An Ultra-Short Baseline Positioning Model Based on Rotating Array & Reusing Elements and Its Error Analysis

Abstract

1. Introduction

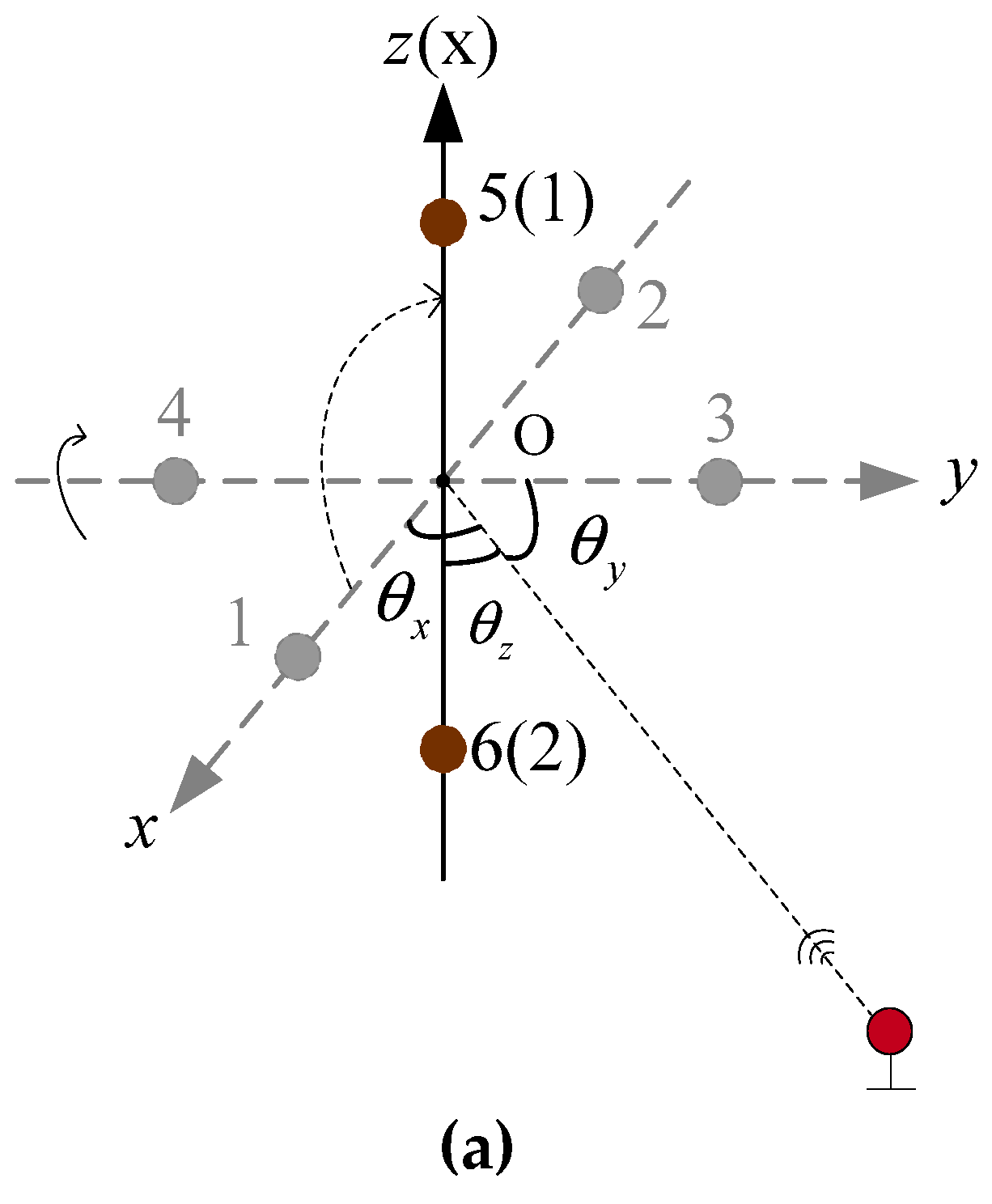

2. The Principle and Error Analysis of Traditional USBL Positioning System Based on Distance and Angle of Incidence

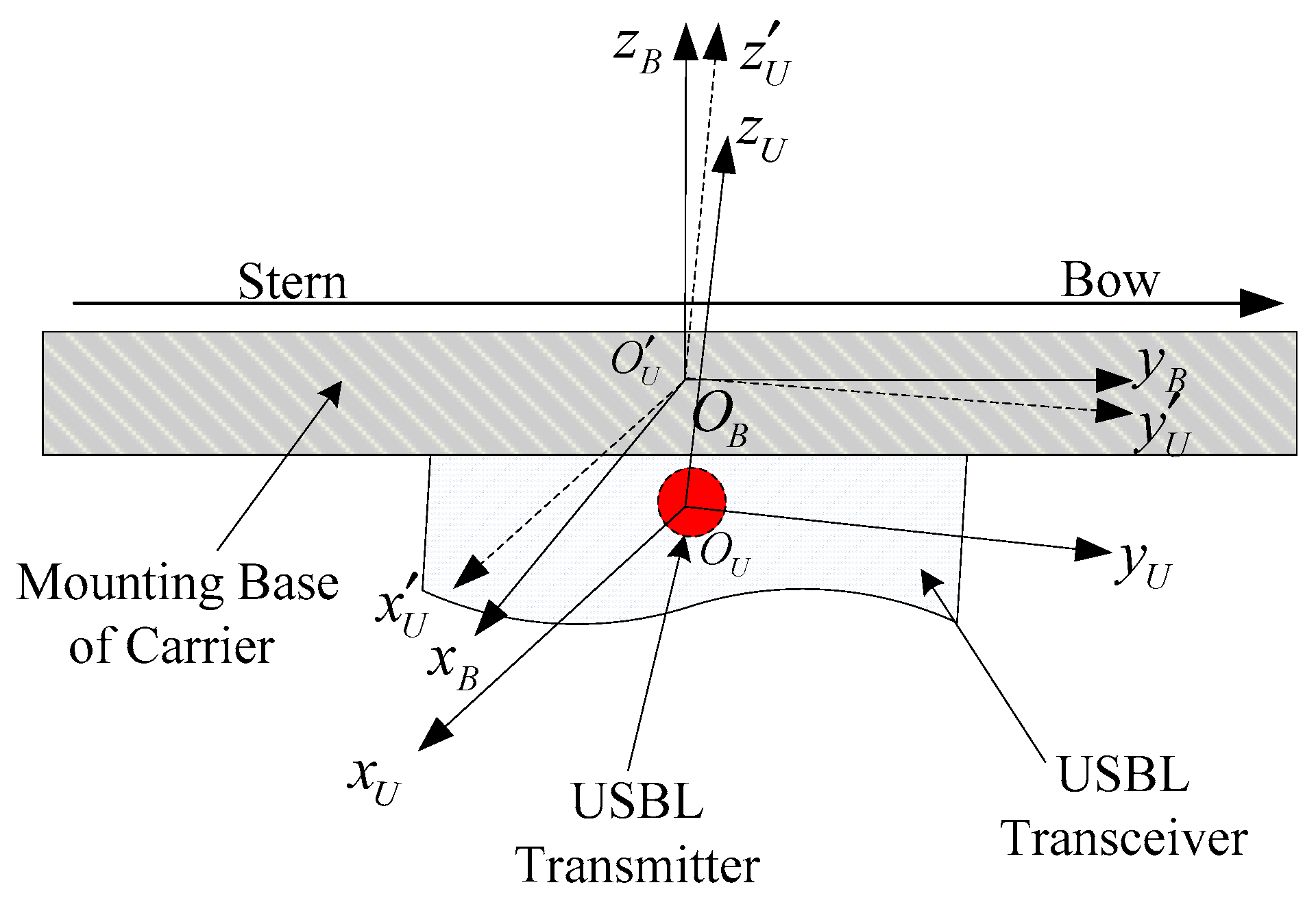

2.1. Coordinate Frame Definition

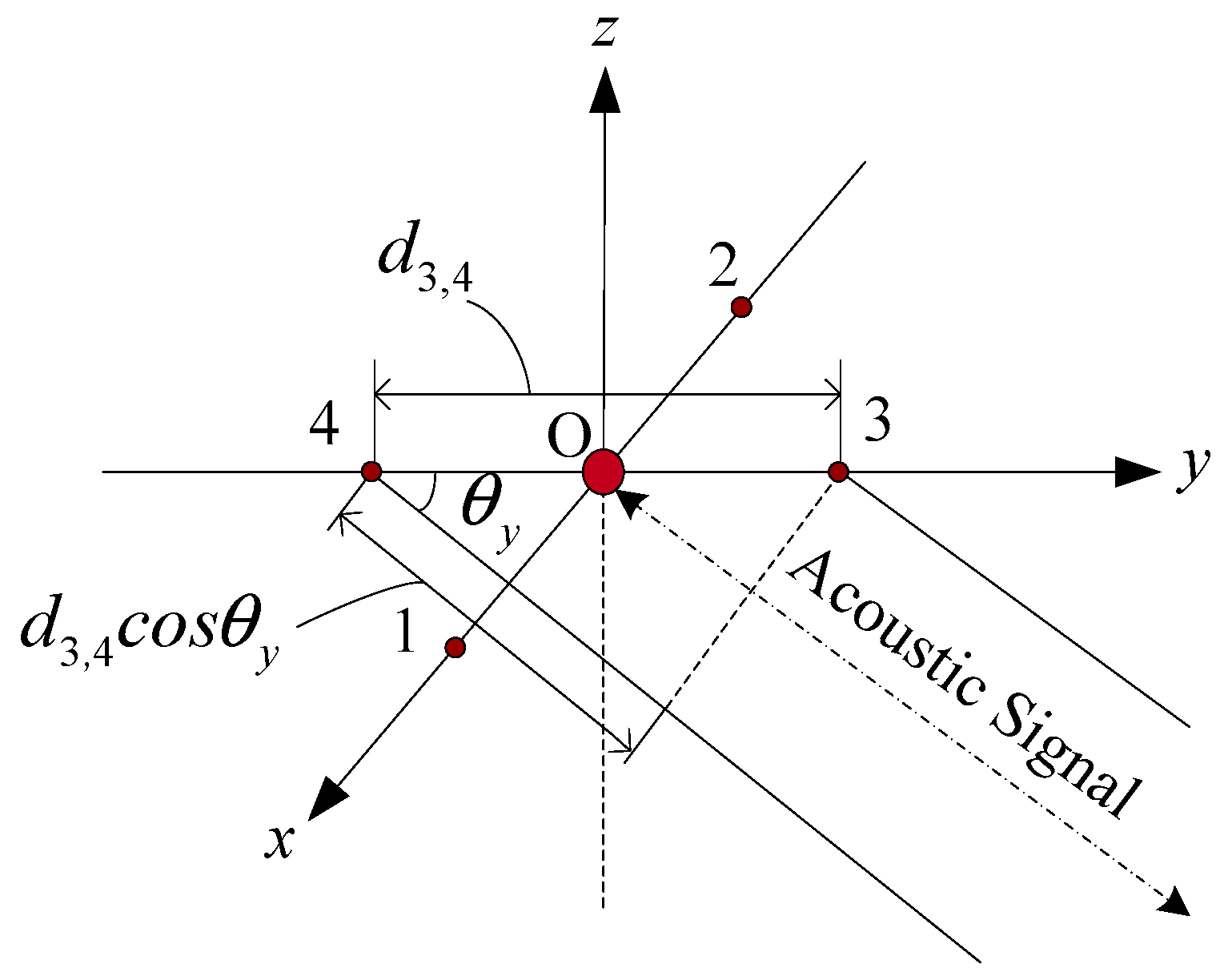

