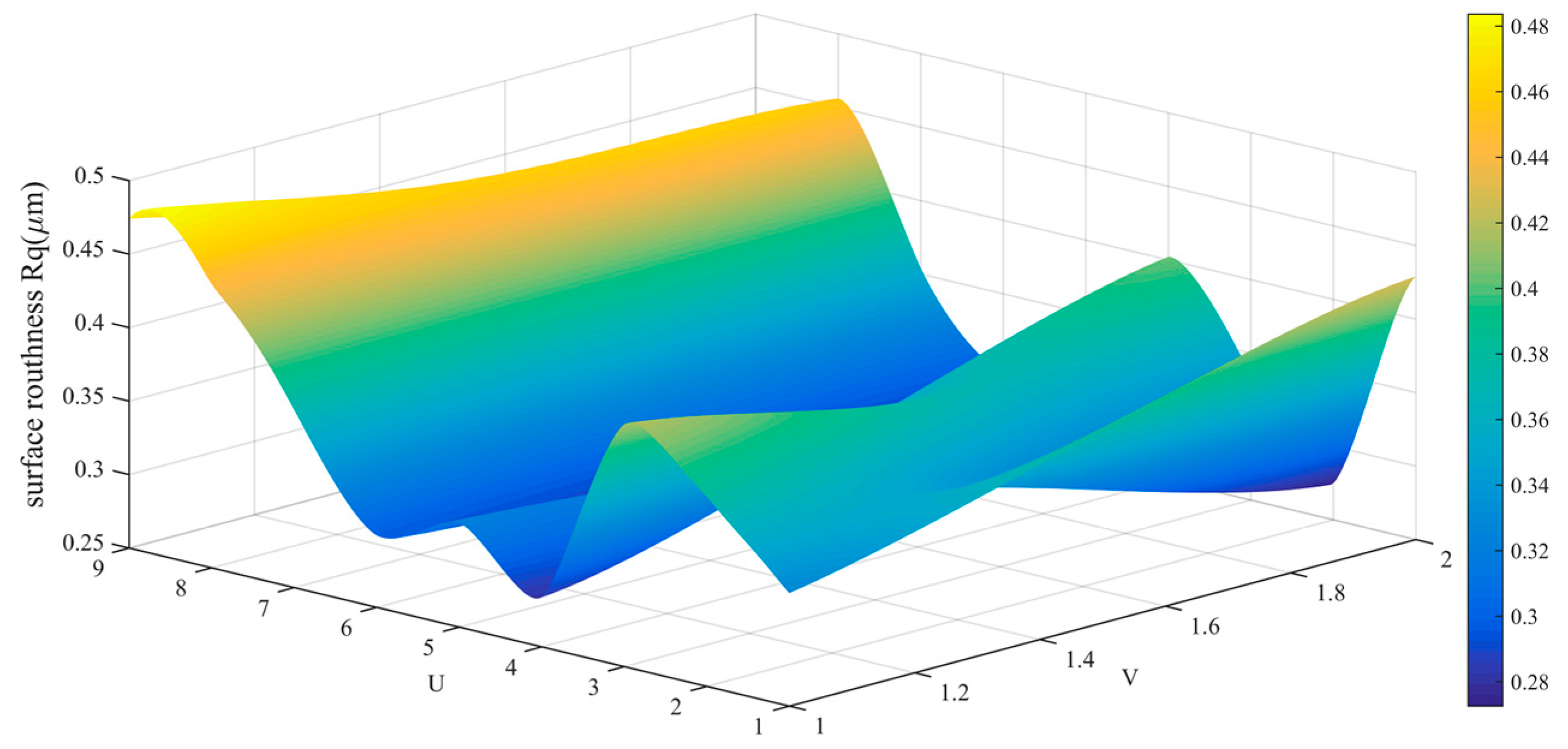

| V1 | V2 | V3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Ra | Rq | Rz | Ra | Rq | Rz | Ra | Rq | Rz | |

