Impact of Thermal Control Measures on the Imaging Quality of an Aerial Optoelectronic Sensor

Abstract

1. Introduction

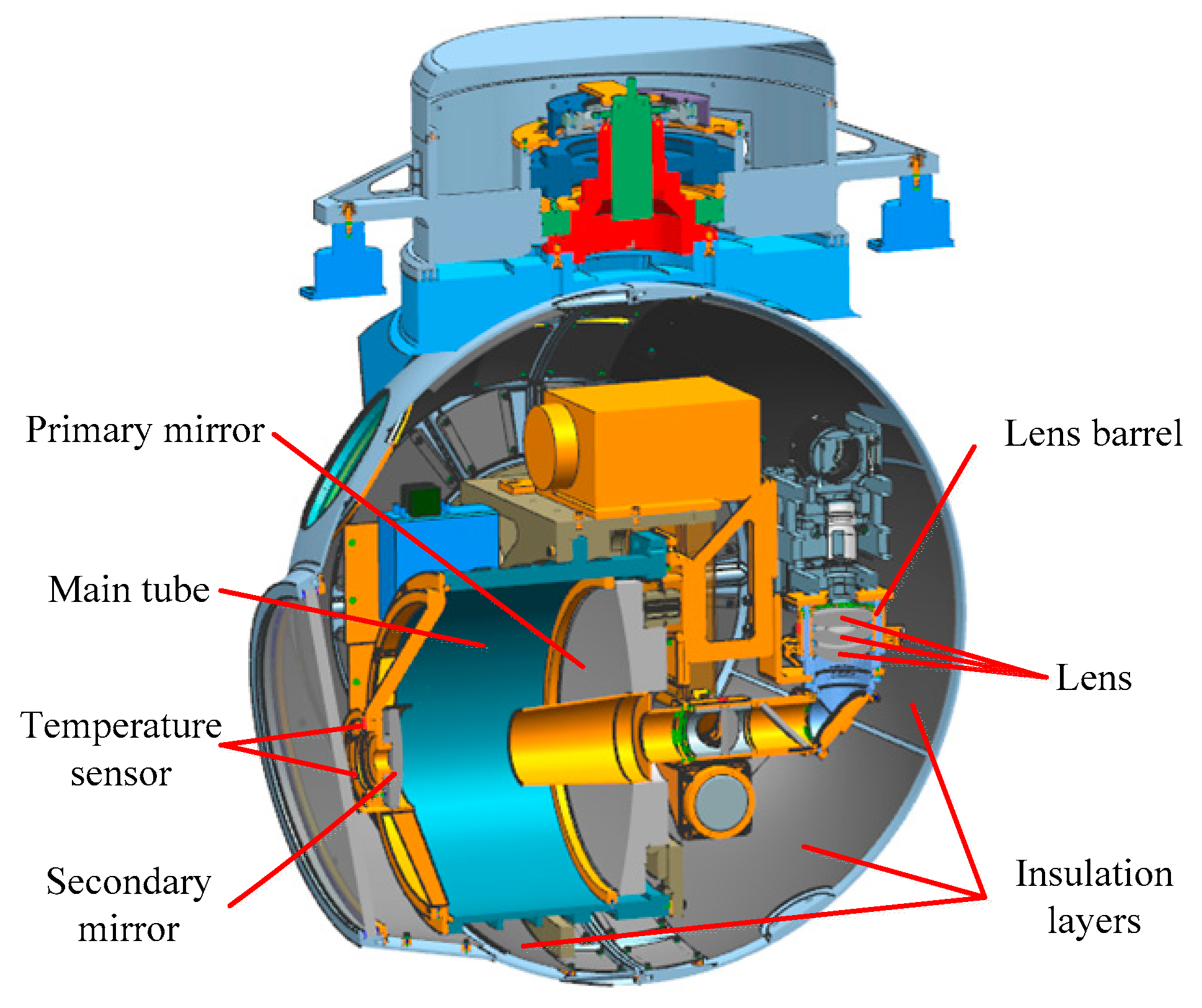

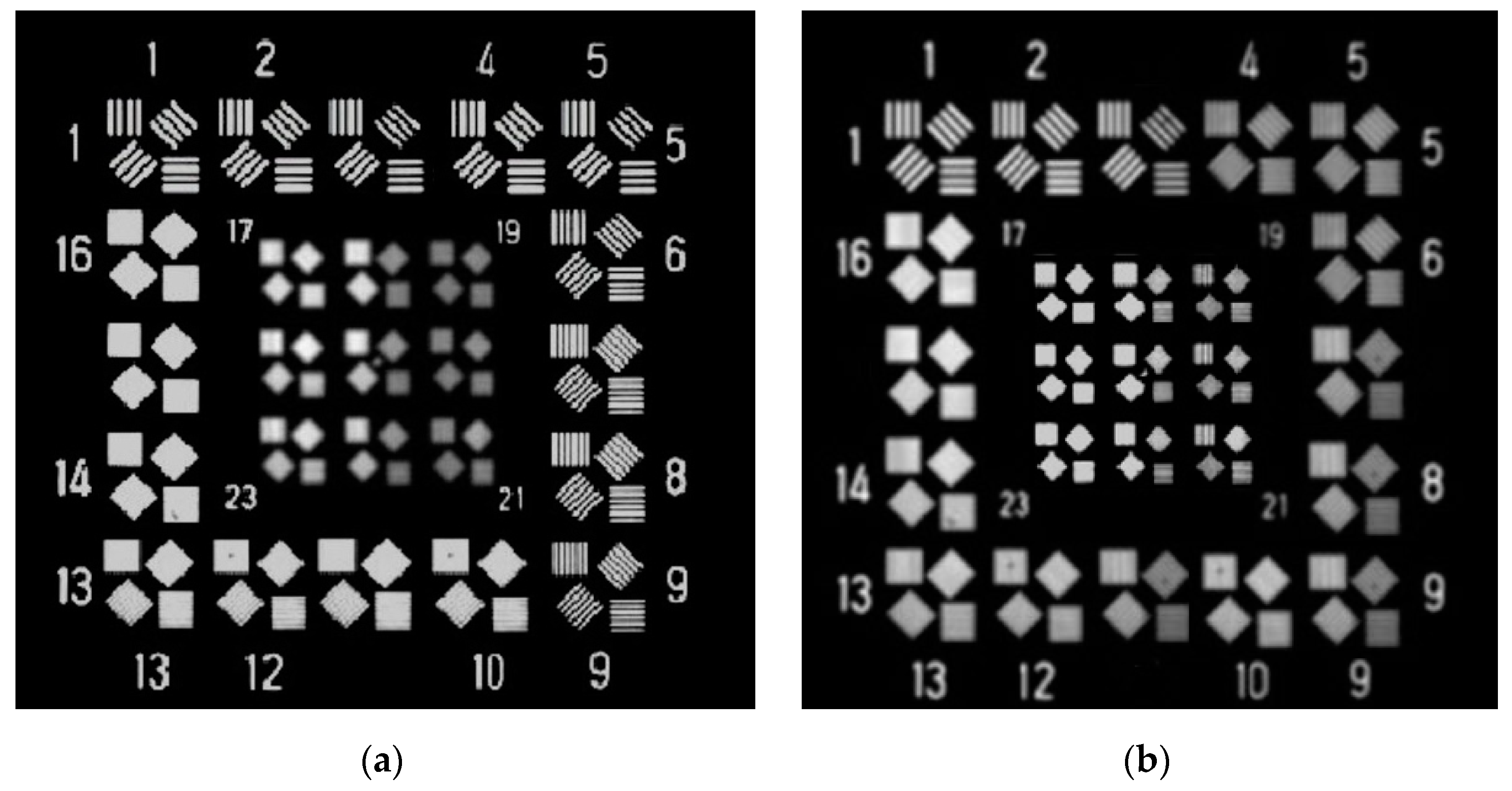

