Design of the Squared Daisy: A Multi-Mode Energy Harvester, with Reduced Variability and a Non-Linear Frequency Response

Abstract

1. Introduction

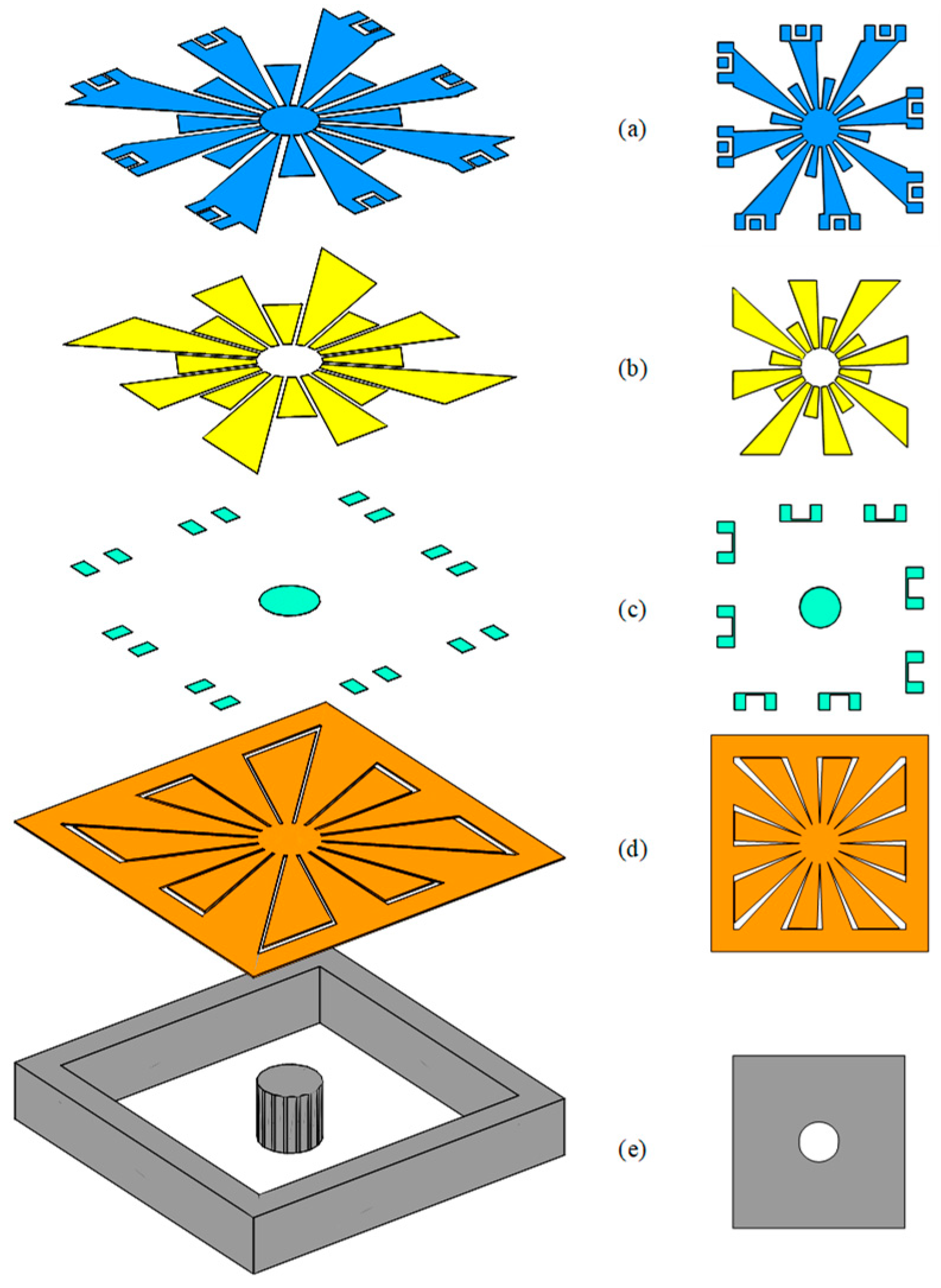

2. Materials and Methods

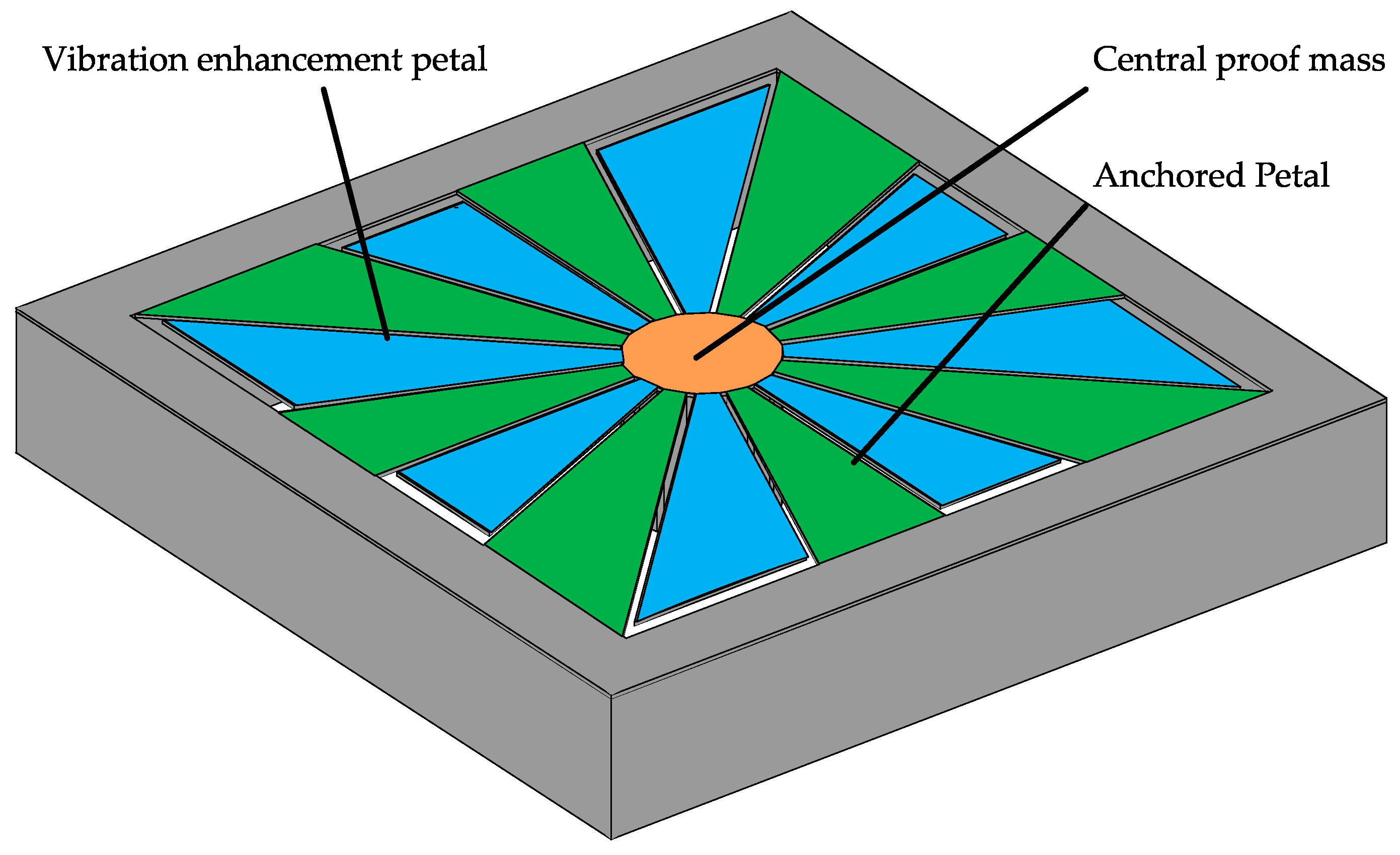

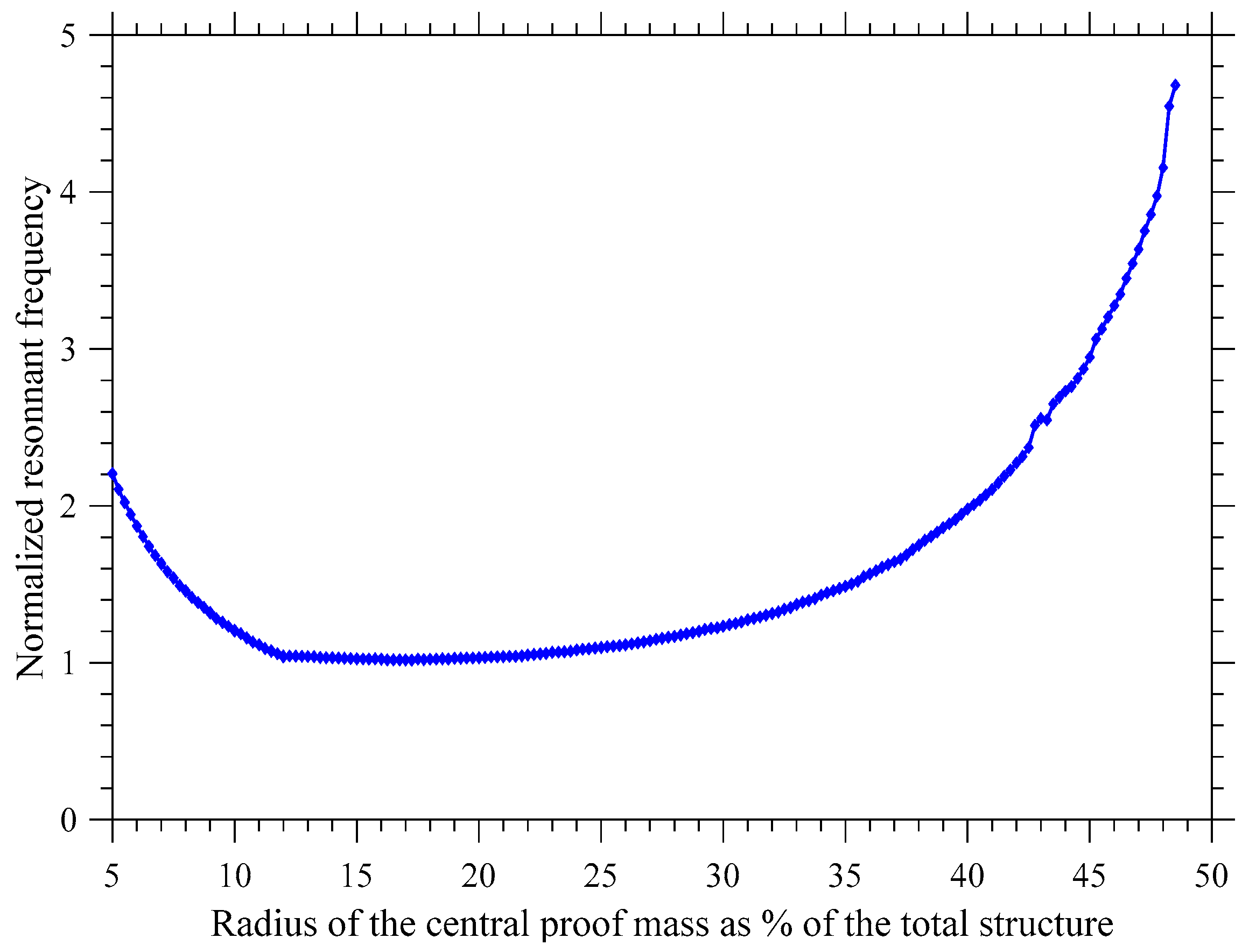

