An Internet of Things (IoT) Application on Volcano Monitoring

Abstract

1. Introduction

- The first IoT implementation to measure soil temperature in volcanic areas, usually influenced by extreme weather conditions, high temperatures, and the presence of acid gases.

- Detailed specifications, design considerations, and experimental results for a temperature wireless network. The network suits required and desirable features for volcanic monitoring such as real-time data acquisition, long-range communications, scalability and easy deployment, and also IoT requirements including low cost, low power, long-term service, and high reliability.

- An extraordinarily energy efficient integration with a specifically design communication protocol.

- A configuration-free, scalable, compact solution for a fast and effective deployment even in the case of volcanic unrest.

2. IoT for Volcano Monitoring

- Endpoints and base stations with LoRa-enabled devices are usually more inexpensive than with Sigfox. This is primarily because is possible to use the same radio device for a receiver on the base and at the endpoint stations

- When true bidirectionality is needed, LoRa is likely the better option because of the symmetric link

- LoRa allows to set up and manage the wireless network at a deeper level than Sigfox. The latter provides an API to interact with the radio module, but no configuration is possible

- LoRa has no data limit to be sent per day, and it is not necessary to pay for a renewable subscription plan for each device

2.1. LoRa for the Thermometers Network

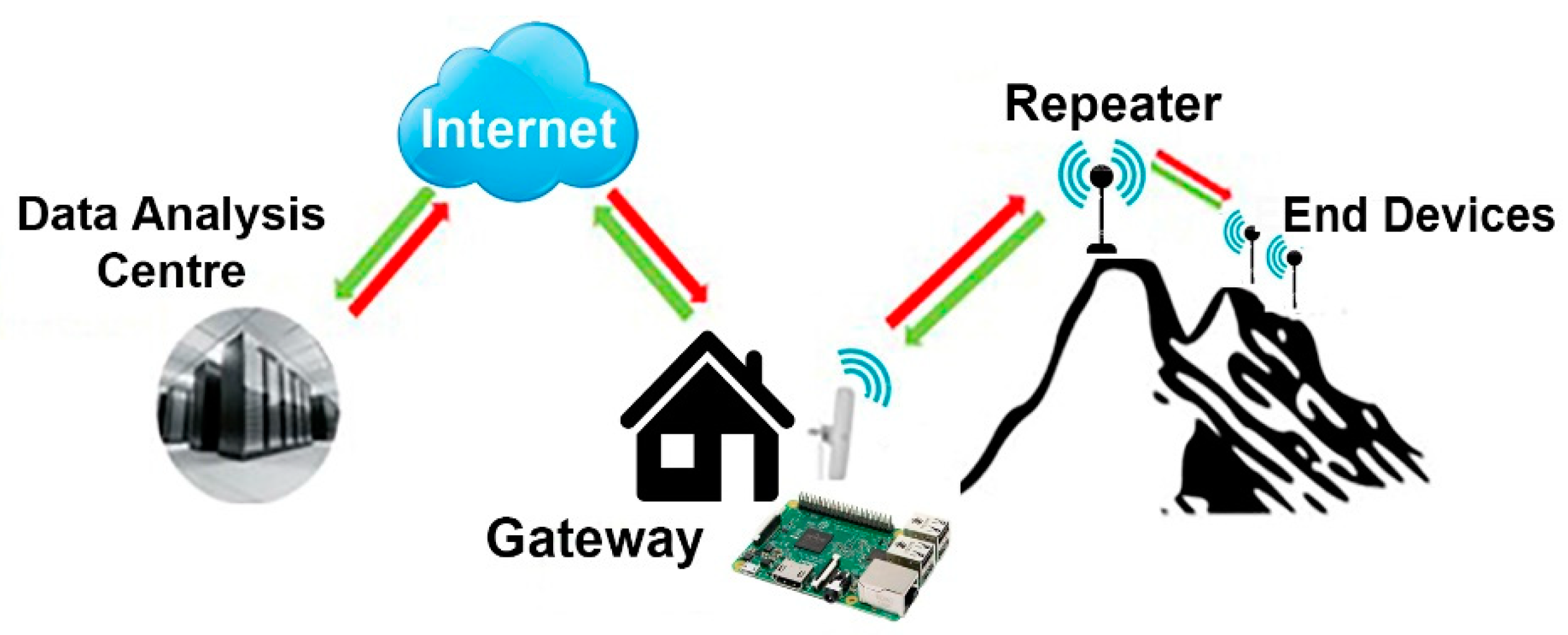

3. IoT Thermometers Network

3.1. Hardware

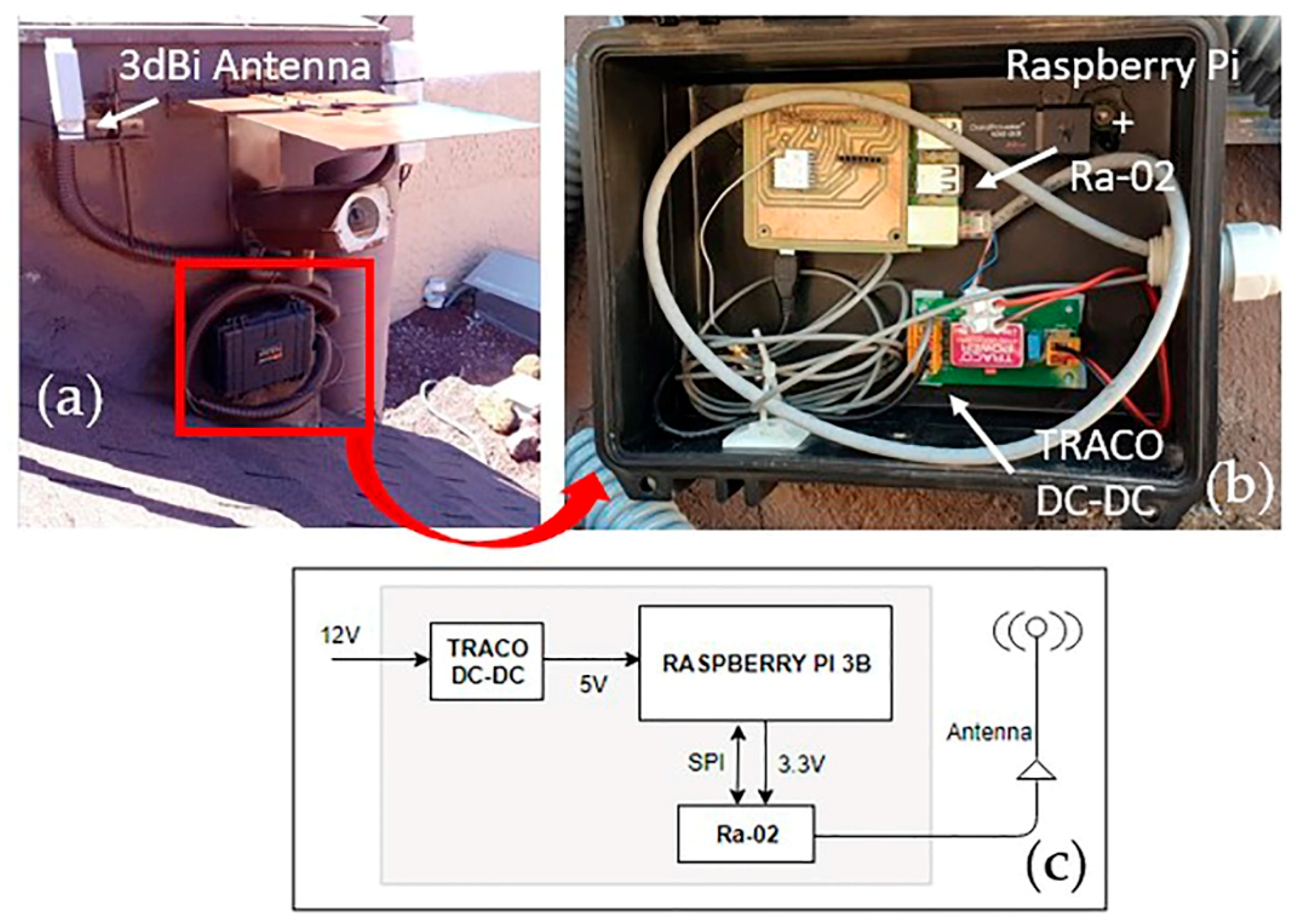

3.1.1. The Gateway

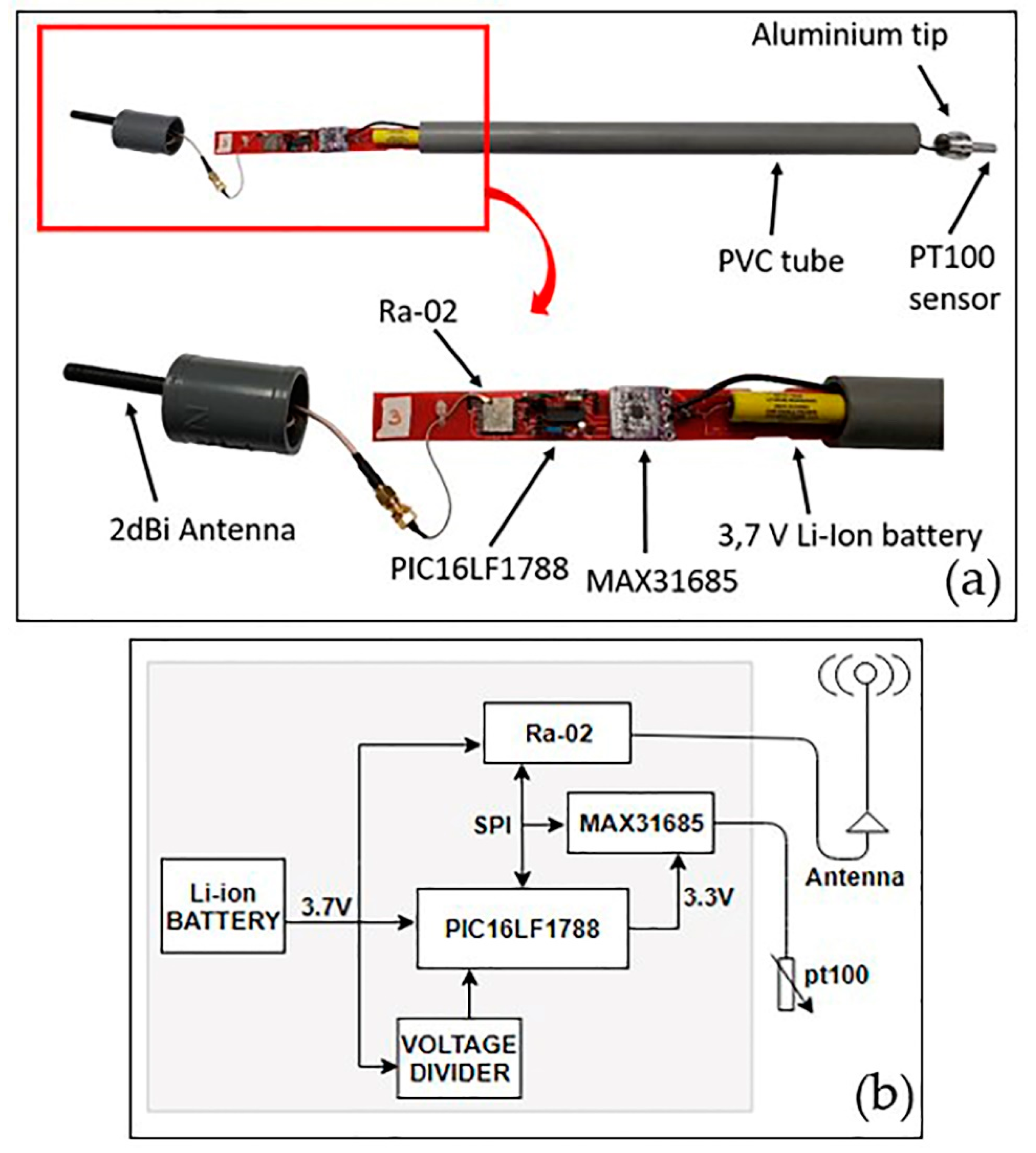

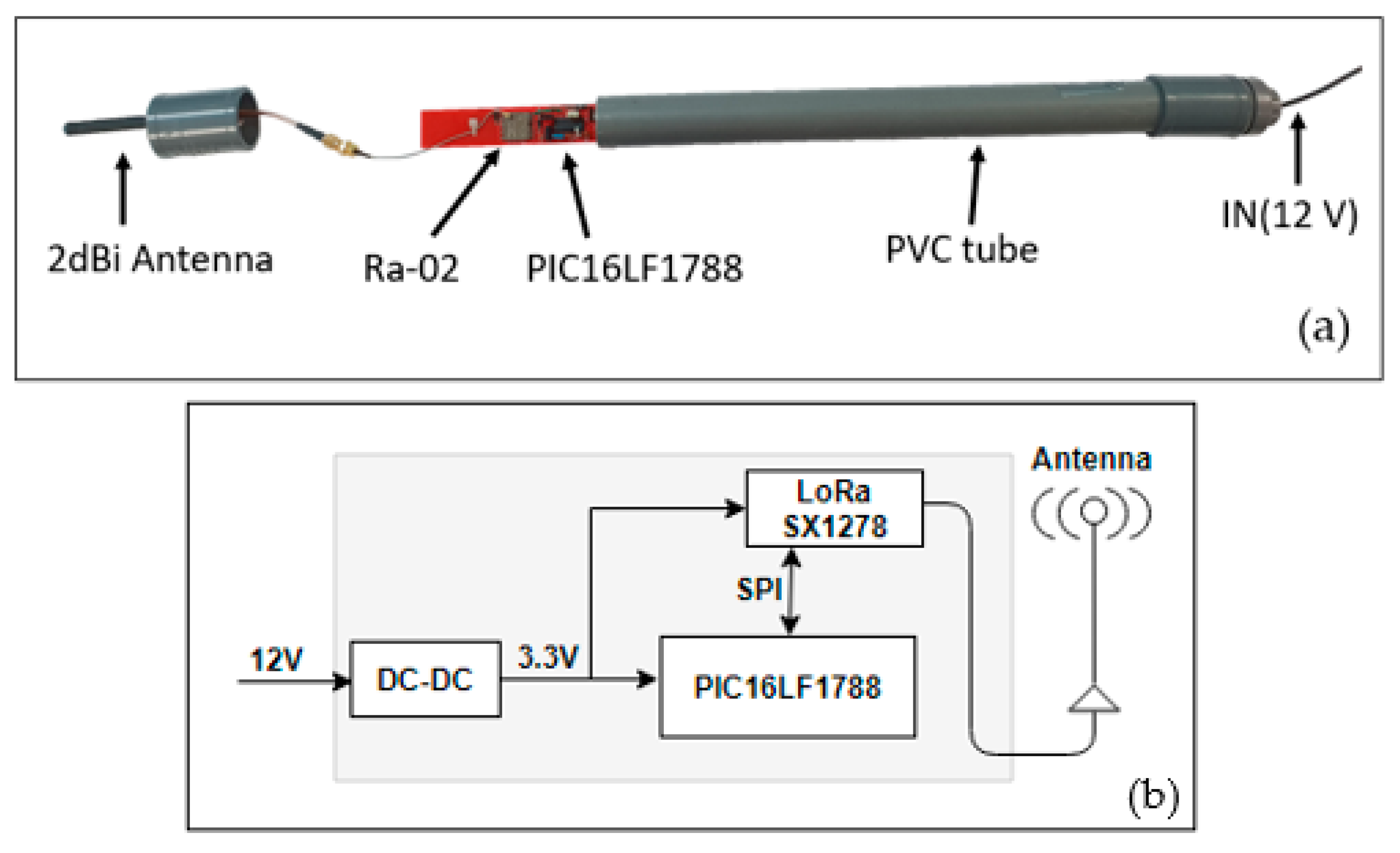

3.1.2. End Devices

Control Unit

Temperature Measurement

Power Supply

3.1.3. Repeater

3.2. Software

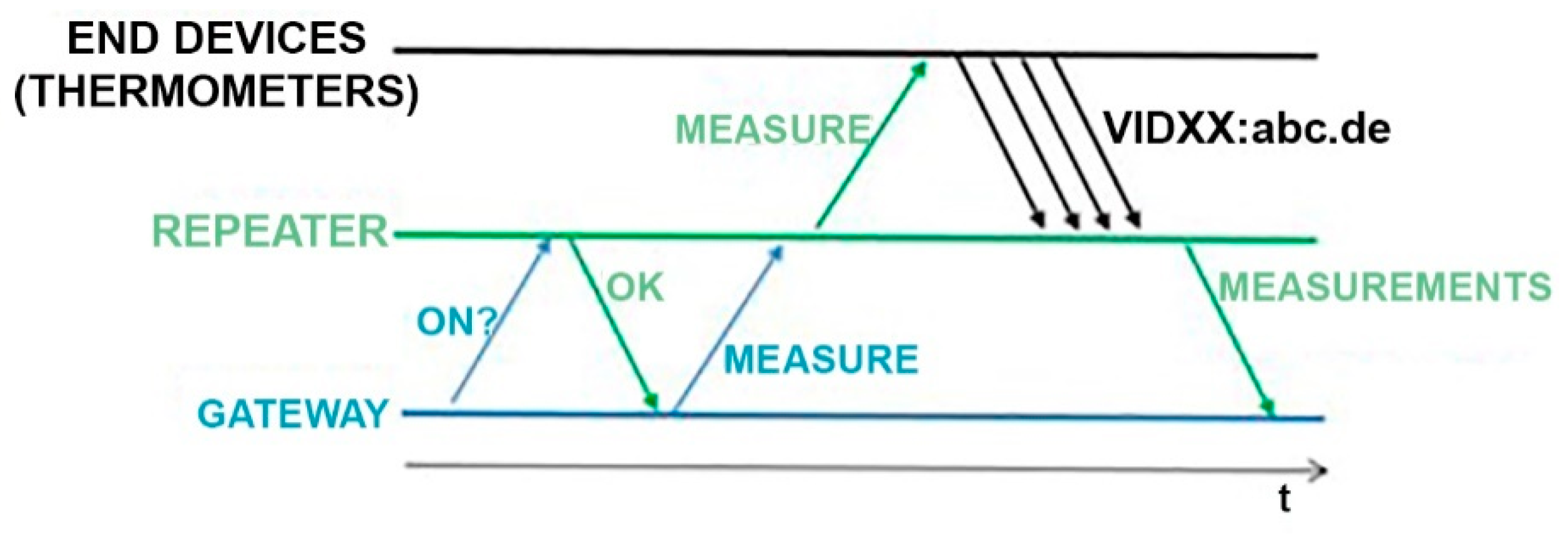

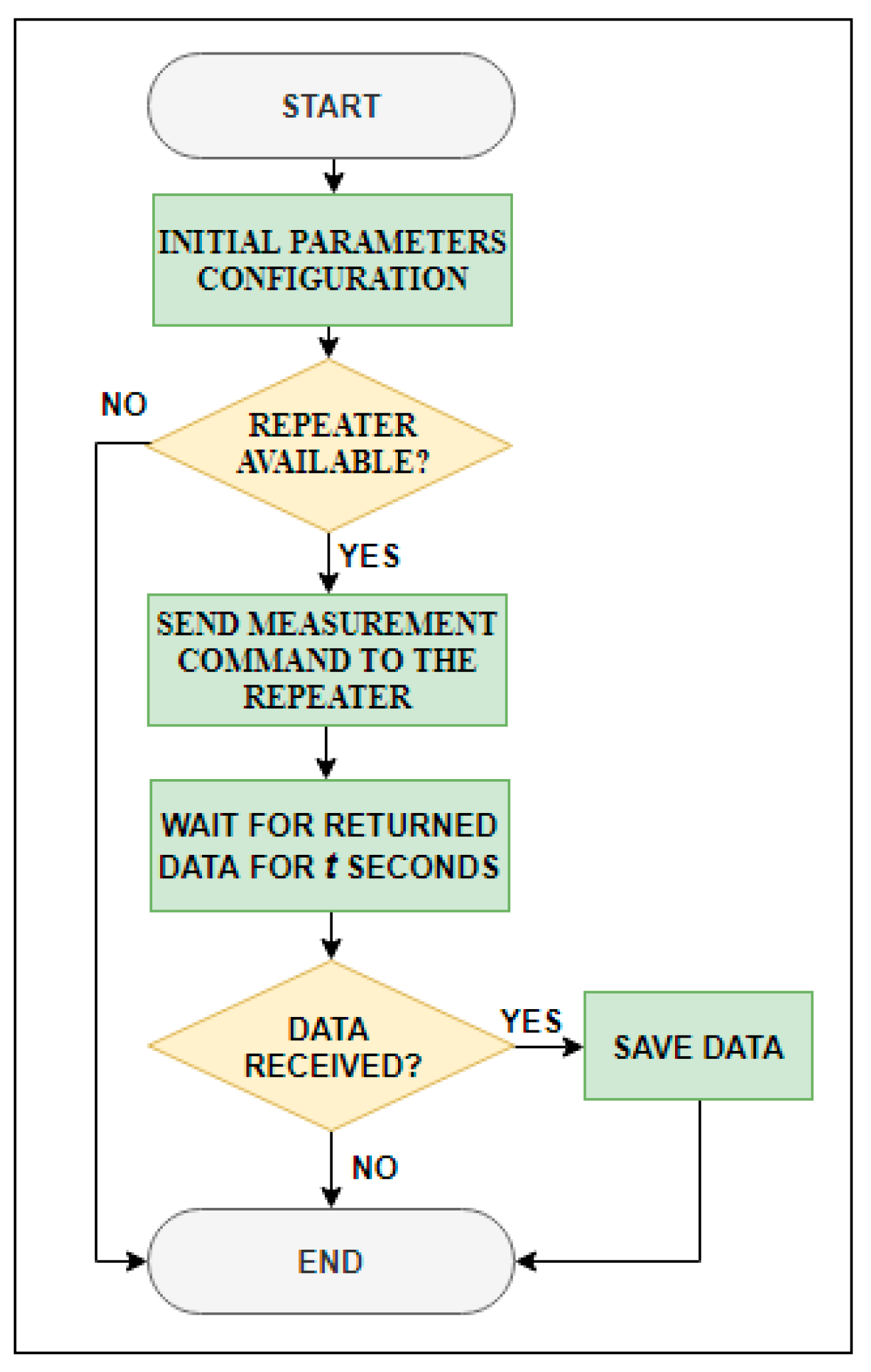

3.2.1. Gateway Software

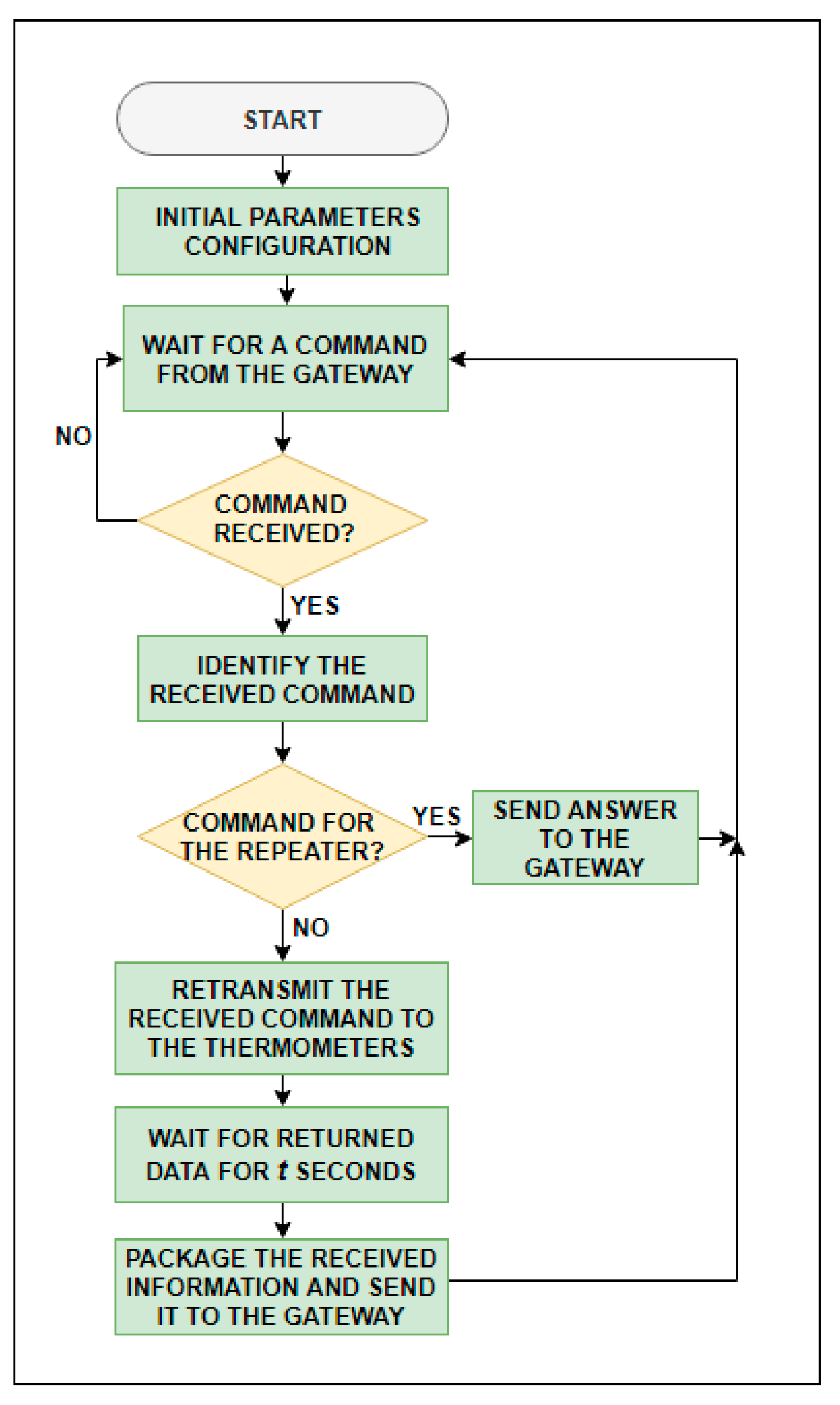

3.2.2. Repeater Software

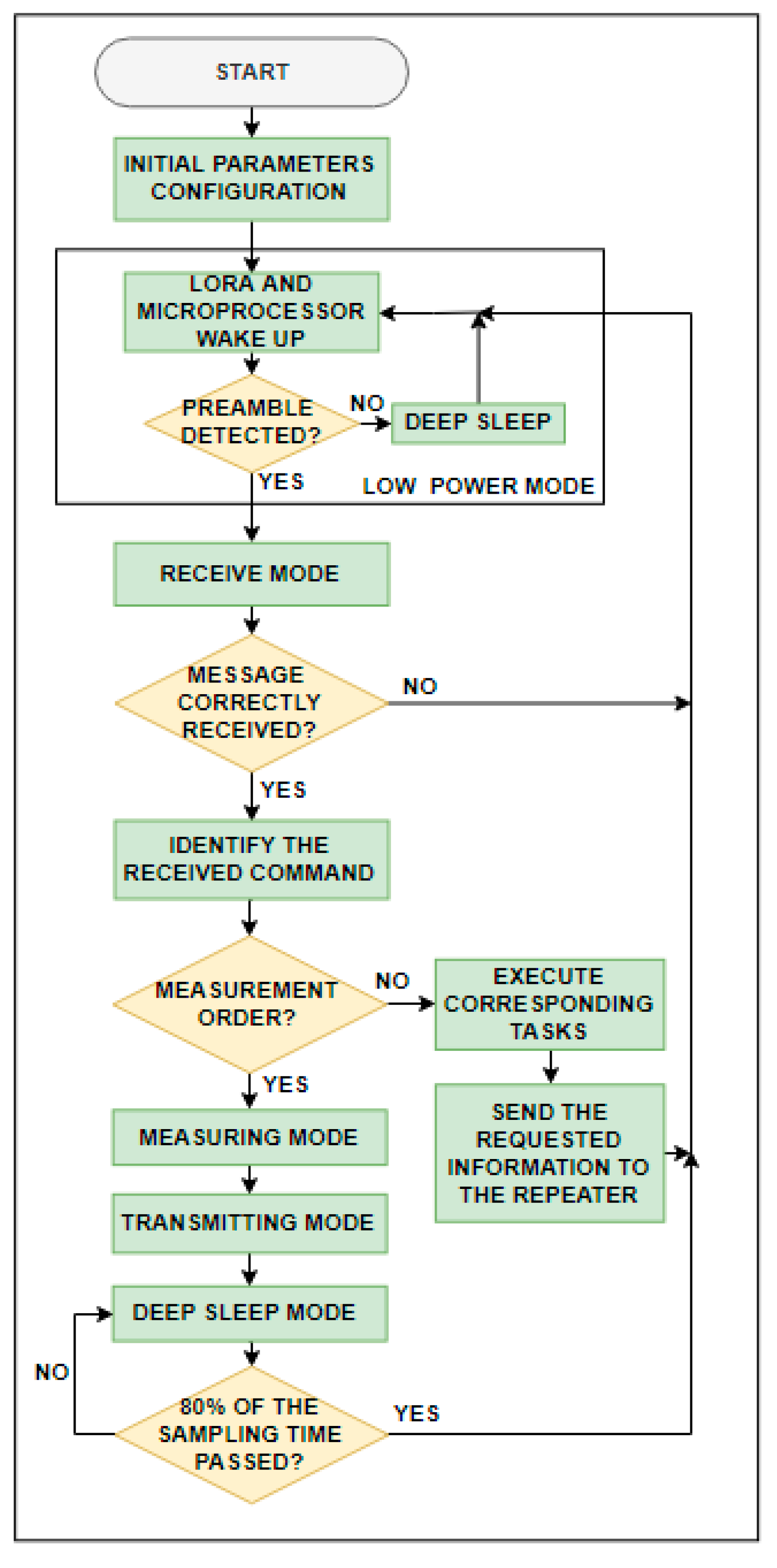

3.2.3. End Devices Software