2.2. The Basic Principle of the USBL Positioning System

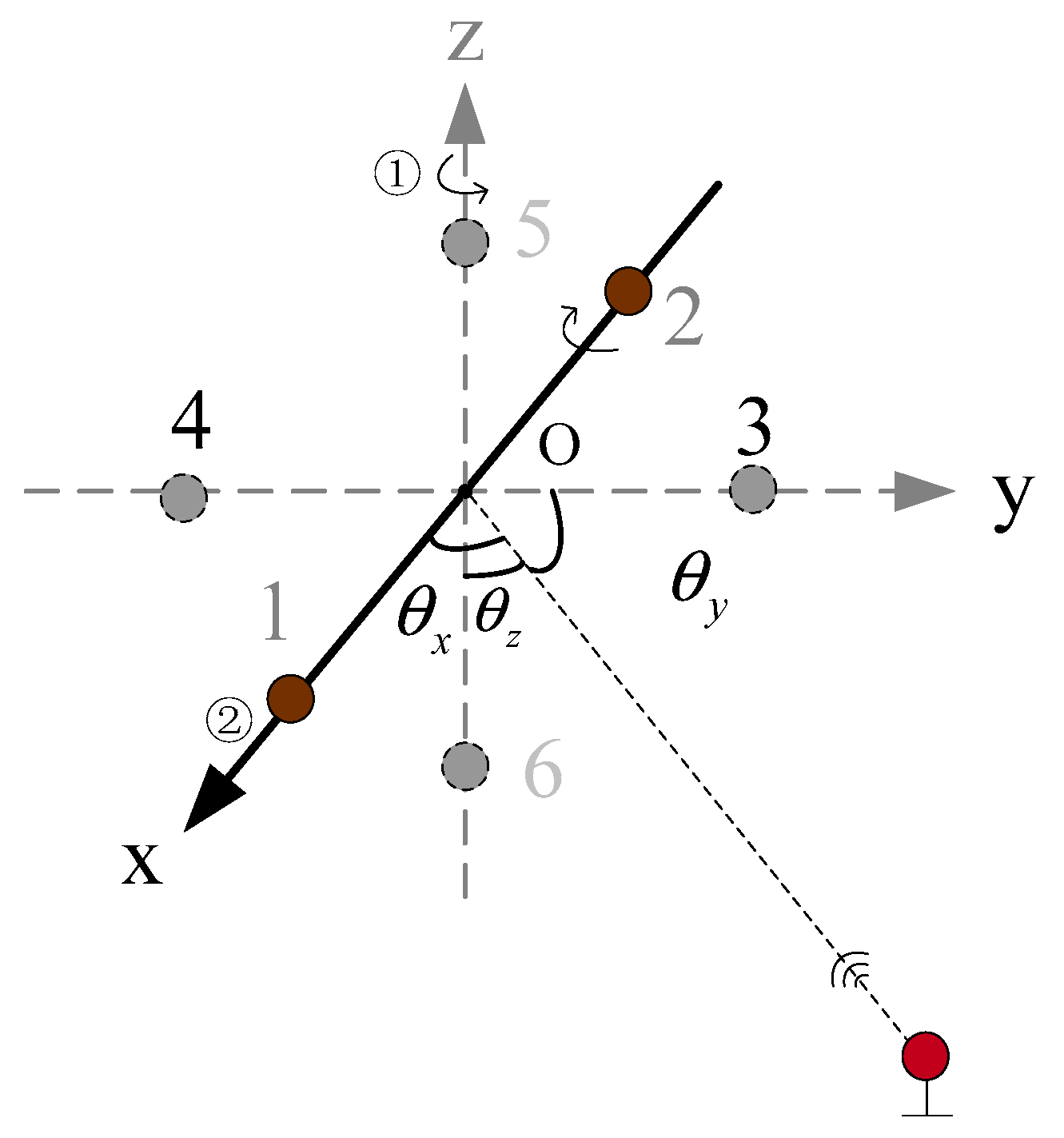

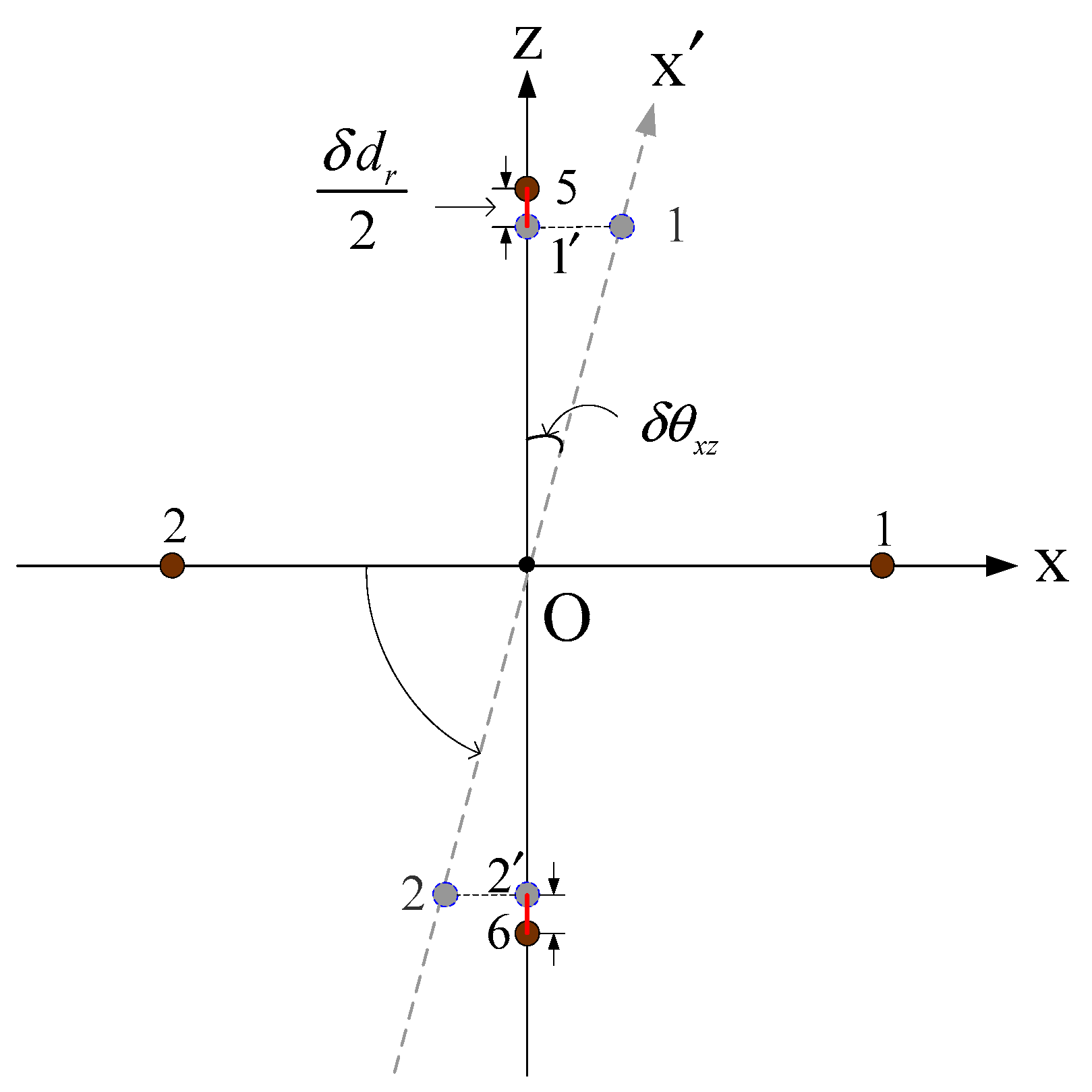

2.3. Array Element Spacing Error Modeling

2.4. The Error Analysis of the USBL Positioning Solution Based on the Slant Range and Azimuth Method

2.5. The Error Analysis of USBL Positioning Calculation Based on the Phase Ratio Method

