Broadband Linear High-Power Amplifier Based on the Parallel Amplification Architecture for Electromagnetic Ultrasonic Guided Wave

Abstract

1. Introduction

2. Configuration Selection

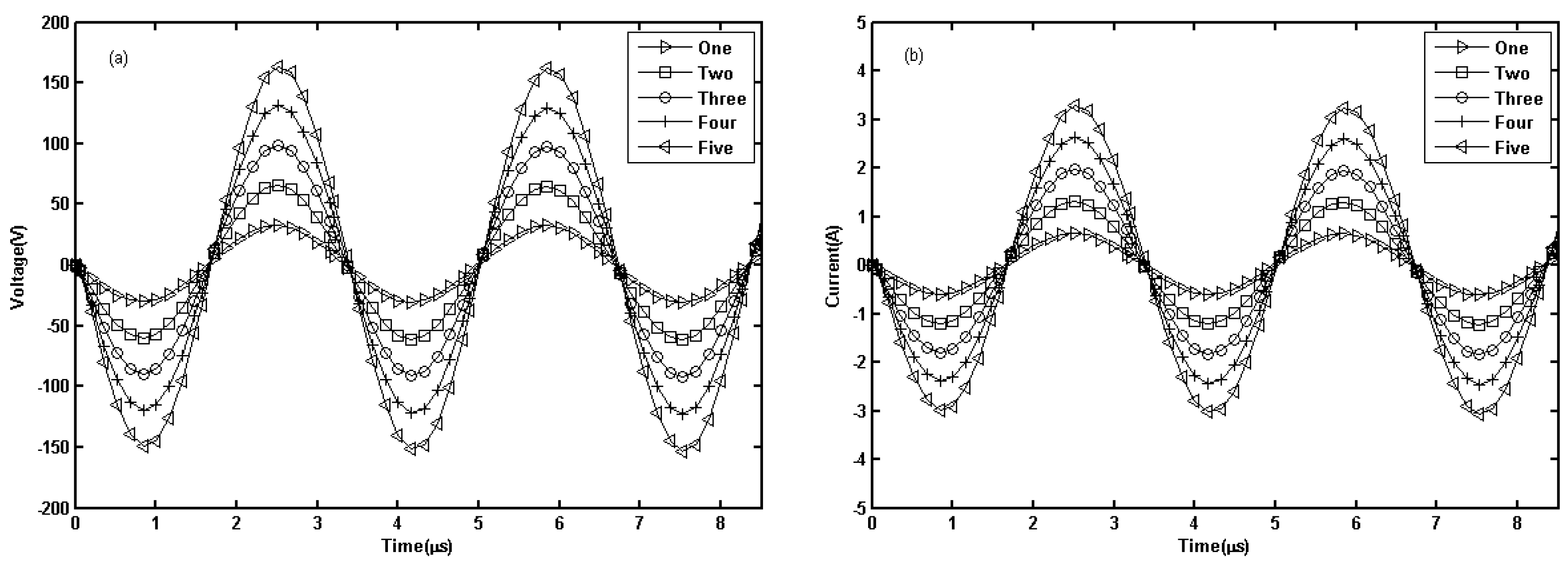

