Surface Plasmon Resonance Based Temperature Sensors in Liquid Environment

Abstract

1. Introduction

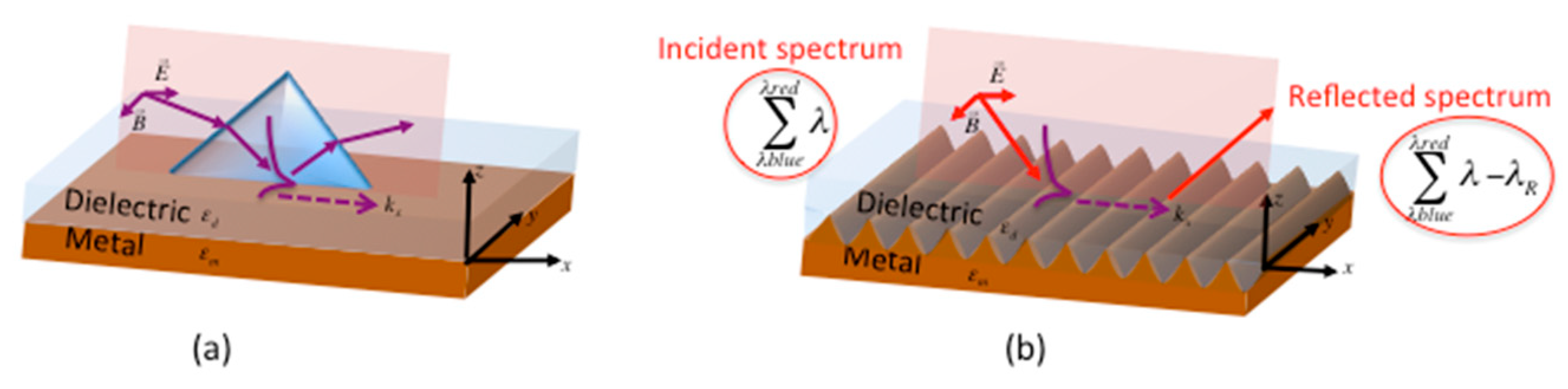

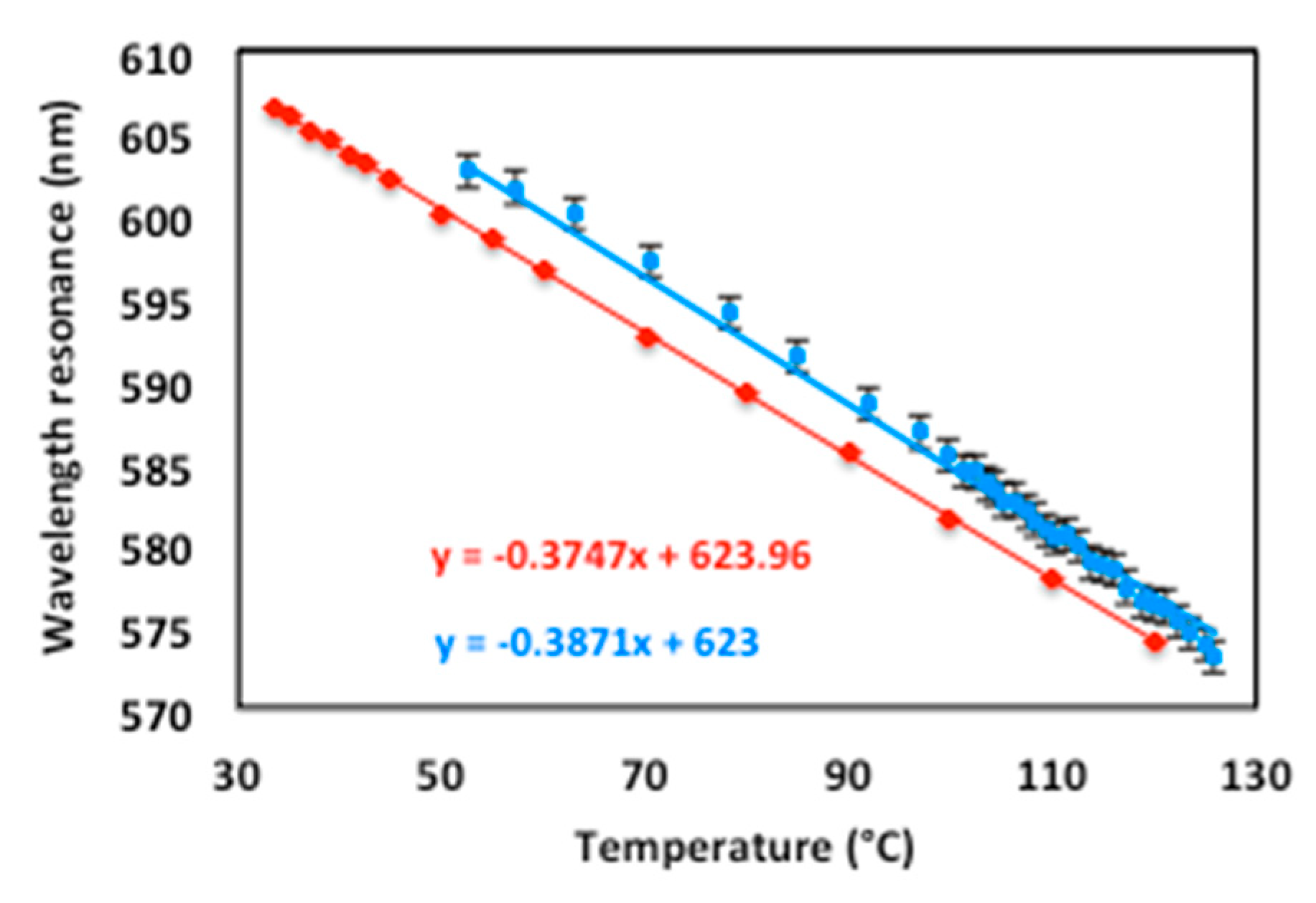

2. Diffractive Structure and Sensor Behavior

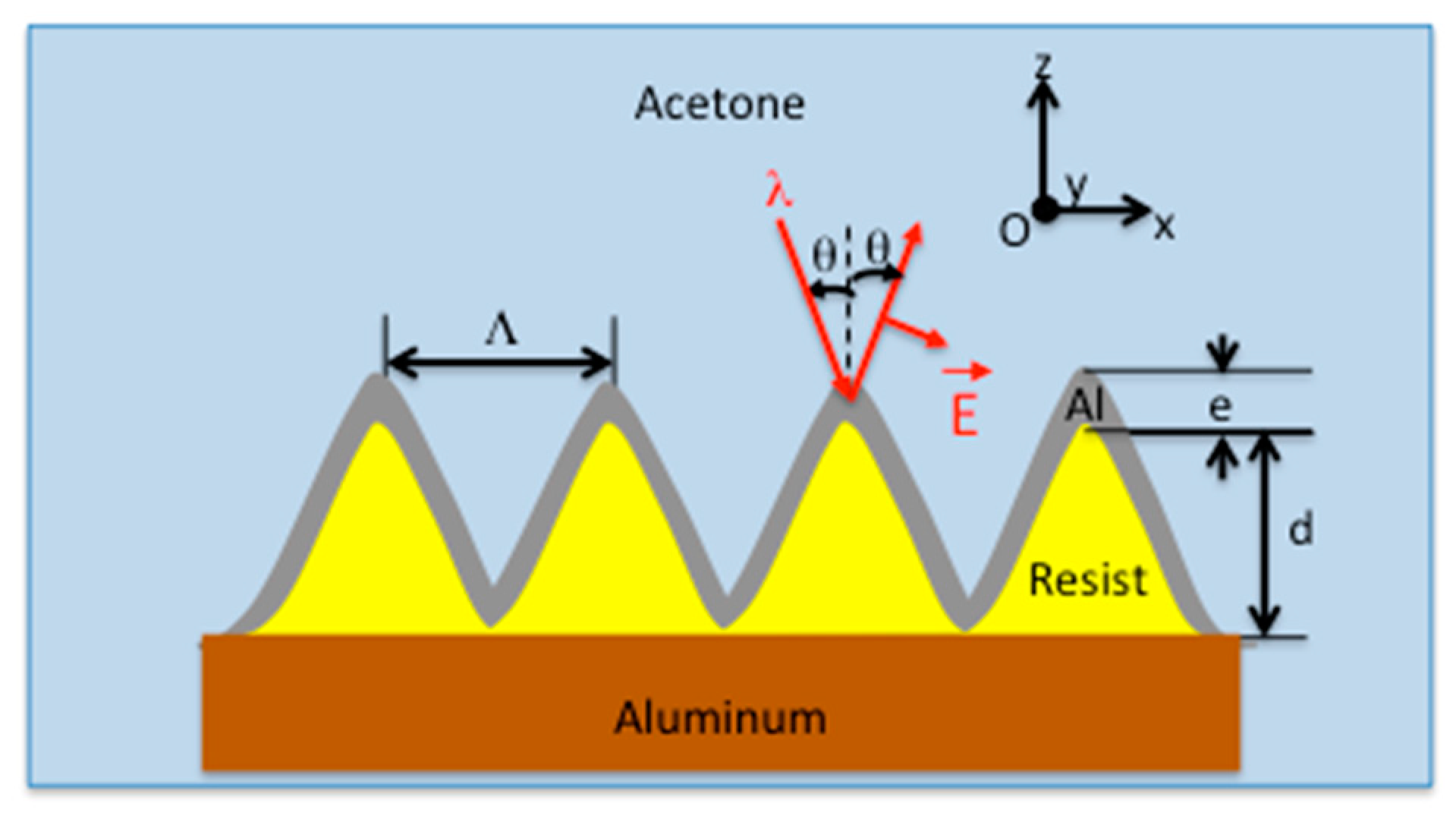

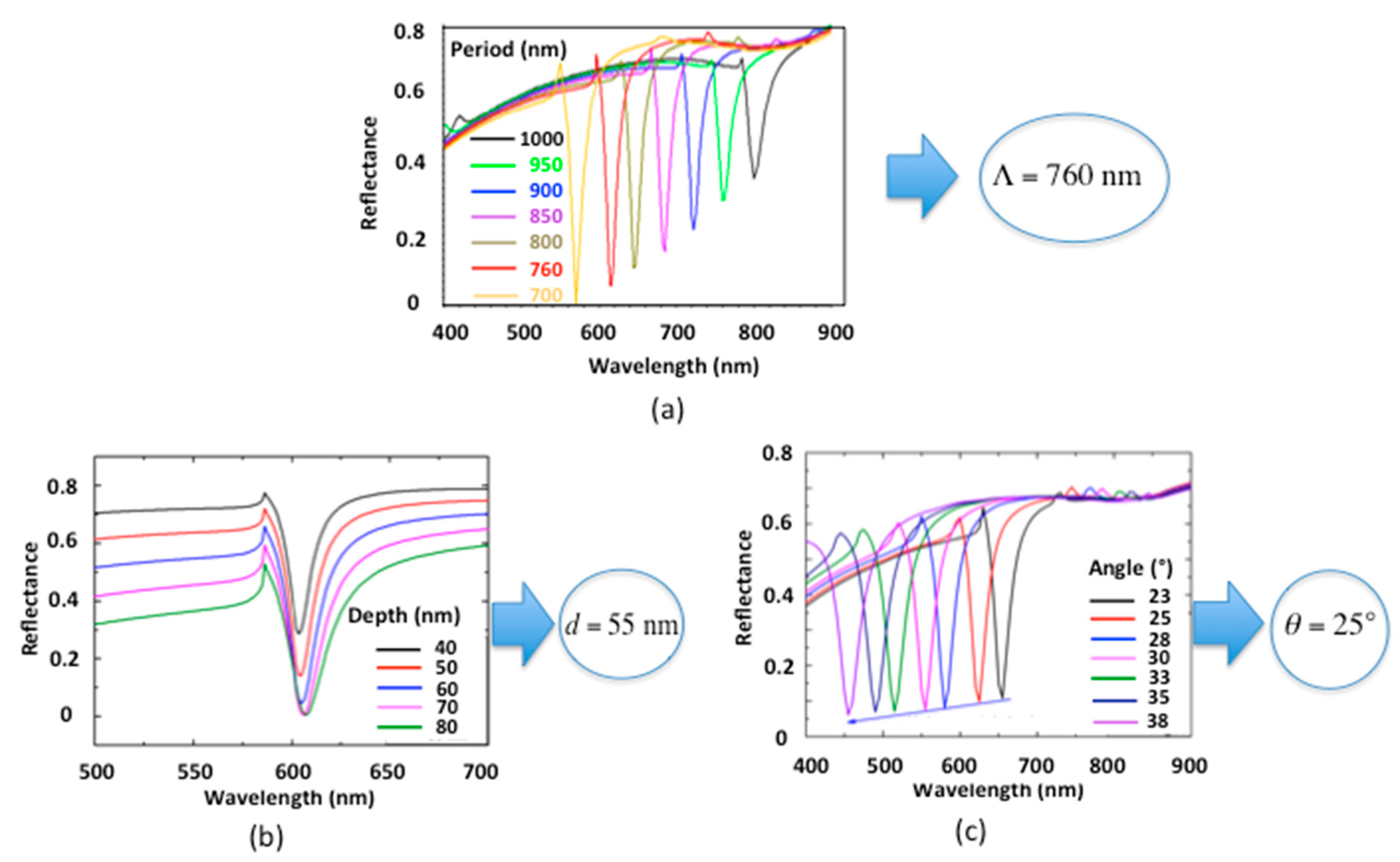

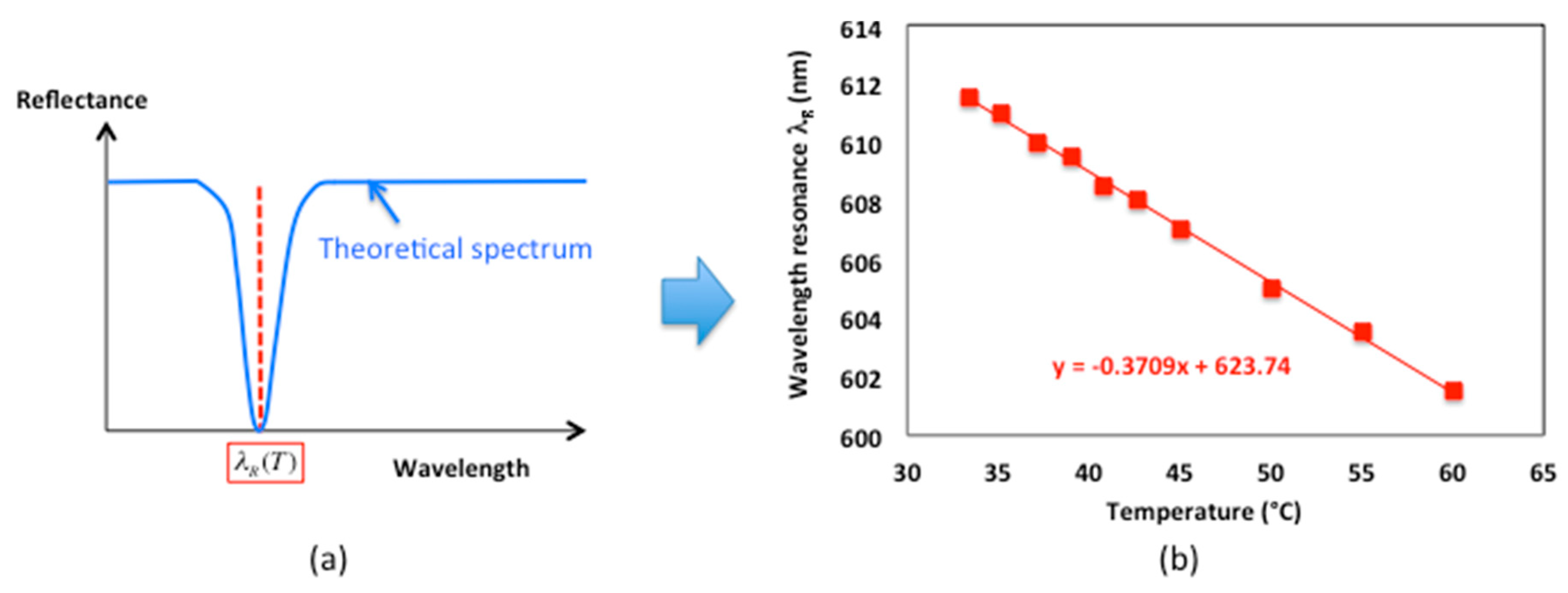

2.1. Grating Design and Sensor Response at the Operation Point

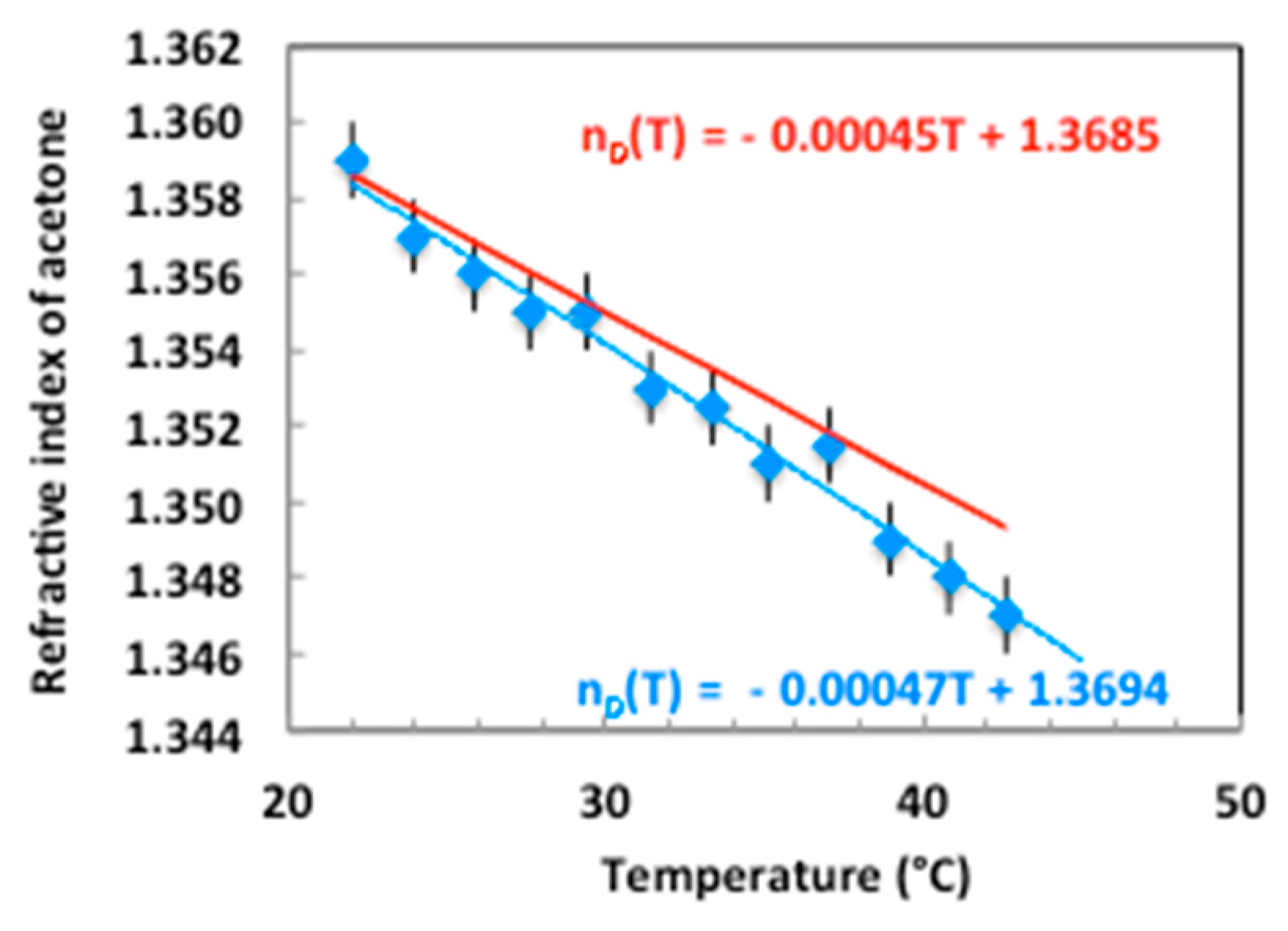

