A Novel Infrared Temperature Measurement with Dual Mode Modulation of Thermopile Sensor

Abstract

:1. Introduction

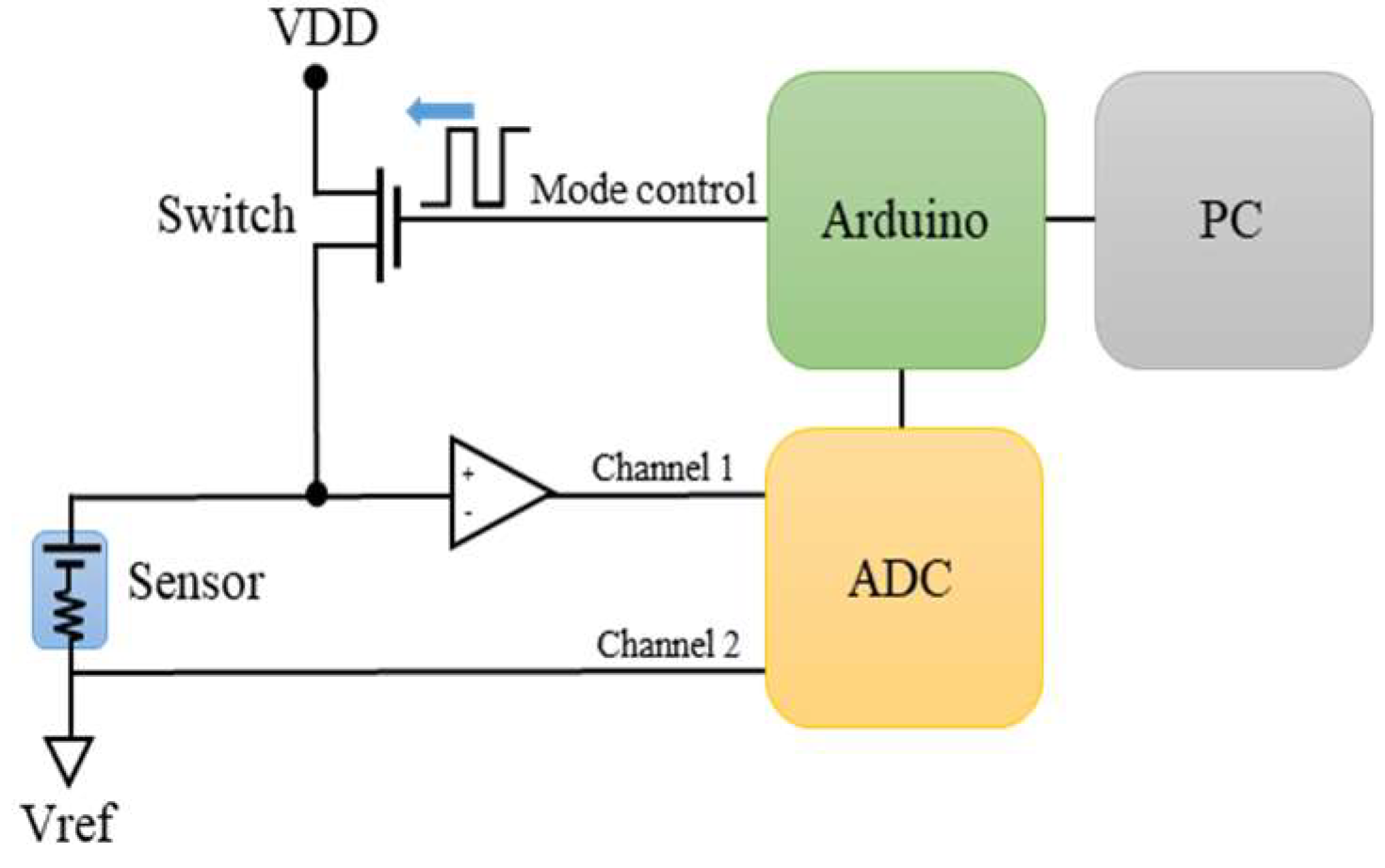

2. Working Principle and Design for Dual Mode Modulation

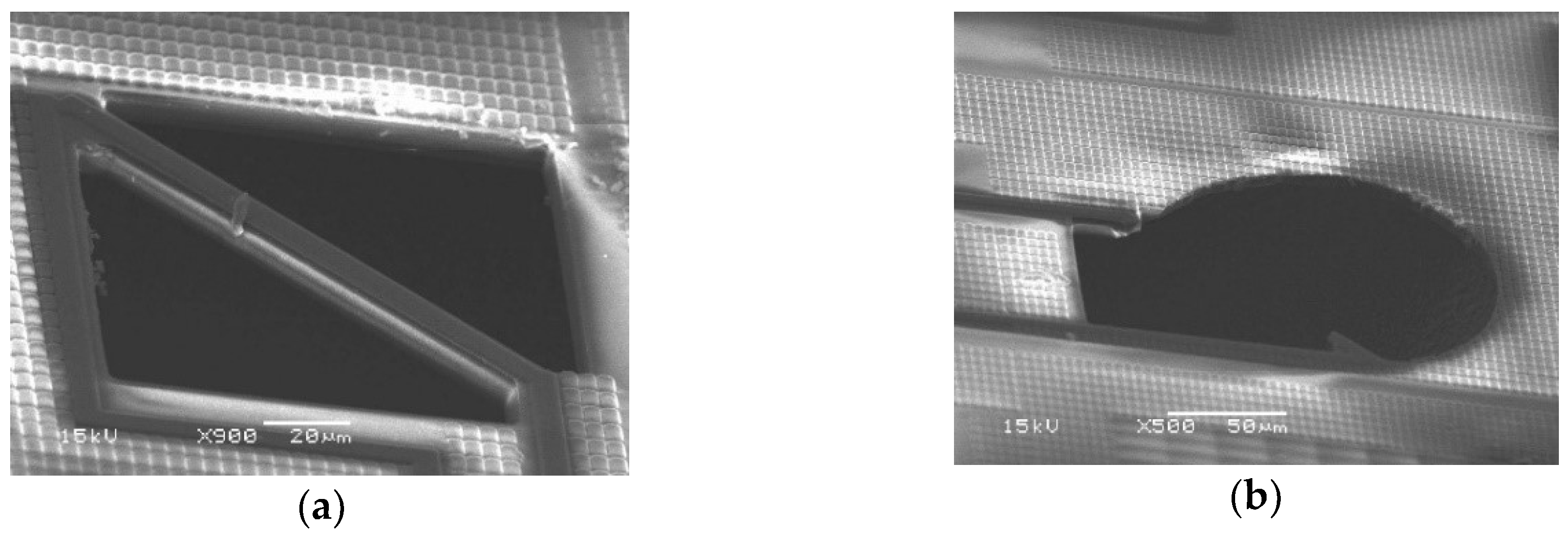

