1. Introduction

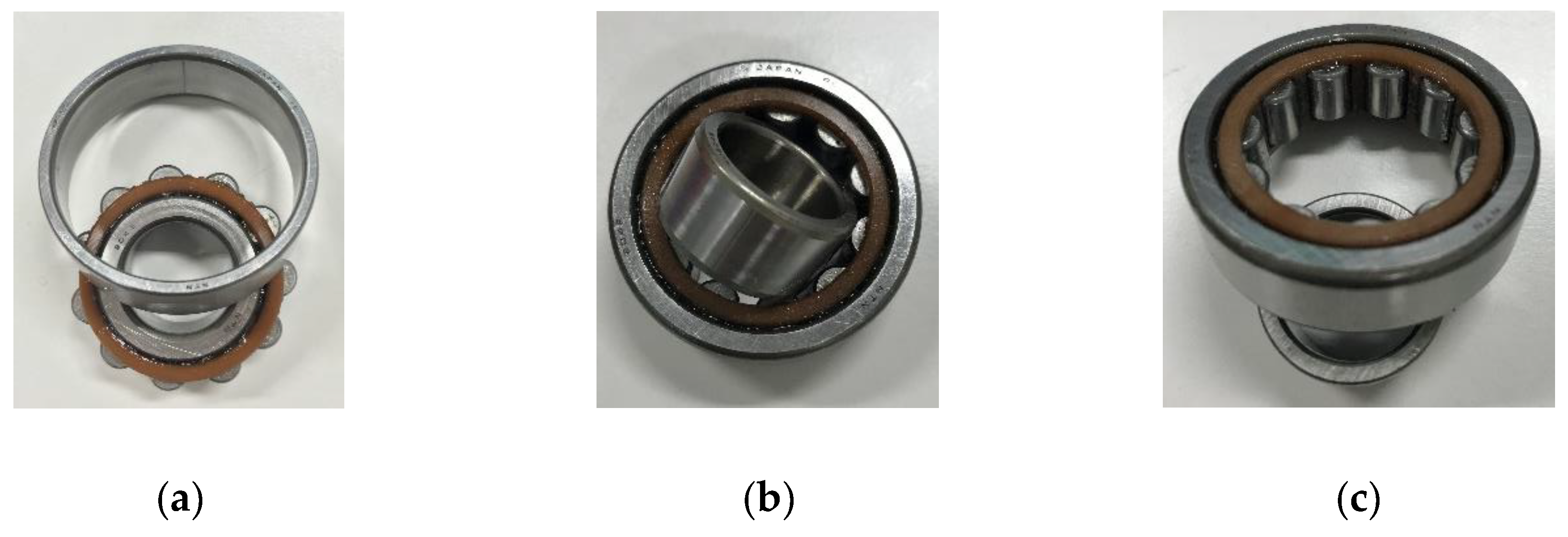

The bearing is the most important component to support the rotating mechanical shafting [

1]. Bearing failures can be classified into initial failures (point injuries caused by local spalling), medium-term failures (large-scale peeling of inner and outer rings), and final failures (fracture of rolling elements and cages) [

2,

3]. The final failure of the bearing often leads to the failure of the rotating shaft and causes a major accident. Therefore, it is very important to effectively detect the bearing failure as soon as possible before the final bearing failure.

After the bearing is damaged, a pulsating vibration occurs due to the rolling element passing through the damage [

4]. This kind of pulsating vibration is the characteristic resonance of the inner or outer ring of the bearing. The frequency of this characteristic resonance is also called the “ringing frequency”. The ringing frequency is generally in the high frequency band, higher than several thousand Hz, depending on the type and Size of bearing [

5]. To detect incipient bearing abnormality by vibration diagnosis, it is important to sense this impulsive vibration wave in the high frequency band and cancel noise by high-pass-filter (HPF) [

6]. Several filter parameters optimization methods have been summarized to extract fault feature from signals of the bearing with incipient fault [

7,

8]. Wang et al. proposed a complex Morlet wavelet filter which parameters are optimized by simplex-simulated annealing [

9]. Jia et al. constructed a high-pass filter based on banded matrices to diagnosis incipient bearing fault efficiency [

10]. A motor fault diagnosis method based on a simple nonlinear observer was proposed, and the effectiveness of the method is confirmed by the experiment with a permanent magnet direct current (DC) motor [

11]. It was evidenced that in the fault diagnosis methods based on principal components analysis(PCA), the number of the principal components to be retained and the data matrix is important which will affect the performance of the algorithm [

12]. Deep Boltzmann machines, deep belief networks and stacked auto-encoders were applied to diagnose the fault of the rolling bearing [

13]. The authors pointed out that feature extraction of the vibration signal is a necessary step for the deep neural networks based (DNN -based) classifiers which can incline the reliability and effectiveness of the fault diagnosis method. The above fault diagnosis methods have certain effects in an off-line diagnosis system. However, when diagnosing bearing faults, if there is a strong noise in the diagnostic signals, such as an early bearing abnormality, or the sensor cannot be placed near the diagnostic object bearing to measure signals, etc., how to extract weaker fault signal from strong noise signal, and how to deal with ambiguous diagnostic information in real plant diagnosis still have many problems to be solved. Furthermore, because when the bearing has an early abnormality (spot injury), it takes a long time (usually several days to several months) to progress to the mid-term anomaly stage (inner and outer ring flaking), so online real-time diagnosis is not required when diagnosing a bearing fault. As long as the fault can be detected after measuring a vibration signal, then the fault type can be identified. Therefore, this paper proposes a method for data training and a fuzzy diagnostic algorithm that can be embedded in the offline bearing diagnostic system.