2.1. Performance Evaluation of the Parallel LAMs

2.2. Gated Linear PA Configuration

3. Implementation

3.1. AC and DC Coupling Circuit

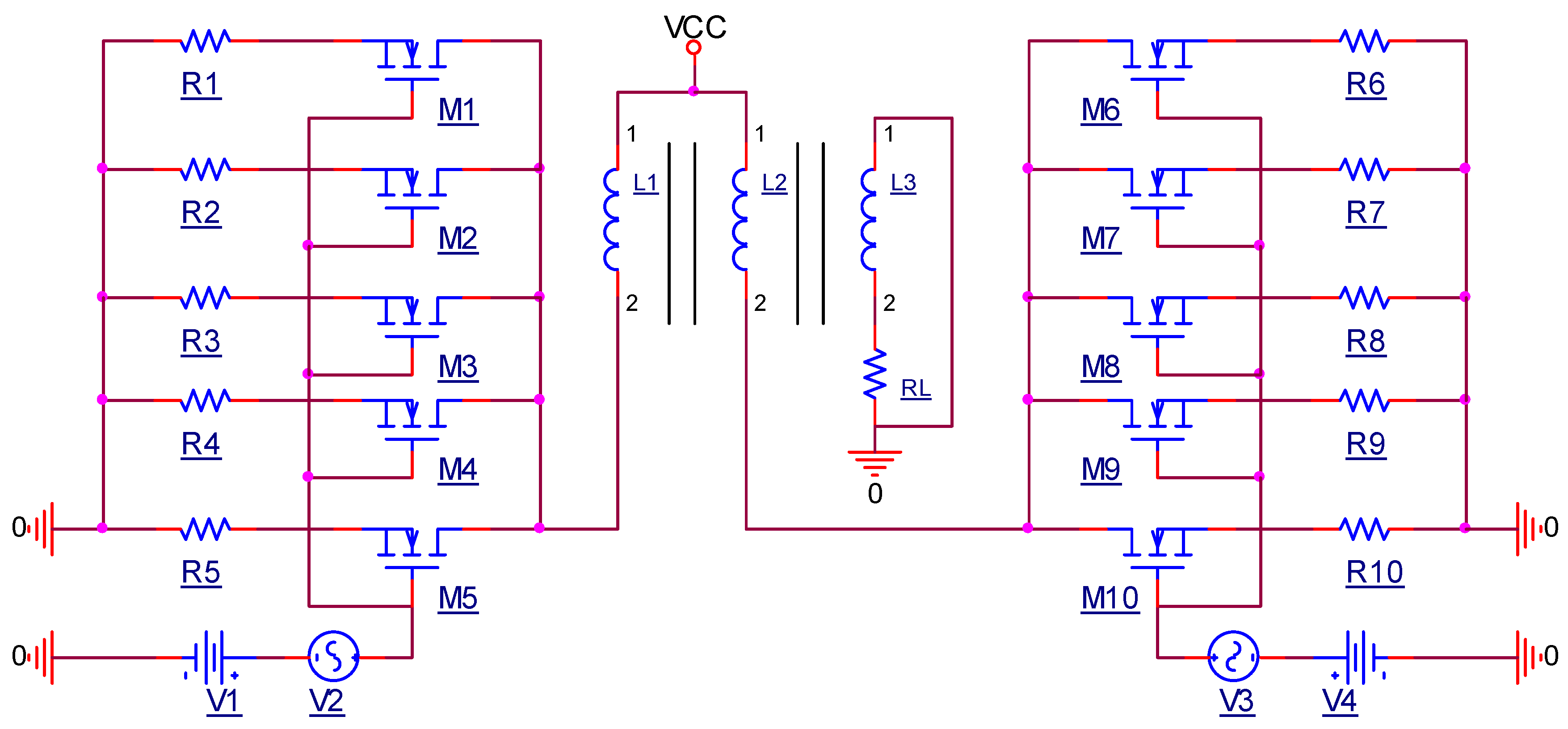

3.2. Amplifier Module

4. Performance Evaluation

4.1. Gating Mode Test

