Alternative Calibration of Cup Anemometers: A Way to Reduce the Uncertainty of Wind Power Density Estimation

Abstract

1. Introduction

2. Materials and Methods

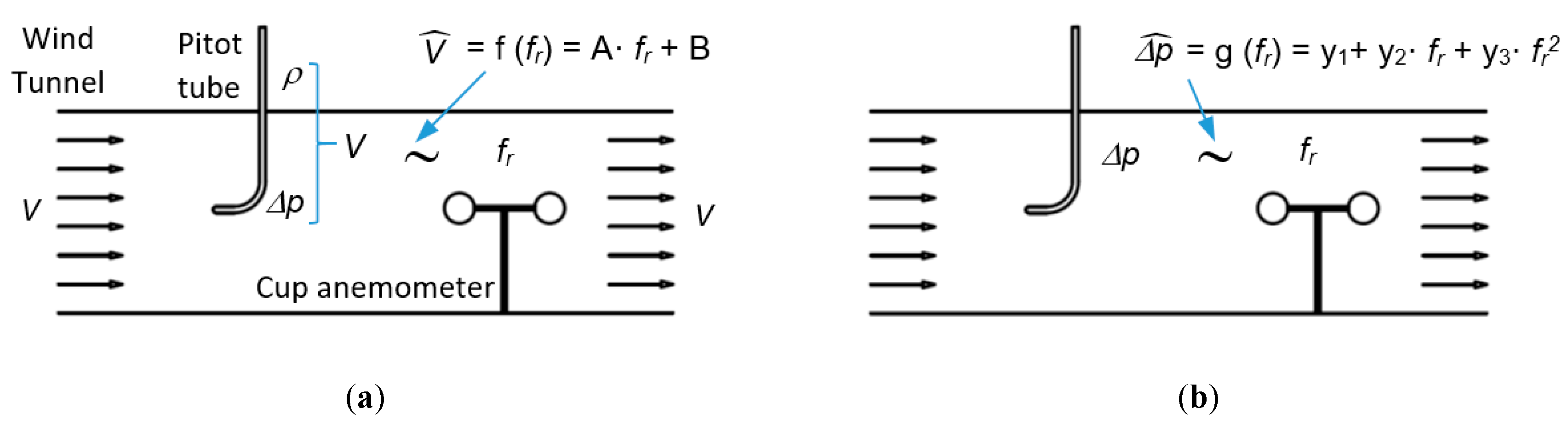

2.1. Experimental Set-up and Measurement Strategy

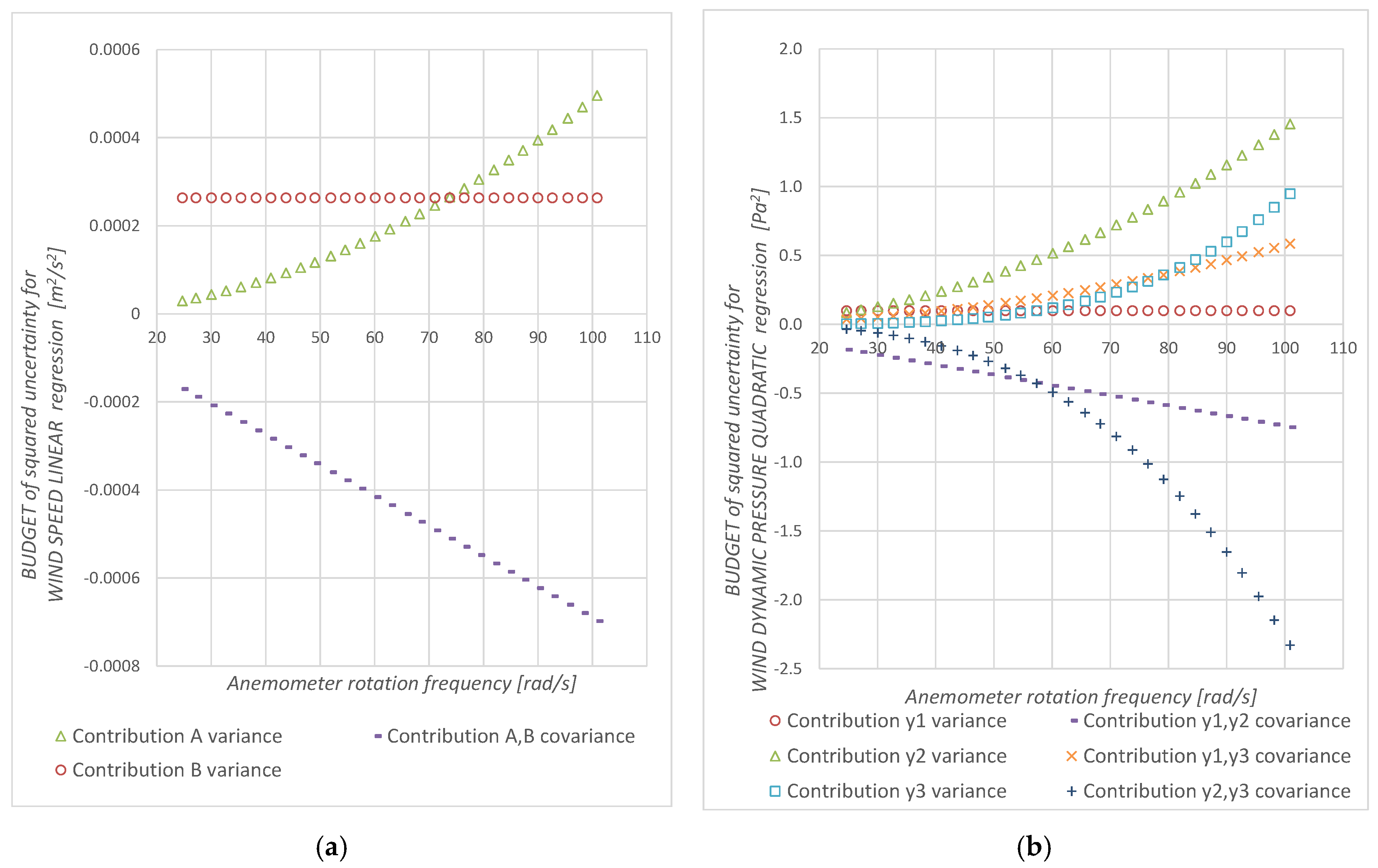

2.2. Quadratic Regression Uncertainty

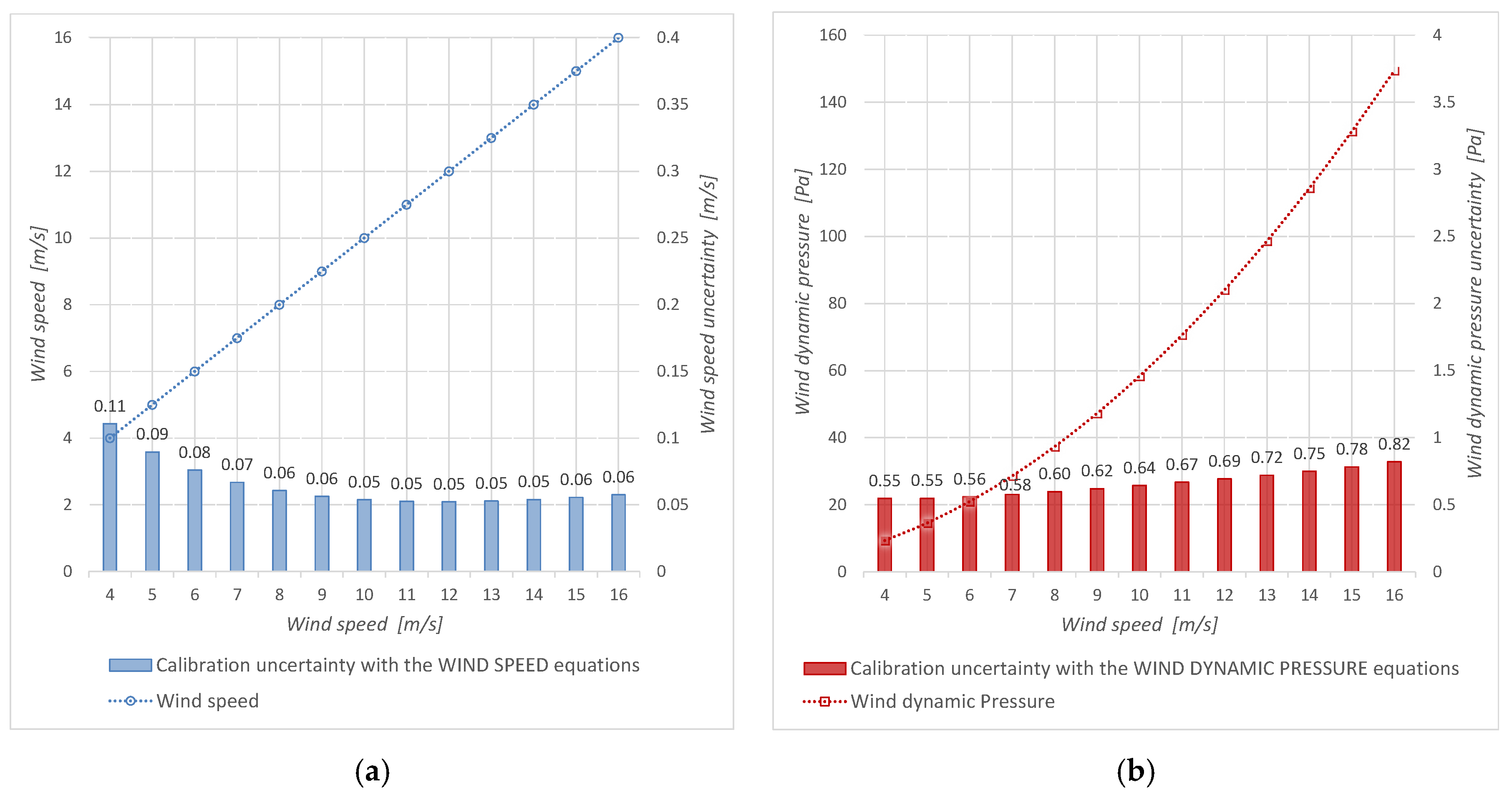

2.3. Wind Speed and Dynamic Pressure Uncertainty

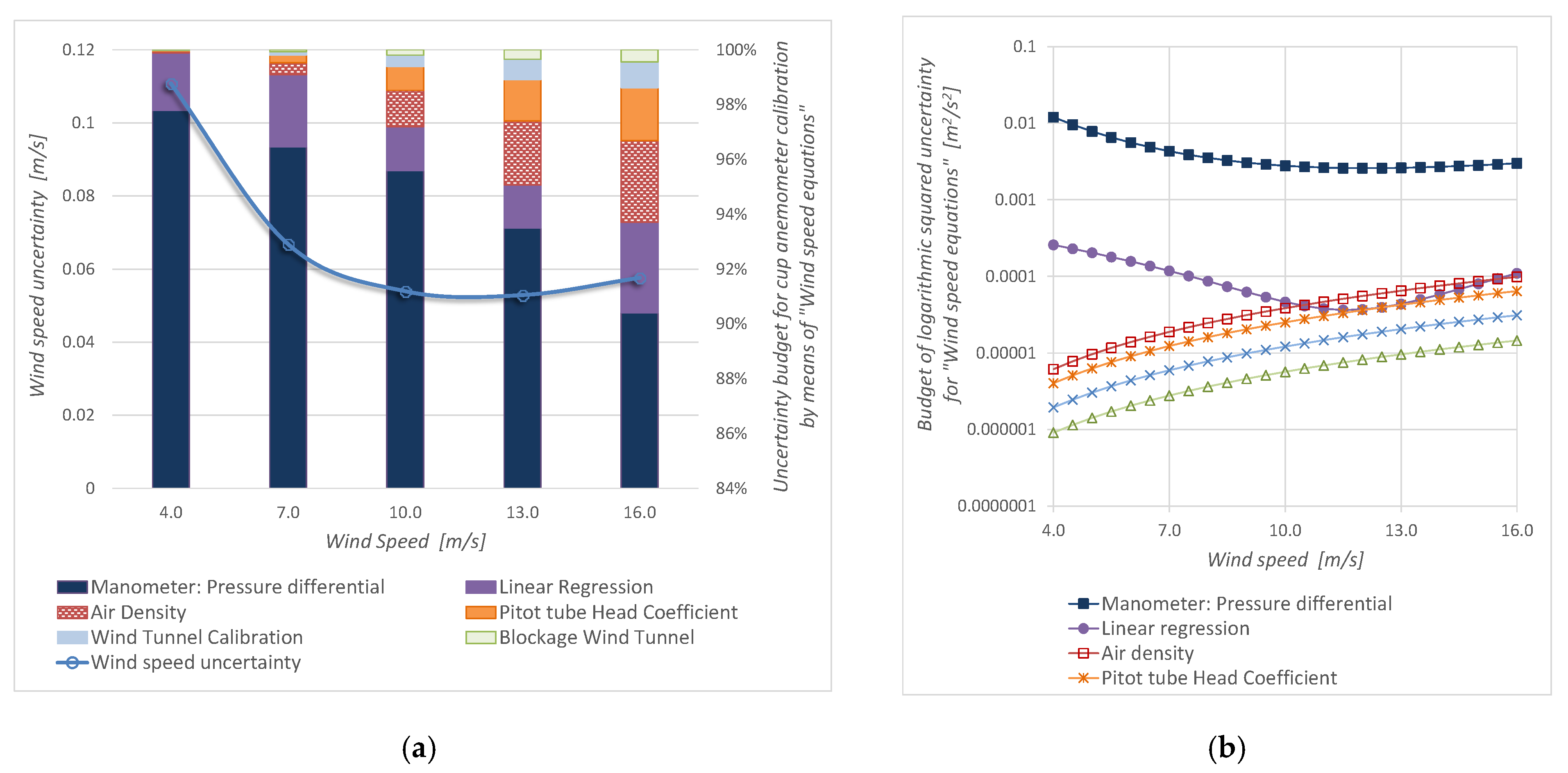

2.4. Wind Power Density Uncertainty

3. Results and Discussion

3.1. Cup Anemometer Regression: Quadratic vs Linear

