Gold-Film-Thickness Dependent SPR Refractive Index and Temperature Sensing with Hetero-Core Optical Fiber Structure

Abstract

:1. Introduction

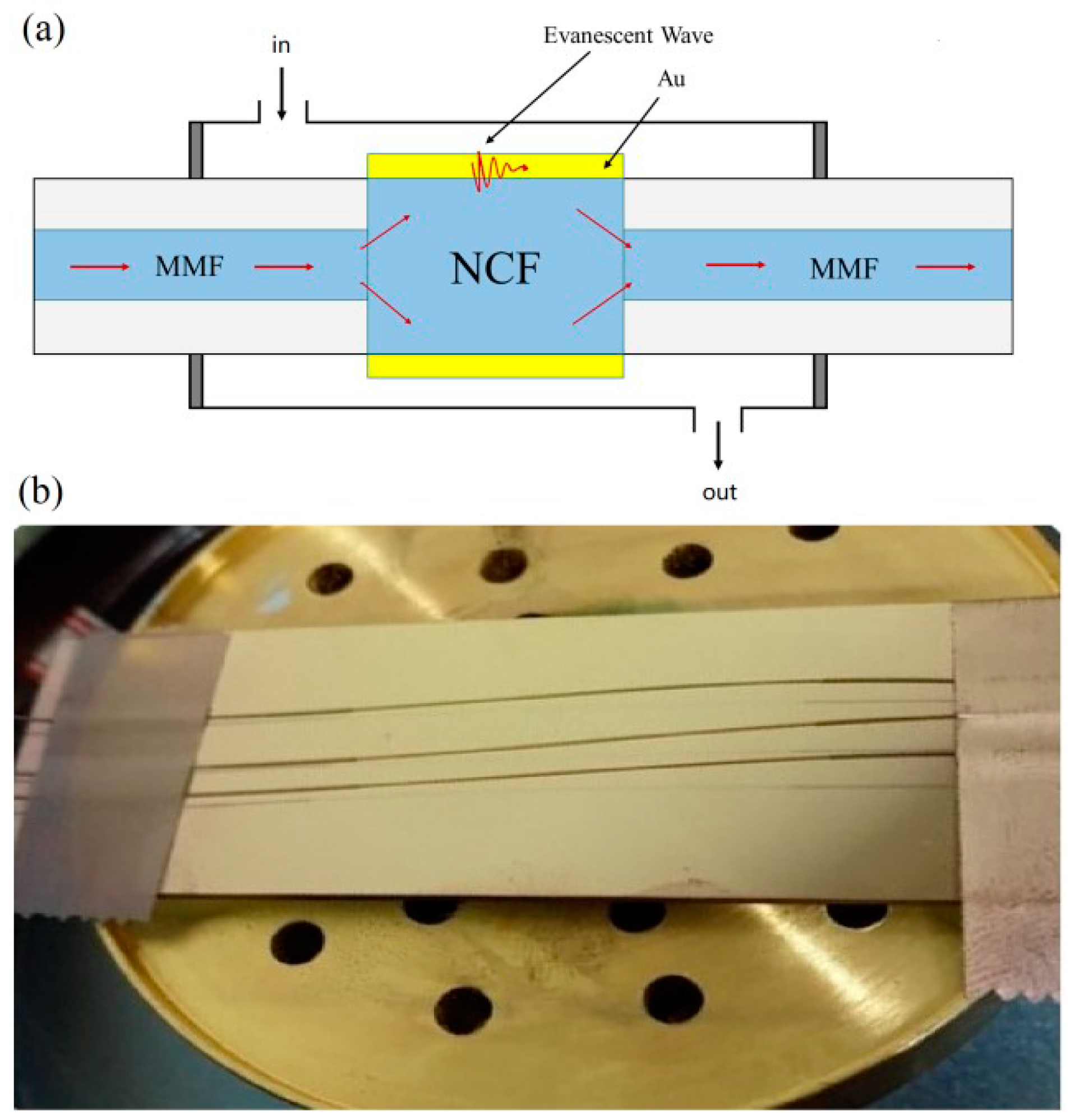

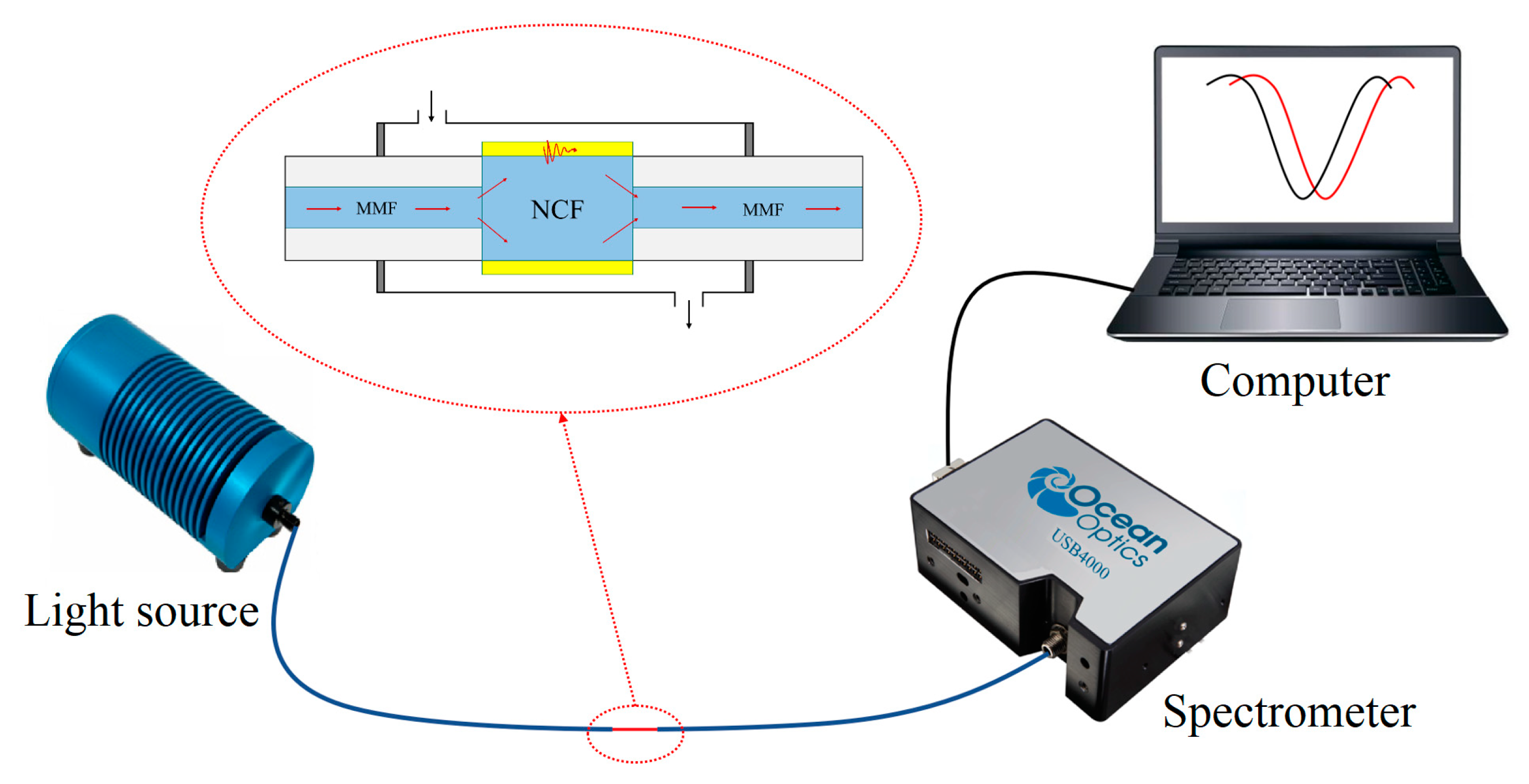

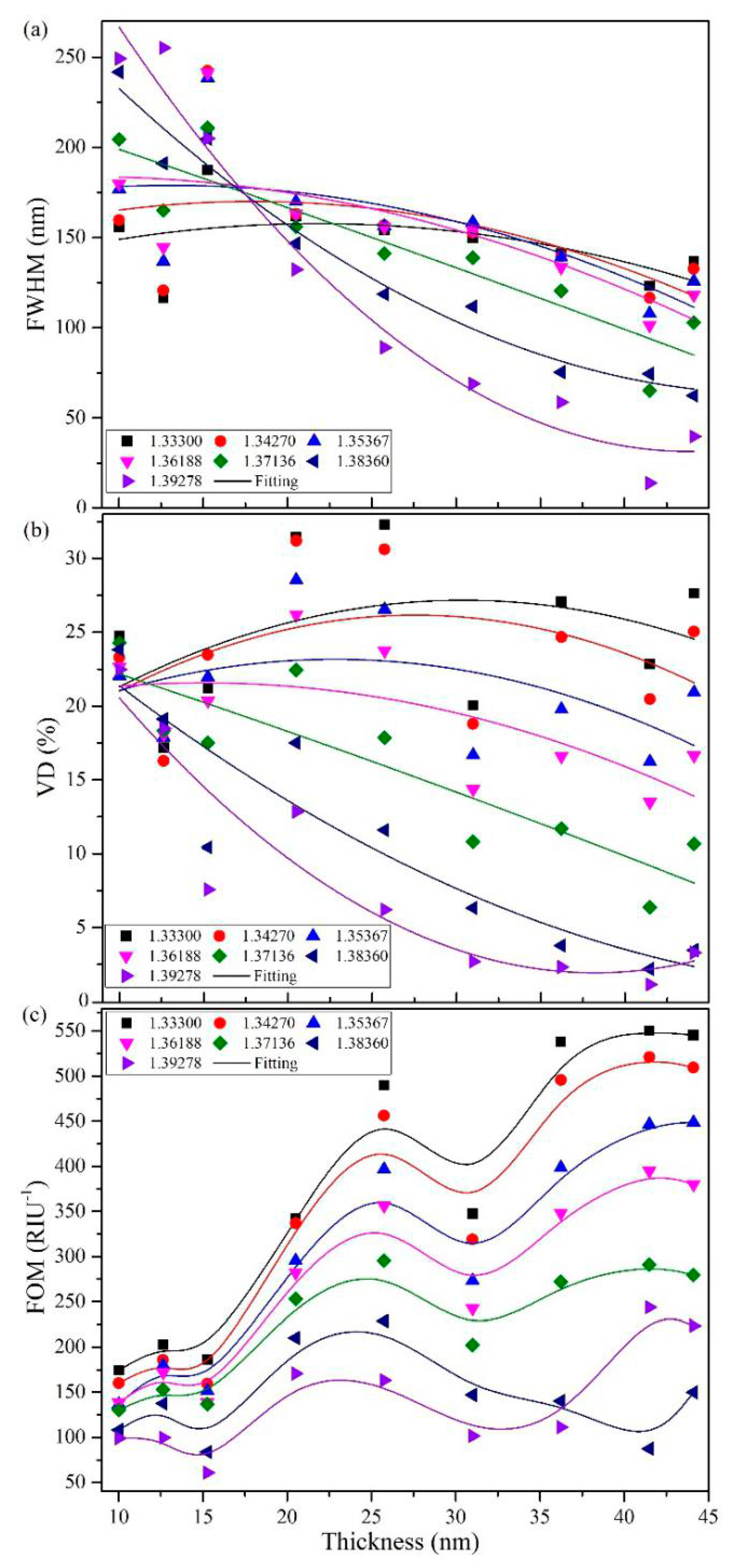

2. Sensor Fabrication and Sensing Principle

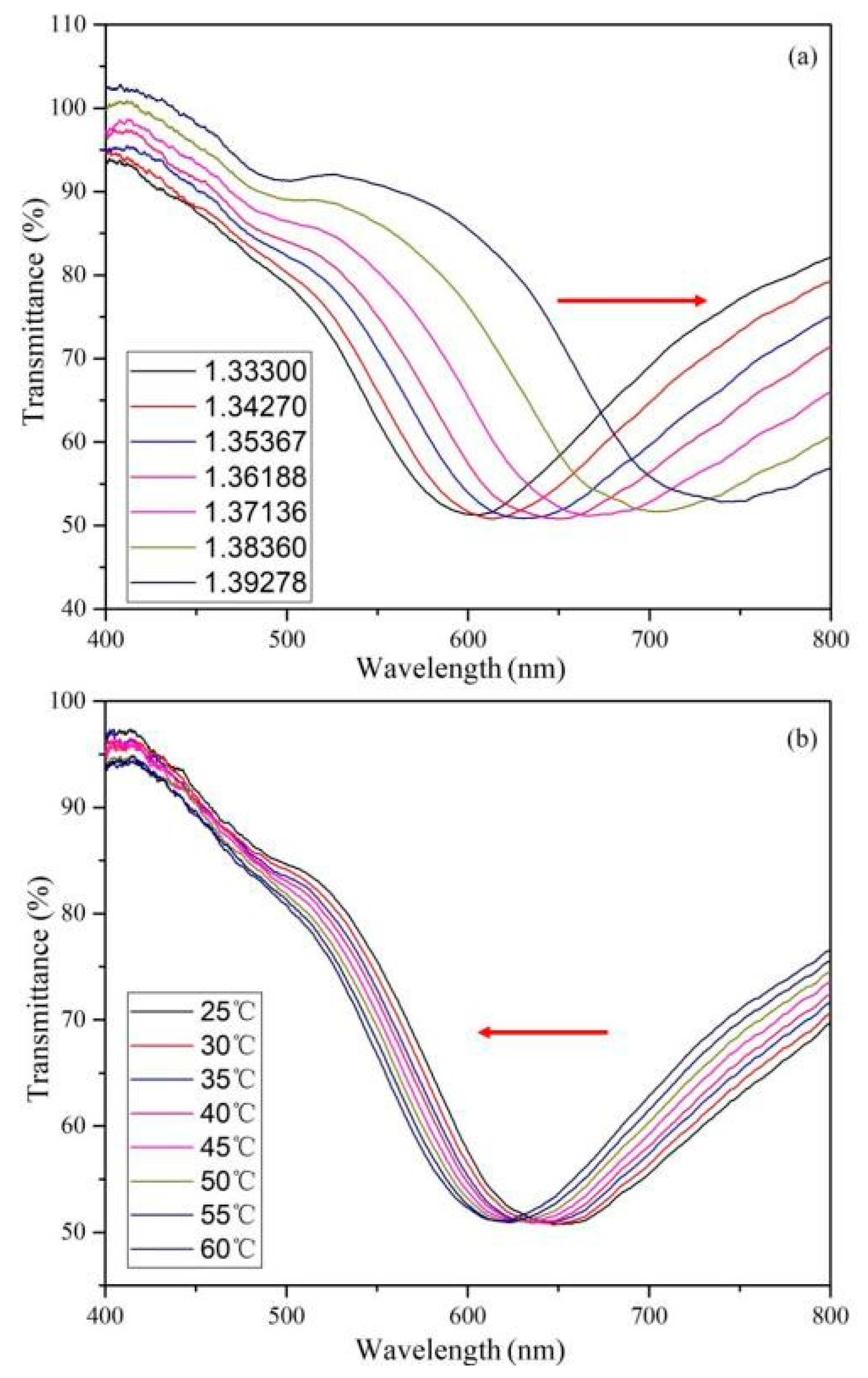

