Corrosion Sensors for Structural Health Monitoring of Oil and Natural Gas Infrastructure: A Review

Abstract

1. Introduction

1.1. Corrosion Problems in Oil and Natural Gas Industry

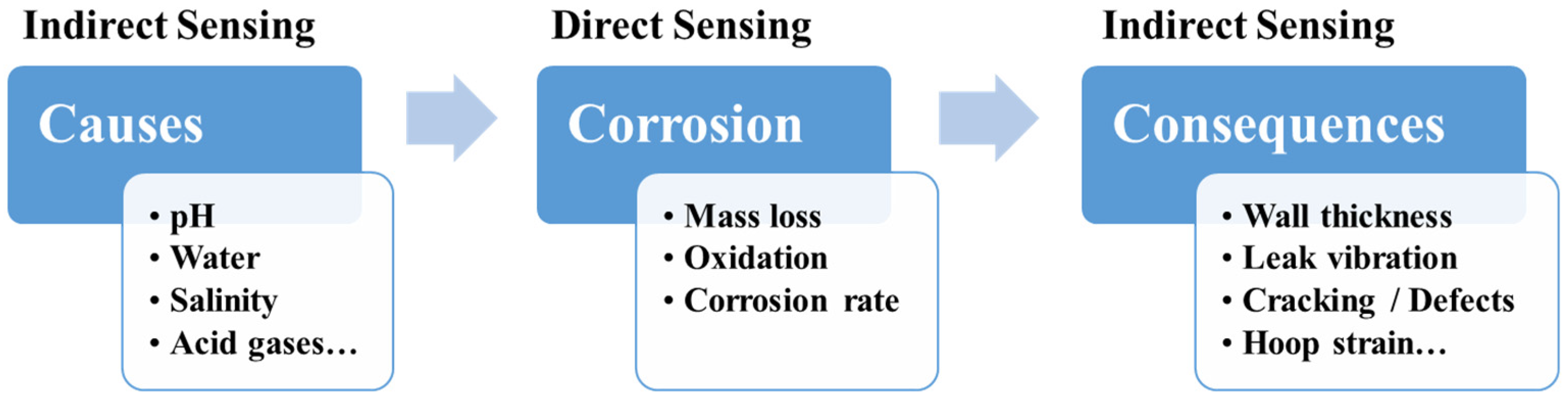

1.2. Functions and Categories of Corrosion Sensors

2. Conventional Corrosion Sensors

2.1. Corrosion Coupon

2.2. Electrical Resistance Probe

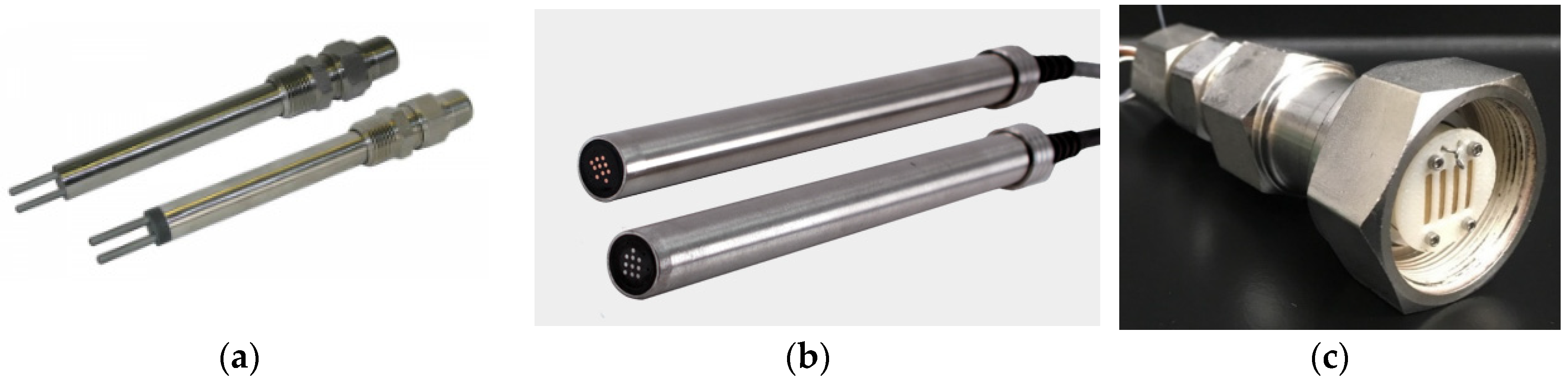

2.3. Electrochemical Sensors

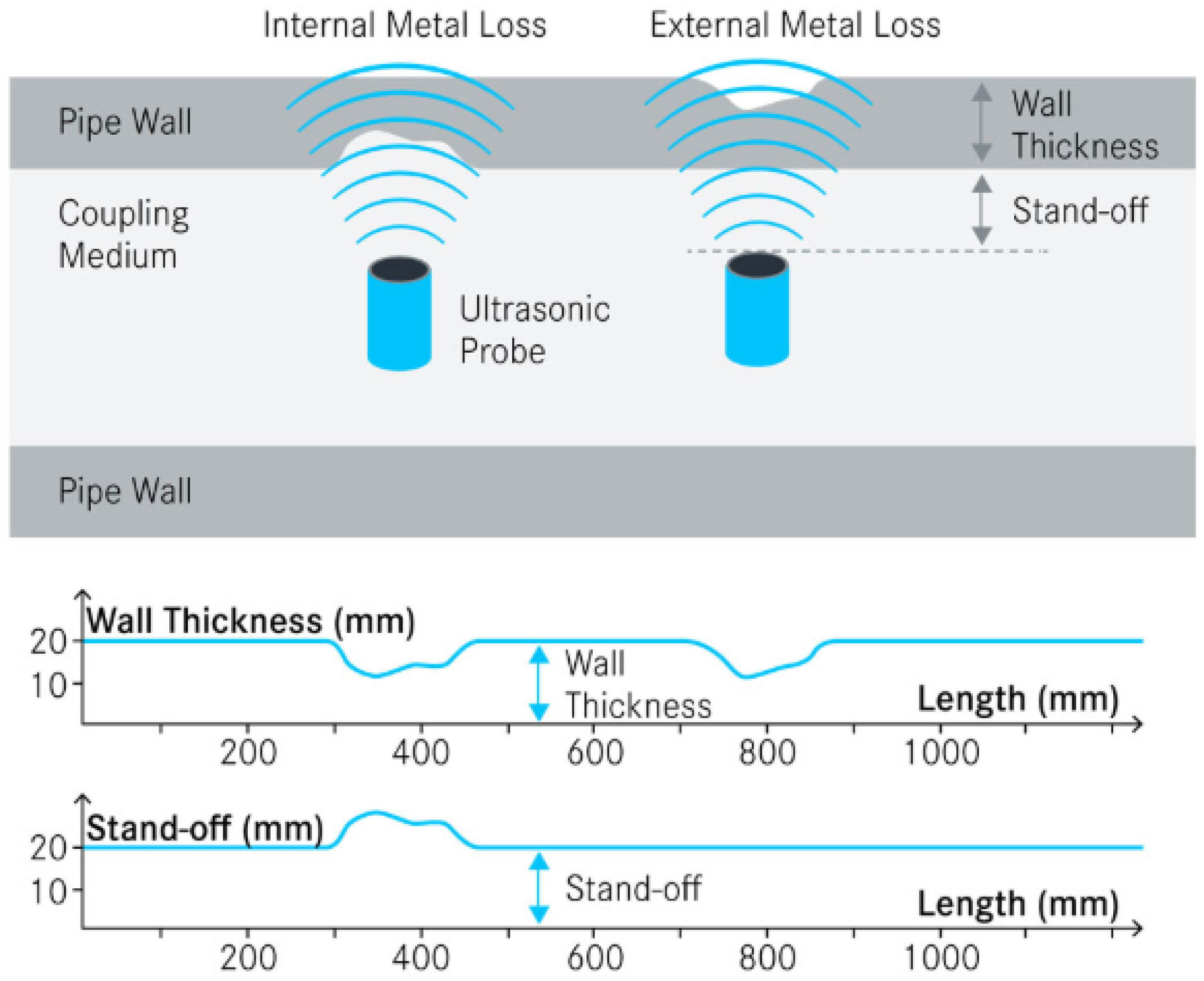

2.4. Ultrasonic Testing Sensor

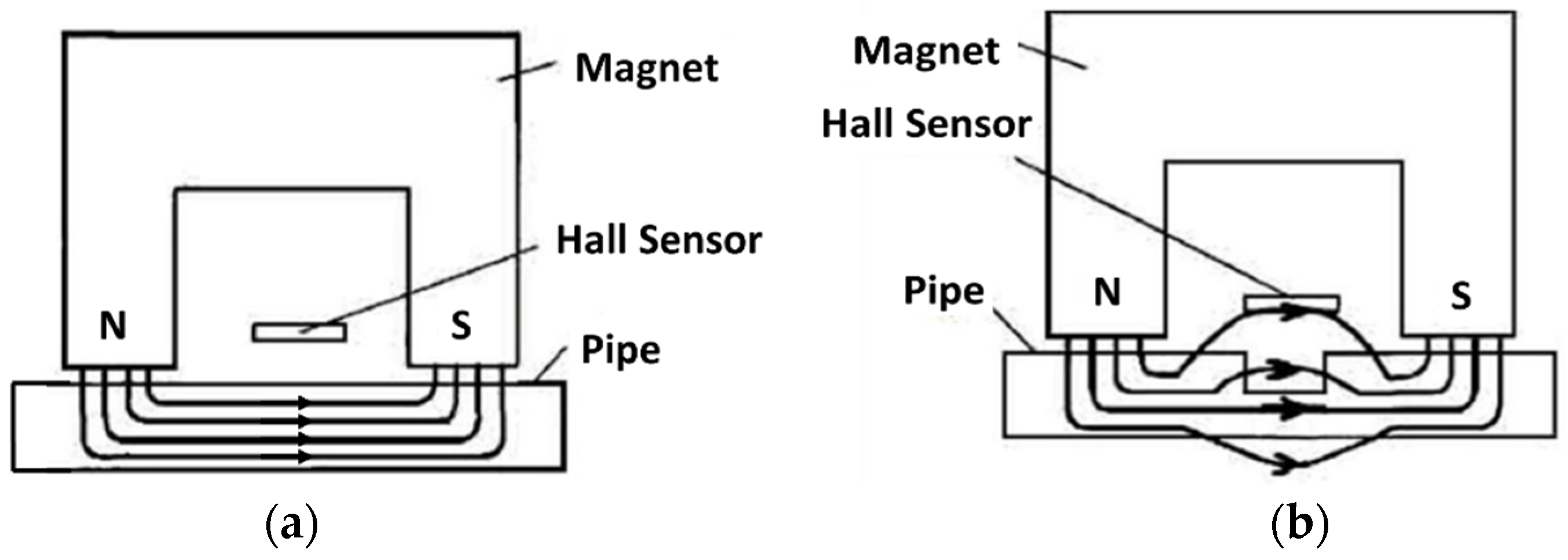

2.5. Magnetic Flux Leakage Method

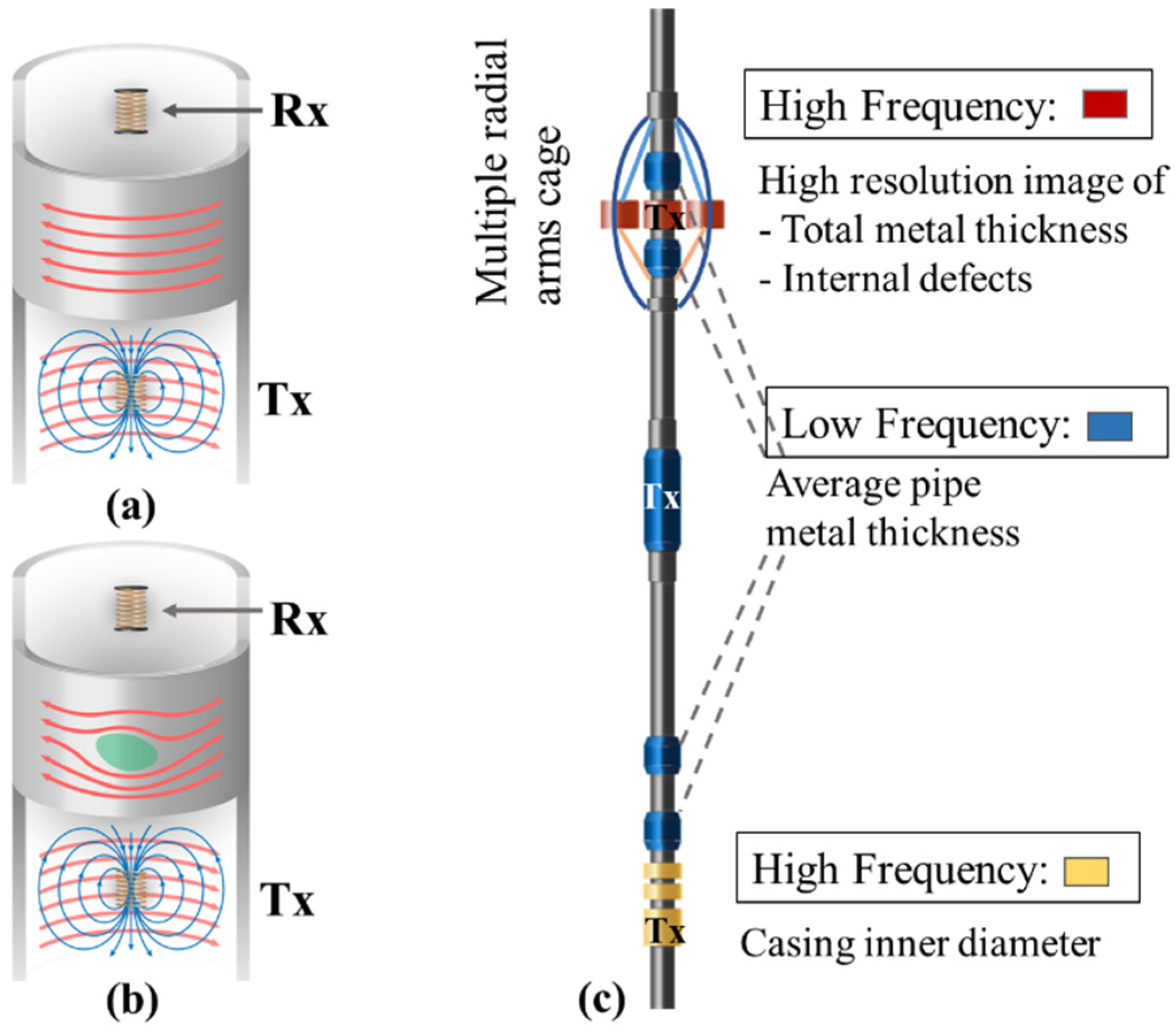

2.6. Multi-Frequency Electromagnetic Sensors

2.7. Pipeline Inspection Gauge

3. Emerging Corrosion Sensing Technologies

3.1. Optical Fiber Sensors

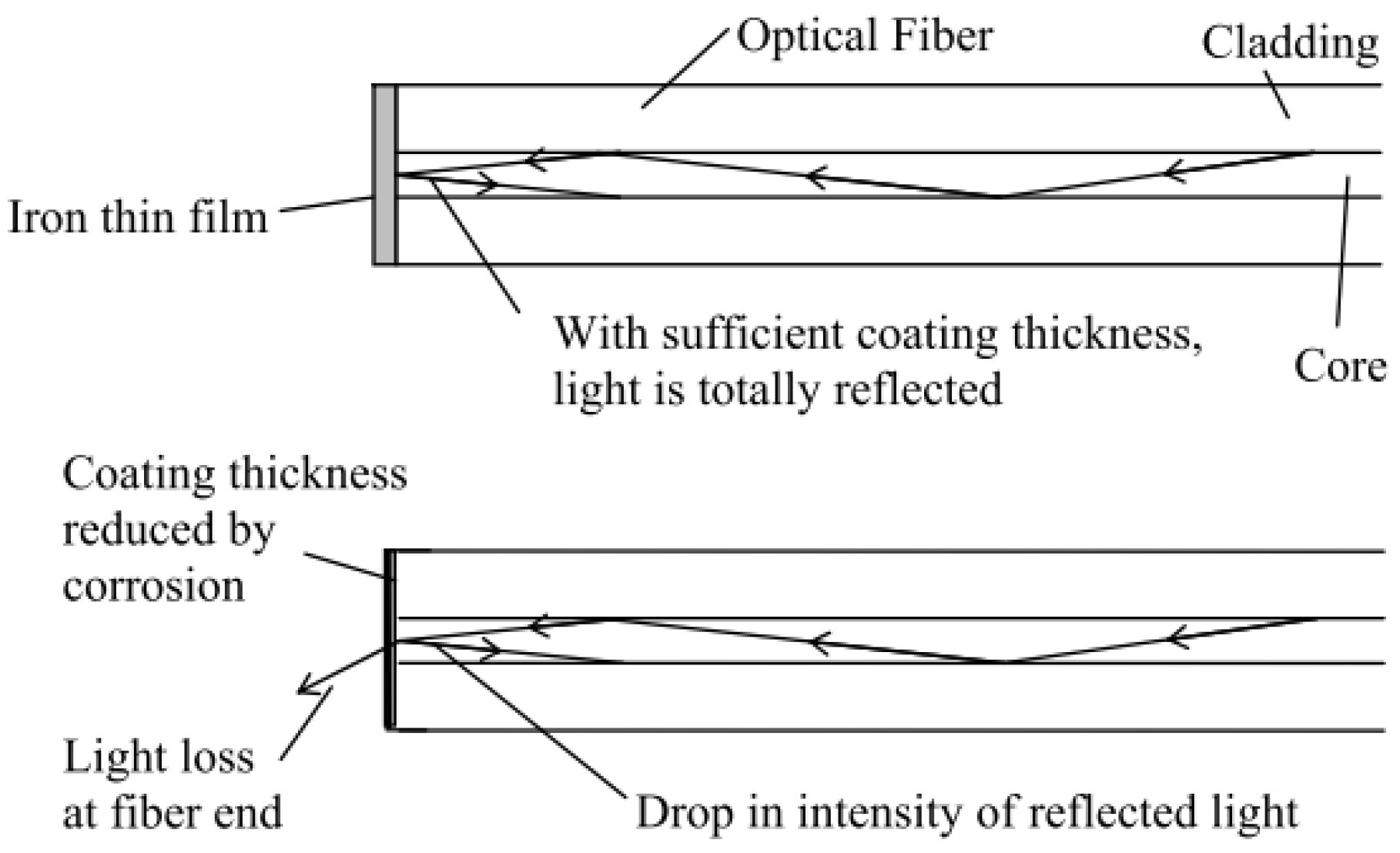

3.1.1. Point OFS for Corrosion

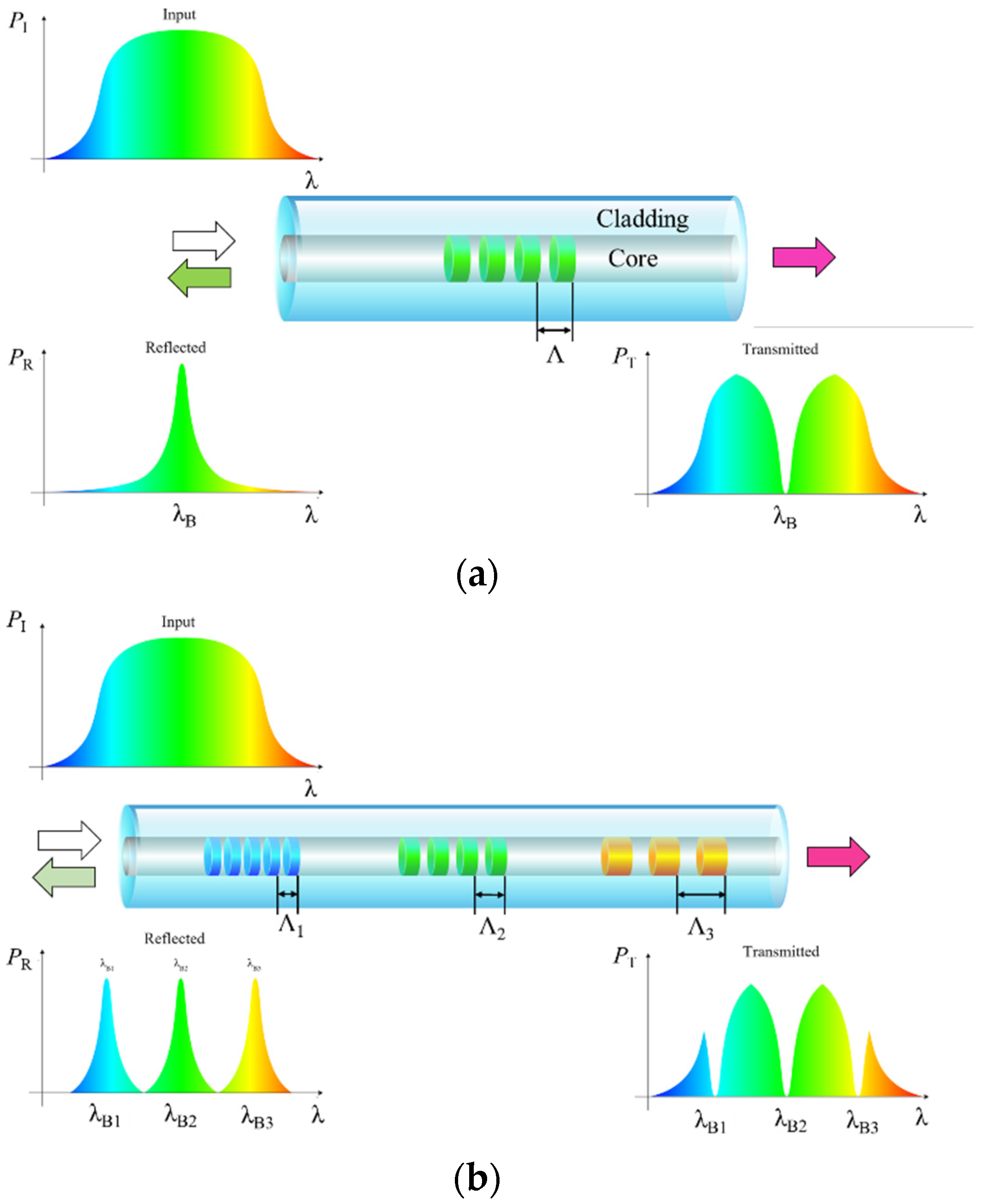

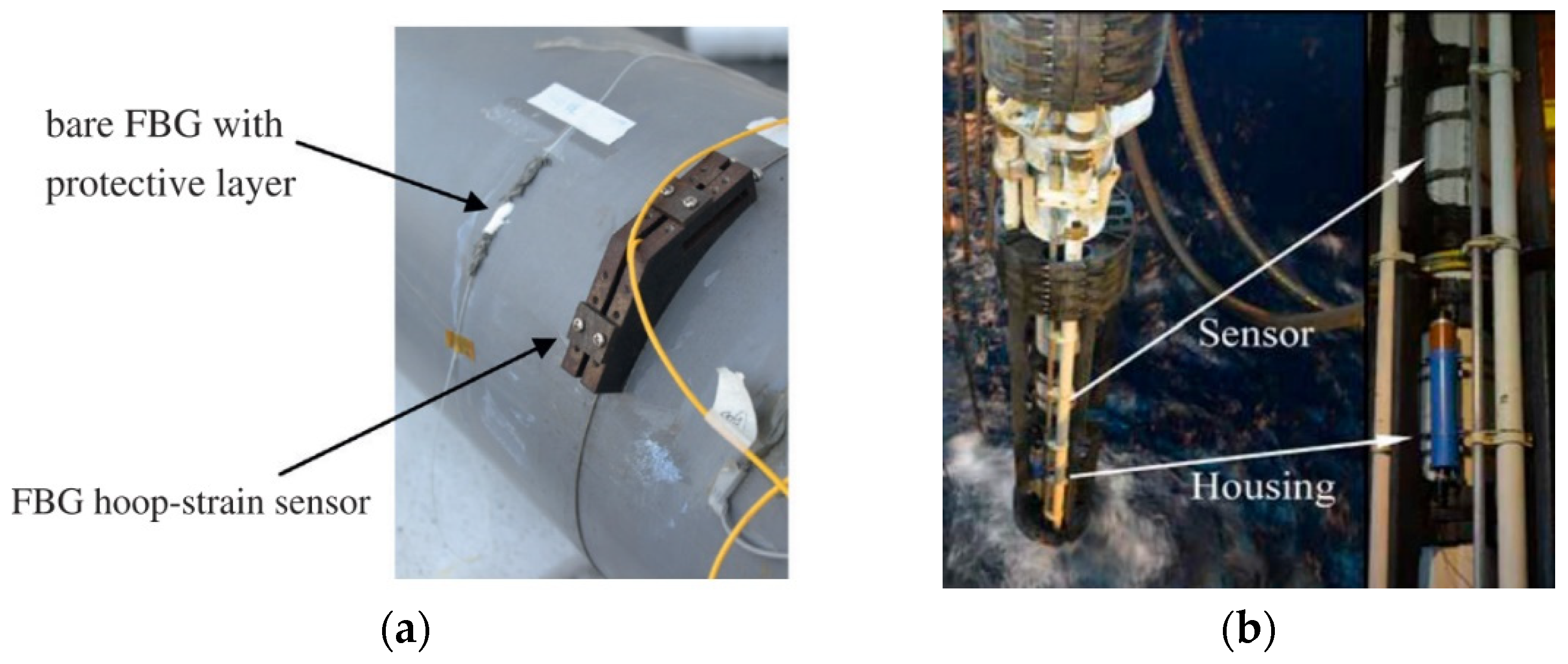

3.1.2. Quasi-Distributed OFS for Corrosion

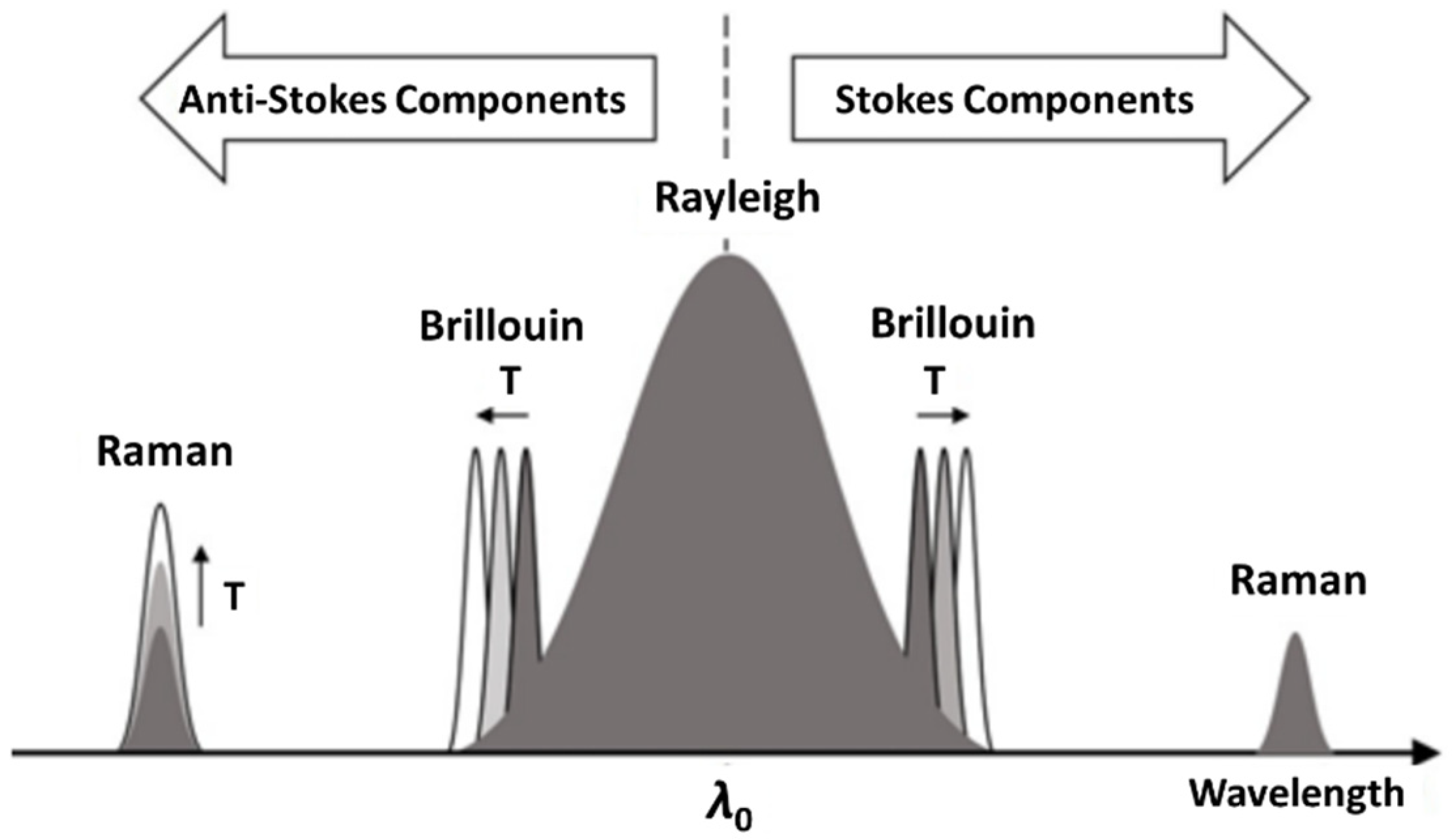

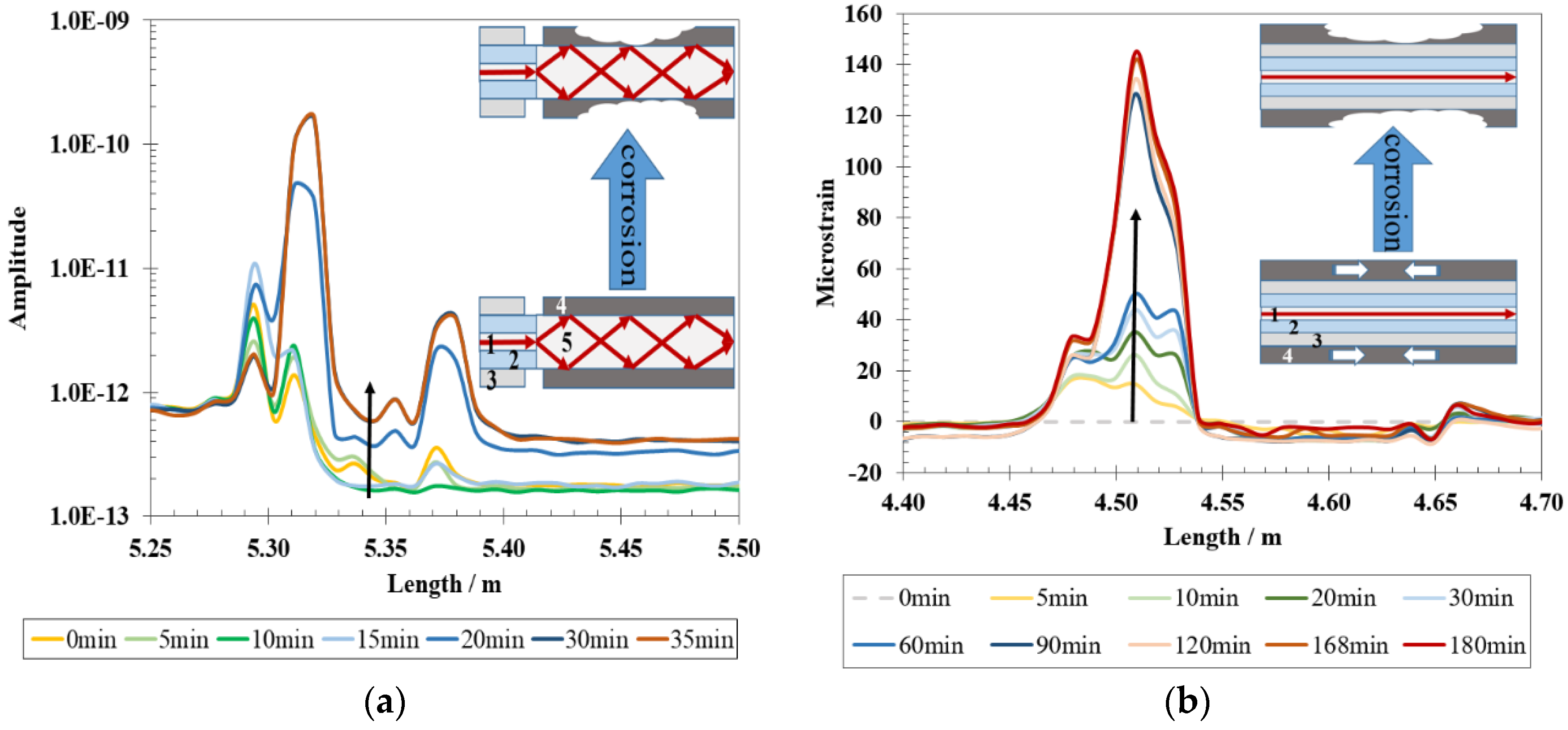

3.1.3. Distributed OFS for Physical Sensing

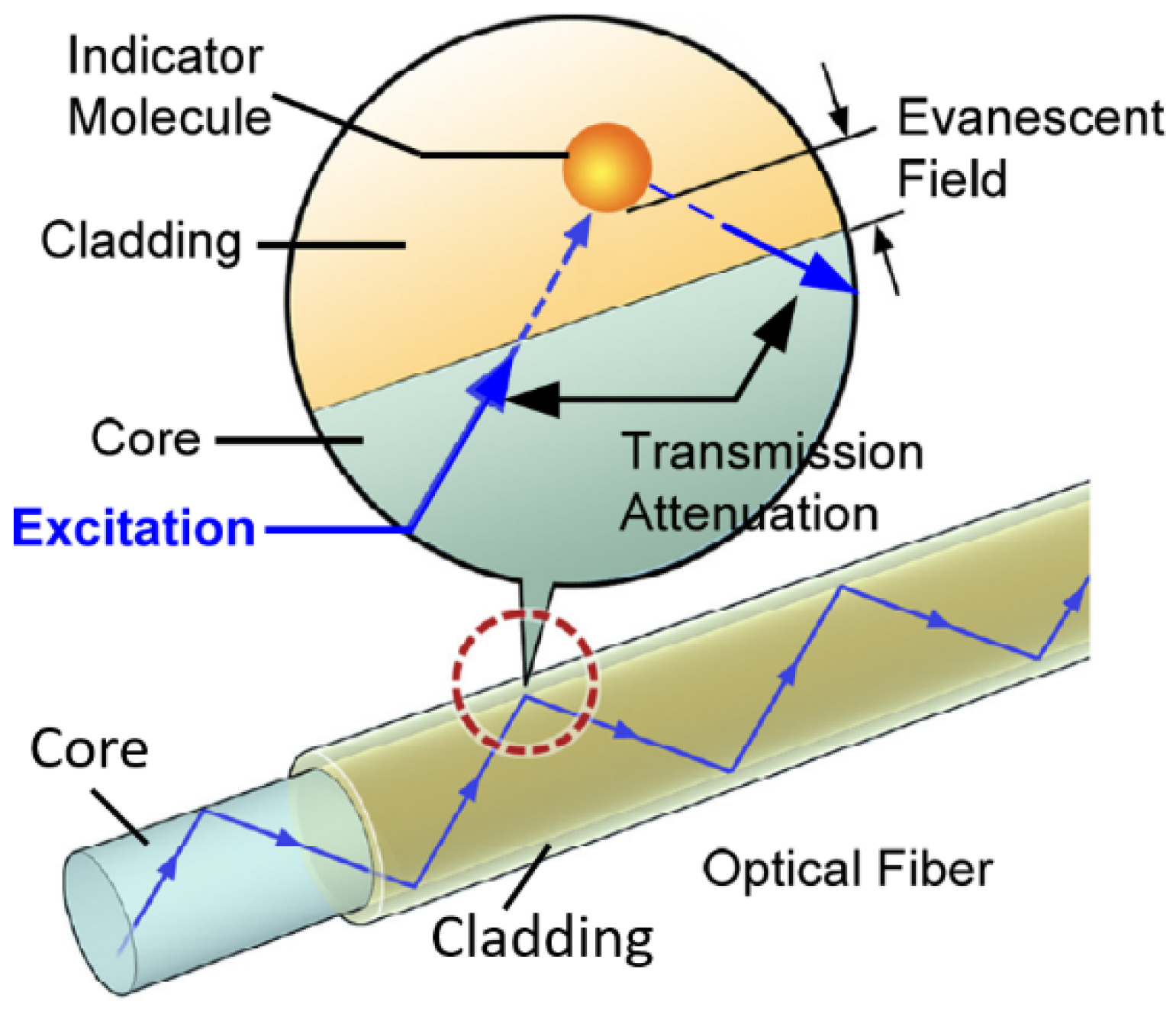

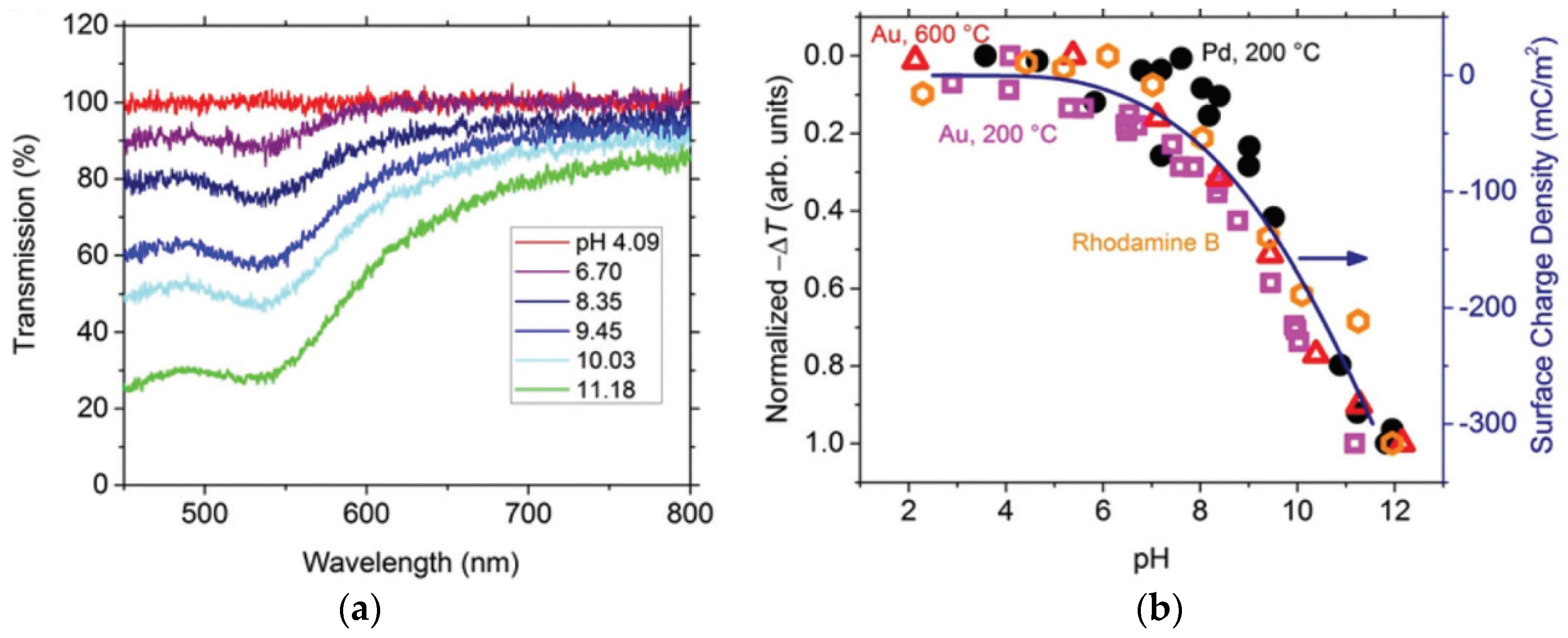

3.1.4. Distributed OFS for Chemical Sensing

3.1.5. Challenges of OFS Application in the O&G Industry

3.2. Passsive Wireless Sensors

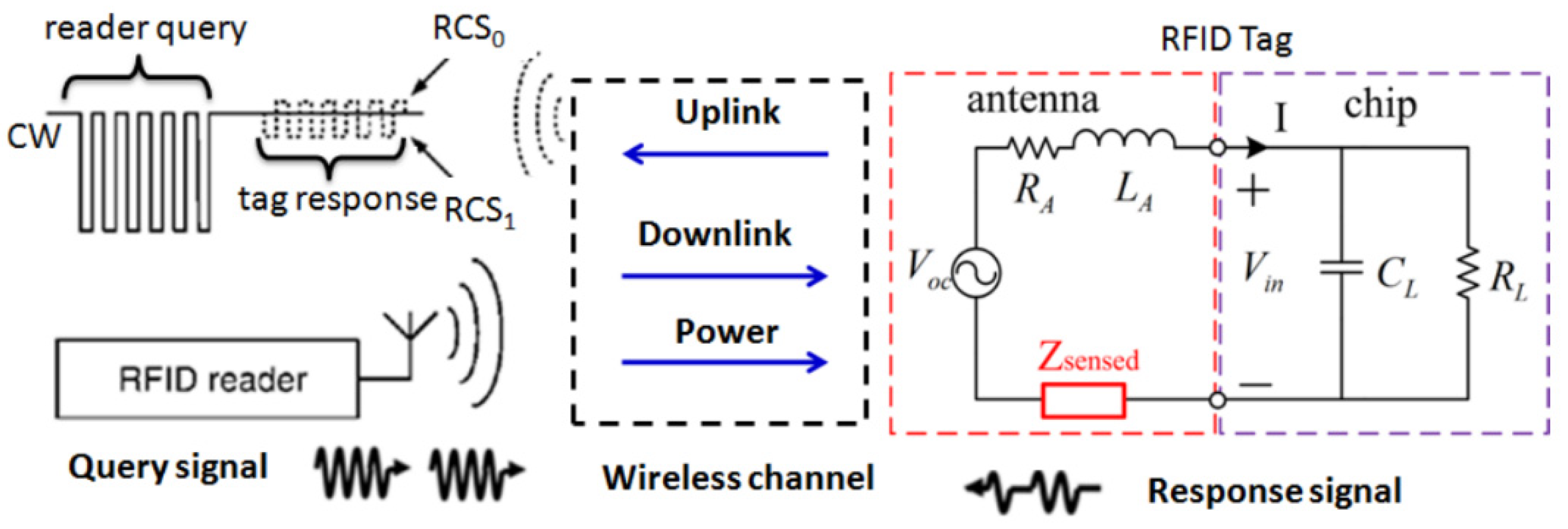

3.2.1. Passive Radio-Frequency Identification Sensors

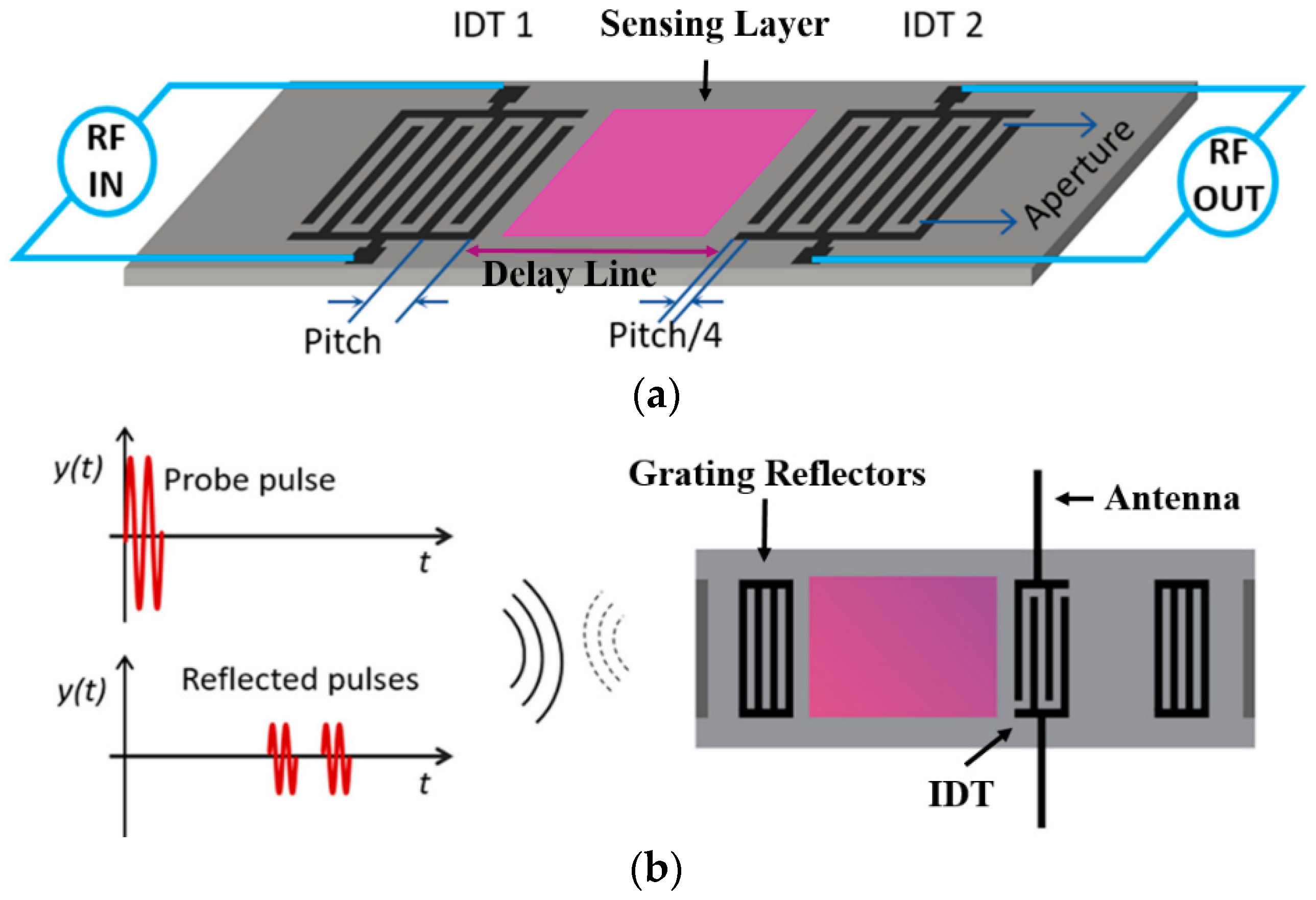

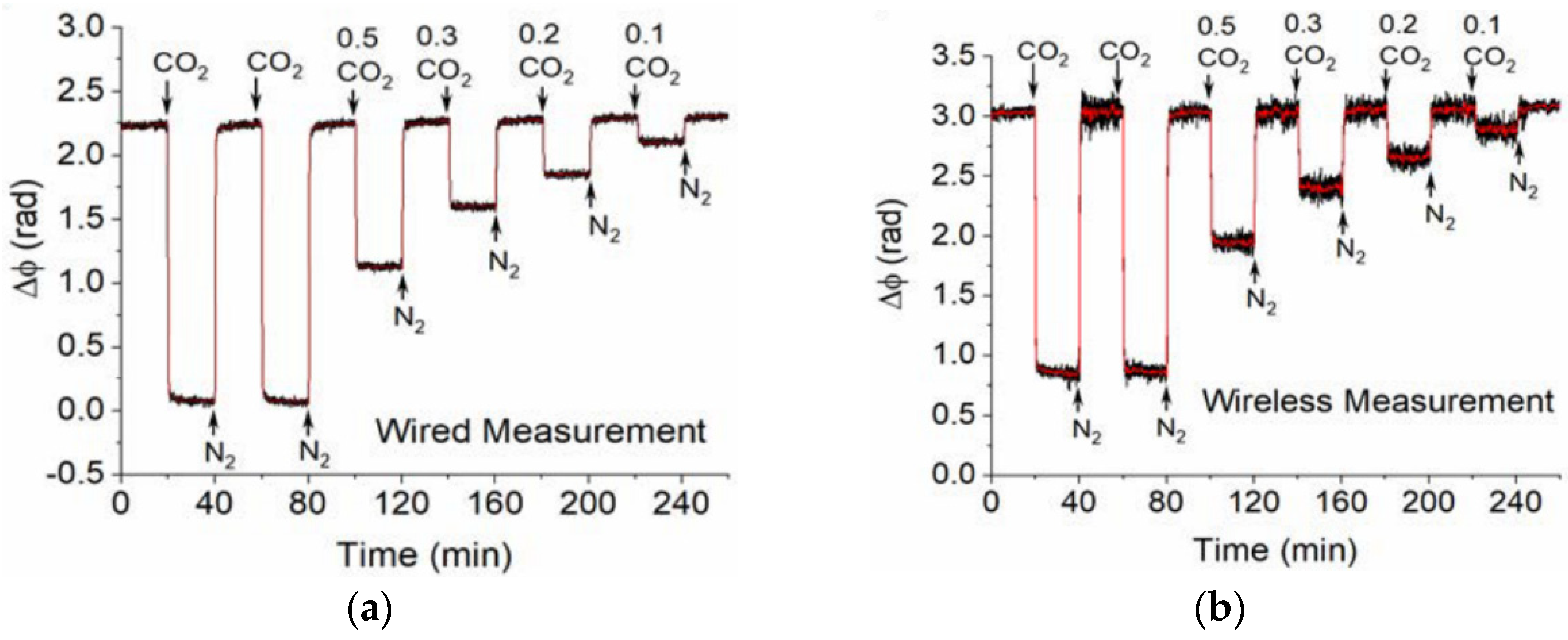

3.2.2. Surface Acoustic Wave Sensors

4. Summary and Outlook

Disclaimer

Author Contributions

Funding

Conflicts of Interest

References

- Beavers, J.A.; Thompson, N.G. External Corrosion of Oil and Natural Gas Pipelines. In ASM Handbook; ASM International: Materials Park, OH, USA, 2006; Volume 13C, pp. 1015–1026. [Google Scholar]

- Popoola, L.T.; Grema, A.S.; Latinwo, G.K.; Gutti, B.; Balogun, A.S. Corrosion problems during oil and gas production and its mitigation. Int. J. Ind. Chem. 2013, 4, 1–15. [Google Scholar] [CrossRef]

- Brondel, D.; Edwards, R.; Hayman, A.; Hill, D.; Semerad, T. Corrosion in the Oil Industry. Oilf. Rev. 1994, 4, 4–18. [Google Scholar]

- Koch, G.H.; Brongers, M.P.; Thompson, N.G.; Virmani, Y.P.; Payer, J.H. Corrosion Costs and Preventive Strategies in the United States; NACE International: Houston, TX, USA, 2002; No. FHWA-RD-01-156; pp. 1–12. [Google Scholar]

- Wright, R.F.; Brand, E.R.; Ziomek-Moroz, M.; Tylczak, J.H.; Ohodnicki, P.R. Effect of HCO3− on electrochemical kinetics of carbon steel corrosion in CO2-saturated brines. Electrochim. Acta 2018, 290, 626–638. [Google Scholar] [CrossRef]

