A New Submersion Detection Sensor Using Two Resistance Temperature Detectors Operating on the Thermal Equilibrium Principle

Abstract

:1. Introduction

2. Materials and Methods

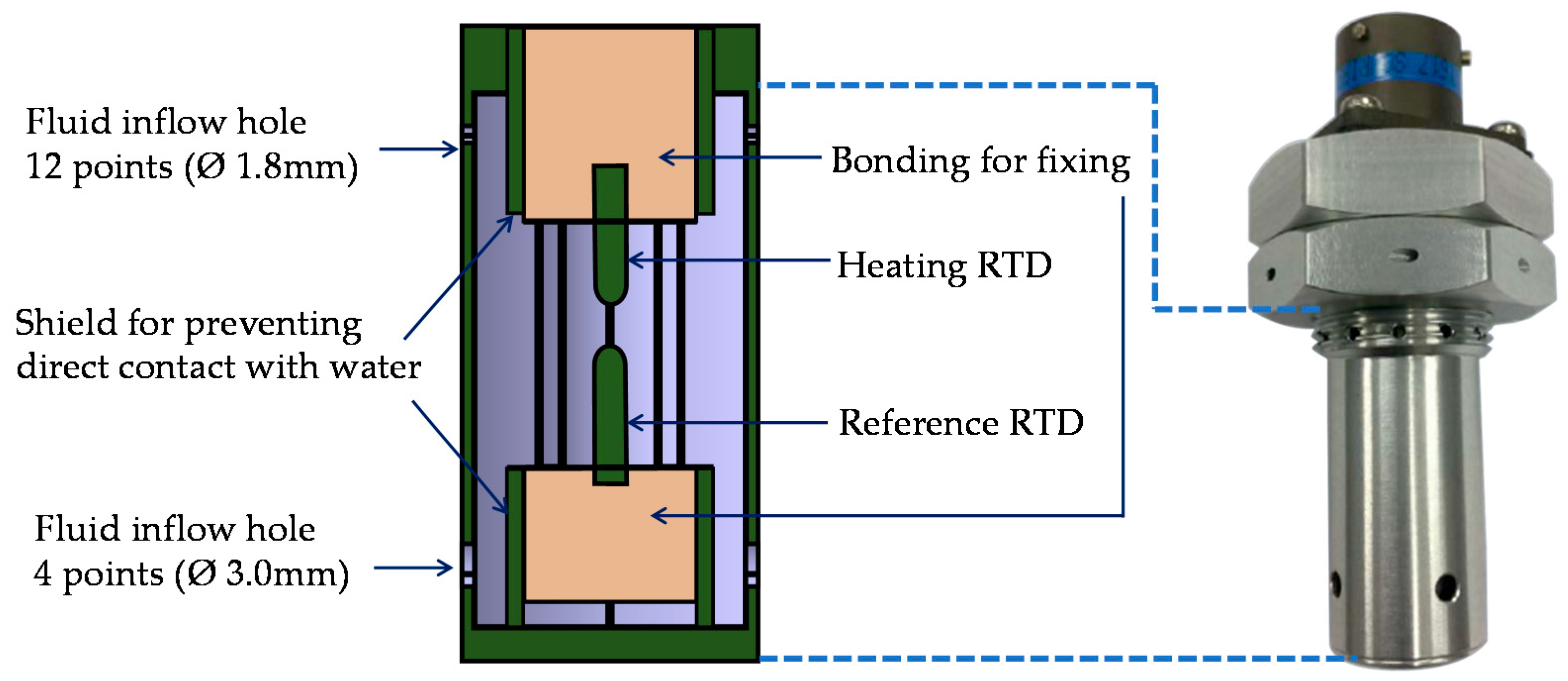

2.1. Materials and Sensor Mechanical Design

2.2. Transient Heat Transfer Analysis and Signal Conditioning Circuit Design

2.3. Self-Diagnosis Circuit

2.4. Test Equipment Design

3. Results

3.1. Static Test

3.1.1. Humidity Test

3.1.2. Rain Test

3.2. Dynamic Characteristics: Submersion Sensing Response Time

3.3. Self-Diagnosis Test

3.4. Repeatability Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abdullahi, S.I.; Habaebi, M.H.; Gunawan, T.S.; Islam, M.R. Miniaturized Water Flow and Level Monitoring System for Flood Disaster Early Warning. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kuala Lumpur, Malaysia, 8–9 August 2017; IOP Publishing: Bristol, UK, 2017; Volume 260, p. 012019. [Google Scholar]

