2.1. Design Considerations

On the way from simple bidirectional thermal flow sensors towards wind sensors, a couple of decisions at system level and design considerations are mandatory in order to achieve superior device performance. Only a restricted part of the vast design possibilities for such devices can be covered by a single research paper. Consequently, we describe only our investigations on the most successful approaches. These 2D flow transducers have square membranes containing eight semiconductor thermistors and optional thin-film heating resistors.

Readout architectures based on resistance bridges are a common choice in almost any case of thermal flow transduction. Four matching membrane thermistors enable an expedient readout of small asymmetric temperature variations within the membrane. To boost the thermal actuation by self-heated thermistor bridges, the setups can be complemented with dedicated heating resistors. For a given bridge supply voltage full bridges offer twice the output of half bridges composed of a single upstream and downstream thermistor combined with two external resistors. Furthermore, any common scaling of the four thermistor resistances, e.g., by changes of the ambient temperature or technology variations, has no perceptible effect on the offset voltage and the conversion of the bridge supply voltage into a bridge detuning signal. Finally, a readout based on a perfect bridge yields zero output signal for zero flow.

As we will show below, there is another important benefit of bridge-based readouts that applies exclusively to 2D flow transducers. When compared with the azimuthal dependence of thermistor temperatures, bridge-based flow transduction signals facilitate a much better approximation to the desired sinusoidal characteristics.

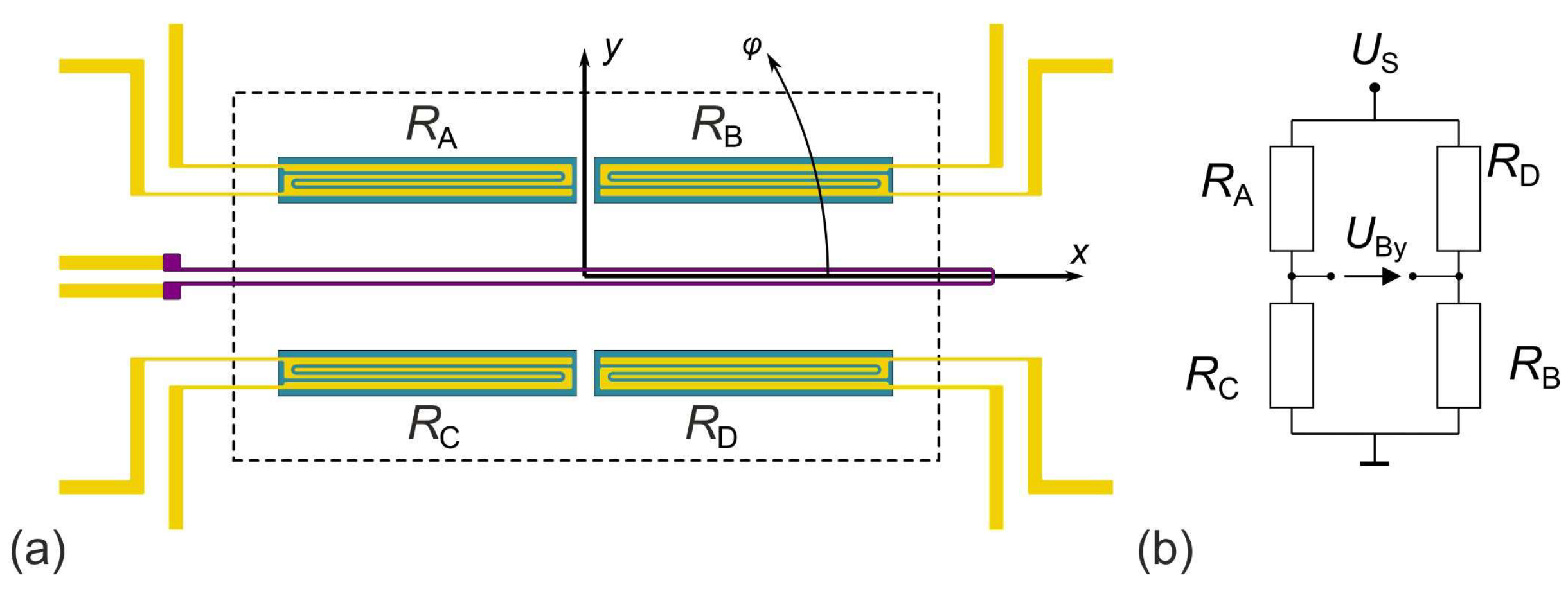

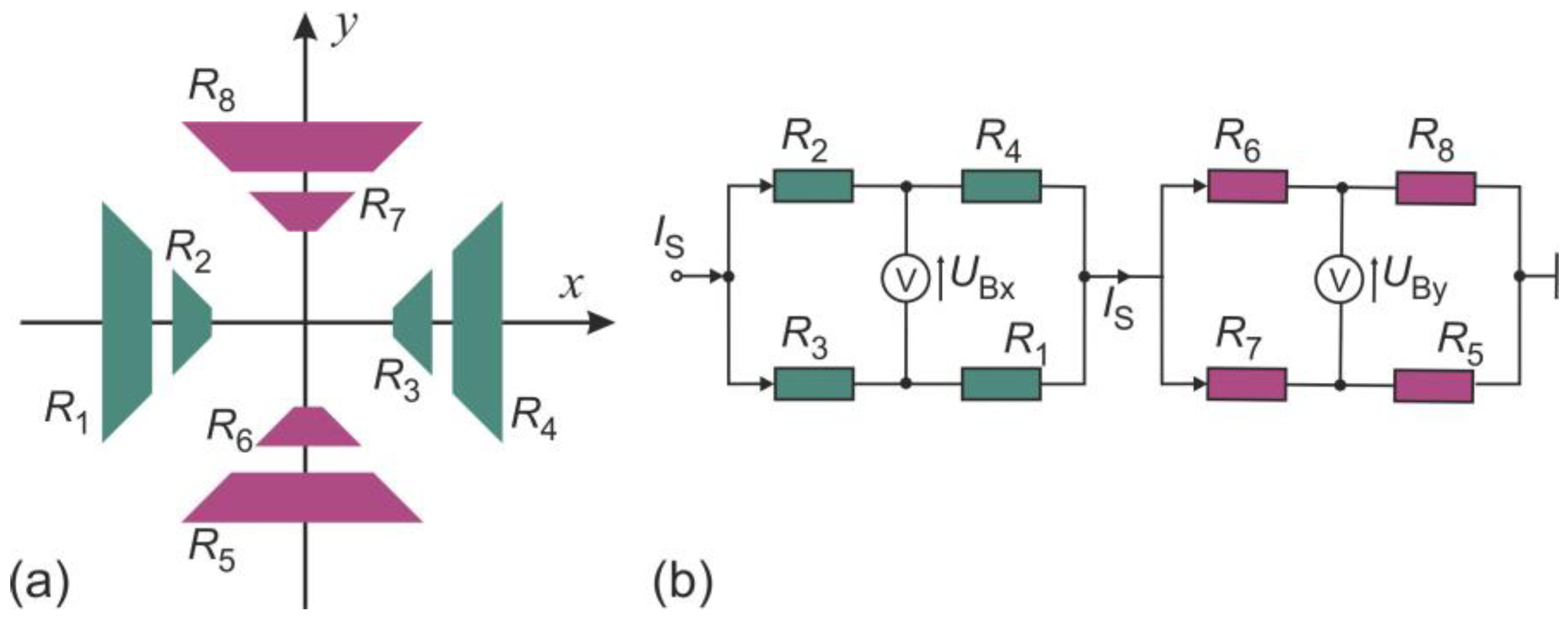

The layout of

Figure 1a arises immediately from a simple bidirectional flow sensor characterized by single thermistors situated up- and downstream of a central heating resistor [

14] by splitting each of them into two equal parts. Interdigitated contacts to the thermistor film deal with the high resistivity thermistor material. Four thermistors enable a Wheatstone bridge configuration for convenient readout of temperature differences between the upper and lower, or, alternatively, left and right half of the device.

A pronounced sensitivity of the bridge voltage to flow in parallel to the

coordinate can be expected if the upper thermistor pair

forms one bridge diagonal while the lower pair

constitutes the other one. Temperature variations in the

direction are suppressed effectively by this configuration. The numerator of the Wheatstone formulas in Equation (1) governs the magnitude of the related bridge unbalance voltages

,

The different denominators, resulting from the interchange of the two resistors of a single bridge diagonal, causes only a very moderate change of , as the four resistance values are approximately equal. denotes the bridge supply voltage.

For flow along the

coordinate, the bridge thermistors are laterally positioned with respect to the resistive heater. As the preferred directions of convective and conducive heat transfer are virtually orthogonal, this configuration is suspected to yield smaller temperature differences due to convection. The best transduction of the

x-component of the velocity can be achieved by swapping the position of

RA and

RD in

Figure 1b.

If both resistance bridge configurations are utilized alternately, two linearly independent flow signals are available. Therefore, 2D flow reconstruction is feasible with this membrane design. A matrix of switches is required for reconfiguration of the resistance network but simultaneous reading of both signals, as mandatory for fast azimuth measurements, is not feasible.

