Lamb Wave-Minimum Sampling Variance Particle Filter-Based Fatigue Crack Prognosis

Abstract

:1. Introduction

2. State–Space Model for Fatigue Crack Growth

2.1. Evolution Equation

2.2. Observation Equation

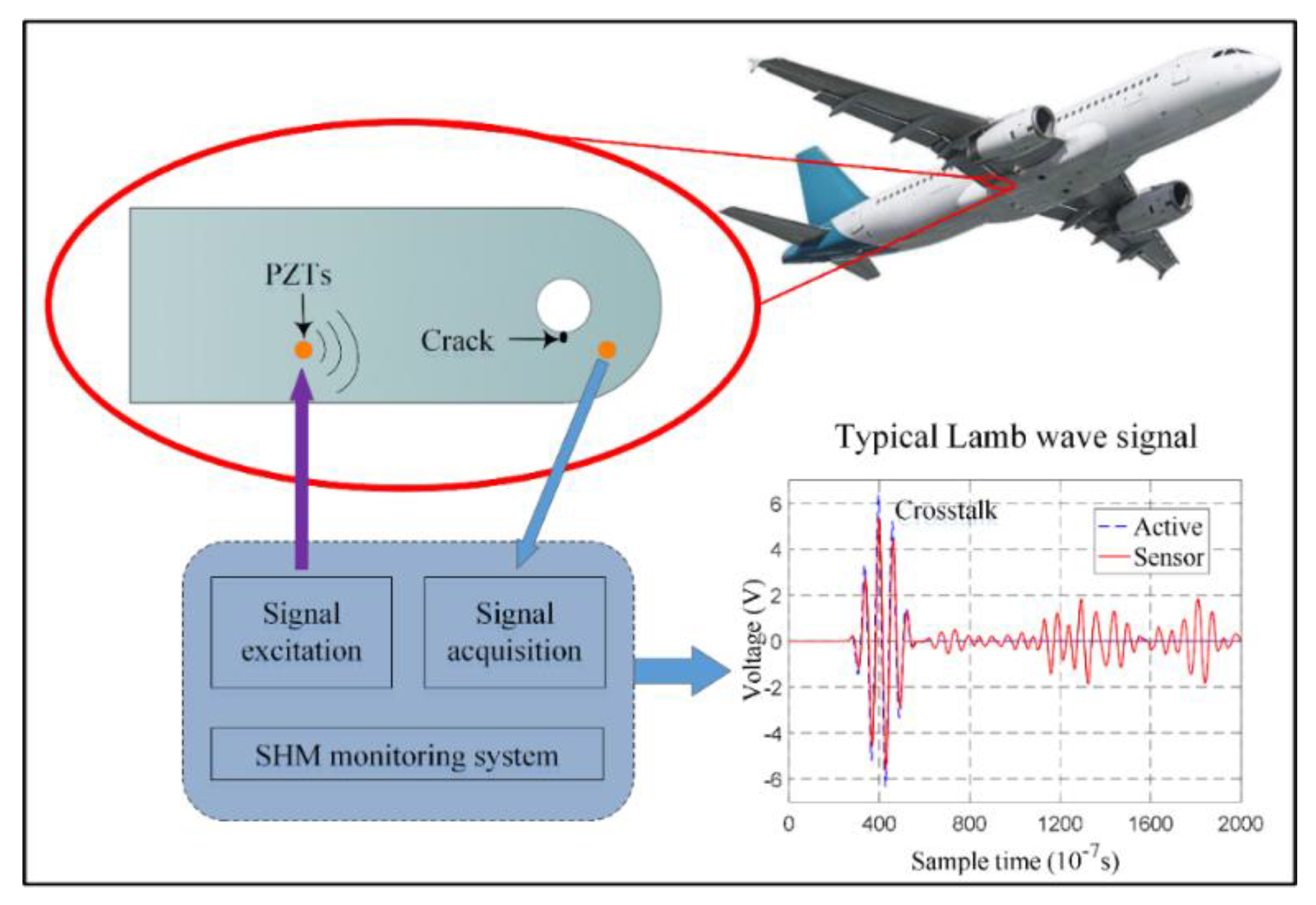

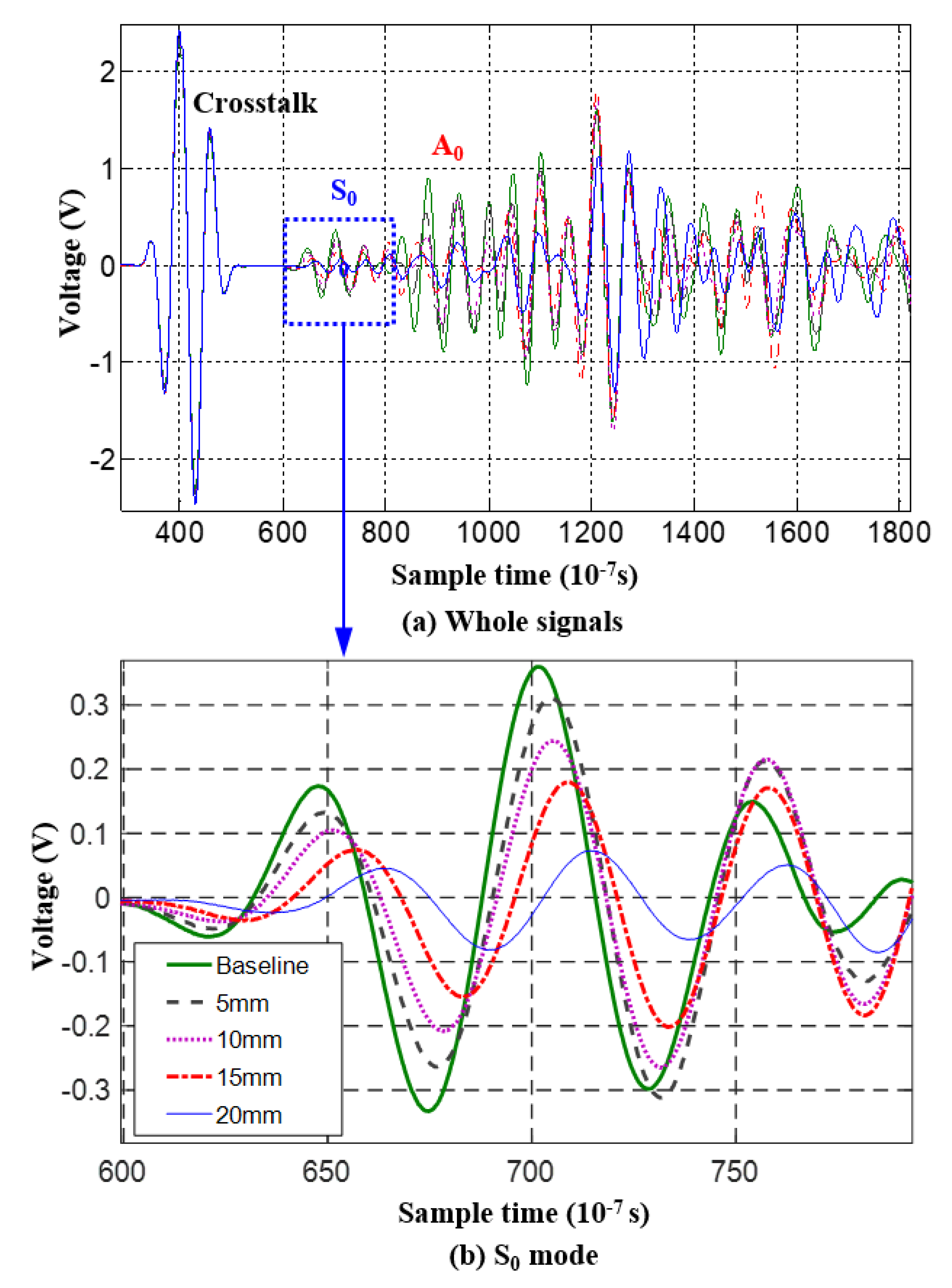

2.2.1. Lamb Wave-Based Fatigue Crack On-line Monitoring Method

2.2.2. Lamb Wave-Based Observation Equation

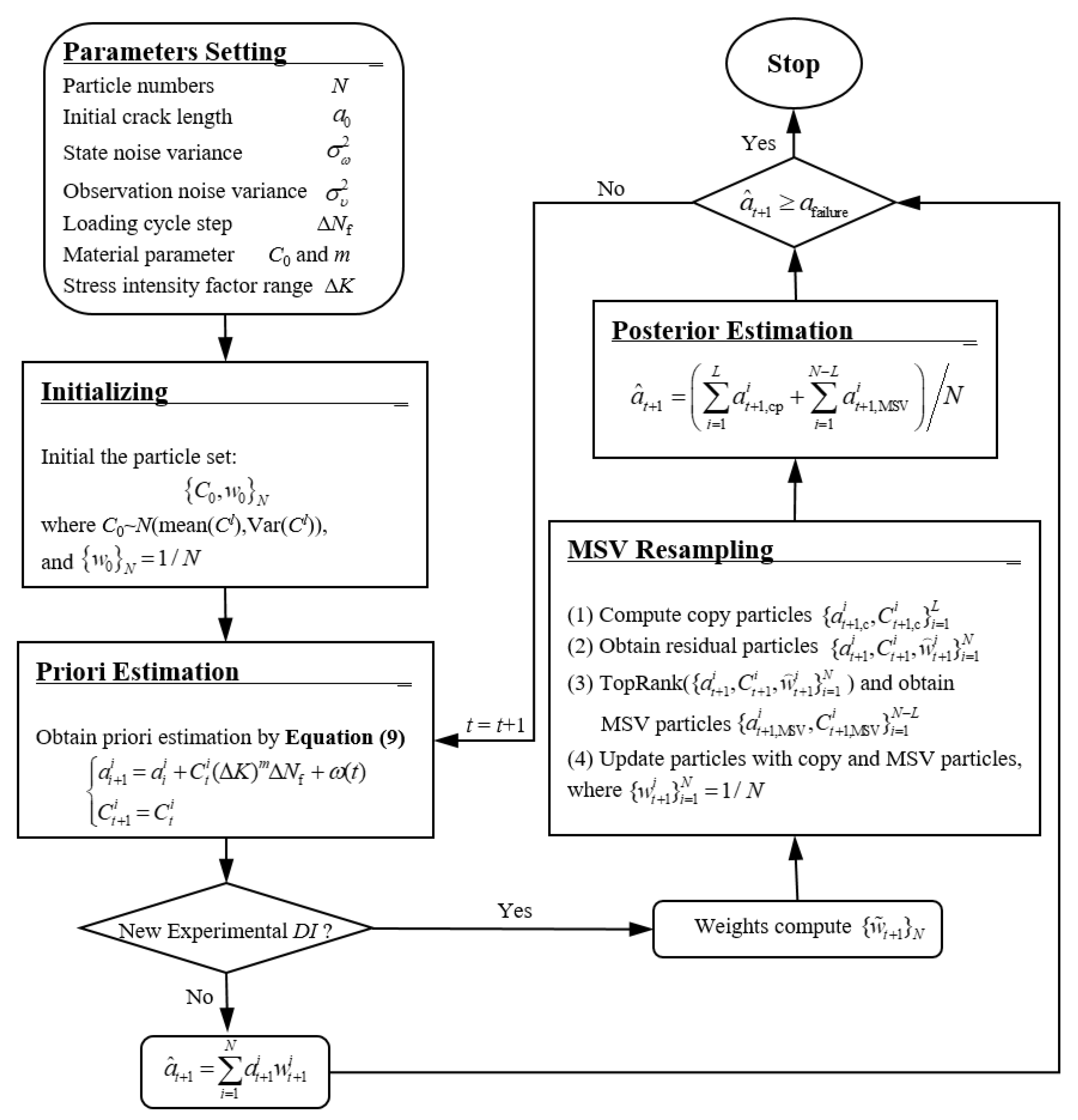