- Wright, R.F.; Ziomek-moroz, M.; Ohodnicki, P.R. Fe Thin Film Coated Optics for Monitoring Internal Corrosion in Natural Gas Pipelines. In Proceedings of the NACE CORROSION, Phoenix, AZ, USA, 15–19 April 2018. No. 10893. [Google Scholar]

- Nesic, S.; Postlethwaite, J.; Olsen, S. An Electrochemical Model for Prediction of Corrosion of Mild Steel in Aqueous Carbon Dioxide Solutions. Corrosion 1996, 52, 280–294. [Google Scholar] [CrossRef]

- Sun, W.; Nešić, S. A Mechanistic Model of H2S Corrosion of Mild Steel. In Proceedings of the NACE CORROSION, Nashville, TN, USA, 11–15 March 2007. No. 07655. [Google Scholar]

- Zheng, Y.; Ning, J.; Brown, B.; Nesic, S. Electrochemical Model of Mild Steel Corrosion in a Mixed H2S/CO2 Aqueous Environment in the Absence of Protective Corrosion Product Layers. Corrosion 2015, 71, 316–325. [Google Scholar] [CrossRef]

- Feng, R.; Beck, J.R.; Hall, D.M.; Buyuksagis, A.; Ziomek-Moroz, M.; Lvov, S.N. Effects of CO2 and H2S on Corrosion of Martensitic Steels in NaCl at Low Temperature. Corrosion 2018, 74, 276–287. [Google Scholar] [CrossRef]

- Feng, R.; Beck, J.; Ziomek-Moroz, M.; Lvov, S.N. Electrochemical Corrosion of Ultra-high Strength Carbon Steel in Alkaline Brines Containing Hydrogen Sulfide. Electrochim. Acta 2016, 212, 998–1009. [Google Scholar] [CrossRef]

- Feng, R.; Beck, J.; Ziomek-Moroz, M.; Lvov, S.N. High-Temperature Electrochemical Corrosion of Ultra-High Strength Carbon Steel in H2S-Containing Alkaline Brines. Electrochim. Acta 2017, 241, 341–352. [Google Scholar] [CrossRef]

- Durr, C.L.; Beavers, J.A. Effect of Oxygen on the Internal Corrosion of Natural Gas Pipelines. In Proceedings of the NACE CORROSION, Denver, CO, USA, 24–29 March 1996. No. 612. [Google Scholar]

- Eyu, G.D.; Will, G.; Dekkers, W.; MacLeod, J. Effect of dissolved oxygen and immersion time on the corrosion behaviour of mild steel in bicarbonate/chloride solution. Materials 2016, 9, 748. [Google Scholar] [CrossRef]

- Heidersbach, R. Corrosive environments. In Metallurgy and Corrosion Control in Oil and Gas Production; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; pp. 15–45. [Google Scholar]

- Ziomek-Moroz, M. Environmentally Assisted Cracking of Drill Pipes in Deep Drilling Oil and Natural Gas Wells. J. Mater. Eng. Perform. 2011, 21, 1061–1069. [Google Scholar] [CrossRef]

- Iverson, W.P. Microbial Corrosion of Metals. Adv. Appl. Microbiol. 1987, 32, 1–36. [Google Scholar]

