Textile-Friendly Interconnection between Wearable Measurement Instrumentation and Sensorized Garments—Initial Performance Evaluation for Electrocardiogram Recordings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Polymer-Based Conductive Elastic Paste

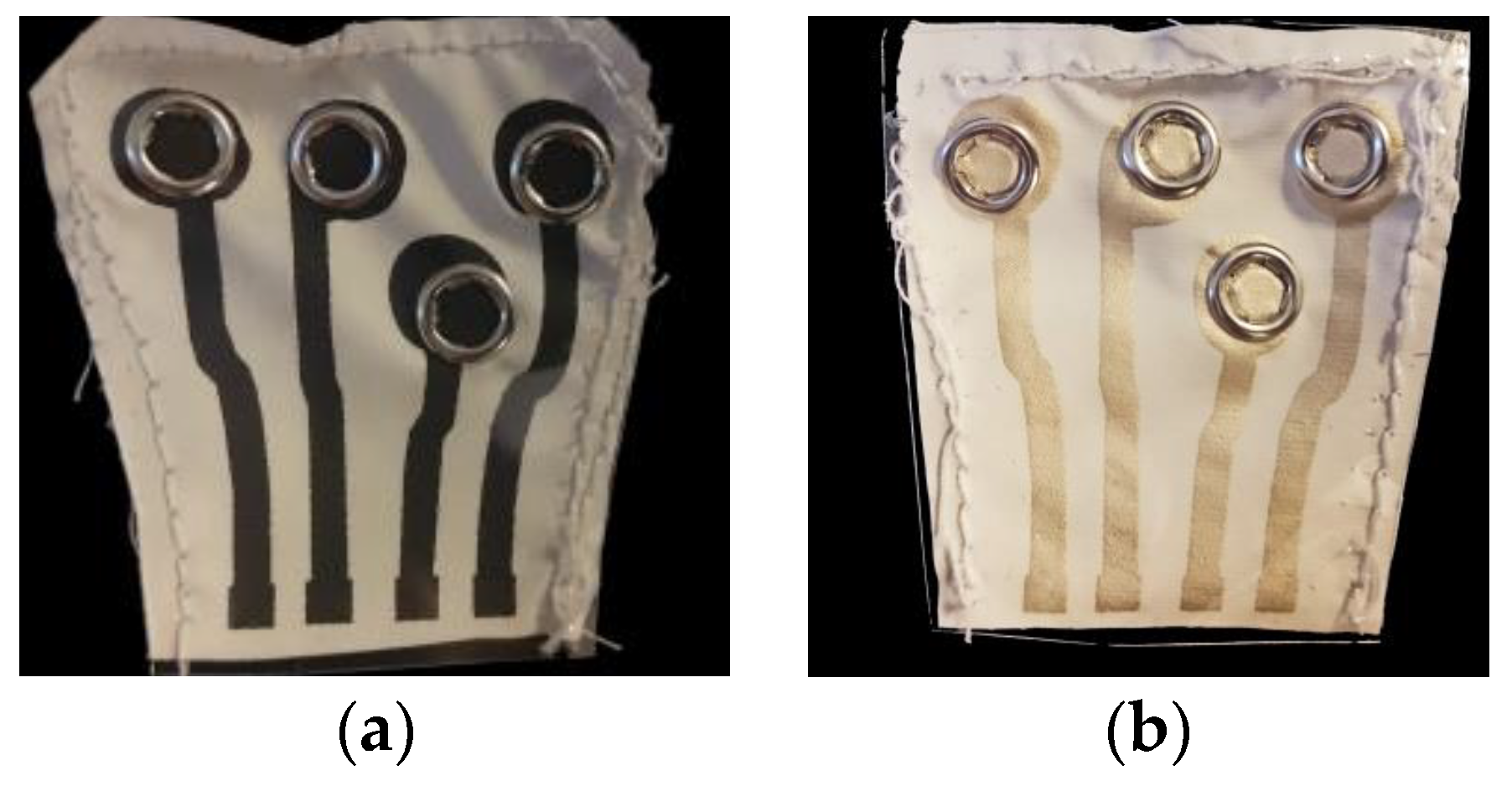

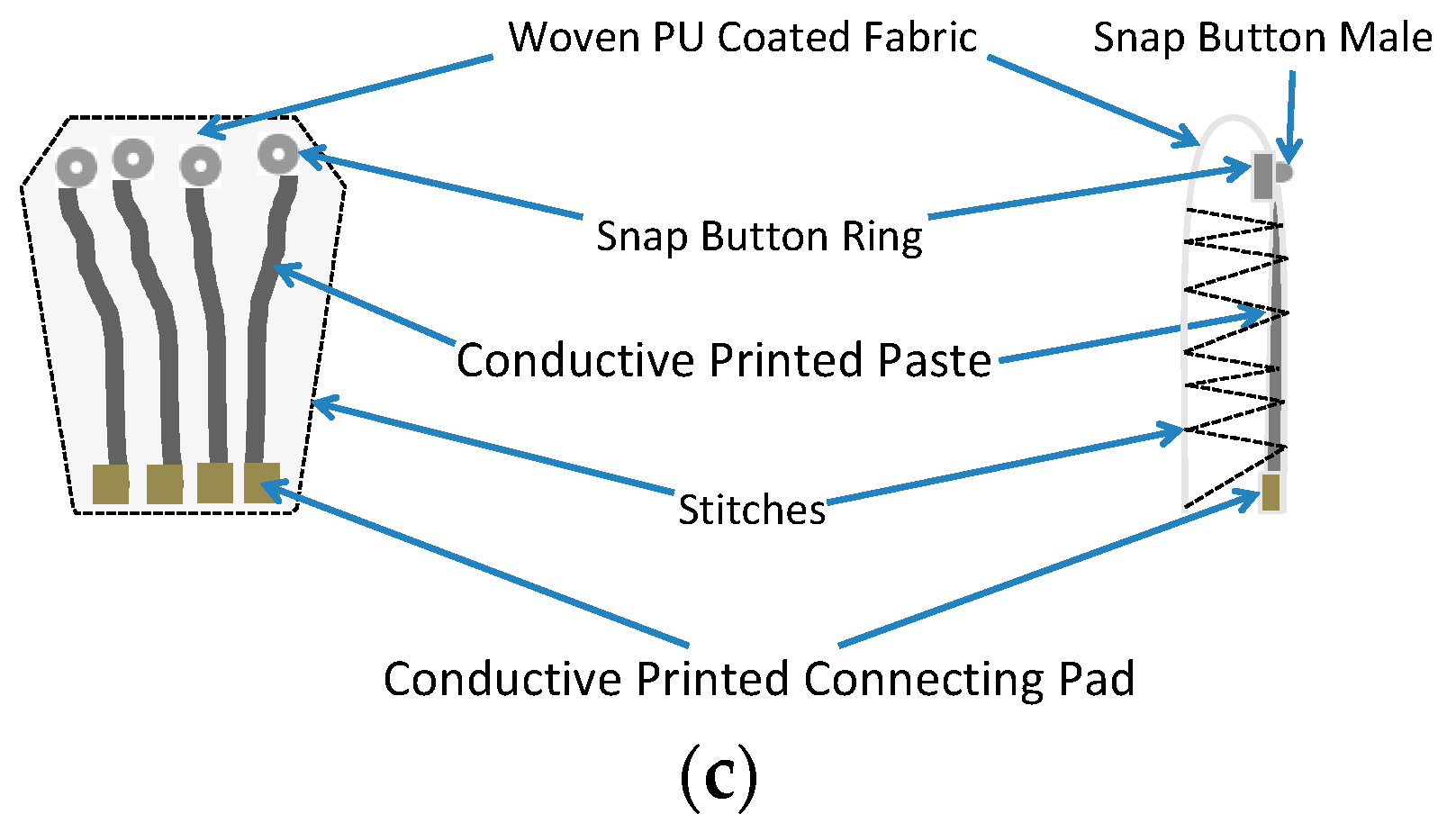

2.2. Connectors