3. LW-MSVPF-Based Fatigue Crack Growth Prognosis

3.1. Standard PF

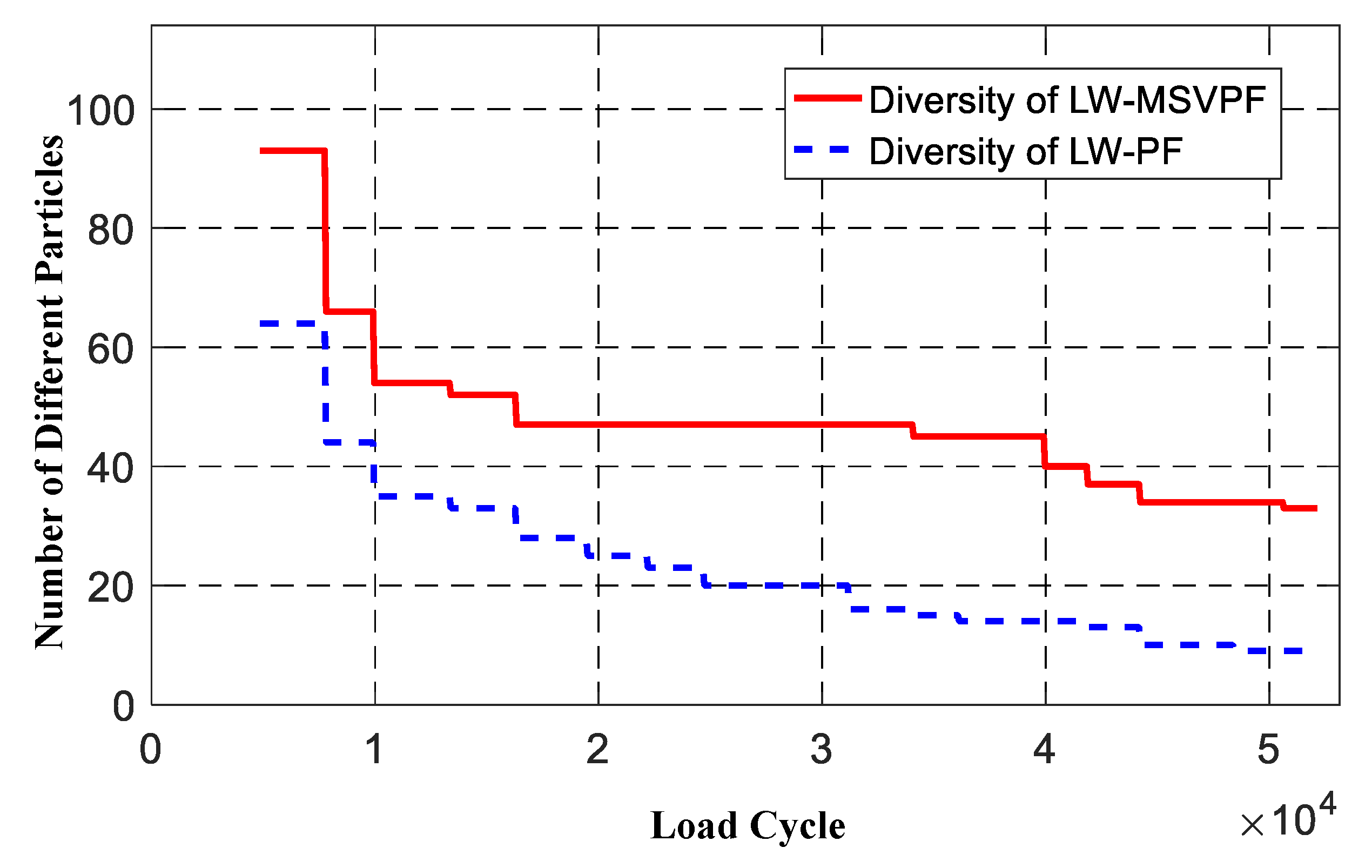

3.2. Minimum Sampling Variance Resampling

- (1)

- Copy particles: For ith particle, if its particle weight is bigger than 1/N, copy this particle for times, where is the integer part of the product, as Equation (27).where Floor(·) is the function rounded towards minus infinity. When the copy process ends, a copy particle set of is obtained, and all of their corresponding particle weights are equal to 1/N. The total number of the copy particle set is .

- (2)

- Residual particles: After extracting copy particles from the original particle set , the residual particle weights can be calculated by Equation (28). The set composed of residual particles and their residue weights are called residual particle set.

