A Short Review on the Role of the Metal-Graphene Hybrid Nanostructure in Promoting the Localized Surface Plasmon Resonance Sensor Performance

Abstract

1. Introduction

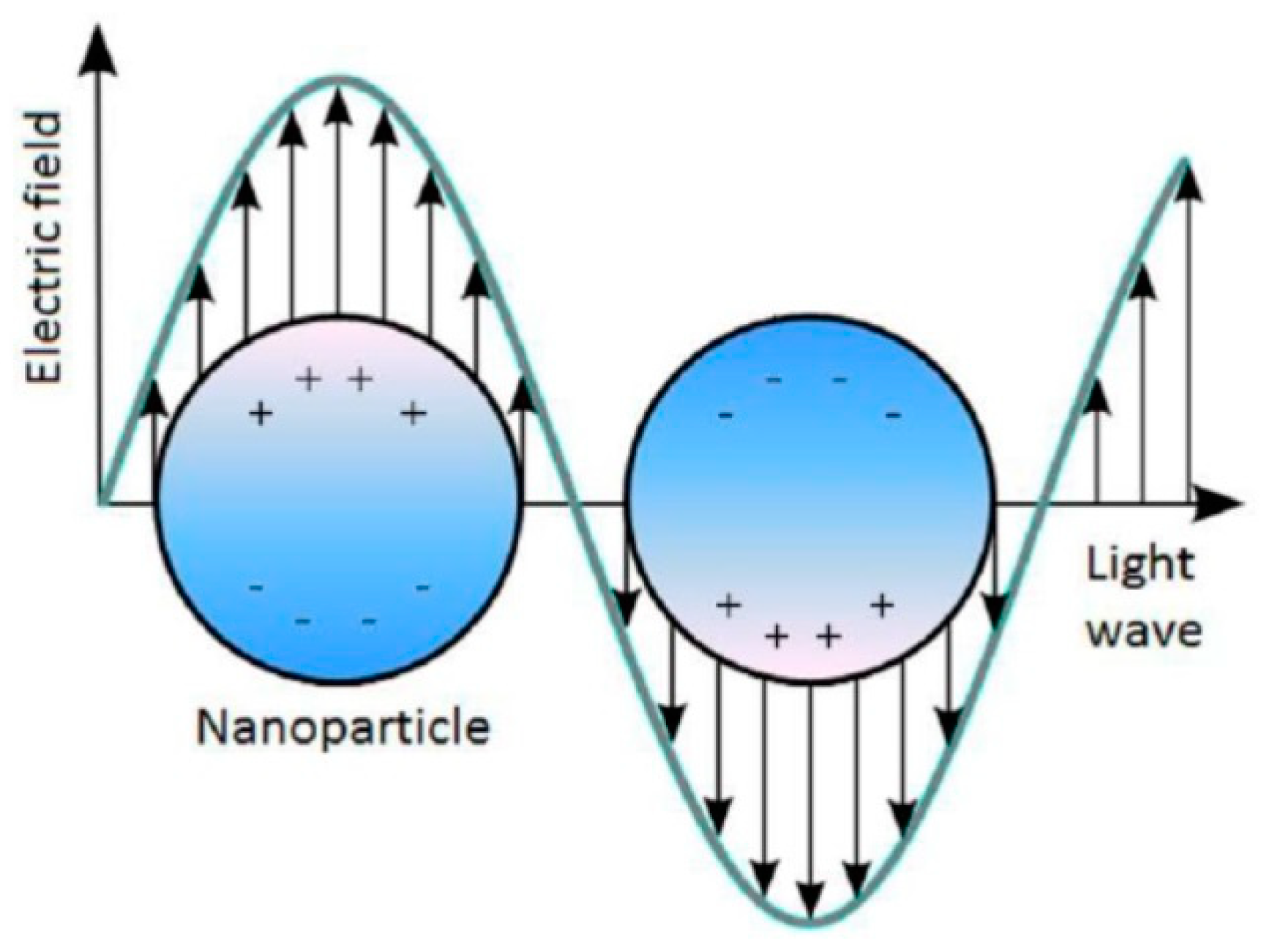

2. Localized Surface Plasmon Resonance Sensor

3. Plasmonic Material

4. Different Approaches Used to Enhance LSPR Sensor Performance

5. Metal-Graphene Hybrid LSPR Sensor

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Homola, J. Surface Plasmon Resonance Sensors for Detection of Chemical and Biological Species. Chem. Rev. 2008, 108, 462–493. [Google Scholar] [CrossRef] [PubMed]