2. Experimental Phenomenon of the Aerial Optoelectronic Sensor

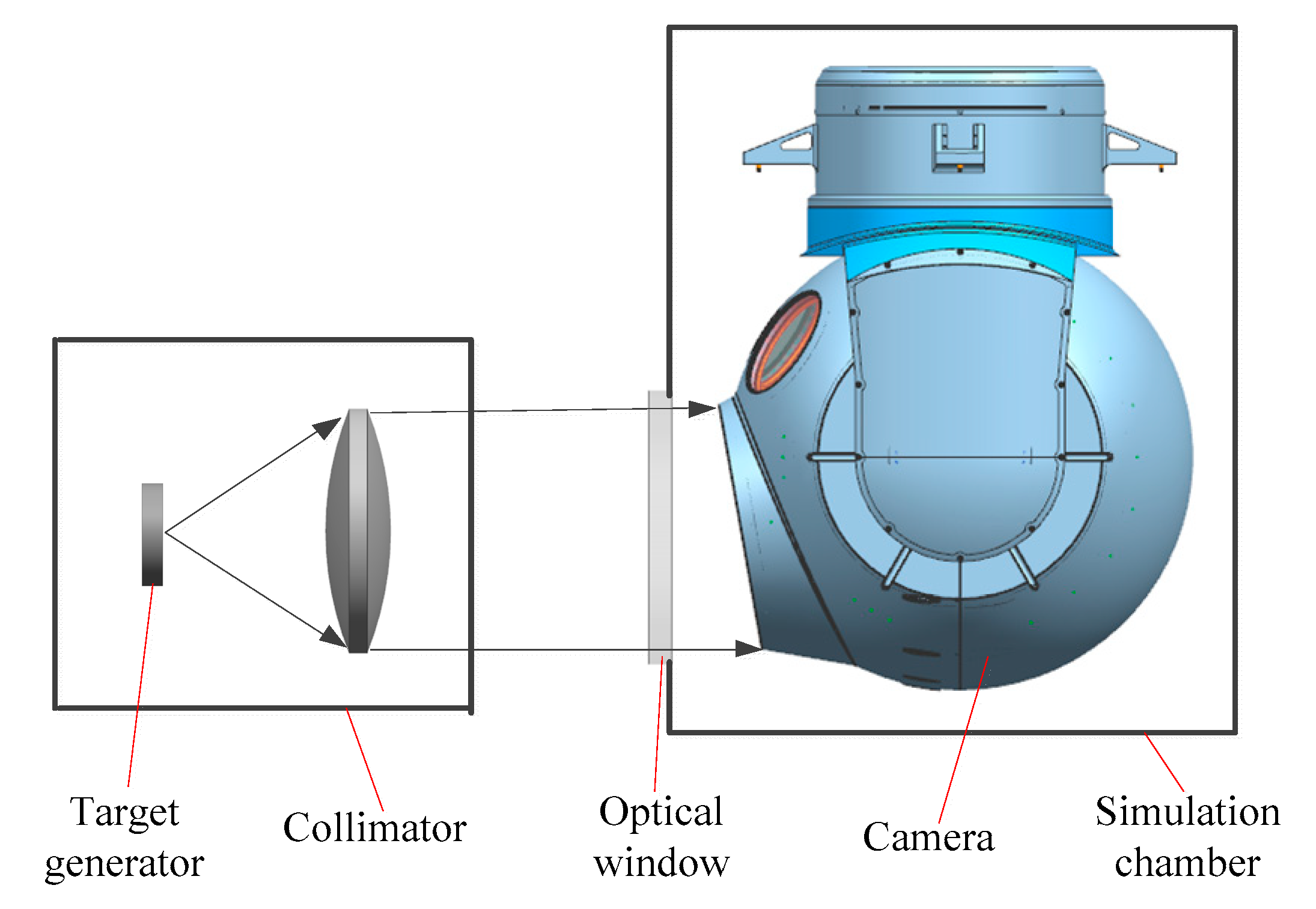

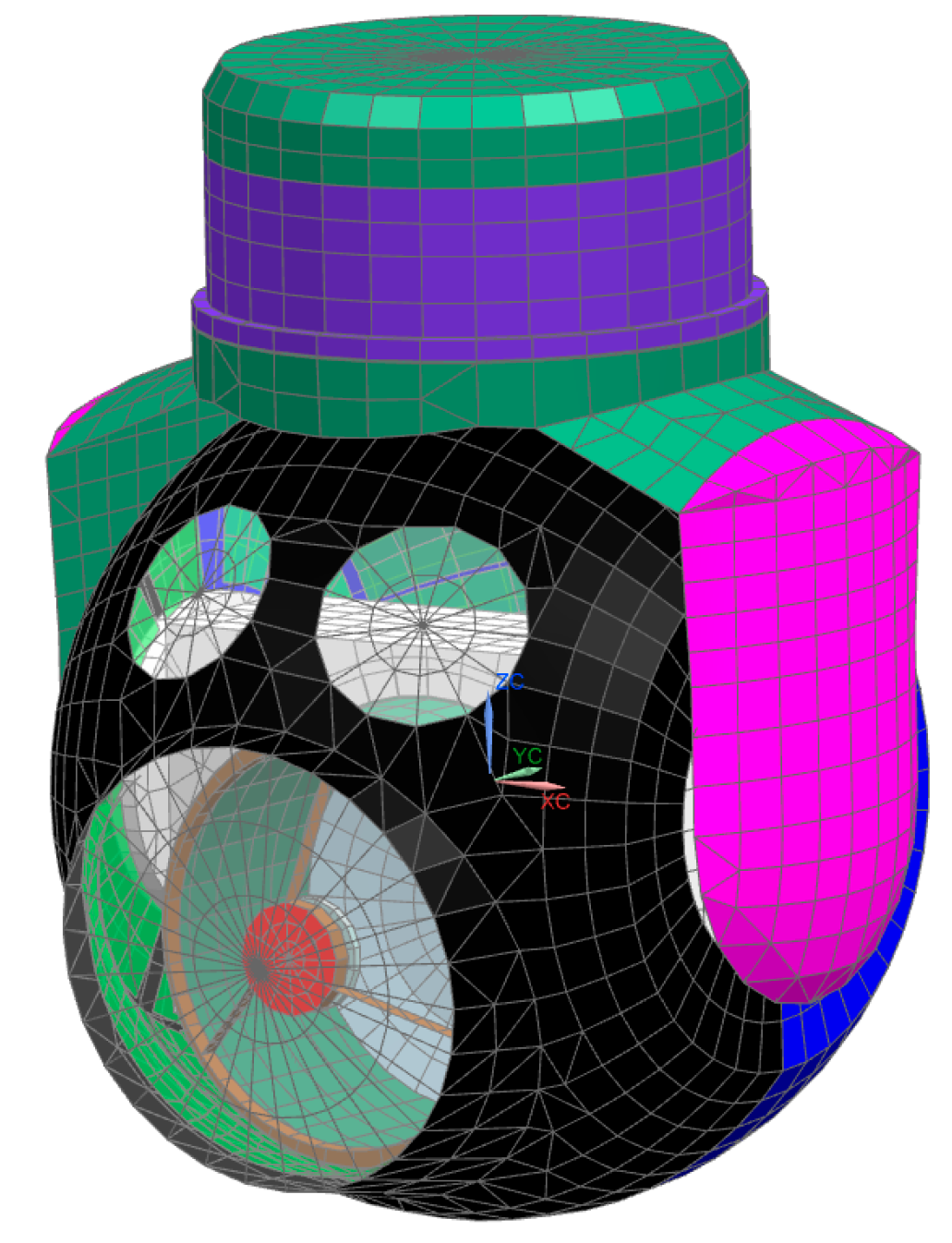

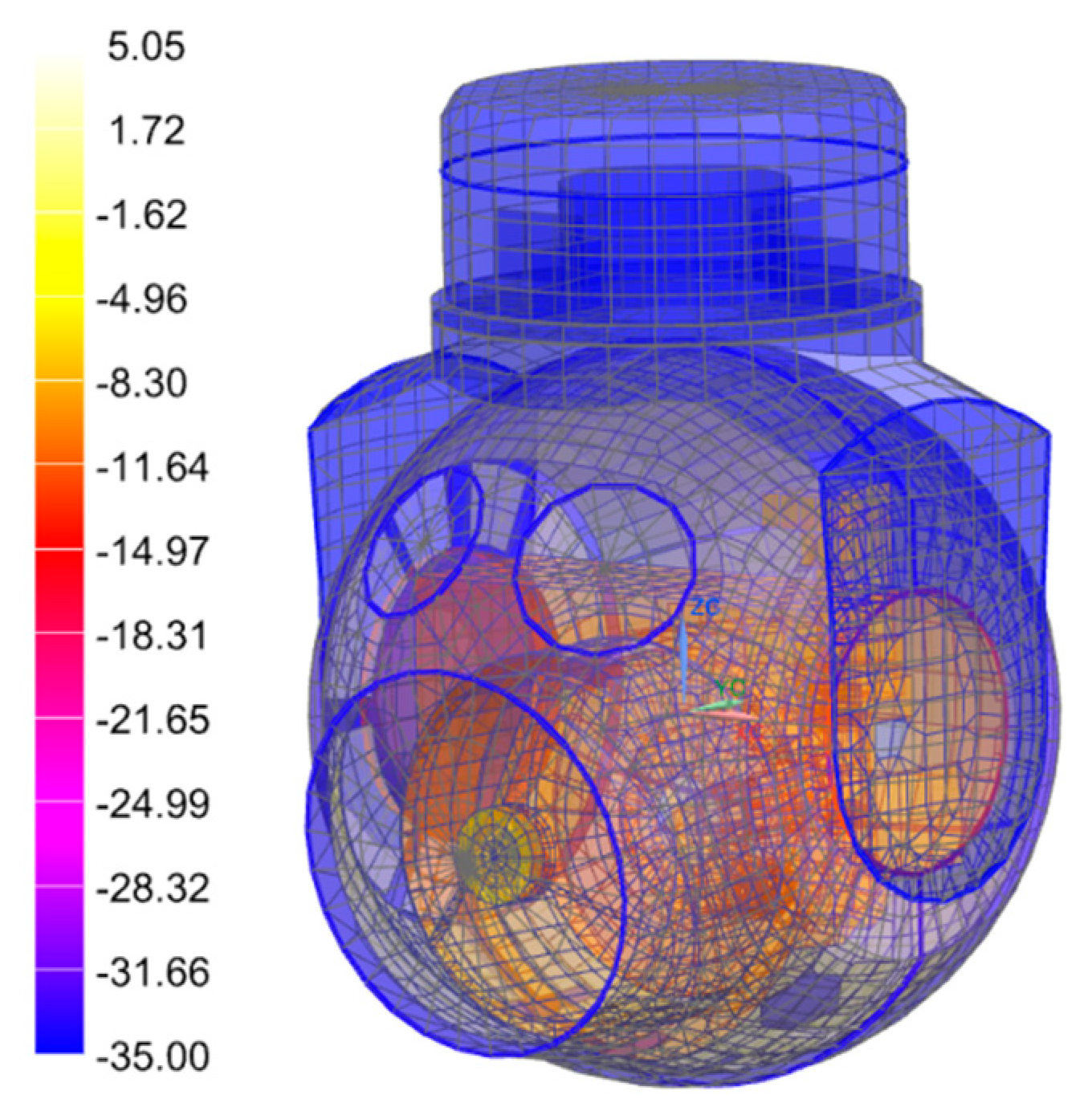

