New Analysis Scheme of Flow-Acoustic Coupling for Gas Ultrasonic Flowmeter with Vortex near the Transducer

Abstract

:1. Introduction

2. New Hybrid Scheme and Numerical Realization for the Ultrasonic Flowmeter

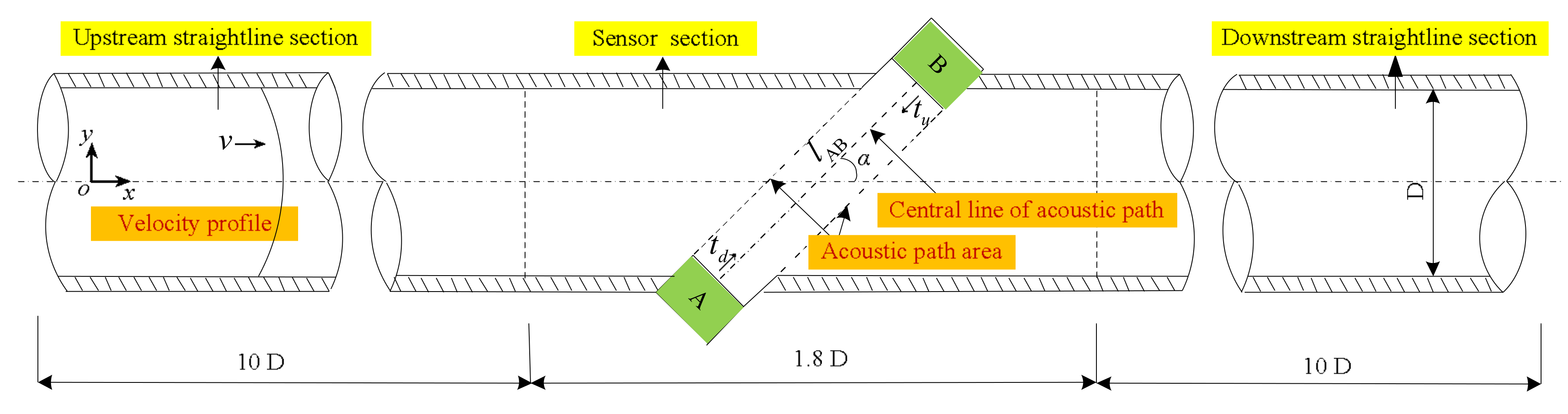

2.1. Principle of the Ultrasonic Flowmeter

- The parameters that impact the flowmeter performance are , , , and the flow velocity (or velocity profile), respectively.

- Although the influence of sound pressure on measurement is not shown in (1), the sound propagation is an interaction process between flow and acoustics. It is known that sound signals from the transmitter are passed through velocity profile first, then received by the receiver, and finally transformed into electrical signals. The sound features play an important role in the design of the transducer and digital processing circuit. Therefore, the influence of the velocity profile on the acoustic pressure and transit time needs to be taken into consideration.