- Brolo, A.G. Plasmonics for Future Biosensors. Nat. Photonics 2012, 6, 709–713. [Google Scholar] [CrossRef]

- Liang, Y.; Lu, M.; Chu, S.; Li, L.; Peng, W. Tunable Plasmonic Resonances in the Hexagonal Nanoarrays of Annular Aperture for Biosensing. Plasmonics 2016, 11, 205–212. [Google Scholar] [CrossRef]

- Toma, M.; Cho, K.; Wood, J.B.; Corn, R.M. Gold Nanoring Arrays for Near Infrared Plasmonic Biosensing. Plasmonics 2014, 9, 765–772. [Google Scholar] [CrossRef]

- Mie, G. Articles on the Optical Characteristics of Turbid Tubes, especially Colloidal Metal Solutions. Ann. Phys. 1908, 25, 377–445. [Google Scholar] [CrossRef]

- Anker, J.N.; Hall, W.P.; Lyandres, O.; Shah, N.C.; Zhao, J.; Van Duyne, R.P. Biosensing with Plasmonic Nanosensors. Nat. Mter. 2008, 7, 442–453. [Google Scholar] [CrossRef] [PubMed]

- Mayer, K.M.; Hafner, J.H. Localized Surface Plasmon Resonance Sensors. Chem. Rev. 2011, 111, 3828–3857. [Google Scholar] [CrossRef]

- Sherry, L.J.; Chang, S.; Schatz, G.C.; Van Duyne, R.P.; Wiley, B.J.; Xia, Y. Localized Surface Plasmon Resonance Spectroscopy of Single Silver Nanocubes. Nano Lett. 2005, 5, 2034–2038. [Google Scholar] [CrossRef]

- Bukasov, R.; Shumaker-Parry, J.S. Highly Tunable Infrared Extinction Properties of Gold Nanocrescents. Nano Lett. 2007, 7, 1113–1118. [Google Scholar] [CrossRef]

- Wang, H.; Brandl, D.W.; Le, F.; Nordlander, P.; Halas, N.J. Nanorice: A Hybrid Plasmonic Nanostructure. Nano Lett. 2006, 6, 827–832. [Google Scholar] [CrossRef]

- West, P.R.; Ishii, S.; Naik, G.V.; Emani, N.K.; Shalaev, V.M.; Boltasseva, A. Searching for Better Plasmonic Materials. Laser Photonics Rev. 2010, 4, 795–808. [Google Scholar] [CrossRef]

- Wu, B.; Mathews, N.; Sum, T. Plasmonic Organic Solar Cells: Charge Generation and Recombination; Springer: Singapore, 2016. [Google Scholar]

- Sönnichsen, C.; Franzl, T.; Wilk, T.; von Plessen, G.; Feldmann, J.; Wilson, O.; Mulvaney, P. Drastic Reduction of Plasmon Damping in Gold Nanorods. Phys. Rev. Lett. 2002, 88, 077402. [Google Scholar] [CrossRef] [PubMed]

- Dmitriev, A. Nanoplasmonic Sensors; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Enoch, S.; Bonod, N. Plasmonics: From Basics to Advanced Topics; Springer: Berlin, Germany, 2012. [Google Scholar]

- Dieringer, J.A.; McFarland, A.D.; Shah, N.C.; Stuart, D.A.; Whitney, A.V.; Yonzon, C.R.; Young, M.A.; Zhang, X.; Van Duyne, R.P. Introductory Lecture Surface Enhanced Raman Spectroscopy: New Materials, Concepts, Characterization Tools, and Applications. Faraday Discuss. 2006, 132, 9–26. [Google Scholar] [CrossRef] [PubMed]

- Hammond, J.L.; Bhalla, N.; Rafiee, S.D.; Estrela, P. Localized Surface Plasmon Resonance as a Biosensing Platform for Developing Countries. Biosensors 2014, 4, 172–188. [Google Scholar] [CrossRef] [PubMed]

- Link, S.; El-Sayed, M.A. Shape and Size Dependence of Radiative, Non-Radiative and Photothermal Properties of Gold Nanocrystals. Int. Rev. Phys. Chem. 2000, 19, 409–453. [Google Scholar] [CrossRef]

- Meier, M.; Wokaun, A. Enhanced Fields on Large Metal Particles: Dynamic Depolarization. Opt. Lett. 1983, 8, 581–583. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Noguez, C. Plasmonic Optical Properties and Applications of Metal Nanostructures. Plasmonics 2008, 3, 127–150. [Google Scholar] [CrossRef]

