Dynamic Measurements Using FDM 3D-Printed Embedded Strain Sensors

Abstract

1. Introduction

2. Materials and Methods

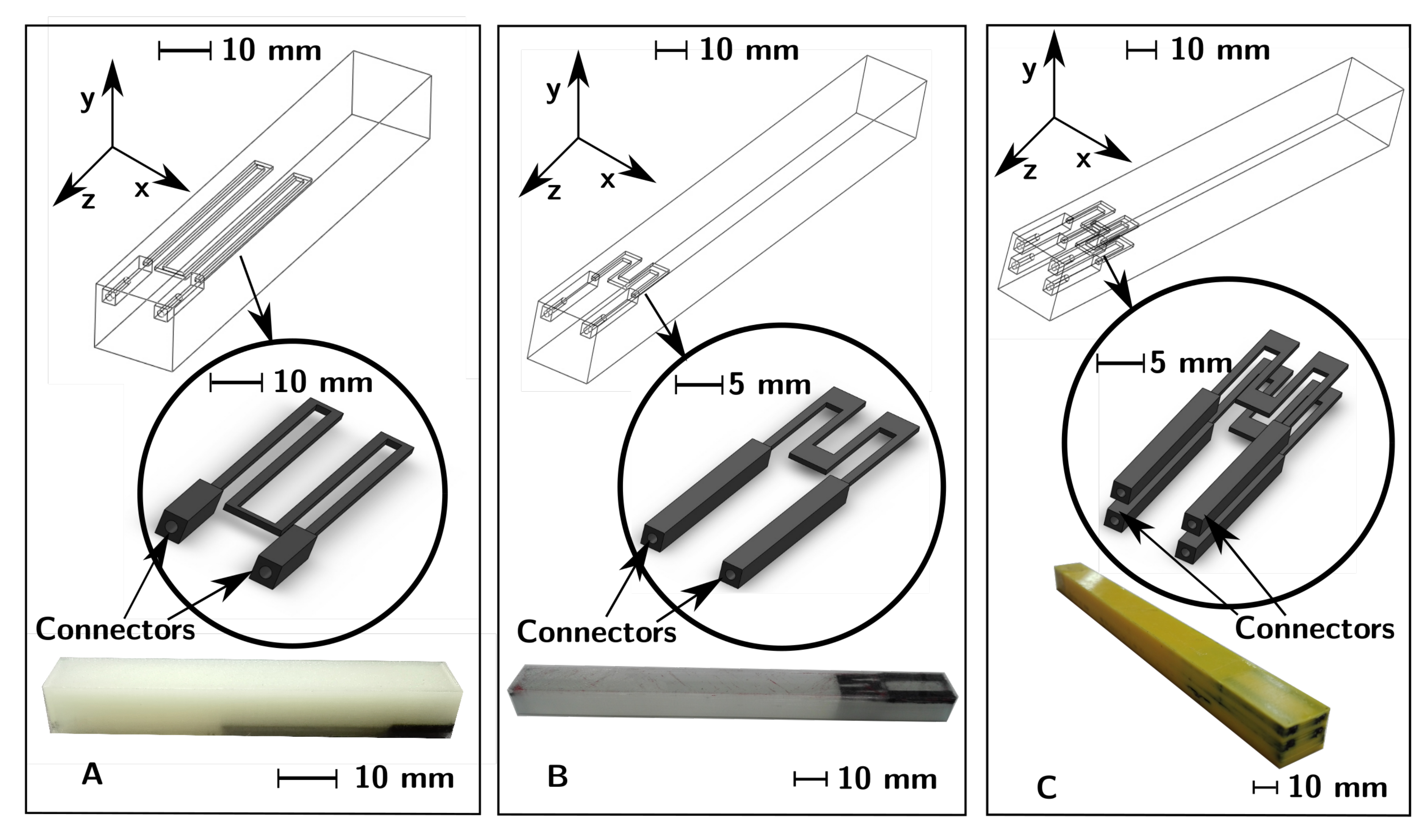

2.1. Materials, Specimen Design and Production

Stress-Waves Propagation and Sensor Length

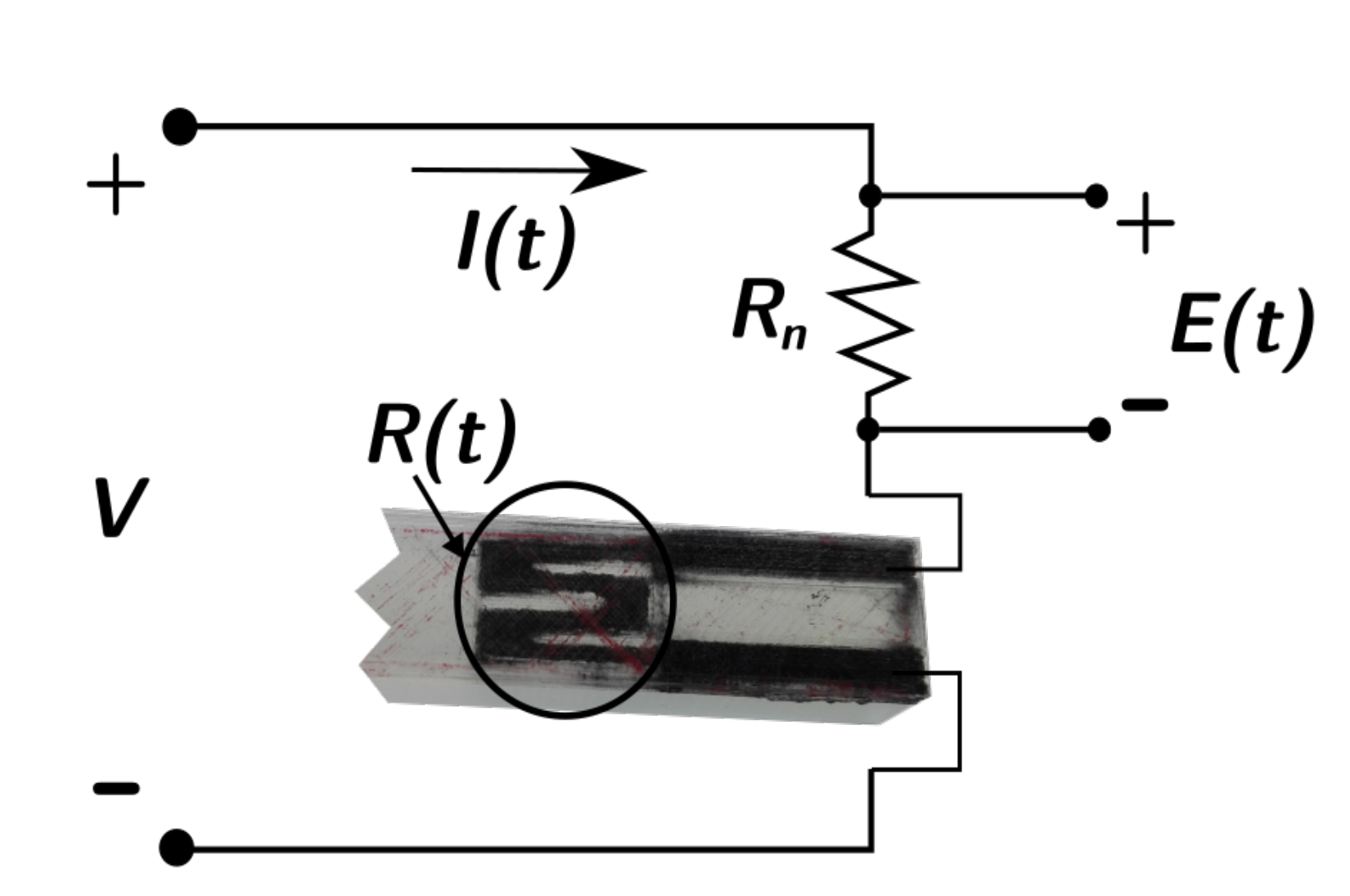

2.2. Dynamic Measurements and Assumptions

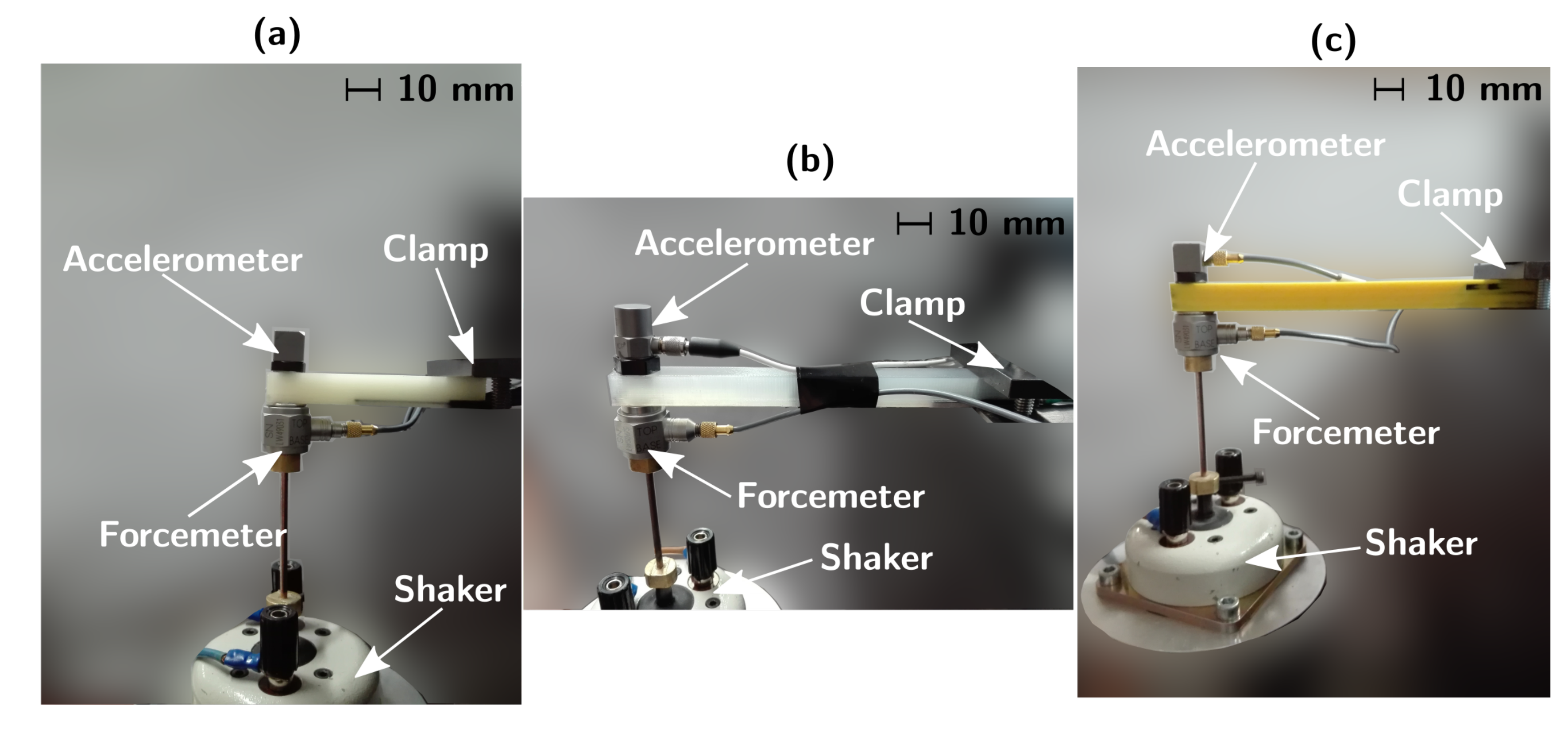

2.3. Experimental Procedure

2.3.1. Quasi-Static Tests

2.3.2. Dynamic Tests