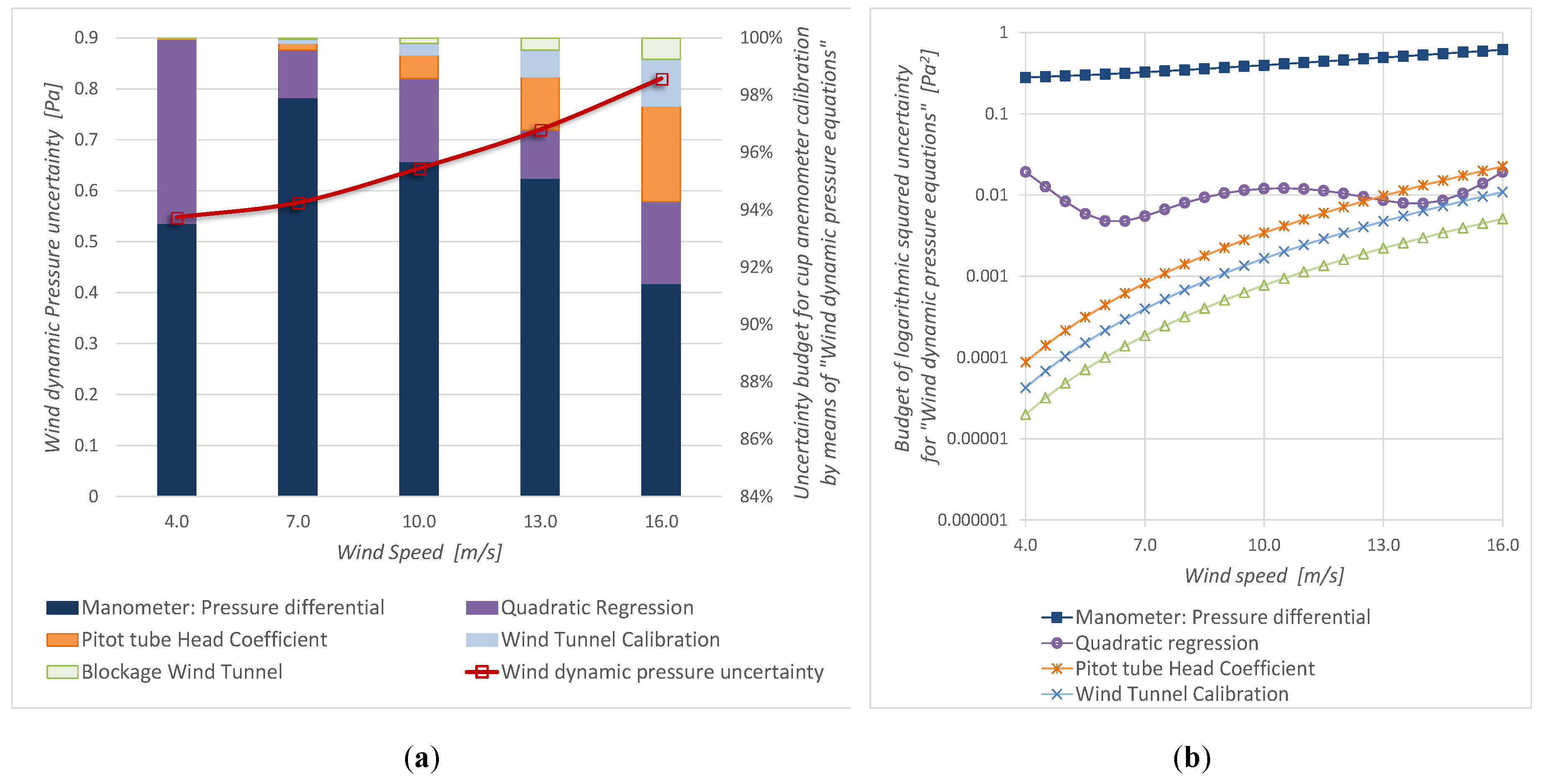

3.2. Wind Dynamic Pressure and Wind Speed Uncertainty

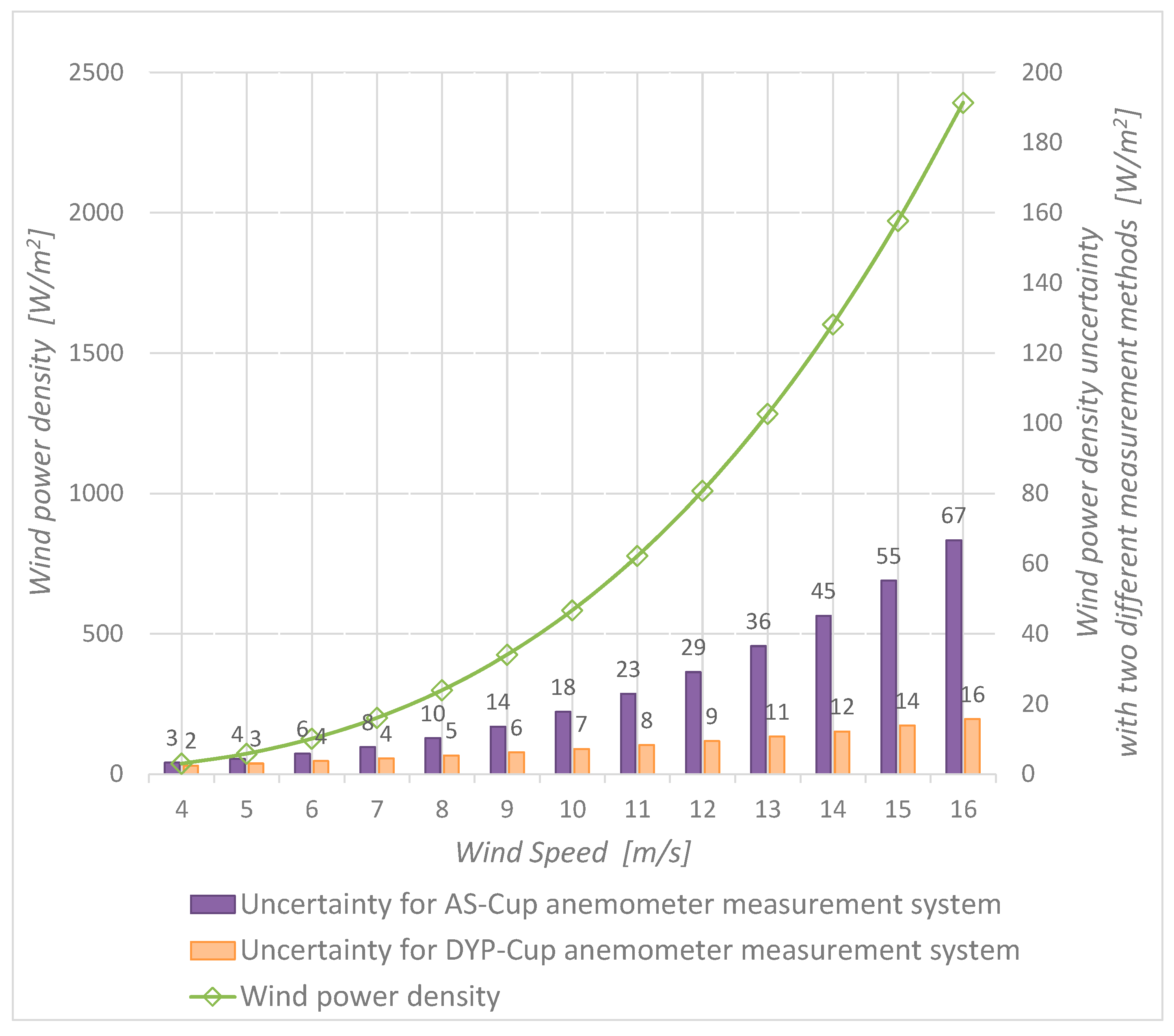

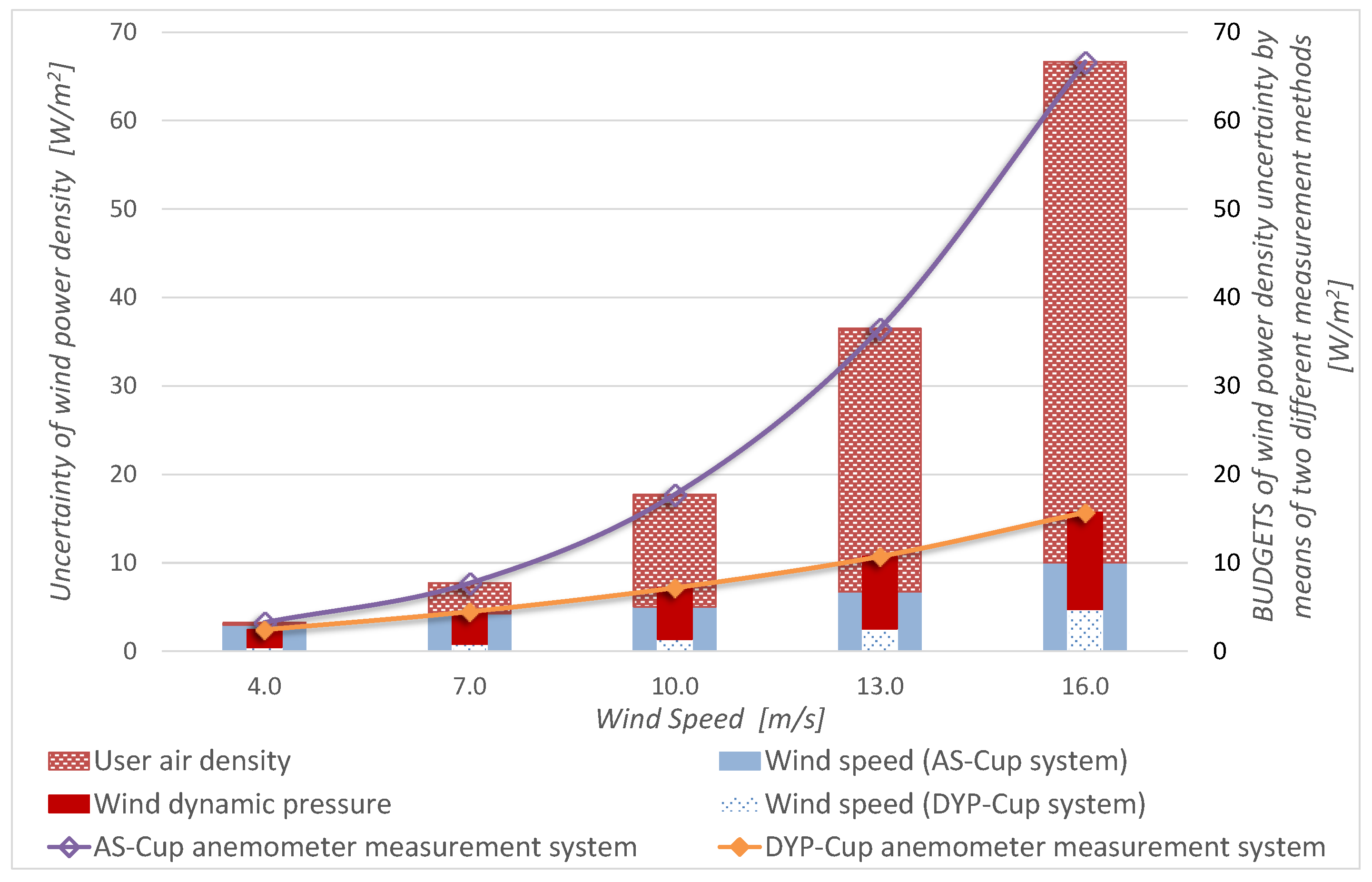

3.3. Power Density Uncertainty: Alternative and Conventional Procedures

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Slope for linear regression [m] | |

| Factor depending on the shape of the structure within the wind tunnel | |

| Intercept or offset for linear regression [m/s] | |

| Blockage ratio | |

| Force coefficient of the structure within the wind tunnel | |