- Vázquez, C.; Gonzalo, A.B.; Vargas, S.; Montalvo, J. Multi-sensor system using plastic optical fibers for intrinsically safe level measurements. Sens. Actuators A Phys. 2004, 116, 22–32. [Google Scholar] [CrossRef] [Green Version]

- Sohn, K.R.; Shim, J.H. Liquid-level monitoring sensor systems using fiber Bragg grating embedded in cantilever. Sens. Actuators A Phys. 2009, 152, 248–251. [Google Scholar] [CrossRef]

- Lomer, M.; Arrue, J.; Jauregui, C.; Aiestaran, P.; Zubia, J.; López-Higuera, J.M. Lateral polishing of bends in plastic optical fibres applied to a multipoint liquid-level measurement. Sens. Actuators A Phys. 2007, 137, 68–73. [Google Scholar] [CrossRef]

- Manut, A.; Zoolfakar, A.S.; Muhammad, N.A.; Zolkapli, M. Characterization of inter digital capacitor for water level sensor. In Proceedings of the 2011 IEEE Regional Symposium on Micro and Nano Electronics, Kota Kinabalu, Malaysia, 28–30 September 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 359–363. [Google Scholar]

- Chetpattananondh, K.; Tapoanoi, T.; Phukpattaranont, P.; Jindapetch, N. A self-calibration water level measurement using an interdigital capacitive sensor. Sens. Actuators A Phys. 2014, 209, 175–182. [Google Scholar] [CrossRef]

- Quoc, T.V.; Dac, H.N.; Quoc, T.P.; Dinh, D.N.; Duc, T.C. A printed circuit board capacitive sensor for air bubble inside fluidic flow detection. Microsyst. Technol. 2015, 21, 911–918. [Google Scholar] [CrossRef]

- Gong, C.S.A.; Chiu, H.K.; Huang, L.R.; Lin, C.H.; Hsu, Z.D.; Tu, P.H. Low-cost comb-electrode capacitive sensing device for liquid-level measurement. IEEE Sens. J. 2016, 16, 911–918. [Google Scholar] [CrossRef]

- Paczesny, D.; Tarapata, G.; Michał, M.; Jachowicz, R. The capacitive sensor for liquid level measurement made with ink-jet printing technology. Procedia Eng. 2015, 120, 911–918. [Google Scholar] [CrossRef]

- Babu, C.S.; Manohar, P. Design of a low-cost signal conditioning circuit for self-compensated non-contact capacitive type multi threshold liquid level sensor. In Proceedings of the International Conference on Circuits, Communication, Control and Computing, Bengaluru, India, 20–22 November 2014; IEEE: Piscataway, NJ, USA, 2014. [Google Scholar]

- Wang, X.; Wang, Y.; Leung, H.; Mukhopadhyay, S.C.; Tian, M.; Zhou, J. Mechanism and experiment of planar electrode sensors in water pollutant measurement. IEEE Trans. Instrum. Meas. 2014, 62, 516–523. [Google Scholar] [CrossRef]

- Casanella, R.; Casas, O.; Pallàs-Areny, R. Oil-water interface level sensor based on an electrode array. In Proceedings of the 2006 IEEE Instrumentation and Measurement Technology Conference, Sorrento, Italy, 24–27 April 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 710–713. [Google Scholar]

- Tomita, S.; Tachino, H.; Kasahara, N. Water sensor with optical fiber. J. Lightwave Technol. 1990, 8, 1829–1832. [Google Scholar] [CrossRef]

- Michie, W.C.; Culshaw, B.; McKenzie, I.; Konstantakis, M.; Graham, N.B.; Moran, C.; Santos, F.; Bergqvist, E.; Carlstrom, B. Distributed sensor for water and pH measurements using fiber optics and swellable polymeric systems. Opt. Lett. 1995, 20, 103–105. [Google Scholar] [CrossRef] [PubMed]

- Arregui, F.J.; Matías, I.R.; Cooper, K.L.; Claus, R.O. Simultaneous measurement of humidity and temperature by combining a reflective intensity-based optical fiber sensor and a fiber Bragg grating. IEEE Sens. J. 2002, 2, 482–487. [Google Scholar] [CrossRef]

- Sohn, K.R.; Kim, K.T.; Song, J.W. Optical fiber sensor for water detection using a side-polished fiber coupler with a planar glass-overlay-waveguide. Sens. Actuators A Phys. 2002, 101, 137–142. [Google Scholar] [CrossRef]