2.4. Finite-Element Modeling Dynamic Simulation

3. Results and Discussion

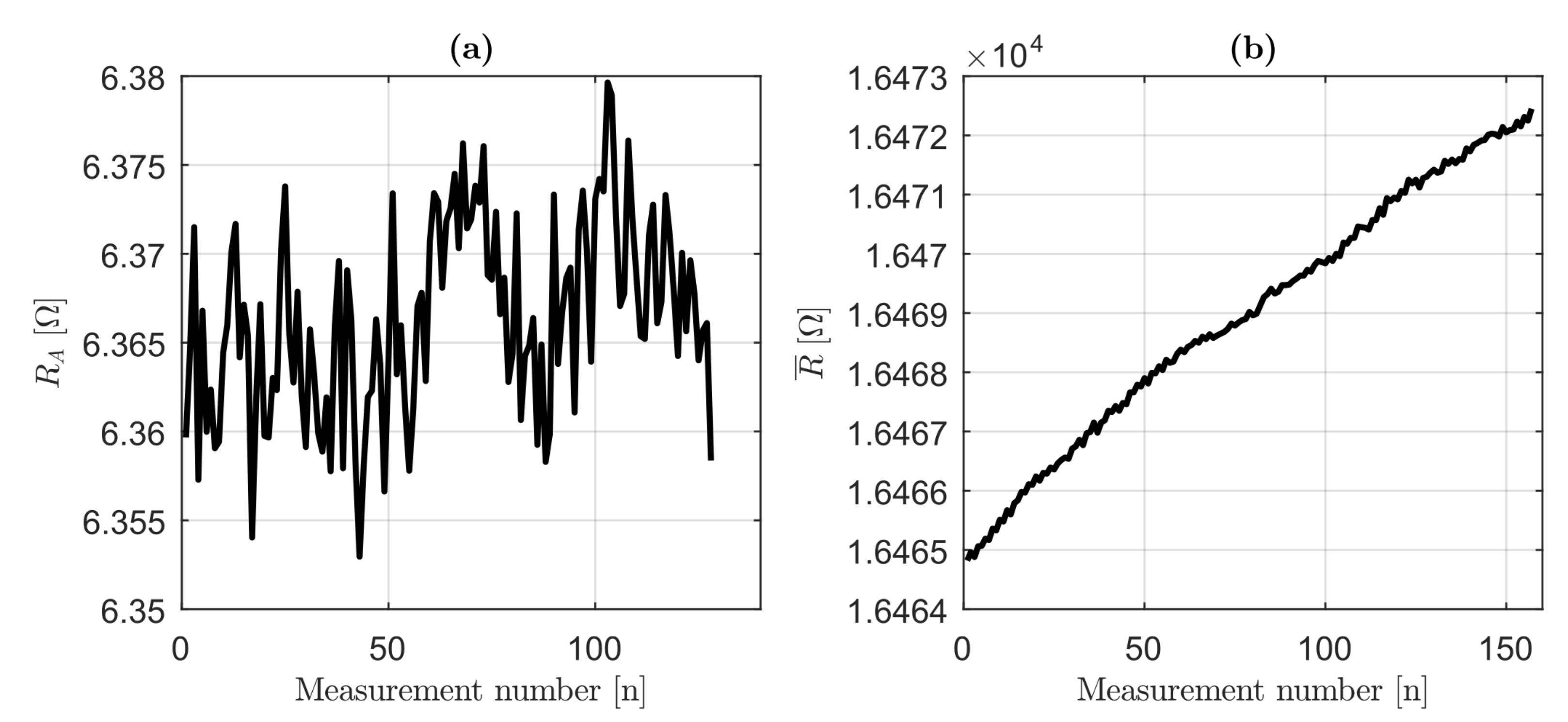

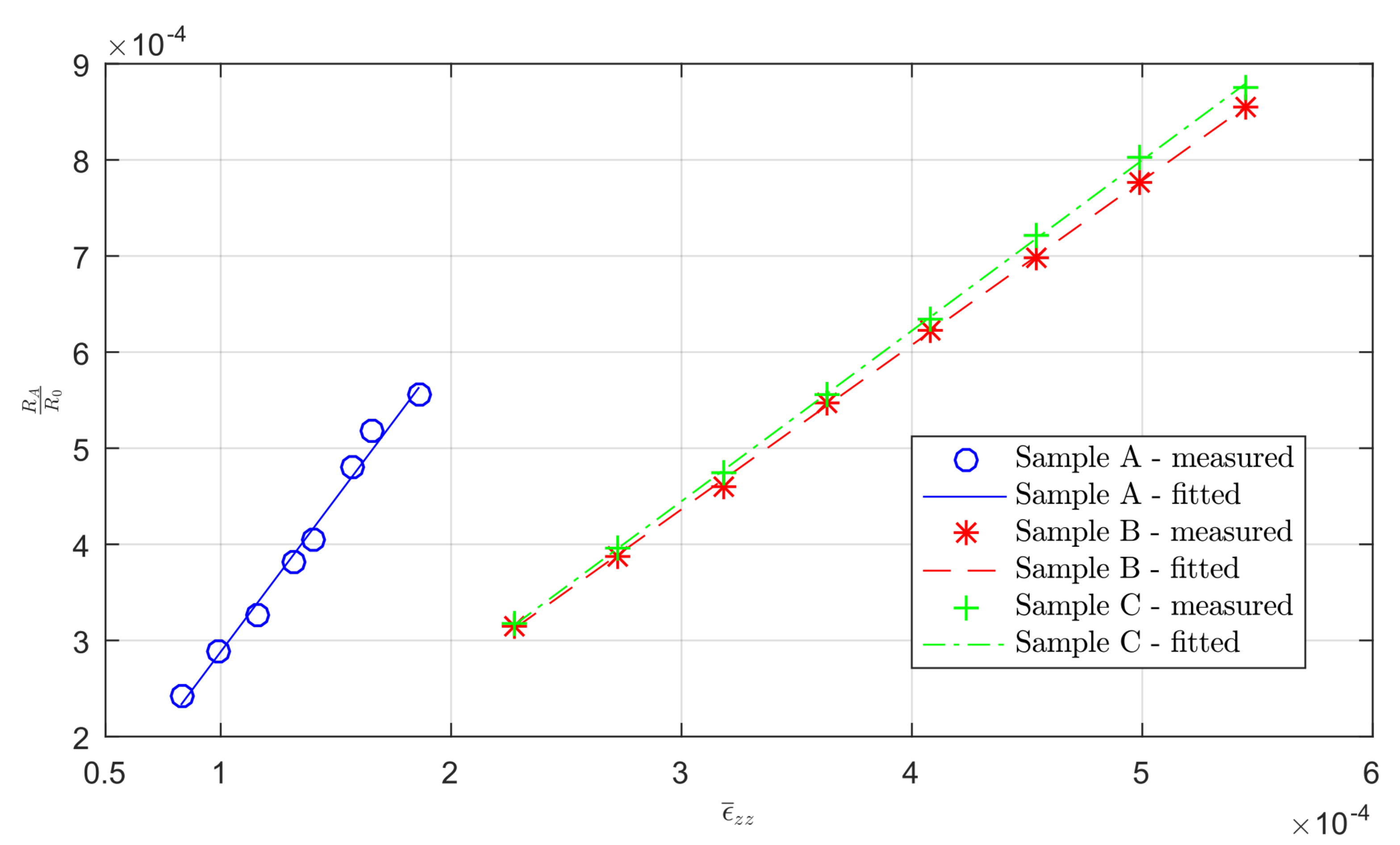

3.1. Quasi-Static Calibration

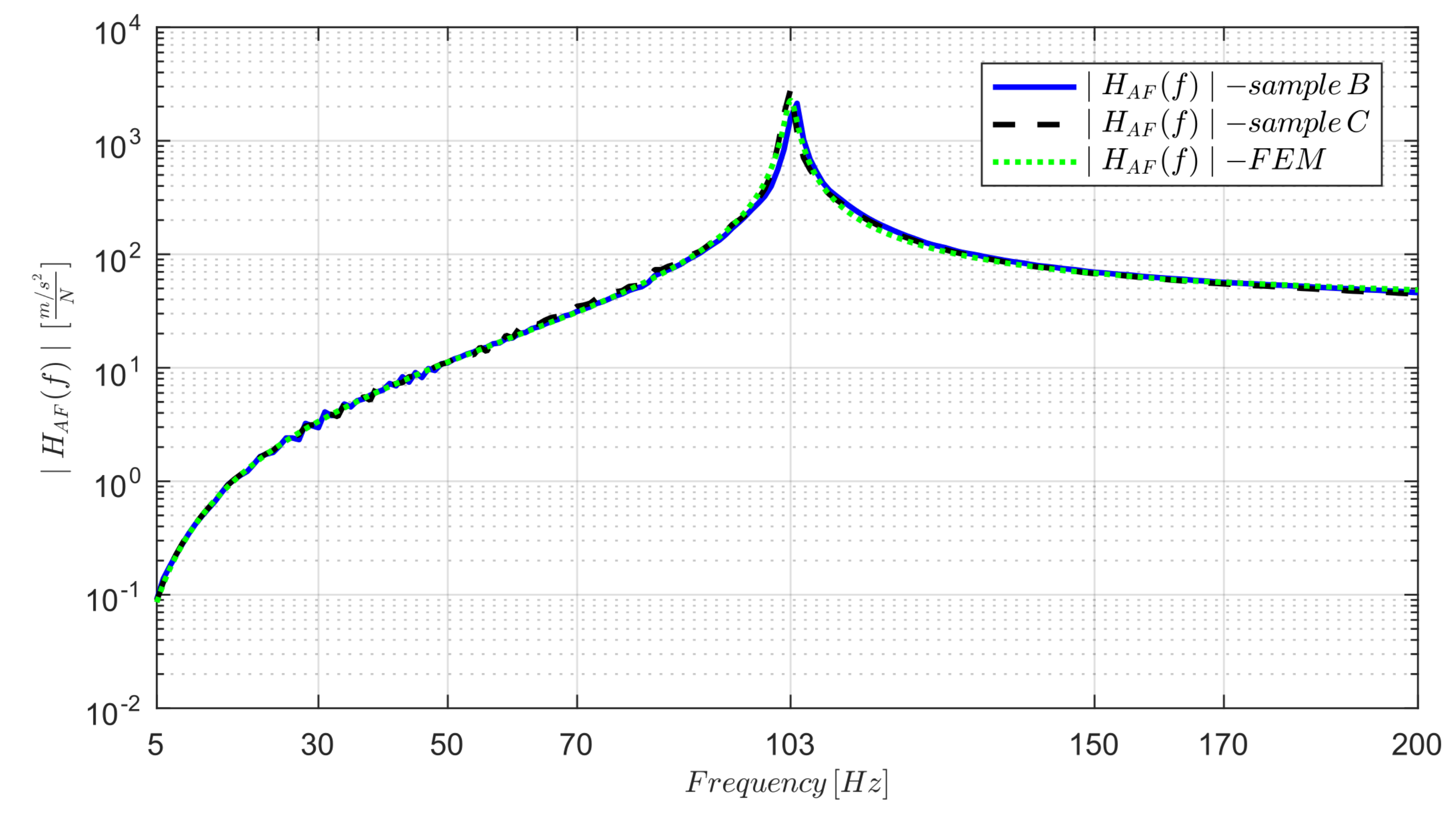

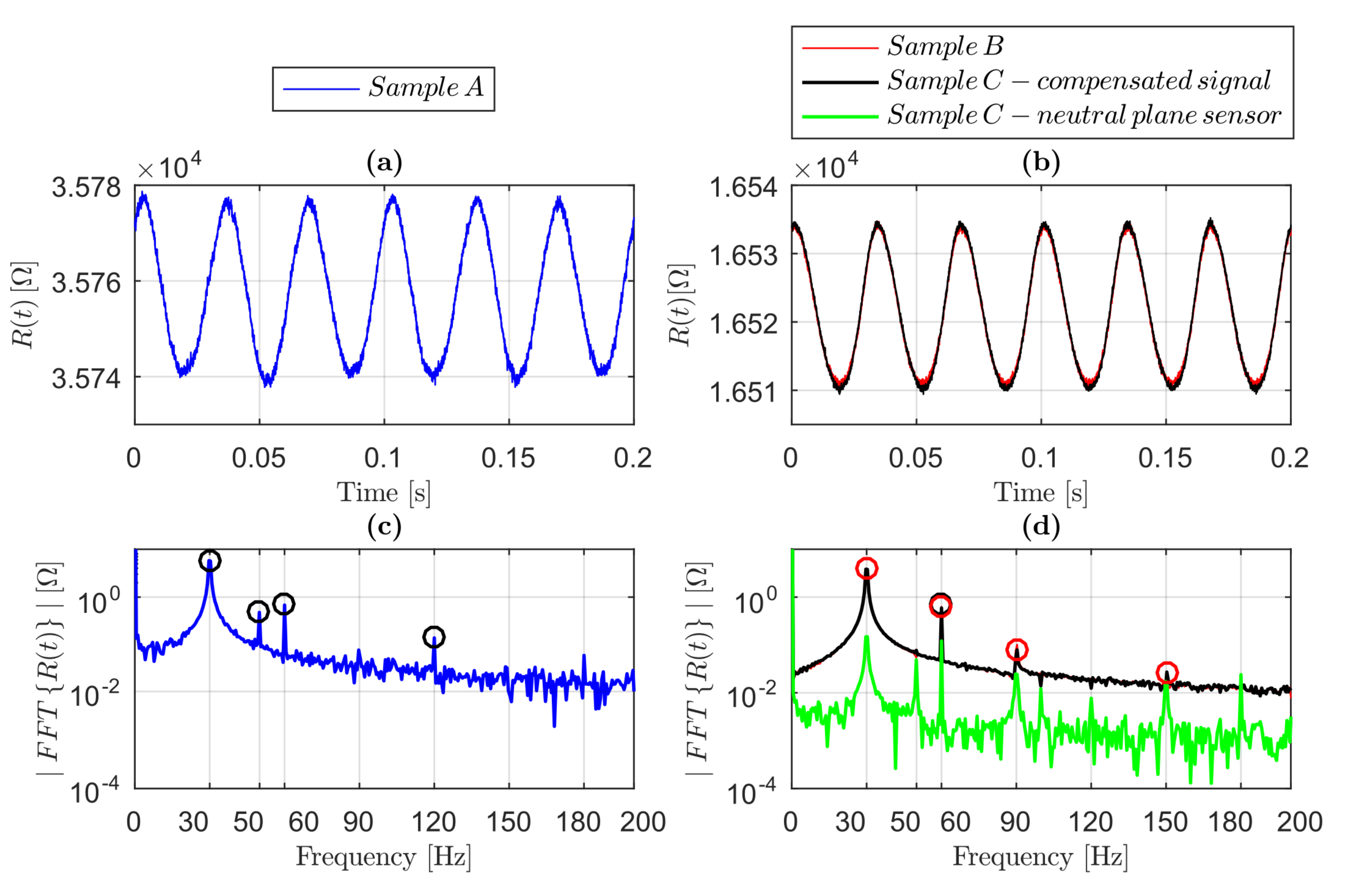

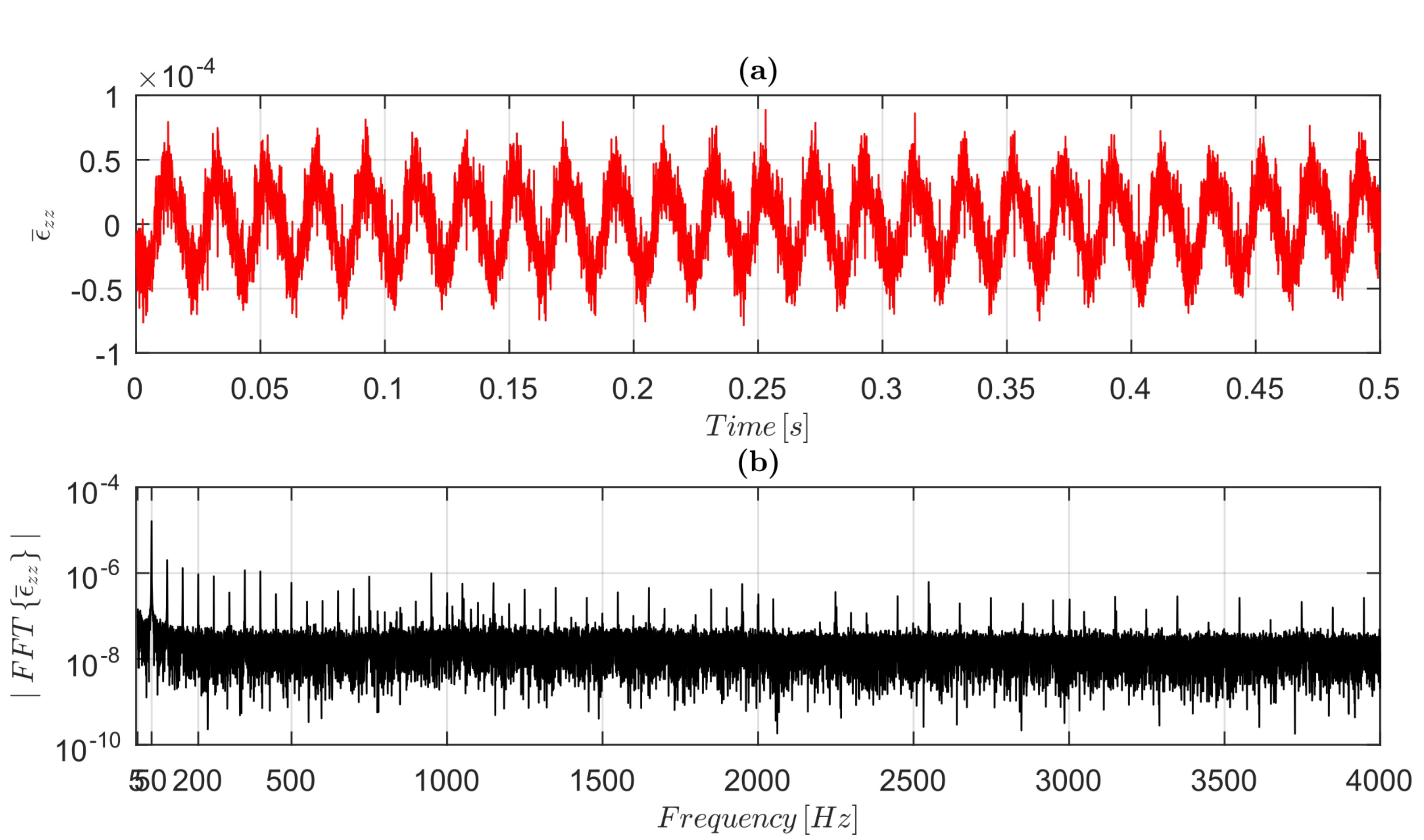

3.2. Dynamic Measurements

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| PLA | Polylactic acid |

| S/M-WCNTs | Single/Multi-walled carbon nanotubes |