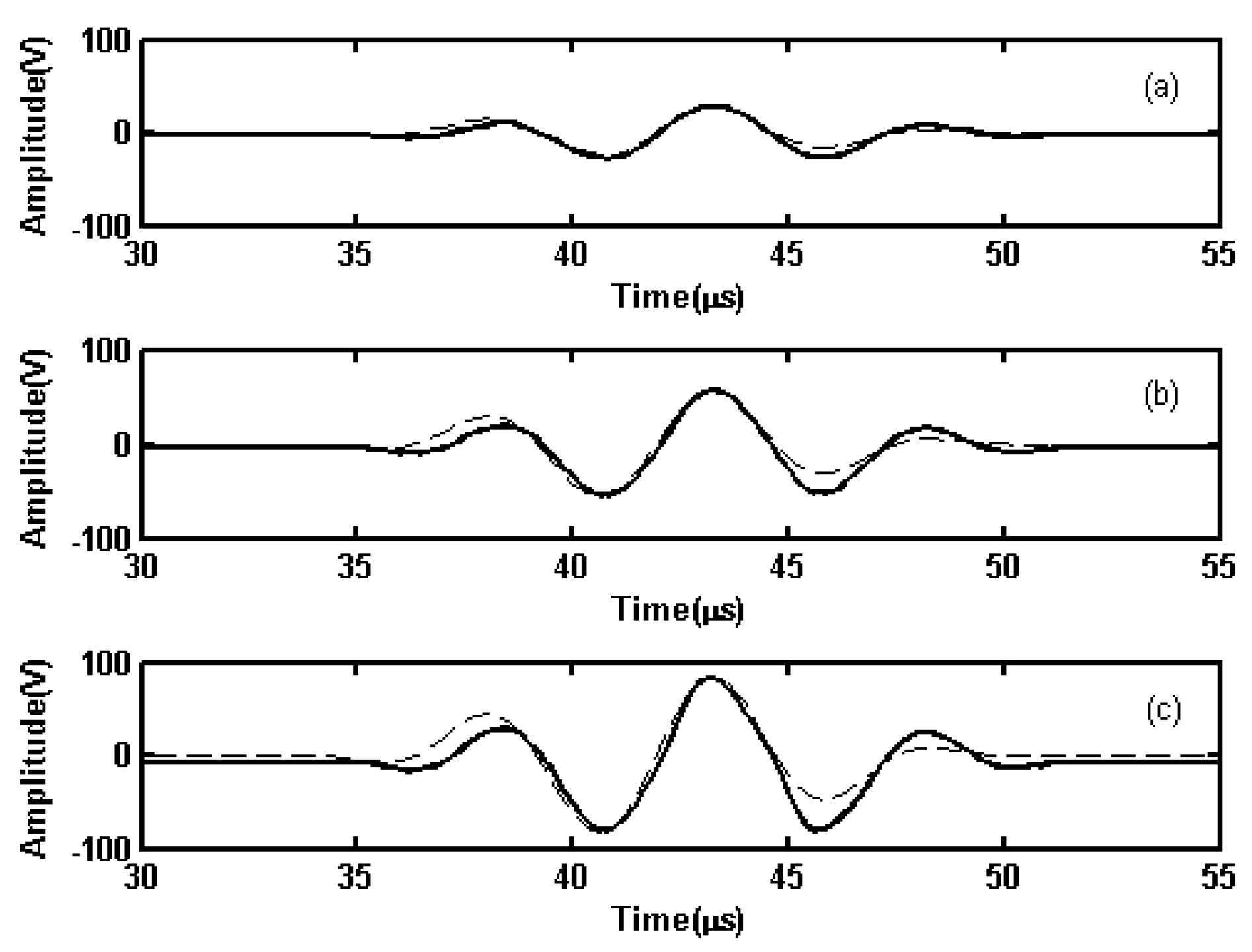

4.2. Measurement with Typical Guided Wave Source Signals

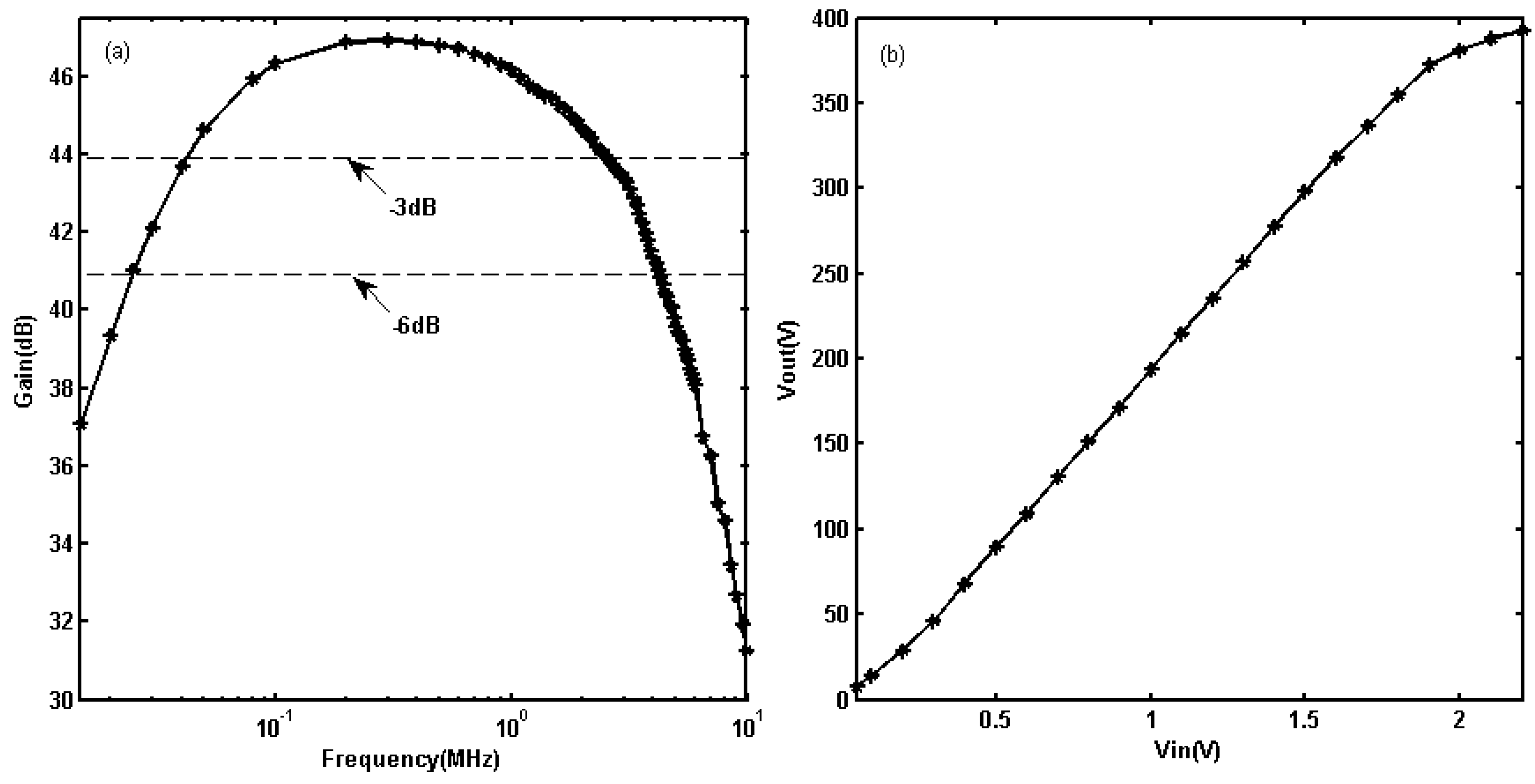

4.3. Evaluation of Voltage Gain and P1dB Compression Point

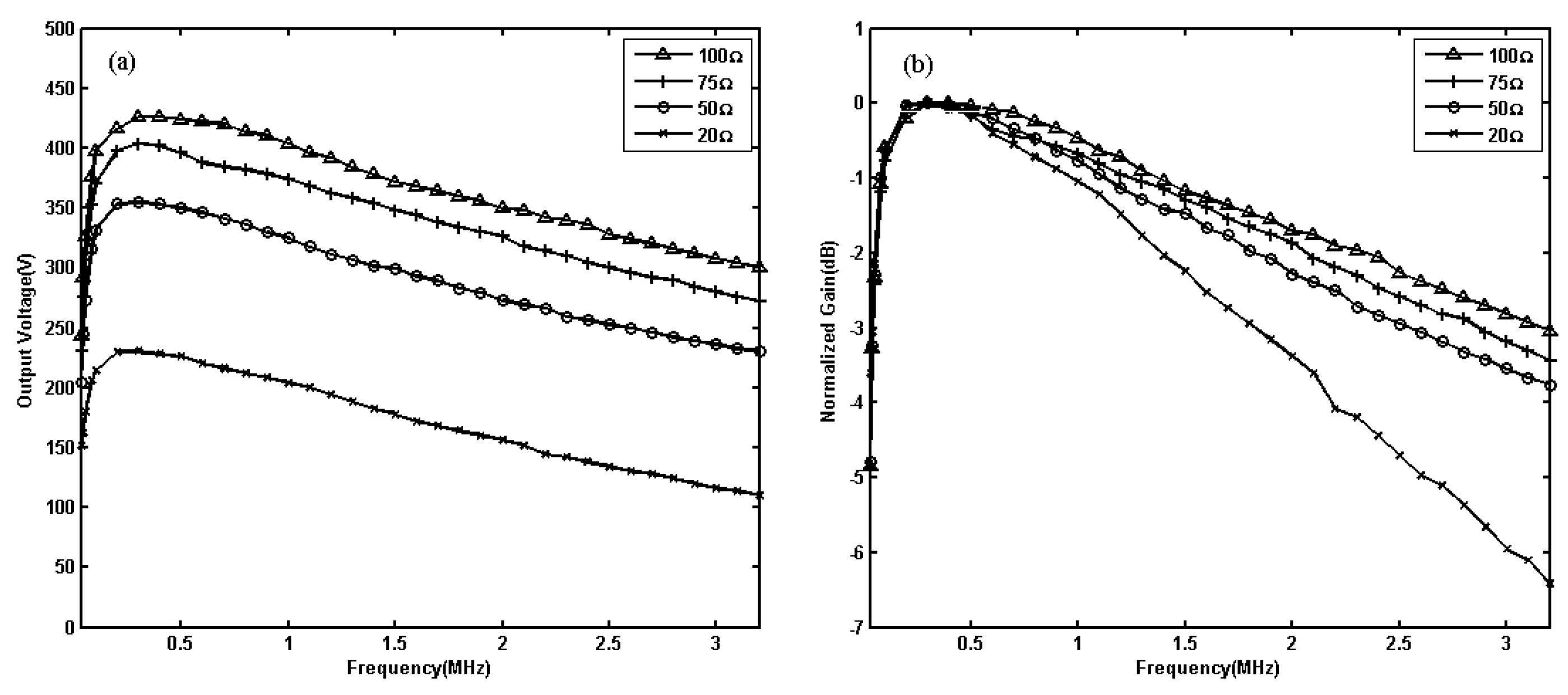