- Craig, B. Materials for Deep Oil and Gas Well Construction. Adv. Mater. Process. 2008, 166, 33–35. [Google Scholar]

- Perkins, A. Technique for Monitoring Corrosion and Related Parameters in Field Applications; NACE International: Houston, TX, USA, 2012; No. 24203, Publ. 3T199. [Google Scholar]

- Agarwala, V.S.; Ahmad, S. Corrosion Detection and Monitoring—A Review. In Proceedings of the NACE CORROSION, Orlando, FL, USA, 26–31 March 2000. No. 00271. [Google Scholar]

- Tullmin, M.A.A.; Roberge, P.R.; Little, M.A. Sensors For Aircraft Corrosion-Review and Future Developments. In Proceedings of the NACE CORROSION, New Orleans, LA, USA, 9–14 March 1997. No. 301. [Google Scholar]

- Qi, X.; Gelling, V.J. A Review of Different Sensors Applied to Corrosion Detection and Monitoring. Recent Patents Corros. Sci. 2011, 1, 1–7. [Google Scholar] [CrossRef]

- ASTM G4-01. Standard Guide for Conducting Corrosion Tests in Field Applications; ASTM International: West Conshohocken, PA, USA, 2008; pp. 1–9. [Google Scholar]

- Corrosion Coupons. Available online: https://www.cosasco.com/ci-corrosion-coupons-corrosion-monitoring.html (accessed on 19 August 2019).

- Electrical Resistance (ER) Monitoring. Available online: http://www.alspi.com/erintro.htm (accessed on 19 August 2019).

- Li, S.; Kim, Y.-G.; Jung, S.; Song, H.-S.; Lee, S.-M. Application of steel thin film electrical resistance sensor for in situ corrosion monitoring. Sens. Actuators B Chem. 2007, 120, 368–377. [Google Scholar] [CrossRef]

- Kuang, F.; Zhang, J.; Zou, C.; Shi, T.; Wang, Y.; Zhang, S.; Xu, H. Electrochemical Methods for Corrosion Monitoring: A Survey of Recent Patents. Recent Patents Corros. Sci. 2010, 2, 34–39. [Google Scholar] [CrossRef]

- Rinaldi, G. A Literature Review of Corrosion Sensing Methods; Defence R&D Canada – Atlantic: Dartmouth, NS, Canada, 2009. [Google Scholar]

- Papavinasam, S.; Doiron, A.; Attard, M.; Demoz, A.; Rahimi, P. Non-Intrusive Techniques to Monitor Internal Corrosion of Oil and Gas Pipelines. In Proceedings of the NACE CORROSION, Salt Lake, UT, USA, 11–15 March 2012. No. 0001261. [Google Scholar]

- LPR Corrosion Monitoring Probes. Available online: https://www.cosasco.com/lpr-corrosion-monitoring-probe-7012-7022.html (accessed on 19 August 2019).

- Yang, L.; Sridhar, N. Coupled multielectrode array systems and sensors for real-time corrosion monitoring- A review. In Proceedings of the NACE CORROSION, San Diego, CA, USA, 12–16 March 2006. No. 06681. [Google Scholar]