3. Analysis of the Thermal Imaging Test

3.1. Impacts of Temperature Level and Temperature Gradient on Imaging Quality

3.2. Optical Analysis of the Sensor Based on the Present Control Measures

4. Improvement of Thermal Control Measures

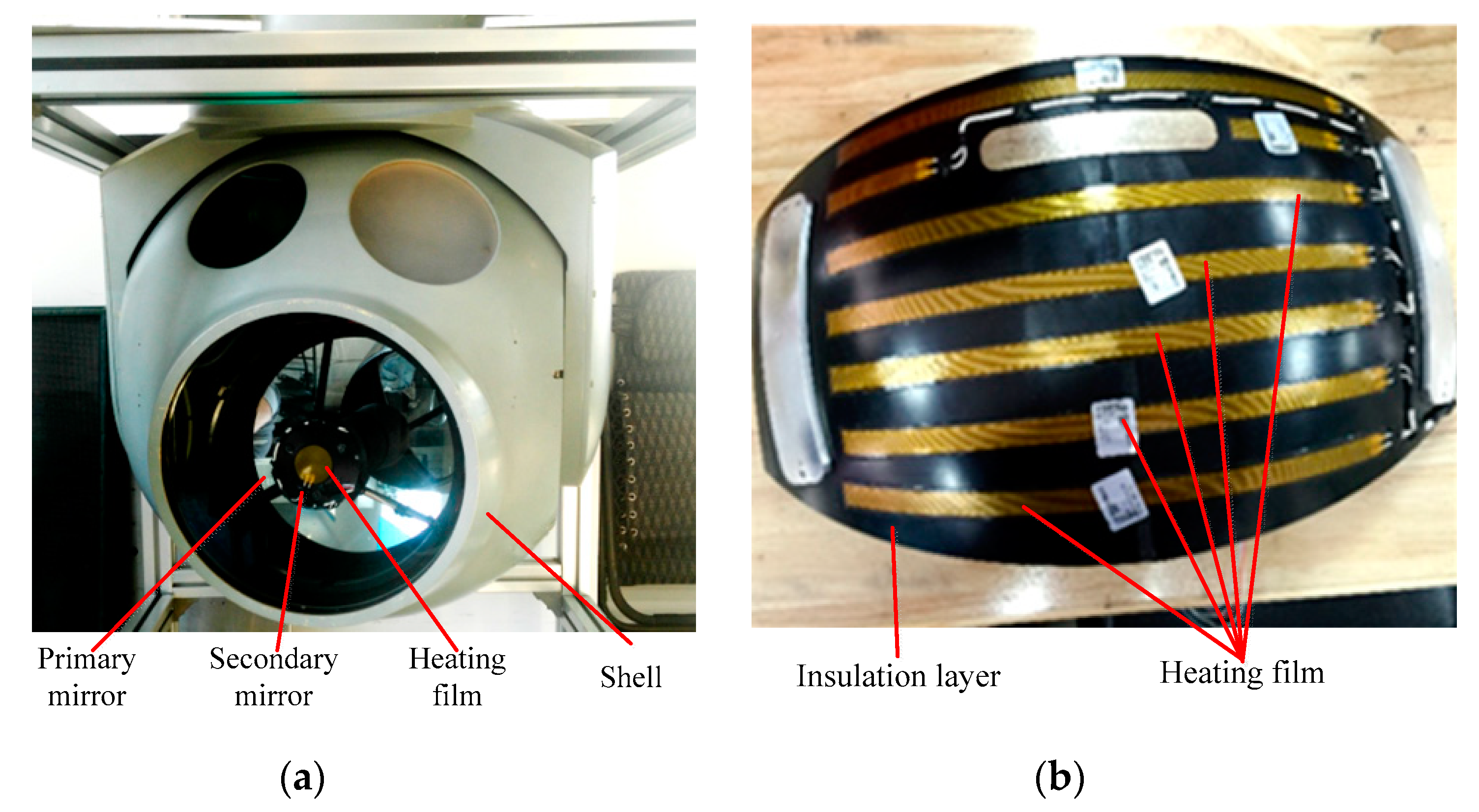

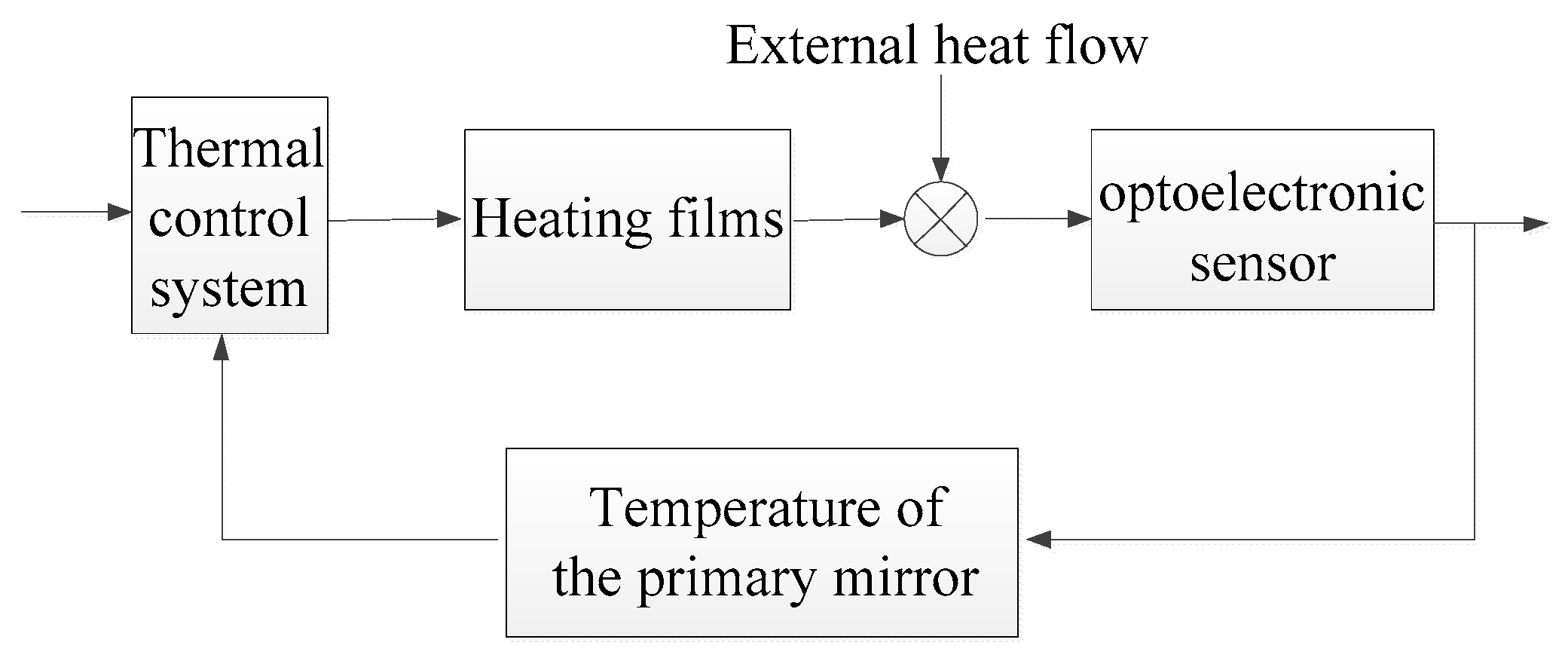

4.1. Design of the Active Thermal Control Methods

- (a)

- The camera temperature level (the average temperature of the three measurement points of the primary mirror) is 0~20 °C;

- (b)

- temperature gradient between the primary mirror and the secondary mirror is less than 5 °C.