3. Design and Fabrication of Thermopile Sensor

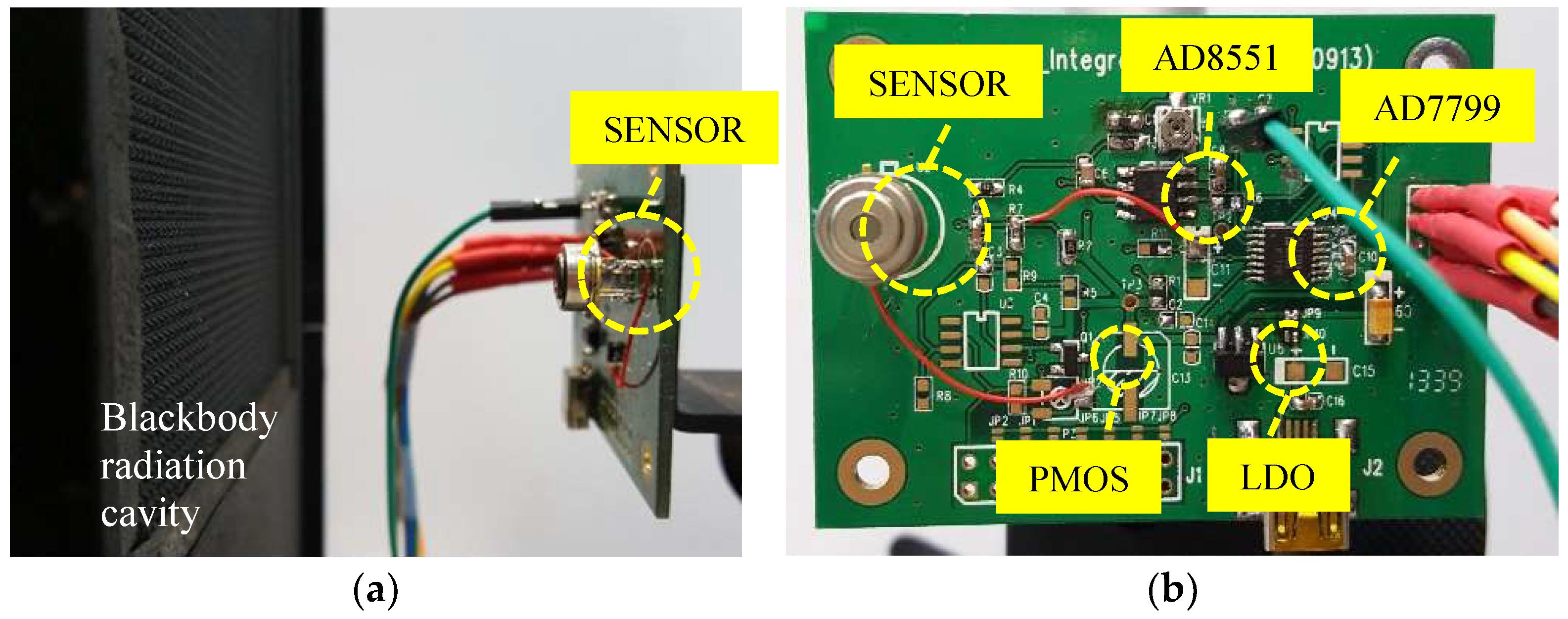

4. Operation of Dual Mode Modulation

4.1. Thermopile Sensing Mode

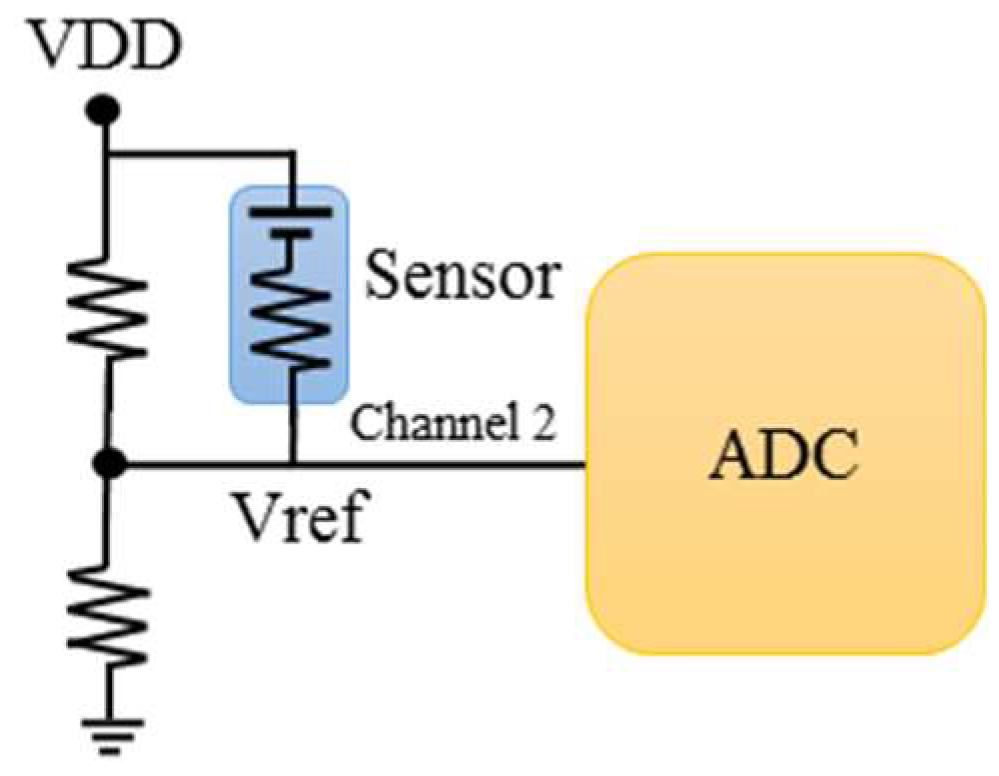

4.2. Effective Thermistor Sensing Mode