2.2. Simulation of the Plasmonic Response versus Temperature

3. Fabrication of the Sensor and Temperature Measurements

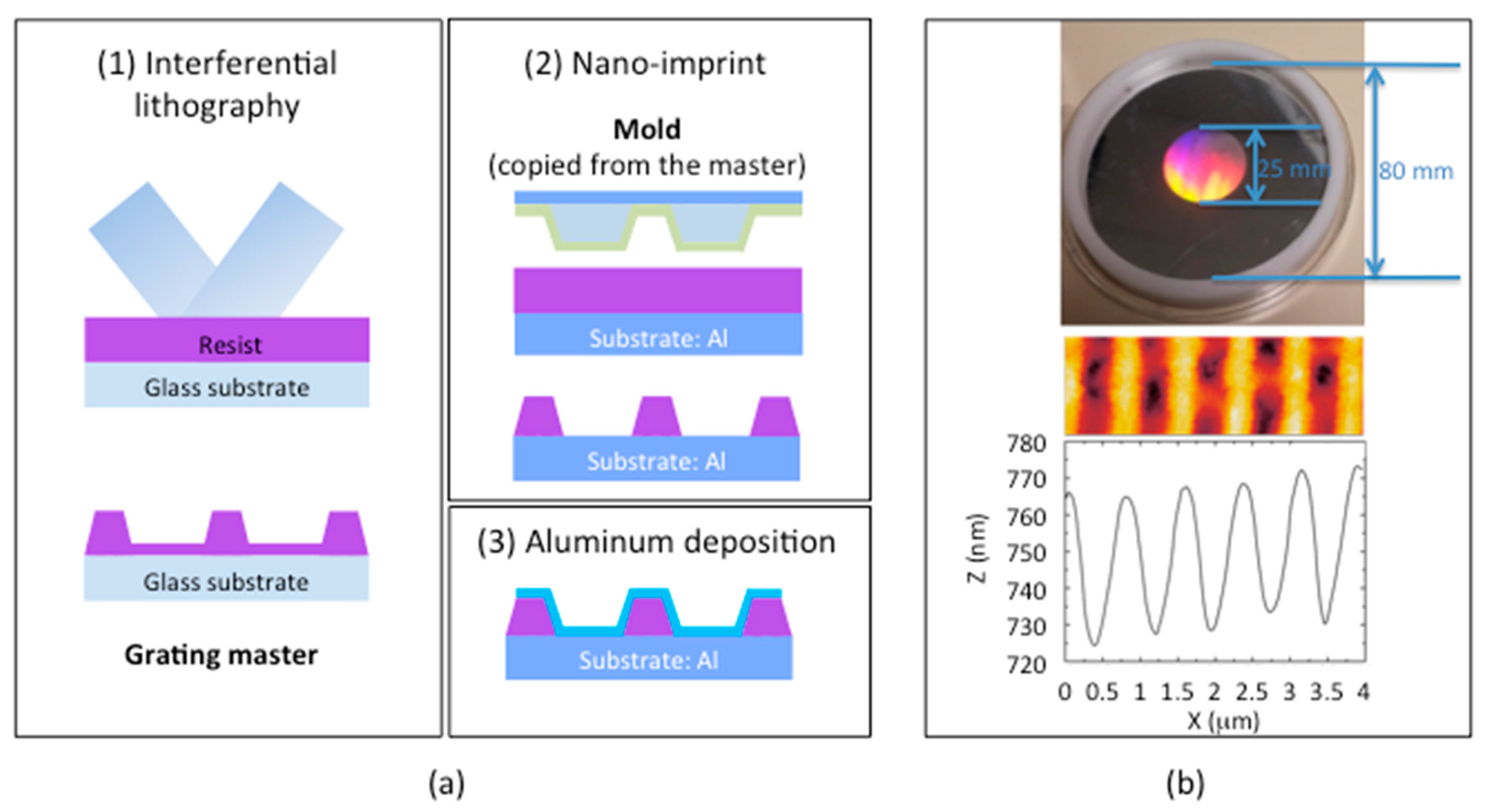

3.1. Fabrication of the Resonant Grating

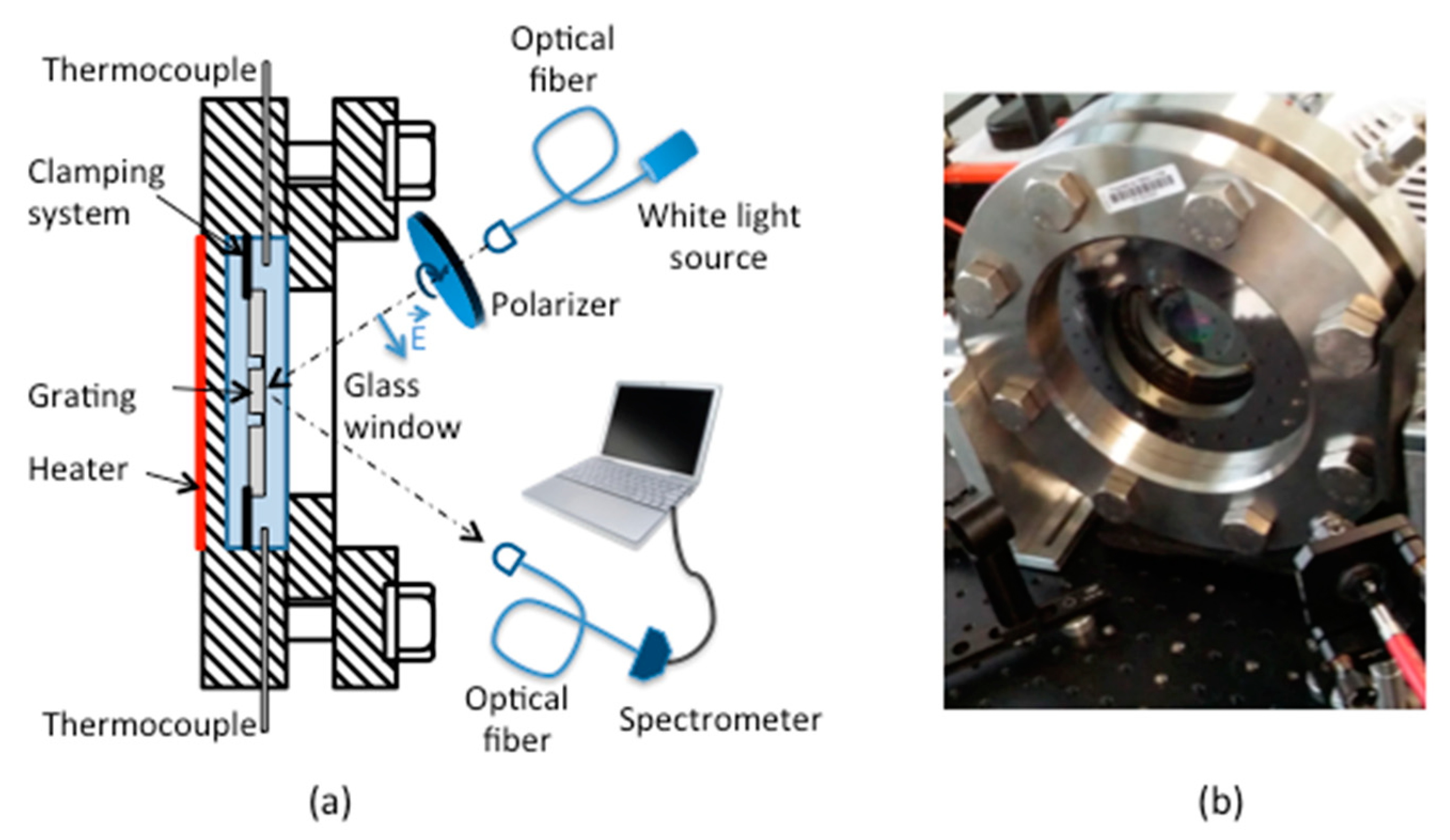

3.2. Set-Up for Temperature Surface Measurement via Plasmonic Effect

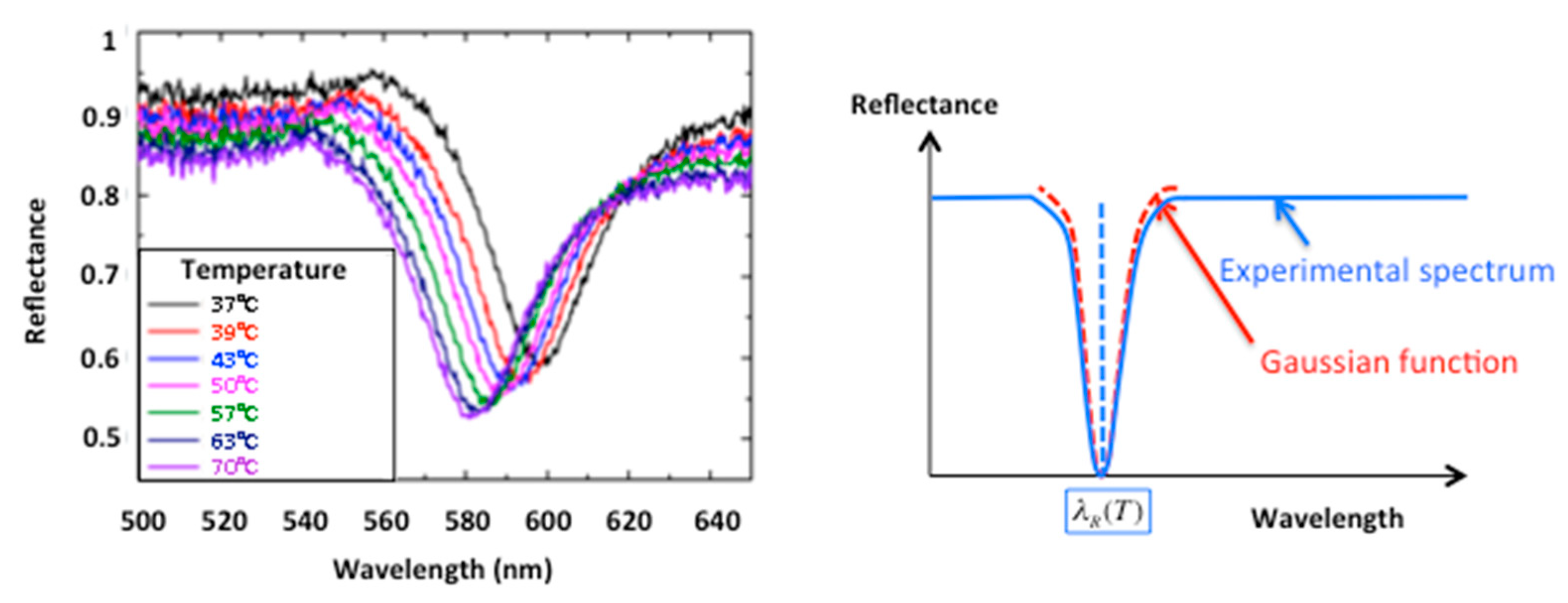

3.3. Experimental Spectra

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Al