| U1 | 0.230 | 0.352 | 1.171 | 0.251 | 0.269 | 0.777 | 0.276 | 0.328 | 0.820 |

| U2 | 0.266 | 0.325 | 1.042 | 0.258 | 0.287 | 0.949 | 0.235 | 0.273 | 0.921 |

| U3 | 0.236 | 0.268 | 0.986 | 0.206 | 0.360 | 1.078 | 0.181 | 0.206 | 0.938 |

| U4 | 0.205 | 0.273 | 0.824 | 0.221 | 0.270 | 0.996 | 0.198 | 0.215 | 1.112 |

| U5 | 0.199 | 0.229 | 0.921 | 0.257 | 0.353 | 0.794 | 0.263 | 0.322 | 1.035 |

| U6 | 0.237 | 0.335 | 1.031 | 0.205 | 0.212 | 0.921 | 0.198 | 0.257 | 0.894 |

| U7 | 0.261 | 0.273 | 0.882 | 0.261 | 0.309 | 1.175 | 0.201 | 0.268 | 0.813 |

| U8 | 0.183 | 0.215 | 1.007 | 0.241 | 0.289 | 0.844 | 0.221 | 0.289 | 0.951 |

| U9 | 0.210 | 0.259 | 0.761 | 0.271 | 0.355 | 0.953 | 0.280 | 0.337 | 0.889 |

| U10 | 0.220 | 0.267 | 0.824 | 0.290 | 0.394 | 0.885 | 0.227 | 0.310 | 1.005 |

| Mean | 0.225 | 0.280 | 0.945 | 0.246 | 0.310 | 0.937 | 0.228 | 0.281 | 0.938 |

| Standard deviation | 0.027 | 0.0446 | 0.125 | 0.028 | 0.0551 | 0.124 | 0.035 | 0.0456 | 0.093 |