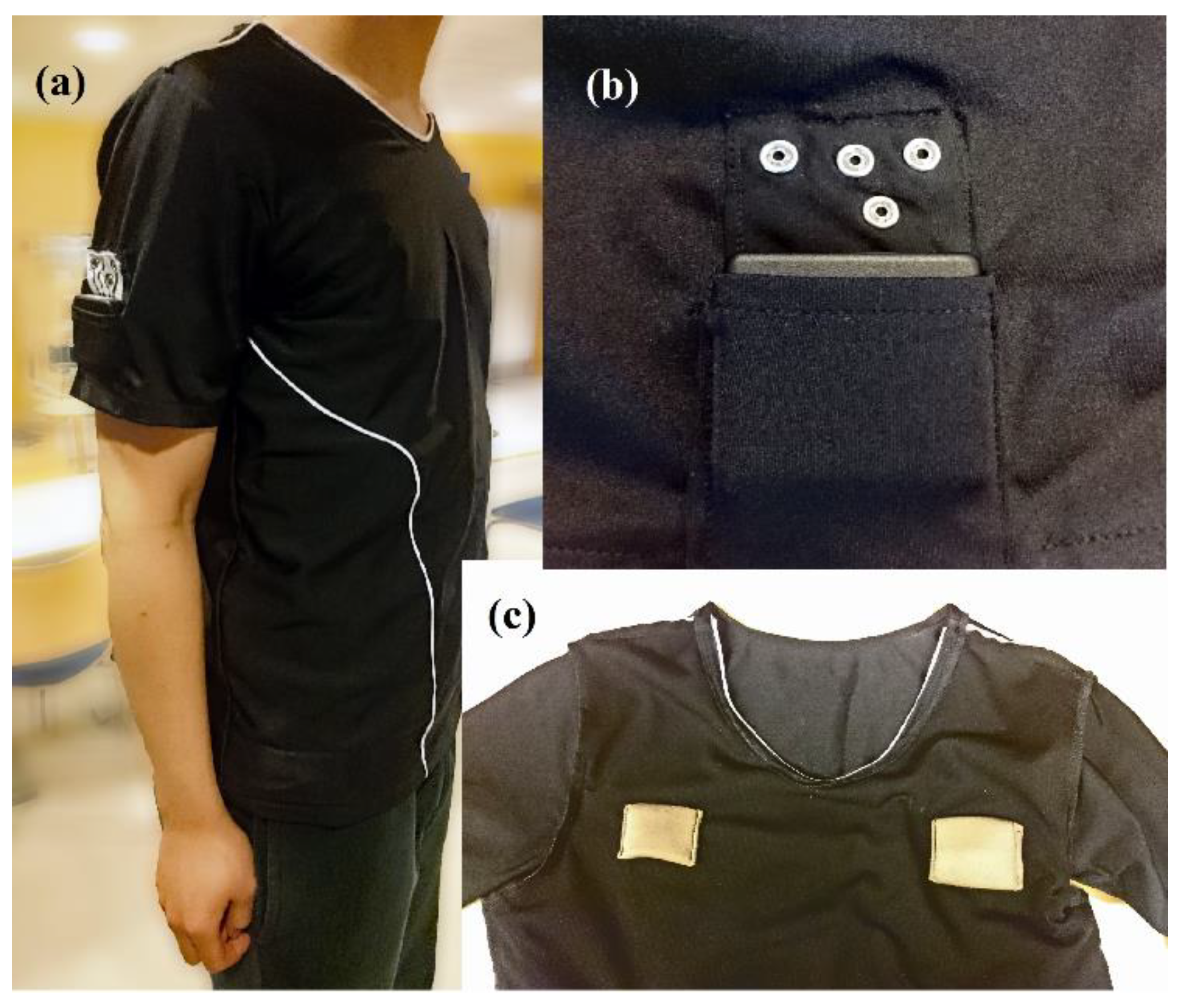

2.3. Sensorized Garment

2.4. Experimental Setup

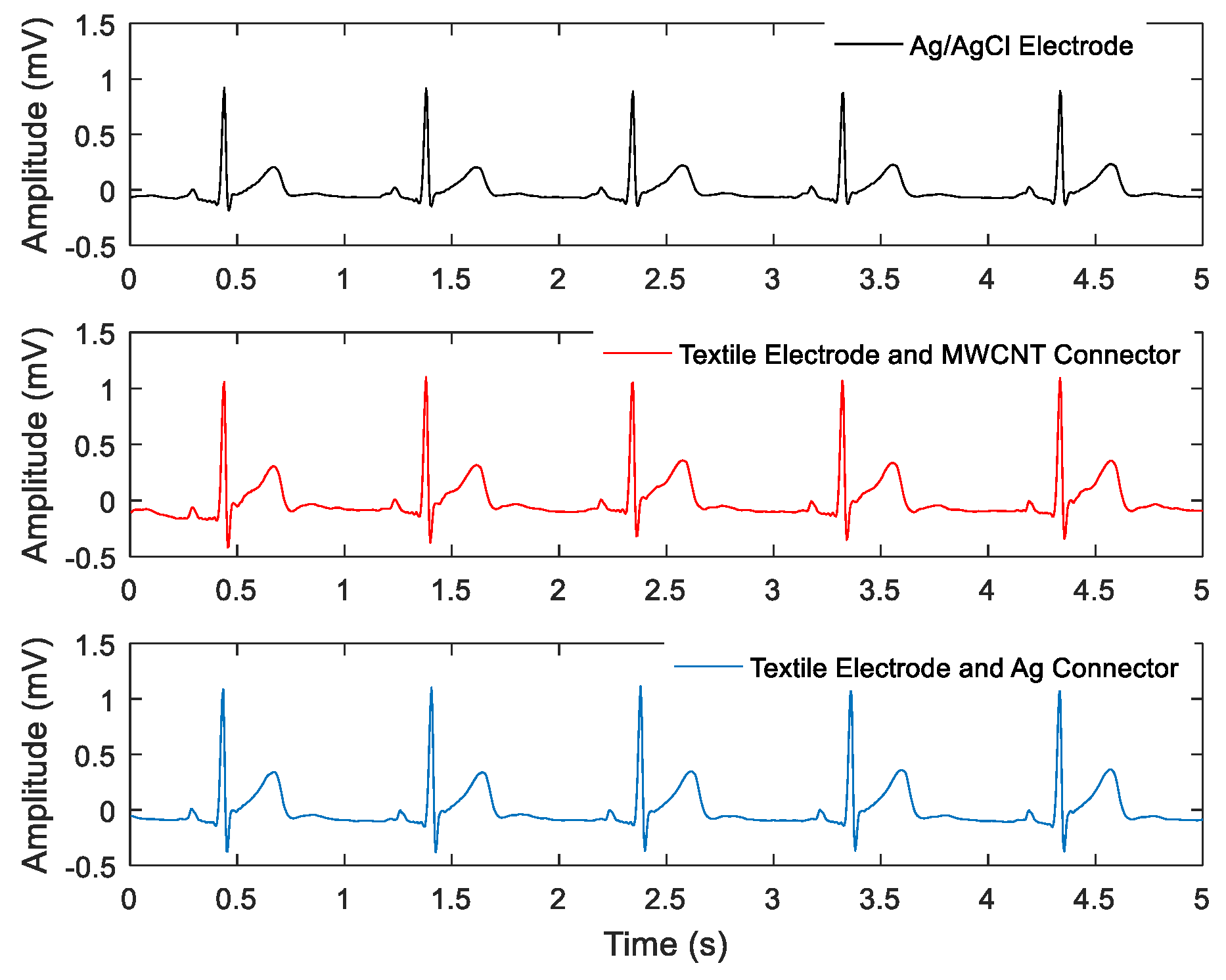

- Simultaneous synchronized ECG recording with gel electrodes and the sensorized garment using the MWCNT connector;

- Simultaneous synchronized ECG recording with gel electrodes and the sensorized garment using the Ag connector.