- Nath, P.; Singh, H.K.; Datta, P.; Sarma, K.C. All-fiber optic sensor for measurement of liquid refractive index. Sens. Actuators A Phys. 2008, 148, 16–18. [Google Scholar] [CrossRef]

- Kazemi, A.A.; Yang, C.; Chen, S. Fiber optic cryogenic liquid level detection system for space applications. In Photonics in the Transportation Industry: Auto to Aerospace II; International Society for Optics and Photonics: Bellingham, WA, USA, 2009. [Google Scholar]

- Key, K.H.; Kim, H.P.; Sohn, K.R. Development of optical dual-sensors for submersion monitoring using zigbee-based wireless sensor networks. J. Sens. Sci. Technol. 2010, 19, 184–190. [Google Scholar] [CrossRef] [Green Version]

- Shao, M.; Qiao, X.; Zhao, X.; Zhang, Y.; Fu, H. Liquid level sensor using fiber Bragg grating assisted by multimode fiber core. IEEE Sens. J. 2016, 16, 2374–2379. [Google Scholar] [CrossRef]

- MathWorks. Available online: https://www.mathworks.com/products/MATLAB.html (accessed on 28 July 2019).

- OMEGA™. Available online: https://www.omega.co.uk/pptst/1PT100G_RTD_ELEMENTS.html (accessed on 28 July 2019).

- Wikipedia. Available online: https://en.wikipedia.org/wiki/Lumped element model (accessed on 28 July 2019).

- Wikipedia. Available online: https://en.wikipedia.org/wiki/Newton%27s_law_of_cooling (accessed on 28 July 2019).

- Wikipedia. Available online: https://en.wikipedia.org/wiki/Thermal_conduction (accessed on 28 July 2019).

- Wikipedia. Available online: http://everyspec.com/MIL-STD/MIL-STD-0800-0899/MIL-STD-810G_12306/ (accessed on 28 July 2019).

- ESPEC CORP. Available online: https://www.espec.co.jp/english/ (accessed on 28 July 2019).

- World Sea Temperatures. Available online: https://www.seatemperature.org (accessed on 28 July 2019).

- K-water. Available online: http://english.kwater.or.kr/eng/main.do (accessed on 28 July 2019).

- NASA’s ‘Salt of the Earth’ Aquarius Reveals First Map. Available online: https://www.nasa.gov/mission_pages/aquarius/multimedia/gallery/pia14786.html (accessed on 28 July 2019).

| Operating Temperature Range [°C,F] | Shape: Cylinder Size: [mm] | Self-Heating Error [°C/mW] @ Air Flow V = 1 [m/s] | Response Time [Second] | |||

|---|---|---|---|---|---|---|

| Flowing Water V = 0.4 [m/s] | Flowing Air V = 1 [m/s] | |||||

| Response 50% | Response 90% | Response 50% | Response 90% | |||

| −220–400, (−365–750) | Radius: 1 Length: 10 | 0.26 | 0.14 | 0.35 | 7.0 | 21.0 |

| Condition | Air = 10 [W/m2 °C] | Air = 30 [W/m2 °C] | Air = 50 [W/m2 °C] | Water = 500 [W/m2 °C] | Water = 700 [W/m2 °C] |

|---|---|---|---|---|---|

| [W/m2 °C] | 8.5 | 8.5 | 8.5 | 15 | 15 |

| 0.0005347 | 0.0016041 | 0.0026735 | 0.01515 | 0.02121 |

| Condition | Simulation Results | Measurement Results | ||||

|---|---|---|---|---|---|---|

| Before Submersion | After Submersion | Difference | Before Submersion | After Submersion | Difference | |