- Chiang, K.T.; Yang, L. High-temperature electrochemical sensor for online corrosion monitoring. Corrosion 2010, 66, 095002. [Google Scholar] [CrossRef]

- Coupled Multielectrode Array Sensor (CMAS) Probes for Localized Corrosion Monitoring and Electrochemical Studies. Available online: http://www.corrinstruments.com/ins/corprobes.html (accessed on 19 August 2019).

- Beck, J.; Hall, D.M.; Ziomek-Moroz, M.; Lvov, S.N. Membrane-Coated Electrochemical Sensor for Corrosion Monitoring in Natural Gas Pipelines. Sens. Transducers 2017, 214, 28–33. [Google Scholar]

- Hall, D.M.; Duffy, T.; Ziomek-Moroz, M.; Lvov, S.N. Electrochemical impedance spectroscopy and finite element analysis modeling of a 4-electrode humidity sensor for natural gas transportation pipelines. Rev. Sci. Instrum. 2019, 90, 015005. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Olivares, N.A.; Cruz-Cruz, J.V.; Gómez-Hernández, A.; Hernández-Alvarado, R.; Nava-Balanzar, L.; Salgado-Jiménez, T.; Soto-Cajiga, J.A. Improvement of ultrasonic pulse generator for automatic pipeline inspection. Sensors 2018, 18, 2950. [Google Scholar] [CrossRef]

- Cegla, F. Ultrasonic Monitoring of Corrosion with Permanently Installed Sensors (PIMS). In Sensors, Algorithms and Applications for Structural Health Monitoring; Chapuis, B., Sjerve, E., Eds.; Springer: Cham, Switzerland, 2018; pp. 13–20. ISBN 9783319692333. [Google Scholar]

- Lakestani, F.; Coste, J.-F.; Denis, R. Application of ultrasonic Rayleigh waves to thickness measurement of metallic coatings. NDT E Int. 1995, 28, 171–178. [Google Scholar] [CrossRef]

- Ultrasonic Corrosion Inspection. Available online: https://www.ndt-global.com/about/our-technology/ut-corrosion-inspection-technology (accessed on 19 August 2019).

- Rao, B.P.C. Magnetic Flux Leakage Technique: Basics. J. Non Destr. Test. Eval. 2012, 11, 7–17. [Google Scholar]

- Shi, Y.; Zhang, C.; Li, R.; Cai, M.; Jia, G. Theory and application of magnetic flux leakage pipeline detection. Sensors 2015, 15, 31036–31055. [Google Scholar] [CrossRef] [PubMed]

- Brill, T.M.; Le Calvez, J.L.; Demichel, C.; Nichols, E.; Bermudez, F.Z. Electromagnetic Casing Inspection Tool for Corrosion Evaluation. In Proceedings of the International Petroleum Technology Conferece, Bangkok, Thailand, 15–17 November 2011. No. IPTC 14865. [Google Scholar]

- Wilt, M.; Alumbaugh, D. Electromagnetic methods for development and production: State of the art. Lead. Edge 1998, 4, 487–490. [Google Scholar] [CrossRef]

- Kirkwood, M. Why Pig a Pipeline? Available online: http://blog.tdwilliamson.com/why-pig-a-pipeline (accessed on 19 August 2019).