2.5. ECG Processing

2.6. Material Characterization

2.7. Signal Comparison

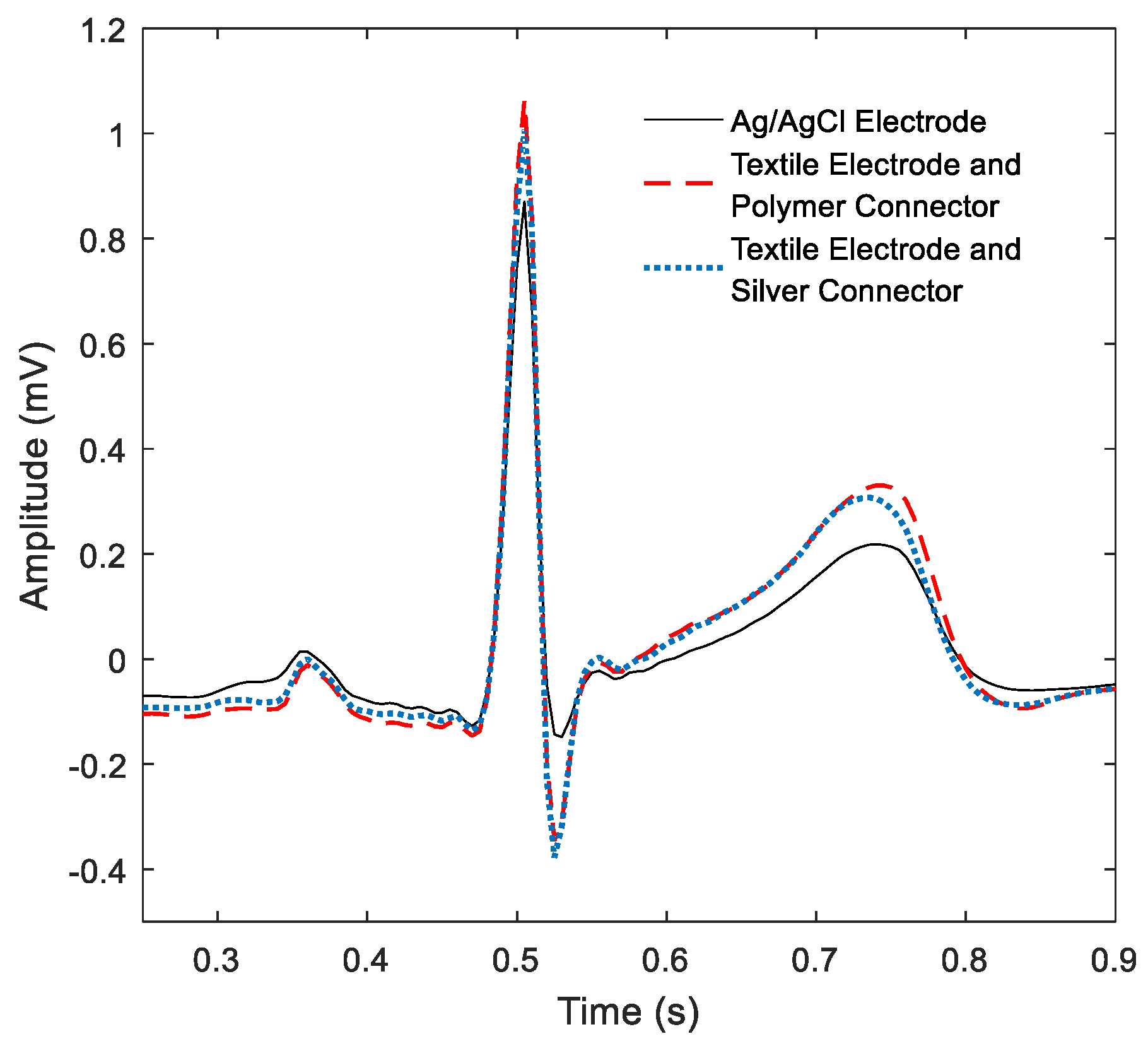

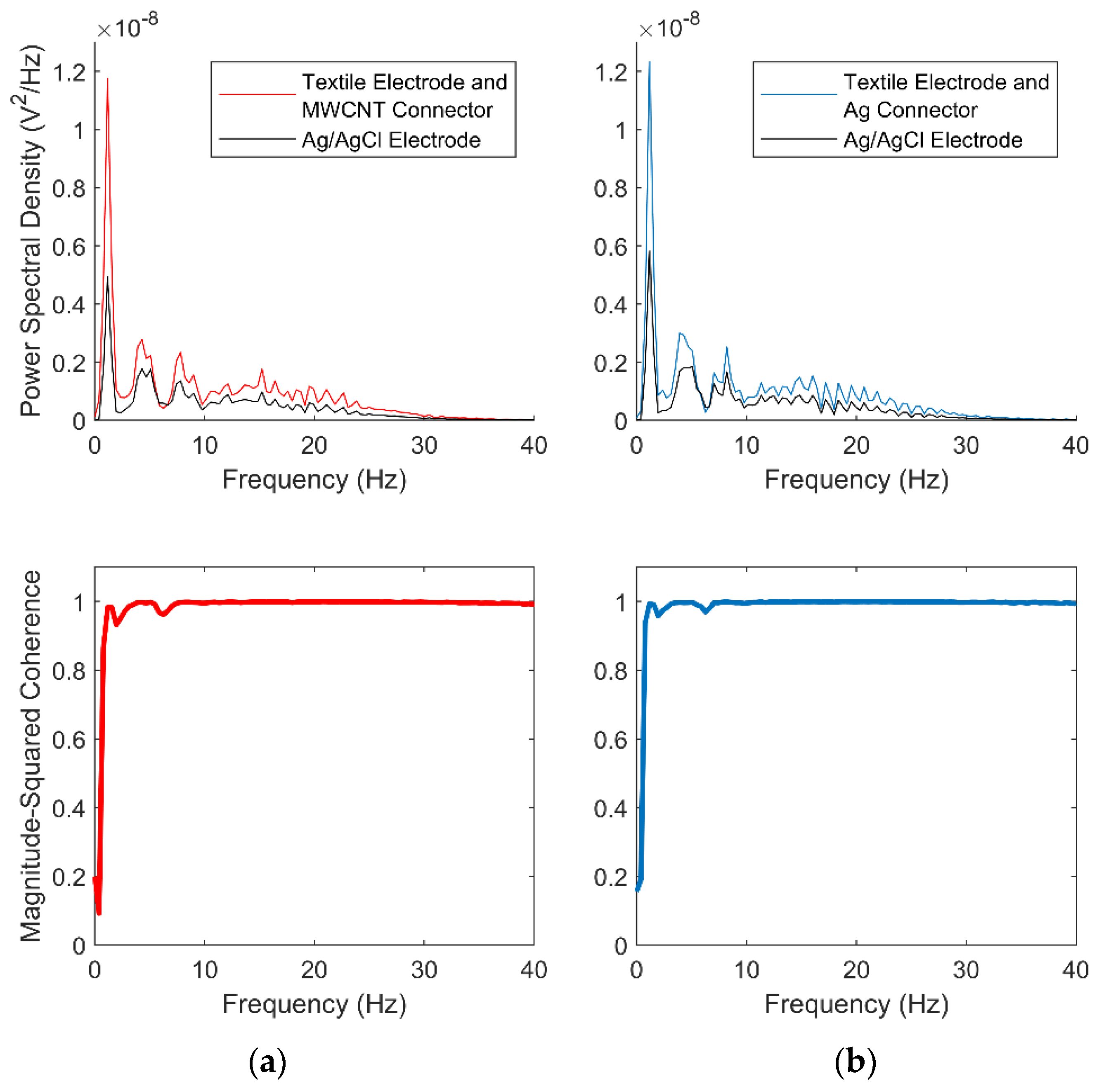

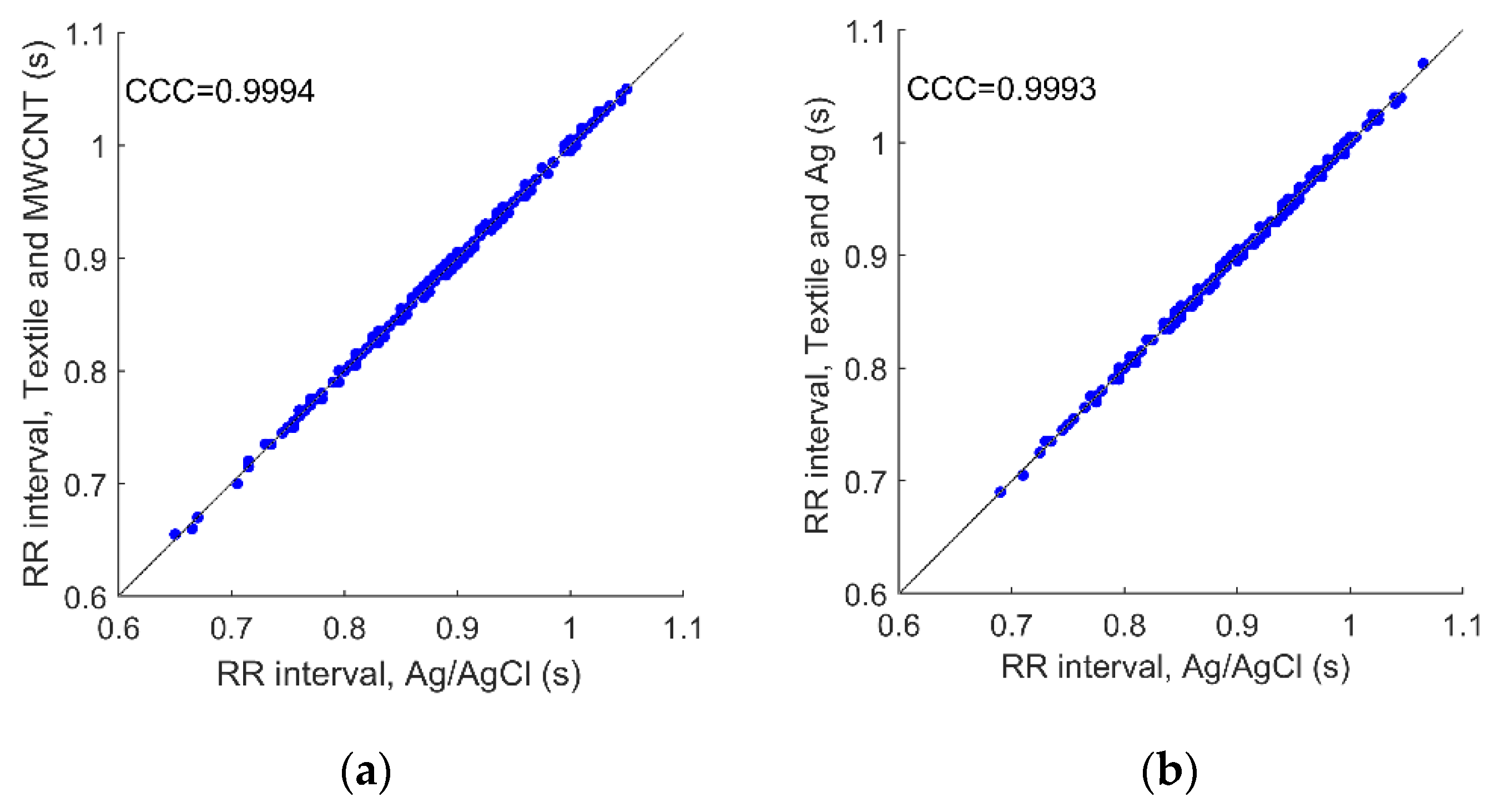

3. Results

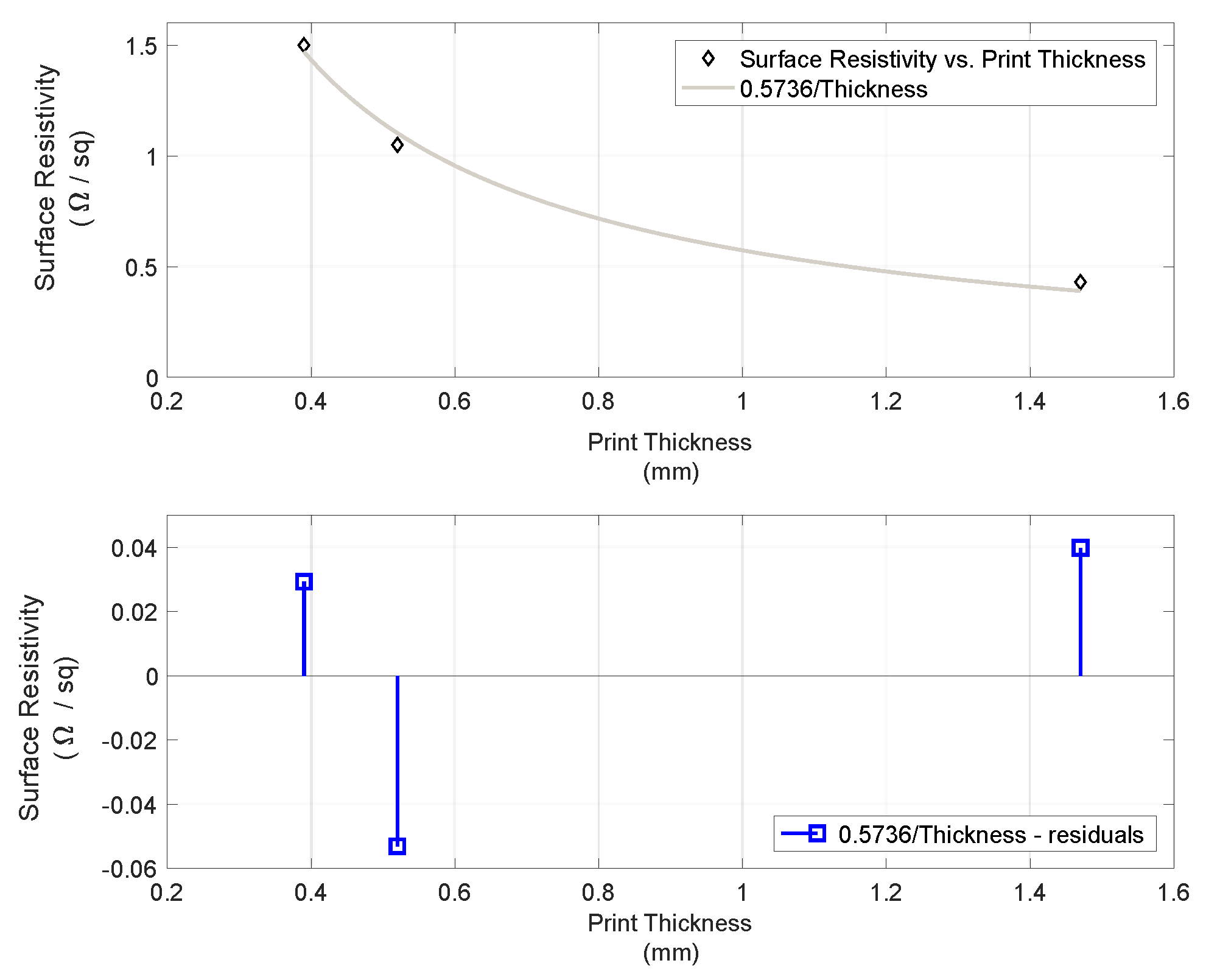

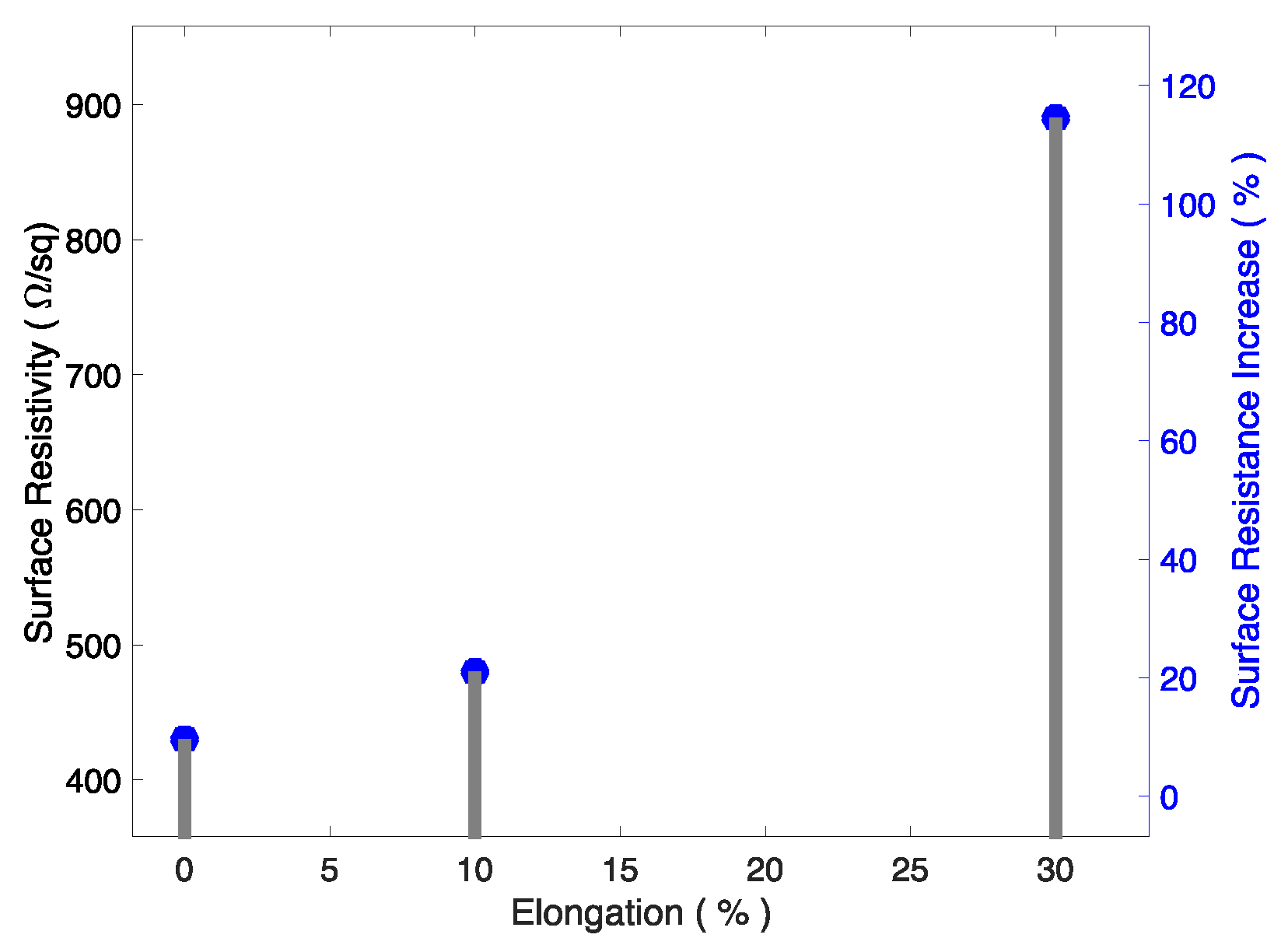

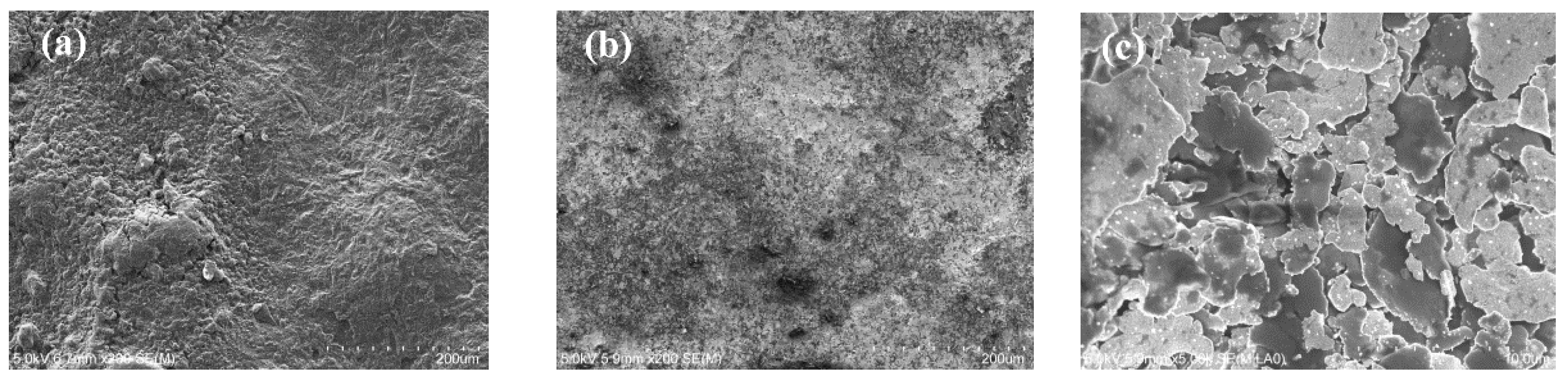

Electrical Characterization of the MWCNT Elastic Paste

4. Discussion

4.1. Resulting Electrical Properties of the Connectors

4.2. Performance as an Interconnector

4.3. Functionalization of Textiles as Textile–Electronic Interconnections

4.4. Textile-Friendly Methods

4.5. Impact in Sensing Performace

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Connector Resistance after Folding

| MWCNT Connector | Silver Connector | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| No. of Folds | 0 | 10 | 20 | 50 | No. of Folds | 0 | 10 | 20 | 50 |