- (3)

- MSV resampling: Sort the residual particle set according to their residue weights, then sample N-L particles with the largest particle weights. The process above can be characterized by the function of TopRankN-L(·), as shown in Equation (29).

- (4)

- Update the particle set: Add N-L MSV particles to the copy particles to restore the total particle number to N, then update the new particle set as , where all particle weights of are equal to 1/N.

3.3. On-Line Fatigue Crack Growth Prognosis Based on LW-MSVPF

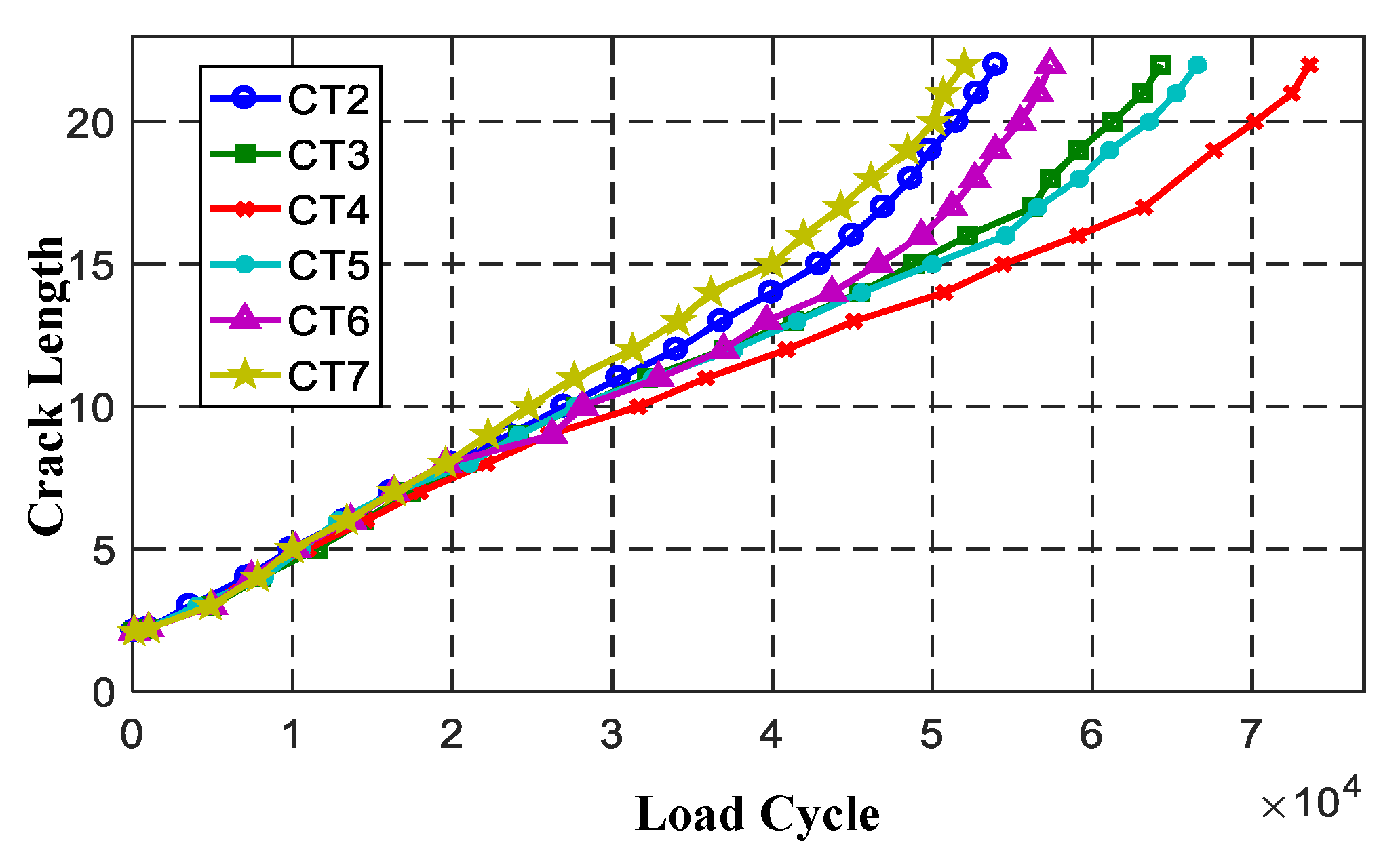