- Krenn, J.; Schider, G.; Rechberger, W.; Lamprecht, B.; Leitner, A.; Aussenegg, F.; Weeber, J. Design of Multipolar Plasmon Excitations in Silver Nanoparticles. Appl. Phys. Lett. 2000, 77, 3379–3381. [Google Scholar] [CrossRef]

- Shuford, K.L.; Ratner, M.A.; Schatz, G.C. Multipolar Excitation in Triangular Nanoprisms. J. Chem. Phys. 2005, 123, 114713. [Google Scholar] [CrossRef]

- Wei, H.; Reyes–Coronado, A.; Nordlander, P.; Aizpurua, J.; Xu, H. Multipolar Plasmon Resonances in Individual Ag Nanorice. ACS Nano 2010, 4, 2649–2654. [Google Scholar] [CrossRef]

- Alharbi, R.; Irannejad, M.; Yavuz, M. Au–Graphene Hybrid Plasmonic Nanostructure Sensor Based on Intensity Shift. Sensors 2017, 17, 191. [Google Scholar] [CrossRef] [PubMed]

- Alharbi, R.; Irannejad, M.; Yavuz, M. Gold-Graphene Core-Shell Nanostructure Surface Plasmon Sensors. Plasmonics 2017, 12, 783–794. [Google Scholar] [CrossRef]

- Miller, M.M.; Lazarides, A.A. Sensitivity of Metal Nanoparticle Surface Plasmon Resonance to the Dielectric Environment. J. Phys. Chem. B 2005, 109, 21556–21565. [Google Scholar] [CrossRef] [PubMed]

- Johnson, P.B.; Christy, R. Optical Constants of the Noble Metals. Phys. Rev. B 1972, 6, 4370. [Google Scholar] [CrossRef]