2.6. The Simulation and Analysis of the Spacing Error of Array Elements

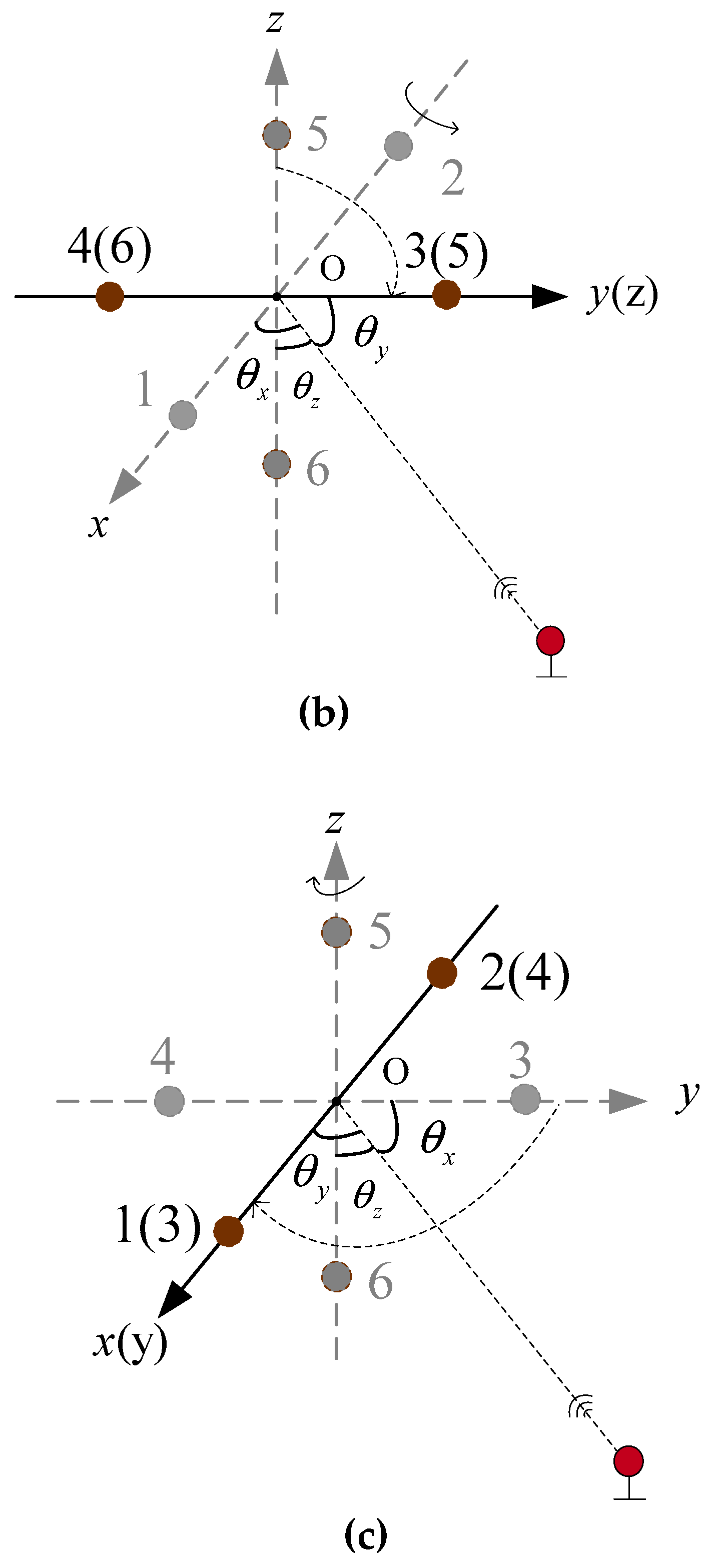

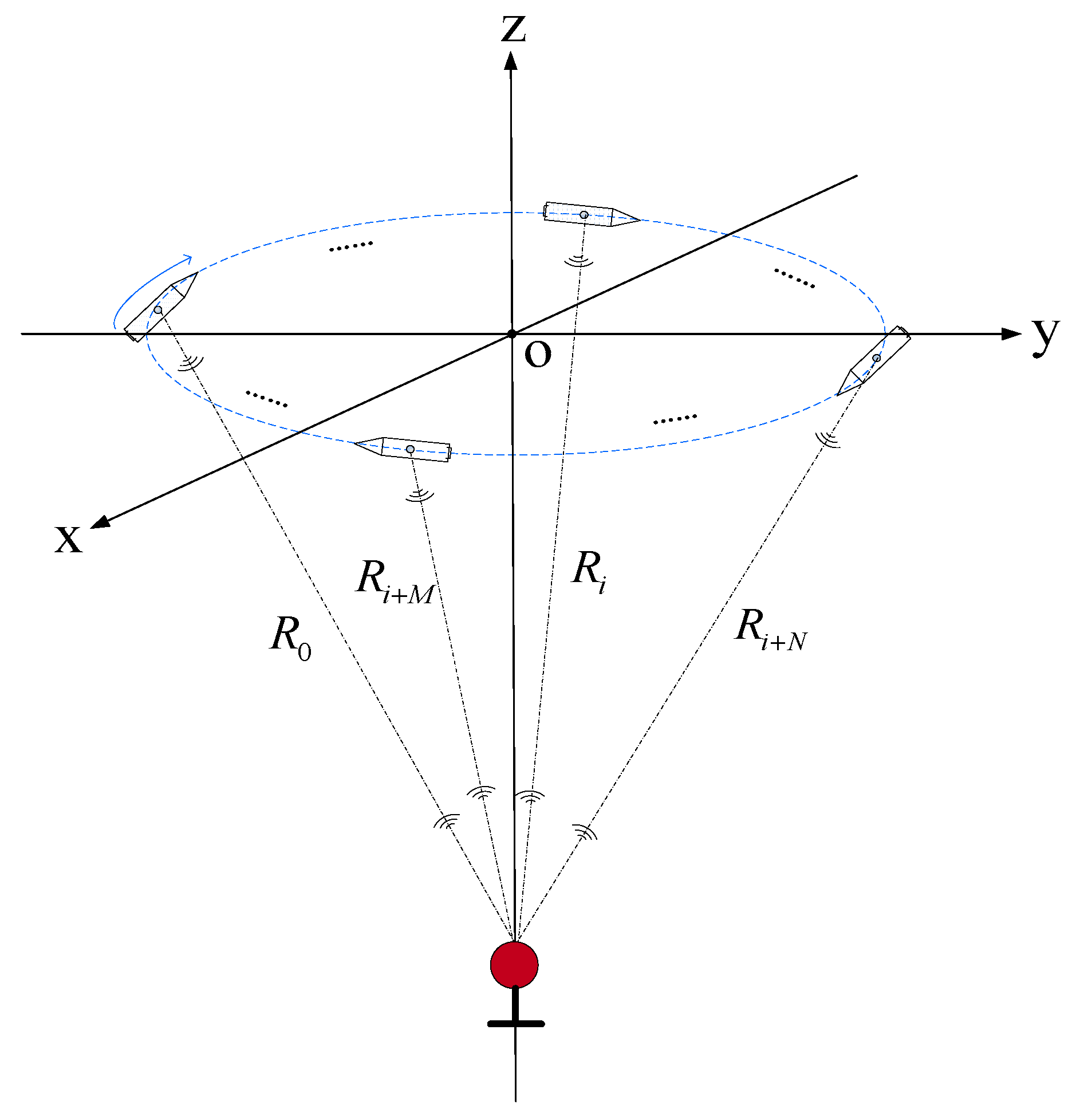

3. A USBL Positioning Model and Its Error Analysis Based on Rotating Array and Reusing Elements

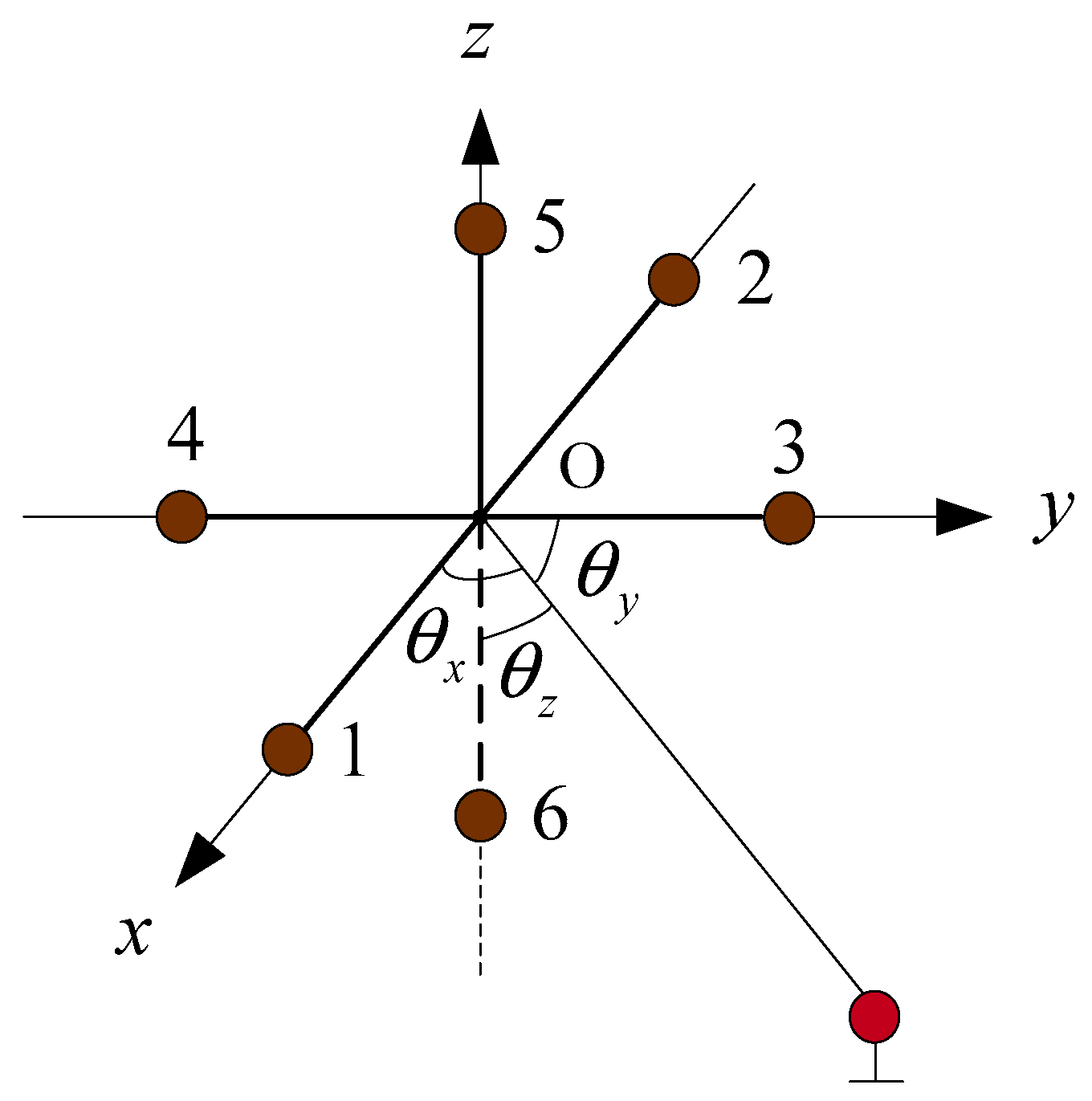

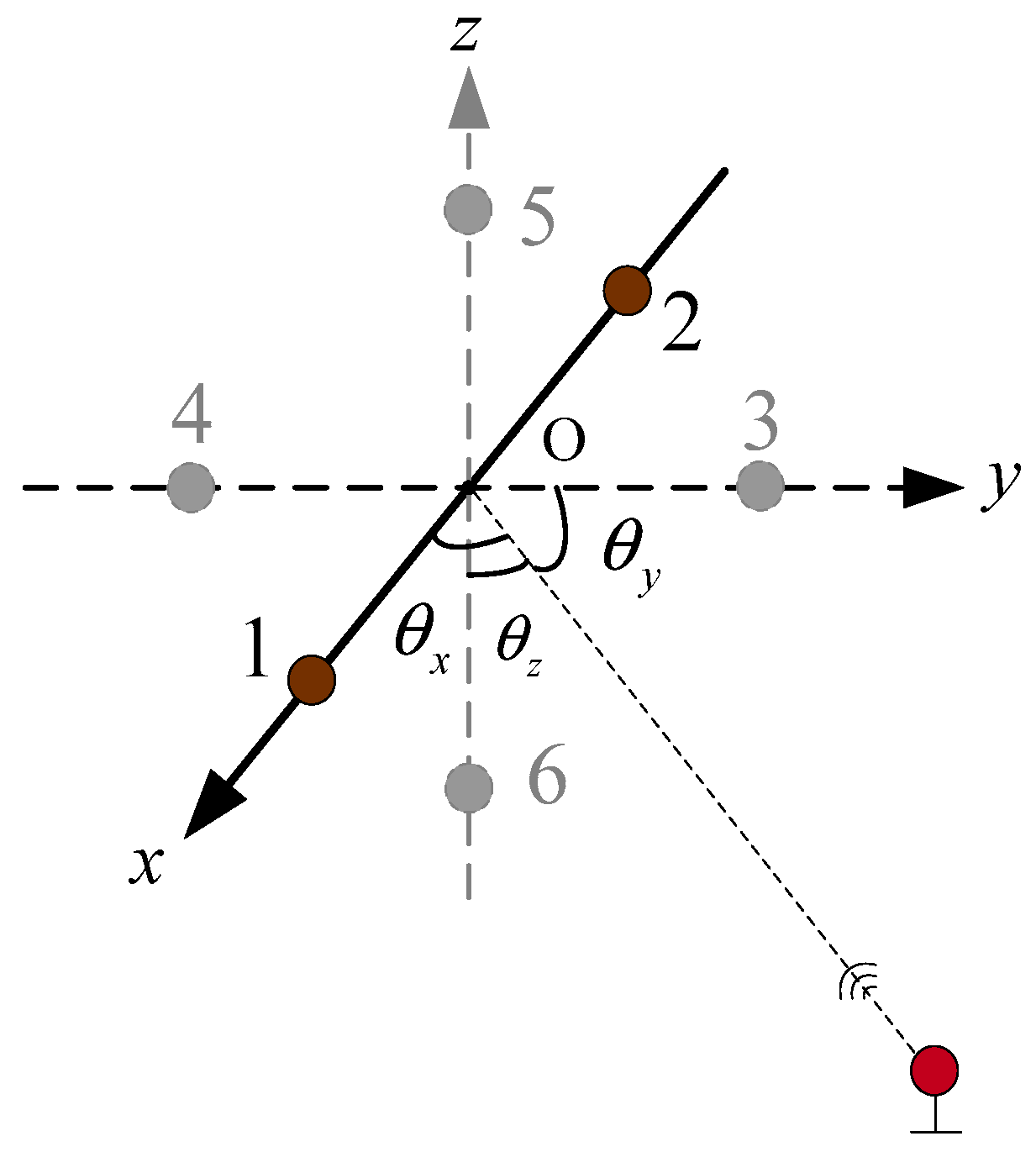

3.1. The Design of the Algorithmic Model

3.2. Error Analysis

4. Simulation and Verification