When identifying the roller bearing anomaly of the field device by the vibration signal, there are the following two problems:

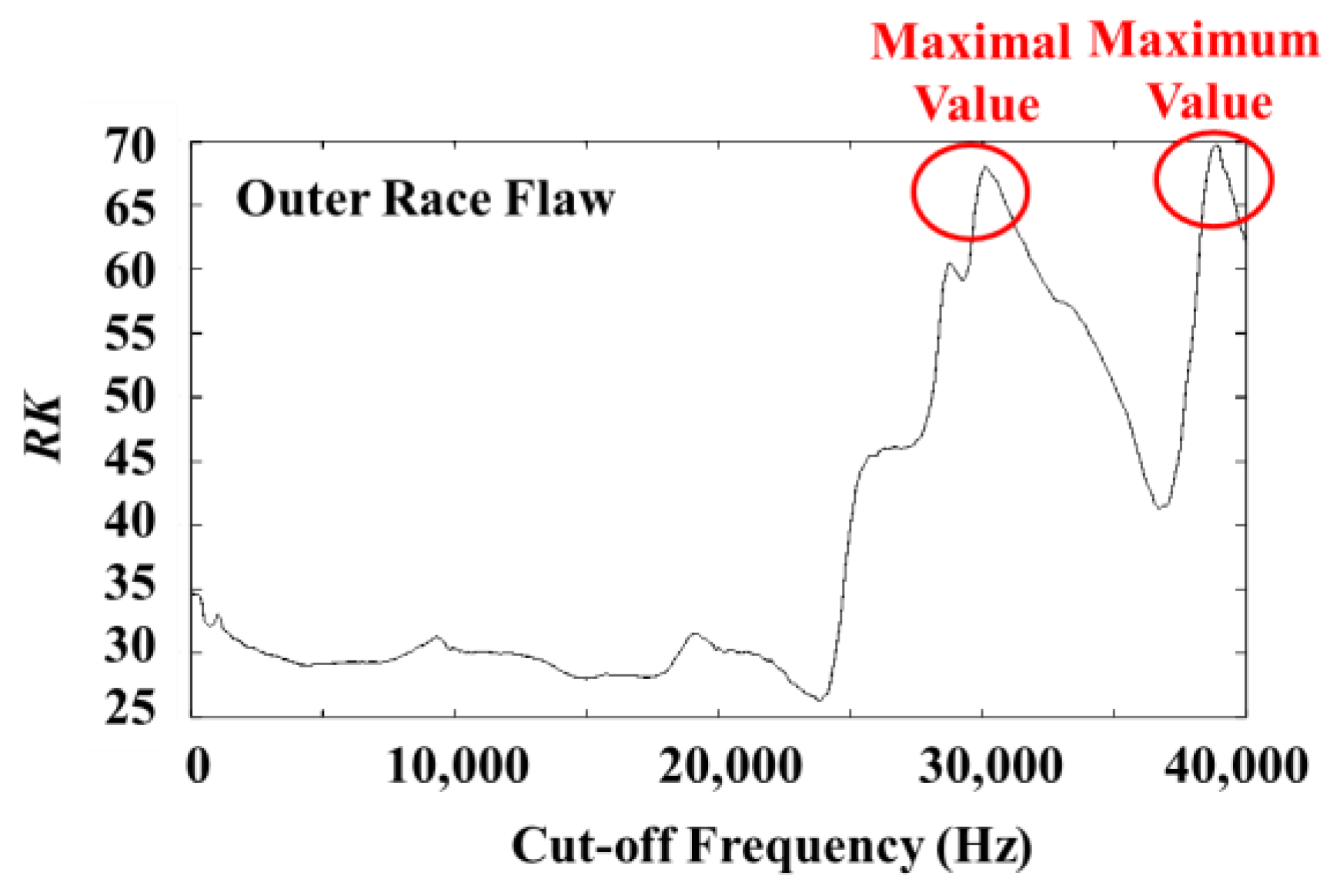

(1) It is needed to decide a cutoff frequency of HPF to extract a fault signal. However, the ideal cutoff frequency is different because the characteristic frequency of inner or outer rings of bearings is different by the type or size of the bearings. Therefore, there is a need to establish a method for automatically determining the optimum cutoff frequency that can be used in a bearing diagnostic system, and the method must have versatility independent on the tested device.