However, devices according to

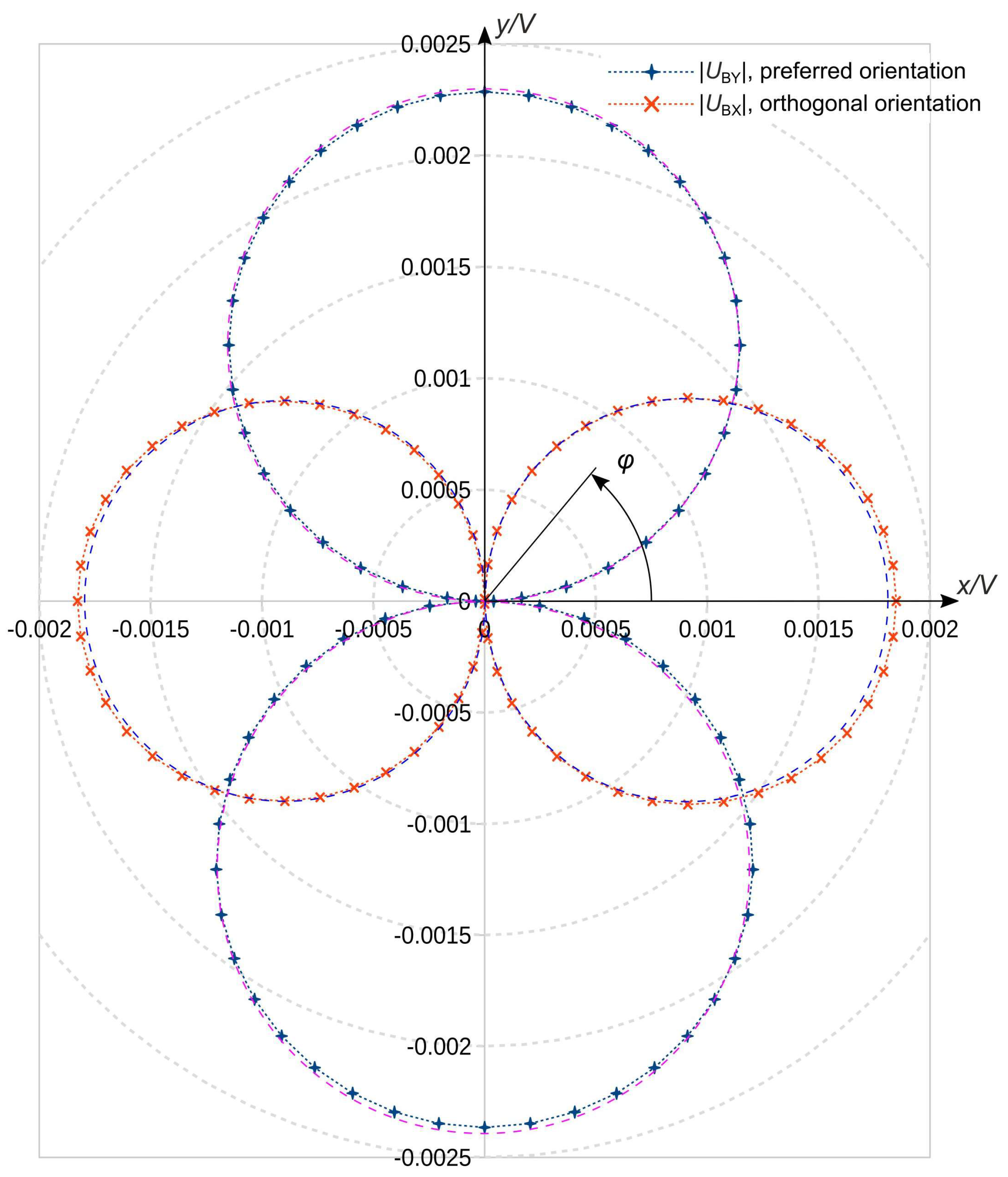

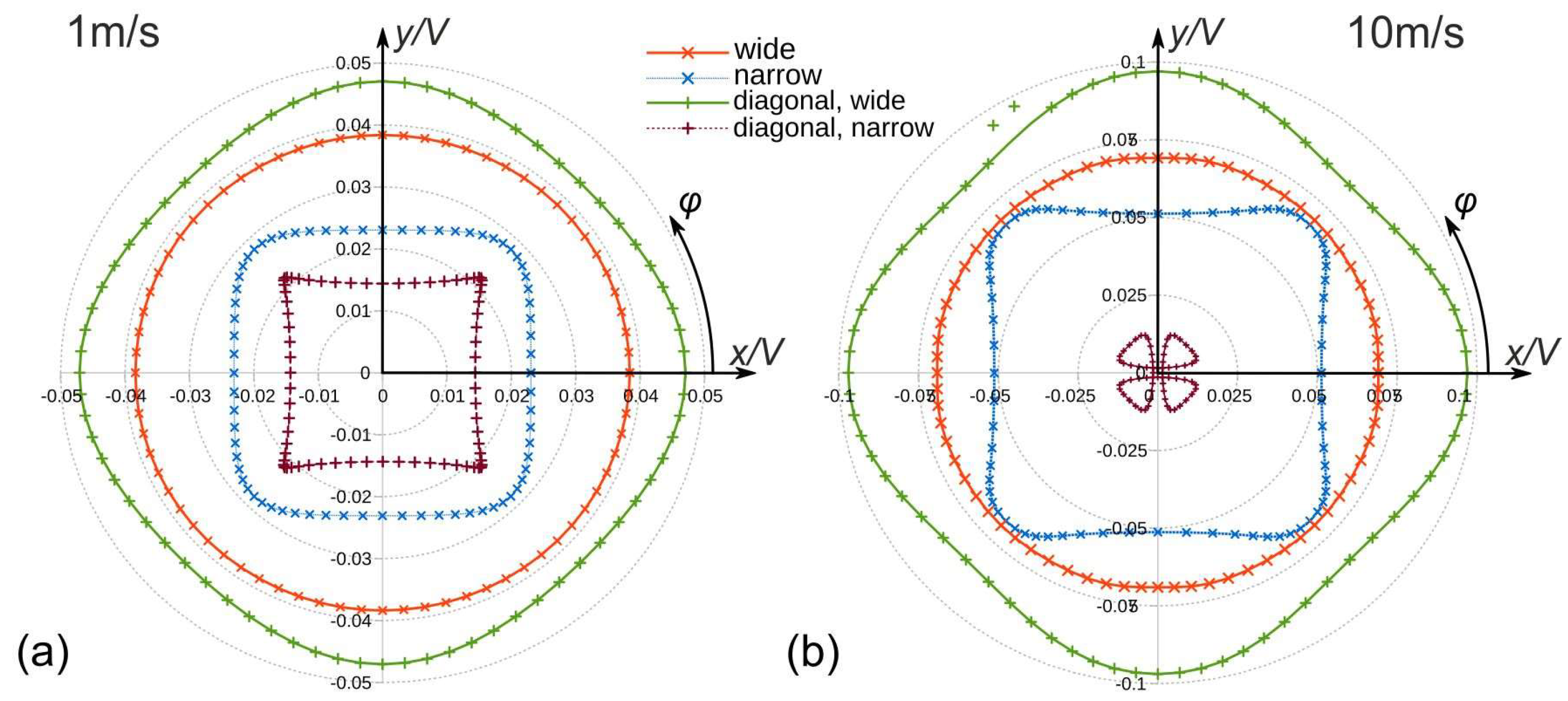

Figure 1 provide an appropriate starting point for the development of 2D flow sensors by thorough simulation studies of flow magnitude and direction transduction. The simulated polar diagrams of

Figure 2 illustrate the azimuth dependencies of

for a certain flow rate of a device according to

Figure 1a. Circular characteristics in the upper as well as in the lower hemisphere indicate a characteristic proportional to

while a

dependency results in circles in the left and right hemisphere of

Figure 2. A close inspection of

Figure 2 reveals minor deviations from the ideal circular shapes. The conversion signal

saturates slightly around its maximum, while the opposite phenomenon is observed for the

characteristic.

A sinusoidal dependency on the azimuth angle indicates, e.g., that the

velocity component (see

Figure 1a) governs the azimuthal variation of the main transducer output. The second double-lobe confirms that the alternative bridge configuration may be used to record the

velocity component via

. The signal diagrams of

Figure 2 can be approximately modeled as

where

denotes the average flow velocity in the channel and

the azimuth angle between the flow direction and the

axis. The magnitude dependencies

and

must be obtained from calibration experiments. In spite of the directional dependencies shown in

Figure 2, the transducer design according to

Figure 1a certainly does not provide means for continuous recording of flow direction and magnitude. The required periodic interchange of bridge resistors prohibits continuous flow velocity transduction. Using two orthogonally oriented bridge transducers of the shown kind, one could continuously resolve flow direction

and magnitude

, although with a moderate spatial resolution simply from

where the indices 1 and 2 distinguish the devices and

is the bridge signal for the preferred orientation of each device (i.e.,

in

Figure 2). Function

f denotes the magnitude dependence for the preferred orientation (i.e.,

fy in Equation (3)).

It would be mandatory for highest spatial resolution and beneficial for economic manufacturing, if the two separated transducers could be merged into a more sophisticated combined transducer design that fits to a single MEMS membrane. Hence, eight membrane thermistors, forming two permanent resistance bridges, must be suitably arranged aside with proper designed heating elements. However, any mutual interference between the orthogonal subsystems must be considered to ensure proper wind sensor operation.