4.2. Optical Analysis of the Sensor Based on the Modified Control Measures

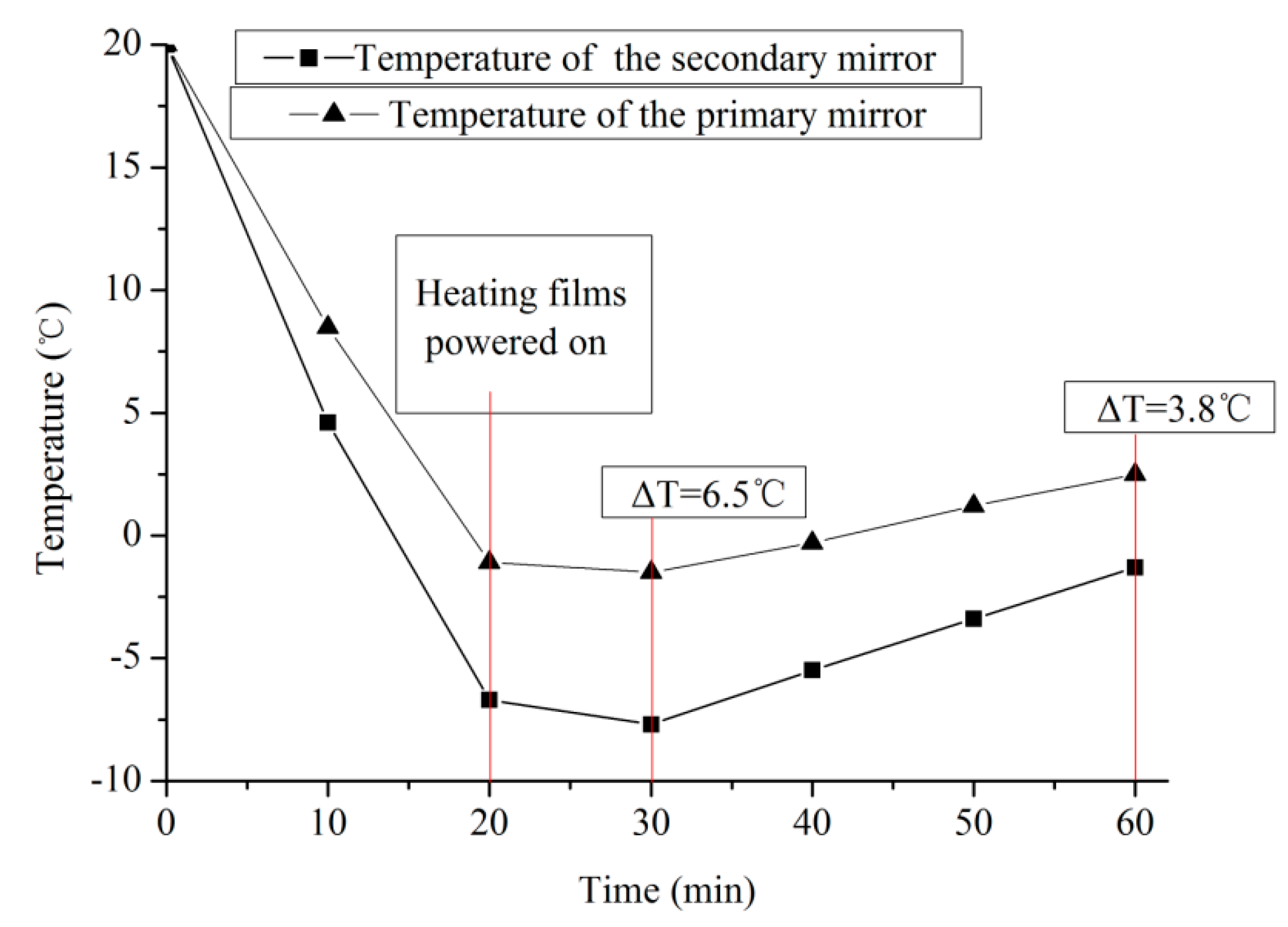

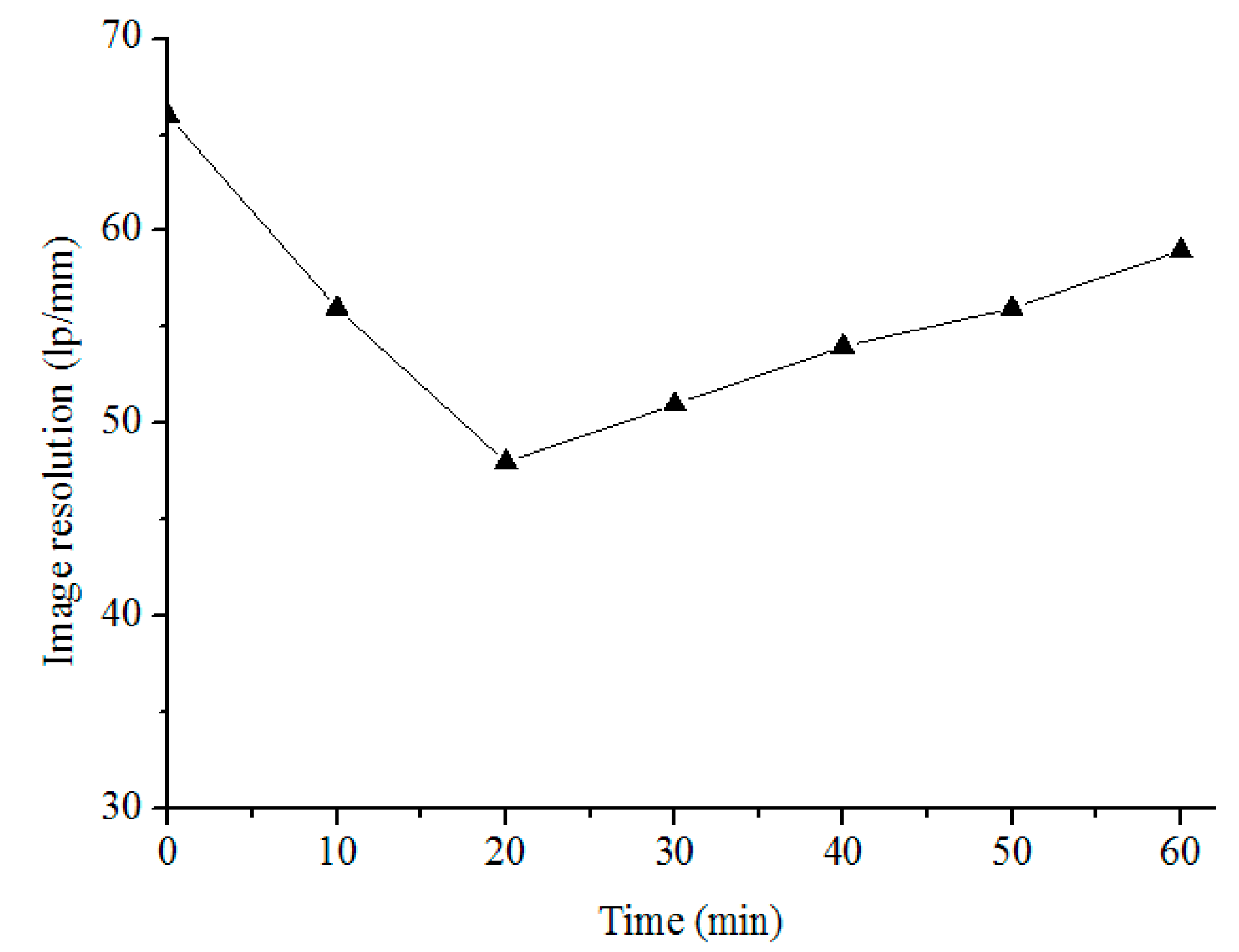

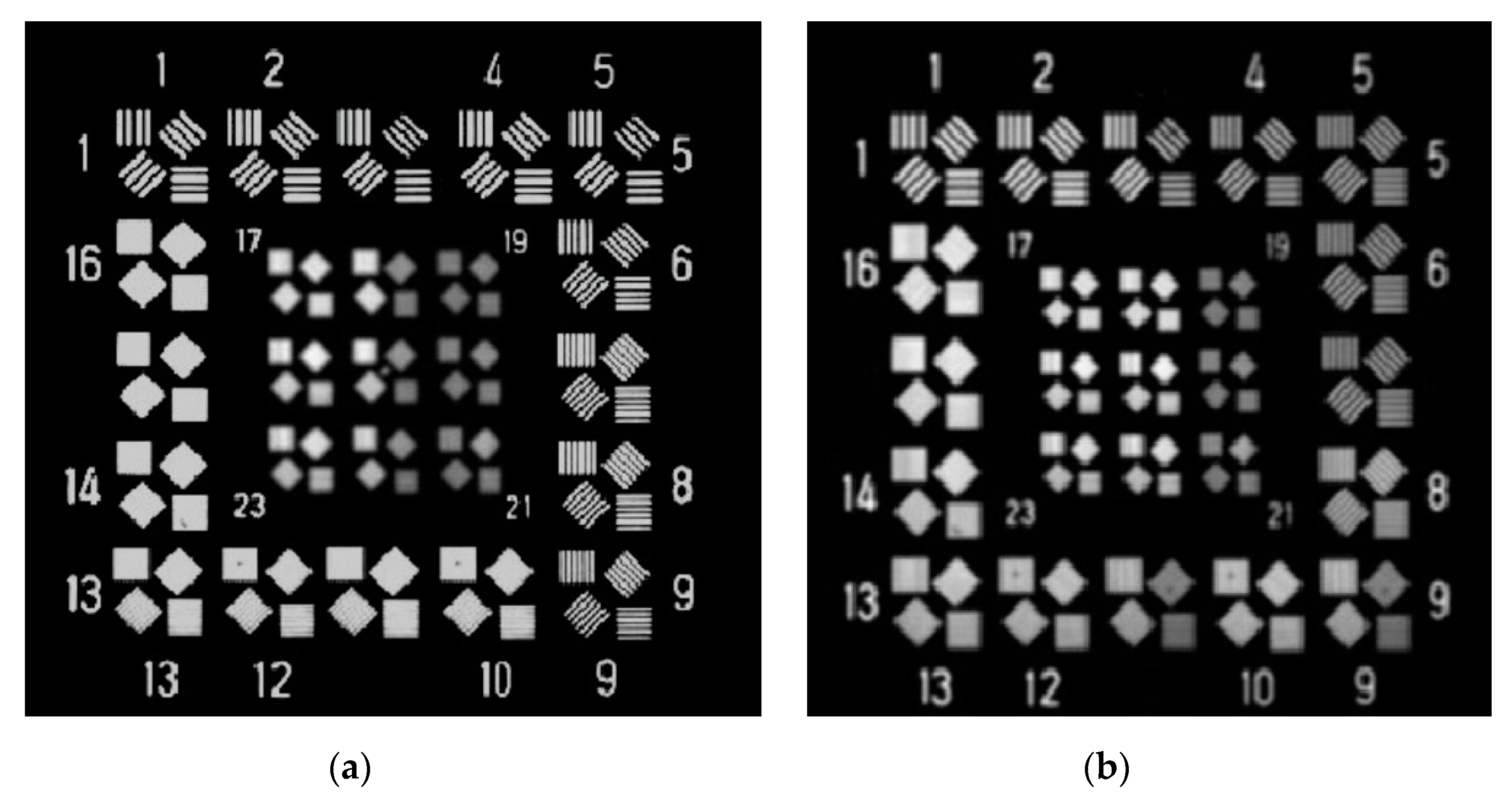

4.3. Experimental Verification

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gao, Y.; Zhang, B.; Chen, L.; Xu, B.; Gu, G. Thermal design and analysis of the high-resolution MWIR/LWIR aerial camera. Optik 2019, 179, 37–46. [Google Scholar] [CrossRef]

- Dutton, T.; Lomheim, T.; Nelson, M.D. Survey and comparison of focal plane MTF measurement techniques. Int. Soc. Opt. Photonics 2002, 4486, 219–246. [Google Scholar]

- Amon, C.H.; Murthy, J.; Yao, S.C.; Narumanchi, S.; Wu, C.F.; Hsieh, C.C. MEMS-enabled thermal management of high-heat-flux devices EDIFICE: embedded droplet impingement for integrated cooling of electronics. Exp. Therm. Fluid 2001, 25, 231–242. [Google Scholar] [CrossRef]

- Liu, W.; Ding, Y.; Wu, Q.; Jia, J.-Q.; Guo, L.; Wang, L.-H. Thermal analysis and design of the aerial camera’s primary optical system components. Appl. Therm. Eng. 2012, 38, 40–47. [Google Scholar] [CrossRef]

- Colomina, I.; Molina, P. Unmanned aerial systems for photogrammetry and remote sensing: A review. ISPRS J. Photogr. Remote Sens. 2014, 92, 79–97. [Google Scholar] [CrossRef]