- Dahl, J. Optimising of Pipeline Maintenance Using Deposit Profile Technology; University of Stavanger: Stavanger, Norway, 2014. [Google Scholar]

- Ye, X.W.; Su, Y.H.; Han, J.P. Structural Health Monitoring of Civil Infrastructure Using Optical Fiber Sensing Technology: A Comprehensive Review. Sci. World J. 2014, 652329, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Joe, H.-E.; Yun, H.; Jo, S.-H.; Jun, M.B.G.; Min, B.-K. A review on optical fiber sensors for environmental monitoring. Int. J. Precis. Eng. Manuf. Technol. 2018, 5, 173–191. [Google Scholar] [CrossRef]

- Lopez-Higuera, J.M.; Rodriguez Cobo, L.; Quintela Incera, A.; Cobo, A. Fiber Optic Sensors in Structural Health Monitoring. J. Light. Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- Yin, M.-J.; Gu, B.; An, Q.-F.; Yang, C.; Guan, Y.L.; Yong, K.-T. Recent development of fiber-optic chemical sensors and biosensors: Mechanisms, materials, micro/nano-fabrications and applications. Coord. Chem. Rev. 2018, 376, 348–392. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, H.; Qian, X.; Zhang, Y.; An, G.; Zhao, Y. Recent advancements in optical fiber hydrogen sensors. Sens. Actuators B Chem. 2017, 244, 393–416. [Google Scholar] [CrossRef]

- Qiao, G.; Zhou, Z.; Ou, J. Thin Fe-C alloy solid film based fiber optic corrosion sensor. In Proceedings of the Proceedings of 1st IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Zhuhai, China, 18–21 January 2006; pp. 541–544. [Google Scholar]

- Leung, C.K.Y.; Wan, K.T.; Chen, L. A Novel Optical Fiber Sensor for Steel Corrosion in Concrete Structures. Sensors 2008, 8, 1960–1976. [Google Scholar] [CrossRef]

- Dong, S.; Liao, Y.; Tian, Q.; Luo, Y.; Qiu, Z.; Song, S. Optical and electrochemical measurements for optical fibre corrosion sensing techniques. Corros. Sci. 2006, 48, 1746–1756. [Google Scholar] [CrossRef]

- Bhatia, V.; D’Alberto, T.; Murphy, K.A.; Claus, R.O.; Nemarich, C.P. Comparison of optical fiber long- period and Bragg grating sensors. In Proceedings of the Proc. SPIE 2718, Smart Structures and Materials 1996: Smart Sensing, Processing, and Instrumentation, San Diego, CA, USA, 30 May 1996; pp. 110–121. [Google Scholar]

- Bhatia, V.; Vengsarkar, A.M. Optical fiber long-period grating sensors. Opt. Lett. 1996, 21, 692–694. [Google Scholar] [CrossRef] [PubMed]

- James, S.W.; Tatam, R.P. Optical fibre long-period grating sensors: characteristics and application. Meas. Sci. Technol. 2003, 14, R49–R61. [Google Scholar] [CrossRef]

- Huang, Y.; Gao, Z.; Chen, G.; Xiao, H. Long period fiber grating sensors coated with nano iron/silica particles for corrosion monitoring. Smart Mater. Struct. 2013, 22, 75018. [Google Scholar] [CrossRef]

- Huang, Y.; Tang, F.; Liang, X.; Chen, G.; Xiao, H.; Azarmi, F. Steel bar corrosion monitoring with long-period fiber grating sensors coated with nano iron/silica particles and polyurethane. Struct. Heal. Monit. 2015, 14, 178–189. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, F.; Bao, Y.; Tang, Y.; Chen, G. A Fe-C coated long-period fiber grating sensor for corrosion-induced mass loss measurement. Opt. Lett. 2016, 41, 2306–2309. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Fan, L.; Wu, C.; Chen, G.; Li, W. Ultrasensitive LPFG corrosion sensor with Fe-C coating electroplated on a Gr/AgNW film. Sens. Actuators B Chem. 2019, 283, 334–342. [Google Scholar] [CrossRef]

- Corres, J.M.; del Villar, I.; Matias, I.R.; Arregui, F.J. Fiber-optic pH-sensors in long-period fiber gratings using electrostatic self-assembly. Opt. Lett. 2007, 32, 29–31. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Klimov, D.; Zbigniew, K. Seawater pH sensor based on the long period grating in a single-mode–multimode–single-mode structure. Opt. Eng. 2009, 48, 034401. [Google Scholar] [CrossRef]

- Mau, J.-C.; Lin, G.-R.; Fu, M.-Y.; Liu, W.-F. A Fiber Optic Sensor Based on Ari-Gap Long Period Gratings for pH Sensing Application. Microw. Opt. Technol. Lett. 2013, 55, 855–857. [Google Scholar] [CrossRef]

- Mishra, S.K.; Zou, B.; Chiang, K.S. Wide-Range pH Sensor Based on a Smart-Hydrogel-Coated Long-Period Fiber Grating. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 5601405. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Zhang, M.; Tu, D.; Mao, X.; Liao, Y. A relative humidity sensor using a hydrogel-coated long period grating. Meas. Sci. Technol. 2007, 18, 3131–3134. [Google Scholar] [CrossRef]

- Venugopalan, T.; Sun, T.; Grattan, K.T.V. Long period grating-based humidity sensor for potential structural health monitoring. Sens. Actuators A Phys. 2008, 148, 57–62. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Zou, F.; Jiang, C.; Mou, C.; Wang, T. Humidity Sensor Based on a Long-Period Fiber Grating Coated with Polymer Composite Film. Sensors 2019, 19, 2263. [Google Scholar] [CrossRef] [PubMed]

- Alwis, L.; Sun, T.; Grattan, K.V. Analysis of polyimide-coated optical fiber long-period grating-based relative humidity sensor. IEEE Sens. J. 2013, 13, 767–771. [Google Scholar] [CrossRef]

- Hromadka, J.; Tokay, B.; Correia, R.; Morgan, S.P.; Korposh, S. Carbon dioxide measurements using long period grating optical fibre sensor coated with metal organic framework HKUST-1. Sens. Actuators B Chem. 2018, 255, 2483–2494. [Google Scholar] [CrossRef]

- Melo, L.; Burton, G.; Davies, B.; Risk, D.; Wild, P. Highly sensitive coated long period grating sensor for CO2 detection at atmospheric pressure. Sens. Actuators B Chem. 2014, 202, 294–300. [Google Scholar] [CrossRef]

- Bao, B.; Melo, L.; Davies, B.; Fadaei, H.; Sinton, D.; Wild, P. Detecting supercritical CO2 in brine at sequestration pressure with an optical fiber sensor. Environ. Sci. Technol. 2013, 47, 306–313. [Google Scholar] [CrossRef] [PubMed]

- Qin, X.; Feng, W.; Yang, X.; Wei, J.; Huang, G. Molybdenum sulfide/citric acid composite membrane-coated long period fiber grating sensor for measuring trace hydrogen sulfide gas. Sens. Actuators B Chem. 2018, 272, 60–68. [Google Scholar] [CrossRef]

- Chen, R.; Liu, W.; Huang, G.; Wang, D.; Qin, X.; Feng, W. Hydrogen sulfide sensor based on tapered fiber sandwiched between two molybdenum disulfide/citric acid composite membrane coated long-period fiber gratings. Appl. Opt. 2018, 57, 9755. [Google Scholar] [CrossRef]

- Chung, C.; Lam, C.; Mandamparambil, R.; Sun, T.; Grattan, K.T.V.; Nanukuttan, S.V.; Taylor, S.E.; Basheer, P.A.M. Optical Fiber Refractive Index Sensor for Chloride Ion Monitoring. IEEE Sens. J. 2009, 9, 525–532. [Google Scholar]

- Abi Kaed Bey, S.K.; Lam, C.C.C.; Sun, T.; Grattan, K.T.V. Chloride ion optical sensing using a long period grating pair. Sens. Actuators A Phys. 2008, 141, 390–395. [Google Scholar] [CrossRef]

- Yang, F.; Hlushko, R.; Wu, D.; Sukhishvili, S.A.; Du, H.; Tian, F. Ocean Salinity Sensing Using Long-Period Fiber Gratings Functionalized with Layer-by-Layer Hydrogels. ACS Omega 2019, 4, 2134–2141. [Google Scholar] [CrossRef] [PubMed]

- Tsuda, H.; Urabe, K. Characterization of long-period grating refractive index sensors and their applications. Sensors 2009, 9, 4559–4571. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.-W.; Wang, Q. Mini review: Recent advances in long period fiber grating biological and chemical sensors. Instrum. Sci. Technol. 2019, 47, 140–169. [Google Scholar] [CrossRef]

- Silva, C.; Coelho, J.M.P.; Caldas, P.; Jorge, P. Fibre Sensing System Based on Long-Period Gratings for Monitoring Aqueous Environments. In Fiber Optic Sensors; Yasin, M., Ed.; InTech: Rijeka, Croatia, 2012; pp. 317–342. ISBN 978-953-307-922-6. [Google Scholar]

- Urrutia, A.; Goicoechea, J.; Ricchiuti, A.L.; Barrera, D.; Sales, S.; Arregui, F.J. Simultaneous measurement of humidity and temperature based on a partially coated optical fiber long period grating. Sens. Actuators B Chem. 2016, 227, 135–141. [Google Scholar] [CrossRef]

- Moon, H.M.; Kwak, S.C.; Im, K.; Kim, J.B.; Kim, S. Wavelength Interrogation System for Quasi-Distributed Fiber Bragg Grating Temperature Sensors Based on a 50-GHz Array Waveguide Grating. IEEE Sens. J. 2019, 19, 2598–2604. [Google Scholar] [CrossRef]

- Hou, Q.; Ren, L.; Jiao, W.; Zou, P.; Song, G. An Improved Negative Pressure Wave Method for Natural Gas Pipeline Leak Location Using FBG Based Strain Sensor and Wavelet Transform. Math. Probl. Eng. 2013, 278794, 1–8. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, L.; Liu, T.; Li, Z.; Sun, T.; Grattan, K.T.V. Novel Negative Pressure Wave-Based Pipeline Leak Detection System Using Fiber Bragg Grating-Based Pressure Sensors. J. Light. Technol. 2017, 35, 3366–3373. [Google Scholar] [CrossRef]

- Ren, L.; Jia, Z.G.; Li, H.N.; Song, G. Design and experimental study on FBG hoop-strain sensor in pipeline monitoring. Opt. Fiber Technol. 2014, 20, 15–23. [Google Scholar] [CrossRef]

- Jiang, T.; Li, D.; Ren, L.; Jia, Z.; Li, H. Application of FBG Based Sensor in Pipeline Safety Monitoring. Appl. Sci. 2017, 7, 540. [Google Scholar] [CrossRef]

- Li, H.; Li, D.; Ren, L.; Jiang, T.; Jia, Z. Pipeline internal corrosion monitoring based on distributed strain measurement technique. Struct. Control Heal. Monit. 2017, 24, e2016. [Google Scholar]

- Freire, J.L.F.; Perrut, V.A.; Braga, A.M.B.; Vieira, R.D.; Ribeiro, A.S.; Rosas, M.A.P. Use of FBG Strain Gages on a Pipeline Specimen Repaired With a CFRE Composite. Exp. Tech. 2012, 39, 70–79. [Google Scholar] [CrossRef]

- Xu, J.; Yang, D.; Qin, C.; Jiang, Y.; Sheng, L.; Jia, X.; Bai, Y.; Shen, X.; Wang, H.; Deng, X.; et al. Study and test of a new bundle-structure riser stress monitoring sensor based on FBG. Sensors 2015, 15, 29648–29660. [Google Scholar] [CrossRef] [PubMed]

- Morrison, D.G.; Dean, J.R. Apparatuses and Methods for Monitoring Stress in Steel Catenary Risers. U.S. Patent US007194913B2, 27 March 2007. [Google Scholar]

- Brower, D.V.; Prescott, N. Real Time Subsea Monitoring and Control Smart Field Solutions. In Proceedings of the Subsea Rio 2004 Conference, Rio de Janeiro, Brazil, 3 June 2004; pp. 1–13. [Google Scholar]

- Yulianti, I.; Supa’at, A.S.M.; Idrus, S.M.; Kurdi, O.; Anwar, M.R.S. Sensitivity improvement of a fibre Bragg grating pH sensor with elastomeric coating. Meas. Sci. Technol. 2012, 23, 015104. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, S.; Wang, M.; Liu, W. Fiber-optic fast response pH sensor in fiber Bragg gating using intelligent hydrogel coatings. Opt. Eng. 2015, 54, 057107. [Google Scholar] [CrossRef]

- Yeo, T.L.; Sun, T.; Grattan, K.T.V.; Parry, D.; Lade, R.; Powell, B.D. Characterisation of a polymer-coated fibre Bragg grating sensor for relative humidity sensing. Sens. Actuators B Chem. 2005, 110, 148–155. [Google Scholar] [CrossRef]

- Yamate, T.; Fujisawa, G.; Ikegami, T. Optical Sensors for the Exploration of Oil and Gas. J. Light. Technol. 2017, 35, 3538–3545. [Google Scholar] [CrossRef]

- Bao, X.; Chen, L. Recent Progress in Distributed Fiber Optic Sensors. Sensors 2012, 12, 8601–8639. [Google Scholar] [CrossRef]

- Ukil, A.; Braendle, H.; Krippner, P. Distributed temperature sensing: Review of technology and applications. IEEE Sens. J. 2012, 12, 885–892. [Google Scholar] [CrossRef]

- Mirzaei, A.; Bahrampour, A.R.; Taraz, M.; Bahrampour, A.; Bahrampour, M.J.; Ahmadi Foroushani, S.M. Transient response of buried oil pipelines fiber optic leak detector based on the distributed temperature measurement. Int. J. Heat Mass Transf. 2013, 65, 110–122. [Google Scholar] [CrossRef]

- Wong, L.; Rathnayaka, S.; Chiu, W.K.; Kodikara, J. Fatigue Damage Monitoring of a Cast Iron Pipeline Using Distributed Optical Fibre Sensors. Procedia Eng. 2017, 188, 293–300. [Google Scholar] [CrossRef]

- Stajanca, P.; Chruscicki, S.; Homann, T.; Seifert, S.; Schmidt, D.; Habib, A. Detection of Leak-Induced Pipeline Vibrations Using Fiber—Optic Distributed Acoustic Sensing. Sensors 2018, 18, 2841. [Google Scholar] [CrossRef] [PubMed]

- Muanenda, Y. Recent Advances in Distributed Acoustic Sensing Based on Phase-Sensitive Optical Time Domain Reflectometry. J. Sens. 2018, 3897873, 1–16. [Google Scholar] [CrossRef]

- Peng, F.; Wu, H.; Jia, X.-H.; Rao, Y.-J.; Wang, Z.-N.; Peng, Z.-P. Ultra-long high-sensitivity Φ-OTDR for high spatial resolution intrusion detection of pipelines. Opt. Express 2014, 22, 13804–13810. [Google Scholar] [CrossRef] [PubMed]

- Wright, R.F.; Egbu, J.; Lu, P.; Buric, M.P.; Ziomek-Moroz, M.; Ohodnicki, P.R.J. Electrolessly Coated Optical Fibers for Distributed Corrosion Monitoring. In Proceedings of the NACE CORROSION, Nashville, TN, USA, 24–28 March 2019. No. 13499. [Google Scholar]

- Jee, Y.; Yu, Y.; Abernathy, H.W.; Lee, S.; Kalapos, T.L.; Hackett, G.A.; Ohodnicki, P.R. Plasmonic Conducting Metal Oxide-Based Optical Fiber Sensors for Chemical and Intermediate Temperature-Sensing Applications. ACS Appl. Mater. Interfaces 2018, 10, 42552–42563. [Google Scholar] [CrossRef] [PubMed]

- Ohodnicki, P.R.; Brown, T.D.; Holcomb, G.R.; Tylczak, J.; Schultz, A.M.; Baltrus, J.P. High temperature optical sensing of gas and temperature using Au-nanoparticle incorporated oxides. Sens. Actuators B Chem. 2014, 202, 489–499. [Google Scholar] [CrossRef]

- Yan, M.; Tylczak, J.; Yu, Y.; Panagakos, G.; Ohodnicki, P. Multi-component optical sensing of high temperature gas streams using functional oxide integrated silica based optical fiber sensors. Sens. Actuators B Chem. 2018, 255, 357–365. [Google Scholar] [CrossRef]

- Sun, C.; Lu, P.; Wright, R.; Ohodnicki, P.R. Low-cost fiber optic sensor array for simultaneous detection of hydrogen and temperature. In Proceedings of the Proc. SPIE 10654, Fiber Optic Sensors and Applications XV, Orlando, FL, USA, 14 May 2018. No. 1065405. [Google Scholar]