Masri, M.; Cioulachtjian, S.; Veillas, C.; Verrier, I.; Jourlin, Y.; Ibrahim, J.; Martin, M.; Pupier, C.; Lefèvre, F. Nucleate boiling on ultra-smooth surfaces: Explosive incipience and homogeneous density of nucleation sites. Exp. Therm. Fluid Sci. 2017, 88, 24–36. [Google Scholar] [CrossRef]

- Carlomagno, G.M.; Cardone, G. Infrared thermography for convective heat transfer measurements. Exp. Fluids 2010, 49, 1187–1218. [Google Scholar] [CrossRef]

- Balaras, C.A.; Argiriou, A.A. Infrared thermography for building diagnostics. Energy Build. 2002, 34, 171–183. [Google Scholar] [CrossRef]

- Maier, S.A. Plasmonics Fundamentals and Applications; Springer: New York, NY, USA, 2007. [Google Scholar]

- Shahbazyan, T.V.; Stockman, M.I. Plasmonics: Theory and Applications; Springer: Dordrecht, The Nedherlands, 2014. [Google Scholar]

- Homola, J.; Yee, S.S.; Gauglitz, G. Surface plasmon resonance sensors: Review. Sens. Actuators B Chem. 1999, 54, 3–15. [Google Scholar] [CrossRef]