| CB | Carbon Black |

| FDM | Fused Deposition Modeling |

| EMI | Electromagnetic interference |

| FRF | Frequency-Response Function |

| SNR | Signal-to-noise ratio |

References

- O’Donnell, J.; Ahmadkhanlou, F.; Yoon, H.S.; Washington, G. All-printed smart structures: A viable option? In Active and Passive Smart Structures and Integrated Systems 2014; International Society for Optics and Photonics: Bellingham, WA, USA, 2014; Volume 9057, p. 905729. [Google Scholar]

- Ota, H.; Emaminejad, S.; Gao, Y.; Zhao, A.; Wu, E.; Challa, S.; Chen, K.; Fahad, H.M.; Jha, A.K.; Kiriya, D.; et al. Application of 3D printing for smart objects with embedded electronic sensors and systems. Adv. Mater. Technol. 2016, 1, 1600013. [Google Scholar] [CrossRef]

- Dunn, C.; Mu, Q.; Wang, L.; Dunn, C.K.; Kuang, X.; Duan, F.; Zhang, Z. Digital light processing 3D printing of conductive complex structures Digital light processing 3D printing of conductive complex structures. Addit. Manuf. 2017, 18, 74–83. [Google Scholar] [CrossRef]

- Lee, J.; Kim, H.C.; Choi, J.W.; Lee, I.H. A review on 3D printed smart devices for 4D printing. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 373–383. [Google Scholar] [CrossRef]

- Vepa, R. Dynamics of Smart Structures; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Sharafeldin, M.; Jones, A.; Rusling, J. 3D-printed biosensor arrays for medical diagnostics. Micromachines 2018, 9, 394. [Google Scholar] [CrossRef] [PubMed]

- Stark, B.; Stevenson, B.; Stow-Parker, K.; Chen, Y. Embedded sensors for the health monitoring of 3D printed unmanned aerial systems. In Proceedings of the 2014 International Conference on Unmanned Aircraft Systems (ICUAS), Orlando, FL, USA, 27–30 May 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 175–180. [Google Scholar]