- Wang, C.; Ohodnicki, P.R.; Su, X.; Keller, M.; Brown, T.D.; Baltrus, J.P. Novel silica surface charge density mediated control of the optical properties of embedded optically active materials and its application for fiber optic pH sensing at elevated temperatures. Nanoscale 2015, 7, 2527–2535. [Google Scholar] [CrossRef]

- Ohodnicki, P.R.; Buric, M.P.; Brown, T.D.; Matranga, C.; Wang, C.; Baltrus, J.; Andio, M. Plasmonic nanocomposite thin film enabled fiber optic sensors for simultaneous gas and temperature sensing at extreme temperatures. Nanoscale 2013, 5, 9030–9039. [Google Scholar] [CrossRef]

- Babeva, T.; Andreev, A.; Grand, J.; Vasileva, M.; Karakoleva, E.; Zafirova, B.S.; Georgieva, B.; Koprinarova, J.; Mintova, S. Optical fiber–Ta2O5 waveguide coupler covered with hydrophobic zeolite film for vapor sensing. Sens. Actuators B Chem. 2017, 248, 359–366. [Google Scholar] [CrossRef]

- Zhao, Q.; Yin, M.; Zhang, A.P.; Prescher, S.; Antonietti, M.; Yuan, J. Hierarchically structured nanoporous poly(ionic liquid) membranes: Facile preparation and application in fiber-optic pH sensing. J. Am. Chem. Soc. 2013, 135, 5549–5552. [Google Scholar] [CrossRef] [PubMed]

- Walsh, J.E.; MacCraith, B.D.; Meaney, M.; Vos, J.G.; Regan, F.; Lancia, A.; Artjushenko, S. Sensing of chlorinated hydrocarbons and pesticides in water using polymer coated mid-infrared optical fibres. Analyst 1996, 121, 789–792. [Google Scholar] [CrossRef]

- Scorsone, E.; Christie, S.; Persaud, K.C.; Kvasnik, F. Evanescent sensing of alkaline and acidic vapours using a plastic clad silica fibre doped with poly(o-methoxyaniline). Sens. Actuators B Chem. 2004, 97, 174–181. [Google Scholar] [CrossRef]

- Renganathan, B.; Sastikumar, D.; Raj, S.G.; Ganesan, A.R. Fiber optic gas sensors with vanadium oxide and tungsten oxide nanoparticle coated claddings. Opt. Commun. 2014, 315, 74–78. [Google Scholar] [CrossRef]

- Ou, J.Z.; Yaacob, M.H.; Campbell, J.L.; Breedon, M.; Kalantar-Zadeh, K.; Wlodarski, W. H2 sensing performance of optical fiber coated with nano-platelet WO3 film. Sens. Actuators B Chem. 2012, 166–167, 1–6. [Google Scholar] [CrossRef]

- Mohammed, H.A.; Rahman, N.A.; Ahmad, M.Z.; Abu Bakar, M.H.; Anas, S.B.A.; Mahdi, M.A.; Yaacob, M.H. Sensing Performance of Modified Single Mode Optical Fiber Coated with Nanomaterials-Based Ammonia Sensors Operated in the C-Band. IEEE Access 2019, 7, 5467–5476. [Google Scholar] [CrossRef]

- Devkota, J.; Kim, K.J.; Ohodnicki, P.R.; Culp, J.T.; Greve, D.W.; Lekse, J.W. Zeolitic imidazolate framework-coated acoustic sensors for room temperature detection of carbon dioxide and methane. Nanoscale 2018, 10, 8075–8087. [Google Scholar] [CrossRef]

- Chong, X.; Kim, K.J.; Li, E.; Zhang, Y.; Ohodnicki, P.R.; Chang, C.H.; Wang, A.X. Near-infrared absorption gas sensing with metal-organic framework on optical fibers. Sens. Actuators B Chem. 2016, 232, 43–51. [Google Scholar] [CrossRef]

- Hingerl, F.F.; Marpu, S.; Guzman, N.; Benson, S.M.; Delgado-Alonso, J. Development and testing of a new fiber optic system for monitoring CO2 solubility in aqueous high-pressure geological systems. Energy Procedia 2014, 63, 4134–4144, Under a Creative Commons License. Available online: https://creativecommons.org/licenses/by-nc-nd/4.0/ (accessed on 19 August 2019). [CrossRef]

- Lu, P.; Wright, R.F.; Ziomek-Moroz, M.; Buric, M.P.; Zandhuis, P.; Ohodnicki, P.R. A Multifunctional Fiber Optic Sensor for Internal Corrosion Monitoring in Natural Gas Transmission Pipelines. In Proceedings of the NACE CORROSION, Phoenix, AZ, USA, 15–19 April 2018. No. 11429. [Google Scholar]

- Knight, J.C.; Broeng, J.; Birks, T.A.; Russell, P.S.J. Photonic Band Gap Guidance in Optical Fibers. Science 1998, 282, 1476–1479. [Google Scholar] [CrossRef]

- Monro, T.M.; Belardi, W.; Furusawa, K.; Baggett, J.C.; Broderick, N.G.R.; Richardson, D.J. Sensing with microstructured optical fibres. Meas. Sci. Technol. 2001, 12, 854–858. [Google Scholar] [CrossRef]

- Pinto, A.M.R.; Lopez-Amo, M. Photonic Crystal Fibers for Sensing Applications. J. Sens. 2012, 598178, 1–21. [Google Scholar] [CrossRef]

- Knight, J.C.; Birks, T.A.; Russell, P.S.J.; Atkin, D.M. All-silica single-mode optical fiber with photonic crystal cladding. Opt. Lett. 1996, 21, 1547–1549. [Google Scholar] [CrossRef] [PubMed]

- Kornaszewski, Ł.; Gayraud, N.; Stone, J.M.; Macpherson, W.N.; George, A.K.; Knight, J.C.; Hand, D.P.; Reid, D.T. Mid-infrared methane detection in a photonic bandgap fiber using a broadband optical parametric oscillator. Opt. Express 2007, 15, 11219–11224. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, J.P.; Lehmann, H.; Bartelt, H.; Magalhaes, F.; Amezcua-Correa, R.; Santos, J.L.; Van Roosbroeck, J.; Araujo, F.M.; Ferreira, L.A.; Knight, J.C. Remote System for Detection of Low-Levels of Methane Based on Photonic Crystal Fibres and Wavelength Modulation Spectroscopy. J. Sens. 2009, 398403, 1–10. [Google Scholar] [CrossRef]

- Tang, D.L.; He, S.; Dai, B.; Tang, X.H. Detection H2S mixed with natural gas using hollow-core photonic bandgap fiber. Optik 2014, 125, 2547–2549. [Google Scholar] [CrossRef]

- Hoo, Y.L.; Jin, W.; Shi, C.; Ho, H.L.; Wang, D.N.; Ruan, S.C. Design and modeling of a photonic crystal fiber gas sensor. Appl. Opt. 2003, 42, 3509–3515. [Google Scholar] [CrossRef] [PubMed]

- Quintero, S.M.M.; Valente, L.C.G.; de Paula Gomes, M.S.; da Silva, H.G.; de Souza, B.C.; Morikawa, S.R.K. All-fiber CO2 sensor using hollow core PCF operating in the 2 µm region. Sensors 2018, 18, 4393. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Li, Z.; Ding, Q.; Shen, X.; Yuan, Y.; Huang, J. Microstructured optical fiber based chloride ion sensing method for concrete health monitoring. Sens. Actuators B Chem. 2018, 260, 763–769. [Google Scholar] [CrossRef]

- Wei, H.; Tao, C.; Krishnaswamy, S. Photonic crystal fiber based chloride chemical sensors for corrosion monitoring. In Proceedings of the Proc. SPIE 9805, Health Monitoring of Structural and Biological Systems, Las Vegas, NV, USA, 1 April 2016. No. 98052A. [Google Scholar]

- Zheng, S.; Zhu, Y.; Krishnaswamy, S. Fiber humidity sensors with high sensitivity and selectivity based on interior nanofilm-coated photonic crystal fiber long-period gratings. Sens. Actuators B Chem. 2013, 176, 264–274. [Google Scholar] [CrossRef]

- McCague, C.; Fabian, M.; Karimi, M.; Bravo, M.; Jaroszewicz, L.R.; Mergo, P.; Sun, T.; Grattan, K.T.V. Novel sensor design using photonic crystal fibres for monitoring the onset of corrosion in reinforced concrete structures. J. Light. Technol. 2014, 32, 891–896. [Google Scholar] [CrossRef]

- Frazão, O.; Santos, J.L.; Araújo, F.M.; Ferreira, L.A. Optical sensing with photonic crystal fibers. Laser Photonics Rev. 2008, 2, 449–459. [Google Scholar] [CrossRef]

- Calcerrada, M.; García-Ruiz, C.; González-Herráez, M. Chemical and biochemical sensing applications of microstructured optical fiber-based systems. Laser Photonics Rev. 2015, 9, 604–627. [Google Scholar] [CrossRef]

- Jin, W.; Ho, H.L.; Cao, Y.C.; Ju, J.; Qi, L.F. Gas detection with micro- and nano-engineered optical fibers. Opt. Fiber Technol. 2013, 19, 741–759. [Google Scholar] [CrossRef]

- Wright, R.F.; Lu, P.; Devkota, J.; Lu, F.; Ziomek-Moroz, M.; Ohodnicki, P.R. Review on corrosion sensors for structural health monitoring of oil and natural gas infrastructure. In Proceedings of the Proc. SPIE 10973, Smart Structures and NDE for Energy Systems and Industry 4.0, Denver, CO, USA, 18 March 2019. No. 109730N. [Google Scholar]

- Thomas, P.J.; Hellevang, J.O. A high response polyimide fiber optic sensor for distributed humidity measurements. Sens. Actuators B Chem. 2018, 270, 417–423. [Google Scholar] [CrossRef]

- Wright, R.F.; Badar, M.; Egbu, J.C.; Lu, P.; Buric, M.; Ohodnicki, P.R. Fully distributed optical fiber sensor for water and humidity monitoring. In Proceedings of the Proc. SPIE 11000, Fiber Optic Sensors and Applications XVI, Baltimore, MD, USA, 14 May 2019. No. 1100007. [Google Scholar]

- Lu, X.; Thomas, P.J.; Hellevang, J.O. A Review of Methods for Fibre-Optic Distributed Chemical Sensing. Sensors 2019, 19, 2876. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.K.; Gupta, B.D. Surface plasmon resonance based fiber optic pH sensor utilizing Ag/ITO/Al/hydrogel layers. Analyst 2013, 138, 2640–2646. [Google Scholar] [CrossRef]

- Rivero, P.J.; Goicoechea, J.; Hernaez, M.; Socorro, A.B.; Matias, I.R.; Arregui, F.J. Optical fiber resonance-based pH sensors using gold nanoparticles into polymeric layer-by-layer coatings. Microsyst. Technol. 2016, 22, 1821–1829. [Google Scholar] [CrossRef]

- Miled, O.B.; Grosso, D.; Sanchez, C.; Livage, J. An optical fibre pH sensor based on dye doped mesostructured silica. J. Phys. Chem. Solids 2004, 65, 1751–1755. [Google Scholar] [CrossRef]

- Gupta, B.D.; Sharma, S. A long-range fiber optic pH sensor prepared by dye doped sol-gel immobilization technique. Opt. Commun. 1998, 154, 282–284. [Google Scholar] [CrossRef]

- Beltrán-Pérez, G.; López-Huerta, F.; Muñoz-Aguirre, S.; Castillo-Mixcóatl, J.; Palomino-Merino, R.; Lozada-Morales, R.; Portillo-Moreno, O. Fabrication and characterization of an optical fiber pH sensor using sol-gel deposited TiO2 film doped with organic dyes. Sens. Actuators B Chem. 2006, 120, 74–78. [Google Scholar] [CrossRef]

- Schyrr, B.; Pasche, S.; Scolan, E.; Ischer, R.; Ferrario, D.; Porchet, J.A.; Voirin, G. Development of a polymer optical fiber pH sensor for on-body monitoring application. Sens. Actuators B Chem. 2014, 194, 238–248. [Google Scholar] [CrossRef]

- Gupta, B.D.; Sharma, D.K. Evanescent wave absorption based fiber optic pH sensor prepared by dye doped sol-gel immobilization technique. Opt. Commun. 1997, 140, 32–35. [Google Scholar] [CrossRef]

- Alvarado-Méndez, E.; Rojas-Laguna, R.; Andrade-Lucio, J.A.; Hernández-Cruz, D.; Lessard, R.A.; Aviña-Cervantes, J.G. Design and characterization of pH sensor based on sol-gel silica layer on plastic optical fiber. Sens. Actuators B Chem. 2005, 106, 518–522. [Google Scholar]

- Nguyen, T.H.; Venugopala, T.; Chen, S.; Sun, T.; Grattan, K.T.V.; Taylor, S.E.; Basheer, P.A.M.; Long, A.E. Fluorescence based fibre optic pH sensor for the pH 10-13 range suitable for corrosion monitoring in concrete structures. Sens. Actuators B Chem. 2014, 191, 498–507. [Google Scholar] [CrossRef]

- Ton, X.A.; Acha, V.; Bonomi, P.; Tse Sum Bui, B.; Haupt, K. A disposable evanescent wave fiber optic sensor coated with a molecularly imprinted polymer as a selective fluorescence probe. Biosens. Bioelectron. 2015, 64, 359–366. [Google Scholar] [CrossRef] [PubMed]

- Rosenberg, M.; Laursen, B.W.; Frankær, C.G.; Sørensen, T.J. A Fluorescence Intensity Ratiometric Fiber Optics–Based Chemical Sensor for Monitoring pH. Adv. Mater. Technol. 2018, 3, 1800205. [Google Scholar] [CrossRef]

- Wallace, P.A.; Campbell, M.; Yang, Y.; Holmes-Smith, A.S.; Uttamlal, M. A distributed optical fibre fluorosensor for pH measurement. J. Lumin. 1997, 72–74, 1017–1019. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Venugopalan, T.; Sun, T.; Grattan, K.T.V. Intrinsic Fiber Optic pH Sensor for Measurement of pH Values in the Range of 0.5-6. IEEE Sens. J. 2016, 16, 881–887. [Google Scholar] [CrossRef]

- Shao, L.-Y.; Yin, M.-J.; Tam, H.-Y.; Albert, J. Fiber optic pH sensor with self-assembled polymer multilayer nanocoatings. Sensors 2013, 13, 1425–1434. [Google Scholar] [CrossRef]

- Jin, Z.; Su, Y.; Duan, Y. An improved optical pH sensor based on polyaniline. Sens. Actuators B Chem. 2000, 71, 118–122. [Google Scholar] [CrossRef]

- Moutsiopoulou, A.; Andreopoulou, A.K.; Lainioti, G.; Bokias, G.; Voyiatzis, G.; Kallitsis, J.K. Quinoline-functionalized cross-linked poly(vinyl acetate) and poly(vinyl alcohol) nanoparticles as potential pH-responsive luminescent sensors. Sens. Actuators B Chem. 2015, 211, 235–244. [Google Scholar] [CrossRef]

- Rivero, P.J.; Goicoechea, J.; Arregui, F.J. Optical fiber sensors based on polymeric sensitive coatings. Polymers 2018, 10, 280. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Gupta, B.D. Fabrication and characterization of a highly sensitive surface plasmon resonance based fiber optic pH sensor utilizing high index layer and smart hydrogel. Sens. Actuators B Chem. 2012, 173, 268–273. [Google Scholar] [CrossRef]