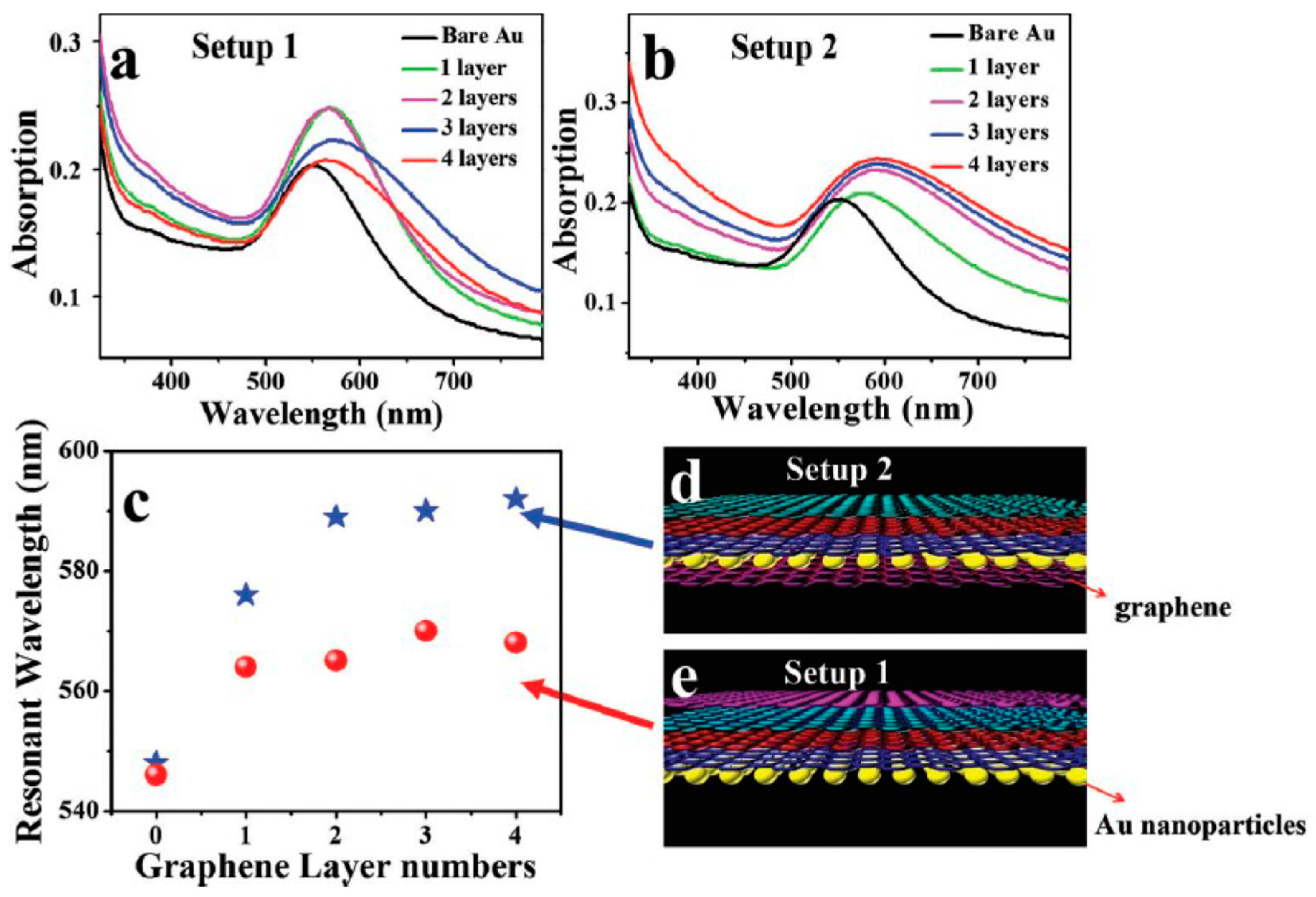

- Maurer, T.; Nicolas, R.; Lévêque, G.; Subramanian, P.; Proust, J.; Béal, J.; Schuermans, S.; Vilcot, J.; Herro, Z.; Kazan, M. Enhancing LSPR Sensitivity of Au Gratings through Graphene Coupling to Au Film. Plasmonics 2014, 9, 507–512. [Google Scholar] [CrossRef]

- Tobiška, P.; Hugon, O.; Trouillet, A.; Gagnaire, H. An Integrated Optic Hydrogen Sensor Based on SPR on Palladium. Sens. Actuators B Chem. 2001, 74, 168–172. [Google Scholar] [CrossRef]

- Baldelli, S.; Eppler, A.S.; Anderson, E.; Shen, Y.; Somorjai, G.A. Surface Enhanced Sum Frequency Generation of Carbon Monoxide Adsorbed on Platinum Nanoparticle Arrays. J. Chem. Phys. 2000, 113, 5432–5438. [Google Scholar] [CrossRef]

- Estevez, M.; Otte, M.A.; Sepulveda, B.; Lechuga, L.M. Trends and Challenges of Refractometric Nanoplasmonic Biosensors: A Review. Anal. Chim. Acta 2014, 806, 55–73. [Google Scholar] [CrossRef]

- Anker, J.N.; Hall, W.P.; Lyandres, O.; Shah, N.C.; Zhao, J.; Van Duyne, R.P. Biosensing with plasmonic nanosensors. In Nanoscience and Technology: A Collection of Reviews from Nature Journals; World Scientific: Singapore, 2010; pp. 308–319. [Google Scholar]

- Luo, X.; Qiu, T.; Lu, W.; Ni, Z. Plasmons in Graphene: Recent Progress and Applications. Mater. Sci. Eng. R Rep. 2013, 74, 351–376. [Google Scholar] [CrossRef]

- Huang, S.; Song, C.; Zhang, G.; Yan, H. Graphene Plasmonics: Physics and Potential Applications. Nanophotonics 2016, 6, 1191–1204. [Google Scholar] [CrossRef]

- Cooper, B.; Ehrenreich, H.; Philipp, H. Optical Properties of Noble Metals. II. Phys. Rev. 1965, 138, A494. [Google Scholar] [CrossRef]

- Ehrenreich, H.; Philipp, H.; Segall, B. Optical Properties of Aluminum. Phys. Rev. 1963, 132, 1918. [Google Scholar] [CrossRef]

- Sun, Y.; Xia, Y. Increased Sensitivity of Surface Plasmon Resonance of Gold Nanoshells Compared to that of Gold Solid Colloids in Response to Environmental Changes. Anal. Chem. 2002, 74, 5297–5305. [Google Scholar] [CrossRef] [PubMed]

- Mock, J.J.; Smith, D.R.; Schultz, S. Local Refractive Index Dependence of Plasmon Resonance Spectra from Individual Nanoparticles. Nano Lett. 2003, 3, 485–491. [Google Scholar] [CrossRef]

- Sepúlveda, B.; Angelomé, P.C.; Lechuga, L.M.; Liz–Marzán, L.M. LSPR–Based Nanobiosensors. Nano Today 2009, 4, 244–251. [Google Scholar] [CrossRef]

- Guo, L.; Yin, Y.; Huang, R.; Qiu, B.; Lin, Z.; Yang, H.; Li, J.; Chen, G. Enantioselective Analysis of Melagatran Via an LSPR Biosensor Integrated with a Microfluidic Chip. Lab Chip 2012, 12, 3901–3906. [Google Scholar] [CrossRef]