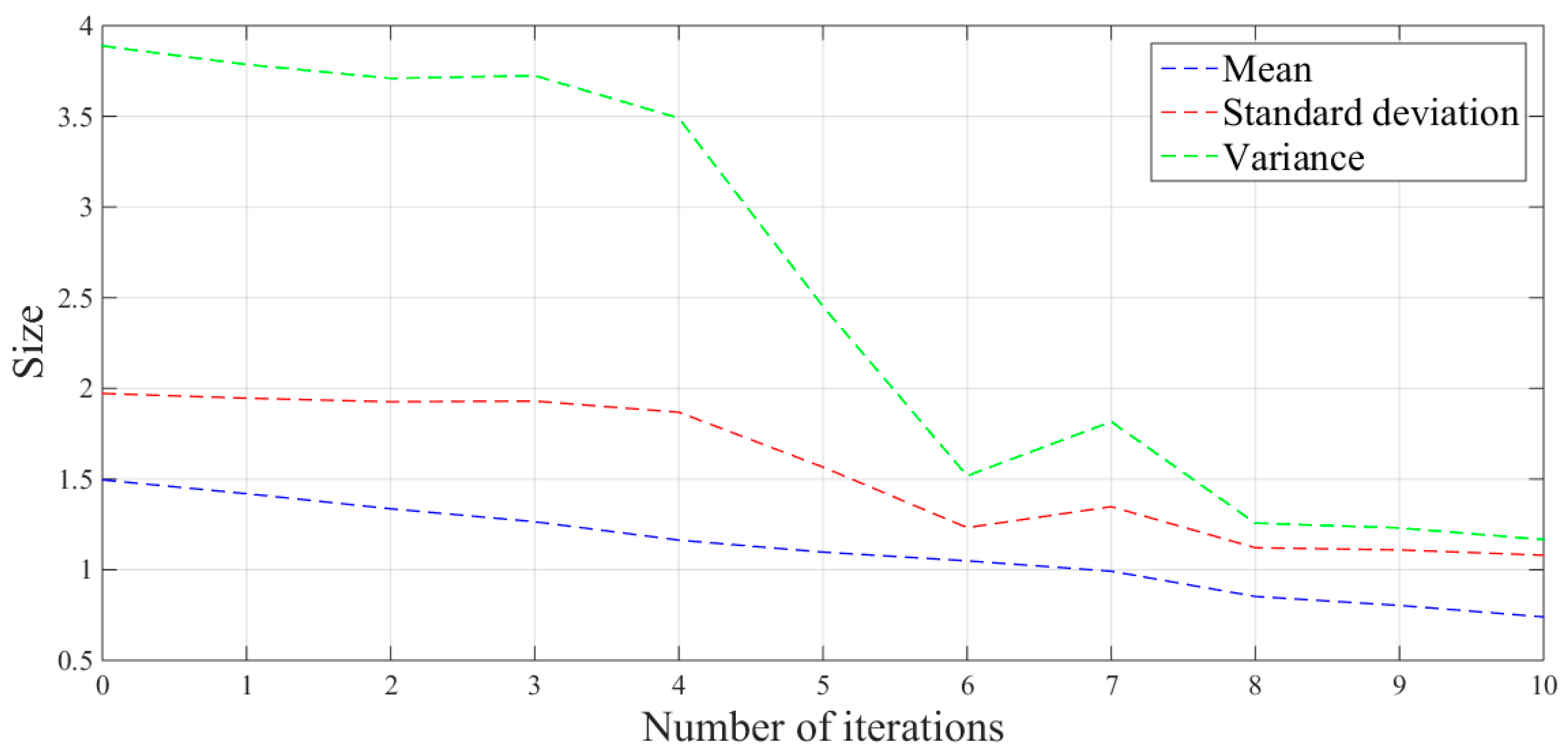

| Iteration Number | Mean | Standard Deviation | Variance |

|---|---|---|---|

| 0 | 1.4953 | 1.9718 | 3.8880 |

| 1 | 1.4192 | 1.9457 | 3.7857 |

| 2 | 1.3361 | 1.9259 | 3.7091 |

| 3 | 1.2646 | 1.9298 | 3.7241 |

| 4 | 1.1632 | 1.8682 | 3.4902 |

| 5 | 1.0971 | 1.5658 | 2.4517 |

| 6 | 1.0490 | 1.2320 | 1.5178 |

| 7 | 0.9918 | 1.3476 | 1.8160 |

| 8 | 0.8523 | 1.1211 | 1.2569 |

| 9 | 0.8031 | 1.1092 | 1.2303 |

| 10 | 0.7398 | 1.0799 | 1.1662 |

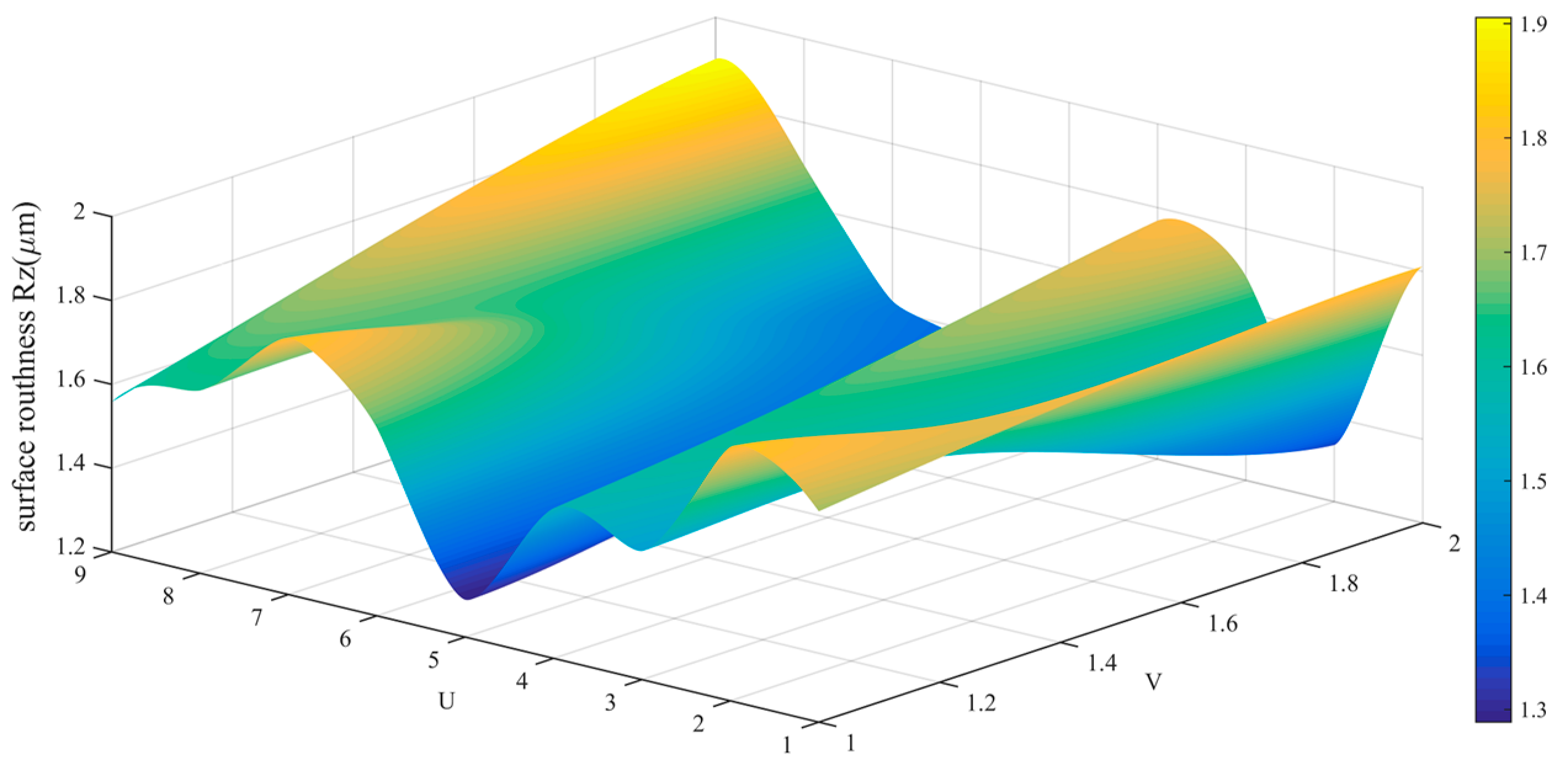

| V1 | V2 | |||||

|---|---|---|---|---|---|---|

| Ra | Rq | Rz | Ra | Rq | Rz | |

| U1 | 0.309 | 0.327 | 1.703 | 0.333 | 0.429 | 1.812 |

| U2 | 0.235 | 0.379 | 1.806 | 0.193 | 0.275 | 1.335 |

| U3 | 0.299 | 0.415 | 1.507 | 0.258 | 0.335 | 1.687 |

| U4 | 0.218 | 0.284 | 1.558 | 0.309 | 0.402 | 1.769 |

| U5 | 0.160 | 0.321 | 1.289 | 0.257 | 0.312 | 1.519 |

| U6 | 0.252 | 0.299 | 1.648 | 0.242 | 0.296 | 1.371 |

| U7 | 0.277 | 0.371 | 1.812 | 0.261 | 0.354 | 1.425 |

| U8 | 0.274 | 0.443 | 1.636 | 0.373 | 0.456 | 1.699 |

| U9 | 0.317 | 0.474 | 1.558 | 0.240 | 0.315 | 1.901 |