4.4. Evaluation of Different Resistance Effects

5. EMAT Inspection Experiment and Results

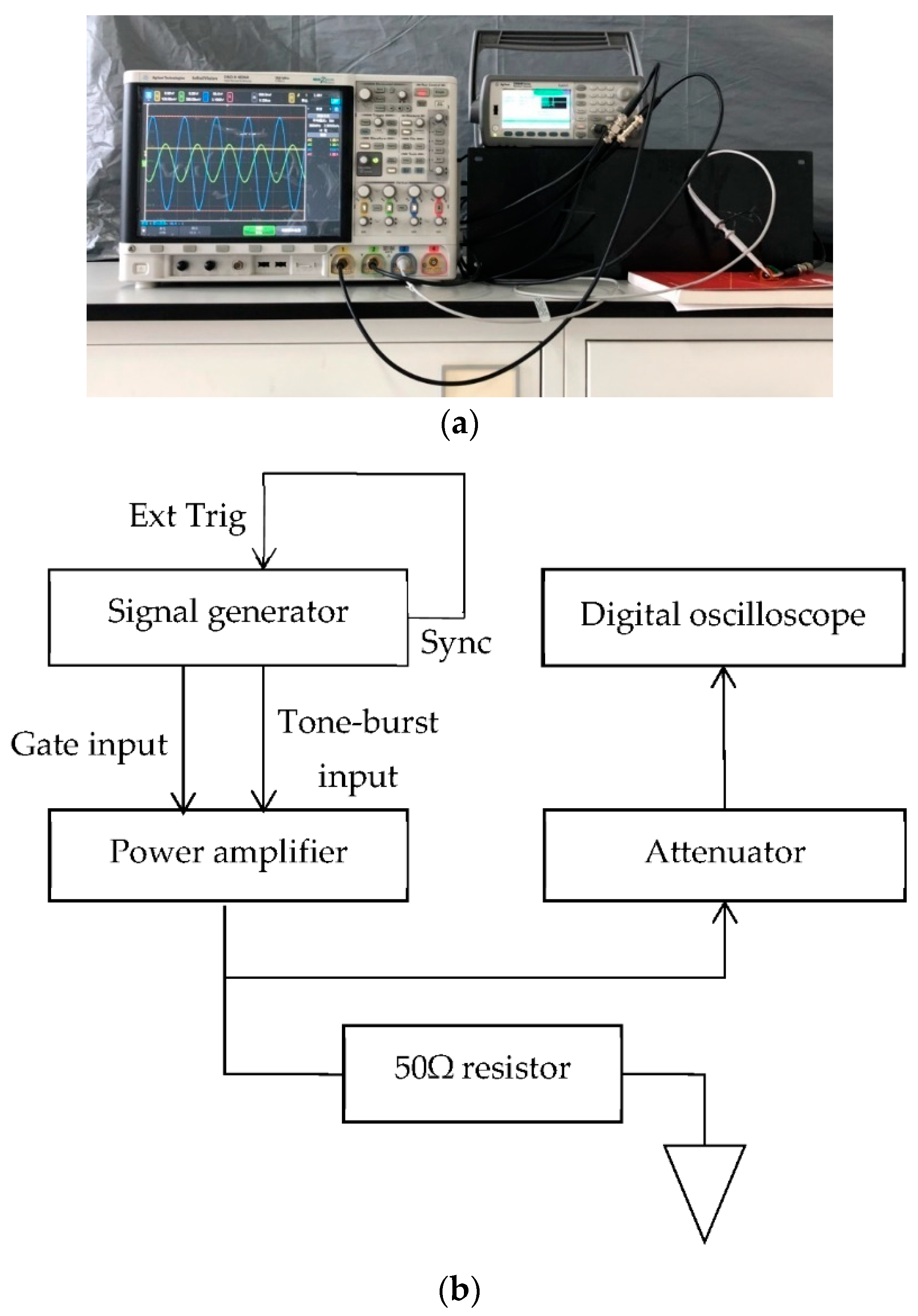

5.1. Experimental System

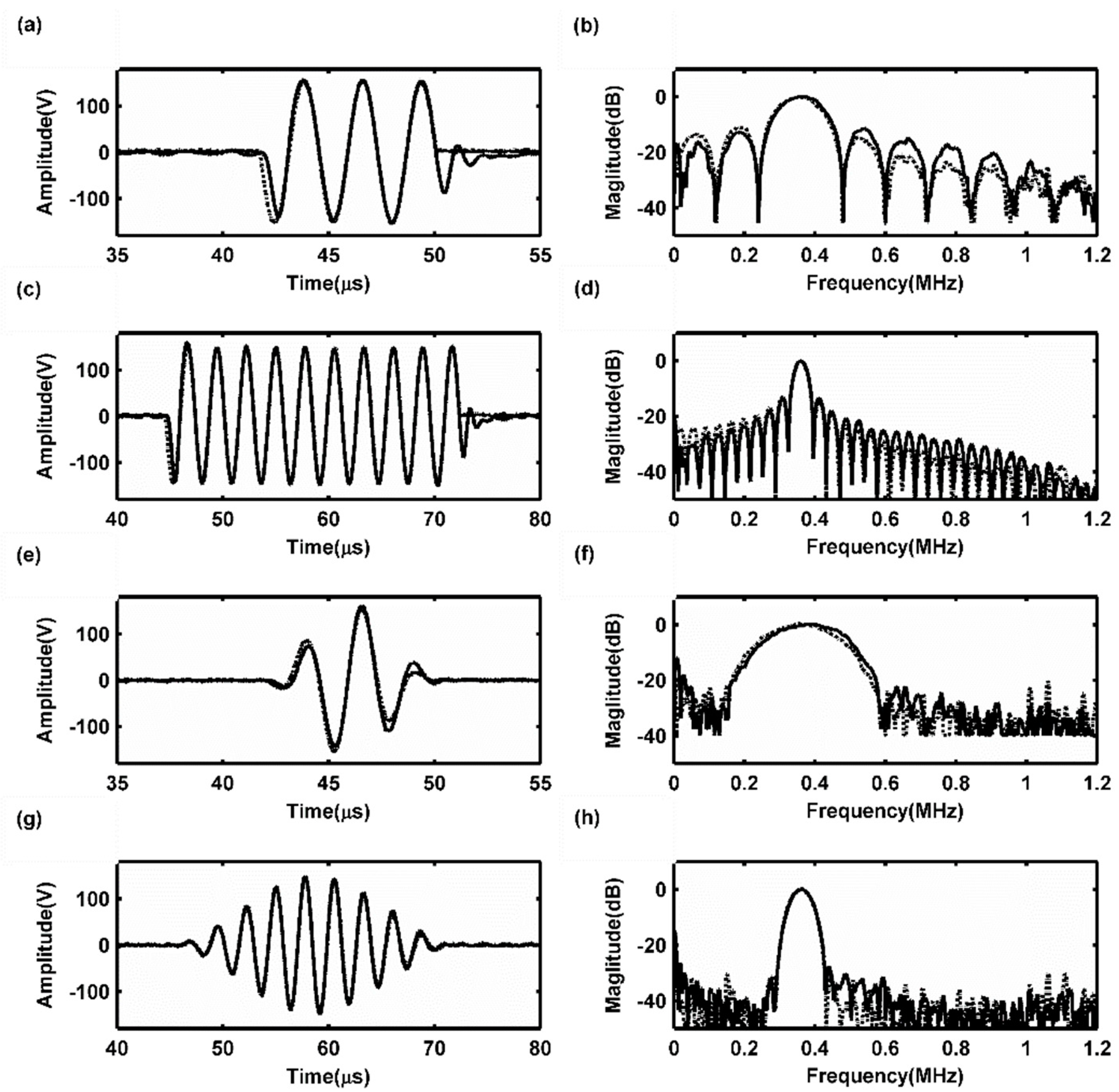

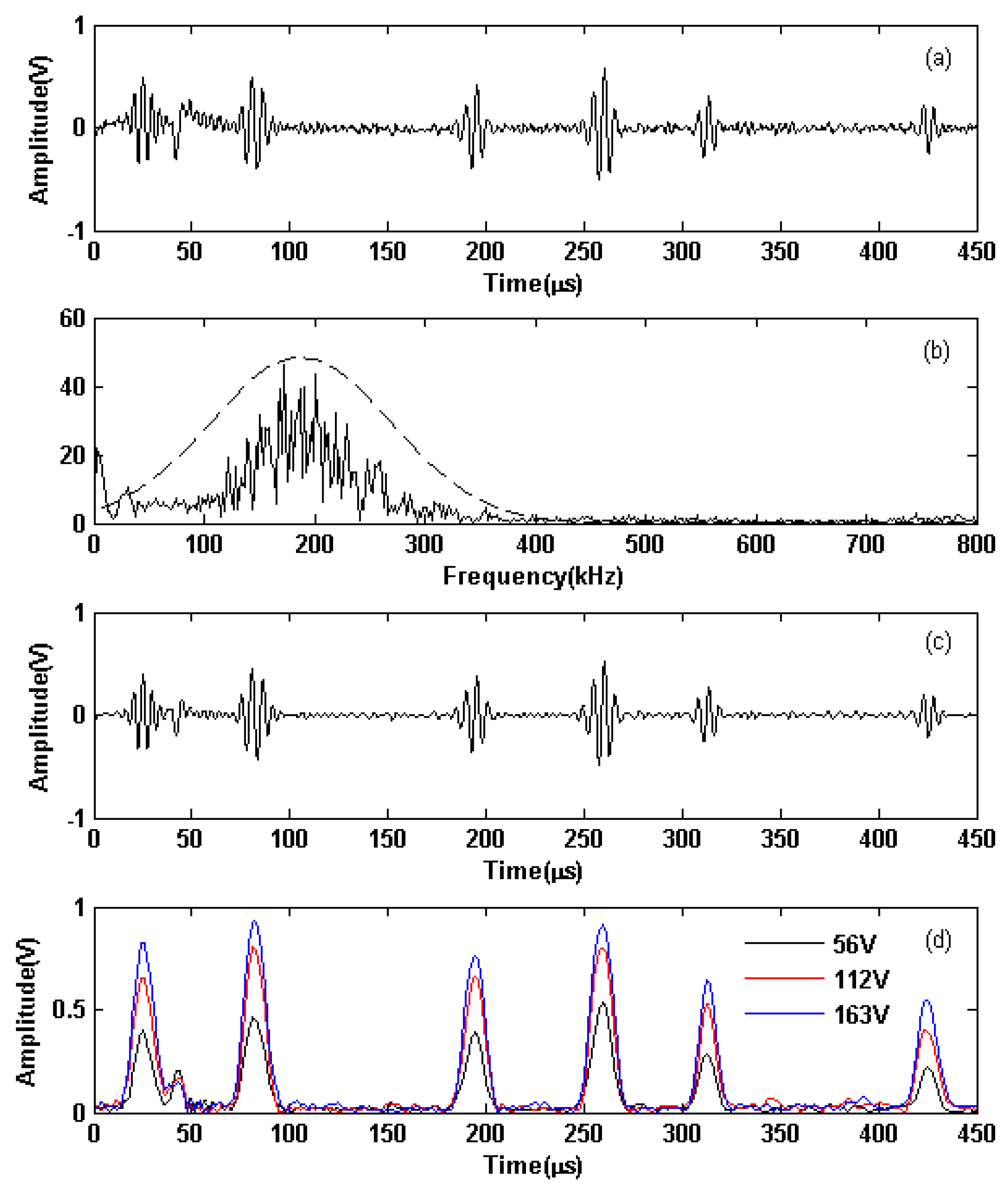

5.2. EMAT Inspection Experiment and Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cong, M.; Wu, X.J.; Qian, C.Q. A longitudinal lode electromagnetic acoustic transducer (EMAT) based on a permanent magnet chain for pipe inspection. Sensors 2016, 16, 740. [Google Scholar] [CrossRef]

- Wilcox, P.; Lowe, M.J.S.; Cawley, P. The excitation and detection of Lamb waves with planar coil electromagnetic acoustic transducers. IEEE Trans. Ultrason. Ferroelec. Freq. Contr. 2005, 52, 2370–2382. [Google Scholar] [CrossRef]