| Pitot tube head coefficient | |

| Power coefficient | |

| Anemometer rotation frequency [rad/s] | |

| Wind tunnel calibration factor | |

| Blockage correction factor | |

| Number of measurements of for each operating condition | |

| Number of measurements of for each operating condition | |

| Air molar mass [kg/mol] | |

| Water vapour molar mass [kg/mol] | |

| Total number of operating conditions | |

| Electrical power [W] | |

| Barometric pressure [Pa] | |

| Static pressure fluid flow [Pa] | |

| Total pressure fluid flow [Pa] | |

| Saturated vapour pressure [Pa] | |

| Wind power density [W/m2] | |

| Ideal gas constant [J/(mol·K)] | |

| Correlation coefficient | |

| Coefficient of determination | |

| S | Blade swept area [m2] |

| Absolute dry bulb temperature [K] | |

| Tv | Absolute wet bulb temperature [K] |

| Standard uncertainty | |

| Combined standard uncertainty | |

| Wind speed [m/s] | |

| Wind speed predicted via linear regression [m/s] | |

| Mean flow field velocity inside wind tunnel, with blockage effect [m/s] | |

| Wind speed determined by the Pitot tube [m/s] | |

| the first variable change to assess the quadratic regression uncertainty [Pa] | |

| the second variable change to assess the quadratic regression uncertainty [Pa/s] | |

| the third variable change to assess the quadratic regression uncertainty [Pa/s2] | |

| Intercept or offset for quadratic regression [Pa] | |

| Slope for quadratic regression [Pa·s] | |

| Curvature for quadratic regression [Pa·s2] | |

| Wind dynamic pressure. Fluid kinetic energy per volume unit [Pa] | |

| Wind dynamic pressure predicted via quadratic regression [Pa] | |

| Wind dynamic pressure function measured with the Pitot tube at the reference position [Pa] | |

| Wind dynamic pressure determined by the Pitot tube [Pa] | |

| Moist air density [kg/m3] | |

| Relative humidity | |

| and | Ferrel coefficients |

References

- Robinson, T. On a New Anemometer. Proc. R. Ir. Acad. (1836–1869) 1847, 4, 566–572. [Google Scholar]

- Fergusson, S. Harvard Meteorological Studies No. 4. Experimental Studies of Cup Anemometers; Harvard University Press: Cambridge, MA, USA, 1939. [Google Scholar]

- Kristensen, L. Cup anemometer behavior in turbulent environments. J. Atmos. Ocean. Technol. 1998, 15, 5–17. [Google Scholar] [CrossRef]