4. Experimental Evaluation

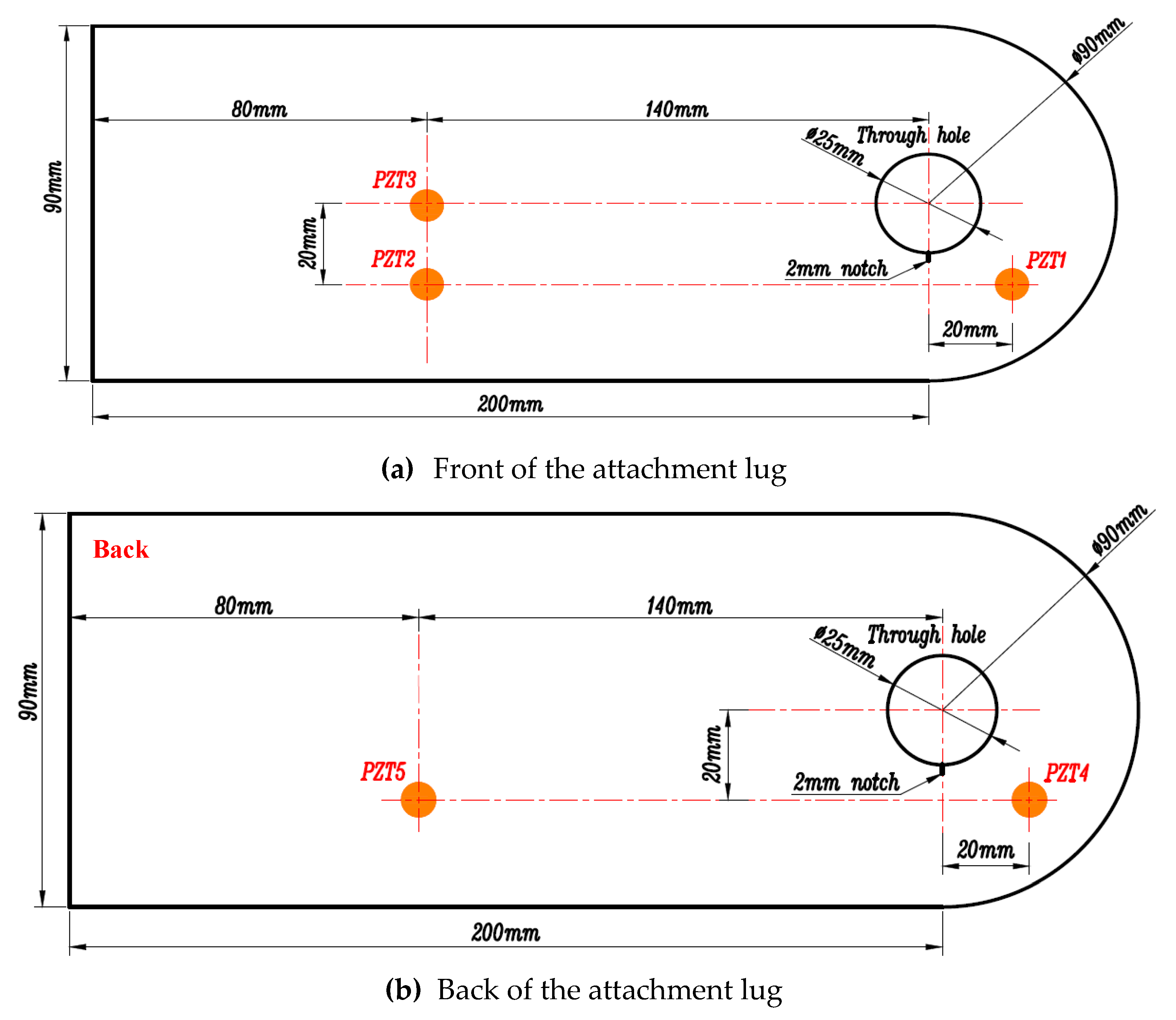

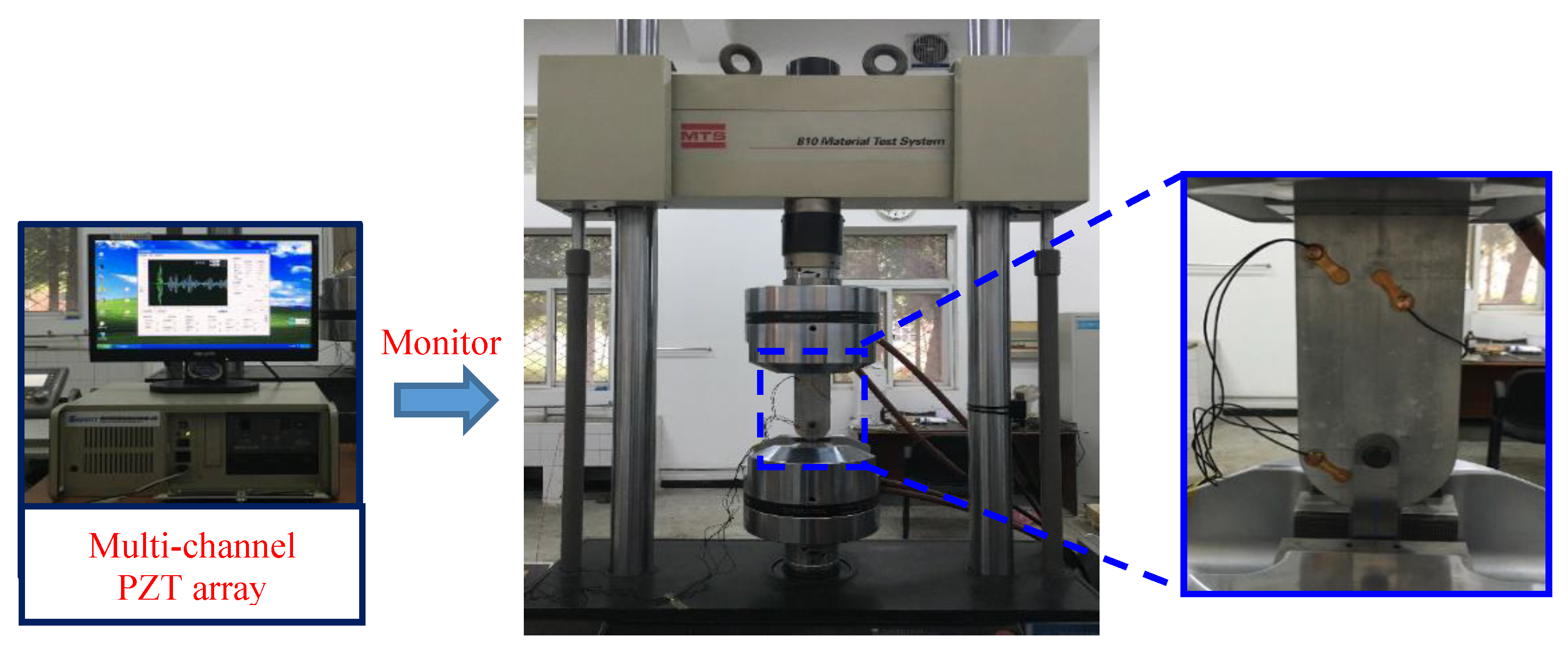

4.1. Experimental Setup

4.2. State–Space Model for Attachment Lug

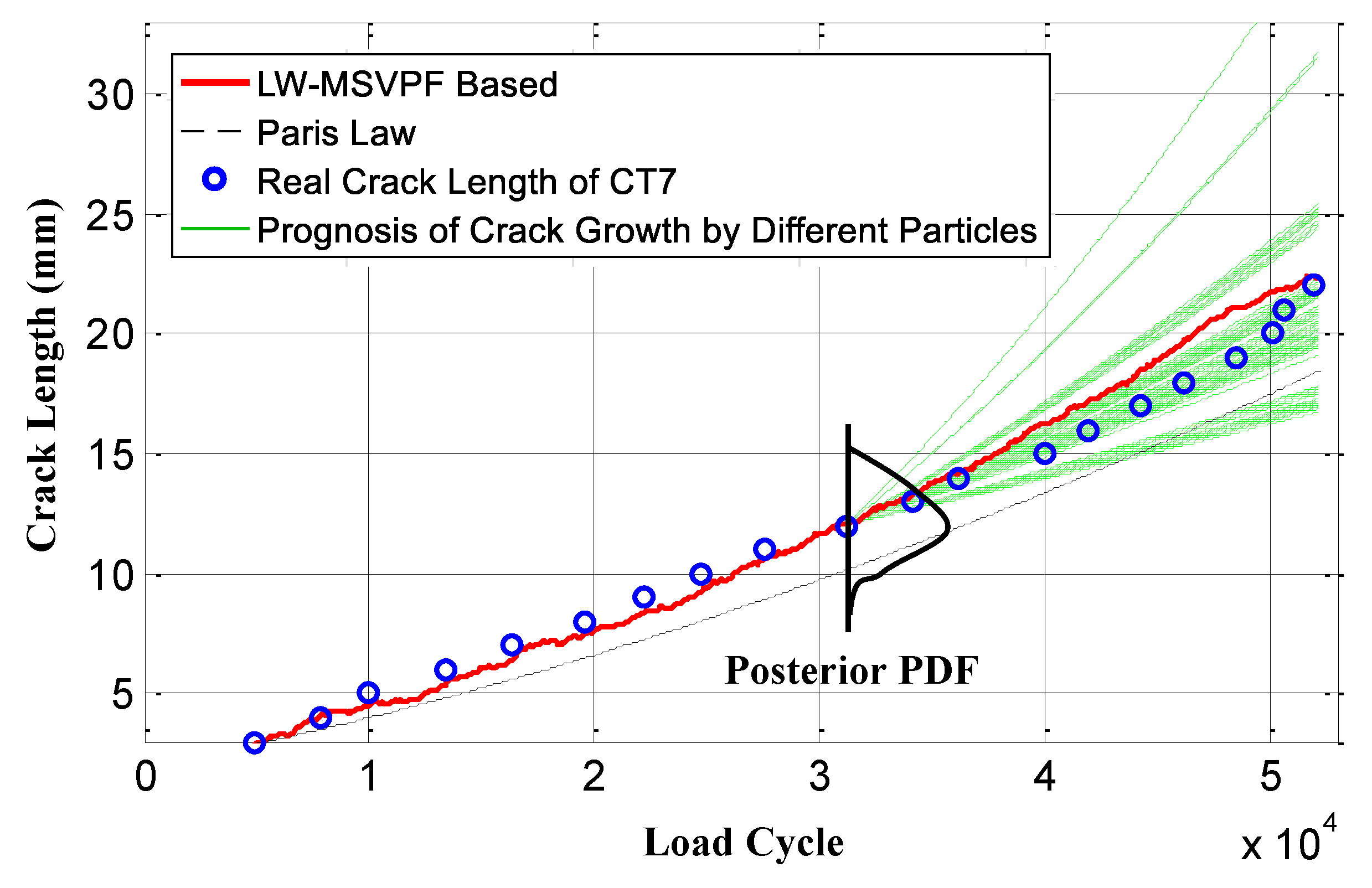

4.3. On-Line Fatigue Crack Growth Prognosis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Campbell, G.S.; Lahey, R. Survey of serious aircraft accidents involving fatigue fracture. Int. J. Fatigue 1984, 6, 25–30. [Google Scholar] [CrossRef]

- Zhang, J.; Johnston, J.; Chattopadhyay, A. Physics-based multiscale damage criterion for fatigue crack prediction in aluminium alloy. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 119–131. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, K.; Luo, C.; Chattopadhyay, A. Crack initiation and fatigue life prediction on aluminum lug joints using statistical volume element–based multiscale modeling. J. Intell. Mater. Syst. Struct. 2013, 24, 2097–2109. [Google Scholar] [CrossRef]

- Groha, S.; Marina, E.B.; Horstemeyera, M.F.; Zbibb, H.M. Multiscale modeling of the plasticity in an aluminum single crystal. Int. J. Plast. 2009, 25, 1456–1473. [Google Scholar] [CrossRef]