- Pathak, A.K.; Singh, V.K. A wide range and highly sensitive optical fiber pH sensor using polyacrylamide hydrogel. Opt. Fiber Technol. 2017, 39, 43–48. [Google Scholar] [CrossRef]

- Zhao, Y.; Lei, M.; Liu, S.X.; Zhao, Q. Smart hydrogel-based optical fiber SPR sensor for pH measurements. Sens. Actuators B Chem. 2018, 261, 226–232. [Google Scholar] [CrossRef]

- Richter, A.; Paschew, G.; Klatt, S.; Lienig, J.; Arndt, K.F.; Adler, H.J.P. Review on hydrogel-based pH sensors and microsensors. Sensors 2008, 8, 561–581. [Google Scholar] [CrossRef]

- Ohodnicki, P.R.; Wang, C. Optical waveguide modeling of refractive index mediated pH responses in silica nanocomposite thin film based fiber optic sensors. J. Appl. Phys. 2016, 119, 064502. [Google Scholar] [CrossRef]

- Lin, J. Recent development and applications of optical and fiber-optic pH sensors. Trends Anal. Chem. 2000, 19, 541–552. [Google Scholar] [CrossRef]

- Kocak, G.; Tuncer, C.; Bütün, V. pH-Responsive polymers. Polym. Chem. 2017, 8, 144–176. [Google Scholar] [CrossRef]

- Thomas, P.J.; Hellevang, J.O. A fully distributed fibre optic sensor for relative humidity measurements. Sens. Actuators B. Chem. 2017, 247, 284–289. [Google Scholar] [CrossRef]

- Huang, Y.; Zhu, W.; Li, Z.; Chen, G.; Chen, L.; Zhou, J.; Lin, H.; Guan, J.; Fang, W.; Liu, X.; et al. High-performance fibre-optic humidity sensor based on a side-polished fibre wavelength selectively coupled with graphene oxide film. Sens. Actuators B Chem. 2018, 255, 57–69. [Google Scholar] [CrossRef]

- Chen, G.Y.; Wu, X.; Schartner, E.P.; Shahnia, S.; Hebert, N.B.; Yu, L.; Liu, X.; Shahraam, A.V.; Newson, T.P.; Ebendorff-Heidepriem, H.; et al. Short-Range Non-Bending Fully Distributed Water/Humidity Sensors. J. Light. Technol. 2019, 37, 2014–2022. [Google Scholar] [CrossRef]

- Qian, Y.; Zhao, Y.; Wu, Q.L.; Yang, Y. Review of salinity measurement technology based on optical fiber sensor. Sens. Actuators B Chem. 2018, 260, 86–105. [Google Scholar] [CrossRef]

- Rahman, H.A.; Harun, S.W.; Yasin, M.; Phang, S.W.; Damanhuri, S.S.A.; Arof, H.; Ahmad, H. Tapered multimode fiber sensor for salinity detection. Sens. Actuators A Phys. 2011, 171, 219–222. [Google Scholar] [CrossRef]

- Wang, J.; Chen, B. Experimental research of optical fiber sensor for salinity measurement. Sens. Actuators A Phys. 2012, 184, 53–56. [Google Scholar] [CrossRef]

- Kim, K.J.; Lu, P.; Culp, J.T.; Ohodnicki, P.R. Metal-Organic Framework Thin Film Coated Optical Fiber Sensors: A Novel Waveguide-Based Chemical Sensing Platform. ACS Sens. 2018, 3, 386–394. [Google Scholar] [CrossRef] [PubMed]

- Chong, X.; Kim, K.J.; Ohodnicki, P.R.; Li, E.; Chang, C.H.; Wang, A.X. Ultrashort Near-Infrared Fiber-Optic Sensors for Carbon Dioxide Detection. IEEE Sens. J. 2015, 15, 5327–5332. [Google Scholar] [CrossRef]

- Wysokiński, K.; Napierała, M.; Stańczyk, T.; Lipiński, S.; Nasiłowski, T. Study on the sensing coating of the optical fibre CO2 sensor. Sensors 2015, 15, 31888–31903. [Google Scholar] [CrossRef]

- Lu, Z.; Dai, M.; Xu, K.; Chen, J.; Liao, Y. A high precision, fast response, and low power consumption in situ optical fiber chemical pCO2 sensor. Talanta 2008, 76, 353–359. [Google Scholar] [CrossRef]

- Wolfbeis, O.S.; Kovacs, B.; Goswami, K.; Klainer, S.M. Fiber-optic fluorescence carbon dioxide sensor for environmental monitoring. Mikrochim. Acta 1998, 129, 181–188. [Google Scholar] [CrossRef]

- Chu, C.S.; Lo, Y.L.; Sung, T.W. Review on recent developments of fluorescent oxygen and carbon dioxide optical fiber sensors. Photonic Sensors 2011, 1, 234–250. [Google Scholar] [CrossRef]

- Chu, C.S.; Lo, Y.L. Highly sensitive and linear optical fiber carbon dioxide sensor based on sol-gel matrix doped with silica particles and HPTS. Sens. Actuators B Chem. 2009, 143, 205–210. [Google Scholar] [CrossRef]

- Chu, C.-S.; Hsieh, M.-W. Optical fiber carbon dioxide sensor based on colorimetric change of α-naphtholphthalein and CIS/ZnS quantum dots incorporated with a polymer matrix. Opt. Mater. Express 2019, 9, 2937–2945. [Google Scholar] [CrossRef]

- Neri, A.; Parvis, M.; Perrone, G.; Grassini, S.; Angelini, E.; Mombello, D. Low-cost Fiber Optic H2S Gas Sensor. In Proceedings of the IEEE Sensors 2008 Conference, Lecce, Italy, 26–29 October 2008; pp. 313–316. [Google Scholar]

- Zhou, H.; Wen, J.Q.; Zhang, X.Z.; Wang, W.; Feng, D.Q.; Wang, Q.; Jia, F. Study on fiber-optic hydrogen sulfide gas sensor. Phys. Procedia 2014, 56, 1102–1106. [Google Scholar] [CrossRef]

- Tabassum, R.; Mishra, S.K.; Gupta, B.D. Surface plasmon resonance-based fiber optic hydrogen sulphide gas sensor utilizing Cu-ZnO thin films. Phys. Chem. Chem. Phys. 2013, 15, 11868–11874. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Yang, X.; Feng, W. Hydrogen sulfide gas sensor based on copper/graphene oxide coated multi-node thin-core fiber interferometer. Appl. Opt. 2019, 58, 2152–2157. [Google Scholar] [CrossRef]

- Usha, S.P.; Mishra, S.K.; Gupta, B.D. Fiber optic hydrogen sulfide gas sensors utilizing ZnO thin film/ZnO nanoparticles: A comparison of surface plasmon resonance and lossy mode resonance. Sens. Actuators B Chem. 2015, 218, 196–204. [Google Scholar] [CrossRef]

- Kitture, R.; Pawar, D.; Rao, C.N.; Choubey, R.K.; Kale, S.N. Nanocomposite modified optical fiber: A room temperature, selective H2S gas sensor: Studies using ZnO-PMMA. J. Alloys Compd. 2017, 695, 2091–2096. [Google Scholar] [CrossRef]

- Keley, M.M.; Borghi, F.F.; Dante, A.; Carvalho, C.; Allil, R.; Dutra, F.; Cardoso, P.; Mok, R.; Garção, L.; Werneck, M.; et al. U-shaped plastic optical fiber functionalized with metal oxides thin film for H2S gas sensor applications. In Proceedings of the 2018 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Houston, TX, USA, 14–17 May 2018. No. 17917120. [Google Scholar]

- Sarma, T.V.S.; Tao, S. An active core fiber optic sensor for detecting trace H2S at high temperature using a cadmium oxide doped porous silica optical fiber as a transducer. Sens. Actuators B Chem. 2007, 127, 471–479. [Google Scholar] [CrossRef]

- Shahriari, M.R.; Ding, J. Active silica-gel films for hydrogen sulfide optical sensor application. Opt. Lett. 1994, 19, 1085–1087. [Google Scholar] [CrossRef] [PubMed]

- Abd-Elaal, A.A.; Tawfik, S.M.; Lee, Y.I. Highly selective fluorescent probe based on new coordinated cationic polyvinylpyrrolidone for hydrogen sulfide sensing in aqueous solution. J. Mol. Liq. 2017, 247, 35–42. [Google Scholar] [CrossRef]

- Urriza-Arsuaga, I.; Bedoya, M.; Orellana, G. Unprecedented Reversible Real-Time Luminescent Sensing of H2S in the Gas Phase. Anal. Chem. 2019, 91, 2231–2238. [Google Scholar] [CrossRef] [PubMed]

- Ali, F.I.M.; Awwad, F.; Greish, Y.E.; Mahmoud, S.T. Hydrogen Sulfide (H2S) Gas Sensor: A Review. IEEE Sens. J. 2019, 19, 2394–2407. [Google Scholar] [CrossRef]

- Pandey, S.K.; Kim, K.H.; Tang, K.T. A review of sensor-based methods for monitoring hydrogen sulfide. TrAC Trends Anal. Chem. 2012, 32, 87–99. [Google Scholar] [CrossRef]

- Dong, S.; Liao, Y.; Tian, Q. Intensity-based optical fiber sensor for monitoring corrosion of aluminum alloys. Appl. Opt. 2005, 44, 5773–5777. [Google Scholar] [CrossRef] [PubMed]

- Adachi, N.; Kaneko, Y.; Sekiguchi, K.; Sugiyama, H.; Sugeno, M. pH-responsive fluorescence chemical sensor constituted by conjugated polymers containing pyridine rings. Luminescence 2015, 30, 1308–1312. [Google Scholar] [CrossRef] [PubMed]

- Esteban, Ó.; Cruz-Navarrete, M.; González-Cano, A.; Bernabeu, E. Measurement of the degree of salinity of water with a fiber-optic sensor. Appl. Opt. 1999, 38, 5267–5271. [Google Scholar] [CrossRef]

- Mishra, S.K.; Rani, S.; Gupta, B.D. Surface plasmon resonance based fiber optic hydrogen sulphide gas sensor utilizing nickel oxide doped ITO thin film. Sens. Actuators B Chem. 2014, 195, 215–222. [Google Scholar] [CrossRef]

- Lemaire, P.J. Hydrogen-induced losses and their effects on optical fiber reliability. In Proceedings of the Proc. SPIE 10272, Fiber Optics Reliability and Testing: A Critical Review, Boston, MA, USA, 8 September 1993. No. 1027207. [Google Scholar]

- OFS Hydrogen Insensitive Core Graded-Index Multimode 50 µm Optical Fiber. Available online: https://www.ofsoptics.com/wp-content/uploads/F80400-web-3.pdf (accessed on 19 August 2019).

- Chen, H.; Buric, M.; Ohodnicki, P.R.; Nakano, J.; Liu, B.; Chorpening, B.T. Review and perspective: Sapphire optical fiber cladding development for harsh environment sensing. Appl. Phys. Rev. 2018, 5, 011102. [Google Scholar] [CrossRef]

- Dong, Y.; Chen, L.; Bao, X. Extending the sensing range of Brillouin optical time-domain analysis combining frequency-division multiplexing and in-line EDFAs. J. Light. Technol. 2012, 30, 1161–1167. [Google Scholar] [CrossRef]

- Mompó, J.J.; Urricelqui, J.; Loayssa, A. Brillouin optical time-domain analysis sensor with pump pulse amplification. Opt. Express 2016, 24, 12672–12681. [Google Scholar] [CrossRef] [PubMed]

- Angulo-Vinuesa, X.; Martin-Lopez, S.; Corredera, P.; Gonzalez-Herraez, M. Raman-assisted Brillouin optical time-domain analysis with sub-meter resolution over 100 km. Opt. Express 2012, 20, 12147–12154. [Google Scholar] [CrossRef] [PubMed]

- Froggatt, M.; Moore, J. High-spatial-resolution distributed strain measurement in optical fiber with Rayleigh scatter. Appl. Opt. 1998, 37, 1735–1740. [Google Scholar] [CrossRef] [PubMed]

- Kreger, S.T.; Gifford, D.K.; Froggatt, M.E.; Soller, B.J.; Wolfe, M.S. High Resolution Distributed Strain or Temperature Measurements in Single- and Multi-mode Fiber Using Swept-Wavelength Interferometry. In Proceedings of the Optical Fiber Sensors, OSA Technical Digest, Cancun, Mexico, 23–27 October 2006. No. ThE42. [Google Scholar]

- Ding, Z.; Yang, D.; Du, Y.; Liu, K.; Zhou, Y.; Zhang, R.; Xu, Z.; Jiang, J.; Liu, T. Distributed Strain and Temperature Discrimination Using Two Types of Fiber in OFDR. IEEE Photonics J. 2016, 8, 6804608. [Google Scholar] [CrossRef]

- Zhou, D.P.; Li, W.; Chen, L.; Bao, X. Distributed temperature and strain discrimination with stimulated brillouin scattering and rayleigh backscatter in an optical fiber. Sensors 2013, 13, 1836–1845. [Google Scholar] [CrossRef] [PubMed]

- Viikari, V.; Song, J.; Pesonen, N.; Pursula, P.; Seppä, H. Review of passive wireless sensors utilizing the intermodulation communication. In Proceedings of the 2014 IEEE RFID Technology and Applications Conference, Tampere, Finland, 8–9 September 2014; pp. 56–61. [Google Scholar]

- Deivasigamani, A.; Daliri, A.; Wang, C.H.; John, S. A review of passive wireless sensors for structural health monitoring. Mod. Appl. Sci. 2013, 7, 57–76. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, G.Y.; Marindra, A.M.J.; Sunny, A.I.; Zhao, A.B. A Review of Passive RFID Tag Antenna-Based Sensors and Systems for Structural Health Monitoring Applications. Sensors 2017, 17, 265. [Google Scholar] [CrossRef] [PubMed]

- Wilson, W.C.; Juarez, P.D. Emerging needs for pervasive passive wireless sensor networks on aerospace vehicles. Procedia Comput. Sci. 2014, 37, 101–108. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, B.; Zhang, G.; Tian, G.Y. Wireless passive ultra high frequency RFID antenna sensor for surface crack monitoring and quantitative analysis. Sensors 2018, 18, 2130. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Visich, J.K.; Khumawala, B.M.; Zhang, C. Radio frequency identification technology: Applications, technical challenges and strategies. Sens. Rev. 2006, 26, 193–202. [Google Scholar] [CrossRef]

- Karmakar, N.C.; Amin, E.M.; Saha, J.K. Passive RFID Sensors. In Chipless RFID Sensors; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 15–20. ISBN 9781118936009. [Google Scholar]

- Malocha, D.C.; Gallagher, M.; Fisher, B.; Humphries, J.; Gallagher, D.; Kozlovski, N. A passive wireless multi-sensor SAW technology device and system perspectives. Sensors 2013, 13, 5897–5922. [Google Scholar] [CrossRef] [PubMed]

- Kang, A.; Zhang, C.; Ji, X.; Han, T.; Li, R.; Li, X. SAW-RFID enabled temperature sensor. Sens. Actuators A Phys. 2013, 201, 105–113. [Google Scholar] [CrossRef]

- Materer, N.; Apblett, A. Passive Wireless Corrosion Sensor. U.S. Patent US007675295B2, 9 March 2010. [Google Scholar]

- He, Y.L.; McLaughlin, S.; Lo, J.S.H.; Shi, C.; Lenos, J.; Vincelli, A. Radio frequency identification (RFID) based corrosion monitoring sensors Part 2—Application and testing of coating materials. Corros. Eng. Sci. Technol. 2014, 49, 695–704. [Google Scholar] [CrossRef]