5. Results and Analysis

5.1. Frequency Response and Thermal Time Constant for Sensor

5.2. Investigation on Transient Response and Sensing Characteristics for Circuit

5.2.1. Relationship between Transition Time and Jitter

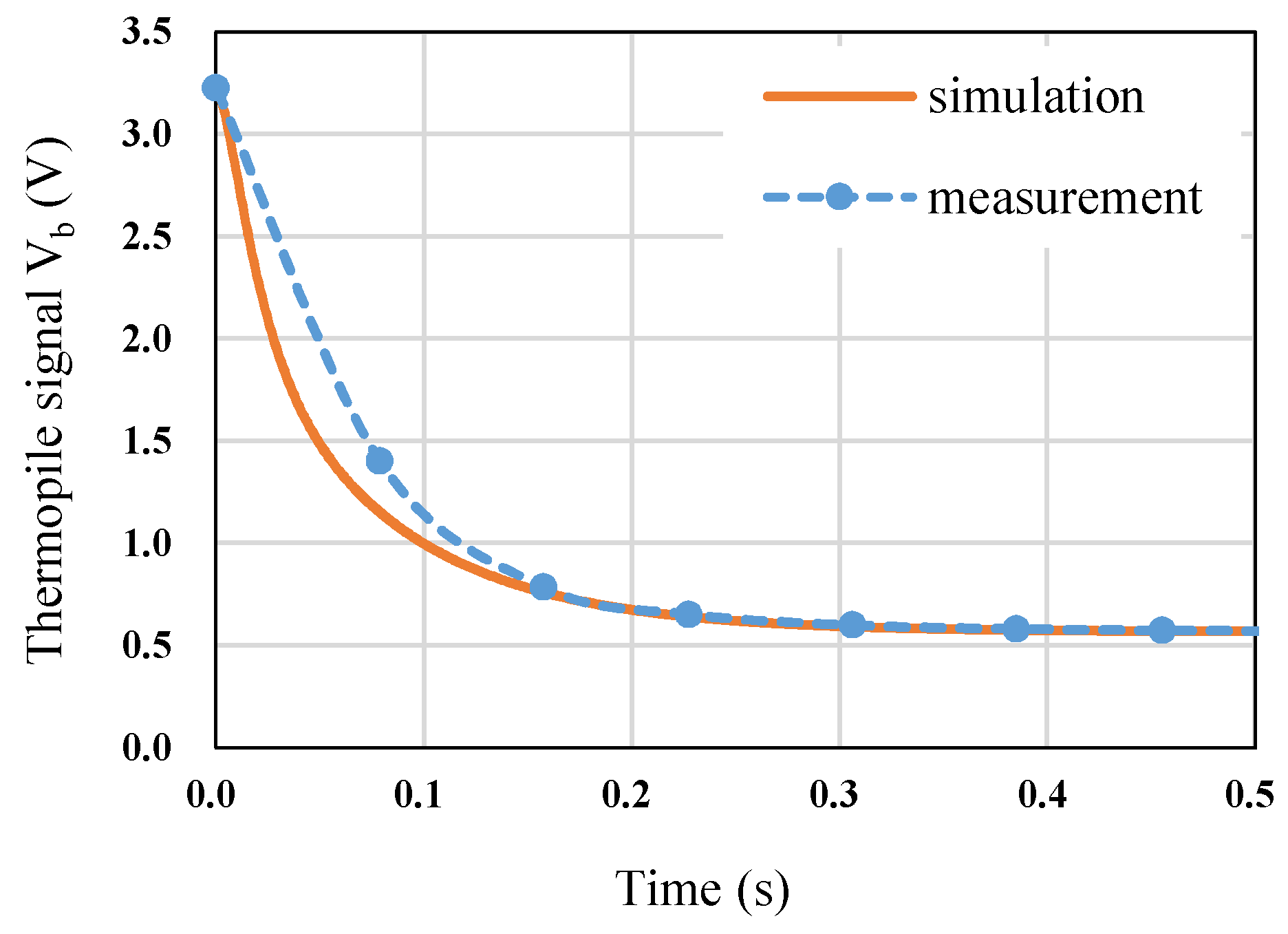

5.2.2. Simulation vs. Measurement

5.2.3. Analysis of Transition Performance of System

5.3. Measuerment Result for Dual Mode Switching Circuit

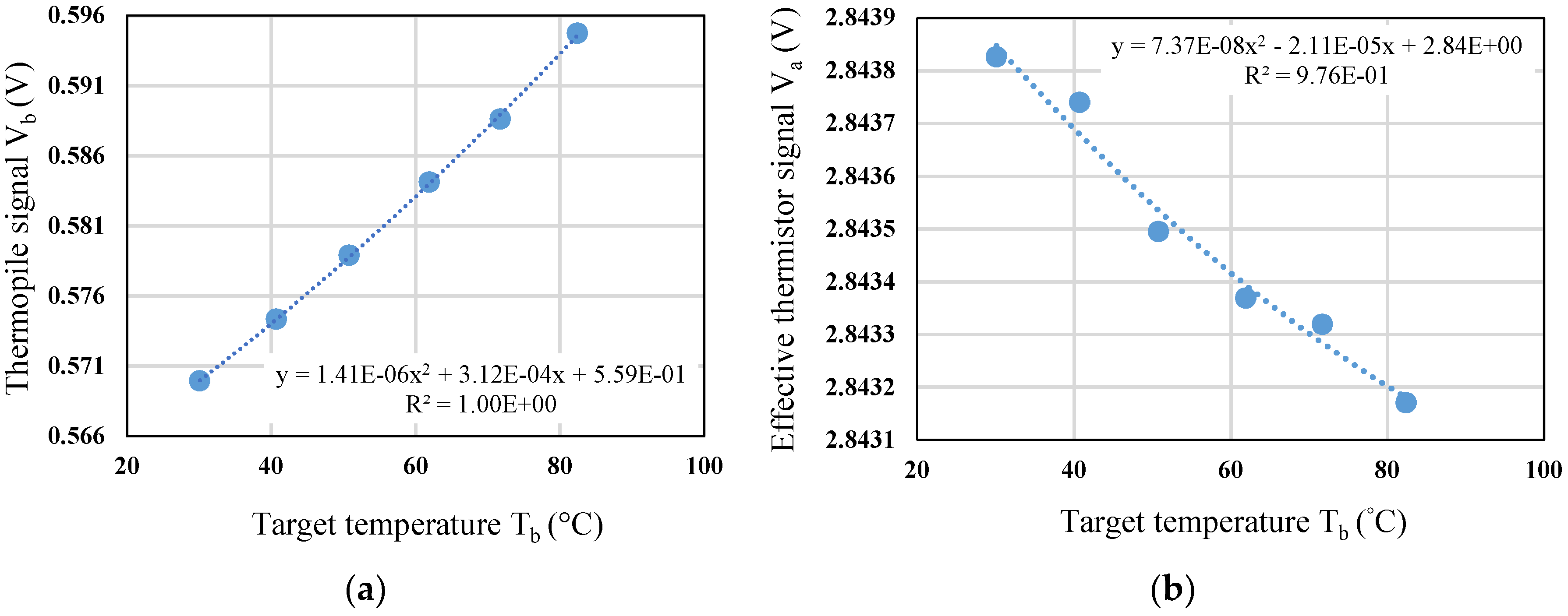