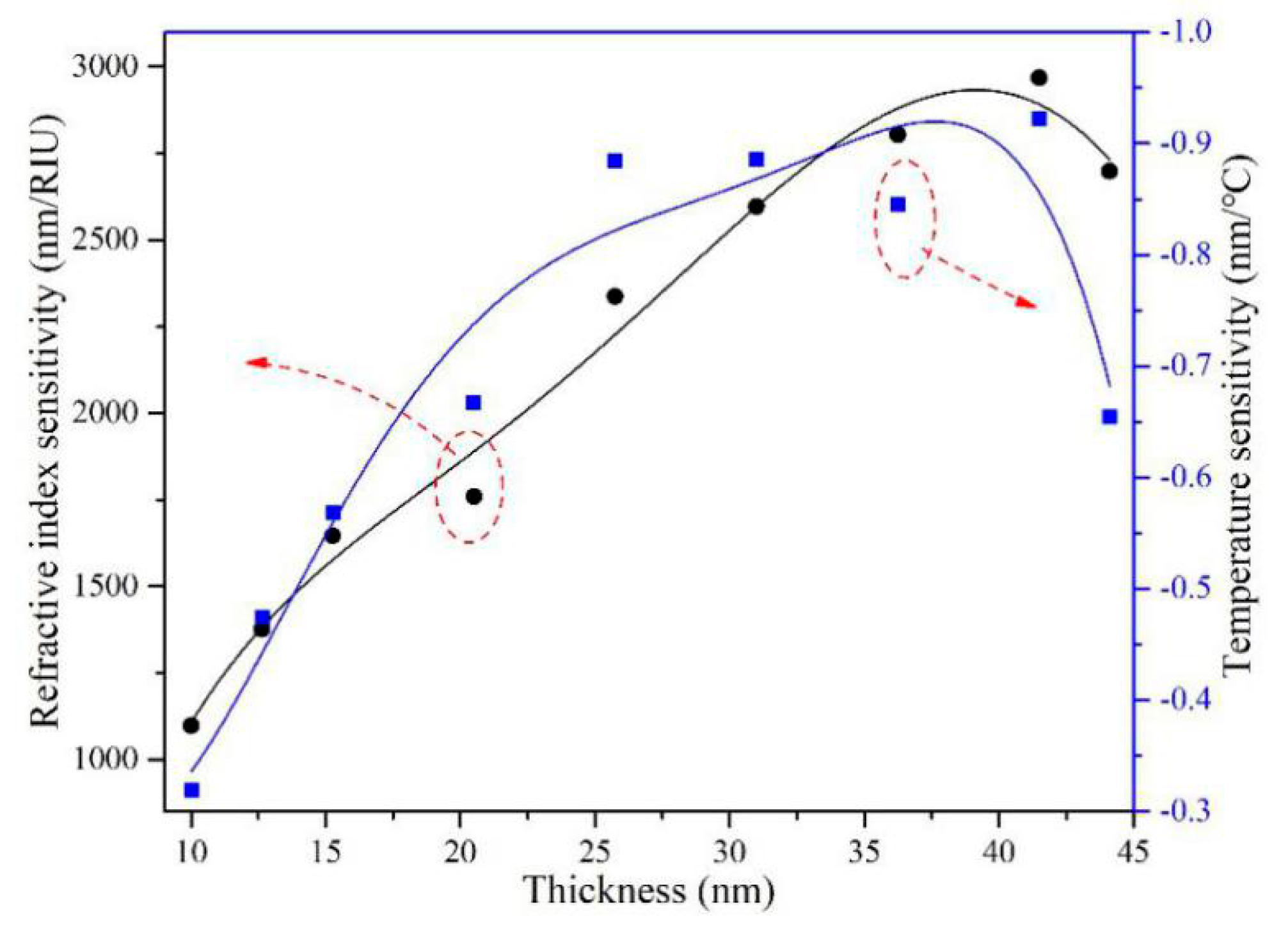

3. Experiments Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, Y.; Lei, M.; Liu, S.-X.; Zhao, Q. Smart hydrogel-based optical fiber SPR sensor for pH measurements. Sensors Actuators B Chem. 2018, 261, 226–232. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, Y.; Cao, S.; Huang, Y.; Zhang, L.; Zhang, F.; Liao, C.; Wang, Y. Mechanism and Characteristics of Humidity Sensing with Polyvinyl Alcohol-Coated Fiber Surface Plasmon Resonance Sensor. Sensors 2018, 18, 2029. [Google Scholar] [CrossRef] [PubMed]

- Lidiya, A.E.; Raja, R.V.J.; Pham, V.D.; Ngo, Q.M.; Vigneswaran, D. Detecting hemoglobin content blood glucose using surface plasmon resonance in D-shaped photonic crystal fiber. Opt. Fiber Technol. 2019, 50, 132–138. [Google Scholar] [CrossRef]

- Caucheteur, C.; Malachovska, V.; Ribaut, C.; Wattiez, R. [INVITED] Cell sensing with near-infrared plasmonic optical fiber sensors. Opt. Laser Technol. 2016, 78, 116–121. [Google Scholar] [CrossRef]

- Guo, T. Fiber grating-assisted surface plasmon resonance for biochemical and electrochemical sensing. J. Lightwave Technol. 2017, 35, 3323–3333. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, B.-T. Surface plasmon resonance biosensor based on graphene oxide/silver coated polymer cladding silica fiber. Sensors Actuators B Chem. 2018, 275, 332–338. [Google Scholar] [CrossRef]