- Porto, J.A.; Garcta-Vidal, F.J.; Pendry, J.B. Transmission resonances on metallic gratings with very narrow slits. Phys. Rev. Lett. 1999, 83, 2845–2848. [Google Scholar] [CrossRef]

- Özdemir, S.K.; Turhan-Sayan, G. Temperature effects on surface plasmon resonance: Design considerations for an optical temperature sensor. J. Lightw. Technol. 2003, 21, 805–814. [Google Scholar] [CrossRef]

- Chylek, J.; Bezdekova, I.; Ciprian, D.; Hlubina, P. Measurement of the dispersion of a liquid analyte using plasmon resonance: A theoretical approach. Proc. SPIE 2018, 10680. [Google Scholar] [CrossRef]

- Kanok, R.; Ciprian, D.; Hlubina, P. Sensing of liquid analytes via phase shift induced by surface plasmon resonance. Proc. SPIE 2018, 10680. [Google Scholar] [CrossRef]

- Homola, J. Surface plasmon resonance sensors for detection of chemical and biological species. Chem. Rev. 2008, 108, 462–493. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Peng, Y.; Ning, B.; Bai, J.; Liu, Y.; Zhang, N.; Gao, Z. Surface plasmon resonance sensor based on molecularly imprinted polymer film for detection of histamine. Sens. Actuators B Chem. 2015, 221, 15–21. [Google Scholar] [CrossRef]

- Vala, M.; Chadt, K.; Piliarik, M.; Homola, J. High-performance compact SPR sensor for multi-analyte sensing. Sens. Actuators B Chem. 2010, 148, 544–549. [Google Scholar] [CrossRef]