5.3.1. Calibration of Thermal Radiation for Dual Mode Operation

5.3.2. Calibration of Effective Thermistor Sensing

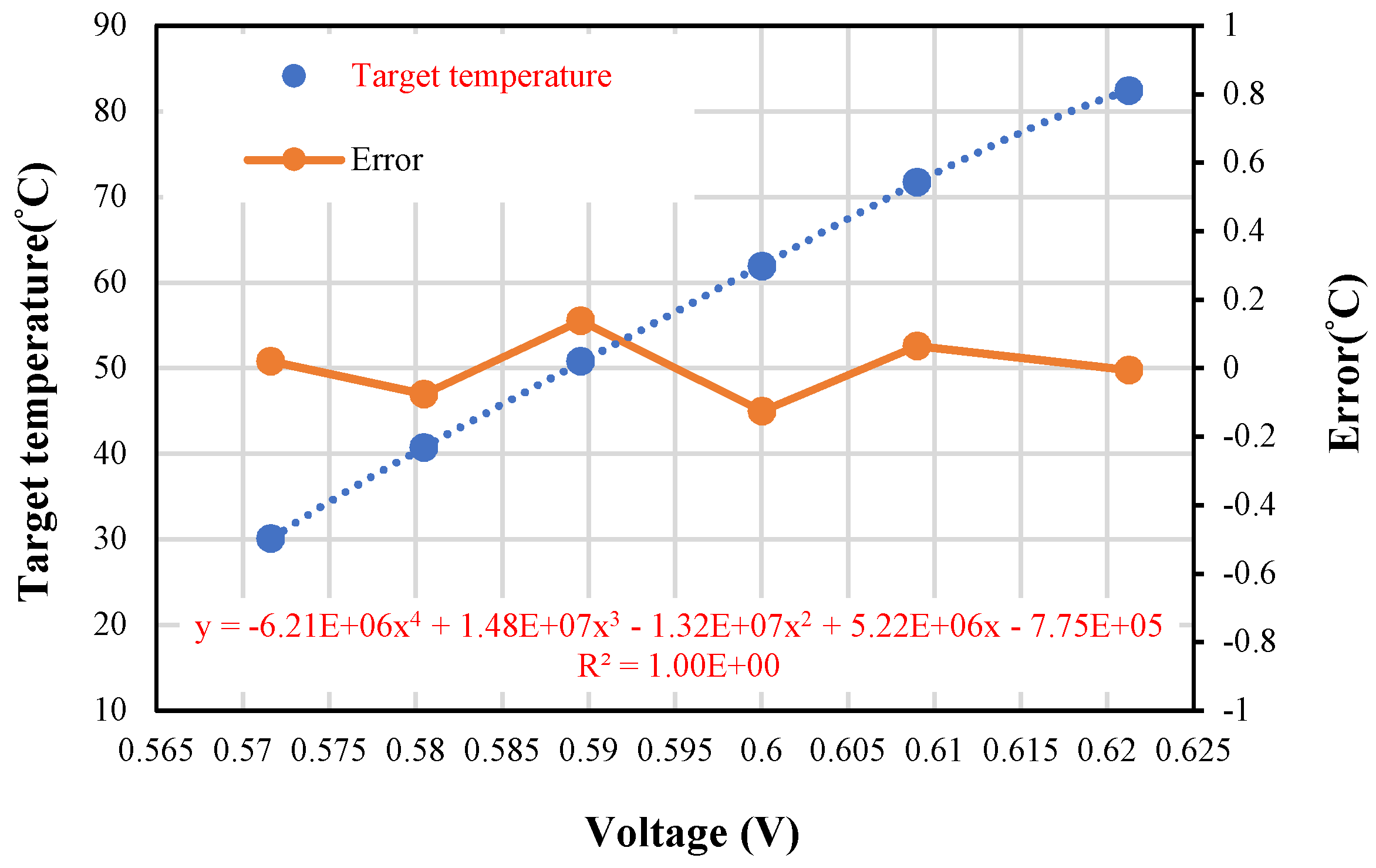

5.3.3. Investigation of Thermopile Sensing with Ambient Temperature Compensation

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Berberig, O.; Mizuno, J. The Prandtl micro flow sensor (PMFS): A novel silicon diaphragm capacitive sensor for flow-velocity measurement. Sens. Actuators A Phys. 1998, 66, 93–98. [Google Scholar] [CrossRef]