Numerous unique flow transducer implementations have been published in the past [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31] but reports on comprehensive exploration of the design space of a given technological approach are not available yet. We have investigated a total of twelve basic flow transducer designs, some of them including subsets, but all simulation models adhere to the aGe microthermistor technology. Each promising design was explored for optional bridge configurations and alternative operational modes with respect to their flow transduction characteristics. The key parameters of 2D-transducer performance are azimuthal uniformity of the flow magnitude conversion as well as the deviation between the flow direction and the estimated azimuth angle aberration. Due to the limited space, only the best performing transducer design is extensively discussed in this paper. Other designs and results are shown in

Appendix A to this paper (

Table A1).

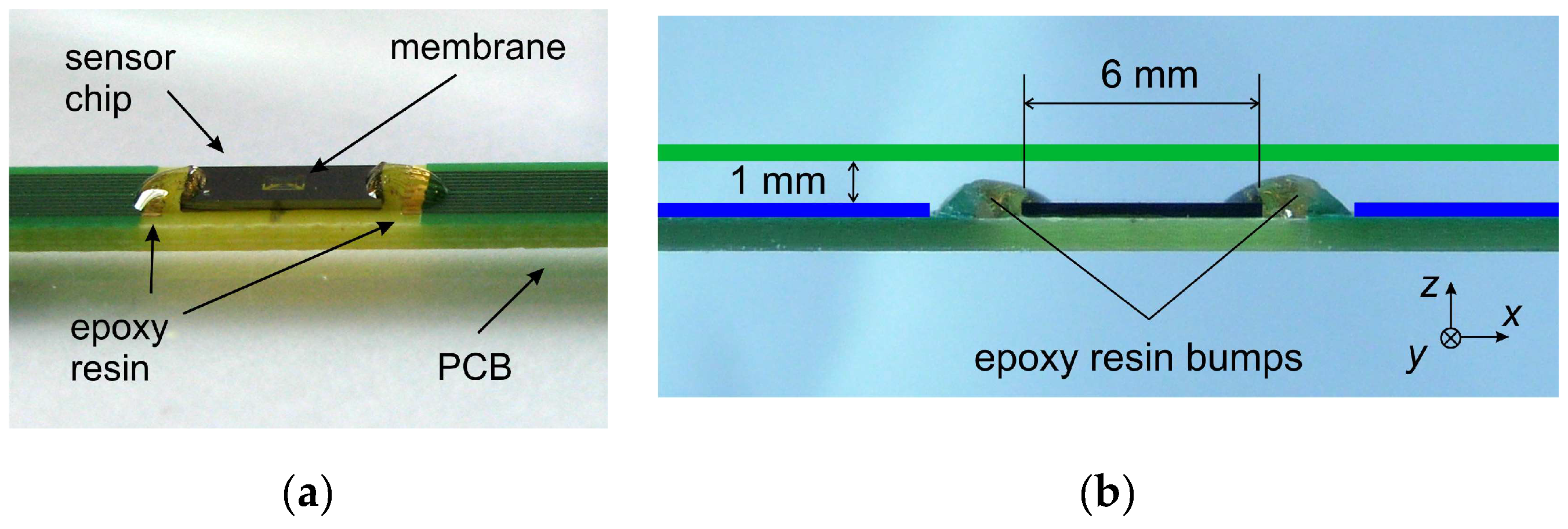

2.2. FEM Modeling

We conducted comprehensive FEM studies of the conjugated heat transfer on a number of promising thermistor array concepts aiming at proper arrangements of heating resistors as well as temperature sensing elements on transducer membranes. Several designs were identified that enable efficient and accurate conversion of flow magnitudes and directions. A 3D FEM modeling is required because of the 2D extension of the membrane elements and an imposed flow velocity profile in the third direction. A modeling approach will be shortly explained by means of the FEM model of the calorimetric transducer depicted in

Figure 1a. FEM models of all other sensors presented in this paper are similar and differ only in dimensions of membrane and active elements (i.e., heaters and thermistors).

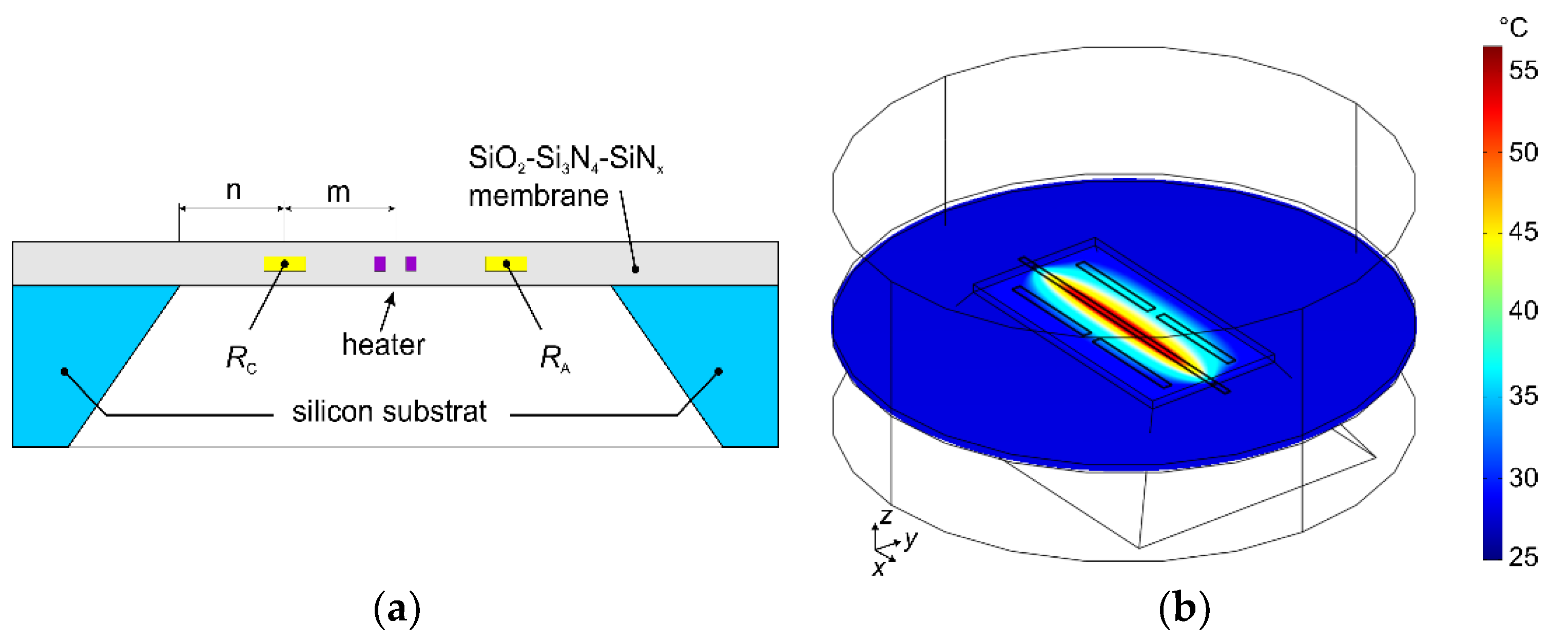

Figure 3a depicts a schematic cross section in the

y-direction through the thermistors

RC and

RA (see

Figure 1a). The membrane of this particular transducer has an area of 0.5 × 1 mm², whereas the membranes of all other sensor layouts presented in this paper measure 1.2 × 1.2 mm². Each membrane is suspended over a 350 μm thick silicon frame and consists of a SiO

2, Si

3N

4, and SiN

x layer sandwich with an overall thickness of 1.57 µm. For simulations, all three layers are combined to one single layer using averaged thermal properties. The temperature sensing elements are embedded 0.32 µm above the bottom membrane surface. A single thermistor measures 400 × 35 μm², exhibiting a total thickness of 0.27 µm. The interdigital metal layers used to contact the thermistors (see

Figure 1a) were not considered by this simple 3D modeling approach. The U-shaped heater consists of two stripes, each 5 µm wide and about 1.2 mm long, with a 15 µm spacing between them. For the sake of simplicity, it was simulated as a single block featuring the same thickness as the adjacent thermistors (

Figure 3b). Due to the high aspect ratio of the membrane and the embedded components, the number of required mesh elements is very high. However, it can be significantly reduced by scaling these subdomains with a factor a = 20. In order to obtain approximately the same temperature distribution, the material properties must be appropriately scaled, too. For more details about the FEM modeling refer to [

28].

A rectangular flow channel of 1mm height and 12 mm width was assumed in accordance with the dimensions of the rectangular flow channel used for experiments. Thus, the modeled flow velocity field exhibits no variation in flow direction and a parabolic dependence across the orthogonal plane to maintain non-slip boundary conditions at the top and bottom boundary of the flow channel. The trapezoidal cavity below the sensor membrane is filled with resting fluid. Its shape accounts for the anisotropic KOH-etching step during the membrane fabrication.

Due to the imposed flow velocity, the solution of the general Navier–Stokes equation is not necessary and only the heat transfer equation incorporating conductive and convective heat transfer must be solved. The boundary condition at the in- and outlet of the flow compartment is implemented as convective flux, the remaining parts of the model circumference were kept at the ambient temperature. This is also the initial temperature condition for all domains.

