Fully Transparent Gas Sensor Based on Carbon Nanotubes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Fabrication Process

2.2. Characterization

3. Results and Discussion

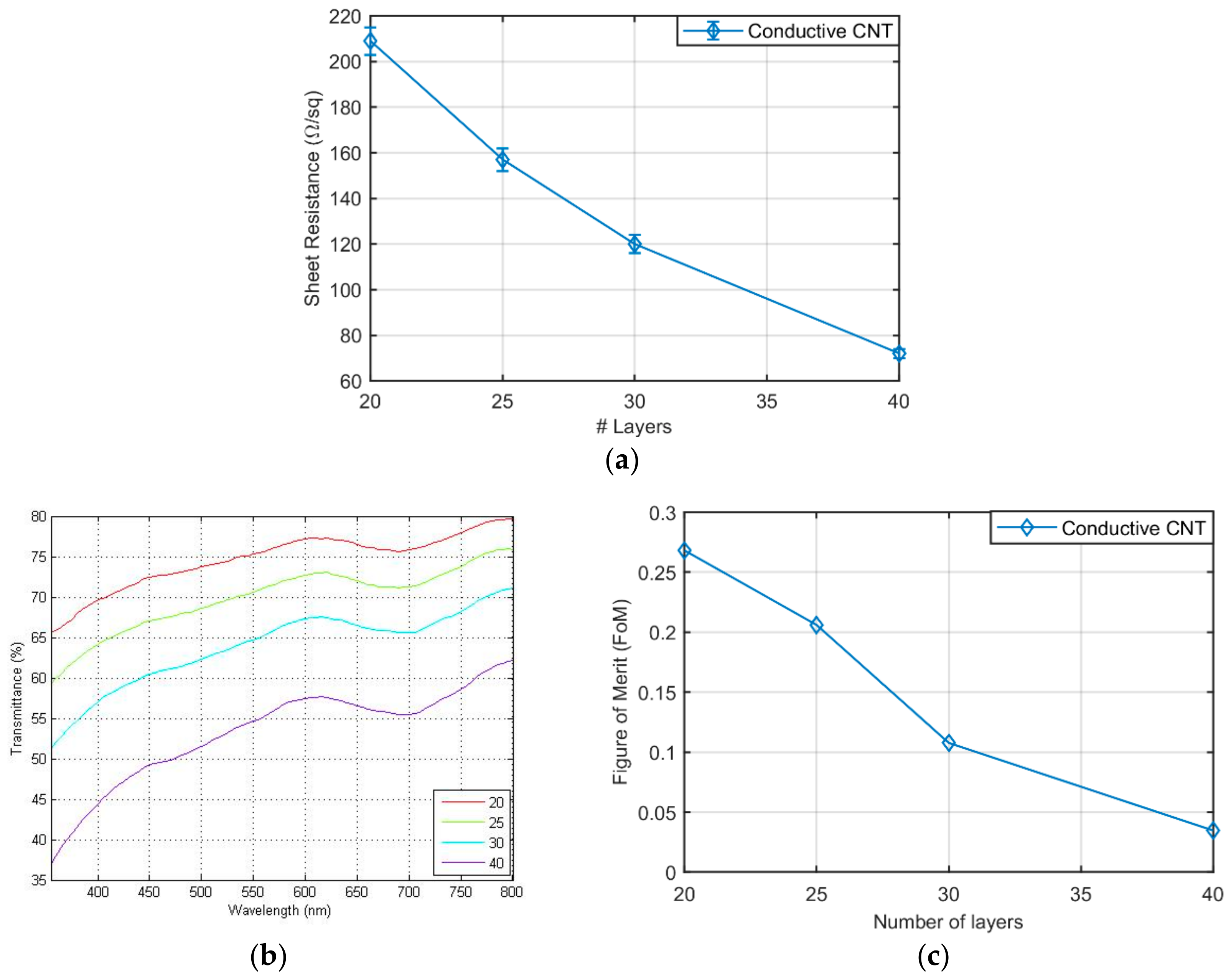

3.1. Optical and Electrical Characterization