3.2.4. Server Software

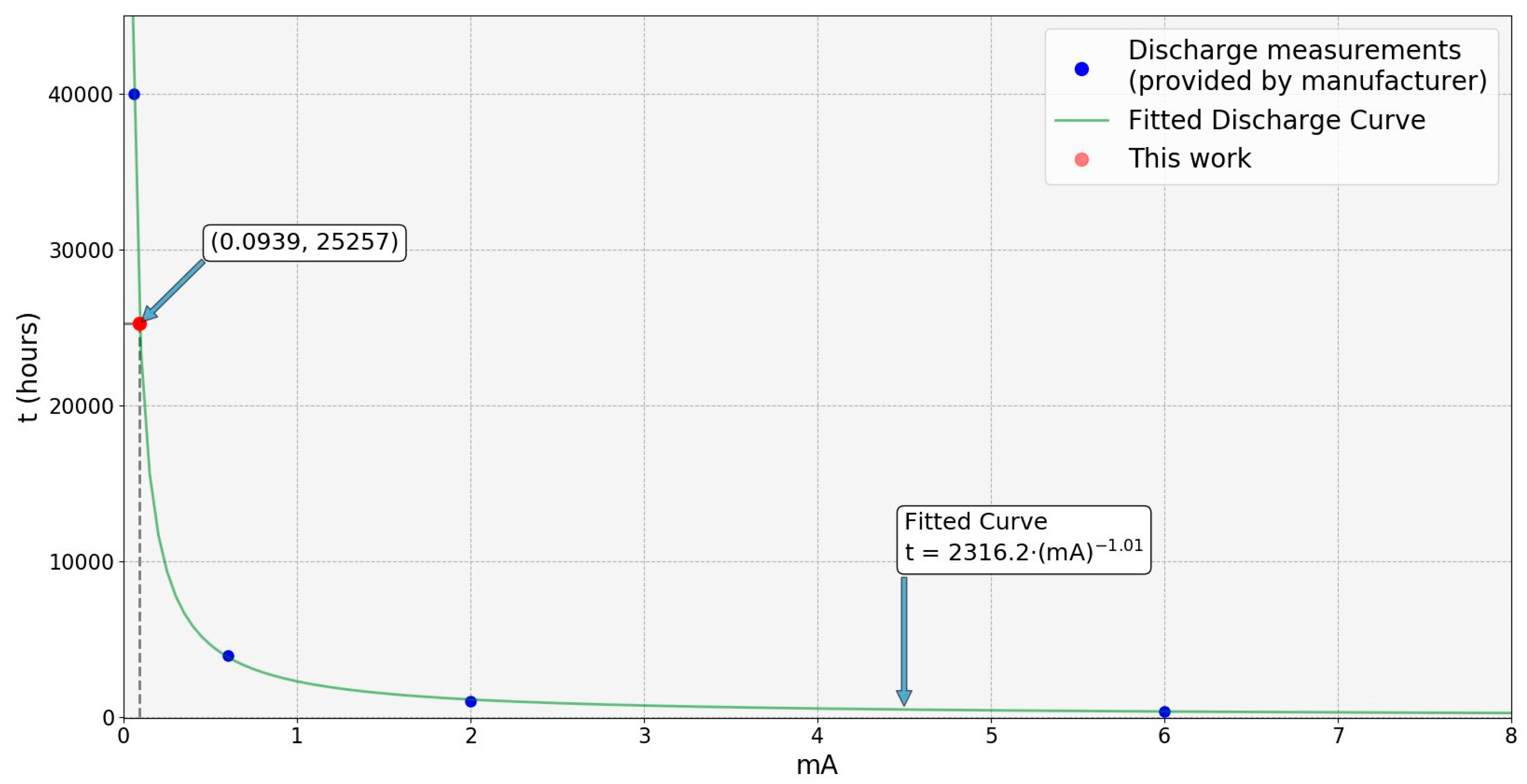

3.3. Power Consumption

3.4. Price

4. Results and Discussion

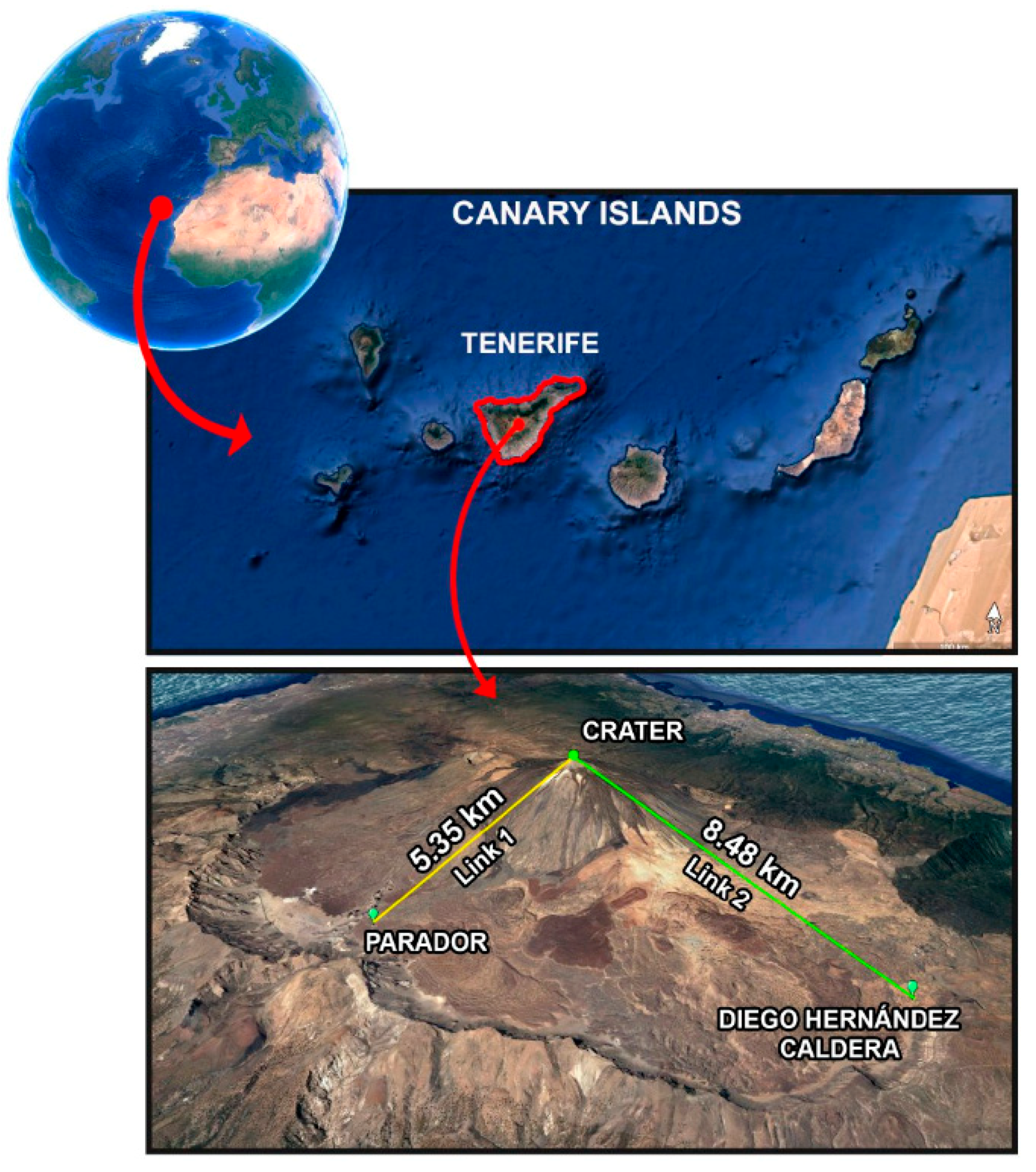

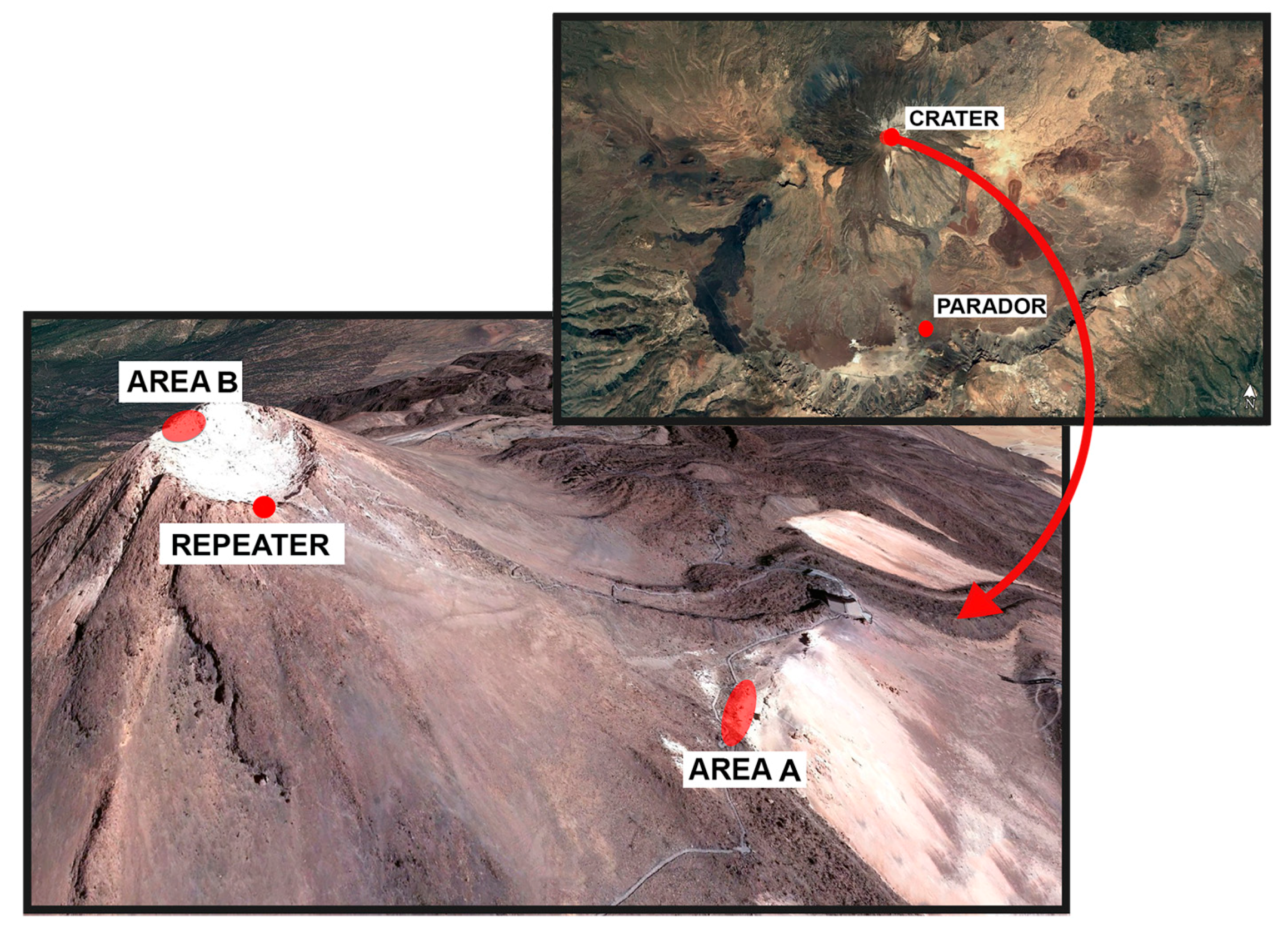

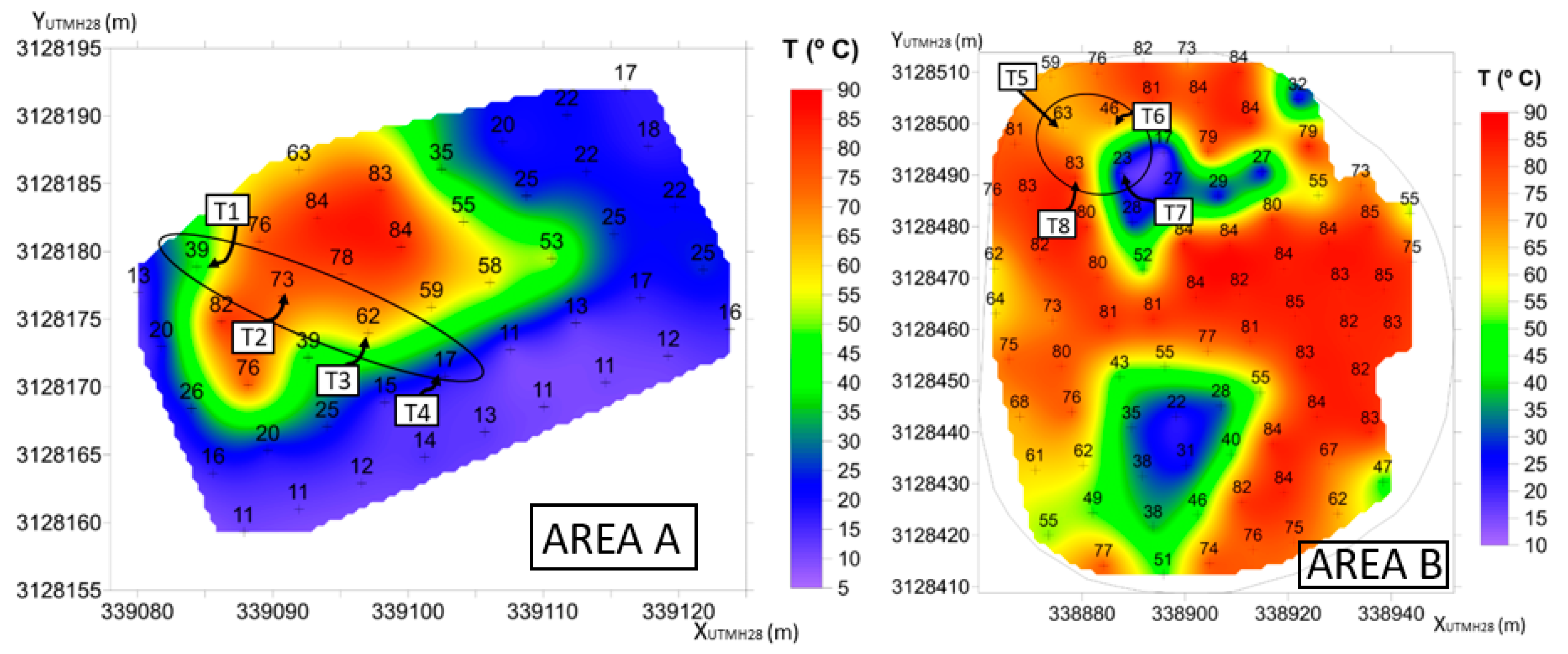

4.1. Site Selection

4.2. Network Configuration

- CF = 433 MHz, the license-free band (Europe) with the greatest range

- TP = 10 dBm (10 mW effectiv radiated power), the maximum transmission power in order to ensure that messages reach the receiver

- CR = 4/5 because there is not too much interference, thus guaranteeing a shorter time on air (see Section 2.1)

- BW = 125 kHz to achieve sufficient sensitivity for the detection

- For SF, the lowest possible value that allows a correct operation of the network has been chosen. A low SF allows for less time on air and therefore less consumption (see Section 2.1). There are several SF configurations within the network: SF = 7 for the repeater–thermometer link, and SF = 8 for the gateway–repeater link because it is longer than the other

- The preamble length is adapted to two different situations. As previously mentioned, at least 4.25 symbols are needed for the detection. In cases where the receiver is not in deep sleep mode, a short preamble will be enough, as in the case of the gateway–repeater communication in both directions, and also when the thermometers talk to the repeater (see Section 3.2.1 and 3.2.2). In this case, the chosen preamble length is 12 symbols. When the repeater communicates with the thermometers, the latest are in low power mode (see Section 3.2.3). Taking into account that one cycle of the low power mode lasts 1000 milliseconds (980 ms in deep sleep mode and 20 ms listening) and the following equation [74]:where Tsymbol stands for the symbol duration in seconds or the time taken to send 2SFchips and BW stands for the bandwidth. For SF = 7 and BW = 125 kHz, Tsymbol = 1.024 milliseconds. Therefore, a preamble length of 1100 symbols has been chosen so that even in the most unfavorable case (preamble transmission starts when the thermometer goes to deep sleep mode), the detection occurs.