- Pindado, S.; Ramos-Cenzano, A.; Cubas, J. Improved analytical method to study the cup anemometer performance. Meas. Sci. Technol. 2015, 26, 107001. [Google Scholar] [CrossRef]

- Roibas-Millan, E.; Cubas, J.; Pindado, S. Studies on cup anemometer performances carried out at idr/upm institute. past and present research. Energies 2017, 10, 1860. [Google Scholar] [CrossRef]

- Jin, Y.; Ju, P.; Rehtanz, C.; Wu, F.; Pan, X. Equivalent modeling of wind energy conversion considering overall effect of pitch angle controllers in wind farm. Appl. Energy 2018, 222, 485–496. [Google Scholar] [CrossRef]

- Sedaghat, A.; Hassanzadeh, A.; Jamali, J.; Mostafaeipour, A.; Chen, W.-H. Determination of rated wind speed for maximum annual energy production of variable speed wind turbines. Appl. Energy 2017, 205, 781–789. [Google Scholar] [CrossRef]

- St Martin, C.M.; Lundquist, J.K.; Clifton, A.; Poulos, G.S.; Schreck, S.J. Wind turbine power production and annual energy production depend on atmospheric stability and turbulence. Wind Energy Sci. (Online) 2016, 1, NREL/JA-5D00-66360. [Google Scholar]

- Commission, I.E. IEC 61400-12-1: 2017, Wind Energy Generation Systems—part 12-1: Power Performance Measurements of Electricity Producing Wind Turbines; European Committee for Electrotechnical Standardization: Brussels, Belgium, 2017. [Google Scholar]

- Assessment, G.E. Global Energy Assessment—toward a Sustainable Future; Cambridge University Press and the International Institute for Applied Systems Analysis: Cambridge, UK; Laxenburg, Austria, 2012. [Google Scholar]

- Pindado, S.; Vega, E.; Martínez, A.; Meseguer, E.; Franchini, S.; Sarasola, I.P. Analysis of calibration results from cup and propeller anemometers. Influence on wind turbine Annual Energy Production (AEP) calculations. Wind Energy 2011, 14, 119–132. [Google Scholar]

- Pindado, S.; Cubas, J.; Sorribes-Palmer, F. The cup anemometer, a fundamental meteorological instrument for the wind energy industry. Research at the IDR/UPM Institute. Sensors 2014, 14, 21418–21452. [Google Scholar] [PubMed]

- MEASNET. Anemometer Calibration Procedure; Version 2; Measuring Network of Wind Energy Institutes: Madrid, Spain, 2009. [Google Scholar]

- Terao, Y.; van der Beek, M.; Yeh, T.T.; Müller, H. Final report on the CIPM air speed key comparison (CCM. FF-K3). Metrologia 2007, 44, 1–20. [Google Scholar]

- Ghaemi-Nasab, M.; Franchini, S.; Davari, A.R.; Sorribes-Palmer, F. A procedure for calibrating the spinning ultrasonic wind sensors. Measurement 2018, 114, 365–371. [Google Scholar] [CrossRef]

- Tavoularis, S. Measurement in Fluid Mechanics; Cambridge University Press: New York, NY, USA, 2005. [Google Scholar]

- Pindado, S.; Pérez, J.; Avila-Sanchez, S. On cup anemometer rotor aerodynamics. Sensors 2012, 12, 6198–6217. [Google Scholar] [CrossRef] [PubMed]

- Anderson, J.D. Fundamentals of Aerodynamics; McGraw-Hill Education: New York, NY, USA, 2016. [Google Scholar]

- Kristensen, L.; Jensen, G.; Hansen, A.; Kirkegaard, P. Field Calibration of Cup Anemometers; Risø National Laboratory: Roskilde, Denmark, 2001. [Google Scholar]

- Aquila, G.; Peruchi, R.S.; Junior, P.R.; Rocha, L.C.S.; de Queiroz, A.R.; de Oliveira Pamplona, E.; Balestrassi, P.P. Analysis of the wind average speed in different Brazilian states using the nested GR&R measurement system. Measurement 2018, 115, 217–222. [Google Scholar]

- Ligęza, P. Model and Simulation Studies of the Method for Optimization of Dynamic Properties of Tachometric Anemometers. Sensors 2018, 18, 2677. [Google Scholar] [CrossRef] [PubMed]

- Díaz, S.; Carta, J.A.; Matías, J.M. Performance assessment of five MCP models proposed for the estimation of long-term wind turbine power outputs at a target site using three machine learning techniques. Appl. Energy 2018, 209, 455–477. [Google Scholar] [CrossRef]

- MATRAS Atmosphere & Solar Radiation Modeling Group. Meteorological Station Database. Available online: http://www.ujaen.es/dep/fisica/estacion/estacion3.htm (accessed on 18 April 2019).