- Kim, J.; Son, C.; Choi, S.; Yoon, W.J.; Ju, H. A plasmonic fiber based glucometer and its temperature dependence. Micromachines 2018, 9, 506. [Google Scholar] [CrossRef] [PubMed]

- Velazquez-Gonzalez, J.S.; Monzon-Hernandez, D.; Moreno-Hernandez, D.; Martinez-Pinon, F.; Hernandez-Romano, I. Simultaneous measurement of refractive index and temperature using a SPR-based fiber optic sensor. Sens. Actuators B Chem. 2017, 242, 912–920. [Google Scholar] [CrossRef]

- Chiang, H.P.; Wang, Y.C.; Leung, P.T.; Tse, W.S. A theoretical model for the temperature-dependent sensitivity of the optical sensor based on surface plasmon resonance. Opt. Commun. 2001, 188, 283–289. [Google Scholar] [CrossRef]

- Ibrahim, J.; Al Masri, M.; Veillas, C.; Celle, F.; Cioulachtjian, S.; Verrier, I.; Lefèvre, F.; Parriaux, O.; Jourlin, Y. Condensation phenomenon detection through surface plasmon resonance. Opt. Express 2017, 25, 24189–24198. [Google Scholar] [CrossRef] [PubMed]

- Hausler, P.; Genslein, C.; Roth, C.; Vitzthumecker, T.; Hirsch, T.; Bierl, R. Miniaturized surface plasmon resonance based sensor system. In Proceedings of the 6th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2018), Madeira, Portugal, 25–27 January 2018; Volume 1, pp. 63–66. [Google Scholar]

- Arriola, A.; Rodriguez, A.; Perez, N.; Tavera, T.; Withford, M.J.; Fuerbach, A.; Olaizola, S.M. Fabrication of high quality sub-micron Au gratings over large areas with pulsed laser interference lithography for SPR sensors. Opt. Mater. Express 2012, 2, 1571–1579. [Google Scholar] [CrossRef]

- Jourlin, Y.; Tonchev, S.; Tishchenko, A.V.; Pedri, C.; Veillas, C.; Parriaux, O.; Last, A.; Lacroute, Y. Spatially and polarization resolved plasmon mediated transmission through continuous metal films. Opt. Express 2009, 17, 12155–12166. [Google Scholar] [CrossRef] [PubMed]

- Qu, Y.; Li, Q.; Gong, H.; Du, K.; Bai, S.; Zhao, D.; Ye, H.; Qiu, M. Spatially and spectrally resolved narrowband optical absorber based on 2D grating nanostructures on metallic films. Adv. Opt. Mat. 2016, 4, 480–486. [Google Scholar] [CrossRef]

- Knight, M.W.; Liu, L.; Wang, Y.; Brown, L.; Mukherjee, S.; King, N.S.; Everitt, H.O.; Nordlander, P.; Halas, N.J. Aluminum plasmonic nanoantennas. Nano Lett. 2012, 12, 6000–6004. [Google Scholar] [CrossRef] [PubMed]

- Lyndin, N.M. MC Grating. Available online: http://mcgrating.com (accessed on 30 July 2019).

- Refractometry. Available online: http://academics.wellesley.edu/Chemistry/chem211lab/Orgo_Lab_Manual/Appendix/Appendix/Instruments/Refractometry/refractometry.html (accessed on 30 July 2019).

- Boltasseva, A. Plasmonic components fabrication via nanoimprint. J. Opt. A 2009, 11, 4801906. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim, J.; Al Masri, M.; Verrier, I.; Kampfe, T.; Veillas, C.; Celle, F.; Cioulachtjian, S.; Lefèvre, F.; Jourlin, Y. Surface Plasmon Resonance Based Temperature Sensors in Liquid Environment. Sensors 2019, 19, 3354. https://doi.org/10.3390/s19153354

Ibrahim J, Al Masri M, Verrier I, Kampfe T, Veillas C, Celle F, Cioulachtjian S, Lefèvre F, Jourlin Y. Surface Plasmon Resonance Based Temperature Sensors in Liquid Environment. Sensors. 2019; 19(15):3354. https://doi.org/10.3390/s19153354

Chicago/Turabian StyleIbrahim, Joyce, Mostafa Al Masri, Isabelle Verrier, Thomas Kampfe, Colette Veillas, Frédéric Celle, Serge Cioulachtjian, Frédéric Lefèvre, and Yves Jourlin. 2019. "Surface Plasmon Resonance Based Temperature Sensors in Liquid Environment" Sensors 19, no. 15: 3354. https://doi.org/10.3390/s19153354

APA StyleIbrahim, J., Al Masri, M., Verrier, I., Kampfe, T., Veillas, C., Celle, F., Cioulachtjian, S., Lefèvre, F., & Jourlin, Y. (2019). Surface Plasmon Resonance Based Temperature Sensors in Liquid Environment. Sensors, 19(15), 3354. https://doi.org/10.3390/s19153354