| temperature of [°C] | 55 | 39 | 16 | 55.6 | 39.3 | 16.3 |

| resistance of [Ω] | 121.17 | 115.01 | 6.16 | 121.40 | 115.13 | 6.27 |

| voltage of [V] @ | 7.02 | 6.90 | 0.12 | 7.04 | 6.92 | 0.11 |

| temperature of [°C] | 20.0 | 20.0 | 0 | 20.6 | 20.3 | 0.3 |

| resistance of [Ω] | 107.7 | 107.7 | 0 | 107.9 | 107.8 | 0.1 |

| voltage of [V] @ | 3.25 | 3.25 | 0 | 3.25 | 3.25 | 0 |

| output of [V] @ | 5.75 | 5.75 | 0 | 5.77 | 5.77 | 0 |

| output of [V] @ | 1.26 | 1.14 | 0.12 | 1.26 | 1.15 | 0.11 |

| output of [V] @ | 7.20 | 6.54 | 1.12 | 7.23 | 6.56 | 0.67 |

| reference of [V] | 6.8 | 6.8 | 0 | 6.78 | 6.78 | 0 |

| sensing margin [V] | 0.40 | 0.26 | - | 0.45 | 0.21 | - |

| output of [V] @ | 0 V (“low”) | 12 V (“high”) | - | 0 V (“low”) | 12 V (“high”) | - |

| Sensing output [V] | 0 V (“low”) | 12 V (“high”) | - | 0 V (“low”) | 12 V (“high”) | - |

| Condition | Temp. of RTDH [°C] | Resistanceof RTDH [Ω] | V1 [V] | V7 [V] | V8 [V] | Self-Diagnosis Output | Sensing Output | Final Sensing Output | |

|---|---|---|---|---|---|---|---|---|---|

| Normal | low temp | −20 | 92.3 | 6.42 | 8.35 | 6.13 | 12 V | 0 V | 0 V |

| high temp | +220 | 184.7 | 6.42 | 8.35 | 6.13 | 12 V | 12 V | 12 V | |

| malfunction | RTD open | - | - | 12 | 8.35 | 6.13 | 0 V | 12 V | 0 V |

| RTD short | - | - | 0 | 8.35 | 6.13 | 0 V | 12 V | 0 V | |

| Test Condition | Sample 1 | Sample 2 | Sample 3 | Sample 4 |

|---|---|---|---|---|

| MIL-STD-801G Method 507.5 Procedure Ⅱ | submersion not detected | submersion not detected | submersion not detected | submersion not detected |

| Test Condition | Description | Sample 1 | Sample 2 | Sample 3 | Sample 4 |

|---|---|---|---|---|---|

| MIL-STD-801G Method 506.4 Procedure Ⅰ | rain and blowing rain | submersion not detected | submersion not detected | submersion not detected | submersion not detected |

| MIL-STD-801G Method 506.4 Procedure Ⅱ | Drip | submersion not detected | submersion not detected | submersion not detected | submersion not detected |

| Water | Minimum Temperature [°C] | Maximum Temperature [°C] | psu (Practical Salinity Unit) |

|---|---|---|---|

| Fresh water | 1 | 29 | - |

| Salt water | −1.7 | 31.7 | maximum 40 psu [30] |

| Air Temperature [°C] | Fresh-Water Temperature [°C] | Submersion Direction | Sample 1 [Second] | Sample 2 [Second] | Sample 3 [Second] | Sample 4 [Second] |

|---|---|---|---|---|---|---|

| −40 | 2 | 0° (vertical) | 0.52 | 0.56 | 0.51 | 0.50 |

| 45° | 0.34 | 0.50 | 0.52 | 0.55 | ||

| 90° (horizontal) | 0.40 | 0.38 | 0.49 | 0.42 | ||

| 32 | 0° (vertical) | 0.47 | 0.46 | 0.53 | 0.43 | |

| 45° | 0.48 | 0.39 | 0.32 | 0.45 | ||

| 90° (horizontal) | 0.39 | 0.42 | 0.43 | 0.39 | ||

| 0 | 2 | 0° (vertical) | 0.41 | 0.59 | 0.54 | 0.40 |

| 45° | 0.33 | 0.45 | 0.47 | 0.44 | ||

| 90° (horizontal) | 0.35 | 0.42 | 0.40 | 0.39 | ||

| 32 | 0° (vertical) | 0.56 | 0.46 | 0.51 | 0.53 | |

| 45° | 0.45 | 0.43 | 0.47 | 0.39 | ||

| 90° (horizontal) | 0.37 | 0.39 | 0.44 | 0.37 | ||

| 71 | 2 | 0° (vertical) | 0.49 | 0.55 | 0.50 | 0.58 |

| 45° | 0.42 | 0.44 | 0.49 | 0.45 | ||

| 90° (horizontal) | 0.35 | 0.42 | 0.38 | 0.41 | ||

| 32 | 0° (vertical) | 0.51 | 0.59 | 0.58 | 0.53 | |

| 45° | 0.49 | 0.45 | 0.48 | 0.49 | ||

| 90° (horizontal) | 0.36 | 0.44 | 0.43 | 0.38 |

| Air Temperature [°C] | Salt-Water Temperature [°C] | Submersion Direction | Sample 1 [Second] | Sample 2 [Second] | Sample 3 [Second] | Sample 4 [Second] |