- He, Y.L.; McLaughlin, S.; Lo, J.S.H.; Shi, C.; Lenos, J.; Vincelli, A. Radio frequency identification (RFID) based corrosion monitoring sensors Part 1 – Component selection and testing. Corros. Eng. Sci. Technol. 2015, 50, 63–71. [Google Scholar] [CrossRef]

- Zarifi, M.H.; Deif, S.; Daneshmand, M. Wireless passive RFID sensor for pipeline integrity monitoring. Sens. Actuators A Phys. 2017, 261, 24–29. [Google Scholar] [CrossRef]

- Sunny, A.I.; Tian, G.Y.; Zhang, J.; Pal, M. Low frequency (LF) RFID sensors and selective transient feature extraction for corrosion characterisation. Sens. Actuators A Phys. 2016, 241, 34–43. [Google Scholar] [CrossRef]

- Zhao, A.; Tian, G.Y.; Zhang, J. IQ signal based RFID sensors for defect detection and characterisation. Sens. Actuators A Phys. 2018, 269, 14–21. [Google Scholar] [CrossRef]

- Perveen, K.; Bridges, G.E.; Bhadra, S.; Thomson, D.J. Corrosion potential sensor for remote monitoring of civil structure based on printed circuit board sensor. IEEE Trans. Instrum. Meas. 2014, 63, 2422–2431. [Google Scholar] [CrossRef]

- Zhou, S.; Sheng, W.; Deng, F.; Wu, X.; Fu, Z. A novel passivewireless sensing method for concrete chloride ion concentration monitoring. Sensors 2017, 17, 2871. [Google Scholar] [CrossRef]

- Bhadra, S.; Thomson, D.J.; Bridges, G. A wireless embedded passive sensor for monitoring the corrosion potential of reinforcing steel. Smart Mater. Struct. 2013, 22, 075019. [Google Scholar] [CrossRef]

- Bhadra, S.; Bridges, G.E.; Thomson, D.J.; Freund, M.S. A wireless passive pH sensor based on pH electrode potential measurement. In Proceedings of the IEEE SENSORS 2010 Conference, Kona, HI, USA, 1–4 November; 2010; pp. 927–930. [Google Scholar]

- Loh, K.J.; Lynch, J.P.; Kotov, N.A. Inductively coupled nanocomposite Wireless strain and pH sensors. Smart Struct. Syst. 2008, 4, 531–548. [Google Scholar] [CrossRef]

- Zhou, S.; Deng, F.; Yu, L.; Li, B.; Wu, X.; Yin, B. A novel passive wireless sensor for concrete humidity monitoring. Sensors 2016, 16, 1535. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Singh, E.; Nalwa, H.S. Inkjet printed nanomaterial based flexible radio frequency identification (RFID) tag sensors for the internet of nano things. RSC Adv. 2017, 7, 48597–48630. [Google Scholar] [CrossRef]

- Sun, G.; Qiao, G.; Zhao, L.; Chen, Z. Events as power source: Wireless sustainable corrosion monitoring. Sensors 2013, 13, 17414–17433. [Google Scholar] [CrossRef] [PubMed]

- Greve, D.W.; Chin, T.L.; Zheng, P.; Ohodnicki, P.; Baltrus, J.; Oppenheim, I.J. Surface acoustic wave devices for harsh environment wireless sensing. Sensors 2013, 13, 6910–6935. [Google Scholar] [CrossRef] [PubMed]

- Devkota, J.; Ohodnicki, P.R.; Greve, D.W. SAW sensors for chemical vapors and gases. Sensors 2017, 17, 801. [Google Scholar] [CrossRef]

- Binder, A.; Fachberger, R. Wireless SAW temperature sensor system for high-speed high-voltage motors. IEEE Sens. J. 2011, 11, 966–970. [Google Scholar] [CrossRef]

- Rodriguez, L.M.; Gallagher, D.R.; Gallagher, M.W.; Fisher, B.H.; Humphries, J.R.; Malocha, D.C. Wireless SAW sensor temperature extraction precision. IEEE Sens. J. 2014, 14, 3830–3837. [Google Scholar] [CrossRef]

- Borrero, G.A.; Bravo, J.P.; Mora, S.F.; Velásquez, S.; Segura-Quijano, F.E. Design and fabrication of SAW pressure, temperature and impedance sensors using novel multiphysics simulation models. Sens. Actuators A Phys. 2013, 203, 204–214. [Google Scholar] [CrossRef]

- Della Lucia, F.; Zambrozi, P.; Frazatto, F.; Piazzetta, M.; Gobbi, A. Design, fabrication and characterization of saw pressure sensors for extreme operation conditions. Procedia Eng. 2014, 87, 540–543. [Google Scholar] [CrossRef]

- Nicolay, P.; Chambon, H.; Bruckner, G.; Gruber, C.; Ballandras, S.; Courjon, E.; Stadler, M. A LN/Si-based SAW pressure sensor. Sensors 2018, 18, 3482. [Google Scholar] [CrossRef] [PubMed]

- Stoney, R.; Geraghty, D.; O’Donnell, G.E. Characterization of differentially measured strain using passive wireless surface acoustic wave (SAW) strain sensors. IEEE Sens. J. 2014, 14, 722–728. [Google Scholar] [CrossRef]

- Shu, L.; Peng, B.; Yang, Z.; Wang, R.; Deng, S.; Liu, X. High-temperature SAW wireless strain sensor with langasite. Sensors 2015, 15, 28531–28542. [Google Scholar] [CrossRef] [PubMed]

- Go, D.B.; Atashbar, M.Z.; Ramshani, Z.; Chang, H.C. Surface acoustic wave devices for chemical sensing and microfluidics: A review and perspective. Anal. Methods 2017, 9, 4112–4134. [Google Scholar] [CrossRef] [PubMed]

- Greve, D.W.W.D.; Devkota, J.; Ohodnicki, P.R. Wireless CO2 SAW Sensors with a Nanoporous ZIF-8 Sensing Layer. In Proceedings of the IEEE International Ultrasonics Symposium, Kobe, Japan, 22–25 October 2018; pp. 1–4. [Google Scholar]

- Xu, S.; Li, C.; Li, H.; Li, M.; Qu, C.; Yang, B. Carbon dioxide sensors based on a surface acoustic wave device with a graphene-nickel-l-alanine multilayer film. J. Mater. Chem. C 2015, 3, 3882–3890. [Google Scholar] [CrossRef]

- Wang, W.; Lee, K.; Kim, T.; Park, I.; Yang, S. A novel wireless, passive CO2 sensor incorporating a surface acoustic wave reflective delay line. Smart Mater. Struct. 2007, 16, 1382–1389. [Google Scholar] [CrossRef]

- Fanget, S.; Grange, H.; Palancade, F.; Ganuchaud, G.; Matheron, M.; Charlot, S.; Bordy, T.; Hoang, T.; Rey, P.; Mercier, D.; et al. CO2 measurement using an AlN/Si SAW sensor. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; No. 12169382. pp. 1136–1139. [Google Scholar]

- Li, D.; Zu, X.; Ao, D.; Tang, Q.; Fu, Y.Q.; Guo, Y.; Bilawal, K.; Faheem, M.B.; Li, L.; Li, S.; et al. High humidity enhanced surface acoustic wave (SAW) H2S sensors based on sol–gel CuO films. Sens. Actuators B Chem. 2019, 294, 55–61. [Google Scholar] [CrossRef]

- Luo, W.; Fu, Q.; Zhou, D.; Deng, J.; Liu, H.; Yan, G. A surface acoustic wave H2S gas sensor employing nanocrystalline SnO2 thin film. Sens. Actuators B Chem. 2013, 176, 746–752. [Google Scholar] [CrossRef]

- Wang, X.; Wang, W.; Li, H.; Fu, C.; Ke, Y.; He, S. Development of a SnO2/CuO-coated surface acoustic wave-based H2S sensor with switch-like response and recovery. Sens. Actuators B Chem. 2012, 169, 10–16. [Google Scholar] [CrossRef]

- Asad, M.; Sheikhi, M.H. Surface acoustic wave based H2S gas sensors incorporating sensitive layers of single wall carbon nanotubes decorated with Cu nanoparticles. Sens. Actuators B Chem. 2014, 198, 134–141. [Google Scholar] [CrossRef]

- Vetelino, J.; Lade, R.K.; Falconer, R.S. Hydrogen Sulfide Surface Acoustic Wave Gas Detector. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1987, 34, 156–161. [Google Scholar] [CrossRef] [PubMed]

- Calabrese, G.S.; Wohltjen, H.; Roy, M.K. Surface Acoustic Wave Devices as Chemical Sensors in Liquids. Evidence Disputing the Importance of Rayleigh Wave Propagation. Anal. Chem. 1987, 59, 833–837. [Google Scholar] [CrossRef]

- Kondoh, J.; Matsui, Y.; Shiokawa, S. Identification of electrolyte solutions using a shear horizontal surface acoustic wave sensor with a liquid-flow system. Sens. Actuators B Chem. 2003, 91, 309–315. [Google Scholar] [CrossRef]

- Arai, Y.; Honda, T. Corrosion Monitoring with Surface Acoustic Wave Devices. Corros. Eng. 1990, 39, 479–483. [Google Scholar] [CrossRef]

- Qiu, X.; Tang, R.; Chen, S.J.; Zhang, H.; Pang, W.; Yu, H. pH measurements with ZnO based surface acoustic wave resonator. Electrochem. commun. 2011, 13, 488–490. [Google Scholar] [CrossRef]

- Malik, A.F.; Burhanudin, Z.A.; Jeoti, V. A flexible Polyimide based SAW delay line for corrosion detection. In Proceedings of the IEEE National Postgraduate Conference, Kuala Lumpur, Malaysia, 19–20 September 2011. No. 12495064. [Google Scholar]

- Oh, H.; Lee, K.J.; Baek, J.; Yang, S.S.; Lee, K. Development of a high sensitive pH sensor based on shear horizontal surface acoustic wave with ZnO nanoparticles. Microelectron. Eng. 2013, 111, 154–159. [Google Scholar] [CrossRef]

- Steele, A.R.; Belkerdid, M.A.; Struble, E. Passive Wireless Surface Acoustic Wave Sensors for Corrosion Monitoring of Steel in Concrete Structures. In Proceedings of the NACE CORROSION, Dallas, TX, USA, 15–19 March 2015. No. 6170. [Google Scholar]

| Sensor | Temporal | Spatial | Advantages | Disadvantages |

|---|---|---|---|---|

| Corrosion coupon | A few months | Point sensor | Gold standard, Simple, Easy to operate | General corrosion, Not real-time |

| Electrical resistance probe | Real-time | Point sensor | Real-time, Remote sensing compatible | Uniform corrosion, Electrical based |

| Electrochemical sensor | Real-time | Point sensor | Various in-situ electrochemical techniques | Electrical based, Mostly for conductive liquids |

| Ultrasonic sensor | Real-time | Point sensor, PIG | Non-intrusive | Not sensitive to small thin features |

| Magnetic flux leakage sensor | Real-time | Point sensor, PIG | Nondestructive | Limited for surface detection |

| Electromagnetic sensor | Real-time | Point sensor, PIG | Nondestructive, Inner wall features | Not sensitive to small defects |

| Pipeline inspection gauge | Every 5–7 years | Run through pipes | Comprehensive sensing/logging, Long distance | Costly, not frequent |

| Optical fiber sensors | Real-time | Distributed linear sensors | Distributed sensing for a long distance, Multi-parameter | Cost of interrogation instrument |

| Passive wireless sensors | Real-time | Ubiquitous point sensors | Small size, Passive, Wireless capability, Low cost | Wireless telemetry in attenuating media |

| Parameter | Sensing layer | Test Condition | Performance and Comments |

|---|---|---|---|

| Corrosion | Fe [136] | 30 °C, 1 atm, CO2 saturated 3.5 wt.% NaCl | Distributed sensing, nm-scale mass loss sensitivity |

| FeC [53] | 0.18–1.8 mol/L H2SO4 | 10s of uW increase in light transmission in <10 min | |

| Al [191] | 0.05 mol/L NaOH | uW increase in light transmission in 5 min | |

| pH | Au-NP in SiO2 matrix [107] | Room temperature (RT) and 80 °C, 1 atm | pH 2–12, quick response |

| Organic dyes in SiO2 matrix [143,146] | RT, 1 atm * | pH 3–12 | |

| Polyaniline [154] | RT, 1 atm * | pH 2–12, >1 month stability in air | |

| fluorescent Poly(p-pyridiniumphenylene ethynylene)s [192] | RT, 1atm | pH 1–10 | |

| pH-sensitive hydrogel [158] | RT, 1atm | Wavelength 1.94 nm/pH, pH 3–10 | |

| Water | Polyimide [137] | 30 – 50 °C, 1atm | 38.5 ± 1.9 microstrain/%Relative Humidity (RH) |

| Graphene oxide film [165] | 27–67 °C, 1atm | Wavelength 0.145–0.915 nm/%RH for 32–97.6% RH; Intensity 0.427 dB/%RH for 58.2–92.5% RH | |

| Salinity or Cl− | SPR based Al/TiO2 [193] | RT, 1atm * | Accuracy of 0.1‰ salinity |

| Fluorescent Lucigenin [129] | RT, 1atm * | Detection limit of 0.02 mol/L Cl− | |

| CO2 | Zeolitic imidazolate framework-8 (ZIF-8) MOF [170] | RT, 1atm | 10s of seconds response, Reversible, Linear calibration |

| Dyes (e.g., methyl red) in SiO2 gel [172] | 15–60 °C, 1atm | 2–3 seconds response | |

| Fluorescent dye HPTS (1-Hydroxypyrene-3,6,8-trisulfonic acid trisodium salt) [174,176] | 5–35 °C, 1atm | Sol–gel matrix doped with silica particles improved sensitivity | |

| H2S | Ag layer [178] | 30 °C, 1 atm | 90% transmittance drop in 15 minutes in 0.1 mol/L H2S solution |

| CdO in porous SiO2 [185] | 450 °C, 1atm | 25–30 minutes response time for 1–100 ppm H2S, Irreversible but regenerable | |

| SPR based Ag/NiO doped indium tin oxide (ITO) [194] | RT, 1atm * | 100 ppb–100 ppm H2S, Sensitivity decreased with H2S concentration |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wright, R.F.; Lu, P.; Devkota, J.; Lu, F.; Ziomek-Moroz, M.; Ohodnicki, P.R., Jr. Corrosion Sensors for Structural Health Monitoring of Oil and Natural Gas Infrastructure: A Review. Sensors 2019, 19, 3964. https://doi.org/10.3390/s19183964

Wright RF, Lu P, Devkota J, Lu F, Ziomek-Moroz M, Ohodnicki PR Jr. Corrosion Sensors for Structural Health Monitoring of Oil and Natural Gas Infrastructure: A Review. Sensors. 2019; 19(18):3964. https://doi.org/10.3390/s19183964

Chicago/Turabian StyleWright, Ruishu F., Ping Lu, Jagannath Devkota, Fei Lu, Margaret Ziomek-Moroz, and Paul R. Ohodnicki, Jr. 2019. "Corrosion Sensors for Structural Health Monitoring of Oil and Natural Gas Infrastructure: A Review" Sensors 19, no. 18: 3964. https://doi.org/10.3390/s19183964

APA StyleWright, R. F., Lu, P., Devkota, J., Lu, F., Ziomek-Moroz, M., & Ohodnicki, P. R., Jr. (2019). Corrosion Sensors for Structural Health Monitoring of Oil and Natural Gas Infrastructure: A Review. Sensors, 19(18), 3964. https://doi.org/10.3390/s19183964