The power density of the heaters is specified while the heat dissipation of the bridge thermistors is computed from the actual thermistor temperatures in conjunction with the applied bridge supply voltage or current levels. In case of self-heating thermistor operation, an iterative solution of the model is scheduled.

Simulations were performed by means of the commercial finite element analysis software COMSOL Multiphysic

®.

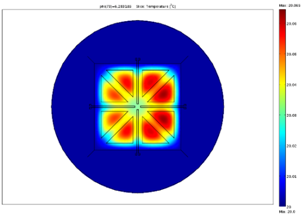

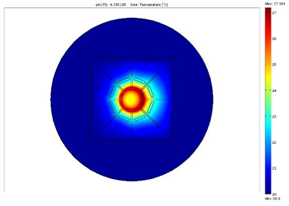

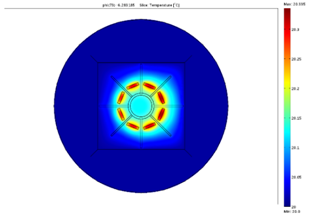

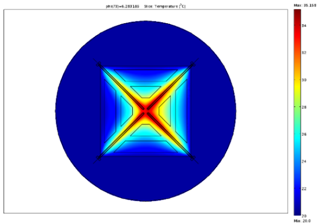

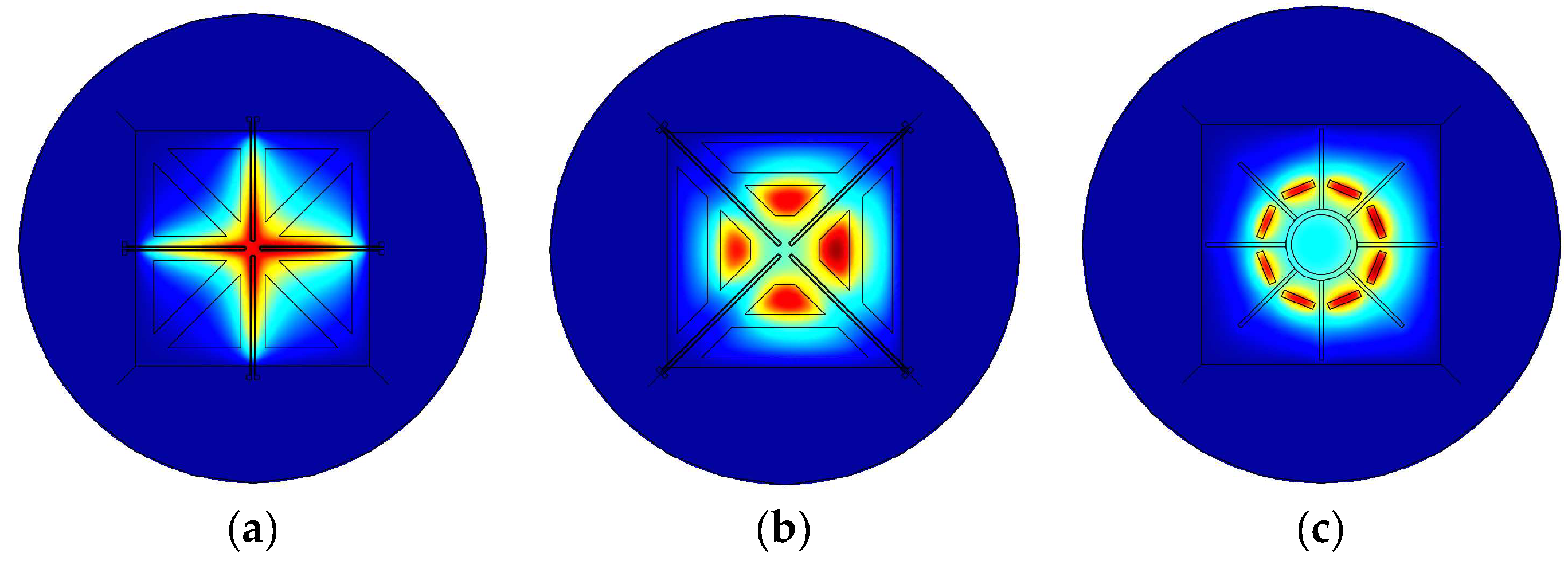

Figure 4 shows membrane regions of three high-performance transducer designs. The thermistors feature triangle (a) or trapezoidal (b) shape. A circular arrangement of eight rectangular thermistors (c) was also considered. Moreover, two operational modes for each transducer were considered. In the calorimetric mode, the heaters were used as a heat source (

Figure 5). Eight membrane thermistors were appropriately connected to form two Wheatstone bridges, each supplied with the same constant voltage. As the supply voltage is assumed to be very low (

= 1V), the self-heating effect of the thermistors can be neglected in this operating mode.

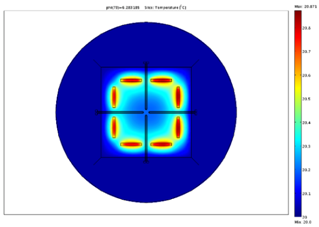

In the second operating mode (

Figure 6), the heaters were switched off and the self-heating effect of the thermistors solely was utilized as a heat source. The bridges were connected in series and supplied with a constant current, rather than with a constant voltage, as it is the case in calorimetric mode. If a thermistor temperature suddenly increases, its resistance decreases due to the negative temperature coefficient (NTC, α = −0.02 K

−1 [

9]). In case of a voltage supply, this results in a rise of the electrical current through the thermistor and a further increase of its temperature. This positive feedback can lead to the thermal destruction of the thermistors. Thus, in the self-heating mode, the constant current supply should be preferred.

Table 1 gives an overview of the best performing transducer layouts and their respective operational modes. The flow transduction errors of three high-performance design alternatives (triangle, circular, trapezoidal) are given for 1 and 10 m/s, respectively. All twelve layouts of the transducer membrane region investigated in the course of this research are unveiled in the supplementary matter. Results obtained for self-heating operation of membrane thermistors are listed along with two cases of the calorimetric operating mode.

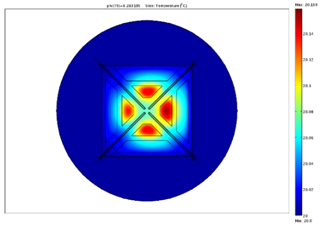

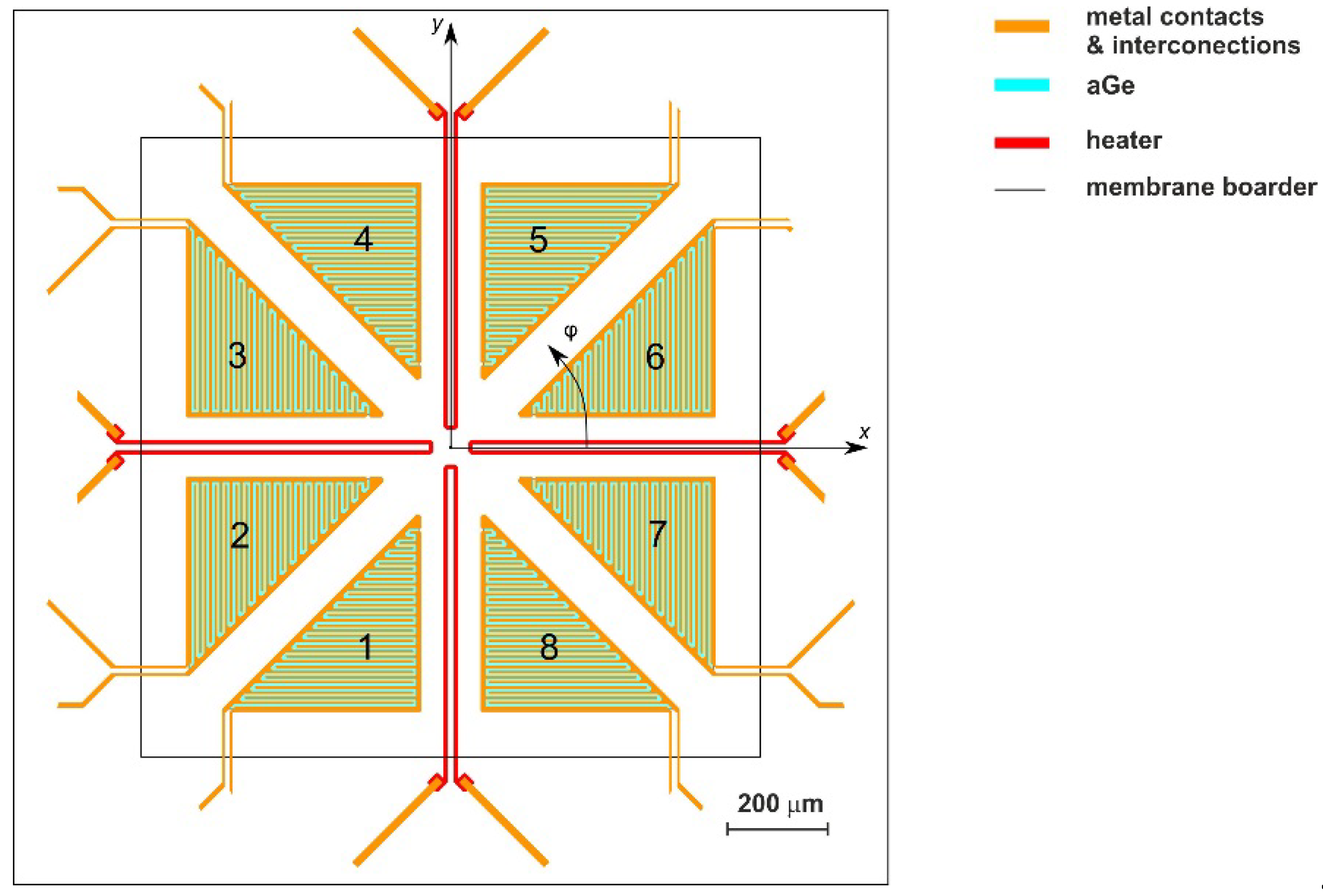

According to

Table 1, best performance is obtained by the “triangular” design in conjunction with the calorimetric mode. The related membrane layout is shown in

Figure 7. The rest of this paper is devoted to describe the underlying synergy of diverse influences as unveiled by the FEM simulations.