- Sekhon, J.S.; Verma, S. Refractive Index Sensitivity Analysis of Ag, Au, and Cu Nanoparticles. Plasmonics 2011, 6, 311–317. [Google Scholar] [CrossRef]

- Chan, G.H.; Zhao, J.; Schatz, G.C.; Van Duyne, R.P. Localized Surface Plasmon Resonance Spectroscopy of Triangular Aluminum Nanoparticles. J. Phys. Chem. C 2008, 112, 13958–13963. [Google Scholar] [CrossRef]

- Park, Y.R.; Liu, N.; Lee, C.J. Photoluminescence Enhancement from Hybrid Structures of Metallic Single–Walled Carbon Nanotube/ZnO Films. Curr. Appl. Phys. 2013, 13, 2026–2032. [Google Scholar] [CrossRef]

- Link, S.; El–Sayed, M.A. Size and Temperature Dependence of the Plasmon Absorption of Colloidal Gold Nanoparticles. J. Phys. Chem. B 1999, 103, 4212–4217. [Google Scholar] [CrossRef]

- Sun, Y.; Xia, Y. Synthesis of Gold Nanoshells and their use in Sensing Applications. MRS Online Proc. Libr. Arch. 2003, 776. [Google Scholar] [CrossRef]

- Mock, J.; Barbic, M.; Smith, D.; Schultz, D.; Schultz, S. Shape Effects in Plasmon Resonance of Individual Colloidal Silver Nanoparticles. J. Chem. Phys. 2002, 116, 6755–6759. [Google Scholar] [CrossRef]

- Hanarp, P.; Käll, M.; Sutherland, D.S. Optical Properties of Short Range Ordered Arrays of Nanometer Gold Disks Prepared by Colloidal Lithography. J. Chem. Phys. B 2003, 107, 5768–5772. [Google Scholar] [CrossRef]

- Ross, M.B.; Mirkin, C.A.; Schatz, G.C. Optical Properties of One–, Two–, and Three–Dimensional Arrays of Plasmonic Nanostructures. T J. Chem. Phys. C 2016, 120, 816–830. [Google Scholar] [CrossRef]

- Martinsson, E.; Sepulveda, B.; Chen, P.; Elfwing, A.; Liedberg, B.; Aili, D. Optimizing the Refractive Index Sensitivity of Plasmonically Coupled Gold Nanoparticles. Plasmonics 2014, 9, 773–780. [Google Scholar] [CrossRef]

- Jain, P.K.; Lee, K.S.; El–Sayed, I.H.; El-Sayed, M.A. Calculated Absorption and Scattering Properties of Gold Nanoparticles of Different Size, Shape, and Composition: Applications in Biological Imaging and Biomedicine. J. Chem. Phys. B 2006, 110, 7238–7248. [Google Scholar] [CrossRef] [PubMed]

- Chung, T.; Lee, S.; Song, E.Y.; Chun, H.; Lee, B. Plasmonic Nanostructures for Nano–Scale Bio–Sensing. Sensors 2011, 11, 10907–10929. [Google Scholar] [CrossRef] [PubMed]

- Prodan, E.; Radloff, C.; Halas, N.J.; Nordlander, P. A Hybridization Model for the Plasmon Response of Complex Nanostructures. Science 2003, 302, 419–422. [Google Scholar] [CrossRef]

- Teo, S.L.; Lin, V.K.; Marty, R.; Large, N.; Llado, E.A.; Arbouet, A.; Girard, C.; Aizpurua, J.; Tripathy, S.; Mlayah, A. Gold Nanoring Trimers: A Versatile Structure for Infrared Sensing. Opt. Express 2010, 18, 22271–22282. [Google Scholar] [CrossRef]

- Tam, F.; Moran, C.; Halas, N. Geometrical Parameters Controlling Sensitivity of Nanoshell Plasmon Resonances to Changes in Dielectric Environment. J. Chem. Phys. B 2004, 108, 17290–17294. [Google Scholar] [CrossRef]

- McPhillips, J.; Murphy, A.; Jonsson, M.P.; Hendren, W.R.; Atkinson, R.; Höök, F.; Zayats, A.V.; Pollard, R.J. High–Performance Biosensing using Arrays of Plasmonic Nanotubes. ACS Nano 2010, 4, 2210–2216. [Google Scholar] [CrossRef] [PubMed]

- Larsson, E.M.; Alegret, J.; Käll, M.; Sutherland, D.S. Sensing Characteristics of NIR Localized Surface Plasmon Resonances in Gold Nanorings for Application as Ultrasensitive Biosensors. Nano Lett. 2007, 7, 1256–1263. [Google Scholar] [CrossRef] [PubMed]