- Gao, S.; Dai, X.; Hang, Y.; Guo, Y.; Ji, Q. Airborne wireless sensor networks for airplane monitoring system. Wirel. Commun. Mob. Comput. 2018, 2018, 6025825. [Google Scholar] [CrossRef]

- Li, K.; Wu, J.; Zhang, Q.; Su, L.; Chen, P. New particle filter based on ga for equipment remaining useful life prediction. Sensors 2017, 17, 696. [Google Scholar] [CrossRef] [PubMed]

- Gordon, N.J.; Salmond, D.J.; Smith, A.F.M. Novel approach to nonlinear/non-Gaussian Bayesian state estimation. IEE Proc. F-Radar Signal Process. 1993, 140, 107–113. [Google Scholar] [CrossRef]

- Yuan, S.; Chen, J.; Yang, W.; Qiu, L. On-line crack prognosis in attachment lug using Lamb wave-deterministic resampling particle filter-based method. Smart Mater. Struct. 2017, 26, 085016. [Google Scholar] [CrossRef]

- Chen, J.; Yuan, S.; Qiu, L.; Cai, J.; Yang, W. Research on a Lamb wave and particle filter-based on-line crack propagation prognosis method. Sensors 2016, 16, 320. [Google Scholar] [CrossRef] [PubMed]

- Orchard, M.E.; Vachtsevanos, G. A particle filtering approach for on-line failure prognosis in a planetary carrier plate. Int. J. Fuzzy Logic Intell. Syst. 2007, 7, 221–227. [Google Scholar] [CrossRef]

- Orchard, M.E.; Vachtsevanos, G. A particle-filtering approach for on-line fault diagnosis and failure prognosis. Trans. Inst. Meas. Control 2009, 31, 221–246. [Google Scholar] [CrossRef]

- Cadini, F.; Zio, E.; Avram, D. Monte Carlo-based filtering for fatigue crack growth estimation. Probab. Eng. Mech. 2009, 24, 367–373. [Google Scholar] [CrossRef]

- Zio, E.; Peloni, G. Particle filtering prognostic estimation of the remaining useful life of nonlinear components. Reliab. Eng. Syst. Saf. 2011, 96, 403–409. [Google Scholar] [CrossRef]

- Myotyri, E.; Pulkkinen, U.; Simola, K. Application of stochastic filtering for lifetime prediction. Reliab. Eng. Syst. Saf. 2006, 91, 200–208. [Google Scholar] [CrossRef]

- Corbetta, M.; Sbarufatti, C.; Manes, A.; Giglio, M. On dynamic state-space models for fatigue-induced structural degradation. Int. J. Fatigue 2014, 61, 202–219. [Google Scholar] [CrossRef]

- Corbetta, M.; Sbarufatti, C.; Manes, A.; Giglio, M. Real-time prognosis of crack growth evolution using sequential Monte Carlo methods and statistical model parameters. IEEE Trans. Reliab. 2015, 64, 736–753. [Google Scholar] [CrossRef]

- An, D.; Kim, N.H.; Choi, J.H. Practical options for selecting data-driven or physics-based prognostics algorithms with reviews. Reliab. Eng. Syst. Saf. 2015, 133, 223–236. [Google Scholar] [CrossRef]

- Yang, W.; Yuan, S.; Qiu, L.; Zhang, H.; Ling, B. A particle filter and Lamb wave based on-line prognosis method of crack propagation in aluminum plates. In Proceedings of the 4th International Symposium on NDT in Aerospace, Augsburg, Germany, 13–15 November 2012. [Google Scholar]

- Yang, W.; Yuan, S.; Chen, J. Application of deterministic resampling particle filter to fatigue prognosis. J. Vibroeng. 2017, 19, 5978–5991. [Google Scholar]

- Chen, J.; Yuan, S.; Qiu, L.; Wang, H.; Yang, W. On-line prognosis of fatigue crack propagation based on Gaussian weight-mixture proposal particle filter. Ultrasonics 2018, 82, 134–144. [Google Scholar] [CrossRef] [PubMed]

- Jouin, M.; Gouriveau, R.; Hissel, D.; Péra, M.C.; Zerhouni, N. Particle filter-based prognostics: Review, discussion and perspectives. Mech. Syst. Signal Process. 2016, 72, 2–31. [Google Scholar] [CrossRef]

- Li, T.; Bolic, M.; Djuric, P.M. Resampling methods for particle filtering: Classification, implementation, and strategies. IEEE Signal Proc. Mag. 2015, 32, 70–86. [Google Scholar] [CrossRef]

- Li, T.; Villarrubia, G.; Sun, S.; Corchado, J.M.; Bajo, J. Resampling methods for particle filtering: Identical distribution, a new method, and comparable study. Front. Inform. Technol. Electr. Eng. 2015, 16, 969–984. [Google Scholar] [CrossRef]

- Doucet, A.; Godsill, S.; Andrieu, C. On sequential Monte Carlo sampling methods for Bayesian filtering. Stat. Cmoput. 2000, 10, 197–208. [Google Scholar] [CrossRef]

- Paris, P.C.; Erdogan, F. A critical analysis of crack propagation laws. J. Fluid Eng. Trans. ASME 1963, 85, 528–533. [Google Scholar] [CrossRef]

- Tada, H.; Paris, P.C.; Irwin, G.R. The Stress Analysis of Cracks Handbook; Del Research: St. Louis, MO, USA, 1985. [Google Scholar]