- Strock, J.D. Development of zero coefficient of thermal expansion composite tubes for stable space structures. Int. Soc. Opt. Photonics 1992, 1690, 223–230. [Google Scholar]

- Selimoglu, O.; Ekinci, M.; Karci, O. Thermal refocusing method for spaceborne high-resolution optical imagers. Appl. Opt. 2016, 55, 4109–4112. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.B.; Zhang, J.L.; Ding, T.; Wei, Z.; Li, H.; Wang, Z. The effect of an electric field on the thermomechanical damage of nodular defects in dielectric multilayer coatings irradiated by nanosecond laser pulses. Light Sci. Appl. 2013, 2, e80. [Google Scholar] [CrossRef]

- Koeber, S.; Palmer, R.; Lauermann, M.; Heni, W.; Elder, D.L.; Korn, D.; Woessner, M.; Alloatti, L.; Koenig, S.; Schindler, P.C.; et al. Femtojouleelectro-optic modulation using a silicon-organic hybrid device. Light Sci. Appl. 2015, 4, e255. [Google Scholar] [CrossRef]

- Fan, Y.; Liang, W.; Ma, W. Thermal design of the optical system in an aerial camera. Opto-Electron. Eng. 2013, 40, 51–58. [Google Scholar]

- Li, Y.; Yuan, G.; Yang, H.; Zhang, H.; Liu, W. Thermal control design and proof test of altitude transmissive optical sensor. Acta Opt. Sin. 2013, 33, 1123001. [Google Scholar]

- Saggin, B.; Tarabini, M.; Lanfranchi, G. A device for the skincontact thermal resistance measurement. IEEE Trans. Instrum. Meas. 2012, 61, 489–495. [Google Scholar] [CrossRef]