2.3. Best Performing Membrane Design

Eight thermistors were “triangularly” arranged together with four slim heating resistors on the membrane. The large triangular thermistor shapes are suspected to promote a large range of efficient transduction of flow magnitudes. The four straight heaters, connected in parallel or series, ensured a four-fold rotational symmetry of power dissipation in the membrane.

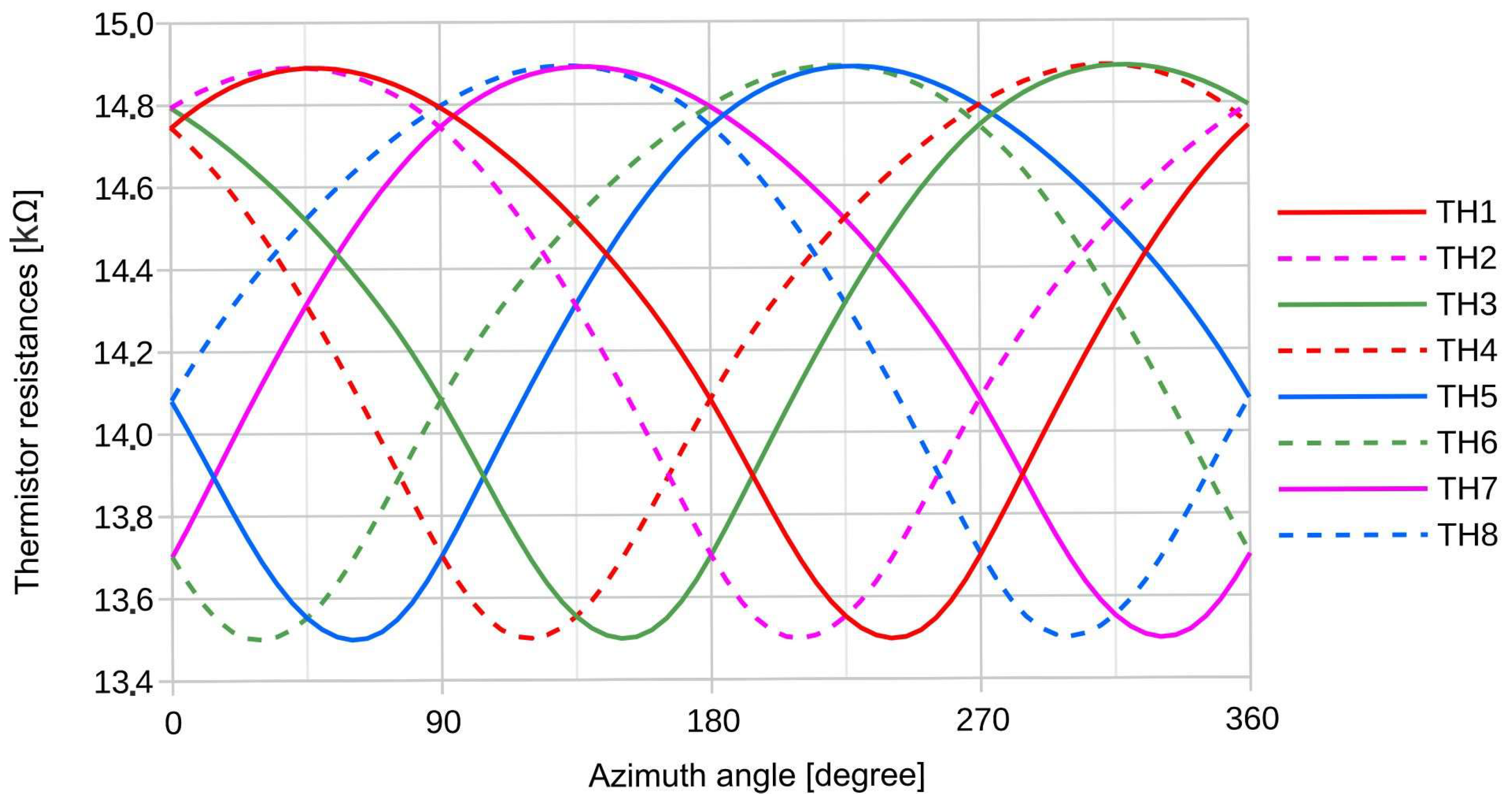

Figure 8 depicts simulation results for the eight thermistor resistances as a function of the flow direction. As we deal with NTC thermistors, resistance maxima correspond to temperature minima and vice versa. Because of the small relative changes, the thermistor temperature curves look like vertically mirrored resistance curves. The shape of these curves is typical for the impact of the convective heat transfer. Around the upstream position (maximum resistance) of a specific thermistor, there is a broad azimuth region where convective cooling dominates resulting in elevated resistance values. In contrast, lowering of resistances takes place only within a smaller azimuthal region around the downstream position. Downstream thermistors are less cooled or even heated by convection since the fluid temperature is somewhat elevated within a narrow lobe in the wake of the power dissipating elements in the membrane. Thus, the different curvature around the maxima and minima of these resistance characteristics is a common feature of all 2D calorimetric flow transducers.

With respect to increments of the azimuthal coordinate

, the rate of resistance decrease of each characteristic of

Figure 8 differs from the rate of its increase, if both are taken at a certain resistance level. The skewed form of the resistance characteristics is a consequence of the triangular shape of each thermistor that is not symmetric with respect to the azimuthal coordinate

(see

Figure 7). The continuous traces (thermistors 1, 3, 5, 7) are skewed left whereas the dashed curves (thermistors 2, 4, 6, 8) are skewed right. As will be shown below, the different skewness of neighboring thermistors enables a better approach to the desired sinusoidal characteristics of double bridge flow transduction.

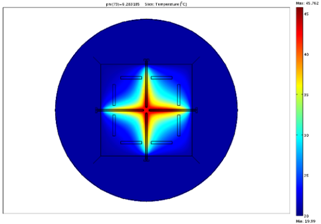

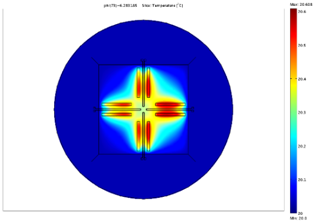

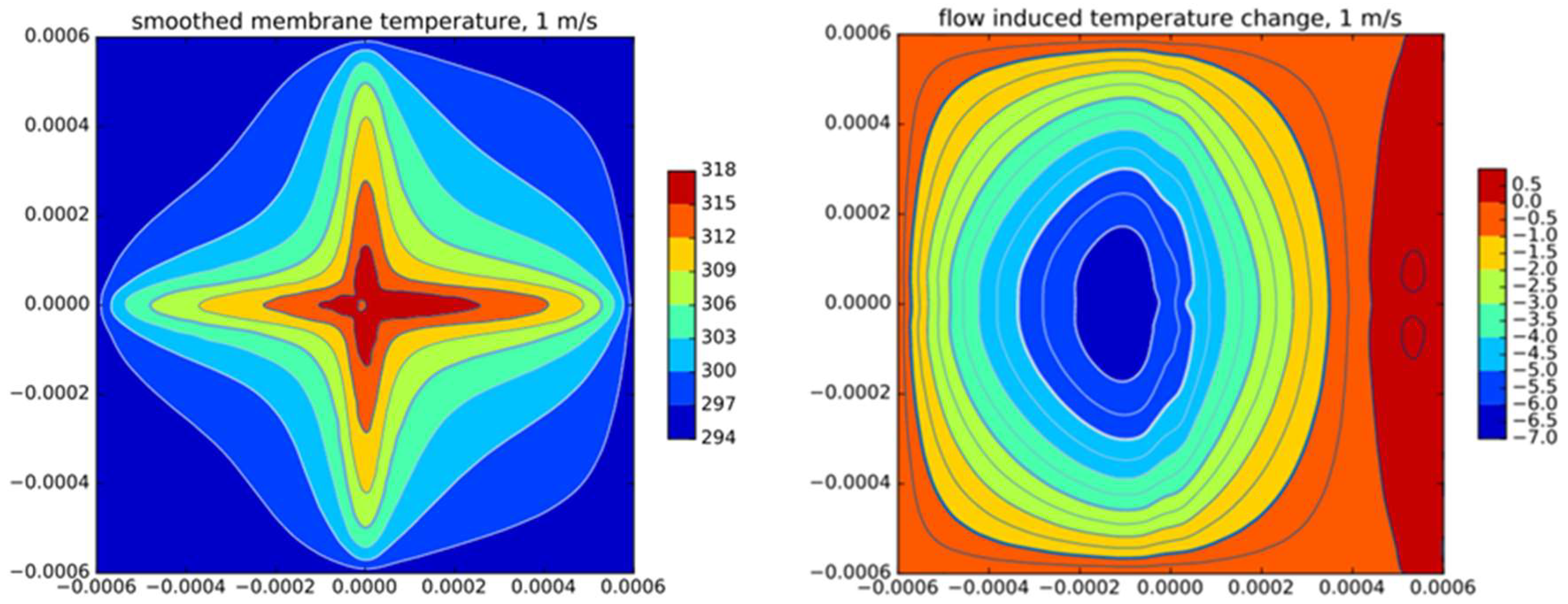

The convection induced membrane temperature change leading to the characteristics of