- McMahon, M.; Lopez, R.; Meyer, H.; Feldman, L.; Haglund, R. Rapid Tarnishing of Silver Nanoparticles in Ambient Laboratory Air. Appl. Phys. B 2005, 80, 915–921. [Google Scholar] [CrossRef]

- Nagpal, P.; Lindquist, N.C.; Oh, S.H.; Norris, D.J. Ultrasmooth Patterned Metals for Plasmonics and Metamaterials. Science 2009, 325, 594–597. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.; Cha, S.; Saito, Y.; Prinz, F.B. Gas–Tight Alumina Films on Nanoporous Substrates through Oxidation of Sputtered Metal Films. Thin Solid Films 2005, 476, 168–173. [Google Scholar] [CrossRef]

- Reed, J.C.; Zhu, H.; Zhu, A.Y.; Li, C.; Cubukcu, E. Graphene–Enabled Silver Nanoantenna Sensors. Nano Lett. 2012, 12, 4090–4094. [Google Scholar] [CrossRef] [PubMed]

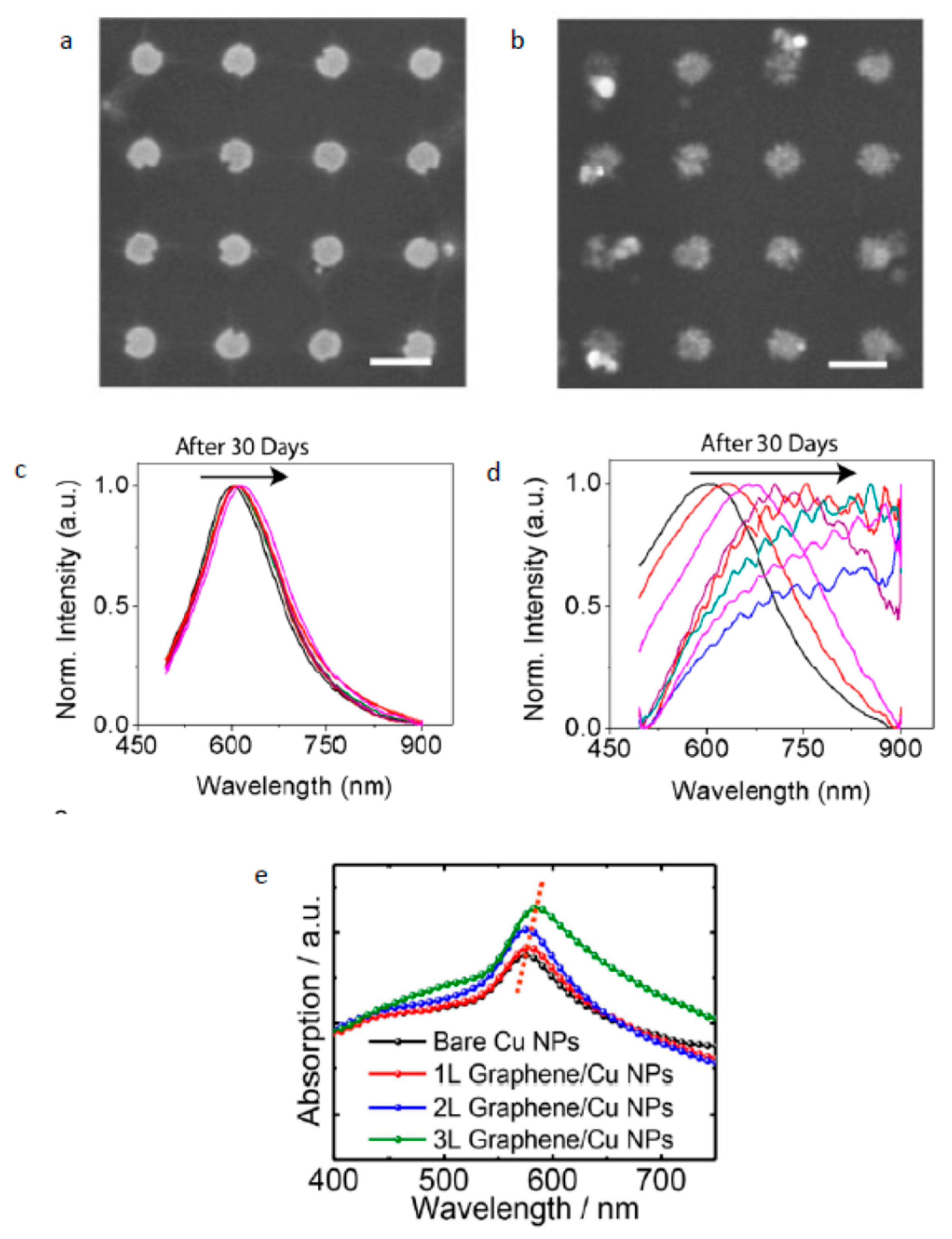

- Li, Y.; Dong, F.; Chen, Y.; Zhang, X.; Wang, L.; Bi, Y.; Tian, Z.; Liu, Y.; Feng, J.; Sun, H. As-Grown Graphene/Copper Nanoparticles Hybrid Nanostructures for Enhanced Intensity and Stability of Surface Plasmon Resonance. Sci. Rep. 2016, 6, 37190. [Google Scholar] [CrossRef] [PubMed]

- Chuang, C.; Aoh, J.; Din, R. Oxidation of Copper Pads and its Influence on the Quality of Au/Cu Bonds during Thermosonic Wire Bonding Process. Microelectron. Reliab. 2006, 46, 449–458. [Google Scholar] [CrossRef]