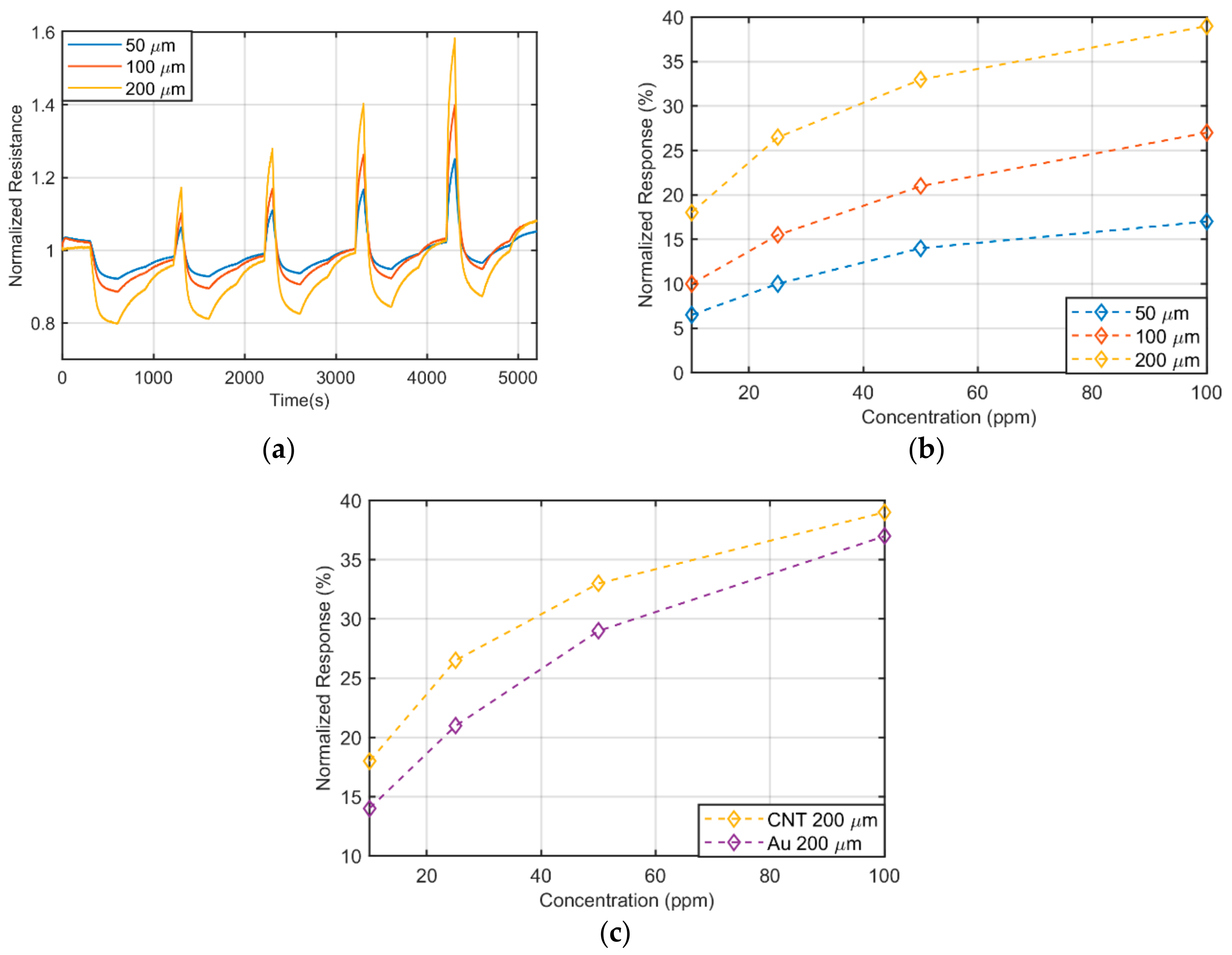

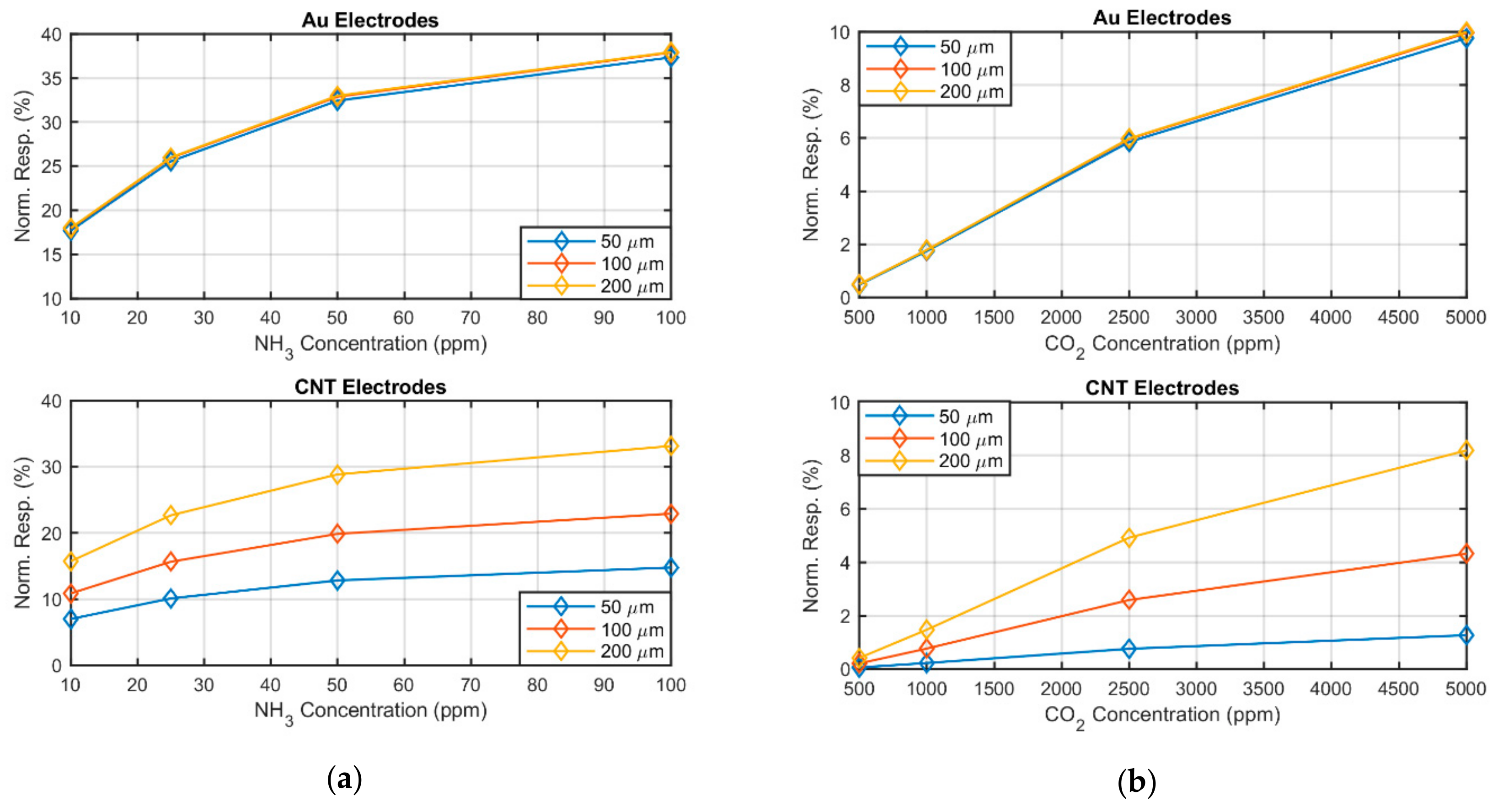

3.2. Gas Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- AGC Inc. Agc Develops a Synthetic Fused Silica Glass Antenna for 5 g. Available online: http://www.agc.com/en/news/detail/1198353_2814.html (accessed on 27 May 2019).

- Research, J. Hybrid Smartwatches to Make up over 50% of Smartwatch Shipments by 2022, as Fashion Beats Function. Available online: https://www.juniperresearch.com/press/press-releases/hybrid-smartwatches-make-up (accessed on 27 May 2019).