- Coppe, A.; Pais, M.J.; Haftka, R.T.; Kim, N.H. Using a simple crack growth model in predicting remaining useful life. J. Aircr. 2012, 49, 1965–1973. [Google Scholar] [CrossRef]

- ASTM. International Standard Test Method for Measurement of Fatigue Crack Growth Rates; ASTM: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Li, W.; Sakai, T.; Li, Q.; Wang, P. Statistical analysis of fatigue crack growth behavior for grade B cast steel. Mater. Des. 2011, 32, 1262–1272. [Google Scholar] [CrossRef]

- Sun, J.; Zuo, H.; Wang, W.; Pecht, M.G. Prognostics uncertainty reduction by fusing on-line monitoring data based on a state-space-based degradation model. Mech. Syst. Signal Process. 2014, 45, 396–407. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Structural Health Monitoring: With Piezoelectric Wafer Active Sensors; Academic Press: Cambridge, MA, USA, 2007. [Google Scholar]

- Giurgiutiu, V.; Xu, B.; Chao, Y.; Liu, S.; Gaddam, R. Smart sensors for monitoring crack growth under fatigue loading conditions. Smart Struct. Syst. 2006, 2, 101–113. [Google Scholar] [CrossRef]

- Boller, C.; Mofakhami, M.R. Ageing of multi-riveted metallic panels and their options for acoustic wave based condition monitoring. In Proceedings of the IV ECCOMAS Thematic Conference on Smart Structures and Materials (SMART’09), Portugal, Porto, 13–15 July 2009. [Google Scholar]

- Liu, Y.; Hu, N.; Xu, H.; Yuan, W.; Yan, C.; Li, Y.; Goda, R.; Alamusi; Qiu, J.; Ning, H.; et al. Damage evaluation based on a wave energy flow map using multiple PZT sensors. Sensors 2014, 14, 1902–1917. [Google Scholar] [CrossRef] [PubMed]

- An, Y.K.; Shen, Z.; Wu, Z. Stripe-PZT sensor-based baseline-free crack diagnosis in a structure with a welded stiffener. Sensors 2016, 16, 1511. [Google Scholar] [CrossRef] [PubMed]

- Qiu, L.; Yuan, S.; Bao, Q.; Mei, H.; Ren, Y. Crack propagation monitoring in a full-scale aircraft fatigue test based on guided wave-Gaussian mixture model. Smart Mater. Struct. 2016, 25, 055048. [Google Scholar] [CrossRef]

- Hammersley, J.M.; Morton, K.W. Poor man’s Monte Carlo. J. R. Stati. Soc. Ser. B (Methodol.) 1954, 16, 23–38. [Google Scholar] [CrossRef]

- Bolić, M.; Djurić, P.M.; Hong, S. Resampling algorithms for particle filters: A computational complexity perspective. EURASIP J. Appl. Signal Process. 2004, 15, 2267–2277. [Google Scholar] [CrossRef]

- Beadle, E.R.; Djuric, P.M. A fast-weighted Bayesian bootstrap filter for nonlinear model state estimation. IEEE Trans. Aerosp. Electr. Syst. 1997, 33, 338–343. [Google Scholar] [CrossRef]

- Lenstra, J.H.W. Integer programming with a fixed number of variables. Math. Oper. Res. 1983, 8, 538–548. [Google Scholar] [CrossRef]

- Boljanović, S.; Maksimović, S. Fatigue crack growth modeling of attachment lugs. Int. J. Fatigue 2014, 58, 66–74. [Google Scholar] [CrossRef]

- Qiu, L.; Yuan, S.; Wang, Q.; Sun, Y.; Yang, W. Design and experiment of PZT network-based structural health monitoring scanning system. Chin. J. Aeronaut. 2009, 22, 505–512. [Google Scholar]

| Specimen | CT2 | CT 3 | CT 4 | CT 5 | CT6 | Mean | Variance |

|---|---|---|---|---|---|---|---|

| logC0 | −7.7759 | −7.5975 | −7.3793 | −7.3684 | −7.9209 | −7.6084 | 0.2172 |

| m | 1.0083 | 0.8222 | 0.6144 | 0.6386 | 1.1163 | 0.8400 | 0.1982 |

| Specimen | CT2 | CT3 | CT4 | CT5 | CT6 | Mean | Variance |

|---|---|---|---|---|---|---|---|

| logC | −21.5201 | −21.1103 | −19.4788 | −19.3082 | −25.0831 | −21.3001 | −21.5201 |

| m | 11.1345 | 10.7800 | 9.5322 | 9.4383 | 13.7625 | 10.9295 | 11.1345 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Gao, P. Lamb Wave-Minimum Sampling Variance Particle Filter-Based Fatigue Crack Prognosis. Sensors 2019, 19, 1070. https://doi.org/10.3390/s19051070

Yang W, Gao P. Lamb Wave-Minimum Sampling Variance Particle Filter-Based Fatigue Crack Prognosis. Sensors. 2019; 19(5):1070. https://doi.org/10.3390/s19051070

Chicago/Turabian StyleYang, Weibo, and Peiwei Gao. 2019. "Lamb Wave-Minimum Sampling Variance Particle Filter-Based Fatigue Crack Prognosis" Sensors 19, no. 5: 1070. https://doi.org/10.3390/s19051070

APA StyleYang, W., & Gao, P. (2019). Lamb Wave-Minimum Sampling Variance Particle Filter-Based Fatigue Crack Prognosis. Sensors, 19(5), 1070. https://doi.org/10.3390/s19051070