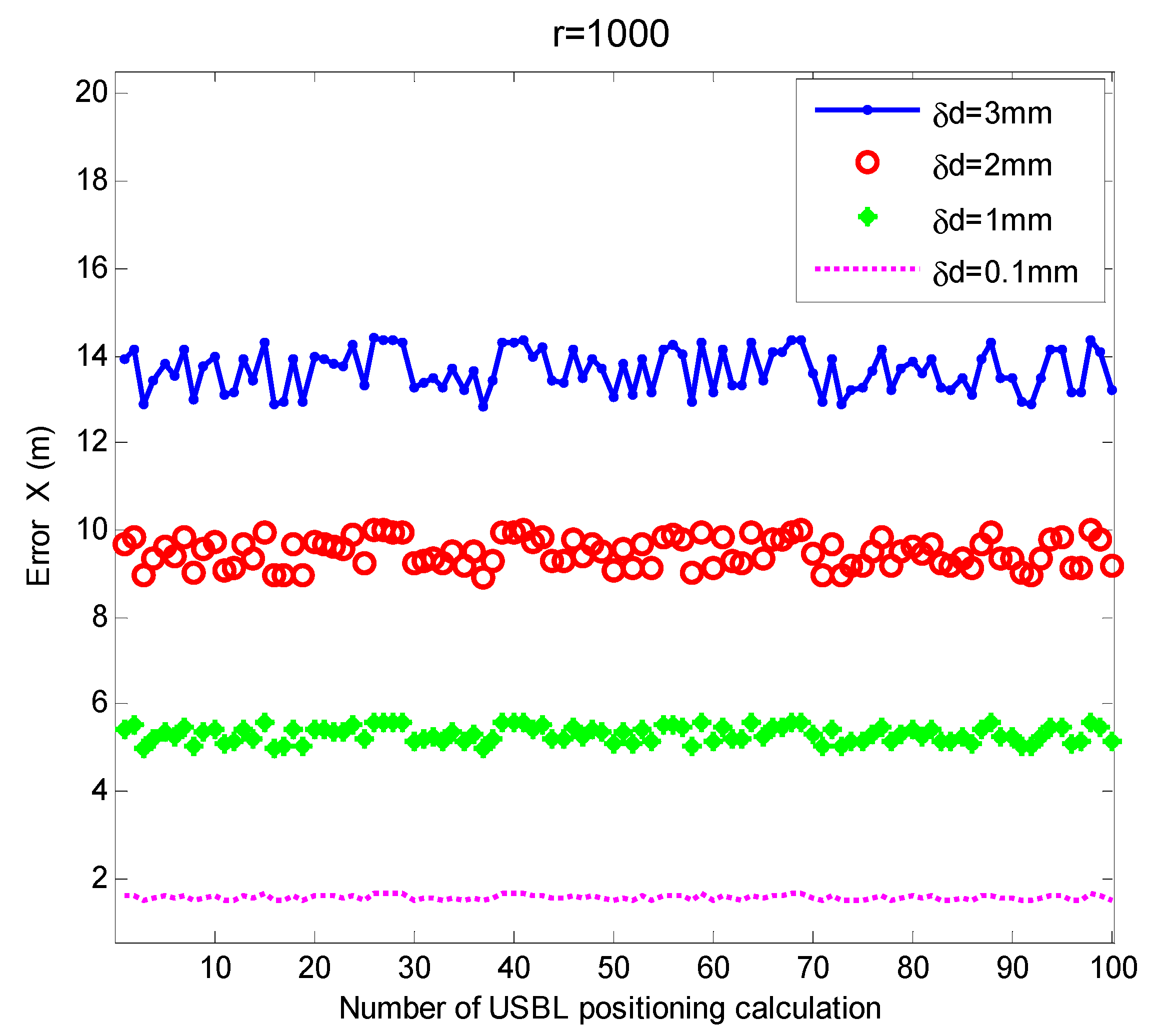

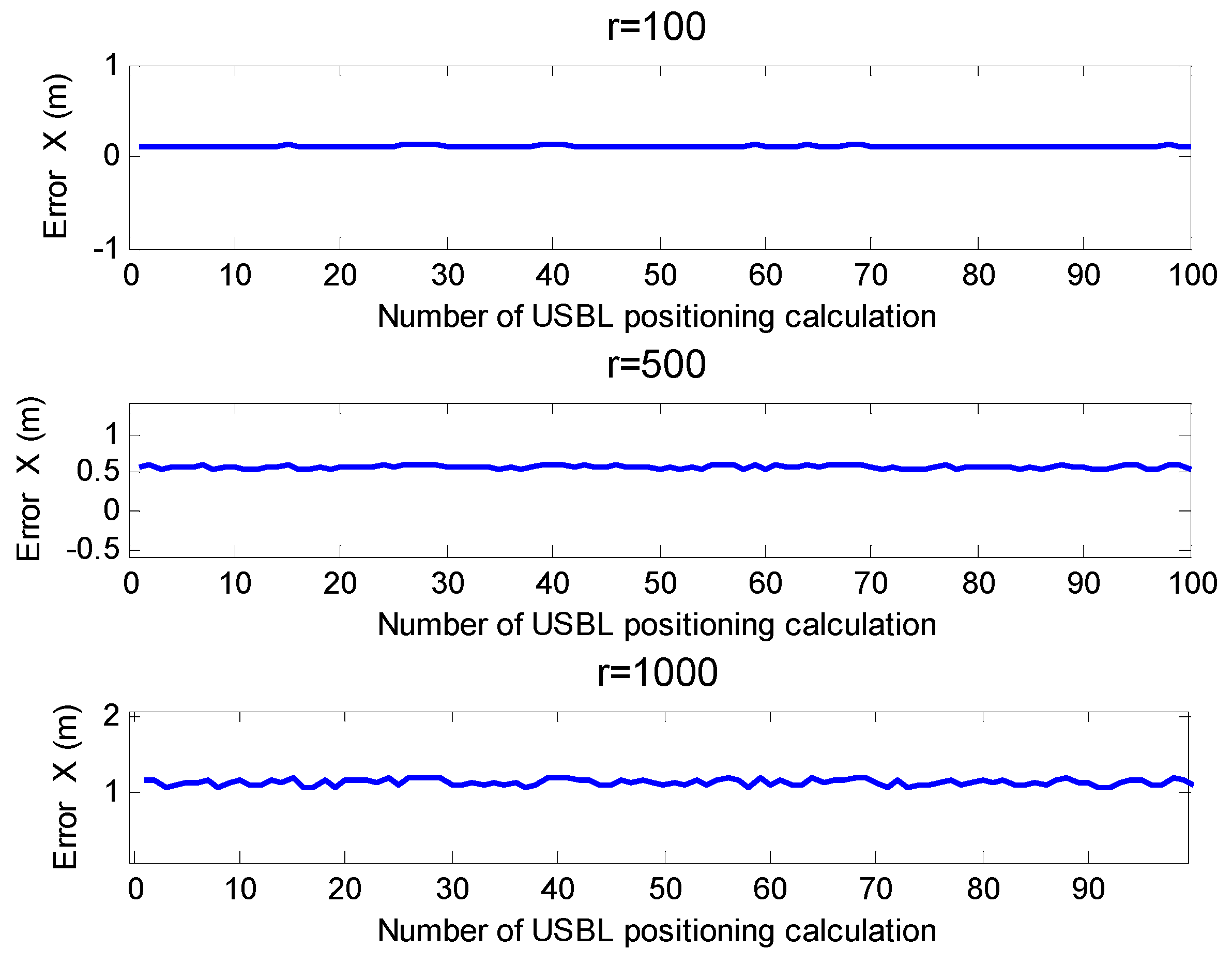

4.1. Simulation Experiment 1

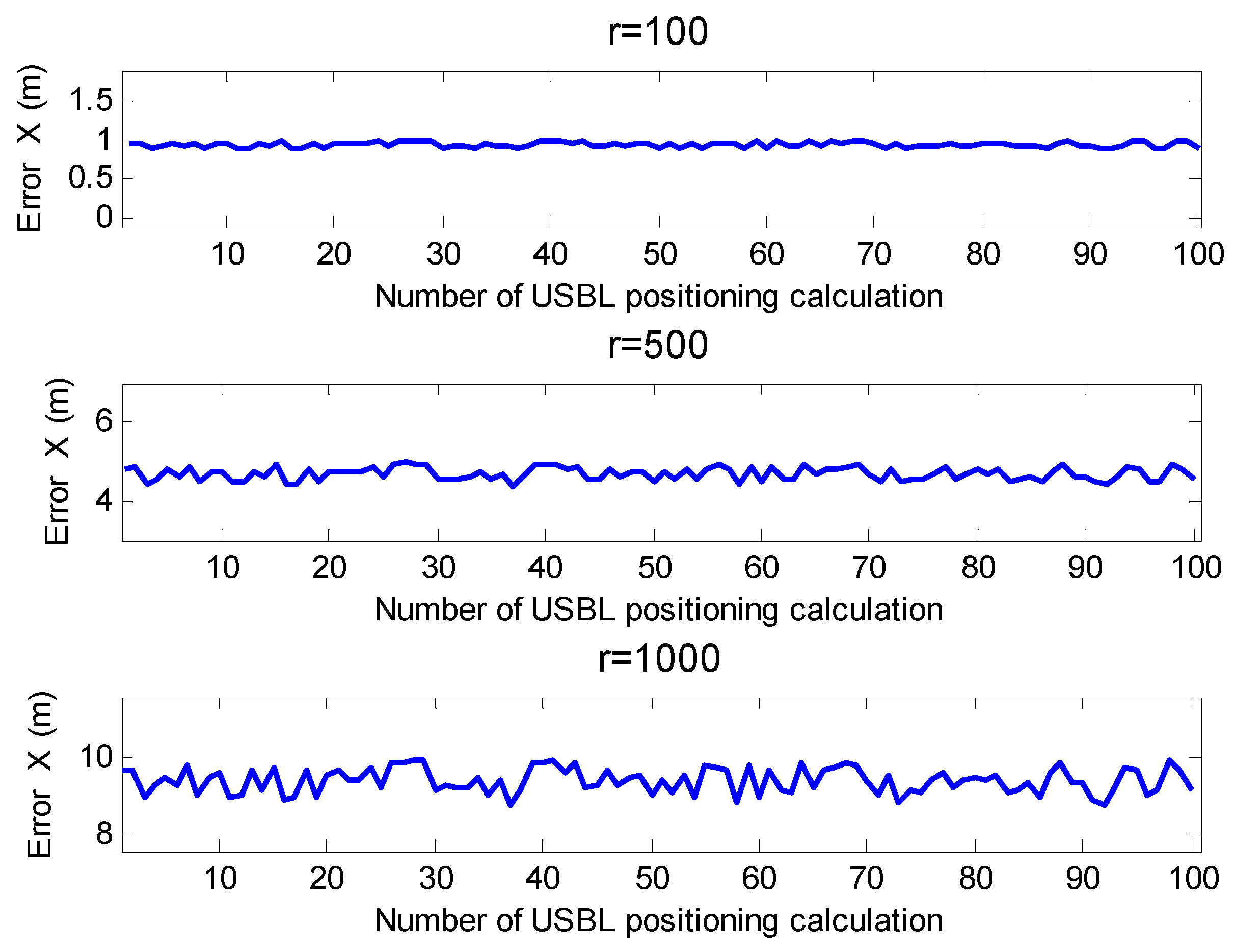

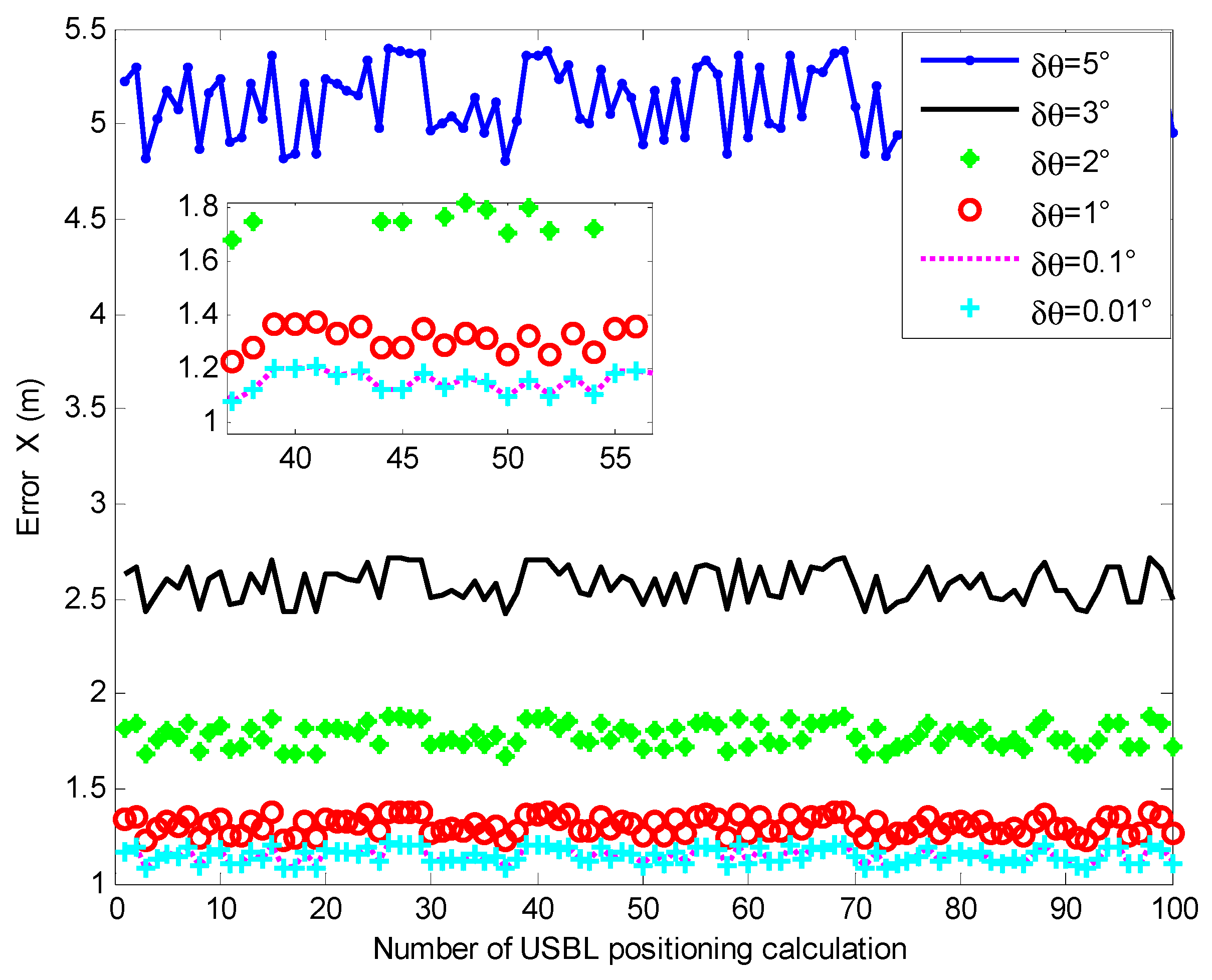

4.2. Simulation Experiment 2

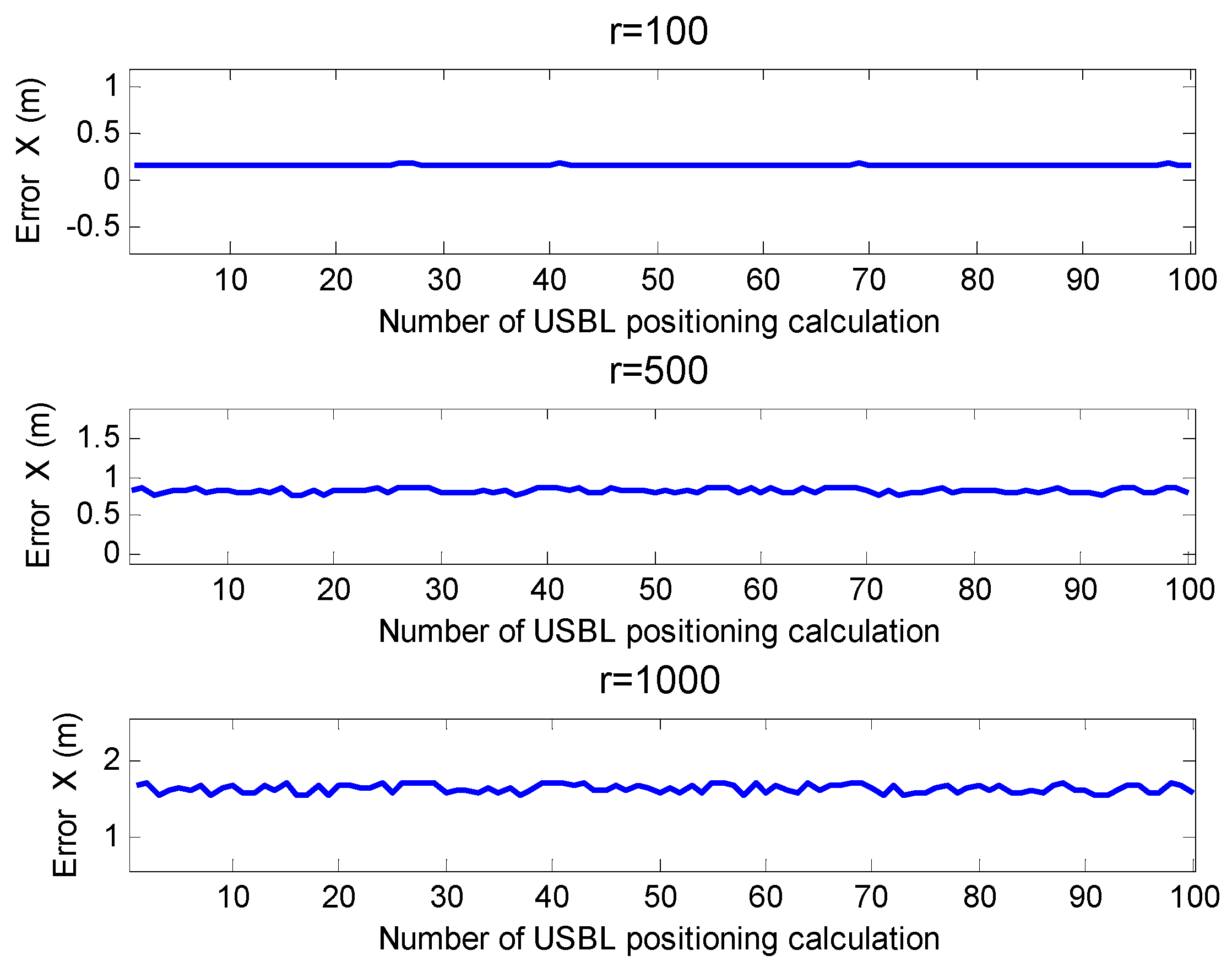

4.3. Simulation Experiment 3

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jin, B.N.; Xu, X.S. USBL Technology and