2.1. Operating Principle of the Squared Daisy

2.2. Vibration Enhancement Petals

2.3. Resilience to Process Variation

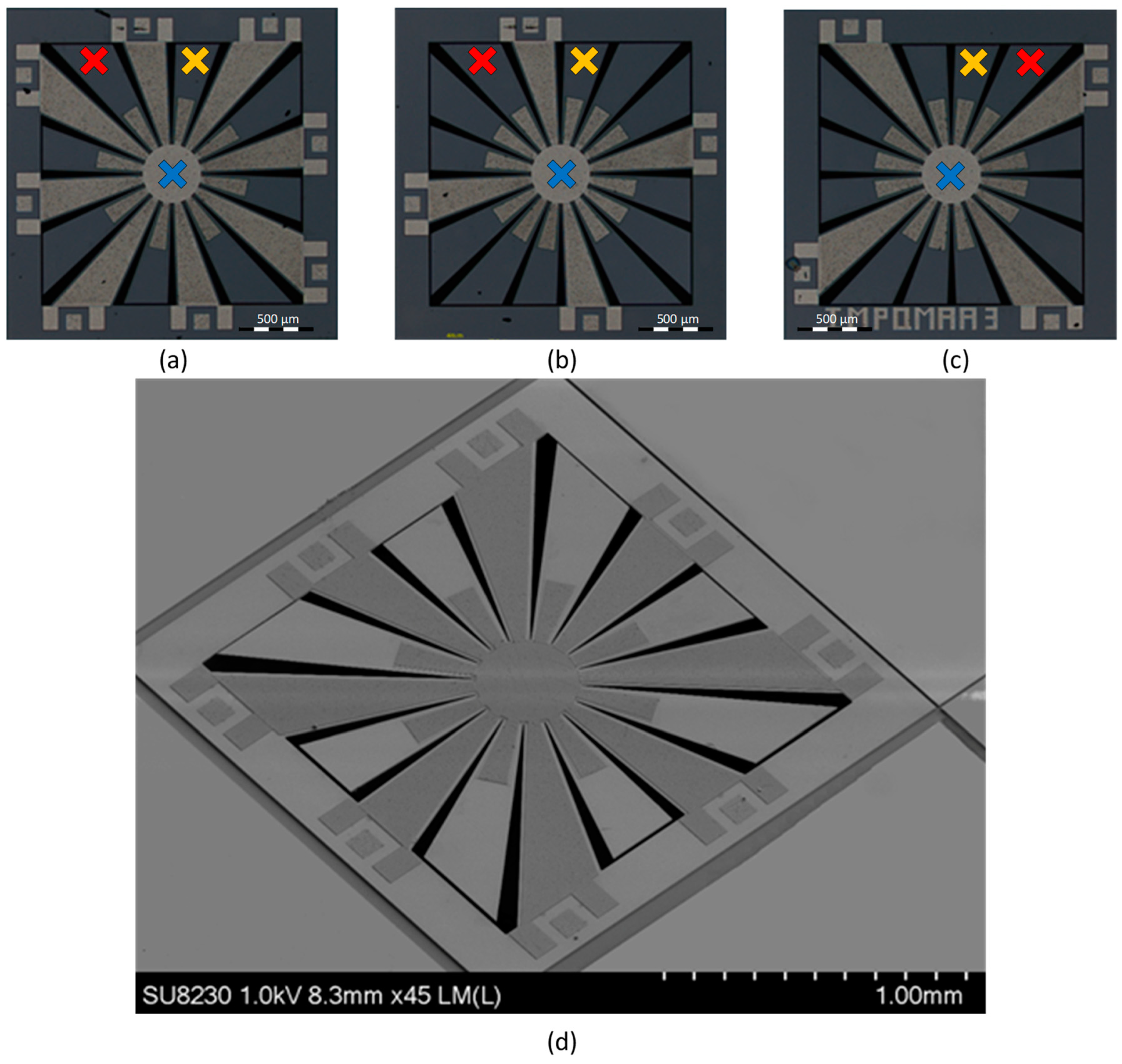

3. Fabrication

4. Measurement Results

4.1. Characterization Using a Vector Network Analyzer