|---|---|---|---|---|---|---|

| −40 | 2 | 0° (vertical) | 0.55 | 0.51 | 0.44 | 0.57 |

| 45° | 0.43 | 0.49 | 0.38 | 0.44 | ||

| 90° (horizontal) | 0.32 | 0.36 | 0.35 | 0.35 | ||

| 32 | 0° (vertical) | 0.52 | 0.48 | 0.56 | 0.55 | |

| 45° | 0.44 | 0.47 | 0.39 | 0.45 | ||

| 90° (horizontal) | 0.39 | 0.41 | 0.38 | 0.40 | ||

| 0 | 2 | 0° (vertical) | 0.50 | 0.47 | 0.58 | 0.41 |

| 45° | 0.43 | 0.55 | 0.46 | 0.44 | ||

| 90° (horizontal) | 0.39 | 0.40 | 0.30 | 0.35 | ||

| 32 | 0° (vertical) | 0.54 | 0.49 | 0.46 | 0.54 | |

| 45° | 0.48 | 0.41 | 0.39 | 0.48 | ||

| 90° (horizontal) | 0.45 | 0.33 | 0.38 | 0.32 | ||

| 71 | 2 | 0° (vertical) | 0.56 | 0.47 | 0.49 | 0.56 |

| 45° | 0.51 | 0.42 | 0.53 | 0.37 | ||

| 90° (horizontal) | 0.48 | 0.35 | 0.36 | 0.35 | ||

| 32 | 0° (vertical) | 0.38 | 0.52 | 0.51 | 0.54 | |

| 45° | 0.40 | 0.43 | 0.46 | 0.43 | ||

| 90° (horizontal) | 0.35 | 0.38 | 0.37 | 0.35 |

| Test Condition | Self-Diagnosis Output (Normal: 12 [V], Detected: 0 [V]) | |||

|---|---|---|---|---|

| Sample1 | Sample2 | Sample3 | Sample4 | |

| Normal | 12 V | 12 V | 12 V | 12 V |

| open | 0 V | 0 V | 0 V | 0 V |

| short | 0 V | 0 V | 0 V | 0 V |

| open | 0 V | 0 V | 0 V | 0 V |

| short | 0 V | 0 V | 0 V | 0 V |

| Water | Temperature [°C] | Submersion Direction | Repeatability Test Condition | Test Result |

|---|---|---|---|---|

| Fresh-water | 2 | 0°, 90° | 1000 times | Pass |

| 32 | 0°, 90° | 1000 times | Pass | |

| Salt-water with 40 psu | 2 | 0°, 90° | 1000 times | Pass |

| 32 | 0°, 90° | 1000 times | Pass |

| Malfunction Possibility | Self-Diagnosis | Response Time [sec] | Electro Magnetic Interference (EMI) Influence | |

|---|---|---|---|---|

| Proposed submersion sensor | none | possible | 0.4–0.6 | none |

| Resistive electrode submersion sensor | medium | impossible | less than 0.1 | none |

| Capacitive submersion sensor | high | possible | less than 0.1 | yes |

| Optical submersion sensor | high | possible | less than 0.1 | none |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.; Lee, Y.S. A New Submersion Detection Sensor Using Two Resistance Temperature Detectors Operating on the Thermal Equilibrium Principle. Sensors 2019, 19, 4310. https://doi.org/10.3390/s19194310

Lee Y, Lee YS. A New Submersion Detection Sensor Using Two Resistance Temperature Detectors Operating on the Thermal Equilibrium Principle. Sensors. 2019; 19(19):4310. https://doi.org/10.3390/s19194310

Chicago/Turabian StyleLee, Youngjun, and Young Sam Lee. 2019. "A New Submersion Detection Sensor Using Two Resistance Temperature Detectors Operating on the Thermal Equilibrium Principle" Sensors 19, no. 19: 4310. https://doi.org/10.3390/s19194310

APA StyleLee, Y., & Lee, Y. S. (2019). A New Submersion Detection Sensor Using Two Resistance Temperature Detectors Operating on the Thermal Equilibrium Principle. Sensors, 19(19), 4310. https://doi.org/10.3390/s19194310