- Leterrier, Y.; Medico, L.; Demarco, F.; Månson, J.-A.; Betz, U.; Escola, M.; Olsson, M.K.; Atamny, F. Mechanical integrity of transparent conductive oxide films for flexible polymer-based displays. Thin Solid Film. 2004, 460, 156–166. [Google Scholar] [CrossRef]

- Huang, J.; Li, G.; Yang, Y. A semi-transparent plastic solar cell fabricated by a lamination process. Adv. Mater. 2008, 20, 415–419. [Google Scholar] [CrossRef]

- Salvatore, G.A.; Münzenrieder, N.; Kinkeldei, T.; Petti, L.; Zysset, C.; Strebel, I.; Büthe, L.; Tröster, G. Wafer-scale design of lightweight and transparent electronics that wraps around hairs. Nat. Commun. 2014, 5, 2982. [Google Scholar] [CrossRef] [PubMed]

- Chae, S.H.; Yu, W.J.; Bae, J.J.; Duong, D.L.; Perello, D.; Jeong, H.Y.; Ta, Q.H.; Ly, T.H.; Vu, Q.A.; Yun, M. Transferred wrinkled al2o3 for highly stretchable and transparent graphene–carbon nanotube transistors. Nat. Mater. 2013, 12, 403–409. [Google Scholar] [CrossRef]

- Song, C.; Zhang, N.; Lin, J.; Guo, X.; Liu, X. Sb2O3/Ag/Sb2O3 multilayer transparent conducting films for ultraviolet organic light-emitting diode. Sci. Rep. 2017, 7, 41250. [Google Scholar] [CrossRef]

- Lai, T.-H.; Lee, J.W.; Manders, J.R.; So, F. Multi-spectral imaging with infrared sensitive organic light emitting diode. Sci. Rep. 2014, 4, 5946. [Google Scholar]

- Zheng, Z.; Yao, J.; Wang, B.; Yang, G. Light-controlling, flexible and transparent ethanol gas sensor based on zno nanoparticles for wearable devices. Sci. Rep. 2015, 5, 11070. [Google Scholar] [CrossRef]

- Jing, Q.; Xie, Y.; Zhu, G.; Han, R.P.; Wang, Z.L. Self-powered thin-film motion vector sensor. Nat. Commun. 2015, 6, 8031. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Lee, J.A.; Vosgueritchian, M.; Tee, B.C.-K.; Bolander, J.A.; Bao, Z. Electronic properties of transparent conductive films of pedot: Pss on stretchable substrates. Chem. Mater. 2012, 24, 373–382. [Google Scholar] [CrossRef]

- Bobinger, M.; Angeli, D.; Colasanti, S.; La Torraca, P.; Larcher, L.; Lugli, P. Infrared, transient thermal, and electrical properties of silver nanowire thin films for transparent heaters and energy-efficient coatings. Phys. Status Solidi 2016, 214, 1600466. [Google Scholar] [CrossRef]

- Gruner, G. Carbon nanotube films for transparent and plastic electronics. J. Mater. Chem. 2006, 16, 3533–3539. [Google Scholar] [CrossRef]

- Kuo, C.Y.; Chan, C.L.; Gau, C.; Liu, C.-W.; Shiau, S.H.; Ting, J.-H. Nano temperature sensor using selective lateral growth of carbon nanotube between electrodes. IEEE Trans. Nanotechnol. 2007, 6, 63–69. [Google Scholar] [CrossRef]

- Han, J.-W.; Kim, B.; Li, J.; Meyyappan, M. Carbon nanotube based humidity sensor on cellulose paper. J. Phys. Chem. C 2012, 116, 22094–22097. [Google Scholar] [CrossRef]

- Zhang, T.; Mubeen, S.; Myung, N.V.; Deshusses, M.A. Recent progress in carbon nanotube-based gas sensors. Nanotechnology 2008, 19, 332001. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.; Kim, H.; Lee, Y.; Xu, X.; Park, J.-S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Kim, H.R.; Song, Y.I. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 2010, 5, 574–578. [Google Scholar] [CrossRef]