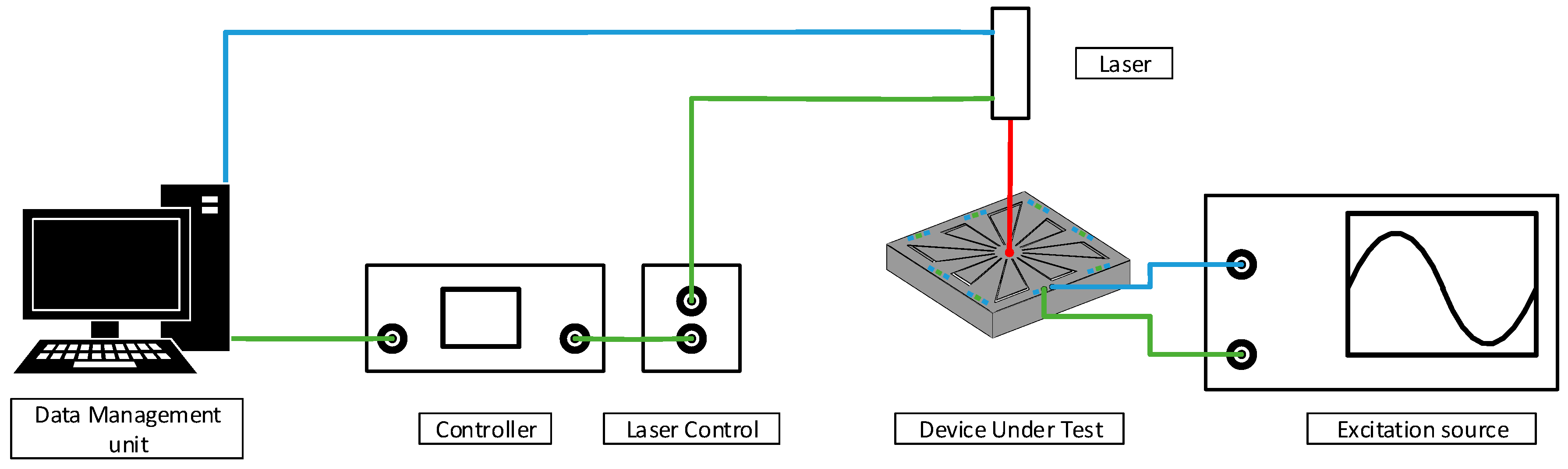

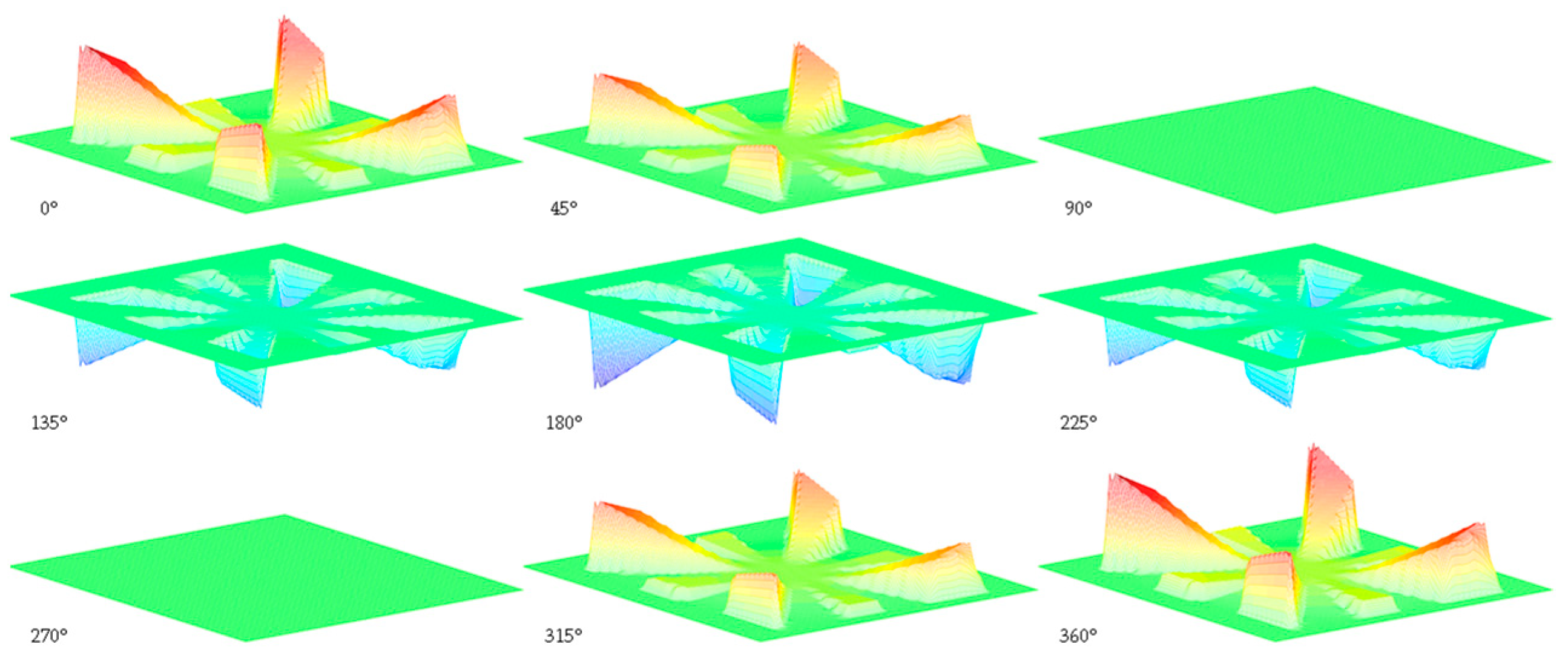

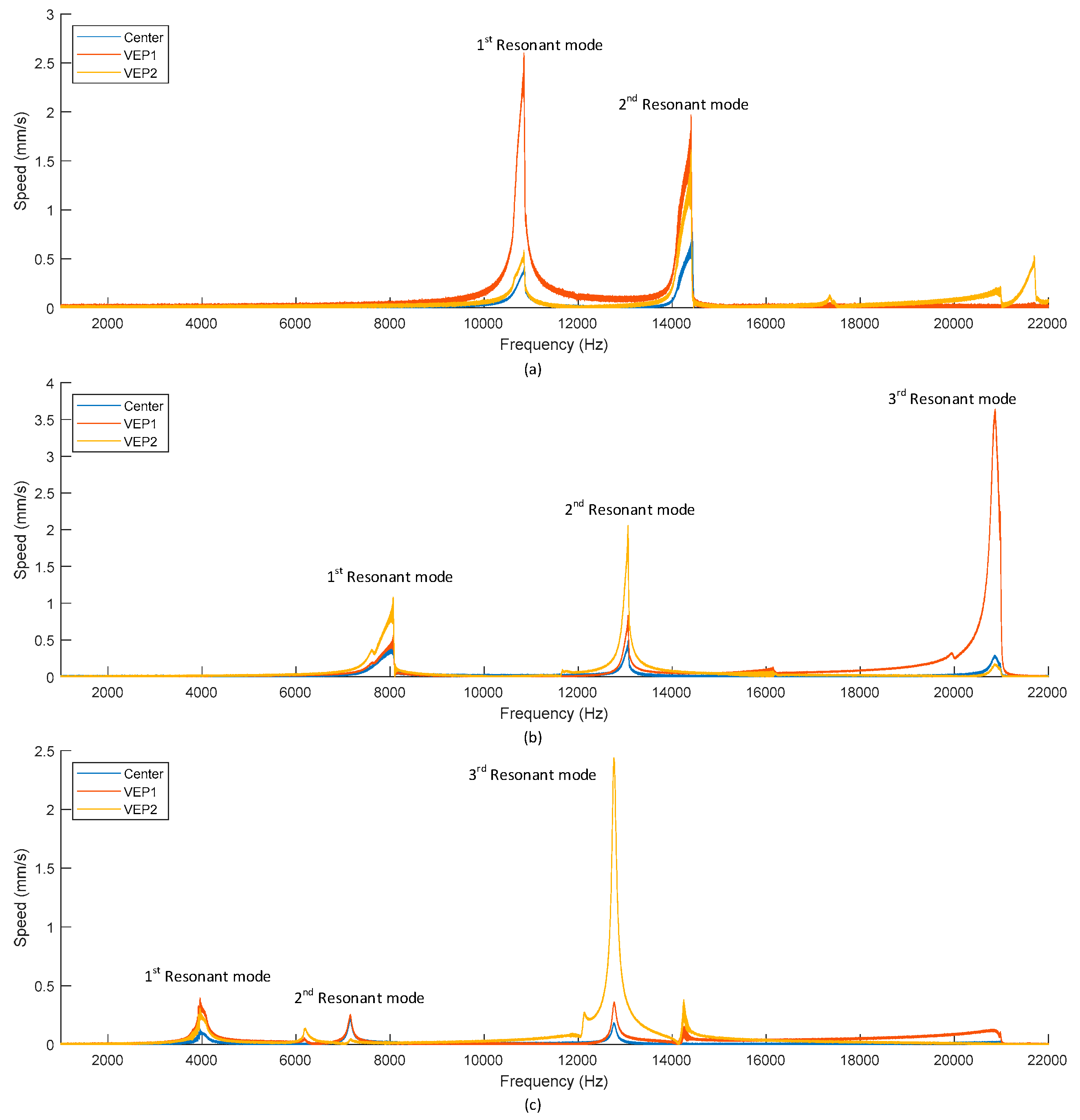

4.2. Characterization Using a Vibrometer

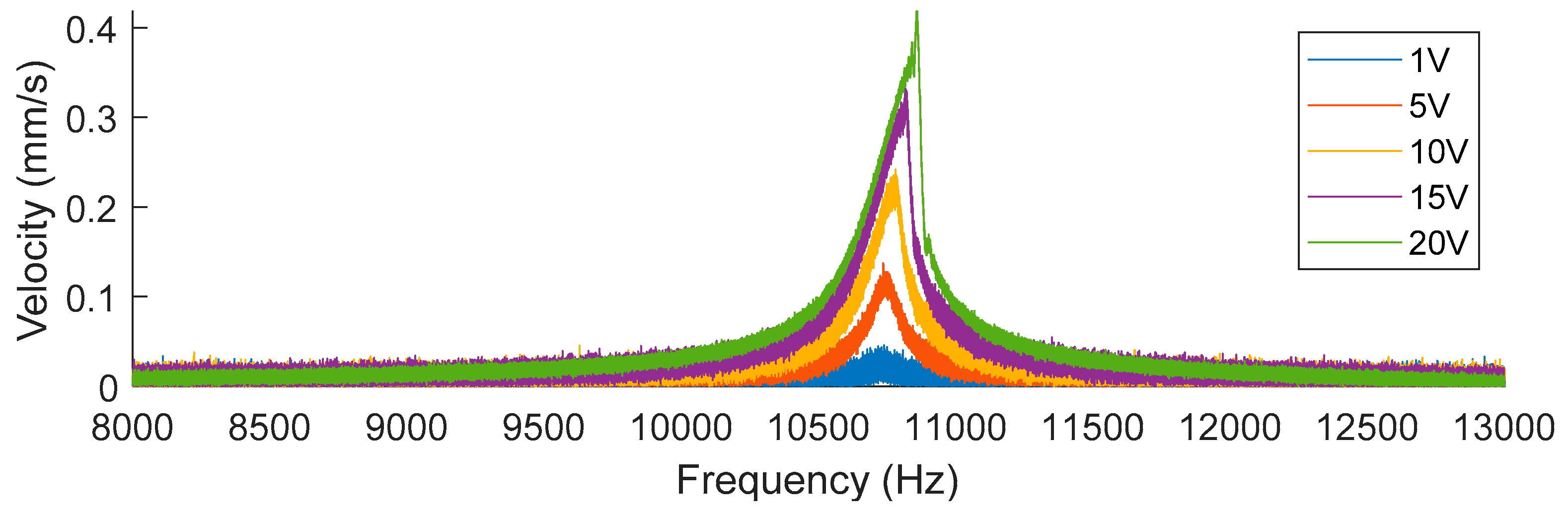

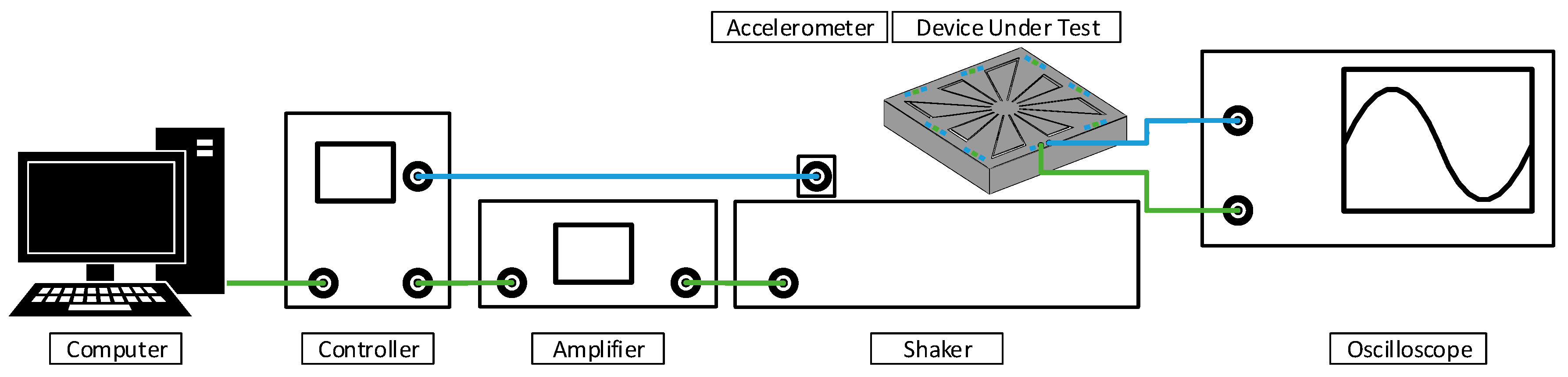

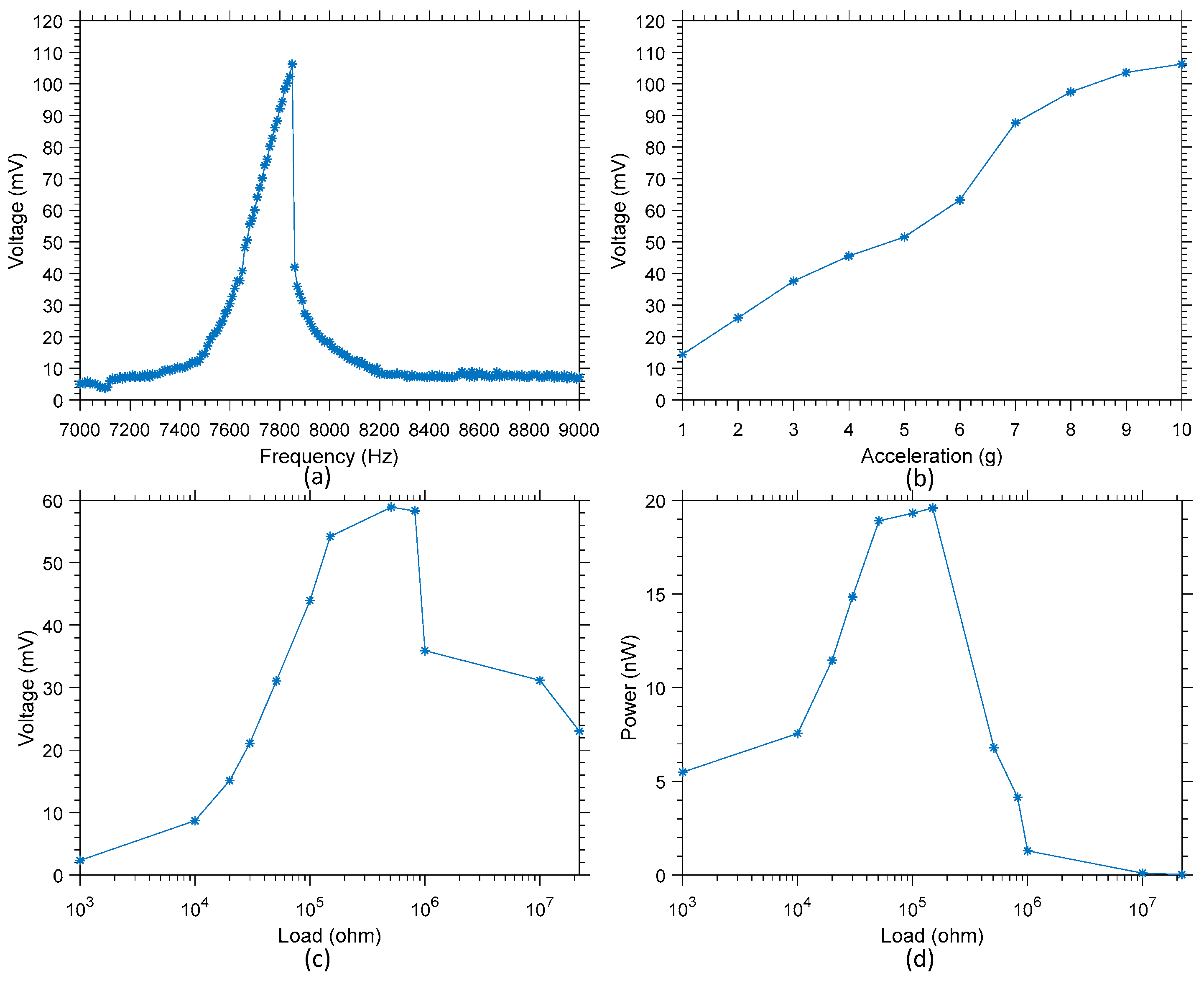