Figure 8 is depicted in the right sub-figure of

Figure 9 for a flow direction parallel to the

x-axis. The shown contour maps cover the transducer membrane measuring 1.2 × 1.2 mm. The applied temperature units are in Kelvin while the diagrams are computed for a total heating power of 3 mW and a flow velocity of 1 m/s. As expected, convective cool down is strongest slightly upstream of the membrane center while a moderate temperature elevation will eventually appear in the downstream region, which is typical for moderate flow velocities. In contrast to the smooth characteristic of convection-induced temperature change, the temperature distribution itself, as depicted in the left sub-figure of

Figure 9, exhibits strong local variations throughout the membrane.

2.4. Wheatstone Bridge Readout Options

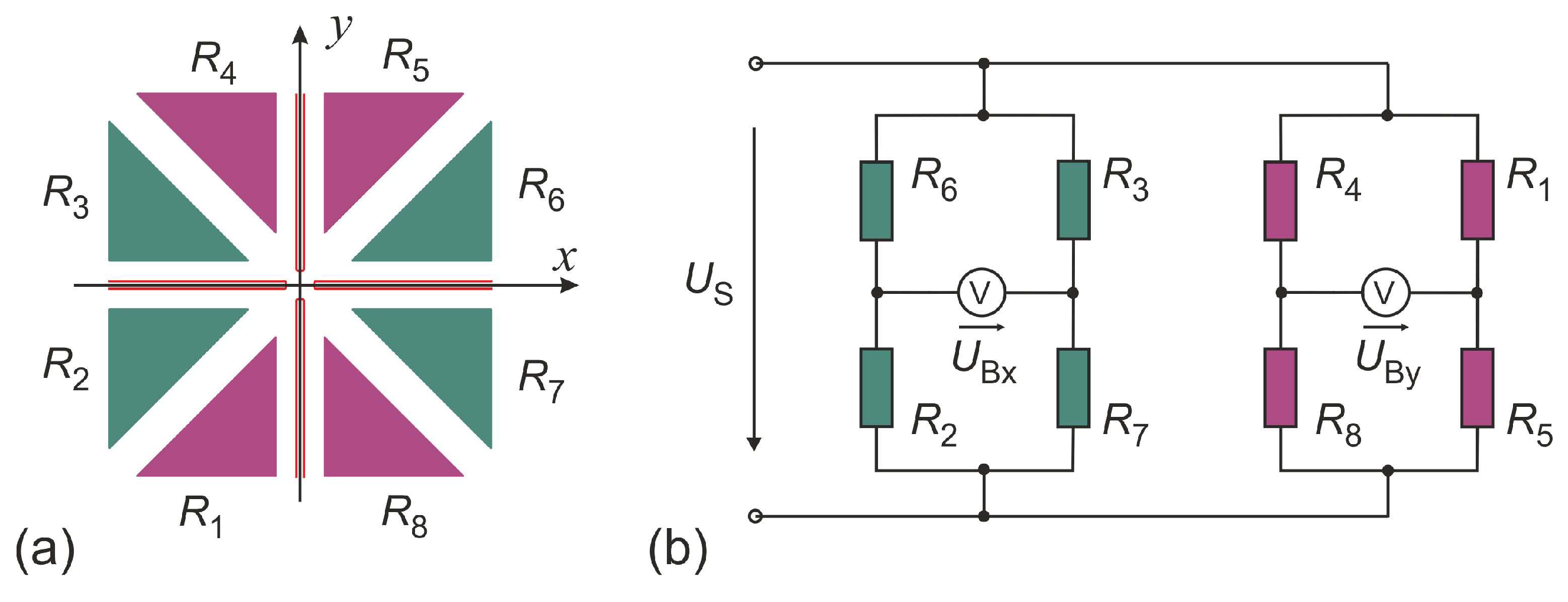

The eight thermistors of the design depicted in

Figure 7 (confer also

Figure 5a, where the thermistors are denoted as

R1–

R8) enable four distinct connection schemes for orthogonal pairs of Wheatstone bridges.

The

Table 2 notation for the “wide” bridge configuration and pronounced

sensitivity, for example, translates into

for the bridge detuning voltage.

An alternative operational mode that is exclusively based on the self-heating operation of the membrane thermistors supplies a controlled current

to the thermistor bridges. In this case the equivalent to Equation (5a) reads

Depending on the simulated characteristics of thermistor resistances versus flow direction depicted in

Figure 8, directional diagrams of the flow transduction can be computed for all four bridge alternatives. A closer inspection of eight distinct variants of Equation (5a) reveals that at least for small variations of the thermistor temperatures the denominator has negligible influence on the directional characteristic whereas the numerator constitutes a sensitive measure of any resistance variation that is asymmetric with respect to the membrane center.

Note that in all numerators according to the scheme of Equations (5a) and (5b), only products of a left-skewing with right-skewing resistance characteristics (see

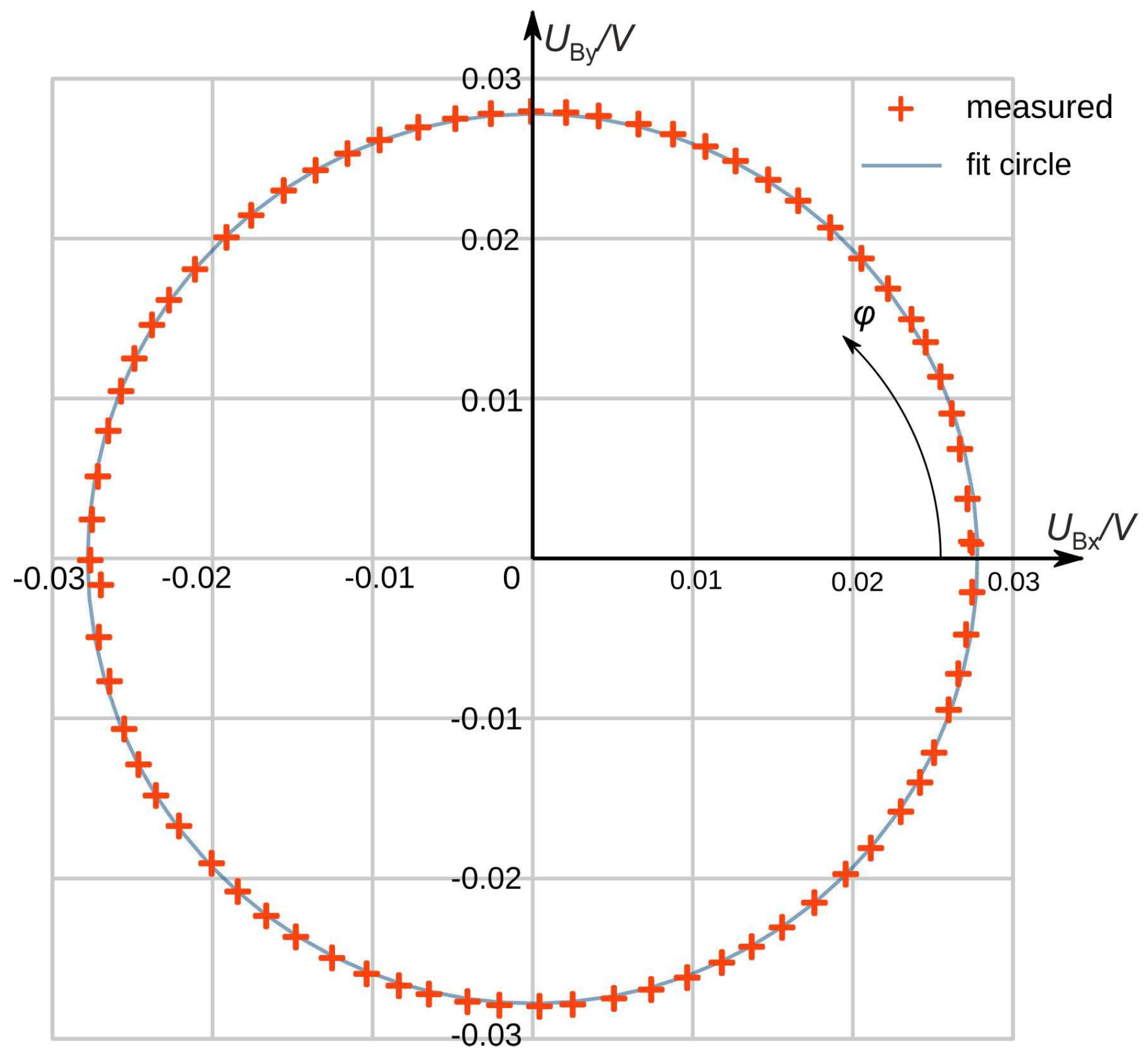

Figure 8) occur. Hence these products are no more skewed with respect to the azimuthal coordinate. The highest dynamic range of a single product can be expected, if the resistance factors are composed from neighboring thermistors on the membrane, i.e., for the “wide” and the “diagonal wide” cases. Furthermore, multiplication of neighboring resistance characteristics promotes a broadening around the product minima and enhance the curvature around the product maxima. Thanks to the thermistor shapes, the bridge detuning signals exhibit much better approximation to sinusoidal azimuth dependencies compared to the azimuthal resistance characteristics of individual membrane thermistors. In fact, this consequence of the Wheatstone bridge readout technique is a mandatory prerequisite to obtain accurate flow vectors by immediate evaluation of the analytical functions given by Equation (4).