- Hockaday, L.A.; Kang, K.H.; Colangelo, N.W.; Cheung, P.Y.C.; Duan, B.; Malone, E.; Wu, J.; Girardi, L.N.; Bonassar, L.J.; Lipson, H.; et al. Rapid 3D printing of anatomically accurate and mechanically heterogeneous aortic valve hydrogel scaffolds. Biofabrication 2012, 43, 035005. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Maurel, A.; Courty, M.; Fleutot, B.; Tortajada, H.; Prashantha, K.; Armand, M.; Grugeon, S.; Panier, S.; Dupont, L. Highly Loaded Graphite Composite PLA-Based Filaments for Lithium-Ion Battery 3D-Printing. Meet. Abstr. 2018, 30, 106. [Google Scholar] [CrossRef]

- Nadgorny, M.; Ameli, A. Functional Polymers and Nanocomposites for 3D Printing of Smart Structures and Devices. ACS Appl. Mater. Interfaces 2018, 10, 17489–17507. [Google Scholar] [CrossRef]

- Dorigato, A.; Moretti, V.; Dul, S.; Unterberger, S.H.; Pegoretti, A. Electrically conductive nanocomposites for fused deposition modelling. Synth. Met. 2017, 226, 7–14. [Google Scholar] [CrossRef]

- Chizari, K.; Daoud, M.A.; Ravindran, A.R.; Therriault, D. 3D Printing of Highly Conductive Nanocomposites for the Functional Optimization of Liquid Sensors. Small 2016, 12, 6076–6082. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Wu, X.; Guo, X.; Kong, B.; Zhang, M.; Qian, X.; Mi, S.; Sun, W. The Boom in 3D-Printed Sensor Technology. Sensors 2017, 17, 1166. [Google Scholar] [CrossRef] [PubMed]

- Espalin, D.; Muse, D.W.; MacDonald, E.; Wicker, R.B. 3D Printing multifunctionality: Structures with electronics. Int. J. Adv. Manuf. Technol. 2014, 72, 963–978. [Google Scholar] [CrossRef]

- Joe Lopes, A.; MacDonald, E.; Wicker, R.B. Integrating stereolithography and direct print technologies for 3D structural electronics fabrication. Rapid Prototyp. J. 2012, 18, 129–143. [Google Scholar] [CrossRef]

- Macdonald, E.; Salas, R.; Espalin, D.; Perez, M.; Aguilera, E.; Muse, D.; Wicker, R.B. 3D printing for the rapid prototyping of structural electronics. IEEE Access 2014, 2, 234–242. [Google Scholar] [CrossRef]

- Wang, L.; Meydan, T.; Williams, P.I. A Two-Axis Goniometric Sensor for Tracking Finger Motion. Sensors 2017, 17, 770. [Google Scholar] [CrossRef]

- Banna, M.; Bera, K.; Sochol, R.; Lin, L.; Najjaran, H.; Sadiq, R.; Hoorfar, M. 3D printing-based integrated water quality sensing system. Sensors 2017, 17, 1336. [Google Scholar] [CrossRef]

- Mannoor, M.S.; Jiang, Z.; James, T.; Kong, Y.L.; Malatesta, K.A.; Soboyejo, W.O.; Verma, N.; Gracias, D.H.; McAlpine, M.C. 3D Printed Bionic Ears. Nano Lett. 2013, 13, 2634–2639. [Google Scholar] [CrossRef]

- Agarwala, S.; Goh, G.L.; Dinh Le, T.S.; An, J.; Peh, Z.K.; Yeong, W.Y.; Kim, Y.J. Wearable Bandage-Based Strain Sensor for Home Healthcare: Combining 3D Aerosol Jet Printing and Laser Sintering. ACS Sens. 2019, 4, 218–226. [Google Scholar] [CrossRef]

- Kang, I.; Schulz, M.J.; Kim, J.H.; Shanov, V.; Shi, D. A carbon nanotube strain sensor for structural health monitoring. Smart Mater. Struct. 2006, 15, 737. [Google Scholar] [CrossRef]

- Shanker, R.; Sethi, A.; Jain, S.; Medury, A.; Bhalla, S.; Shanker, M.R.; Sethi, M.A.; Jain, M.S. Performance and Condition Monitoring of Structures Using Discrete Strain Measurements. Int. J. Comadem 2009, 12, 2–14. [Google Scholar]

- Yin, F.; Ye, D.; Zhu, C.; Qiu, L.; Huang, Y. Stretchable, highly durable ternary nanocomposite strain sensor for structural health monitoring of flexible aircraft. Sensors 2017, 17, 2677. [Google Scholar] [CrossRef] [PubMed]

- Farahani, R.D.; Dalir, H.; le Borgne, V.; Gautier, L.A.; el Khakani, M.A.; Lévesque, M.; Therriault, D. Direct-write fabrication of freestanding nanocomposite strain sensors. Nanotechnology 2012, 23. [Google Scholar] [CrossRef] [PubMed]

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Pötschke, P. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Bessonov, A.; Kirikova, M.; Haque, S.; Gartseev, I.; Bailey, M.J. Highly reproducible printable graphite strain gauges for flexible devices. Sens. Actuators Phys. 2014, 206, 75–80. [Google Scholar] [CrossRef]

- Alsharari, M.; Chen, B.; Shu, W. 3D Printing of Highly Stretchable and Sensitive Strain Sensors Using Graphene Based Composites. Proceedings 2018, 2, 792. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Strain sensing behaviour of 3D printed carbon black fi lled ABS. J. Manuf. Process. 2018, 35, 337–342. [Google Scholar] [CrossRef]

- Dijkshoorn, A.; Werkman, P.; Welleweerd, M.; Wolterink, G.; Eijking, B.; Delamare, J.; Sanders, R.; Krijnen, G.J. Embedded sensing: Integrating sensors in 3-D printed structures. J. Sens. Sens. Syst. 2018, 7, 169. [Google Scholar] [CrossRef]