| Connector #1 | Connector #1 | ||||||||

| Line 1 | 11.5 | 11.2 | 11.5 | 12.0 | Line 1 | 7.5 | 7.5 | 7.8 | 8 |

| Line 2 | 11.1 | 10.9 | 11.4 | 11.7 | Line 2 | 7.6 | 7.7 | 8 | 8.2 |

| Line 3 | 9.2 | 9.4 | 9.1 | 9.8 | Line 3 | 7.2 | 7.1 | 7.5 | 7.9 |

| Line 4 | 9.8 | 10.0 | 9.9 | 10.2 | Line 4 | 7.3 | 7.4 | 7.5 | 7.8 |

| Mean #1 | 10.4 | 10.4 | 10.5 | 10.9 | Mean #1 | 7.4 | 7.4 | 7.7 | 8.0 |

| Connector #2 | Connector #2 | ||||||||

| Line 1 | 10.4 | 10.7 | 10.6 | 11.0 | Line 1 | 8.1 | 8.3 | 8.5 | 8.8 |

| Line 2 | 10.7 | 10.3 | 11.1 | 11.1 | Line 2 | 7.8 | 8 | 8.1 | 8.5 |

| Line 3 | 9.0 | 9.2 | 9.1 | 9.6 | Line 3 | 7.3 | 7.5 | 7.9 | 8.1 |

| Line 4 | 10.0 | 9.8 | 10.1 | 10.4 | Line 4 | 7.3 | 7.3 | 7.6 | 8 |

| Mean #2 | 10.0 | 10.0 | 10.2 | 10.5 | Mean #2 | 7.6 | 7.8 | 8.0 | 8.4 |

| Connector #3 | Connector #3 | ||||||||

| Line 1 | 11.0 | 10.7 | 10.6 | 11.4 | Line 1 | 7.4 | 7.7 | 8 | 8.2 |