| Mean | 0.271 | 0.368 | 1.613 | 0.274 | 0.353 | 1.613 |

| Standard deviation | 0.051 | 0.066 | 0.161 | 0.055 | 0.063 | 0.206 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Yu, Y.; Zou, Y. An Adaptive Sliding-Mode Iterative Constant-force Control Method for Robotic Belt Grinding Based on a One-Dimensional Force Sensor. Sensors 2019, 19, 1635. https://doi.org/10.3390/s19071635

Zhang T, Yu Y, Zou Y. An Adaptive Sliding-Mode Iterative Constant-force Control Method for Robotic Belt Grinding Based on a One-Dimensional Force Sensor. Sensors. 2019; 19(7):1635. https://doi.org/10.3390/s19071635

Chicago/Turabian StyleZhang, Tie, Ye Yu, and Yanbiao Zou. 2019. "An Adaptive Sliding-Mode Iterative Constant-force Control Method for Robotic Belt Grinding Based on a One-Dimensional Force Sensor" Sensors 19, no. 7: 1635. https://doi.org/10.3390/s19071635

APA StyleZhang, T., Yu, Y., & Zou, Y. (2019). An Adaptive Sliding-Mode Iterative Constant-force Control Method for Robotic Belt Grinding Based on a One-Dimensional Force Sensor. Sensors, 19(7), 1635. https://doi.org/10.3390/s19071635