- Kang, H.; Jung, S.; Jeong, S.; Kim, G.; Lee, K. Polymer-metal hybrid transparent electrodes for flexible electronics. Nat. Commun. 2015, 6, 6503. [Google Scholar] [CrossRef]

- Lee, S.; Reuveny, A.; Reeder, J.; Lee, S.; Jin, H.; Liu, Q.; Yokota, T.; Sekitani, T.; Isoyama, T.; Abe, Y. A transparent bending-insensitive pressure sensor. Nat. Nanotechnol. 2016, 11, 472. [Google Scholar] [CrossRef]

- Sun, Q.; Kim, D.H.; Park, S.S.; Lee, N.Y.; Zhang, Y.; Lee, J.H.; Cho, K.; Cho, J.H. Transparent, low-power pressure sensor matrix based on coplanar-gate graphene transistors. Adv. Mater. 2014, 26, 4735–4740. [Google Scholar] [CrossRef]

- Trung, T.Q.; Ramasundaram, S.; Hwang, B.U.; Lee, N.E. An all-elastomeric transparent and stretchable temperature sensor for body-attachable wearable electronics. Adv. Mater. 2016, 28, 502–509. [Google Scholar] [CrossRef]

- Liang, J.; Li, L.; Chen, D.; Hajagos, T.; Ren, Z.; Chou, S.-Y.; Hu, W.; Pei, Q. Intrinsically stretchable and transparent thin-film transistors based on printable silver nanowires, carbon nanotubes and an elastomeric dielectric. Nat. Commun. 2015, 6, 7647. [Google Scholar] [CrossRef]

- Kordás, K.; Mustonen, T.; Tóth, G.; Jantunen, H.; Lajunen, M.; Soldano, C.; Talapatra, S.; Kar, S.; Vajtai, R.; Ajayan, P.M. Inkjet printing of electrically conductive patterns of carbon nanotubes. Small 2006, 2, 1021–1025. [Google Scholar] [CrossRef] [PubMed]

- Falco, A.; Salmerón, J.; Loghin, F.; Abdelhalim, A.; Lugli, P.; Rivadeneyra, A. Optimization of process parameters for inkjet printing of cnt random networks on flexible substrates. In Proceedings of the 2016 IEEE 16th International Conference on Nanotechnology (IEEE-NANO), Sendai, Japan, 22–25 August 2016; pp. 487–490. [Google Scholar]

- Abdellah, A.; Abdelhalim, A.; Loghin, F.; Kohler, P.; Ahmad, Z.; Scarpa, G.; Lugli, P. Flexible carbon nanotube based gas sensors fabricated by large-scale spray deposition. Sens. J. IEEE 2013, 13, 4014–4021. [Google Scholar] [CrossRef]

- Loghin, F.; Colasanti, S.; Weise, A.; Falco, A.; Abdelhalim, A.; Lugli, P.; Abdellah, A. Scalable spray deposition process for highly uniform and reproducible cnt-tfts. Flex. Print. Electron. 2016, 1, 045002. [Google Scholar] [CrossRef]

- Commission Directive 2000/39/ec. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:02000L0039-20100108&from=EN (accessed on 8 June 2000).

- United States Department of LABOR. Occupational Safety and Health Administration. Available online: https://www.osha.gov/dts/chemicalsampling/data/CH_218300.html (accessed on 1 October 2019).

- Teerapanich, P.; Myint, M.T.Z.; Joseph, C.M.; Hornyak, G.L.; Dutta, J. Development and improvement of carbon nanotube-based ammonia gas sensors using ink-jet printed interdigitated electrodes. IEEE Trans. Nanotechnol. 2013, 12, 255–262. [Google Scholar] [CrossRef]

- Schütt, F.; Postica, V.; Adelung, R.; Lupan, O. Single and networked zno–cnt hybrid tetrapods for selective room-temperature high-performance ammonia sensors. ACS Appl. Mater. Interfaces 2017, 9, 23107–23118. [Google Scholar] [CrossRef] [PubMed]