| Line 2 | 11.2 | 11.0 | 11.5 | 11.7 | Line 2 | 7.3 | 7.8 | 8 | 8.3 |

| Line 3 | 9.6 | 9.8 | 9.7 | 10.0 | Line 3 | 7.1 | 7.4 | 8.2 | 8.5 |

| Line 4 | 10.3 | 10.4 | 10.1 | 10.4 | Line 4 | 7.2 | 7.7 | 8.1 | 8.4 |

| Mean #3 | 10.5 | 10.5 | 10.5 | 10.9 | Mean #3 | 7.3 | 7.7 | 8.1 | 8.4 |

| Total mean | 10.3 | 10.3 | 10.4 | 10.8 | Total mean | 7.4 | 7.6 | 7.9 | 8.2 |

| Total Δ (%) | 0 | −0.3 | 0.7 | 4.4 | Total Δ (%) | 0 | 2.6 | 6.8 | 10.8 |

References

- Li, L.; Au, W.M.; Li, Y.; Wan, K.M.; Wan, S.H.; Wong, K.S. Design of intelligent garment with transcutaneous electrical nerve stimulation function based on the intarsia knitting technique. Text. Res. J. 2010, 80, 279–286. [Google Scholar] [CrossRef]

- Seoane, F.; Ferreira, J.; Alvarez, L.; Buendia, R.; Ayllon, D.; Llerena, C.; Gil-Pita, R. Sensorized Garments and Textrode-Enabled Measurement Instrumentation for Ambulatory Assessment of the Autonomic Nervous System Response in the ATREC Project. Sensors 2013, 13, 8997–9015. [Google Scholar] [CrossRef] [PubMed]

- Yoo, J.; Yan, L.; Lee, S.; Kim, H.; Yoo, H.-J. A wearable ECG acquisition system with compact planar-fashionable circuit board-based shirt. IEEE Trans. Inf. Technol. Biomed. 2009, 13, 897–902. [Google Scholar] [CrossRef] [PubMed]

- Abtahi, F.; Ji, G.; Lu, K.; Rodby, K.; Seoane, F. A knitted garment using intarsia technique for Heart Rate Variability biofeedback: Evaluation of initial prototype. In Proceedings of the 2015 37th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Milan, Italy, 25–29 August 2015; pp. 3121–3124. [Google Scholar]

- Nick Langston, J.; Connectivity, T.; Menlo Park, C. Connectivity Challenges in Smart Textiles. Available online: https://www.telecomengine.com/article/connectivity-challenges-smart-textiles/ (accessed on 10 December 2018).