- Bouwstra, S.; Legtenberg, R. Resonating microbridge mass flow sensor. Sens. Actuators A Phys. 1990, 21–23, 332–335. [Google Scholar] [CrossRef]

- Hsieh, H.Y.; Spetz, A. Pyroelectric anemometry: Vektor and swirl measurement. Sens. Actuators A Phys. 1995, 49, 141–147. [Google Scholar] [CrossRef]

- Moser, D.; Lenggenhager, R. Silicon gas flow sensors using industrial CMOS and bipolar IC technology. Sens. Actuators A Phys. 1991, 27, 577–581. [Google Scholar] [CrossRef]

- De Bree, H.E.; Jansen, H.V. Bi-directional fast flow sensor with a large dynamic range. J. Micromech. Microeng. 1999, 9, 186–189. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Dötzel, W. Asymmetrical locations of heaters and sensors relative to each other using heater arrays: A novel method for designing multi-range electrocalorimetric mass-flow sensors. Sens. Actuators A Phys. 1997, 62, 506–512. [Google Scholar] [CrossRef]

- Graf, A.; Arndt, M. Review of micromachined thermopiles for infrared detection. Meas. Sci. Technol. 2007, 18, R59. [Google Scholar] [CrossRef]

- Alexander, G.; Michael, A. Seebeck’s effect in micromachined thermopiles for infrared detection. Proc. Est. Acad. Sci. Eng. 2007, 13, 338–353. [Google Scholar]

- Shen, C.H.; Chang, T.D. Modelling and infrared radiation compensation for non-contact temperature measurement. In Proceedings of the International Conference on Technological Advances of Sensors and Instrumentation, Kuala Lumpur, Malaysia, 26–28 January 2018. [Google Scholar]

- Shen, C.H.; Lin, P.H. Research on an ultra-low power thermoelectric-type anemometer. In Proceedings of the International Conference on Technological Advances of Sensors and Instrumentation, Kuala Lumpur, Malaysia, 26–28 January 2018. [Google Scholar]

- Clocker, K.; Sengupta, S.; Lindsay, M.; Johnston, M.L. Single-element thermal flow sensor using dual-slope control scheme. In Proceedings of the IEEE Sensors, Glasgow, UK, 29 October–1 November 2017. [Google Scholar]

| Target Temperature (K) | Relative Cut-off Frequency (Hz) | Relative Thermal Time Constant (ms) |

|---|---|---|

| 373.15 | 1 | 1 |

| 473.15 | 85.5 | 1.17 |

| 573.15 | 83.7 | 1.20 |

| 673.15 | 78.0 | 1.29 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, C.-H.; Chen, S.-J.; Guo, Y.-T. A Novel Infrared Temperature Measurement with Dual Mode Modulation of Thermopile Sensor. Sensors 2019, 19, 336. https://doi.org/10.3390/s19020336

Shen C-H, Chen S-J, Guo Y-T. A Novel Infrared Temperature Measurement with Dual Mode Modulation of Thermopile Sensor. Sensors. 2019; 19(2):336. https://doi.org/10.3390/s19020336

Chicago/Turabian StyleShen, Chih-Hsiung, Shu-Jung Chen, and Yi-Ting Guo. 2019. "A Novel Infrared Temperature Measurement with Dual Mode Modulation of Thermopile Sensor" Sensors 19, no. 2: 336. https://doi.org/10.3390/s19020336

APA StyleShen, C.-H., Chen, S.-J., & Guo, Y.-T. (2019). A Novel Infrared Temperature Measurement with Dual Mode Modulation of Thermopile Sensor. Sensors, 19(2), 336. https://doi.org/10.3390/s19020336