- Srivastava, S.K.; Verma, R.; Gupta, B.D. Surface plasmon resonance based fiber optic sensor for the detection of low water content in ethanol. Sensors Actuators B Chem. 2011, 153, 194–198. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, L. Distance control surface-enhanced fluorescence properties of nanoporous gold. J. Univ. Shanghai Sci. Technol. 2017, 39, 58–62. (In Chinese) [Google Scholar]

- Kurihara, K.; Ohkawa, H.; Iwasaki, Y.; Niwa, O.; Tobita, T.; Suzuki, K. Fiber-optic conical microsensors for surface plasmon resonance using chemically etched single-mode fiber. Anal. Chim. Acta 2004, 523, 165–170. [Google Scholar] [CrossRef]

- Zhao, Y.; Deng, Z.-Q.; Hu, H.-F. Fiber-Optic SPR Sensor for Temperature Measurement. IEEE Trans. Instrum. Meas. 2015, 64, 1. [Google Scholar] [CrossRef]

- Dong, J.; Zhang, Y.; Wang, Y.; Yang, F.; Hu, S.; Chen, Y.; Zhu, W.; Qiu, W.; Guan, H.; Lu, H.; et al. Side-polished few-mode fiber based surface plasmon resonance biosensor. Opt. Express 2019, 27, 11348–11360. [Google Scholar] [CrossRef]

- Cao, S.; Shao, Y.; Wang, Y.; Wu, T.; Zhang, L.; Huang, Y.; Zhang, F.; Liao, C.; He, J.; Wang, Y. Highly sensitive surface plasmon resonance biosensor based on a low-index polymer optical fiber. Opt. Express 2018, 26, 3988–3994. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Schwendtner, E.; Díaz-Herrera, N.; Navarrete, M.; González-Cano, A.; Esteban, Ó. Plasmonic sensor based on tapered optical fibers and magnetic fluids for measuring magnetic fields. Sensors Actuators A Phys. 2017, 264, 58–62. [Google Scholar] [CrossRef]

- Ding, Z.-W.; Lang, T.-T.; Wang, Y.; Zhao, C.-L. Surface Plasmon Resonance Refractive Index Sensor Based on Tapered Coreless Optical Fiber Structure. J. Light. Technol. 2017, 35, 4734–4739. [Google Scholar] [CrossRef]

- Ying, Y.; Xu, K.; Sun, L.-L.; Zhang, R.; Guo, X.-F.; Si, G.-Y. D-Shaped Fiber Magnetic-Field Sensor Based on Fine-Tuning Magnetic Fluid Grating Period. IEEE Trans. Electron Devices 2017, 64, 1735–1741. [Google Scholar] [CrossRef]

- Patnaik, A.; Senthilanathan, K.; Jha, R. Graphene Based Conducting Metal Oxide Coated D-Shaped Optical Fiber SPR Sensor. IEEE Photon- Technol. Lett. 2015, 27, 1. [Google Scholar] [CrossRef]

- Wang, Q.; Jing, J.-Y.; Wang, B.-T. Highly Sensitive SPR Biosensor Based on Graphene Oxide and Staphylococcal Protein A Co-Modified TFBG for Human IgG Detection. IEEE Trans. Instrum. Meas. 2019, 68, 3350–3357. [Google Scholar] [CrossRef]

- Li, Z.; Yu, Z.; Shen, Y.; Ruan, X.; Dai, Y. Graphene Enhanced Leaky Mode Resonance in Tilted Fiber Bragg Grating: A New Opportunity for Highly Sensitive Fiber Optic Sensor. IEEE Access 2019, 7, 26641–26651. [Google Scholar] [CrossRef]

- Arasu, P.; Noor, A.; Shabaneh, A.; Yaacob, M.; Lim, H.; Mahdi, M.; Arasu, P. Fiber Bragg grating assisted surface plasmon resonance sensor with graphene oxide sensing layer. Opt. Commun. 2016, 380, 260–266. [Google Scholar] [CrossRef]

- Arasu, P.T.; Al-Qazwini, Y.; Onn, B.I.; Noor, A.S.M.; Arasu, P.; Noor, A.S.M. Fiber Bragg grating based surface plasmon resonance sensor utilizing FDTD for alcohol detection applications. In Proceedings of the 2012 IEEE 3rd International Conference on Photonics; Institute of Electrical and Electronics Engineers (IEEE), Penang, Malaysia, 1–3 October 2012; pp. 93–97. [Google Scholar]