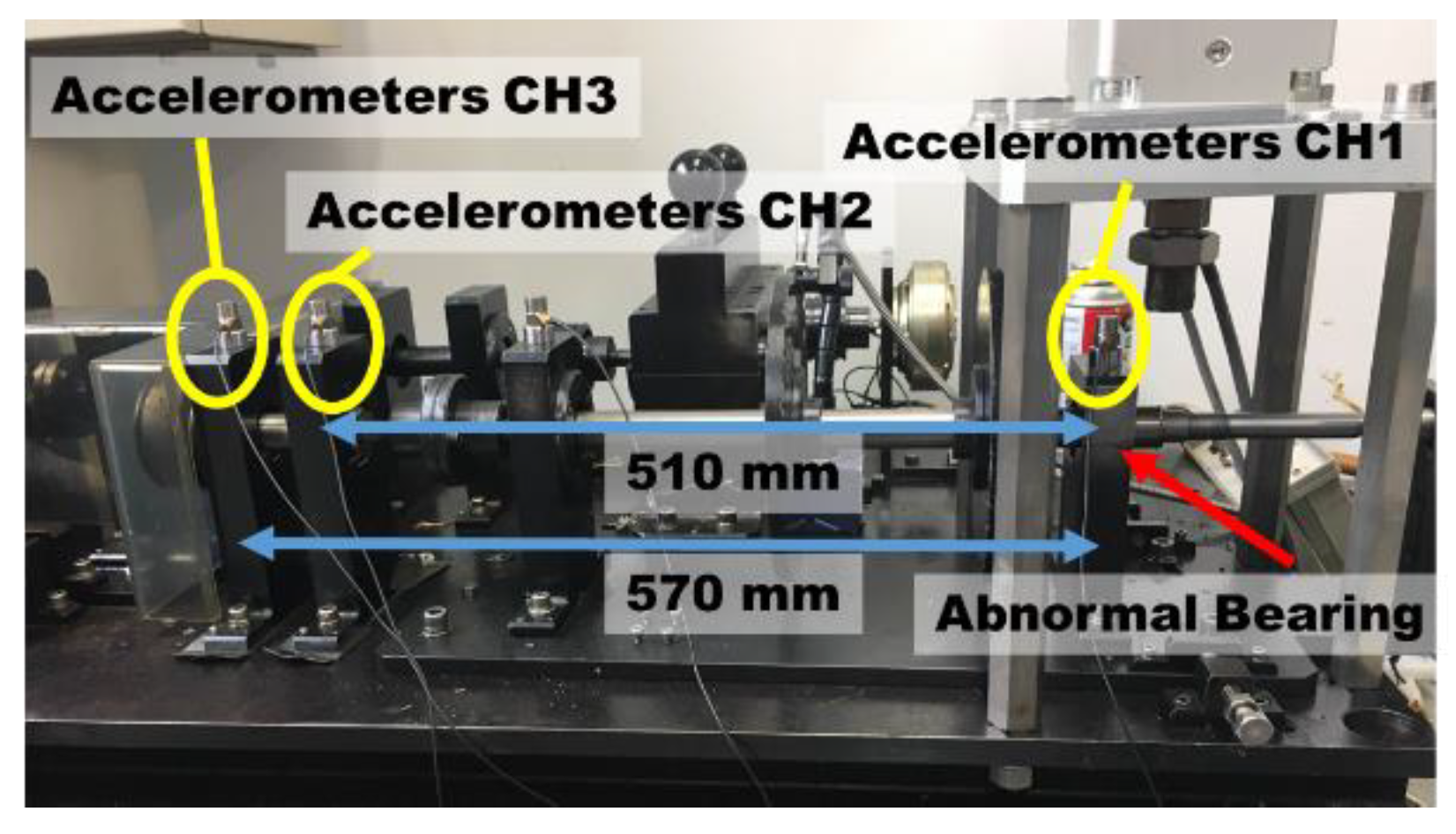

(2) To catch abnormal vibration signals of bearings sensitively, it is necessary to set accelerometers as near to the diagnosed bearings as possible. However, in some field equipment, it is difficult to set accelerometers near the diagnose bearings, the vibration signals can only be measured at a position far from the bearing. Since, in these cases, the measured signals contain stronger noise than the signal measured near the diagnosed bearing, it is more difficult to diagnose the bearing faults.

In this research, to solve the problems described above, novel methods by which bearing faults can be automatically, simply and precisely diagnosed using the signals measured by the acceleration sensors at distant points from the diagnosed bearings was proposed as follows:

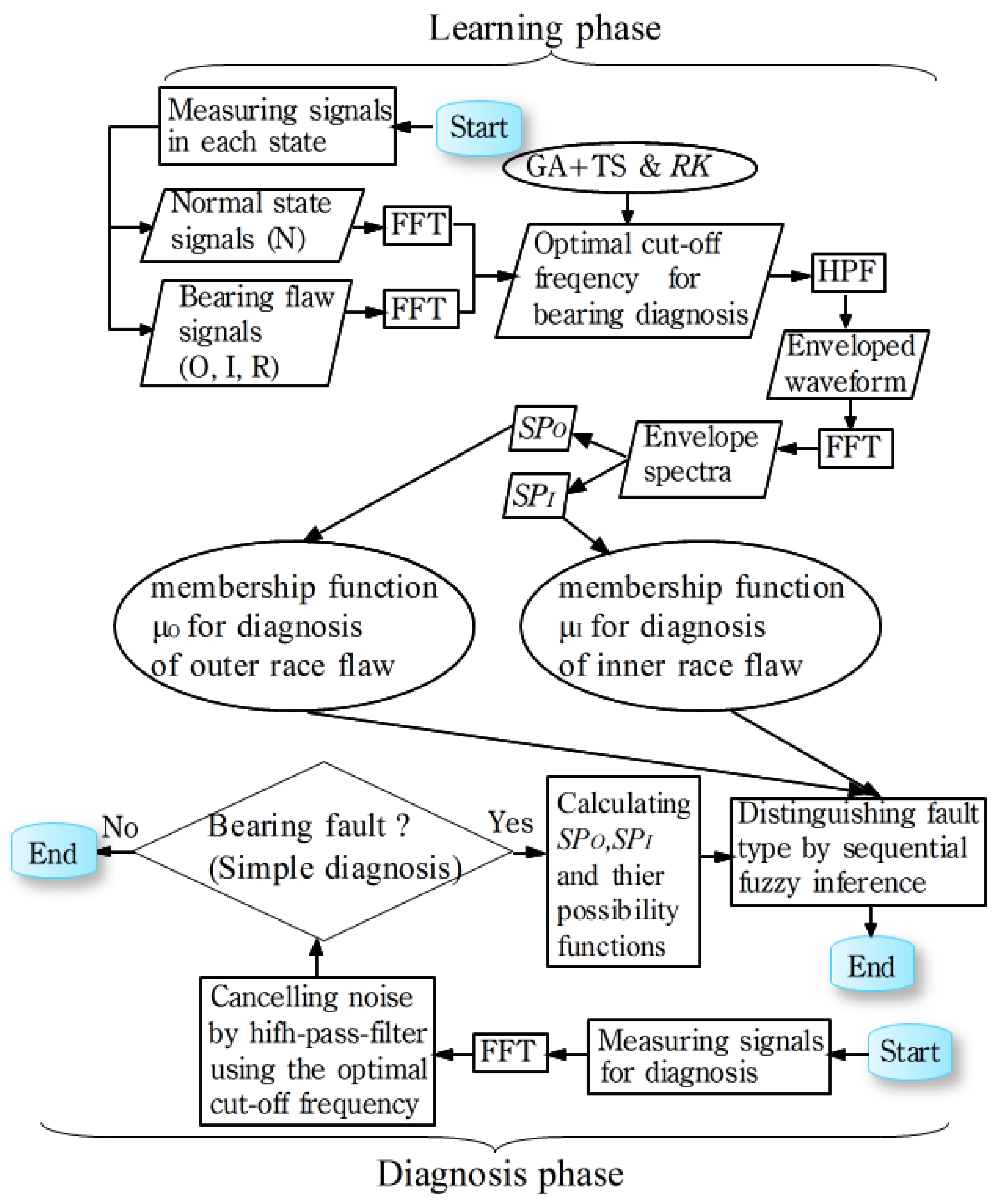

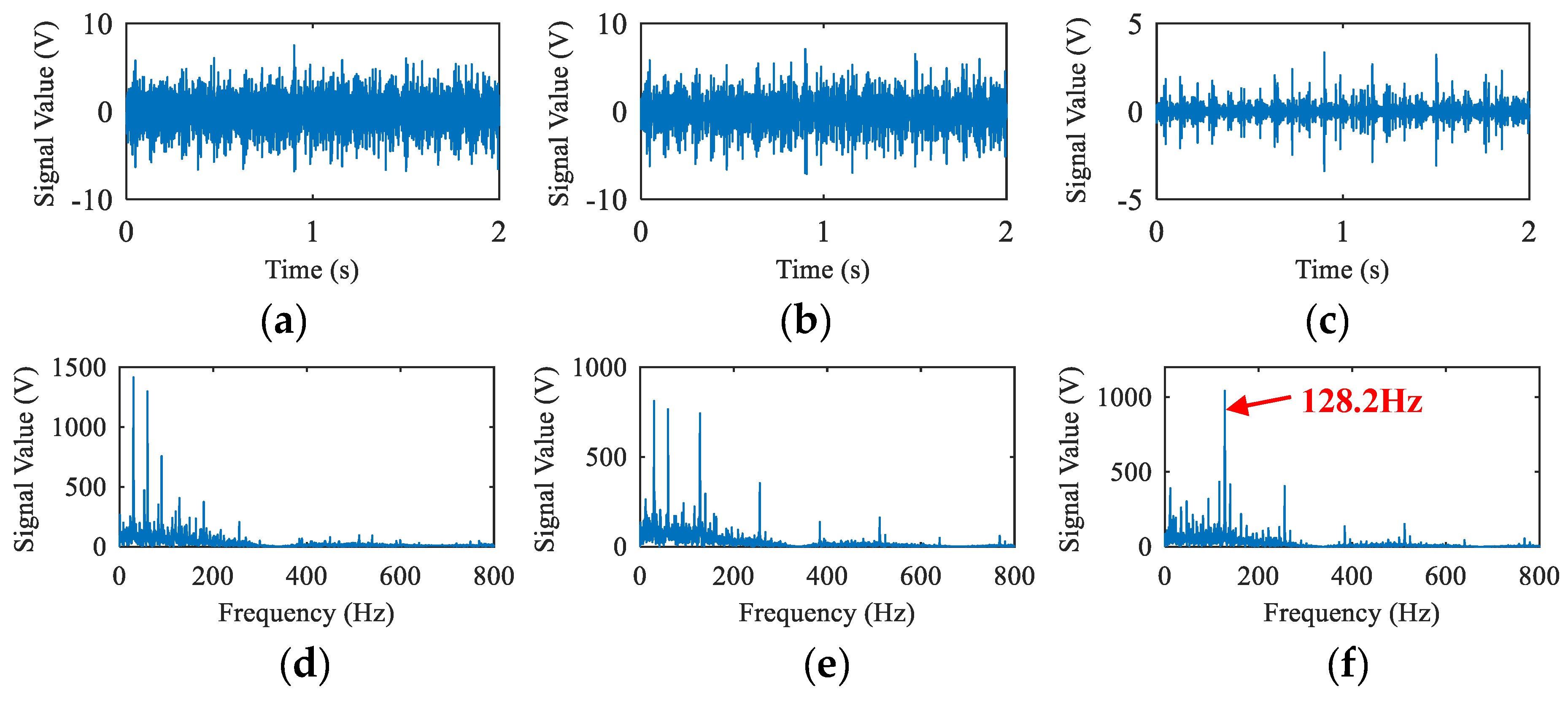

(1) In order to extract the characteristic signal of a fault bearing from the signal measured far from the bearing as sensitively as possible, a method by which the optimal cutoff frequency of HPF is automatically searched and decided by hybrid GA (the combination of genetic algorithm and tabu search, GA+TS) is proposed.