Its Applications in Ocean Engineering. Navig. Position. Timing 2018, 5, 8–20. [Google Scholar]

- Tong, J.W.; Xu, X.S.; Zhang, T.; Zhang, L.; Li, Y. Study on Installation Error Analysis and Calibration of Acoustic Transceiver Array Based on SINS/USBL Integrated System. IEEE Access 2018, 6, 66923–66939. [Google Scholar]

- Sun, D.J.; Zheng, C.E.; Zhang, J.C.; Han, Y.F.; Cui, H.Y. Development and Prospect for Underwater Acoustic Positioning and Navigation Technology. J. Chin. Acad. Sci. 2019, 3, 331–338. [Google Scholar]

- Lee, P.M.; Jun, B.H.; Kim, K.; Lee, J.; Aoki, T.; Hyakudome, T. Simulation of an Inertial Acoustic Navigation System With Range Aiding for an Autonomous Underwater Vehicle. IEEE J. Oceanic Eng. 2007, 32, 2. [Google Scholar] [CrossRef]

- Tian, T. Underwater Positioning and Navigation Technology; Liu, P., Ed.; National Defense Industry Press: Beijing, China, 2007; pp. 1–150. [Google Scholar]

- Hu, H.Q. Research on AUV navigation technology based on USBL aided SINS. Master’s Thesis, Southeast University, Nanjing China, 2017. [Google Scholar]

- Ixblue. Gaps. Available online: https://www.ixblue.com/products/gaps-pre-calibrated-insusbl-system (accessed on 6 October 2019).