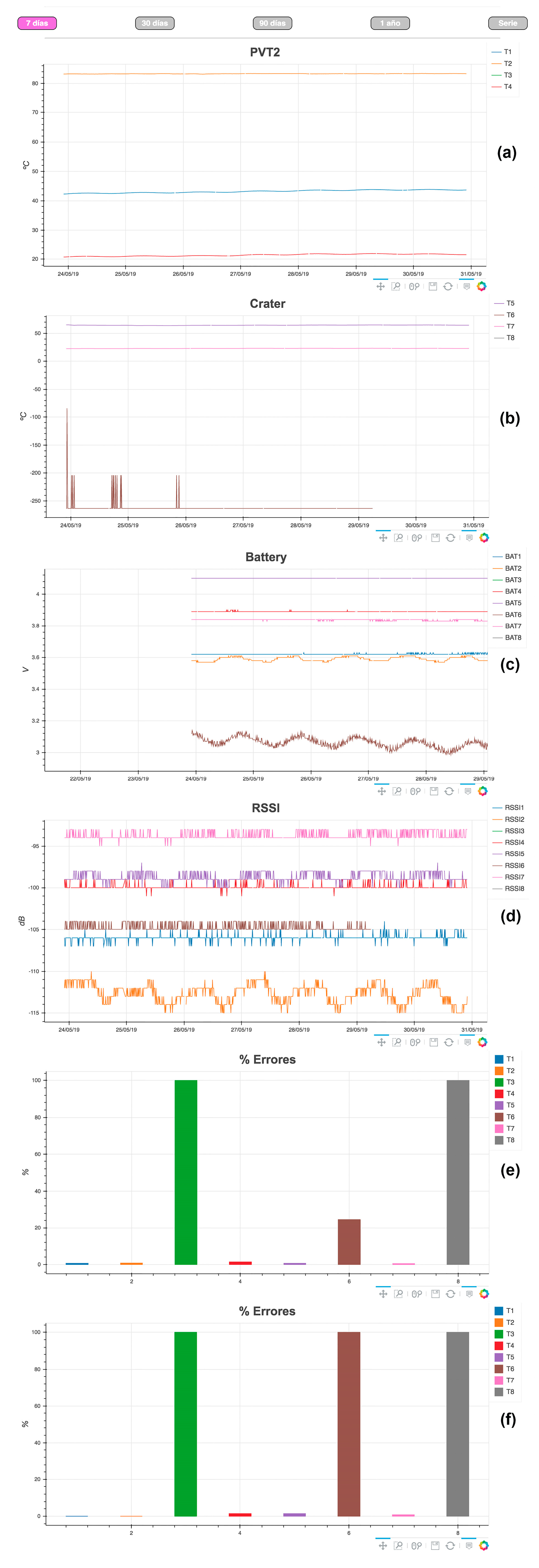

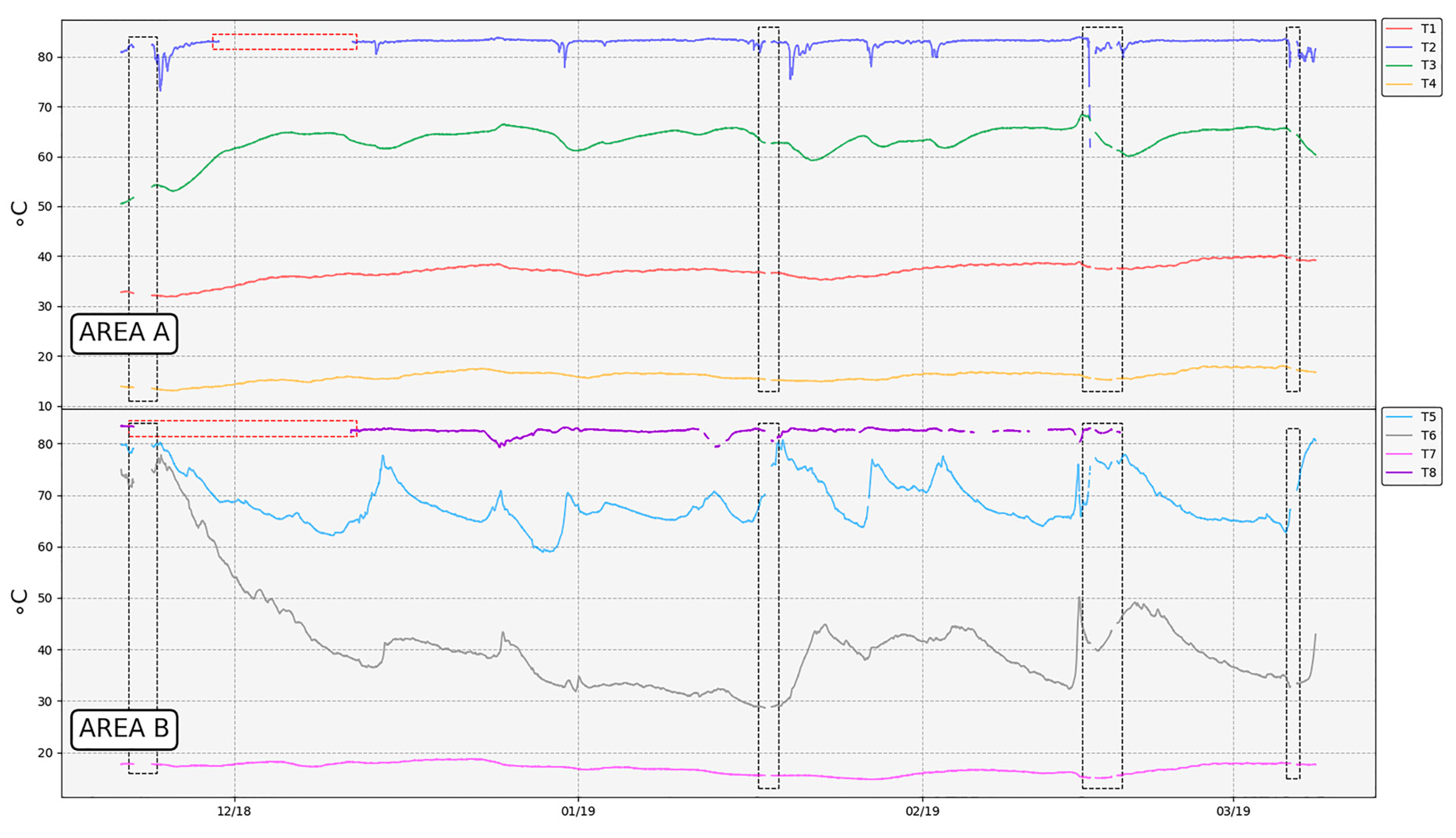

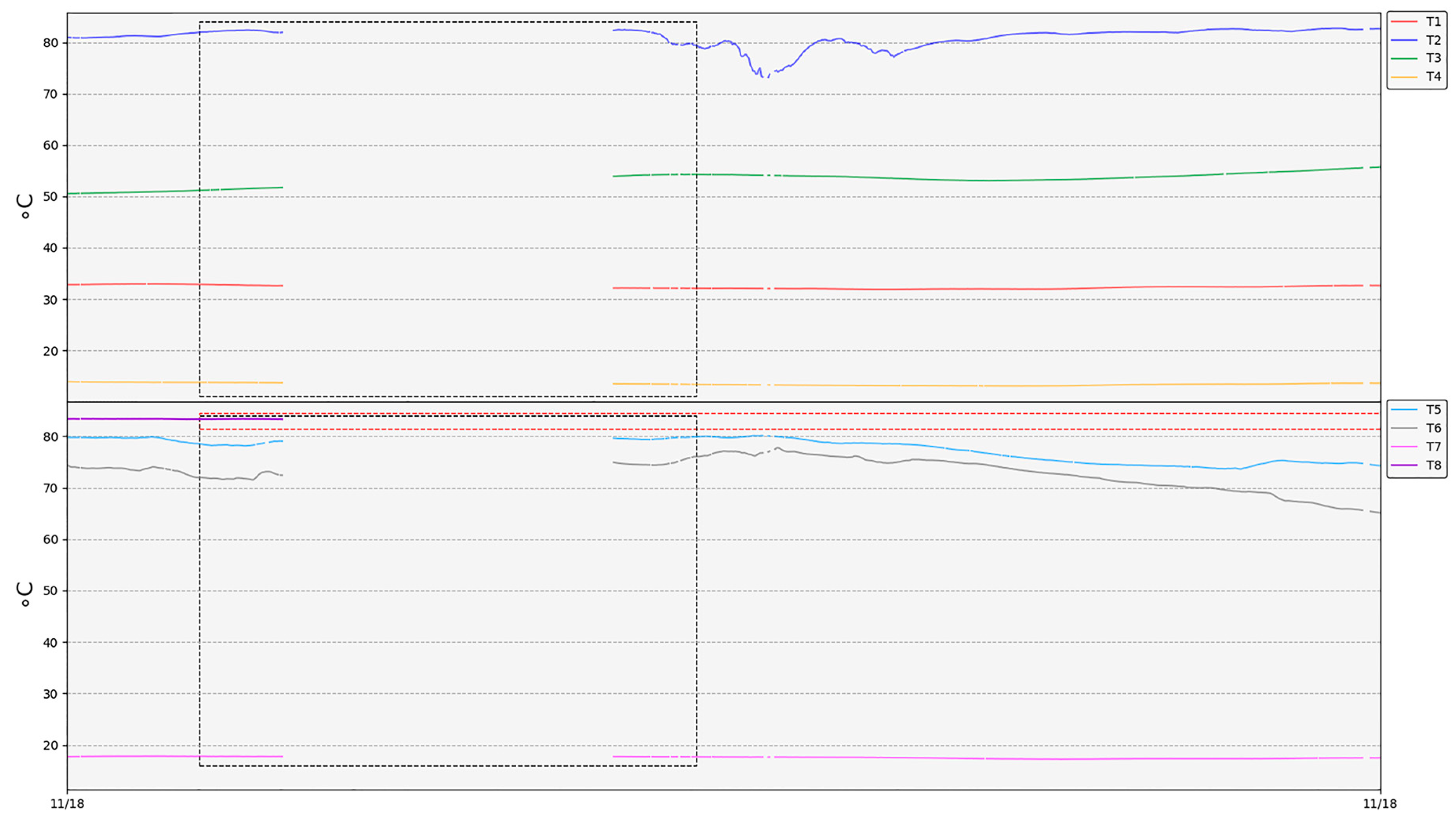

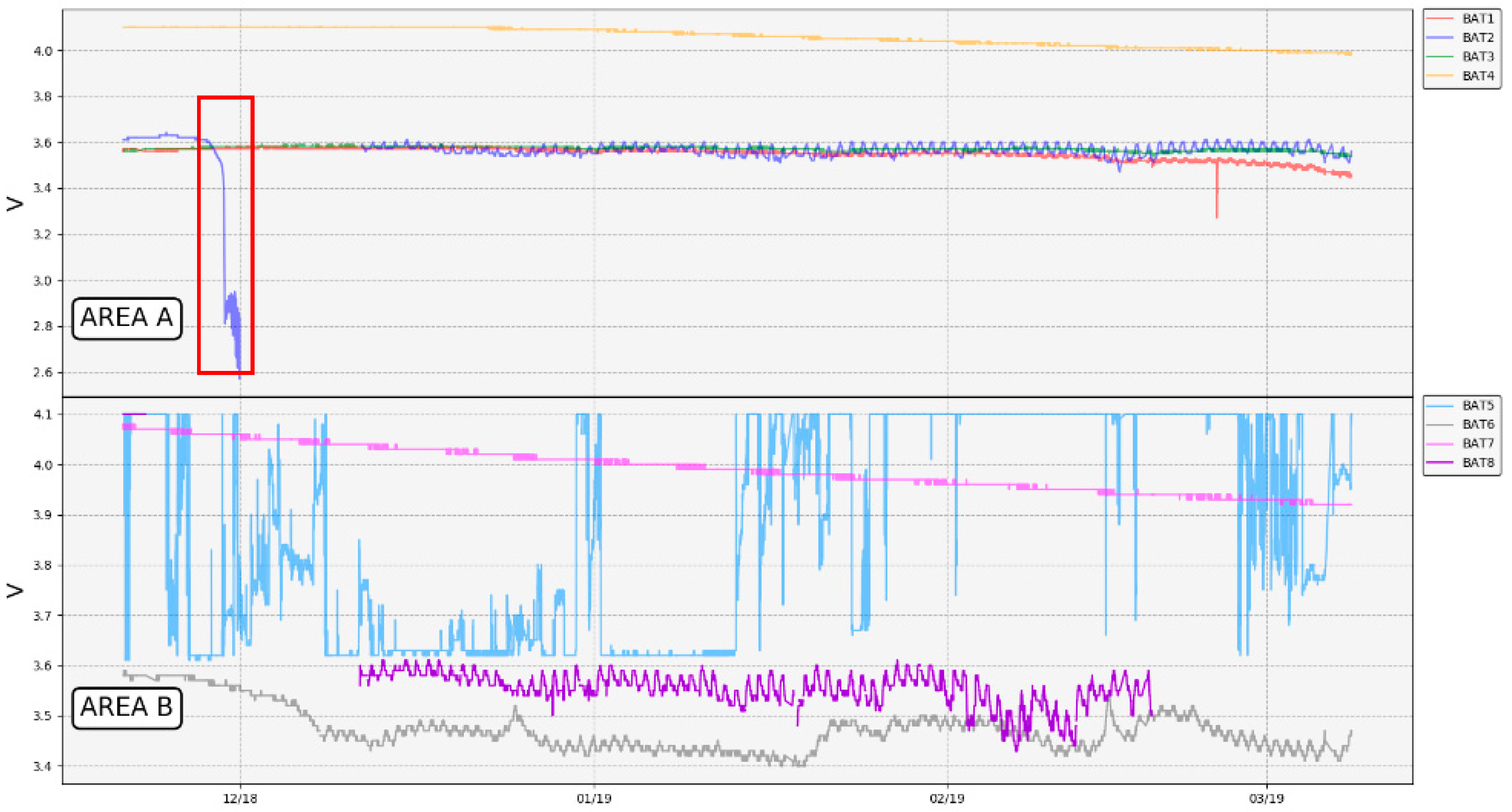

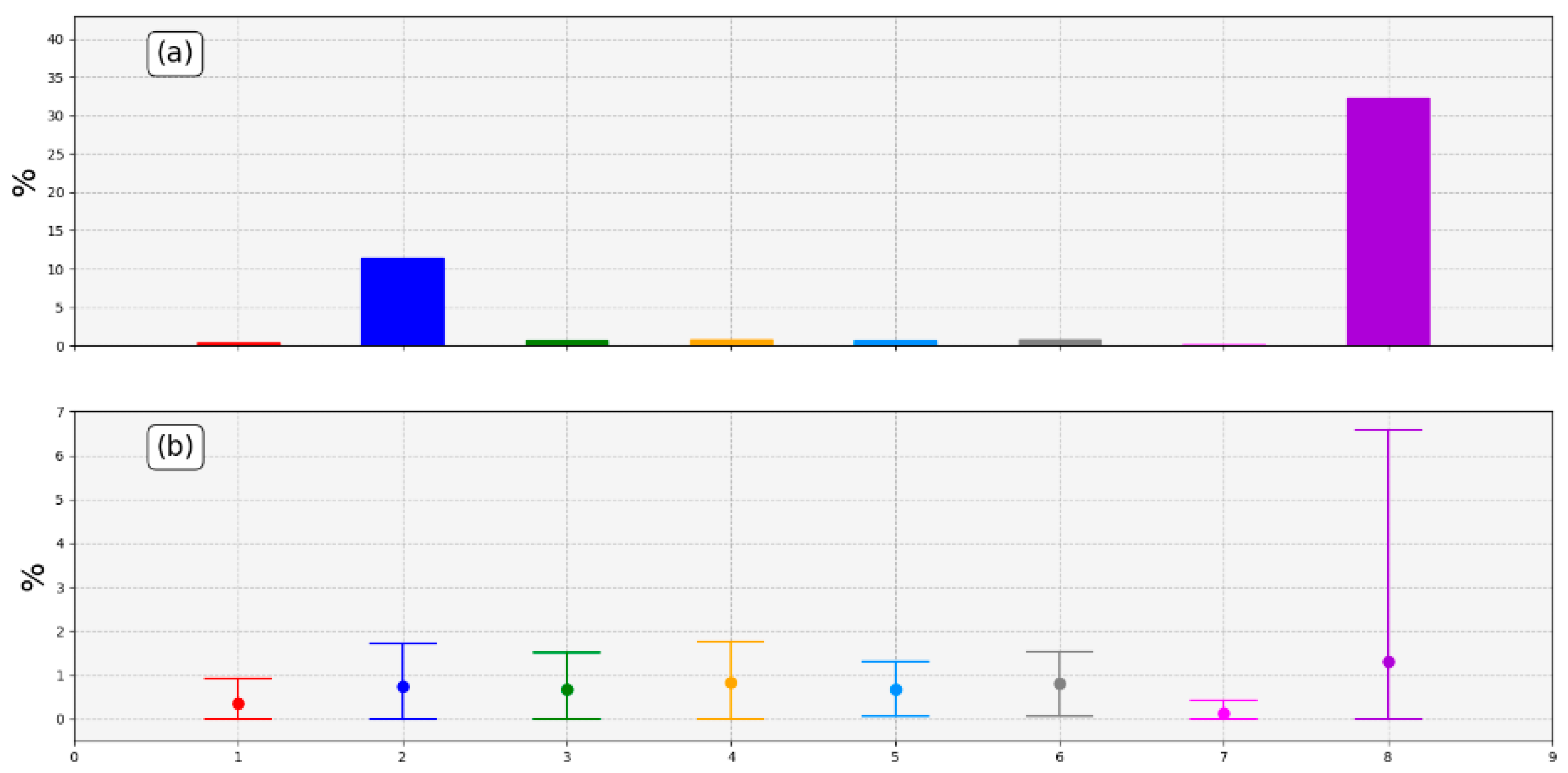

4.3. Data Records

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

- Transmission Power (TP) due to limits in hardware implementation is restricted from 2 dBm to 20 dBm, and for higher levels than 17 dBm, only 1% duty cycle can be used

- Carrier Frequency (CF) is the center frequency that can be programmed in steps of 61 Hz from 137 MHz to 1020 MHz. In some LoRa chips, this frequency range is limited between 860 MHz and 1020 MHz

- Bandwidth (BW): The higher it is, the higher the data rate (thus the shorter time on air); however, sensitivity decreases. LoRa provides three selectable BWs: 125 kHz, 250 kHz, and 500 kHz. Data is sent out at a chip rate equal to the bandwidth in chips per second per Hertz; a bandwidth of 125 kHz corresponds to a chip rate of 125 kcps.

- Coding Rate (CR) refers to the proportion of the transmitted bits that actually carries information. Forward error correction (FEC) techniques are used in LoRa to further increase the receiver sensitivity, which is done by encoding 4-bit data with redundancies into 5-bit, 6-bit, 7-bit, or 8-bit. Using this redundancy will allow the LoRa signal to endure short interferences. The LoRa allowed coding rate values are 4/5, 4/6, 4/7, and 4/8. The more correction bits are used, the easier the data can be corrected, but the duration for the transmission is higher, and the effective data rate is lower.

- Spreading Factor (SF) is the ratio between the symbol rate and chip rate (a LoRa symbol is composed of 2SF chips). Selecting SF from 6 to 12, radio communications with different SF values are orthogonal to each other. SF must be known in advance by the transmitter and receiver in order to detect the message preamble (in other words, to detect at least 4.25 symbols), as the preamble size scales with SF, and there is no single preamble for all SFs.A higher SF increases the signal-to-noise ratio (SNR), and thus the sensitivity and range, but also increases the packet airtime. With the same BW, a longer time on air obviously results in less data transmitted per unit of time. Each increase in SF halves the transmission rate, and hence doubles the transmission duration and ultimately energy consumption.

References

- López, C.; Blanco, M.J.; Abella, R.; Brenes, B.; Cabrera Rodríguez, V.M.; Casas, B.; Domínguez Cerdeña, I.; Felpeto, A.; Villalta, M.F. Monitoring the volcanic unrest of El Hierro (Canary Islands) before the onset of the 2011–2012 submarine eruption. Geophys. Res. Lett. 2012, 39, L13303. [Google Scholar] [CrossRef]

- Phillipson, G.; Sobradelo, R.; Gottsmann, J. Global volcanic unrest in the 21st century: An analysis of the first decade. J. Volcanol. Geotherm. Res. 2013, 264, 183–196. [Google Scholar] [CrossRef]