- Kim, D.; Yoo, S.M.; Park, T.J.; Yoshikawa, H.; Tamiya, E.; Park, J.Y.; Lee, S.Y. Plasmonic Properties of the Multispot Copper–Capped Nanoparticle Array Chip and its Application to Optical Biosensors for Pathogen Detection of Multiplex DNAs. Anal. Chem. 2011, 83, 6215–6222. [Google Scholar] [CrossRef]

- Giovannetti, G.; Khomyakov, P.; Brocks, G.; Karpan, V.v.; Van den Brink, J.; Kelly, P.J. Doping Graphene with Metal Contacts. Phys. Rev. Lett. 2008, 101, 026803. [Google Scholar] [CrossRef]

- Xu, G.; Liu, J.; Wang, Q.; Hui, R.; Chen, Z.; Maroni, V.A.; Wu, J. Plasmonic Graphene Transparent Conductors. Adv. Mater. 2012, 24, OP71–OP76. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Xu, G.; Rochford, C.; Lu, R.; Wu, J.; Edwards, C.M.; Berrie, C.L.; Chen, Z.; Maroni, V.A. Doped Graphene Nanohole Arrays for Flexible Transparent Conductors. Appl. Phys. Lett. 2011, 99, 023111. [Google Scholar] [CrossRef]

- Nan, H.; Chen, Z.; Jiang, J.; Li, J.; Zhao, W.; Ni, Z.; Gu, X.; Xiao, S. The Effect of Graphene on Surface Plasmon Resonance of Metal Nanoparticles. Phys. Chem. Chem. Phys. 2018, 20, 25078–25084. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Li, X.; Wang, J.; Tao, L.; Long, M.; Liang, S.; Ang, L.K.; Shu, C.; Tsang, H.K.; Xu, J. Synergistic Effects of Plasmonics and Electron Trapping in Graphene Short–Wave Infrared Photodetectors with Ultrahigh Responsivity. ACS Nano 2017, 11, 430–437. [Google Scholar] [CrossRef] [PubMed]