- Lee, J.K.; Kim, Y.Y. Tuned double-coil EMATs for omnidirectional symmetric mode lamb wave generation. NDT E Int. 2016, 83, 38–47. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, D.H. Integrity evaluation of pipe welding zones using wavelet transforms, and specific sensitivities based on SH-EMAT Pulse-Echo Method. Int. J. Precis. Eng. Manufac. 2014, 15, 2051–2057. [Google Scholar] [CrossRef]

- Clough, M.; Fleming, M.; Dixon, S. Circumferential guided wave EMAT system for pipeline screening using shear horizontal ultrasound. NDT E Int. 2017, 86, 20–27. [Google Scholar] [CrossRef]

- Kogia, M.; Gan, T.H.; Balachandran, W.; Livadas, M.; Kappatos, V.; Szabo, I.; Mohimi, A.; Round, A. High temperature shear horizontal electromagnetic acoustic transducer for guided wave inspection. Sensors 2016, 16, 582. [Google Scholar] [CrossRef]

- Kogia, M.; Cheng, L.; Mohimi, A.; Kappatos, A.; Gan, T.H.; Balachandran, W.; Selcuk, C. Electromagnetic acoustic transducers applied to high temperature plates for potential use in the solar thermal industry. Appl. Sci. 2015, 5, 1715–1734. [Google Scholar] [CrossRef]

- Lunna, N.; Dixona, S.; Potterb, M.D.G. High temperature EMAT design for scanning or fixed point operation on magnetite coated steel. NDT E Int. 2017, 89, 74–80. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhao, J.C.; Wu, B.; Zhang, L.N.; He, C.F. Configuration optimization of magnetostrictive transducers for longitudinal guided wave inspection in seven-wire steel strands. NDT E Int. 2010, 43, 484–492. [Google Scholar] [CrossRef]

- Wilcox, P.; Lowe, M.J.S.; Cawley, P. The effect of dispersion on long range inspection using guided waves. NDT E Int. 2001, 34, 1–9. [Google Scholar] [CrossRef]

- Boonsang, S.; Dewhurst, R.J. A sensitive electromagnetic acoustic transducer for picometer-scale ultrasonic displacement measurements. Sens. Actuator A 2006, 127, 345–354. [Google Scholar] [CrossRef]

- Isla, J.; Cegla, F. EMAT phased array: A feasibility study of surface crack detection. Ultrasonics 2017, 78, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Jeremy, A.B.; Geoffrey, R.L. A low-cost, high-performance pulse generator for ultrasound imaging. IEEE Trans. Ultrason. Ferroelec. Freq. Contr. 2002, 49, 848–851. [Google Scholar]

- Salazar, J.; Turó, A.J.; Chhvez, J.A.; Ortega, J.A.; Garcia, M.J. High-power high-resolution pulser for air-coupled ultrasonic NDE applications. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference, Budapest, Hungary, 21–23 May 2001. [Google Scholar]

- Rodríguez-Olivares, N.A.; Cruz-Cruz, J.V.; Gómez-Hernández, A.; Hernández-Alvarado, R.; Nava-Balanzar, L.; Salgado-Jiménez, T.; Soto-Cajiga, J.A. Improvement of ultrasonic pulse generator for automatic pipeline inspection. Sensors 2018, 18, 2950. [Google Scholar] [CrossRef] [PubMed]

- Svilainis, L.; Chaziachmetovas, A.; Dumbrava, V. Efficient high voltage pulser for piezoelectric air coupled transducer. Ultrasonics 2013, 53, 225–231. [Google Scholar] [CrossRef] [PubMed]

- Svilainis, L.; Chaziachmetovas, A.; Dumbrava, V. Half bridge topology 500 V pulser for ultrasonic transducer excitation. Ultrasonics 2015, 59, 79–85. [Google Scholar] [CrossRef]

- Svilainis, L.; Dumbrava, V.; Chaziachmetovas, A. Investigation of the half bridge and transformer push–pull pulser topologies for ultrasonic transducer excitation. J. Circuits Syst. Comput. 2015, 24, 1550062. [Google Scholar] [CrossRef]

- Xu, X.C.; Yen, J.T.; Shung, K.K. A low-cost bipolar pulse generator for high-frequency ultrasound applications. IEEE Trans. Ultrason. Ferroelec. Freq. Contr. 2007, 54, 443–447. [Google Scholar] [CrossRef]

- Peng, H.; Sabate, J.; Wall, K.A.; Glaser, J.S. GaN-based high-frequency high-energy delivery transformer push–pull inverter for ultrasound pulsing application. IEEE Trans. Power Electron. 2018, 33, 6794–6805. [Google Scholar] [CrossRef]

- Gao, H.D.; Lopez, B. Development of single-channel and phased array electromagnetic acoustic transducers for austenitic weld testing. Mater. Eval. 2010, 68, 821–827. [Google Scholar]

- Agbossou, K.; Dion, J.L.; Carignan, S.; Abdelkrim, M.; Cheriti, A. Class D amplifier for a power piezoelectric load. IEEE Trans. Ultrason. Ferroelec. Freq. Contr. 2000, 47, 1036–1041. [Google Scholar] [CrossRef] [PubMed]

- Svilainis, L.; Motiejunas, G. Power amplifier for ultrasonic transducer excitation. Ultragarsas 2006, 58, 30–36. [Google Scholar]