- Shemelya, C.; Banuelos-Chacon, L.; Melendez, A.; Kief, C.; Espalin, D.; Wicker, R.; Krijnen, G.; MacDonald, E. Multi-functional 3D printed and embedded sensors for satellite qualification structures. In Proceedings of the 2015 IEEE SENSORS, Busan, Korea, 1–4 November 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–4. [Google Scholar]

- Emon, M.; Choi, J.W. Flexible piezoresistive sensors embedded in 3D printed tires. Sensors 2017, 17, 656. [Google Scholar] [CrossRef]

- Czyżewski, J.; Burzyński, P.; Gaweł, K.; Meisner, J. Rapid prototyping of electrically conductive components using 3D printing technology. J. Mater. Process. Technol. 2009, 209, 5281–5285. [Google Scholar] [CrossRef]

- Gooding, J.; Fields, T. 3D Printed Strain Gauge Geometry and Orientation for Embedded Sensing. In Proceedings of the 58th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Grapevine, TX, USA, 9–13 January 2017; p. 0350. [Google Scholar]

- Gnanasekaran, K.; Heijmans, T.; van Bennekom, S.; Woldhuis, H.; Wijnia, S.; de With, G.; Friedrich, H. 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Additive manufacturing of flexible electrically conductive polymer composites via CNC-assisted fused layer modeling process. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 175. [Google Scholar] [CrossRef]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef] [PubMed]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A Simple, Low-Cost Conductive Composite Material for 3D Printing of Electronic Sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef] [PubMed]

- Burstyn, J.; Fellion, N.; Strohmeier, P.; Vertegaal, R. PrintPut: Resistive and Capacitive Input Widgets for Interactive 3D Prints, INTERACT 2015. In Proceedings of the IFIP Conference on Human-Computer Interaction, Bamberg, Germany, 14–18 September 2015. [Google Scholar]

- Hohimer, C.C.C.J.; Petrossian, G.; Ameli, A.; Mo, C.; Pötschke, P. Electrical Conductivity and Piezoresistive Response of 3D Printed Thermoplastic Polyurethane/Multiwalled Carbon Nanotube Composites. In Behavior and Mechanics of Multifunctional Materials and Composites XII (Vol. 10596, p. 105960J); International Society for Optics and Photonics: Bellingham, WA, USA, 2018. [Google Scholar] [CrossRef]

- Rausch, J. Printed piezoresistive strain sensors for monitoring of light-weight structures. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 6–10 March 2011; pp. 216–221. [Google Scholar] [CrossRef]

- Eijking, B.; Sanders, R.; Krijnen, G. Development of whisker inspired 3D multi-material printed flexible tactile sensors. In Proceedings of the 2017 IEEE SENSORS, Glasgow, UK, 29 October 29–1 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–3. [Google Scholar]

- Lee, J.M.; Sing, S.L.; Zhou, M.; Yeong, W.Y. 3D bioprinting processes: A perspective on classification and terminology. Int. J. Bioprint. 2018, 4. [Google Scholar] [CrossRef]

- Kranjc, T.; Slavič, J.; Boltežar, M. A comparison of strain and classic experimental modal analysis. J. Vib. Control. 2016, 22, 371–381. [Google Scholar] [CrossRef]

- Abramson, H.; Plass, H.; Ripperger, E. Stress wave propagation in rods and beams. In Advances in Applied Mechanics; Elsevier: Amsterdam, The Netherlands, 1958; Volume 5, pp. 111–194. [Google Scholar]

- Doyle, J.F. Modern Experimental Stress Analysis: Completing the Solution of Partially Specified Problems; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Kreuzer, M. Linearity and Sensitivity Error in the Use of Single Strain Gages with Voltage-fed and Current-fed Circuits. Exp. Tech. 2008, 8, 30–36. [Google Scholar] [CrossRef]

- Shin, K.; Hammond, J. Fundamentals of Signal Processing for Sound and Vibration Engineers; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Cianetti, F.; Palmieri, M.; Slavič, J.; Braccesi, C.; Morettini, G. The effort of the dynamic simulation on the fatigue damage evaluation of flexible mechanical systems loaded by non-Gaussian and non stationary loads. Int. J. Fatigue 2017, 103, 60–72. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maurizi, M.; Slavič, J.; Cianetti, F.; Jerman, M.; Valentinčič, J.; Lebar, A.; Boltežar, M. Dynamic Measurements Using FDM 3D-Printed Embedded Strain Sensors. Sensors 2019, 19, 2661. https://doi.org/10.3390/s19122661

Maurizi M, Slavič J, Cianetti F, Jerman M, Valentinčič J, Lebar A, Boltežar M. Dynamic Measurements Using FDM 3D-Printed Embedded Strain Sensors. Sensors. 2019; 19(12):2661. https://doi.org/10.3390/s19122661

Chicago/Turabian StyleMaurizi, Marco, Janko Slavič, Filippo Cianetti, Marko Jerman, Joško Valentinčič, Andrej Lebar, and Miha Boltežar. 2019. "Dynamic Measurements Using FDM 3D-Printed Embedded Strain Sensors" Sensors 19, no. 12: 2661. https://doi.org/10.3390/s19122661

APA StyleMaurizi, M., Slavič, J., Cianetti, F., Jerman, M., Valentinčič, J., Lebar, A., & Boltežar, M. (2019). Dynamic Measurements Using FDM 3D-Printed Embedded Strain Sensors. Sensors, 19(12), 2661. https://doi.org/10.3390/s19122661