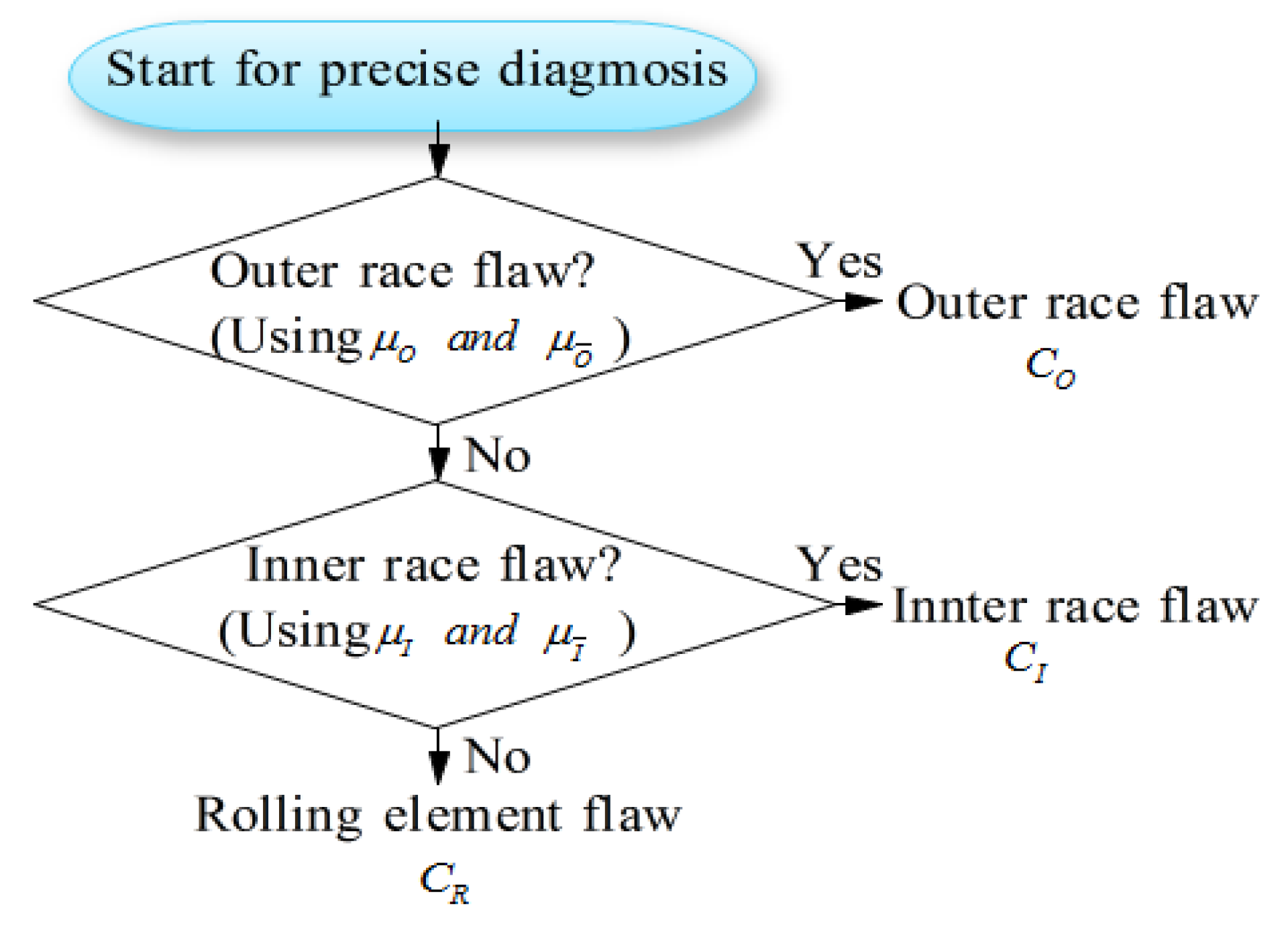

(2) Since the noise in the measured signals for diagnosing the bearing cannot be completely cancelled, and due to the influence of the degree of bearing damage, there is often an ambiguity when diagnosing the bearing fault. In order to solve this problem, a sequential fuzzy diagnosis method is proposed by which the bearing faults can be automatically and sequentially diagnosed.