- Kilburn, C.R.J. Multiscale fracturing as a key to forecasting volcanic eruptions. J. Volcanol. Geotherm. Res. 2003, 125, 271–289. [Google Scholar] [CrossRef]

- Jousset, P.; Budi-Santoso, A.; Jolly, A.D.; Boichu, M.; Surono; Dwiyono, S.; Sumarti, S.; Hidayati, S.; Thierry, P. Signs of magma ascent in LP and VLP seismic events and link to degassing: An example from the 2010 explosive eruption at Merapi volcano, Indonesia. J. Volcanol. Geotherm. Res. 2013, 261, 171–192. [Google Scholar] [CrossRef]

- Hooper, A.; Prata, F.; Sigmundsson, F. Sigmundsson Remote Sensing of Volcanic Hazards and Their Precursors. Proc. IEEE 2012, 100, 2908–2930. [Google Scholar] [CrossRef]

- Williams-Jones, G.; Rymer, H. Detecting volcanic eruption precursors: A new method using gravity and deformation measurements. J. Volcanol. Geotherm. Res. 2002, 113, 379–389. [Google Scholar] [CrossRef]

- Sainz-Maza Aparicio, S.; Arnoso Sampedro, J.; González Montesinos, F.; Martí Molist, J. Volcanic signatures in time gravity variations during the volcanic unrest on El Hierro (Canary Islands). J. Geophys. Res. 2014, 119, 5033–5051. [Google Scholar] [CrossRef]

- Villasante-Marcos, V.; Finizola, A.; Abella, R.; Barde-Cabusson, S.; Blanco, M.J.; Brenes, B.; Cabrera, V.; Casas, B.; De Agustín, P.; Di Gangi, F. Hydrothermal system of central tenerife volcanic complex, Canary Islands (Spain), inferred from self-potential measurements. J. Volcanol. Geotherm. Res. 2014, 272, 59–77. [Google Scholar] [CrossRef]

- Finizola, A.; Sortino, F.; Lénat, J.-F.; Aubert, M.; Ripepe, M.; Valenza, M. The summit hydrothermal system of Stromboli. New insights from self-potential, temperature, CO2 and fumarolic fluid measurements, with structural and monitoring implications. Bull. Volcanol. 2003, 65, 486–504. [Google Scholar] [CrossRef]

- Schmincke, H.U. Volcanism; Springer: Berlin, Germany, 2004; ISBN 978-3-540-43650-8. [Google Scholar]

- Parfitt, L.; Wilson, L. Fundamentals of Physical Volcanology; Wiley: Hoboken, NJ, USA, 2009; ISBN 978-1-4443-0756-6. [Google Scholar]

- Oppenheimer, C.; Pyle, D.M.; Barclay, J.; London, G.S. Volcanic Degassing; Geological Society: London, UK, 2003; ISBN 978-1-86239-136-9. [Google Scholar]

- Melián, G.; Tassi, F.; Pérez, N.; Hernández, P.; Sortino, F.; Vaselli, O.; Padrón, E.; Nolasco, D.; Barrancos, J.; Padilla, G.; et al. A magmatic source for fumaroles and diffuse degassing from the summit crater of Teide Volcano (Tenerife, Canary Islands): A geochemical evidence for the 2004–2005 seismic–volcanic crisis. Bull. Volcanol. 2012, 74, 1465–1483. [Google Scholar] [CrossRef]

- Spampinato, L.; Calvari, S.; Oppenheimer, C.; Boschi, E. Volcano surveillance using infrared cameras. Earth Sci. Rev. 2011, 106, 63–91. [Google Scholar] [CrossRef]

- Remote Sensing|Free Full-Text|The Development of a Low-Cost, Near Infrared, High-Temperature Thermal Imaging System and Its Application to the Retrieval of Accurate Lava Lake Temperatures at Masaya Volcano, Nicaragua|HTML. Available online: https://www.mdpi.com/2072-4292/10/3/450/htm (accessed on 15 October 2019).