Figure 10 depicts directional diagrams of the flow transduction signals generated from simulated bridge detuning signals of four distinct combinations of two perpendicular Wheatstone bridges. They reveal the strong dependency of the output signals on the involved combination of thermistor locations on the membrane. The azimuth angles of the diagrams refer to the flow velocity azimuth

φ where

φ = 0 coincides with the

x-axis of

Figure 7. To highlight the influence of the velocity magnitude, directional diagrams for 1 m/s as well as 10 m/s are illustrated in

Figure 10.

Owing to the concurrence of preferential direction and largest distance to the Si frame, the most efficient flow transduction is obtained by the “diagonal wide” configuration. The slightly less sensitive “wide” configuration excels with the most uniform conversion of the flow magnitude with respect to the azimuth angle. In contrast to intuition, the magnitude of the voltage vector for the “narrow” configuration is largest for odd multiples of π/4. In this case, constructive contributions by the action of both heater orientations occur, which boosts the flow conversion efficiency. The most intriguing directional characteristic, however, is obtained for the “diagonal narrow” configuration, where occasionally flow direction and voltage vector show opposite azimuthal progress (see

Figure 10b). Obviously, a destructive superposition of contributions of the two orthogonal heater branches occurs.

All simulated flow transduction signals are sub-linear functions of the mean fluid velocity in the flow channel of the model. However, the saturation of flow transduction is most pronounced for the “diagonal narrow” and the “wide” bridge configuration as revealed by the comparison of

Figure 10a,b.

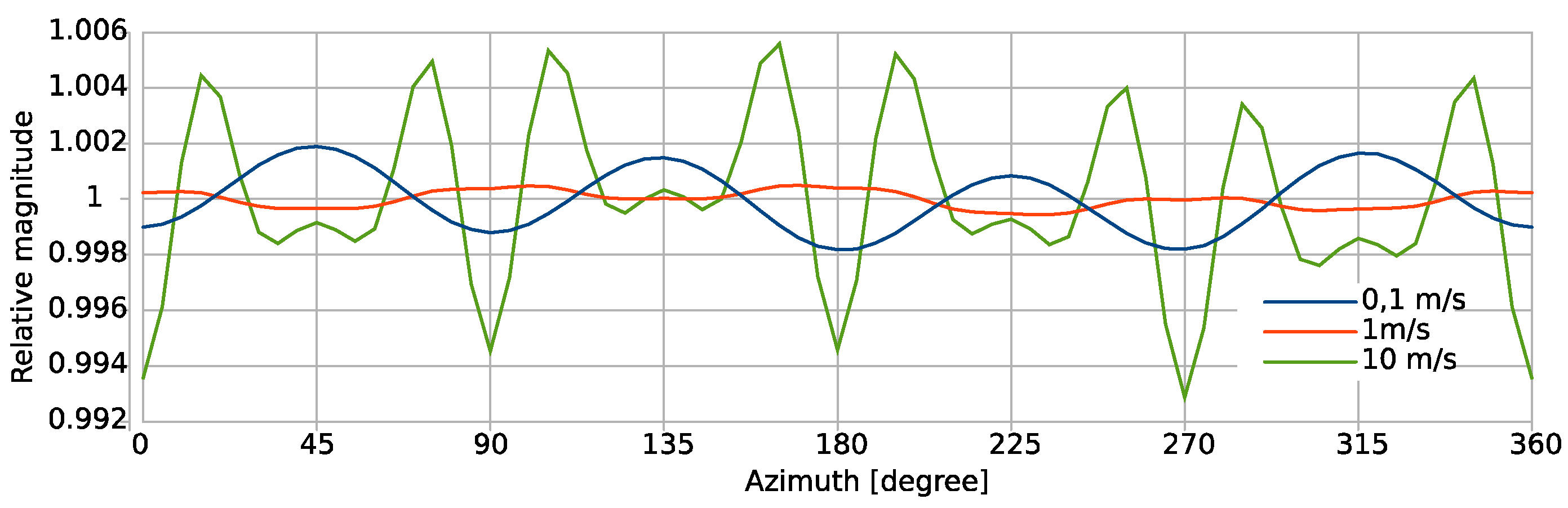

Only the “wide” configuration of the Wheatstone bridge delivers a directional characteristic that promises a uniform transduction of the flow velocity magnitude without the need for extensive post processing of the magnitude output. The following results refer always to this configuration.

Figure 11 presents the uniformity of the computed magnitude conversion as a function of the flow direction. The relative signal magnitude of this configuration is within an interval of 1 ± 0.006 for all flow angles and magnitudes. Remarkably, the magnitude variation for 1 m/s is smaller than that of 0.1 m/s. In case of the smallest flow rate, the magnitude variation closely approximates a −cos(4

φ) dependence. All traces contain such variations with a period of π/2 or 90 degrees. This is a consequence of the period of π for each Wheatstone bridge arrangement and the π/2 rotation between the two orthogonally oriented bridges employed for flow magnitude and azimuth transduction. Although the quantitative effect of strong convection on the transduction uniformity seems very moderate, the qualitative dependence on the azimuth angle becomes quite different due to the emergence of higher harmonics. This behavior demonstrates the complex interdependences between design and strong convective heat transfer. At the highest flow rate, the strongest variation of magnitude conversion is seen for flow directions close to the ±

x and ±

y axes.