- Abdelhalim, A.; Winkler, M.; Loghin, F.; Zeiser, C.; Lugli, P.; Abdellah, A. Highly sensitive and selective carbon nanotube-based gas sensor arrays functionalized with different metallic nanoparticles. Sens. Actuators B Chem. 2015, 220, 1288–1296. [Google Scholar] [CrossRef]

- Falco, A.; Cinà, L.; Scarpa, G.; Lugli, P.; Abdellah, A. Fully-sprayed and flexible organic photodiodes with transparent carbon nanotube electrodes. ACS Appl. Mater. Interfaces 2014, 6, 10593–10601. [Google Scholar] [CrossRef]

- Abdellah, A.; Abdelhalim, A.; Horn, M.; Scarpa, G.; Lugli, P. Scalable spray deposition process for high-performance carbon nanotube gas sensors. Nanotechnol. IEEE Trans. 2013, 12, 174–181. [Google Scholar] [CrossRef]

- Chien, Y.-M.; Lefevre, F.; Shih, I.; Izquierdo, R. A solution processed top emission oled with transparent carbon nanotube electrodes. Nanotechnology 2010, 21, 134020. [Google Scholar] [CrossRef]

- Haacke, G. New figure of merit for transparent conductors. J. Appl. Phys. 1976, 47, 4086–4089. [Google Scholar] [CrossRef]

- Colasanti, S.; Bhatt, V.D.; Abdelhalim, A.; Lugli, P. 3-d percolative model-based multiscale simulation of randomly aligned networks of carbon nanotubes. IEEE Trans. Electron Devices 2016, 63, 1346–1351. [Google Scholar] [CrossRef]

- Star, A.; Joshi, V.; Skarupo, S.; Thomas, D.; Gabriel, J.-C.P. Gas sensor array based on metal-decorated carbon nanotubes. J. Phys. Chem. B 2006, 110, 21014–21020. [Google Scholar] [CrossRef] [PubMed]

| Spacing (µm) | Electrode Material | Initial Resistance (kΩ) | Sensitivity (%norm.Response/ppm NH3) | Linearity (R2) |

|---|---|---|---|---|

| 50 | CNT | 6.16 | 0.1164 | 0.9621 |

| 100 | CNT | 10.29 | 0.1831 | 0.9627 |

| 200 | Au | 27.80 | 0.2165 | 0.9687 |

| CNT | 27.09 | 0.2484 | 0.9428 |

| Spacing (µm) | Electrode Material | Initial Resistance (kΩ) | Sensitivity (%norm.Response/ppm CO2) | Linearity (R2) |

|---|---|---|---|---|

| 50 | CNT | 4.00 | 0.000386 | 0.9973 |

| 100 | CNT | 12.95 | 0.001856 | 0.9870 |

| 200 | Au | 34.74 | 0.001230 | 0.9596 |

| CNT | 31.55 | 0.002114 | 0.9930 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loghin, F.C.; Falco, A.; Salmeron, J.F.; Lugli, P.; Abdellah, A.; Rivadeneyra, A. Fully Transparent Gas Sensor Based on Carbon Nanotubes. Sensors 2019, 19, 4591. https://doi.org/10.3390/s19204591

Loghin FC, Falco A, Salmeron JF, Lugli P, Abdellah A, Rivadeneyra A. Fully Transparent Gas Sensor Based on Carbon Nanotubes. Sensors. 2019; 19(20):4591. https://doi.org/10.3390/s19204591

Chicago/Turabian StyleLoghin, Florin C., Aniello Falco, Jose F. Salmeron, Paolo Lugli, Alaa Abdellah, and Almudena Rivadeneyra. 2019. "Fully Transparent Gas Sensor Based on Carbon Nanotubes" Sensors 19, no. 20: 4591. https://doi.org/10.3390/s19204591

APA StyleLoghin, F. C., Falco, A., Salmeron, J. F., Lugli, P., Abdellah, A., & Rivadeneyra, A. (2019). Fully Transparent Gas Sensor Based on Carbon Nanotubes. Sensors, 19(20), 4591. https://doi.org/10.3390/s19204591