- Radebaugh, J.; Lopes, R.M.; Howell, R.R.; Lorenz, R.D.; Turtle, E.P. Eruptive behavior of the Marum/Mbwelesu lava lake, Vanuatu and comparisons with lava lakes on Earth and Io. J. Volcanol. Geotherm. Res. 2016, 322, 105–118. [Google Scholar] [CrossRef]

- Akyildiz, I.F.; Su, W.; Sankarasubramaniam, Y.; Cayirci, E. Wireless sensor networks: A survey. Comput. Netw. 2002, 38, 393–422. [Google Scholar] [CrossRef]

- Zheng, J.; Jamalipour, A. Wireless Sensor Networks: A Networking Perspective; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Amin, R.; Islam, S.H.; Biswas, G.P.; Khan, M.K.; Kumar, N. A robust and anonymous patient monitoring system using wireless medical sensor networks. Future Gener. Comput. Syst. 2018, 80, 483–495. [Google Scholar] [CrossRef]

- Liu, F.; Chen, Z.; Wang, J. Intelligent medical IoT system based on WSN with computer vision platforms. Concurr. Comput. 2018. [Google Scholar] [CrossRef]

- Hsu, W.-C.; Kuo, C.-W.; Chang, W.-W.; Chang, J.-J.; Hou, Y.-T.; Lan, Y.-C.; Sung, T.-J.; Yang, Y.-J. A WSN smart medication system. Procedia Eng. 2010, 5, 588–591. [Google Scholar] [CrossRef]

- Ye, D.; Gong, D.; Wang, W. Application of wireless sensor networks in environmental monitoring. In Proceedings of the 2009 2nd International Conference on Power Electronics and Intelligent Transportation System (PEITS), Shenzhen, China, 19–20 December 2009; Volume 1, pp. 205–208. [Google Scholar]

- Vairamani, K.; Mathivanan, N.; Arun Venkatesh, K.; Dinesh Kumar, U. Environmental parameter monitoring using wireless sensor network. Instrum. Exp. Tech. 2013, 56, 468–471. [Google Scholar] [CrossRef]

- Qian, H.; Sun, P.; Rong, Y. Design Proposal of Self-Powered WSN Node for Battle Field Surveillance. Energy Procedia 2012, 16, 753–757. [Google Scholar] [CrossRef]

- Li, Y.-X.; Guan, H.; Zhang, Y.-L. Energy efficient and reliable target monitoring in the tactical battlefield. Commun. Comput. Inf. Sci. 2011, 143, 115–121. [Google Scholar]

- Bapat, V.; Kale, P.; Shinde, V.; Deshpande, N.; Shaligram, A. WSN application for crop protection to divert animal intrusions in the agricultural land. Comput. Electron. Agric. 2017, 133, 88–96. [Google Scholar] [CrossRef]

- Srbinovska, M.; Gavrovski, C.; Dimcev, V.; Krkoleva, A.; Borozan, V. Environmental parameters monitoring in precision agriculture using wireless sensor networks. J. Clean Prod. 2015, 88, 297–307. [Google Scholar] [CrossRef]

- Nikolidakis, S.A.; Kandris, D.; Vergados, D.D.; Douligeris, C. Energy efficient automated control of irrigation in agriculture by using wireless sensor networks. Comput. Electron. Agric. 2015, 113, 154–163. [Google Scholar] [CrossRef]

- Vera-Amaro, R.; Angeles, M.E.R.; Luviano-Juarez, A. Design and Analysis of Wireless Sensor Networks for Animal Tracking in Large Monitoring Polar Regions Using Phase-Type Distributions and Single Sensor Model. IEEE Access 2019, 7, 45911–45929. [Google Scholar] [CrossRef]

- Boulmaiz, A.; Messadeg, D.; Doghmane, N.; Taleb-Ahmed, A. Robust acoustic bird recognition for habitat monitoring with wireless sensor networks. Int. J. Speech Technol. 2016, 19, 631–645. [Google Scholar] [CrossRef]

- Suryadevara, N.K.; Mukhopadhyay, S.C.; Kelly, S.D.T.; Gill, S.P.S. WSN-Based Smart Sensors and Actuator for Power Management in Intelligent Buildings. IEEE/ASME Trans. Mechatron. 2015, 20, 564–571. [Google Scholar] [CrossRef]

- Sri Jahnavi, V.; Ahamed, S.F. Smart wireless sensor network for automated greenhouse. IETE J. Res. 2015, 61, 180–185. [Google Scholar] [CrossRef]

- Mostafaei, H.; Chowdhury, M.U.; Obaidat, M.S. Border Surveillance With WSN Systems in a Distributed Manner. IEEE Syst. J. 2018, 12, 3703–3712. [Google Scholar] [CrossRef]

- Ismail, S.; Alkhader, E.; Ahmad, A. Prison perimeter surveillance system using WSN. J. Comput. Sci. 2017, 13, 674–679. [Google Scholar] [CrossRef][Green Version]

- Hulu, E.; Riyanto, B.; Widyantoro, S. Wireless Sensor Networks for Volcano Activity Monitoring: A Survey. Sci. J. Inform. 2016, 2, 53–62. [Google Scholar] [CrossRef]

- Lopes Pereira, R.; Trindade, J.; Gonçalves, F.; Suresh, L.; Barbosa, D.; Vazão, T. A wireless sensor network for monitoring volcano-seismic signals. Nat. Hazards Earth Syst. Sci. 2014, 14, 3123–3142. [Google Scholar] [CrossRef]

- Manrique, J.A.; Rueda-Rueda, J.S.; Portocarrero, J.M.T. Contrasting Internet of Things and Wireless Sensor Network from a Conceptual Overview. In Proceedings of the 2016 IEEE International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Chengdu, China, 15–18 December 2016; pp. 252–257. [Google Scholar]

- Buyya, R.; Dastjerdi, A.V. Internet of Things: Principles and Paradigms; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Lazarescu, M.T. Design of a WSN Platform for Long-Term Environmental Monitoring for IoT Applications. IEEE J. Emerg. Sel. Top. Circuits Syst. 2013, 3, 45–54. [Google Scholar] [CrossRef]

- Alphonsa, A.; Ravi, G. Earthquake early warning system by IOT using Wireless sensor networks. In Proceedings of the 2016 International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), Chennai, India, 23–25 March 2016; pp. 1201–1205. [Google Scholar]

- Kamruzzaman, J.; Wang, G.; Karmakar, G.; Ahmad, I.; Bhuiyan, M.Z.A. Acoustic sensor networks in the Internet of Things applications. Future Gener. Comput. Syst. 2018, 86, 1167–1169. [Google Scholar] [CrossRef]

- Veerubhotla, R.; Nag, S.; Das, D. Internet of Things temperature sensor powered by bacterial fuel cells on paper. J. Power Sources 2019, 438, 226947. [Google Scholar] [CrossRef]

- Zanella, A.; Bui, N.; Castellani, A.; Vangelista, L.; Zorzi, M. Internet of Things for Smart Cities. IEEE Internet Things J. 2014, 1, 22–32. [Google Scholar] [CrossRef]

- Jin, J.; Gubbi, J.; Marusic, S.; Palaniswami, M. An Information Framework for Creating a Smart City through Internet of Things. IEEE Internet Things J. 2014, 1, 112–121. [Google Scholar] [CrossRef]

- Risteska Stojkoska, B.L.; Trivodaliev, K.V. A review of Internet of Things for smart home: Challenges and solutions. J. Clean. Prod. 2017, 140, 1454–1464. [Google Scholar] [CrossRef]

- Khan, M.; Silva, B.N.; Han, K. Internet of Things Based Energy Aware Smart Home Control System. IEEE Access 2016, 4, 7556–7566. [Google Scholar] [CrossRef]

- Le, D.N.; Le Tuan, L.; Dang Tuan, M.N. Smart-building management system: An Internet-of-Things (IoT) application business model in Vietnam. Technol. Forecast. Soc. Chang. 2019, 141, 22–35. [Google Scholar] [CrossRef]

- Xu, L.D.; He, W.; Li, S. Internet of Things in Industries: A Survey. IEEE Trans. Ind. Inf. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Yin, Y.; Zeng, Y.; Chen, X.; Fan, Y. The internet of things in healthcare: An overview. J. Ind. Inf. Integr. 2016, 1, 3–13. [Google Scholar] [CrossRef]

- Rego Mañez, A.; Canovas Solbes, A.; Jimenez, J.M.; Lloret, J. An Intelligent System for Video Surveillance in IoT Environments. IEEE Access 2018, 6, 31580–31598. [Google Scholar] [CrossRef]

- Hilal, A.R.; Sayedelahl, A.; Tabibiazar, A.; Kamel, M.S.; Basir, O.A. A distributed sensor management for large-scale IoT indoor acoustic surveillance. Future Gener. Comput. Syst. 2018, 86, 1170–1184. [Google Scholar] [CrossRef]

- Aubert, M.; Diliberto, S.; Finizola, A.; Chébli, Y. Double origin of hydrothermal convective flux variations in the Fossa of Vulcano (Italy). Bull. Volcanol. 2008, 70, 743–751. [Google Scholar] [CrossRef]

- Giammanco, S.; Sims, K.; Neri, M. Measurements of Rn-220 and Rn-222 and CO2 emissions in soil and fumarole gases on Mt. Etna volcano (Italy): Implications for gas transport and shallow ground fracture. Geochem. Geophys. Geosyst. 2007, 8, Q10001. [Google Scholar] [CrossRef]

- Salazar, J.M.L.; Hernández, P.A.; Pérez, N.M.; Melián, G.; Álvarez, J.; Segura, F.; Notsu, K. Diffuse emission of carbon dioxide from Cerro Negro Volcano, Nicaragua, Central America. Geophys. Res. Lett. 2001, 28, 4275–4278. [Google Scholar] [CrossRef]

- Chiodini, G.; Frondini, F.; Cardellini, C.; Granieri, D.; Marini, L.; Ventura, G. CO2 degassing and energy release at Solfatara volcano, Campi Flegrei, Italy. J. Geophys. Res. Solid Earth 2001, 106, 16213–16221. [Google Scholar] [CrossRef]

- Lewicki, J.L.; Connor, C.; St-Amand, K.; Stix, J.; Spinner, W. Self-potential, soil CO2 flux, and temperature on Masaya volcano, Nicaragua. Geophys. Res. Lett. 2003, 30. [Google Scholar] [CrossRef]

- Hoglund, A.; Lin, X.; Liberg, O.; Behravan, A.; Yavuz, E.A.; Van Der Zee, M.; Sui, Y.; Tirronen, T.; Ratilainen, A.; Eriksson, D. Overview of 3GPP Release 14 Enhanced NB-IoT. IEEE Network 2017, 31, 16–22. [Google Scholar] [CrossRef]

- Sinha, R.S.; Wei, Y.; Hwang, S.-H. A survey on LPWA technology: LoRa and NB-IoT. ICT Express 2017, 3, 14–21. [Google Scholar] [CrossRef]

- Home Page|LoRa AllianceTM. Available online: https://lora-alliance.org/ (accessed on 16 August 2018).

- Augustin, A.; Yi, J.; Clausen, T.; Townsley, W.M. A Study of LoRa: Long Range & Low Power Networks for the Internet of Things. Sensors 2016, 16, 1466. [Google Scholar]

- Sigfox-The Global Communications Service Provider for the Internet of Things (IoT). Available online: https://www.sigfox.com/en (accessed on 16 August 2018).

- Sigfox Technology Overview|Sigfox. Available online: https://www.sigfox.com/en/sigfox-iot-technology-overview (accessed on 5 February 2019).

- Mahmoud, M.; Mohamad, A. A Study of Efficient Power Consumption Wireless Communication Techniques/ Modules for Internet of Things (IoT) Applications. Adv. Internet Things 2016, 6, 19–29. [Google Scholar] [CrossRef]

- Raza, U.; Kulkarni, P.; Sooriyabandara, M. Low Power Wide Area Networks: An Overview. IEEE Commun. Surv. Tutor. 2017, 19, 855–873. [Google Scholar] [CrossRef]

- Pothuganti, K.; Chitneni, A. A comparative study of wireless protocols: Bluetooth, UWB, ZigBee, and Wi-Fi. Adv. Electron. Electr. Eng. 2014, 4, 655–662. [Google Scholar]

- Sanchez-Iborra, R.; Cano, M.-D. State of the Art in LP-WAN Solutions for Industrial IoT Services. Sensors 2016, 16, 708. [Google Scholar] [CrossRef] [PubMed]

- Mekki, K.; Bajic, E.; Chaxel, F.; Meyer, F. A comparative study of LPWAN technologies for large-scale IoT deployment. ICT Express 2019, 5, 1–7. [Google Scholar] [CrossRef]

- LTE. Available online: https://www.3gpp.org/technologies/keywords-acronyms/98-lte (accessed on 17 September 2019).