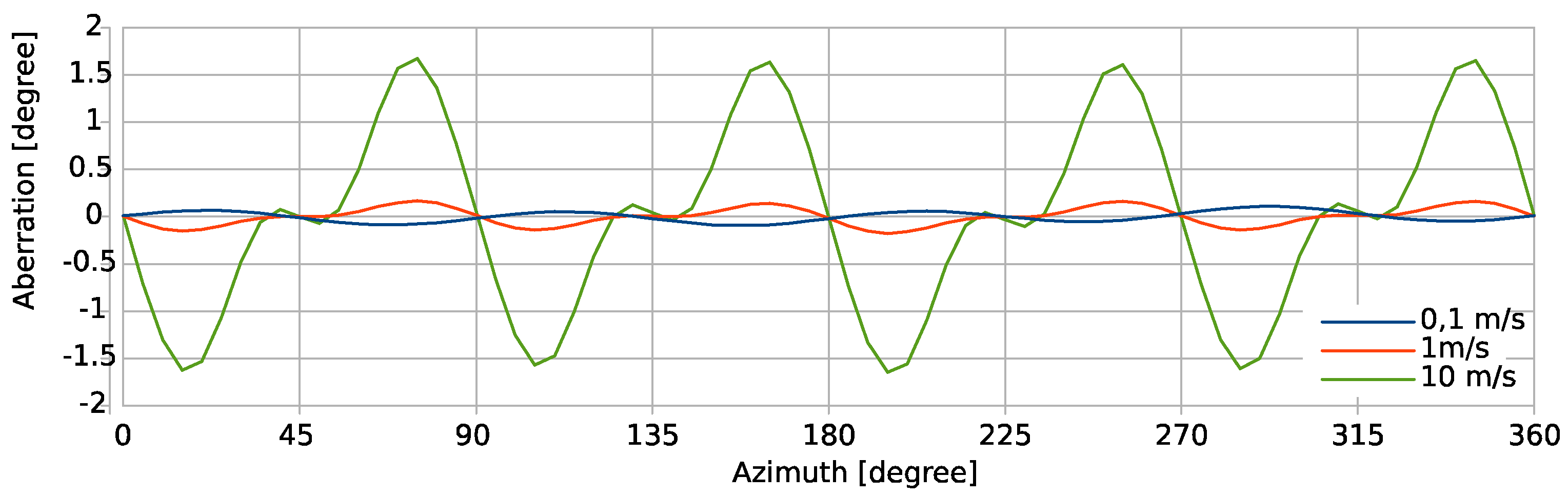

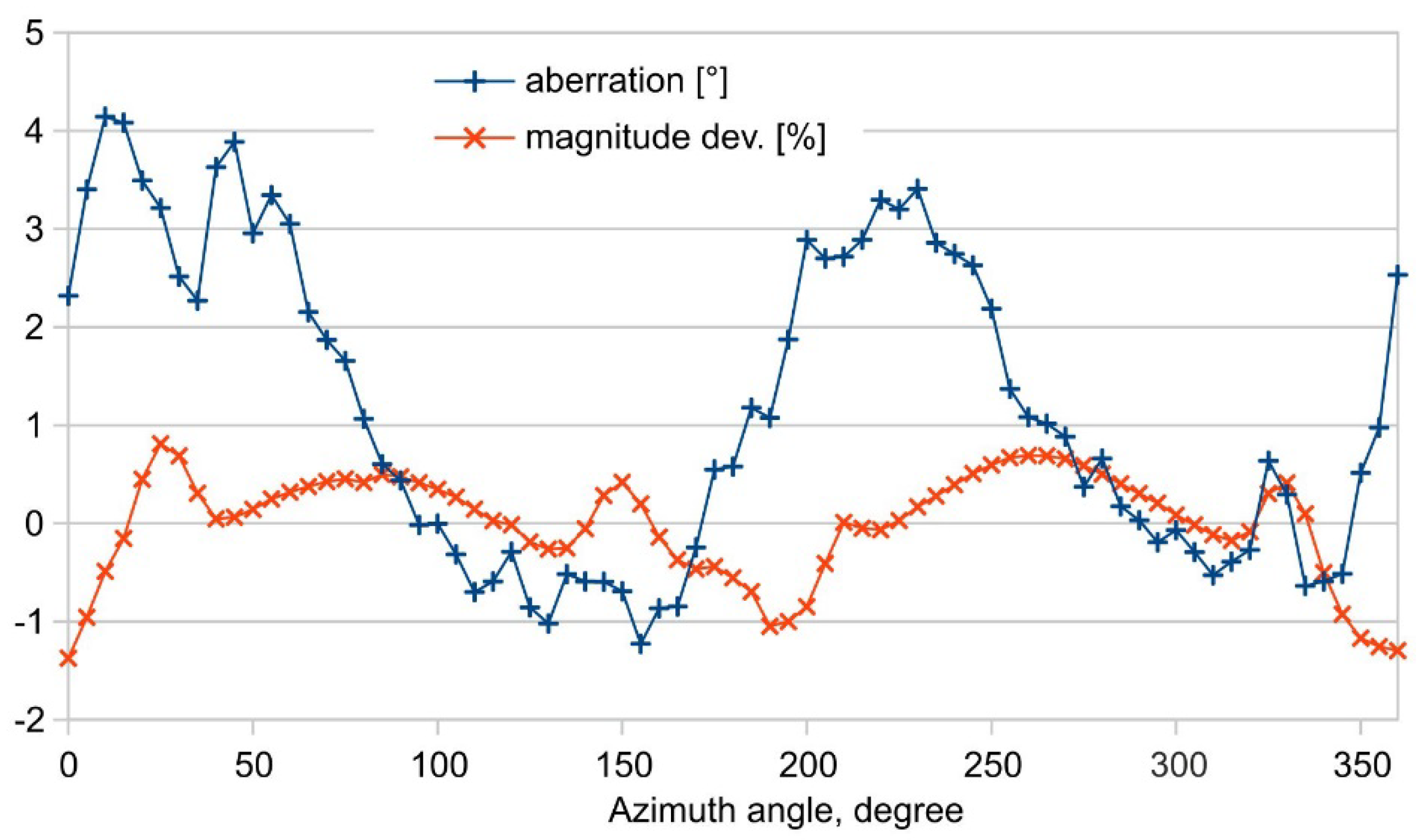

The markers on the curves in

Figure 10 indicate uniform increments of the rotation angle of the flow direction by five degree each. The stronger the flexion of the directional characteristic, the tighter the marker positions. Therefore, the direction of the 2D vectors composed of the detuning signals of orthogonal thermistors bridges do not coincide perfectly with the respective flow direction.

Figure 12 highlights the azimuthal deviation between the actual flow direction and the azimuth angle computed from simulated transducer signals for the preferable “wide” bridge configuration. The diagram reveals that the aberration changes its sign between 0.1 m/s and 1 m/s. Beyond 1 m/s the aberration grows drastically when the flow velocity is increased.

The azimuth deviation is largest for the highest flow rate with peak values of about ±1.5 degree located about ±15 degrees from the coordinate axes. All traces show a variation period of π/2. The trace for a mean flow velocity of 0.1 m/s is the smallest and approximates a sin(4φ) azimuthal dependence very well.

Just for reference, the computed peak-to-peak azimuth and magnitude deviation of the “narrow” configuration of Wheatstone bridges amounted to 12 degrees and 20%, respectively, at a flow velocity of 1 m/s.

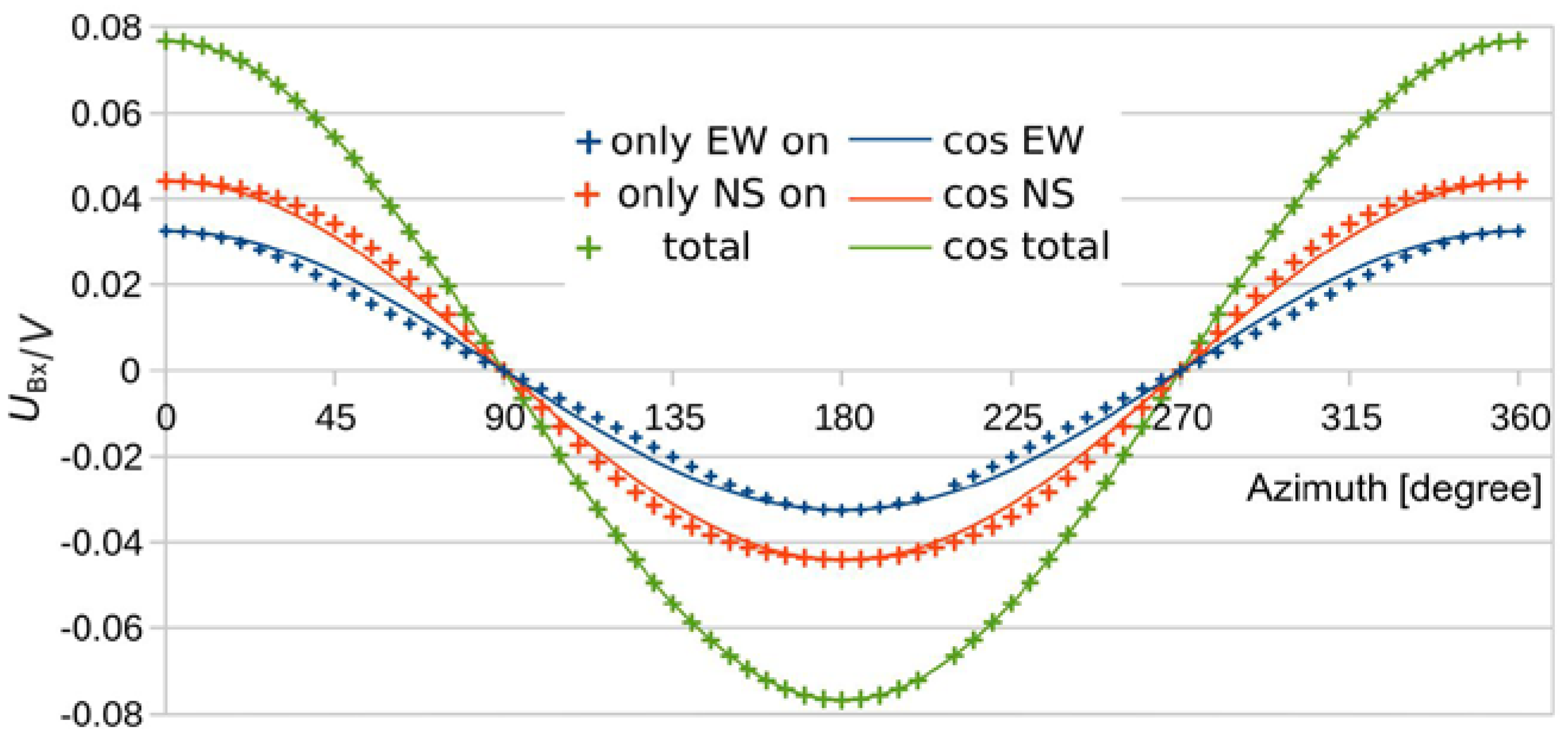

Figure 13 shows simulated bridge detuning voltage

UBx for three heater configurations, i.e., (i) all four heating resistors operated (total), (ii) the two heaters extended in

x direction are heated exclusively (only_EW_on), and (iii) only the heaters extended in

y direction are operated (only_NS_on). Each characteristic is displayed together with respective fits with cosine functions. The flow magnitude conversion induced by a single pair of heating resistors exhibits marked deviations from the wanted sinusoidal azimuth dependence, as

Figure 13 illustrates. However, the different partial heater operations cause opposite signal deviations from ideal cosine characteristics. As these contributions are superimposed to the total signal, a nearly perfect compensation of conversion errors takes place. Thus, the excellent uniformity of the flow magnitude conversion envisioned in

Figure 11 turned out to be a beneficial coincidence. Hence the action of all four heating resistors is required to achieve bridge detuning signals that deliver a nearly perfect magnitude uniformity over the full azimuthal range.

The nearly perfect sinusoidal azimuthal dependency of the total

signal together with the

rotational symmetry of the membrane layout enables the evaluation of the transducer signals from the expressions