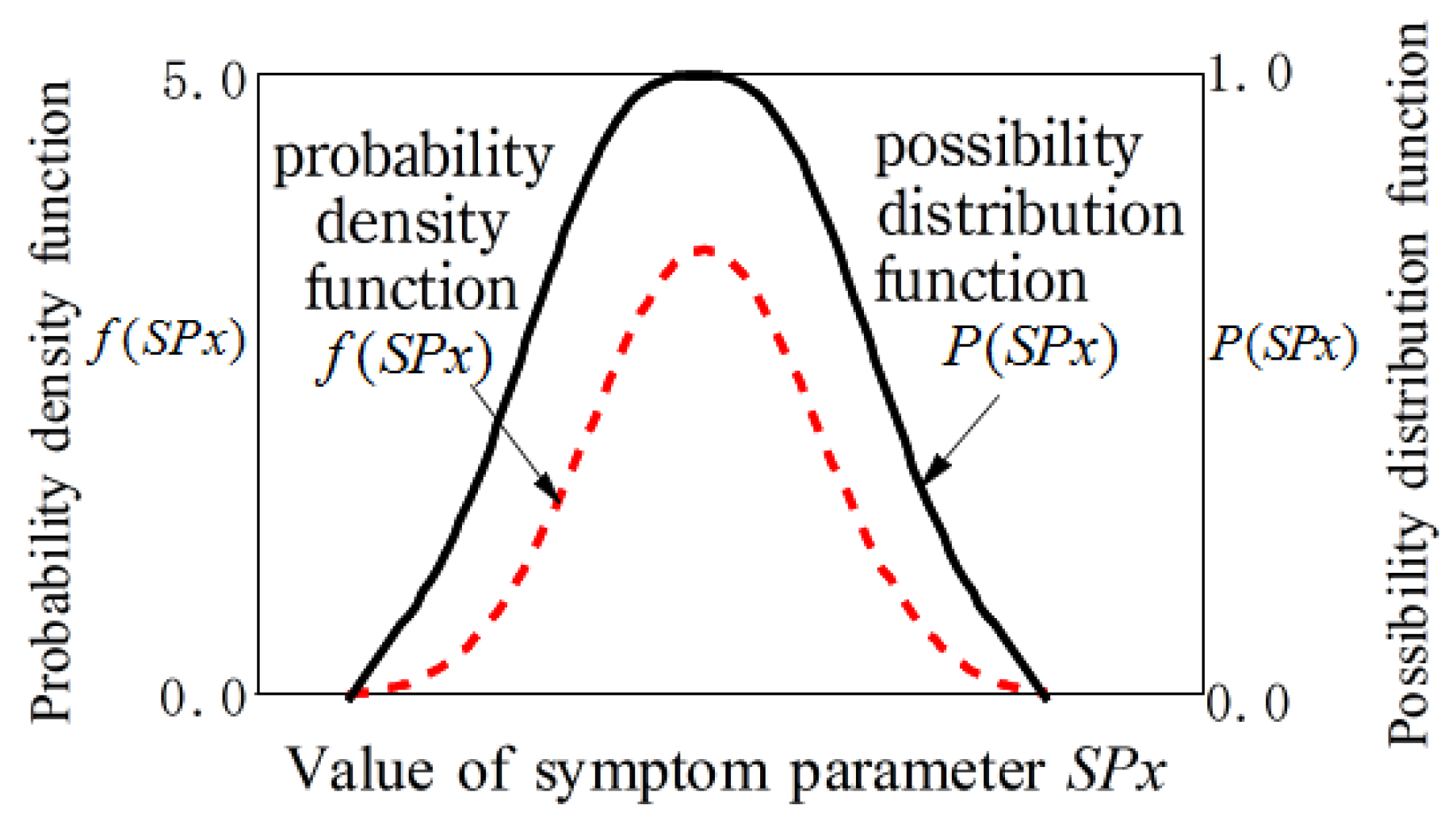

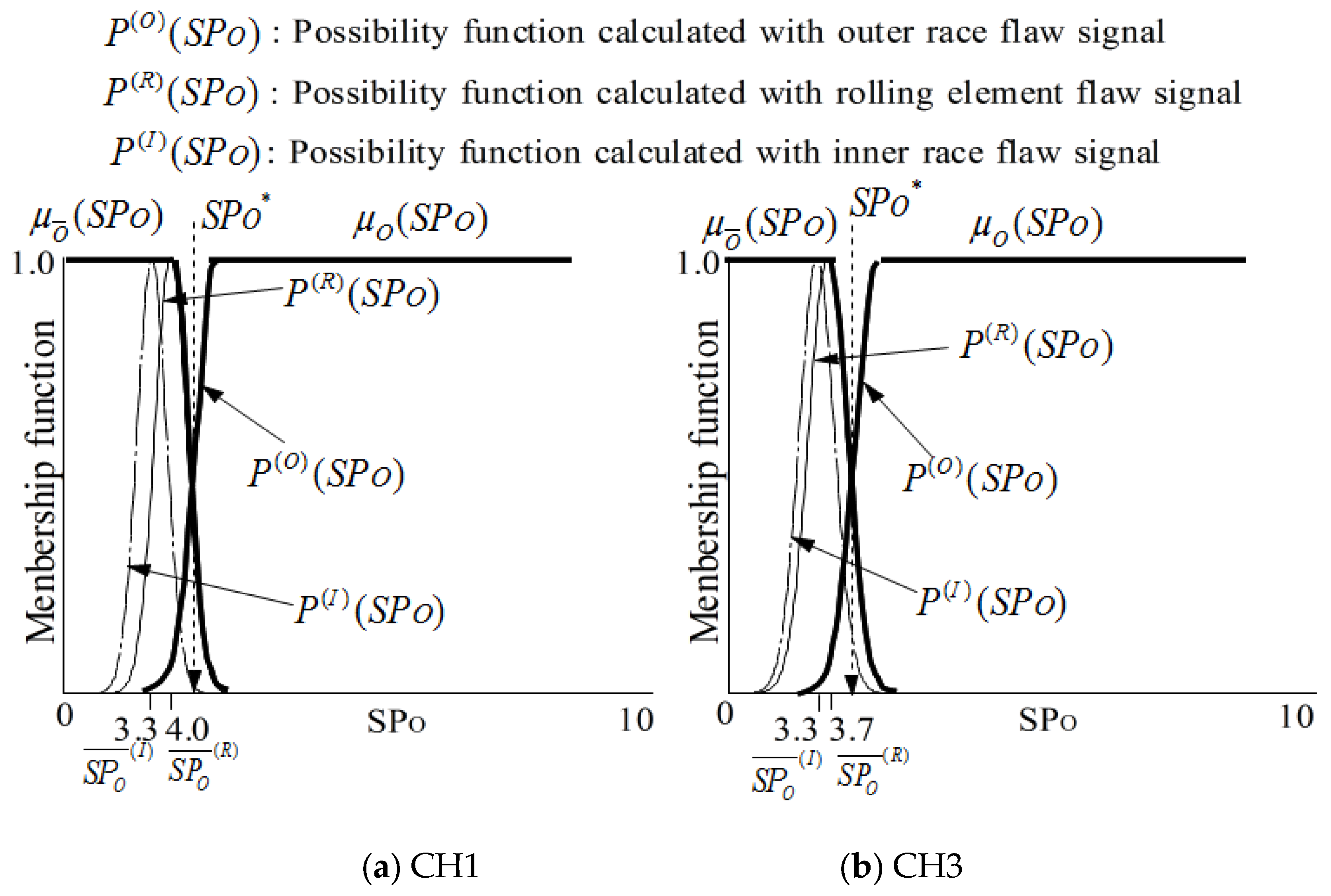

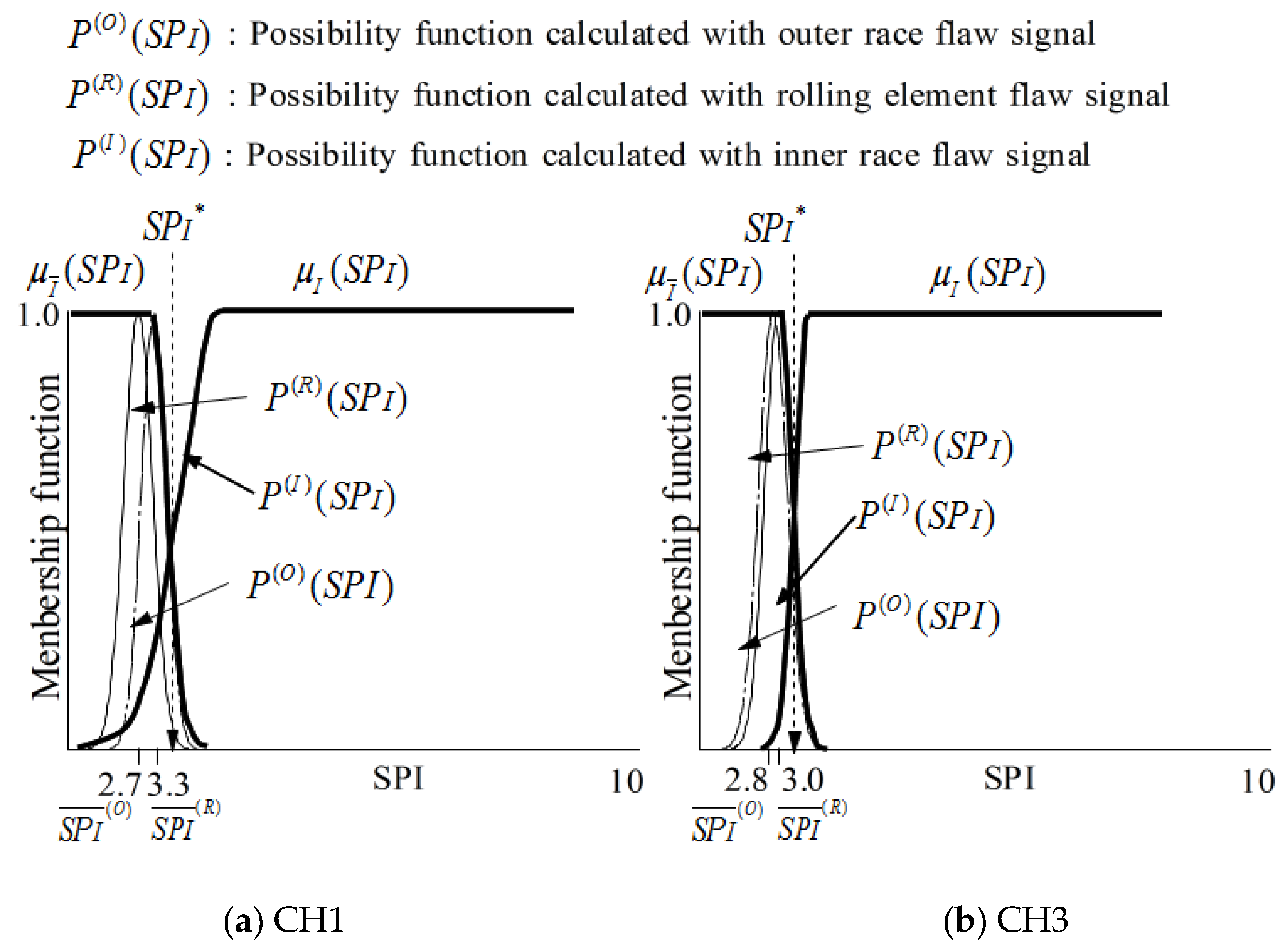

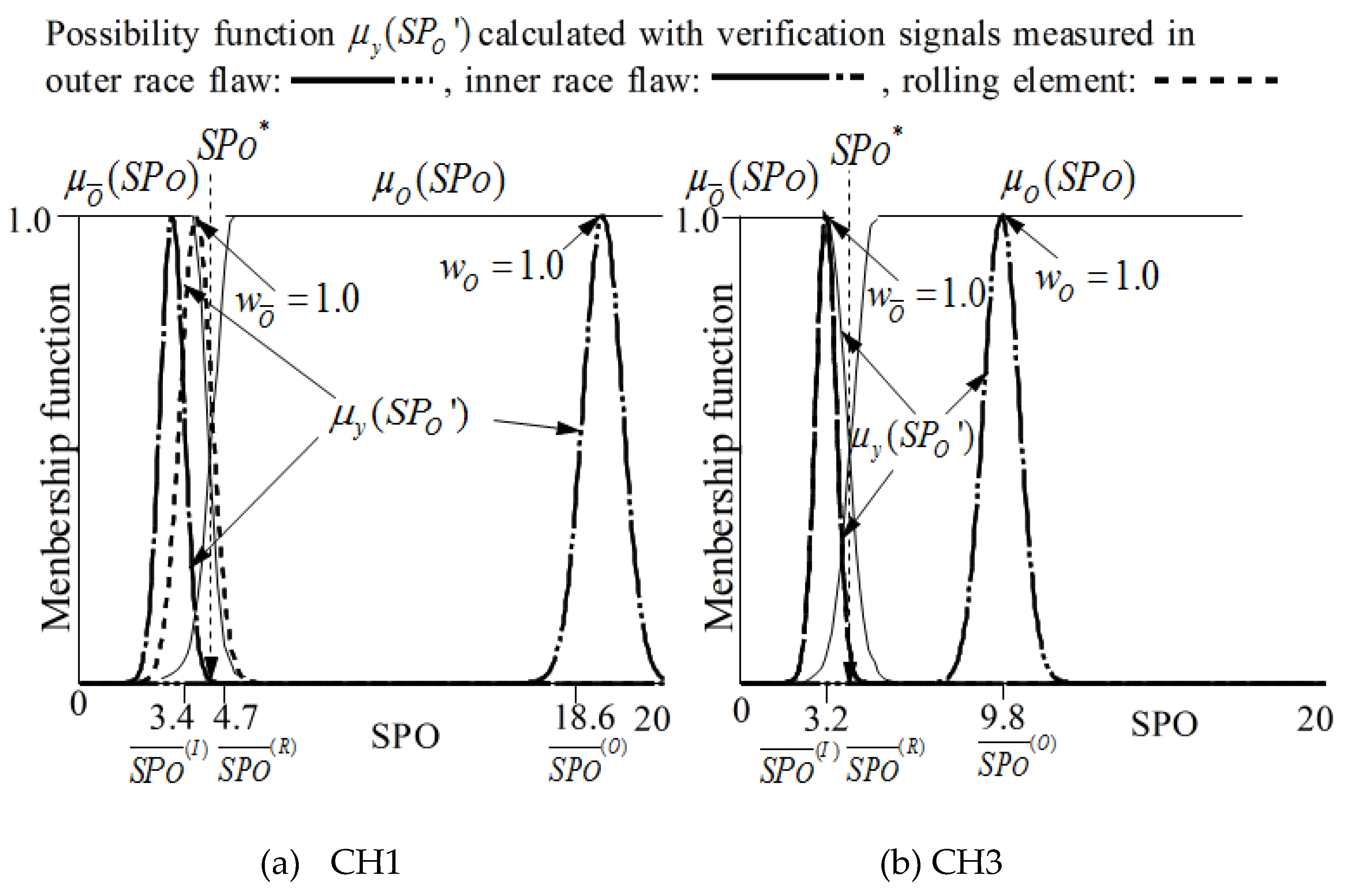

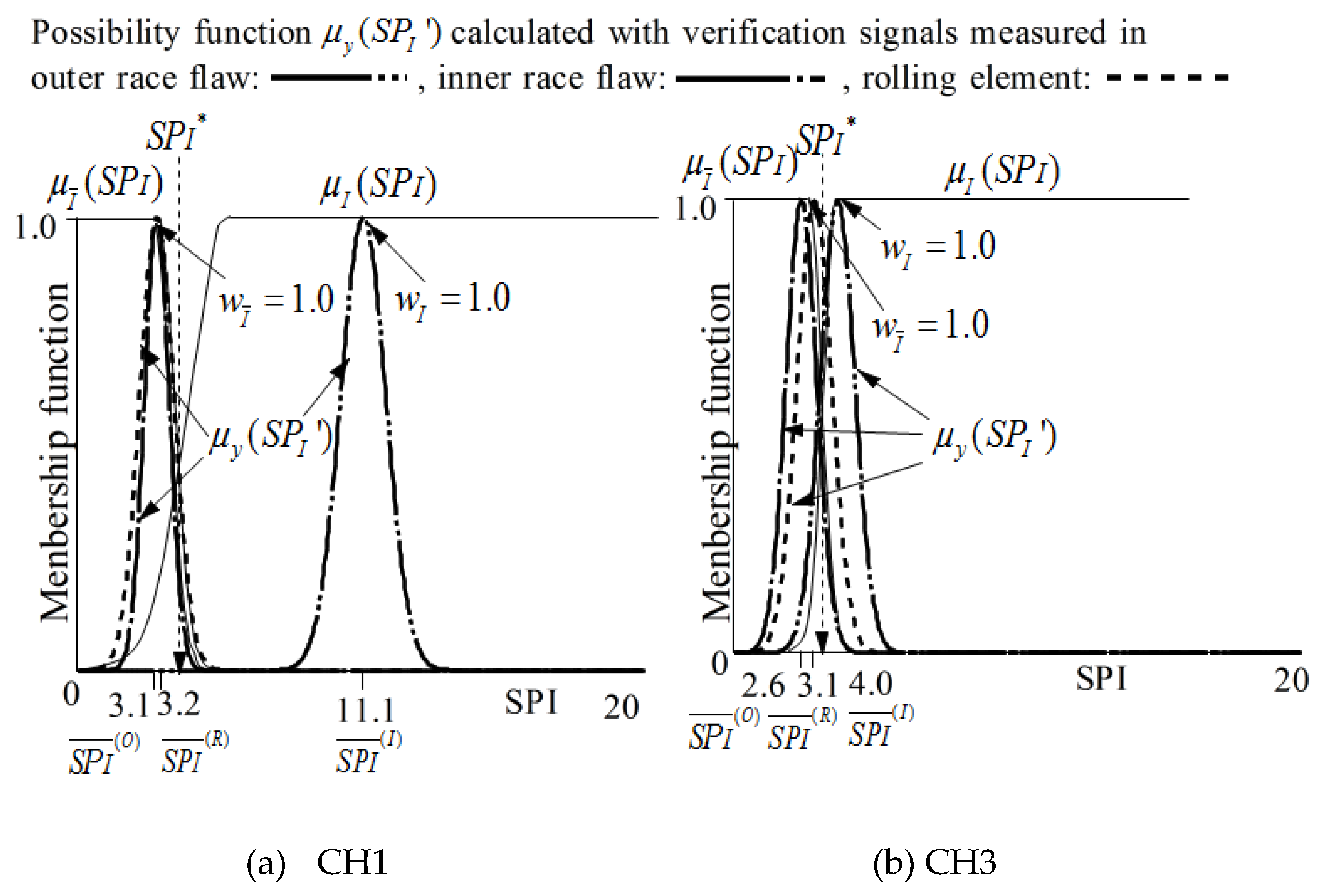

(3) In order to effectively carry out the sequential fuzzy diagnosis of a bearing, new symptom parameters specific to diagnose bearing are defined, and the method of defining the membership function of these symptom parameters by using possibility function is also proposed.

(4) Finally, these methods were applied to bearing diagnosis using the vibration signals measured at distant points from the diagnosed rolling bearings, and the efficiency of these methods have been verified by the results of the automatic bearing faults diagnosis.

4. Conclusions

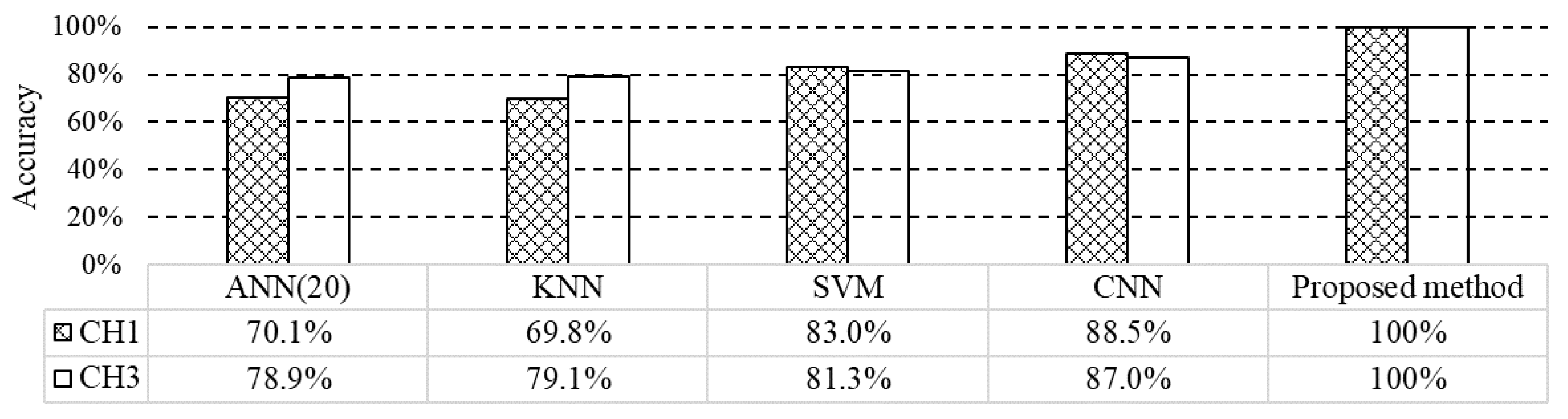

This paper proposed a new fault auto-detection method for a roller bearing, by which the optimum cutoff frequency for removing noise from the vibration signal measured for the bearing diagnosis can be automatically searched and the state of the bearing can be automatically diagnosed. With this method, even if the accelerometer cannot be placed near the diagnosed bearing and is located away from the bearing to be diagnosed, it is also possible to diagnose the bearing fault more accurately.

In order to detect the bearing fault signals, a method of searching optimal cutoff frequency of high-pass filter by hybrid GA combining GA and TS is proposed, and RK is used as the fitness of GA, and the fault detection of the bearing is also carried out. In order to precisely determine the type of the bearing fault, the symptom parameters specific for bearing diagnosis are proposed, and the membership functions of the symptom parameters are established according to possibility theory for fuzzy diagnosis. After the bearing is judged as abnormality by the fault detection, the membership functions of the symptom parameters dedicated to bearing diagnosis and the fuzzy inference are used to sequentially and precisely identify the type of the bearing fault, and it has been confirmed that the feature vibration signal caused by bearing faults can be detected with an accelerometer set at a distant point from the diagnosed bearing by using the proposed algorithms.

From now on, we will do the same research on sliding bearings, aiming to construct useful high-precision sliding bearing diagnostic methods.