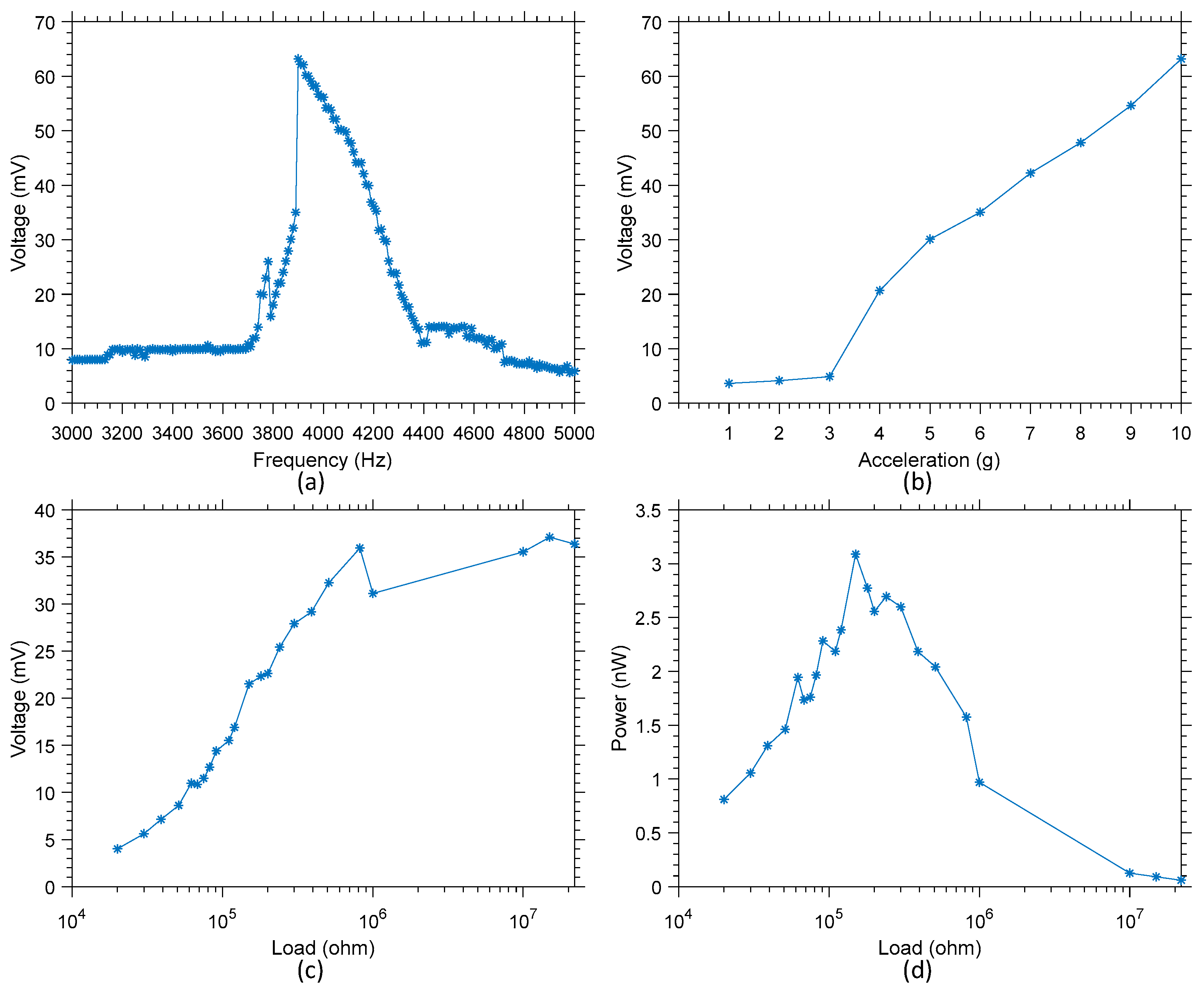

4.3. Characterization Using a Shaker

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jia, Y.; Du, S.; Seshia, A.A. Twenty-Eight Orders of Parametric Resonance in a Microelectromechanical Device for Multi-band Vibration Energy Harvesting. Sci. Rep. 2016, 6, 30167. [Google Scholar] [CrossRef] [PubMed]

- Toyabur, R.M.; Salauddin, M.; Park, J.Y. Design and experiment of piezoelectric multimodal energy harvester for low frequency vibration. Ceram. Int. 2017, 43, 675–681. [Google Scholar] [CrossRef]

- Iannacci, J.; Serra, E.; Sordo, G.; Bonaldi, M.; Borrielli, A.; Schmid, U.; Bittner, A.; Schneider, M.; Kuenzig, T.; Schrag, G.; et al. MEMS-based multi-modal vibration energy harvesters for ultra-low power autonomous remote and distributed sensing. Microsyst. Technol. 2018, 24, 5027–5036. [Google Scholar] [CrossRef]