- Miles, C.; Leslie, W. Textile Printing, 2nd ed.; Amer Assn of Textile: Bradford, UK, 2010. [Google Scholar]

- Perelaer, J.; Smith, P.J.; Mager, D.; Soltman, D.; Volkman, S.K.; Subramanian, V.; Korvink, J.G.; Schubert, U.S. Printed electronics: The challenges involved in printing devices, interconnects, and contacts based on inorganic materials. J. Mater. Chem. 2010, 20, 8446–8453. [Google Scholar] [CrossRef]

- Cohen, S.R. A review of the health hazards from copper exposure. J. Occup. Environ. Med. 1974, 16, 621–624. [Google Scholar] [CrossRef] [PubMed]

- Norman, R.H. Conductive Rubbers and Plastics: Their Production, Application and Test Methods; Elsevier Publishing Company, Inc.: New York, NY, USA, 1957. [Google Scholar]

- Lötters, J.; Olthuis, W.; Veltink, P.; Bergveld, P. The mechanical properties of the rubber elastic polymer polydimethylsiloxane for sensor applications. J. Micromech. Microeng. 1997, 7, 145. [Google Scholar] [CrossRef]

- Li, F.; Qi, L.; Yang, J.; Xu, M.; Luo, X.; Ma, D. Polyurethane/conducting carbon black composites: Structure, electric conductivity, strain recovery behavior, and their relationships. J. Appl. Polym. Sci. 2000, 75, 68–77. [Google Scholar] [CrossRef]

- Gubbels, F.; Blacher, S.; Vanlathem, E.; Jérôme, R.; Deltour, R.; Brouers, F.; Teyssie, P. Design of electrical composites: Determining the role of the morphology on the electrical properties of carbon black filled polymer blends. Macromolecules 1995, 28, 1559–1566. [Google Scholar] [CrossRef]

- Shin, M.K.; Oh, J.; Lima, M.; Kozlov, M.E.; Kim, S.J.; Baughman, R.H. Elastomeric conductive composites based on carbon nanotube forests. Adv. Mater. 2010, 22, 2663–2667. [Google Scholar] [CrossRef]

- Marinho, B.; Ghislandi, M.; Tkalya, E.; Koning, C.E.; de With, G. Electrical conductivity of compacts of graphene, multi-wall carbon nanotubes, carbon black, and graphite powder. Powder Technol. 2012, 221, 351–358. [Google Scholar] [CrossRef]

- Lin, C.-T.; Chang, K.-C.; Lin, C.-L.; Chiang, C.-C.; Lu, S.-W.; Chang, S.-S.; Lin, B.-S.; Liang, H.-Y.; Chen, R.-J.; Lee, Y.-T. An intelligent telecardiology system using a wearable and wireless ECG to detect atrial fibrillation. IEEE Trans. Inf. Technol. Biomed. 2010, 14, 726–733. [Google Scholar] [PubMed]

- Nemati, S.; Ghassemi, M.M.; Ambai, V.; Isakadze, N.; Levantsevych, O.; Shah, A.; Clifford, G.D. Monitoring and detecting atrial fibrillation using wearable technology. In Proceedings of the 2016 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Orlando, FL, USA, 16–20 August 2016; pp. 3394–3397. [Google Scholar]

- Yang, L.; Lu, K.; Diaz-Olivares, J.A.; Seoane, F.; Lindecrantz, K.; Forsman, M.; Abtahi, F.; Eklund, J.A. Towards smart work clothing for automatic risk assessment of physical workload. IEEE Access 2018, 6, 40059–40072. [Google Scholar] [CrossRef]

- Lu, K.; Yang, L.; Seoane, F.; Abtahi, F.; Forsman, M.; Lindecrantz, K. Fusion of Heart Rate, Respiration and Motion Measurements from a Wearable Sensor System to Enhance Energy Expenditure Estimation. Sensors 2018, 18, 3092. [Google Scholar] [CrossRef] [PubMed]

- Lu, K.; Yang, L.; Abtahi, F.; Lindecrantz, K.; Rödby, K.; Seoane, F. Wearable Cardiorespiratory Monitoring System for Unobtrusive Free-Living Energy Expenditure Tracking; Springer: Singapore, 2019; pp. 433–437. [Google Scholar]

- Seoane, F.; Mohino-Herranz, I.; Ferreira, J.; Alvarez, L.; Buendia, R.; Ayllón, D.; Llerena, C.; Gil-Pita, R. Wearable biomedical measurement systems for assessment of mental stress of combatants in real time. Sensors 2014, 14, 7120–7141. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D. Wavelet approach for ECG baseline wander correction and noise reduction. In Proceedings of the 2005 IEEE Engineering in Medicine and Biology 27th Annual Conference, Shanghai, China, 17–18 Januar 2006; pp. 1212–1215. [Google Scholar]

- Donoho, D.L.; Johnstone, I.M. Adapting to unknown smoothness via wavelet shrinkage. J. Am. Stat. Assoc. 1995, 90, 1200–1224. [Google Scholar] [CrossRef]

- Tikkanen, P. Nonlinear wavelet and wavelet packet denoising of electrocardiogram signal. Biol. Cybern. 1999, 80, 259–267. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.; Tompkins, W.J. A real-time QRS detection algorithm. Biomed. Eng. IEEE Trans. 1985, 32, 230–236. [Google Scholar] [CrossRef]

- Willems, J. Recommendations for measurement standards in quantitative electrocardiography. Eur. Heart J. 1985, 6, 815–825. [Google Scholar]

- Abtahi, F.; Seoane, F.; Lindecrantz, K.; Löfgren, N. Elimination of ECG Artefacts in Foetal EEG Using Ensemble Average Subtraction and Wavelet Denoising Methods: A Simulation. In Proceedings of the XIII Mediterranean Conference on Medical and Biological Engineering and Computing 2013, Seville, Spain, 25–28 September 2013; pp. 551–554. [Google Scholar]

- Lawrence, I.; Lin, K. A concordance correlation coefficient to evaluate reproducibility. Biometrics 1989, 255–268. [Google Scholar]

- Kim, S.; Leonhardt, S.; Zimmermann, N.; Kranen, P.; Kensche, D.; Muller, E.; Quix, C. Influence of contact pressure and moisture on the signal quality of a newly developed textile ECG sensor shirt. In Proceedings of the 2008 5th International Summer School and Symposium on Medical Devices and Biosensors, Hong Kong, China, 1–3 June 2008; pp. 256–259. [Google Scholar]

- Feng, C.; Liu, K.; Wu, J.S.; Liu, L.; Cheng, J.S.; Zhang, Y.; Sun, Y.; Li, Q.; Fan, S.; Jiang, K. Flexible, stretchable, transparent conducting films made from superaligned carbon nanotubes. Adv. Funct. Mater. 2010, 20, 885–891. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Tee, B.C.K.; Vosgueritchian, M.; Bao, Z. Stretchable organic solar cells. Adv. Mater. 2011, 23, 1771–1775. [Google Scholar] [CrossRef] [PubMed]

- Lee, P.; Lee, J.; Lee, H.; Yeo, J.; Hong, S.; Nam, K.H.; Lee, D.; Lee, S.S.; Ko, S.H. Highly stretchable and highly conductive metal electrode by very long metal nanowire percolation network. Adv. Mater. 2012, 24, 3326–3332. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Zhu, Y. Highly conductive and stretchable silver nanowire conductors. Adv. Mater. 2012, 24, 5117–5122. [Google Scholar] [CrossRef] [PubMed]

- Suikkola, J.; Björninen, T.; Mosallaei, M.; Kankkunen, T.; Iso-Ketola, P.; Ukkonen, L.; Vanhala, J.; Mäntysalo, M. Screen-printing fabrication and characterization of stretchable electronics. Sci. Rep. 2016, 6, 25784. [Google Scholar] [CrossRef]

- Du, D.; Yang, X.; Yang, Y.; Zhao, Y.; Wang, Y. Silver Nanowire Ink for Flexible Circuit on Textiles. Micromachines 2019, 10, 42. [Google Scholar] [CrossRef]

- Maheshwari, N.; Abd-Ellah, M.; Goldthorpe, I.A. Transfer printing of silver nanowire conductive ink for E-textile applications. Flex. Print. Electron. 2019, 4, 2. [Google Scholar] [CrossRef]

- 5000 Silver Conductor-DuPont. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=2ahUKEwi0yMvj65XlAhVYFogKHdaOC0YQFjAAegQIAxAC&url=https%3A%2F%2Fwww.dupont.com%2Fcontent%2Fdam%2Fdupont%2Fproducts-and-services%2Felectronic-and-electrical-materials%2Fdocuments%2Fprodlib%2F5000.pdf&usg=AOvVaw1LHS6FbW7Y5qrYZMvMsu1s (accessed on 10 October 2019).