- Park, J.; Hu, C.; Shung, K.K. Stand-alone front-end system for high-frequency, high-frame-rate coded excitation ultrasonic imaging. IEEE Trans. Ultrason. Ferroelec. Freq. Contr. 2011, 58, 2620–2630. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Park, J.; Hu, C.; Li, X.; Zhou, Q.; Shung, K.K. Wideband linear power amplifier for high-frequency ultrasonic coded excitation imaging. IEEE Trans. Ultrason. Ferroelec. Freq. Contr. 2012, 59, 825–832. [Google Scholar] [CrossRef] [PubMed]

- Gaspar, M.; Pedrozzi, M.; Ferreira, L.F.R.; Garvey, T. A compact 500 MHz 4 kW solid-state power amplifier for accelerator applications. Nucl. Instrum. Methods Phys. Res. A 2011, 637, 18–24. [Google Scholar] [CrossRef]

- Jain, A.; Hannurkar, P.R.; Sharma, D.K.; Gupta, A.K.; Tiwari, A.K.; Lad, M.; Kumar, R.; Badapanda, M.K.; Gupta, P.D. Modular 20 kW solid state RF amplifier for Indus-2 syncrotron radiation source. Nucl. Instrum. Methods Phys. Res. A 2012, 676, 74–83. [Google Scholar] [CrossRef]

- Ramarao, B.V.; Sonal, S.; Mishra, J.K.; Pande, M.; Singh, P.; Kumar, G.; Mukherjee, J. Development of 3 kW at 325 MHz solid-state RF power amplifier using four power amplifier modules. Nucl. Instrum. Methods Phys. Res. A 2014, 735, 283–290. [Google Scholar] [CrossRef]

- Song, K.; Zhang, F.; Hu, S.; Fan, Y. Ku-band 200-W pulsed power amplifier based on waveguide spatially power-combining technique for industrial applications. IEEE Trans. Ind. Electron. 2014, 61, 4274–4280. [Google Scholar] [CrossRef]

- Jia, P.C.; Chen, L.Y.; Alexanian, A.; York, R.A. Broad-band high power amplifier using spatial power-combining technique. IEEE Trans. Mircow. Theory Tech. 2003, 51, 2469–2475. [Google Scholar]

- Lewis, G.K.; Olbricht, W.L. Development of a portable therapeutic and high intensity ultrasound system for military, medical, and research use. Rev. Sci. Instrum. 2008, 80, 114302. [Google Scholar] [CrossRef]

- Lewis, G.K.; Olbricht, W.L. Design and characterization of a high-power ultrasound driver with ultralow-output impedance. Rev. Sci. Instrum. 2009, 80, 114704. [Google Scholar] [CrossRef] [PubMed]

- Mingyang, L.; Anthony, P.; Wuliang, Y. Acceleration of frequency sweeping in eddy-current computation. IEEE Trans. Magn. 2017, 53, 1–8. [Google Scholar]

- Mingyang, L.; Liyuan, Y.; Anthony, P.; Wuliang, Y. A novel compensation algorithm for thickness measurement immune to lift-off variations using eddy current method. IEEE Trans. Instrum. Meas. 2016, 65, 2773–2779. [Google Scholar]

- Mingyang, L.; Wenqian, Z.; Liyuan, Y.; Anthony, P.; Wuliang, Y.; Zhigang, Q. Reducing the lift-off effect on permeability measurement for magnetic plates from multifrequency induction data. IEEE Trans. Instrum. Meas. 2017, 67, 167–174. [Google Scholar]

- Mingyang, L.; Hanyang, X.; Wenqian, Z.; Liyuan, Y.; Qian, Z.; Anthony, P.; Wuliang, Y. Conductivity lift-off invariance and measurement of permeability for ferrite metallic plates. NDT E Int. 2018, 95, 36–44. [Google Scholar]

| Experimental No. | Materials | L1/mm | L2/mm | H/mm | L3/mm | L4/mm |

|---|---|---|---|---|---|---|

| 1 | Al | 1200 | 1200 | 3 | 300 | 300 |

| 2 | Fe | 500 | 600 | 1.5 | 70 | 230 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Zheng, Y. Broadband Linear High-Power Amplifier Based on the Parallel Amplification Architecture for Electromagnetic Ultrasonic Guided Wave. Sensors 2019, 19, 2924. https://doi.org/10.3390/s19132924

Zhou J, Zheng Y. Broadband Linear High-Power Amplifier Based on the Parallel Amplification Architecture for Electromagnetic Ultrasonic Guided Wave. Sensors. 2019; 19(13):2924. https://doi.org/10.3390/s19132924

Chicago/Turabian StyleZhou, Jinjie, and Yang Zheng. 2019. "Broadband Linear High-Power Amplifier Based on the Parallel Amplification Architecture for Electromagnetic Ultrasonic Guided Wave" Sensors 19, no. 13: 2924. https://doi.org/10.3390/s19132924

APA StyleZhou, J., & Zheng, Y. (2019). Broadband Linear High-Power Amplifier Based on the Parallel Amplification Architecture for Electromagnetic Ultrasonic Guided Wave. Sensors, 19(13), 2924. https://doi.org/10.3390/s19132924