- Nabavi, S.; Zhang, L. Frequency Tuning and Efficiency Improvement of Piezoelectric MEMS Vibration Energy Harvesters. J. Microelectromech. Syst. 2019, 28, 77–87. [Google Scholar] [CrossRef]

- Vyas, A.; Staaf, H.; Rusu, C.; Ebefors, T.; Liljeholm, J.; Smith, A.D.; Lundgren, P.; Enoksson, P. A Micromachined Coupled-Cantilever for Piezoelectric Energy Harvesters. Micromachines 2018, 9, 252. [Google Scholar] [CrossRef] [PubMed]

- Brini, O.; Deslandes, D.; Nabki, F. A System-Level Methodology for the Design of Reliable Low-Power Wireless Sensor Networks. Sensors 2019, 19, 1800. [Google Scholar] [CrossRef] [PubMed]

- Erturk, A.; Inman, D.J. Front Matter. In Piezoelectric Energy Harvesting; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Priya, S.; Inman, D.J. (Eds.) Energy Harvesting Technologies; Springer: Raleigh, NC, USA, 2009. [Google Scholar]

- Podder, P.; Constantinou, P.; Mallick, D.; Amann, A.; Roy, S. Magnetic Tuning of Nonlinear MEMS Electromagnetic Vibration Energy Harvester. J. Microelectromech. Syst. 2017, 26, 539–549. [Google Scholar] [CrossRef]

- Markowski, P. Thermoelectric energy harvester fabricated in thick-film/LTCC technology. Microelectron. Int. 2014, 31, 176–185. [Google Scholar] [CrossRef]

- Fowler, A.G.; Moheimani, S.O.R. A 4-DOF MEMS Energy Harvester Using Ultrasonic Excitation. IEEE Sens. J. 2016, 16, 7774–7783. [Google Scholar] [CrossRef]

- Beeby, S.P.; Tudor, M.J.; White, N.M. Energy harvesting vibration sources for microsystems applications. Meas. Sci. Technol. 2006, 17, 175–195. [Google Scholar] [CrossRef]

- Iannacci, J.; Sordo, G.; Serra, E.; Schmid, U. A novel MEMS-based piezoelectric multi-modal vibration energy harvester concept to power autonomous remote sensing nodes for Internet of Things (IoT) applications. In Proceedings of the 2015 IEEE SENSORS, Busan, Korea, 1–4 November 2015; pp. 1–4. [Google Scholar]

- Brand, O.; Dufour, I.; Heinrich, S.; Josse, F.; Fedder, G.K.; Hierold, C.; Korvink, J.G.; Tabata, O. (Eds.) Resonant MEMS: Fundamentals, Implementation, and Application; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Yu, H.; Zhou, J.; Deng, L.; Wen, Z. A vibration-based MEMS piezoelectric energy harvester and power conditioning circuit. Sensors 2014, 14, 3323–3341. [Google Scholar] [CrossRef] [PubMed]

- Chew, Z.; Li, L. Design and characterisation of a piezoelectric scavenging device with multiple resonant frequencies. Sens. Actuators A Phys. 2010, 162, 82–92. [Google Scholar] [CrossRef]

- Li, S.; Crovetto, A.; Peng, Z.; Zhang, A.; Hansen, O.; Wang, M.; Li, X.; Wang, F. Bi-resonant structure with piezoelectric PVDF films for energy harvesting from random vibration sources at low frequency. Sens. Actuators A Phys. 2016, 247, 547–554. [Google Scholar] [CrossRef]

- Seddik, B.A.; Despesse, G.; Boisseau, S.; Defay, E. Strategies for Wideband Mechanical Energy Harvester; IntechOpen: London, UK, 2012. [Google Scholar]

- Zhu, D.; Beeby, S.P. Scaling effects for piezoelectric energy harvesters. In Proceedings of the Smart Sensors, Actuators, and MEMS VII; and Cyber Physical Systems, Barcelona, Spain, 21 May 2015; p. 95170. [Google Scholar]

- Alameh, A.; Gratuze, M.; Elsayed, M.; Nabki, F. Effects of Proof Mass Geometry on Piezoelectric Vibration Energy Harvesters. Sensors 2018, 18, 1584. [Google Scholar] [CrossRef] [PubMed]

- Alameh, A.H.; Gratuze, M.; Robichaud, A.; Nabki, F. Study and Design of MEMS Cross-Shaped Piezoelectric Vibration Energy Harvesters. In Proceedings of the 2018 25th IEEE International Conference on Electronics, Circuits and Systems (ICECS), Bordeaux, France, 9–12 December 2018; pp. 305–308. [Google Scholar]

- Dompierre, A.; Vengallatore, S.; Fréchette, L.G.; Vengallatore, S.; Fréchette, L.G. Piezoelectric Vibration Energy Harvesters Modeling, Design, Limits, and Benchmarking. In Energy Harvesting with Functional Materials and Microsystems; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Beeby, S.P. Energy Harvesting Devices. In Resonant MEMS; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015; pp. 451–474. [Google Scholar]

- Dhote, S.; Yang, Z.; Zu, J. Modeling and experimental parametric study of a tri-leg compliant orthoplanar spring based multi-mode piezoelectric energy harvester. Mech. Syst. Signal Process. 2018, 98, 268–280. [Google Scholar] [CrossRef]

- Yaghootkar, B.; Azimi, S.; Bahreyni, B. Wideband piezoelectric mems vibration sensor. In Proceedings of the 2016 IEEE SENSORS, Orlando, FL, USA, 30 October–3 November 2016; pp. 1–3. [Google Scholar]

- Hoffmann, D.; Bechtold, T.; Hohlfeld, D. Design optimization of MEMS piezoelectric energy harvester. In Proceedings of the 2016 17th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Montpellier, France, 18–20 April 2016; pp. 1–6. [Google Scholar]

- Zhu, D.; Tudor, M.J.; Beeby, S.P. Strategies for increasing the operating frequency range of vibration energy harvesters: A review. Meas. Sci. Technol. 2009, 21, 22001. [Google Scholar] [CrossRef]

- Cowen, A.; Hames, G.; Glukh, K.; Hardy, B. PiezoMUMPs Design Handbook; MEMSCAP Inc.: Crolles, France, 2014. [Google Scholar]

- Robichaud, A.; Deslandes, D.; Cicek, P.; Nabki, F. A Novel Topology for Process Variation-Tolerant Piezoelectric Micromachined Ultrasonic Transducers. J. Microelectromech. Syst. 2018, 27, 1204–1212. [Google Scholar] [CrossRef]