- Vidal-Pardo, A.; Pindado, S. Design and Development of a 5-Channel Arduino-Based Data Acquisition System (ABDAS) for Experimental Aerodynamics Research. Sensors 2018, 18, 2382. [Google Scholar] [CrossRef] [PubMed]

- ISO-3966:2008 Measurement of Fluid Flow in Closed Conduits-Velocity Area Method Using Pitot Static Tubes; The International Organization for Standardization: Geneva, Switzerland, 2008.

- Hansen, O.; Hansen, S.; Kristensen, L. Wind tunnel calibration of cup anemometers. In Proceedings of the AWEA Wind Power Conference, Atlanta, GA, USA, 3–6 June 2012; pp. 1–22. [Google Scholar]

- Barlow, J.B.; Rae, W.; Pope, A. Low-Speed Wind Tunnel Testing; John Wiley & Sons: New York, NY, USA, 2015. [Google Scholar]

- Ilić, B.; Miloš, M.; Isaković, J. Cascade nonlinear feedforward-feedback control of stagnation pressure in a supersonic blowdown wind tunnel. Measurement 2017, 95, 424–438. [Google Scholar] [CrossRef]

- GUM, I. Guide to the Expression of Uncertainty in Measurement, (1995), with Supplement 1, Evaluation of measurement data, JCGM 101: 2008; Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- Hibbert, D.B. The uncertainty of a result from a linear calibration. Analyst 2006, 131, 1273–1278. [Google Scholar] [CrossRef] [PubMed]

- Wexler, A. Humidity and Moisture: Measurement and Control in Science and Industry (volume three): Fundamentals and standards; Reinhold Publishing Corporation: New York, NY, USA, 1965; p. 79. [Google Scholar]

- Picard, A.; Davis, R.; Gläser, M.; Fujii, K. Revised formula for the density of moist air (CIPM-2007). Metrologia 2008, 45, 149. [Google Scholar] [CrossRef]

- Zuckerwar, A.J.; Meredith, R.W. Low-frequency absorption of sound in air. J. Acoust. Soc. Am. 1985, 78, 946–955. [Google Scholar] [CrossRef]

- Ulazia, A.; Gonzalez-Rojí, S.J.; Ibarra-Berastegi, G.; Carreno-Madinabeitia, S.; Sáenz, J.; Nafarrate, A. Seasonal air density variations over the East of Scotland and the consequences for offshore wind energy. In Proceedings of the 7th International Conference on Renewable Energy Research and Applications (ICRERA), Paris, France, 14–17 October 2018; pp. 261–265. [Google Scholar]

- Tindal, A.; Harman, K.; Johnson, C.; Schwarz, A.; Garrad, A.; Hassan, G. Validation of GH energy and uncertainty predictions by comparison to actual production. In Proceedings of the AWEA Wind Resource and Project Energy Assessment Workshop, Portland, OR, USA, 18–19 September 2007. [Google Scholar]

| Parameters | Standard Uncertainty | Sensibility Coefficients: Equation (12) | Sensibility Coefficients: Equation (14) |

|---|---|---|---|

| Blockage correction factor (kf) | |||

| Wind tunnel calibration factor (kc) | |||

| Pitot tube head coefficient (Ch) | |||

| Air density (ρ) | u(ρ) | ||

| Wind Dynamic pressure (Pitot tube) () | |||

| Linear regression (A, B) | - | - | |

| Quadratic regression (y1, y2, y3) | Equation (11) | - | - |

| Parameters | Standard Uncertainty | Sensibility Coefficients: Equation (20) | Sensibility Coefficients: Equation (3) | |

|---|---|---|---|---|

| User air density | ||||

| Wind speed | V | = | ||

| Anemometer dynamic pressure | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guerrero-Villar, F.; Dorado-Vicente, R.; Medina-Sánchez, G.; Torres-Jiménez, E. Alternative Calibration of Cup Anemometers: A Way to Reduce the Uncertainty of Wind Power Density Estimation. Sensors 2019, 19, 2029. https://doi.org/10.3390/s19092029

Guerrero-Villar F, Dorado-Vicente R, Medina-Sánchez G, Torres-Jiménez E. Alternative Calibration of Cup Anemometers: A Way to Reduce the Uncertainty of Wind Power Density Estimation. Sensors. 2019; 19(9):2029. https://doi.org/10.3390/s19092029

Chicago/Turabian StyleGuerrero-Villar, Francisca, Rubén Dorado-Vicente, Gustavo Medina-Sánchez, and Eloísa Torres-Jiménez. 2019. "Alternative Calibration of Cup Anemometers: A Way to Reduce the Uncertainty of Wind Power Density Estimation" Sensors 19, no. 9: 2029. https://doi.org/10.3390/s19092029

APA StyleGuerrero-Villar, F., Dorado-Vicente, R., Medina-Sánchez, G., & Torres-Jiménez, E. (2019). Alternative Calibration of Cup Anemometers: A Way to Reduce the Uncertainty of Wind Power Density Estimation. Sensors, 19(9), 2029. https://doi.org/10.3390/s19092029