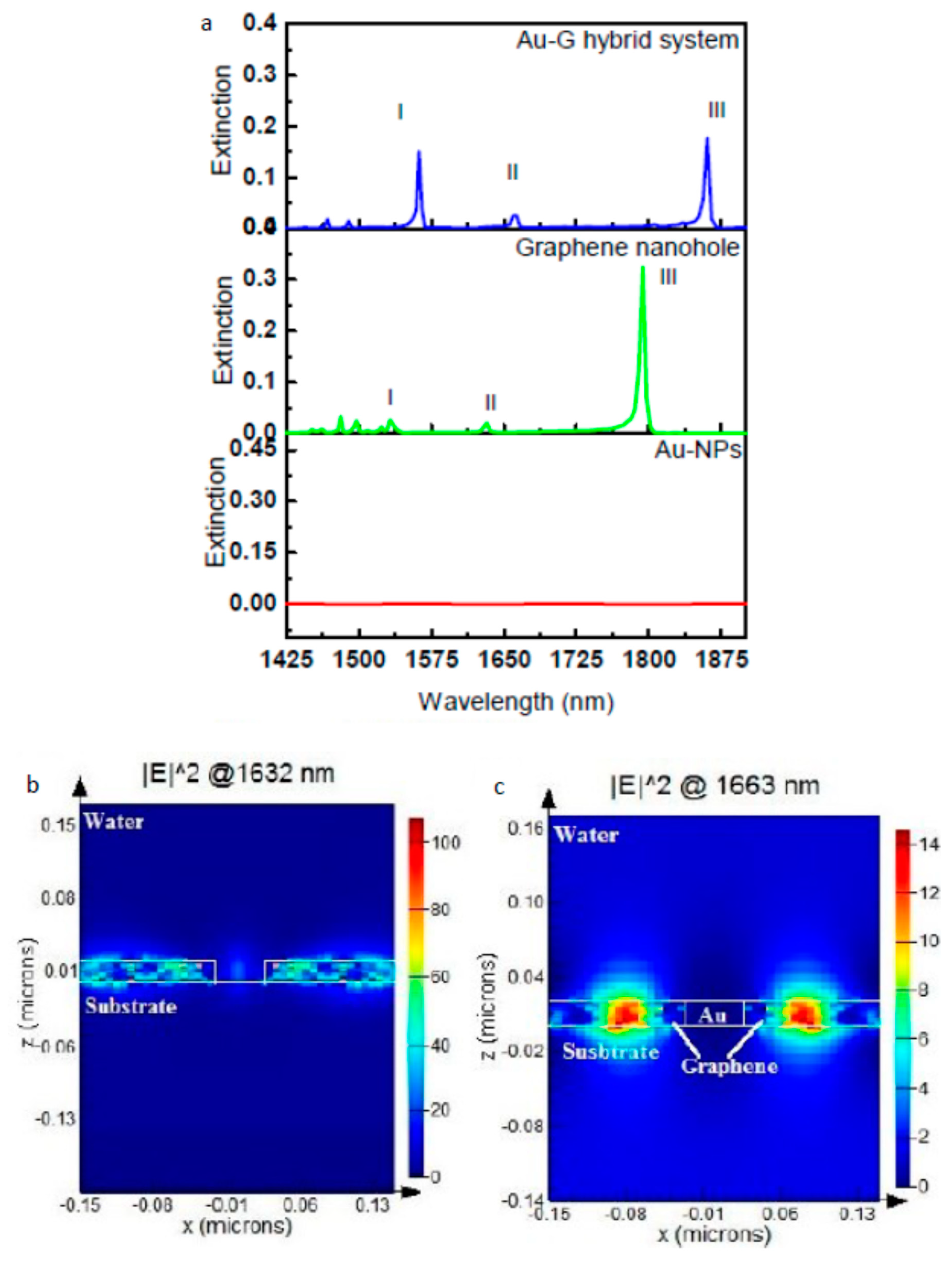

- Wu, Y.; Niu, J.; Danesh, M.; Liu, J.; Chen, Y.; Ke, L.; Qiu, C.; Yang, H. Localized Surface Plasmon Resonance in Graphene Nanomesh with Au Nanostructures. Appl. Phys. Lett. 2016, 109, 041106. [Google Scholar] [CrossRef]

- Lee, S.; hyung Lee, M.; Shin, H.; Choi, D. Control of Density and LSPR of Au Nanoparticles on Graphene. Nanotechnology 2013, 24, 275702. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Zhou, J.; Liu, T.; Tao, Y.; Jiang, R.; Liu, M.; Xiao, G.; Zhu, J.; Zhou, Z.; Wang, X. Plasmonic Gold Mushroom Arrays with Refractive Index Sensing Figures of Merit Approaching the Theoretical Limit. Nat. Commun. 2013, 4, 2381. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alharbi, R.; Irannejad, M.; Yavuz, M. A Short Review on the Role of the Metal-Graphene Hybrid Nanostructure in Promoting the Localized Surface Plasmon Resonance Sensor Performance. Sensors 2019, 19, 862. https://doi.org/10.3390/s19040862

Alharbi R, Irannejad M, Yavuz M. A Short Review on the Role of the Metal-Graphene Hybrid Nanostructure in Promoting the Localized Surface Plasmon Resonance Sensor Performance. Sensors. 2019; 19(4):862. https://doi.org/10.3390/s19040862

Chicago/Turabian StyleAlharbi, Raed, Mehrdad Irannejad, and Mustafa Yavuz. 2019. "A Short Review on the Role of the Metal-Graphene Hybrid Nanostructure in Promoting the Localized Surface Plasmon Resonance Sensor Performance" Sensors 19, no. 4: 862. https://doi.org/10.3390/s19040862

APA StyleAlharbi, R., Irannejad, M., & Yavuz, M. (2019). A Short Review on the Role of the Metal-Graphene Hybrid Nanostructure in Promoting the Localized Surface Plasmon Resonance Sensor Performance. Sensors, 19(4), 862. https://doi.org/10.3390/s19040862