- Pons-Nin, J.; Gorreta, S.; Dominguez, M.; Blokhina, E.; O’Connell, D.; Feely, O. Design and test of resonators using PiezoMUMPS technology. In Proceedings of the 2014 Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS (DTIP), Cannes, France, 1–4 April 2014; pp. 1–6. [Google Scholar]

- Elsayed, M.Y.; Nabki, F. Piezoelectric Bulk Mode Disk Resonator Post-Processed for Enhanced Quality Factor Performance. J. Microelectromech. Syst. 2017, 26, 75–83. [Google Scholar] [CrossRef]

- Nabavi, S.; Zhang, L. Nonlinear Multi-mode Wideband Piezoelectric MEMS Vibration Energy Harvester. IEEE Sens. J. 2019, 19, 4837–4848. [Google Scholar] [CrossRef]

- Kovacic, I.; Brennan, M.J. The Duffing Equation: Nonlinear Oscillators and Their Behaviour; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Rezaeisaray, M.; Gowini, M.E.; Sameoto, D.; Raboud, D.; Moussa, W. Low frequency piezoelectric energy harvesting at multi vibration mode shapes. Sens. Actuators A Phys. 2015, 228, 104–111. [Google Scholar] [CrossRef]

- Wang, N.; Sun, C.; Siow, L.Y.; Ji, H.; Chang, P.; Zhang, Q.; Gu, Y. AlN wideband energy harvesters with wafer-level vacuum packaging utilizing three-wafer bonding. In Proceedings of the 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems (MEMS), Las Vegas, NV, USA, 22–26 January 2017; pp. 841–844. [Google Scholar]

- Aktakka, E.E.; Najafi, K. Three-axis piezoelectric vibration energy harvester. In Proceedings of the 2015 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 1141–1144. [Google Scholar]

| Variant 1 | Variant 2 | Variant 3 | |

|---|---|---|---|

| Size of the design (µm) | 1700 | 1700 | 1700 |

| Radius of the proof mass, Rm (µm) | 200 | 200 | 200 |

| Separation on the VEP (µm) | 10 | 10 | 10 |

| Radius of the circle of deposited piezo material on VEP(µm) | 500 | 500 | 500 |

| Petals used as anchors | 1 3 5 7 9 11 13 15 | 1 5 9 13 | 3 7 11 15 |

| Petals used as a VEP | 2 4 6 8 10 12 16 | 2 3 4 6 7 8 10 11 12 14 15 16 | 1 2 4 5 6 8 9 10 12 13 14 16 |

| Variant 1 | Variant 2 | Variant 3 * | |

|---|---|---|---|

| Simulation (Hz) | 10,600 | 8100 | 7300 |

| Median (Hz) | 10,680 | 8120 | 7286 |

| Mean (Hz) | 10,637 | 8141 | 7308 |

| Standard deviation (Hz) | 129 | 196 | 227 |

| Standard deviation (%) | 1.21 | 2.41 | 3.11 |

| Variant 1 | Variant 2 | Variant 3 | ||

|---|---|---|---|---|

| Resonant Mode 1 | Start Frequency (Hz) | 10,696 | 7466 | 3906 |

| Measured | Simulated Resonant Frequency (Hz) | 10,860 | 10,800 | 7902 | 8100 | 3971 | 4050 | |

| Stop Frequency (Hz) | 10,887 | 7922 | 4138 | |

| Linearity | Non-linear | Non-linear | Non-linear | |

| Resonant Mode 2 | Start Frequency (Hz) | 14,216 | 12,839 | 7098 |

| Measured | Simulated Resonant Frequency (Hz) | 14,485 | 15,000 | 12,941 | 13,100 | 7166 | 7243 | |

| Stop Frequency (Hz) | 14,507 | 12,973 | 7243 | |

| Linearity | Non-linear | Non-linear | Linear | |

| Resonant Mode 3 | Start Frequency (Hz) | -- | 20,744 | 12,688 |

| Measured | Simulated Resonant Frequency (Hz) | -- | 20,871 | 20,987 | 12,757 | 12,833 | |

| Stop Frequency (Hz) | -- | 20,987 | 12,833 | |

| Linearity | -- | Non-linear | Linear |

| Variant 2 | Variant 3 | [1] | [13] | [34] | [35] | [36] | |

|---|---|---|---|---|---|---|---|

| Volume (mm3) | 1.156 | 1.156 | 57.6 | 25.6 | 14.4 | 112 | 6500 |

| Piezo material | AlN | AlN | AlN | AlN | AlN | AlN | PZT |

| Operating bandwidth (Hz) | 7466–7922 | 3906–4138 | 730–1000 | 190 | 85–95 | 859.9–924.5 | 387–398 |

| Linearity | Non-linear | Non-linear | Non-linear | Linear | Non-linear | Non-linear | Linear |

| Acceleration (g) | 10 | 10 | 1 | 15 | 0,2 | 2 | 0.05 |

| Output Voltage (mV) | 54.2 | 21.52 | 770.3 | 130 | 1000 | 4433 | 1000 |

| Load | 150 kΩ | 150 kΩ | 70 kΩ | 1 MΩ | 1 MΩ | 100 kΩ | 1 MΩ |

| Output Power (nW) | 20 | 3.1 | 1730 | 169 | 136 | 82240 | 52900 |

| FOM nW·mm−3·g−2 | 0.17 | 0.3 | 30.03 | 0.03 | 236.11 | 183.82 | 3255 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gratuze, M.; Alameh, A.H.; Nabki, F. Design of the Squared Daisy: A Multi-Mode Energy Harvester, with Reduced Variability and a Non-Linear Frequency Response. Sensors 2019, 19, 3247. https://doi.org/10.3390/s19153247

Gratuze M, Alameh AH, Nabki F. Design of the Squared Daisy: A Multi-Mode Energy Harvester, with Reduced Variability and a Non-Linear Frequency Response. Sensors. 2019; 19(15):3247. https://doi.org/10.3390/s19153247

Chicago/Turabian StyleGratuze, Mathieu, Abdul Hafiz Alameh, and Frederic Nabki. 2019. "Design of the Squared Daisy: A Multi-Mode Energy Harvester, with Reduced Variability and a Non-Linear Frequency Response" Sensors 19, no. 15: 3247. https://doi.org/10.3390/s19153247

APA StyleGratuze, M., Alameh, A. H., & Nabki, F. (2019). Design of the Squared Daisy: A Multi-Mode Energy Harvester, with Reduced Variability and a Non-Linear Frequency Response. Sensors, 19(15), 3247. https://doi.org/10.3390/s19153247