- Ma, Q.; Ma, S. Experimental investigation of the systematic error on photomechanic methods induced by camera self-heating. Opt. Express 2013, 21, 7686–7698. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Huang, F.; Shi, F.; Liu, B.; Yu, H. Plane chessboard-based calibration method for a LWIR ultra-wide-angle camera. Appl. Opt. 2019, 58, 744–751. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y. Thermal imaging response characteristics analysis of ultrawide field of view infrared fish-eye warning system. Opt. Quantum Electron. 2012, 44, 741–747. [Google Scholar] [CrossRef]

| Sensor Location | Temperature (°C) |

|---|---|

| Primary mirror | −8.3 |

| Secondary mirror | −14.9 |

| Main tube | −8.5 |

| Lens barrel | −7.6 |

| SA | TCO | TAS | SAS | |

|---|---|---|---|---|

| (a) Temperature level difference of 20 °C | ||||

| 1 | −3.366 | 0.936 | −0.038 | −0.007 |

| 2 | 1.909 | −0.451 | 0.027 | 0.002 |

| 3 | 0.042 | −0.019 | 0.001 | 0.003 |

| 4 | 0.017 | 0.008 | 0.002 | 0.001 |

| 5 | 0.048 | 0.087 | 0.078 | 0.036 |

| 6 | −0.023 | −0.036 | −0.051 | −0.015 |

| 7 | −0.239 | −0.172 | −0.037 | −0.022 |

| 8 | 0.004 | 0.013 | 0.032 | 0.005 |

| 9 | −0.004 | 0.017 | −0.009 | 0.003 |

| 10 | 0.135 | 0.092 | 0.023 | 0.011 |

| 11 | −0.009 | 0.021 | −0.006 | −0.002 |

| 12 | 0.018 | −0.015 | 0.005 | 0.006 |

| Sum | −1.468 | 0.481 | 0.066 | 0.021 |

| (b) Temperature gradient of 20 °C | ||||

| 1 | −3.985 | 1.539 | −0.361 | −0.093 |

| 2 | 2.297 | −0.885 | 0.236 | 0.003 |

| 3 | 0.061 | −0.092 | 0.043 | 0.009 |

| 4 | 0.013 | 0.035 | 0.027 | 0.012 |

| 5 | 0.082 | 0.405 | 0.056 | 0.237 |

| 6 | −0.032 | −0.205 | −0.576 | −0.573 |

| 7 | −0.121 | −0.243 | −0.529 | −0.162 |

| 8 | 0.019 | 0.103 | 0.231 | 0.006 |

| 9 | −0.013 | 0.075 | −0.132 | 0.063 |

| 10 | 0.098 | 0.274 | 0.285 | 0.097 |

| 11 | −0.008 | 0.047 | −0.139 | −0.003 |

| 12 | 0.037 | −0.066 | 0.103 | 0.035 |

| Sum | −1.552 | 0.987 | −0.756 | −0.369 |

| SA | TCO | TAS | SAS | |

|---|---|---|---|---|

| 1 | −5.359 | 1.623 | −0.164 | −0.021 |

| 2 | 2.891 | −0.563 | 0.035 | 0.008 |

| 3 | 0.068 | −0.024 | 0.008 | 0.009 |

| 4 | 0.023 | 0.012 | 0.006 | 0.005 |

| 5 | 0.057 | 0.095 | 0.086 | 0.053 |

| 6 | −0.033 | −0.041 | −0.072 | −0.022 |

| 7 | −0.265 | −0.187 | −0.043 | −0.036 |

| 8 | 0.007 | 0.027 | 0.039 | 0.008 |

| 9 | −0.015 | 0.031 | −0.024 | 0.011 |

| 10 | 0.215 | 0.125 | 0.037 | 0.023 |

| 11 | −0.015 | 0.033 | −0.022 | −0.018 |

| 12 | 0.021 | −0.032 | 0.021 | 0.031 |

| Sum | −2.405 | 1.123 | −0.093 | 0.053 |

| SA | TCO | TAS | SAS | |

|---|---|---|---|---|

| 1 | −2.085 | 0.351 | −0.159 | −0.016 |

| 2 | 1.093 | −0.216 | 0.047 | 0.007 |

| 3 | 0.057 | −0.022 | 0.009 | 0.017 |

| 4 | 0.019 | 0.011 | 0.005 | 0.013 |

| 5 | 0.058 | 0.088 | 0.075 | 0.028 |

| 6 | −0.029 | −0.035 | −0.098 | −0.015 |

| 7 | −0.158 | −0.101 | −0.040 | −0.041 |

| 8 | 0.009 | 0.032 | 0.035 | 0.009 |

| 9 | −0.016 | 0.017 | −0.033 | 0.018 |

| 10 | 0.117 | 0.102 | 0.052 | 0.036 |

| 11 | −0.012 | 0.029 | −0.078 | −0.025 |

| 12 | 0.018 | −0.018 | 0.009 | 0.029 |

| Sum | −0.927 | 0.238 | −0.136 | 0.061 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Cheng, Z.; Jia, P.; Zhang, B.; Liu, X.; Hu, R. Impact of Thermal Control Measures on the Imaging Quality of an Aerial Optoelectronic Sensor. Sensors 2019, 19, 2753. https://doi.org/10.3390/s19122753

Liu F, Cheng Z, Jia P, Zhang B, Liu X, Hu R. Impact of Thermal Control Measures on the Imaging Quality of an Aerial Optoelectronic Sensor. Sensors. 2019; 19(12):2753. https://doi.org/10.3390/s19122753

Chicago/Turabian StyleLiu, Fuhe, Zhifeng Cheng, Ping Jia, Bao Zhang, Xiaofeng Liu, and Rizha Hu. 2019. "Impact of Thermal Control Measures on the Imaging Quality of an Aerial Optoelectronic Sensor" Sensors 19, no. 12: 2753. https://doi.org/10.3390/s19122753

APA StyleLiu, F., Cheng, Z., Jia, P., Zhang, B., Liu, X., & Hu, R. (2019). Impact of Thermal Control Measures on the Imaging Quality of an Aerial Optoelectronic Sensor. Sensors, 19(12), 2753. https://doi.org/10.3390/s19122753