- Semtech. Available online: https://www.semtech.com (accessed on 14 May 2019).

- Seller, O.B.A.; Sornin, N. Low Power Long Range Transmitter. EP2763321A1, 24 August 2014. [Google Scholar]

- Hornbuckle, C.A. Fractional-N Synthesized Chirp Generator. US7791415B2, 7 September 2010. [Google Scholar]

- Ra-02 Ai-Thinker. Available online: http://wiki.ai-thinker.com/_media/lora/docs/c048ps01a1_ra-02_product_specification_v1.1.pdf (accessed on 14 March 2019).

- SX1278|Semtech. Available online: https://www.semtech.com/products/wireless-rf/lora-transceivers/SX1278 (accessed on 20 August 2018).

- Lora Design Guide. SX1272/3/6/7/8. Available online: https://www.semtech.com/uploads/documents/LoraDesignGuide_STD.pdf (accessed on 22 May 2019).

- Foundation, R.P. Raspberry Pi—Teach, Learn, and Make with Raspberry Pi. Available online: https://www.raspberrypi.org (accessed on 16 August 2018).

- Fox, R. Linux with Operating System Concepts; CRC Press: Boca Raton, FL, USA, 2014; ISBN 1-4822-3589-7. [Google Scholar]

- Moure, D.; Torres, P.; Casas, B.; Toma, D.; Blanco, J.M.; Del Río, J.; Manuel, A. Use of Low-Cost Acquisition Systems with an Embedded Linux Device for Volcanic Monitoring. Sensors 2015, 15, 20436–20462. [Google Scholar] [CrossRef]

- Wilkes, C.T.; Pering, D.T.; McGonigle, J.A.; Tamburello, G.; Willmott, R.J. A Low-Cost Smartphone Sensor-Based UV Camera for Volcanic SO2 Emission Measurements. Remote Sens. 2017, 9, 27. [Google Scholar] [CrossRef]

- Earthquake Seismograph & Infrasound Monitor|Shake & Boom. Available online: https://raspberryshake.org/products/raspberry-shake-boom/ (accessed on 15 October 2019).

- Raspberry Pi 3 Model B. Available online: https://www.raspberrypi.org/products/raspberry-pi-3-model-b/ (accessed on 6 March 2019).

- ATmega328-8-bit AVR Microcontrollers-Microcontrollers and Processors-Microcontrollers and Processors. Available online: https://www.microchip.com/wwwproducts/en/atmega328 (accessed on 4 February 2019).

- STM32F103C8-Mainstream Performance LIne, ARM Cortex-M3 MCU with 64 Kbytes Flash, 72 MHz CPU, Motor Control, USB and CAN-STMicroelectronics. Available online: https://www.st.com/en/microcontrollers/stm32f103c8.html (accessed on 21 August 2018).

- PIC18F25K40-Microcontrollers and Processors-Microcontrollers and Processors. Available online: https://www.microchip.com/wwwproducts/en/PIC18F25K40 (accessed on 21 August 2018).

- PIC16F1788-Microcontrollers and Processors-Microcontrollers and Processors. Available online: https://www.microchip.com/wwwproducts/en/PIC16F1788 (accessed on 21 August 2018).

- RS PT100 Specifications. Available online: https://docs-emea.rs-online.com/webdocs/15e5/0900766b815e5304.pdf (accessed on 6 March 2019).

- Industries, A. Adafruit PT100 RTD Temperature Sensor Amplifier-MAX31865. Available online: https://www.adafruit.com/product/3328 (accessed on 21 August 2018).

- Samsung ICR18650 Lithium-Ion Rechargeable Battery. Available online: https://docs-emea.rs-online.com/webdocs/15d2/0900766b815d2388.pdf (accessed on 22 May 2019).

- PT-2100 Keeper®|EaglePicher Technologies, LLC. Available online: https://www.eaglepicher.com/sites/default/files/pt2100.pdf (accessed on 6 March 2019).

- Tridgell, A. Efficient Algorithms for Sorting and Synchronization. PhD Thesis, Australian National University, Canberra, Australia, 1999. [Google Scholar]

- p5.js|home. Available online: https://p5js.org/ (accessed on 6 March 2019).

- MultiTeide. Available online: http://www.multiteide.es/ (accessed on 23 May 2019).

- Richter, G.; Wassermann, J.; Zimmer, M.; Ohrnberger, M. Correlation of seismic activity and fumarole temperature at the Mt. Merapi volcano (Indonesia) in 2000. J. Volcanol. Geotherm. Res. 2004, 135, 331–342. [Google Scholar] [CrossRef]

- All About LoRa and LoRaWAN: LoRa: Orthogonality. Available online: https://www.sghoslya.com/p/lora_6.html (accessed on 17 September 2019).

| Frequency Bands (MHz) 1 | Nominal Range | Data Rates 1 | |

|---|---|---|---|

| NFC | 13.56 | 10 cm | 100–424 kbps |

| Bluetooth | 2400 | 0.5–100 m | 1 Mbps |

| ZigBee | 2400 | 10–100 m | 250 kbps |

| WiFi | 2400/5000 | 50–100 m | 150–250 Mbps (typical) |

| Cellular | 900/1800/ 1900/2100 | 35 km max for GSM, 200 km max for HSPA | 35–170 kbps (GPRS) 120–384 kbps (EDGE) 384 kbps–2 Mbps (UMTS) 600 kbps–10 Mbps (HSPA) 3–10 Mbps (LTE) |

| NB-IoT | Licensed LTE frequency bands | 10 km (rural), 1 km (urban) | 20/200 kbps 2 |

| Sigfox | 868 | 30–50 km (rural), 3–10 km (urban) | 100/600bps 2 |

| LoRa | 433/868 | 15–20 km (rural), 2–5 km (urban) | 0.3–50 kbps |

| Microcontroller | Sleep (µW) | ON (mW) |

|---|---|---|

| ATMEGA328 | 16.28 | 89.54 |

| STM32F103C8T6 | 12.58 | 190.92 |

| PIC18LF25K40 | 45.88 | 69.93 |

| PIC16LF1788 | 2.96 | 70.3 |

| PIC16LF1788 Features | |

|---|---|

| Program Memory Size | 28 KB (Flash) |

| CPU Speed/Internal oscillator | 8 MIPS/ 32 MHz |

| SRAM | 2048 Bytes |

| Data EEPROM | 256 Bytes |

| Digital Communication Peripherals | 1-UART, 1-SPI, 1-I2C1MSSP(SPI/I2C) |

| Timers | 2 × 8-bit 1 × 16-bit |

| ADC Input | 11 ch, 12-bit |

| Temperature Range | −40 to 125 °C |

| Operating Voltage Range | 1.8 to 5.5 V |

| Low Power | Yes |

| Li-Ion Rechargeable Battery | Lithium Thionyl Chloride Non-Rechargeable Battery | |

|---|---|---|

| Type | 18650 | AA |

| Nominal Voltage | 3.7 V | 3.6 V |

| Charging Voltage | 4.2 ±0.05 V | - |

| Discharge Cut-Off Voltage | 2.75 V | 2.0 V |

| Capacity | 2600 mAh | 2400 mAh |

| Operating Temperature Range | −20 → +60 °C | −55 → +85 °C |

| Device | Software/Script | Execution | Programming Language | Purpose |

|---|---|---|---|---|

| Gateway | master_main.py | Every 10 min (default) | Python | Asks the end devices for temperature value |

| synch.sh | Every 10 min | Linux Bash shell | Synchronizes data between gateway and server | |

| Rssi.py | At user’s will | Python | Asks for the RSSI of any device in the network | |

| master_1sample.py | At user’s will | Python | Asks the end devices for temperature value | |

| Repeater | Repeater.cpp | Continuous | C | Relays messages between the gateway and the end devices |

| End device | End_device.cpp | Continuous | C | Temperature measurement |

| Data Analysis Center | join.py | Every 10 min | Python | Joins all temperature daily files in a single one |

| LoRa_represent.py | Every 10 min | Python | Takes the joined file and creates a graphical representation in HTML |

| Mode | Power Consumption (mA) | Time Percent Per Hour | |

|---|---|---|---|

| Transmitting | 70 | 0.0075% | |

| Receive mode | 12.2 | 0.2% | |

| Deep Sleep mode | 0.0035 | 80% | |

| Low Power mode | Sleep | 0.0035 | 19.0699% |

| Receive | 12.2 | 0.3891% | |

| Measuring | 4 | 0.3333% |

| END DEVICE (THERMOMETER) COMPONENTS | Price (€) |

|---|---|

| PT100 sensor | 5.50 |

| MAX31685 | 4.11 |

| PIC16LF1788 | 6.04 |

| External structure (PVC pipe + aluminum tip) | 1.37 |

| Ra-02 | 3.00 |

| Antenna | 5.45 |

| Lithium battery | 9.54 |

| Wires, cases and components | 2.00 |

| Total price of one end device | 37.01 |

| GATEWAY COMPONENTS | |

| Raspberry Pi 3B | 35.66 |

| Ra-02 | 3.00 |

| Antenna | 22.61 |

| Total price of the gateway | 61.27 |

| REPEATER COMPONENTS | |

| PIC16LF1788 | 6.04 |

| External structure (PVC pipe + aluminum tip) | 1.37 |

| Ra-02 | 3.00 |

| Antenna | 5.45 |

| Lithium battery | 9.54 |

| Wires, cases, and components | 2.00 |

| Total price of the repeater | 27.40 |

| Samples | T (°C) | RSSI (dBm) | BAT (V) | ||

|---|---|---|---|---|---|

| T1 | 14522 | MIN | 31.87 | –101 | 3.27 |

| MED | 36.95 | –92 | 3.55 | ||

| MAX | 40.18 | –89 | 3.58 | ||

| T2 | 13005 | MIN | 61.91 | –107 | 2.57 |

| MED | 82.82 | –95 | 3.56 | ||

| MAX | 83.88 | –92 | 3.64 | ||

| T3 | 14480 | MIN | 50.52 | –123 | 3.54 |

| MED | 63.17 | –89 | 3.57 | ||

| MAX | 68.31 | –84 | 3.59 | ||

| T4 | 14445 | MIN | 13.04 | –102 | 3.98 |

| MED | 15.95 | –92 | 4.06 | ||

| MAX | 18.00 | –89 | 4.10 | ||

| T5 | 14466 | MIN | 58.89 | –114 | 3.61 |

| MED | 68.70 | –101 | 3.87 | ||

| MAX | 81.09 | –95 | 4.10 | ||

| T6 | 14445 | MIN | 28.68 | –115 | 3.40 |

| MED | 41.08 | –103 | 3.47 | ||

| MAX | 77.77 | –99 | 3.59 | ||

| T7 | 14551 | MIN | 14.75 | –116 | 3.92 |

| MED | 16.90 | –103 | 3.99 | ||

| MAX | 18.75 | –94 | 4.08 | ||

| T8 | 9565 | MIN | 79.29 | –104 | 3.43 |

| MED | 82.43 | –90 | 3.56 | ||

| MAX | 83.41 | –86 | 4.10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awadallah, S.; Moure, D.; Torres-González, P. An Internet of Things (IoT) Application on Volcano Monitoring. Sensors 2019, 19, 4651. https://doi.org/10.3390/s19214651

Awadallah S, Moure D, Torres-González P. An Internet of Things (IoT) Application on Volcano Monitoring. Sensors. 2019; 19(21):4651. https://doi.org/10.3390/s19214651

Chicago/Turabian StyleAwadallah, Shadia, David Moure, and Pedro Torres-González. 2019. "An Internet of Things (IoT) Application on Volcano Monitoring" Sensors 19, no. 21: 4651. https://doi.org/10.3390/s19214651

APA StyleAwadallah, S., Moure, D., & Torres-González, P. (2019). An Internet of Things (IoT) Application on Volcano Monitoring. Sensors, 19(21), 4651. https://doi.org/10.3390/s19214651