- Schuster, T.; Herschel, R.; Neumann, N.; Schaffer, C.G. Miniaturized long-period fiber grating assisted surface plasmon resonance sensor. J. Lightwave Technol. 2012, 30, 1003–1008. [Google Scholar] [CrossRef]

- Coelho, L.; Queiros, R.B.; Santos, J.L.; Martins, M.C.L.; Viegas, D.; Jorge, P.A.S. DNA-Aptamer optical biosensors based on a LPG-SPR optical fiber platform for point-of-care diagnostic. Proc. SPIE 2014, 8957, 89570K. [Google Scholar]

- Iga, M.; Seki, A.; Watanabe, K. Gold thickness dependence of SPR-based hetero-core structured optical fiber sensor. Sensors Actuators B Chem. 2005, 106, 363–368. [Google Scholar] [CrossRef]

- May-Arrioja, D.A.; Hernandez-Romano, I.; Velazquez-Gonzalez, J.S.; Monzon-Hernandez, D.; Martinez-Pinon, F. Surface Plasmon Resonance-Based Optical Fiber Embedded in PDMS for Temperature Sensing. IEEE J. Sel. Top. Quantum Electron. 2016, 23, 1. [Google Scholar]

- Yong, W.; Qing, H.; Wenjie, Z.; Minghong, Y.; Elfed, L. Novel optical fiber SPR temperature sensor based on MMF-PCF-MMF structure and gold-PDMS film. Opt. Express 2018, 26, 1910–1917. [Google Scholar]

- Velázquez-González, J.S.; Monzón-Hernández, D.; Moreno-Hernández, D.; Martínez-Piñón, F.; Hernández-Romano, I. Simultaneous measurement of refractive index and temperature using a SPR-based fiber optic sensor. Sensors Actuators B Chem. 2017, 242, 912–920. [Google Scholar] [CrossRef]

- Tian, K.; Farrell, G.; Wang, X.; Xin, Y.; Du, Y.; Yang, W.; Liang, H.; Lewis, E.; Wang, P. High sensitivity temperature sensor based on singlemode-no-core-singlemode fibre structure and alcohol. Sensors Actuators A: Phys. 2018, 284, 28–34. [Google Scholar] [CrossRef] [Green Version]

- Baharin, N.F.; Musa, S.M.A.; Azmi, A.I.; Razak, M.A.A.; Abdullah, A.S.; Salim, M.R.; Noor, M.Y.M. Compact and high sensitivity low-temperature sensor based on coreless silica fiber Mach-Zehnder interferometer. Microw. Opt. Technol. Lett. 2018, 60, 1929–1934. [Google Scholar] [CrossRef]

- Homola, J. Present and future of surface plasmon resonance biosensors. Anal. Bioanal. Chem. 2003, 377, 528–539. [Google Scholar] [CrossRef]

- Boltovets, P.M.; Snopok, B.A. Measurement uncertainty in analytical studies based on surface plasmon resonance. Talanta 2009, 80, 466–472. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Pu, S.; Li, X. Gold-Film-Thickness Dependent SPR Refractive Index and Temperature Sensing with Hetero-Core Optical Fiber Structure. Sensors 2019, 19, 4345. https://doi.org/10.3390/s19194345

Zhang R, Pu S, Li X. Gold-Film-Thickness Dependent SPR Refractive Index and Temperature Sensing with Hetero-Core Optical Fiber Structure. Sensors. 2019; 19(19):4345. https://doi.org/10.3390/s19194345

Chicago/Turabian StyleZhang, Rui, Shengli Pu, and Xinjie Li. 2019. "Gold-Film-Thickness Dependent SPR Refractive Index and Temperature Sensing with Hetero-Core Optical Fiber Structure" Sensors 19, no. 19: 4345. https://doi.org/10.3390/s19194345

APA StyleZhang, R., Pu, S., & Li, X. (2019). Gold-Film-Thickness Dependent SPR Refractive Index and Temperature Sensing with Hetero-Core Optical Fiber Structure. Sensors, 19(19), 4345. https://doi.org/10.3390/s19194345