- Khandpur, R.S. Printed Circuit Boards: Design, Fabrication, Assembly and Testing; Tata McGraw-Hill Education: New Delhi, India, 2005. [Google Scholar]

- Lee, J.W.; Kim, D.M.; Park, I.Y.; Park, H.J.; Cho, J.H. Characteristics of human skin impedance including at biological active points. IEEE Trans. Fundam. Electron. Commun. Comput. Sci. 2003, E86A, 1476–1479. [Google Scholar]

- Scharfetter, H.; Hartinger, P.; Hinghofer-Szalkay, H.; Hutten, H. A model of artefacts produced by stray capacitance during whole body or segmental bioimpedance spectroscopy. Physiol. Meas. 1998, 19, 247–261. [Google Scholar] [CrossRef]

- Buendía, R.; Bogonez-Franco, P.; Nescolarde, L.; Seoane, F. Influence of electrode mismatch on Cole parameter estimation from Total Right Side Electrical Bioimpedance Spectroscopy measurements. Med. Eng. Phys. 2012, 34, 1024–1028. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Qi, K.; Xin, J. Functionalization of cotton with carbon nanotubes. J. Mater. Chem. 2008, 18, 3454–3460. [Google Scholar] [CrossRef]

- Kazani, I.; Hertleer, C.; De Mey, G.; Schwarz, A.; Guxho, G.; Van Langenhove, L. Electrical conductive textiles obtained by screen printing. Fibres Text. East. Eur. 2012, 20, 57–63. [Google Scholar]

- Locher, I.; Tröster, G. Screen-printed textile transmission lines. Text. Res. J. 2007, 77, 837–842. [Google Scholar] [CrossRef]

- Scarpello, M.L.; Kazani, I.; Hertleer, C.; Rogier, H.; Ginste, D.V. Stability and efficiency of screen-printed wearable and washable antennas. IEEE Antennas Wirel. Propag. Lett. 2012, 11, 838–841. [Google Scholar] [CrossRef]

- Sekitani, T.; Nakajima, H.; Maeda, H.; Fukushima, T.; Aida, T.; Hata, K.; Someya, T. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors. Nat. Mater. 2009, 8, 494–499. [Google Scholar] [CrossRef] [PubMed]

- Sekitani, T.; Noguchi, Y.; Hata, K.; Fukushima, T.; Aida, T.; Someya, T. A rubberlike stretchable active matrix using elastic conductors. Science 2008, 321, 1468–1472. [Google Scholar] [CrossRef]

- Mehmann, A.; Varga, M.; G, K. A ball-grid-array-like electronics-to-textile pocket connector for wearable electronics. In Proceedings of the 2015 ACM International Symposium on Wearable Computers, Osaka, Japan, 7–11 September 2015; pp. 57–60. [Google Scholar]

- Poupyrev, I.; Gong, N.-W.; Fukuhara, S.; Karagozler, M.E.; Schwesig, C.; Robinson, K.E. Project Jacquard: Interactive digital textiles at scale. In Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems, San Jose, CA, USA, 7–12 May 2016; pp. 4216–4227. [Google Scholar]

- Tan, E.; Jing, Q.; Smith, M.; Kar-Narayan, S.; Occhipinti, L. Needs and enabling technologies for stretchable electronics commercialization. MRS Adv. 2017, 2, 1721–1729. [Google Scholar] [CrossRef]

- Seifert, T.; Sowade, E.; Roscher, F.; Wiemer, M.; Gessner, T.; Baumann, R.R. Additive manufacturing technologies compared: Morphology of deposits of silver ink using inkjet and aerosol jet printing. Ind. Eng. Chem. Res. 2015, 54, 769–779. [Google Scholar] [CrossRef]

- Meziane, N.; Yang, S.; Shokoueinejad, M.; Webster, J.; Attari, M.; Eren, H. Simultaneous comparison of 1 gel with 4 dry electrode types for electrocardiography. Physiol. Meas. 2015, 36, 513. [Google Scholar] [CrossRef]

| Type of Connector | No. of Folds | ||

|---|---|---|---|

| 10 | 20 | 50 | |

| MWCNT | −0.3 | 0.7 | 4.4 |

| Silver | 2.6 | 6.8 | 10.8 |

| (Mean ± SD) | Gel Electrode and Cable Connection | Textile Electrodes with Printed Connectors | |

|---|---|---|---|

| MWCNT Paste | Silver Paste | ||

| Powerline Interference RMS (mV) | 0.02 ± 0.00 | 0.07 ± 0.01 | 0.05 ± 0.01 |

| Short Time Baseline Wander (mV) | 0.07 ± 0.02 | 1.60 ± 0.96 | 2.20 ± 1.40 |

| R-peak Amplitude (mV) | 0.70 ± 0.05 | 1.00 ± 0.06 | 0.99 ± 0.05 |

| Correlation with Gel Electrode | N/A | 0.96 ± 0.01 | 0.97 ± 0.00 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seoane, F.; Soroudi, A.; Lu, K.; Nilsson, D.; Nilsson, M.; Abtahi, F.; Skrifvars, M. Textile-Friendly Interconnection between Wearable Measurement Instrumentation and Sensorized Garments—Initial Performance Evaluation for Electrocardiogram Recordings. Sensors 2019, 19, 4426. https://doi.org/10.3390/s19204426

Seoane F, Soroudi A, Lu K, Nilsson D, Nilsson M, Abtahi F, Skrifvars M. Textile-Friendly Interconnection between Wearable Measurement Instrumentation and Sensorized Garments—Initial Performance Evaluation for Electrocardiogram Recordings. Sensors. 2019; 19(20):4426. https://doi.org/10.3390/s19204426

Chicago/Turabian StyleSeoane, Fernando, Azadeh Soroudi, Ke Lu, David Nilsson, Marie Nilsson, Farhad Abtahi, and Mikael Skrifvars. 2019. "Textile-Friendly Interconnection between Wearable Measurement Instrumentation and Sensorized Garments—Initial Performance Evaluation for Electrocardiogram Recordings" Sensors 19, no. 20: 4426. https://doi.org/10.3390/s19204426

APA StyleSeoane, F., Soroudi, A., Lu, K., Nilsson, D., Nilsson, M., Abtahi, F., & Skrifvars, M. (2019). Textile-Friendly Interconnection between Wearable Measurement Instrumentation and Sensorized Garments—Initial Performance Evaluation for Electrocardiogram Recordings. Sensors, 19(20), 4426. https://doi.org/10.3390/s19204426