- Morgado, M.; Oliveira, P.; Silvestre, C.; Vasconcelos, J.F. USBL/INS Tightly-Coupled Integration Technique for Underwater Vehicles. In Proceedings of the 9th International Conference on Information Fusion, Florence, Italy, 10–13 July 2006; pp. 1–8. [Google Scholar]

- Morgado, M.; Oliveira, P.; Silvestre, C.; Vasconcelos, J.F. Embedded Vehicle Dynamics Aiding for USBL/INS Underwater Navigation System. IEEE Trans. Control Syst. Technol. 2014, 22, 322–330. [Google Scholar] [CrossRef]

- Morgado, M.; Oliveira, P.; Silvestre, C. Tightly coupled ultrashort baseline and inertial navigation system for underwater vehicles: An experimental validation. J. Field Robotics 2013, 30, 142–170. [Google Scholar] [CrossRef]

- Zhang, Y.W. An algorithm used in underwater SINS/USBL integrated navigation. Navig. Position. Timing 2016, 7–13. [Google Scholar]

- Gao, B.B. Research on SINS/USBL/DVL integrated navigation system and high performance algorithm for underwater vehicles. Master’s Thesis, Northwestern Polytechnical University, Xi’an, China, 2015. [Google Scholar]

- Dong, P.; Cheng, J.H.; Liu, L.Q.; Mou, H.J. INS/USBL nonlinear integrated navigation method based on observations of relative information. J. Syst. Eng. Electron. 2019, 41, 179–185. [Google Scholar]

- Hu, G.G.; Gao, S.S. A derivative UKF for tightly coupled INS/GPS integrated navigation. ISA Trans. 2015, 56, 135–144. [Google Scholar] [CrossRef] [PubMed]

- Chang, L.B.; Hu, B.Q. Robust Initial Attitude Alignment for SINS/DVL. IEEE/ASME Trans. Mechatron. 2018, 23, 2016–2021. [Google Scholar] [CrossRef]

- Chen, H.H. The Estimation of Angular Misalignments for Ultra Short Baseline Navigation Systems. Part I: Numerical Simulations. J. Navig. 2013, 66, 561–578. [Google Scholar] [CrossRef]

- Chen, H.H. In-situ alignment calibration of attitude and ultra short baseline sensors for precision underwater positioning. Ocean Eng. 2008, 35, 1448–1462. [Google Scholar] [CrossRef]

- Tong, J.W.; Xu, X.S.; Zhang, T.; Li, Y.; Yao, Y.Q.; Weng, C.C.; Hou, L.H.; Zhang, L. A misalignment angle error calibration method of underwater acoustic array in strapdown inertial navigation system/ultrashort baseline integrated navigation system based on single transponder mode. Rev. Sci. Instrum. 2019, 90, 085001. [Google Scholar] [CrossRef] [PubMed]

- Yu, M. Research on Long Range Ultra Short Baseline System. Ph.D. Thesis, Harbin University of Engineering, Harbin, China, 2005; pp. 1–143. [Google Scholar]

- Wang, Y.H.; Sun, G.Q.; Lai, X.Q.; Liu, R.B. Research of ultrashort baseline positioning method based on depth information. In Proceedings of the IEEE 2nd Information Technology, Networking, Electronic and Automation Control Conference, Chengdu, China, 15–17 December 2017; pp. 18–22. [Google Scholar]

- Chen, H.H. The Estimation of Angular Misalignments for Ultra Short Baseline Navigation Systems. Part II: Experimental Results. J. Navig. 2013, 66, 773–787. [Google Scholar] [CrossRef]

- Yu, M. In-situ calibration of transceiver alignment for a high-precision USBL system, In Proceedings of the International Conference on Computer Application and System Modeling, Taiyuan, China. 22–24 October 2010. pp. V11-84–V11-87.

- Sun, D.J.; Ding, J.; Zheng, C.E. Array geometry calibration for underwater compact arrays. Appl. Acoust. 2019, 145, 374–384. [Google Scholar] [CrossRef]

| Error Term | |||

|---|---|---|---|

| Error value | 1 | 0.05 | 2 |

| (m/s) | (m) | (mm) |

|---|---|---|

| 1500 | 1000 | 250 |

| (m) | 10 | 50 | 100 | 200 | 500 | 1000 | 2000 | 3000 | 4000 |

|---|---|---|---|---|---|---|---|---|---|

| (m) | 0.0794 | 0.3968 | 0.7937 | 1.5873 | 3.9683 | 7.9365 | 15.8730 | 23.8095 | 31.7460 |

| (m) | 0.0398 | 0.1992 | 0.3984 | 0.7968 | 1.9920 | 3.9840 | 7.9681 | 11.9522 | 15.9363 |

| (m) | 0.0048 | 0.0240 | 0.0480 | 0.0960 | 0.2399 | 0.4798 | 0.9595 | 1.4393 | 1.9191 |

| (m) | 10 | 50 | 100 | 200 | 500 | 1000 | 2000 | 3000 | 4000 |

|---|---|---|---|---|---|---|---|---|---|

| (m) | 0.0398 | 0.1992 | 0.3984 | 0.7968 | 1.9920 | 3.9841 | 7.9681 | 11.9522 | 15.9363 |

| (m) | 0.0199 | 0.0998 | 0.1996 | 0.3992 | 0.9980 | 1.9960 | 3.9920 | 5.9880 | 7.9840 |

| (m) | 0.0024 | 0.0120 | 0.0239 | 0.0479 | 0.1199 | 0.2399 | 0.4799 | 0.7198 | 0.9598 |

| NO. | ||||

|---|---|---|---|---|

| 1 | 5 | 0.087266 | 0.951325 | 3.805302 |

| 2 | 3 | 0.052360 | 0.342616 | 1.370465 |

| 3 | 2 | 0.034907 | 0.152293 | 0.609173 |

| 4 | 1 | 0.017453 | 3.807621 × 10−2 | 0.152305 |

| 5 | 0.1 | 0.001745 | 3.807717 × 10−4 | 1.523087 × 10−3 |

| 6 | 0.01 | 0.000175 | 3.807718 × 10−5 | 1.523087 × 10−5 |

| Parameter | Value |

|---|---|

| Depth of transponder (beacon) (m) | 100 ± 2 |

| Circumnavigate sailing radius of the mother ship (m) | 100, 500, 1000 |

| Water acoustic velocity (m/s) | 1500 |

| Water acoustic velocity error (m/s) | ±0.3%v + 0.005 |

| Time delay estimation error (s) | 0.001 |

| Depth measurement error (m) | ±0.1%h + 0.01 |

| Distance of array elements (mm) | 250 |

| Spacing error of array elements , (mm) | ±3, ±2, ±0.1 |

| Hydro acoustic signal frequency (kHz) | 25 |

| Hydro acoustic signal wavelength (m) | 0.06 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, J.; Xu, X.; Hou, L.; Li, Y.; Wang, J.; Zhang, L. An Ultra-Short Baseline Positioning Model Based on Rotating Array & Reusing Elements and Its Error Analysis. Sensors 2019, 19, 4373. https://doi.org/10.3390/s19204373

Tong J, Xu X, Hou L, Li Y, Wang J, Zhang L. An Ultra-Short Baseline Positioning Model Based on Rotating Array & Reusing Elements and Its Error Analysis. Sensors. 2019; 19(20):4373. https://doi.org/10.3390/s19204373

Chicago/Turabian StyleTong, Jinwu, Xiaosu Xu, Lanhua Hou, Yao Li, Jian Wang, and Liang Zhang. 2019. "An Ultra-Short Baseline Positioning Model Based on Rotating Array & Reusing Elements and Its Error Analysis" Sensors 19, no. 20: 4373. https://doi.org/10.3390/s19204373

APA StyleTong, J., Xu, X., Hou, L., Li, Y., Wang, J., & Zhang, L. (2019). An Ultra-Short Baseline Positioning Model Based on Rotating Array & Reusing Elements and Its Error Analysis. Sensors, 19(20), 4373. https://doi.org/10.3390/s19204373