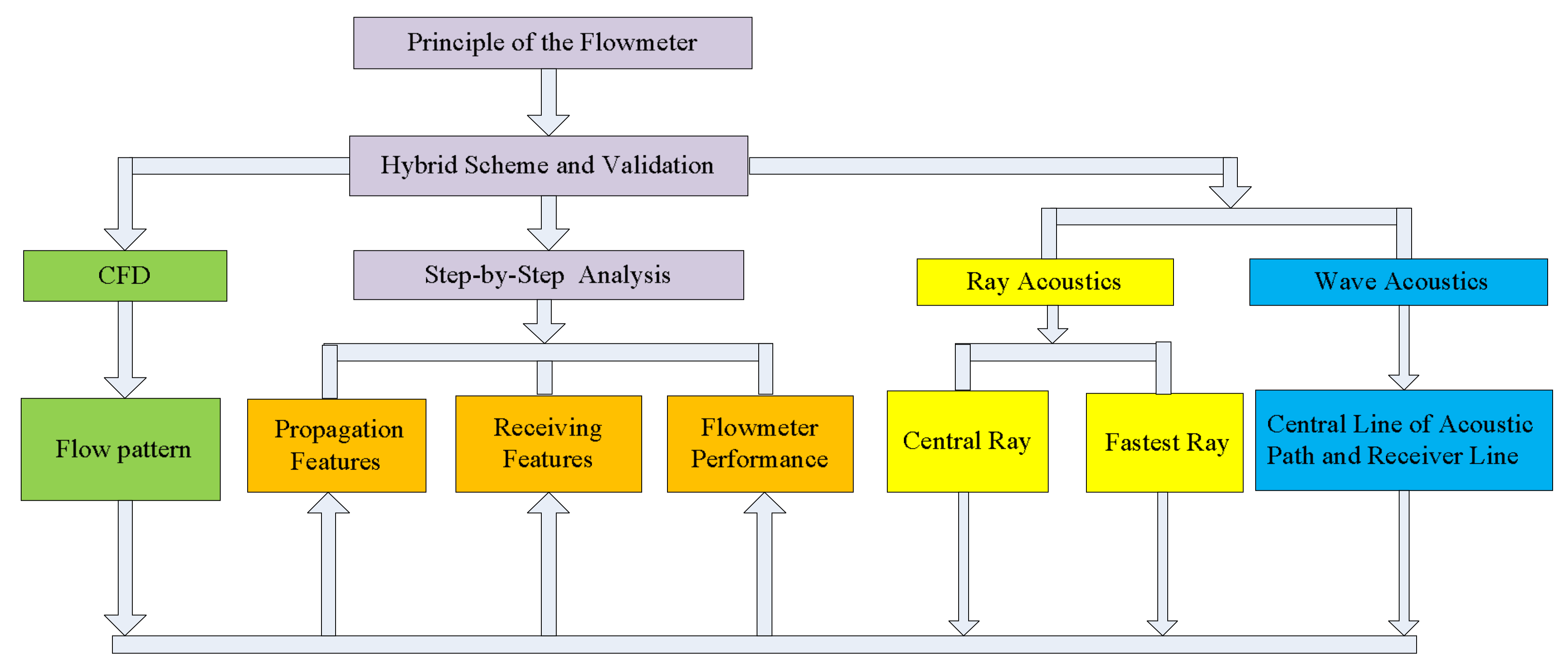

2.2. New Hybrid Scheme

- In the scheme, the advantages of the three theories are comprehensively utilized including CFD, ray acoustics, and wave acoustics. In the implementation, the SST turbulence model, the ray tracing equation, and the linear potential flow equation are solved by using the FEM. Also, three simple examples with analytical solutions are used for the scheme verification. A new “step-by-step approach” is used for the combination of the three theories.

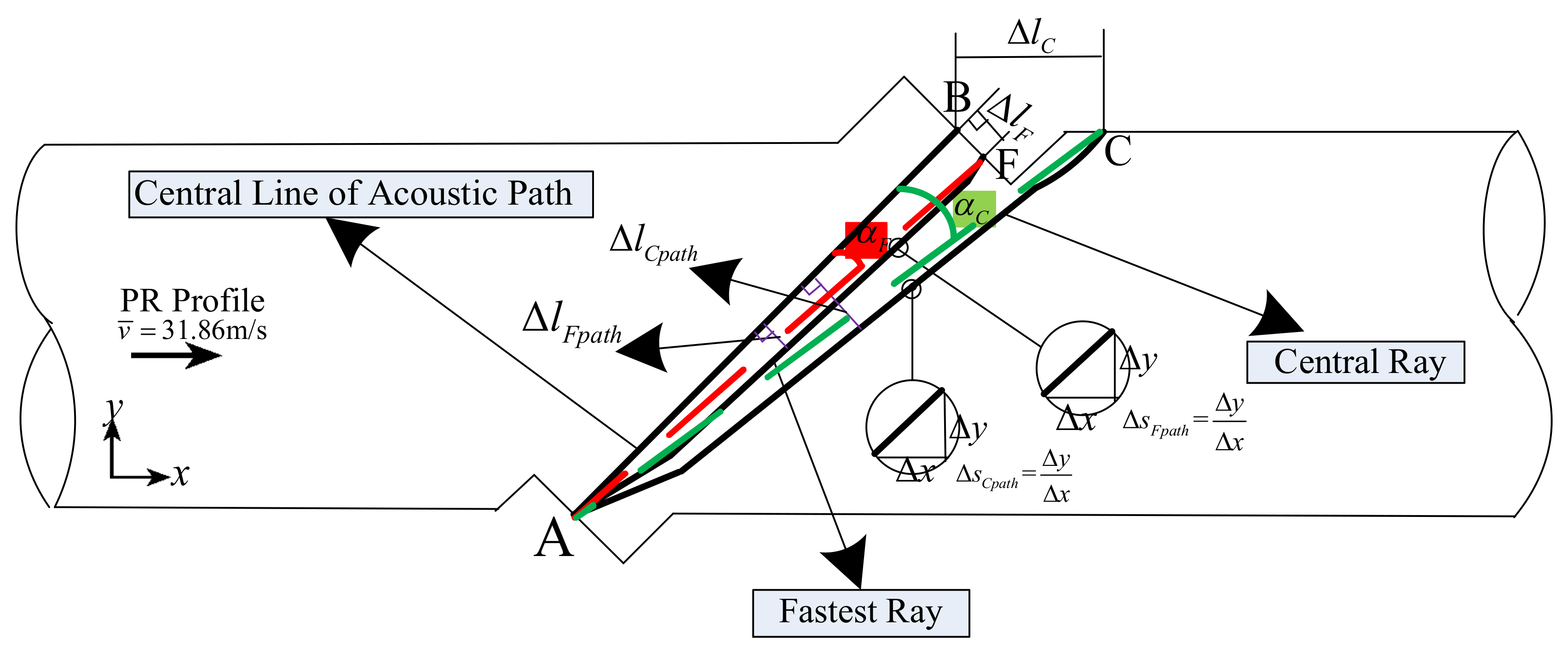

- Then, some representative locations or objects such as the crosssection of the sensor, central line of the acoustic path, receiver line, central ray, and fastest ray are chosen for analyses. On those locations, the flow patterns are obtained such as flow velocity profile, velocity distribution, upstream and downstream, velocity profile partition, and vortex intensity, etc.

- After that, in accordance with the flow patterns, the acoustic propagation features, for instance, ray trajectory, slope along trajectory, offset al.ong trajectory, ray trajectory length, and acoustic pressure on the central line of the sound path, are obtained using the central ray and acoustic beam. Moreover, the receiving features, for example, deflection angle, offset, sound pressure on the receiver, and transit time influenced by flow pattern, are also discussed in detail.

- Finally, the instrument coefficient of regarding the flowmeter performance is also analyzed.

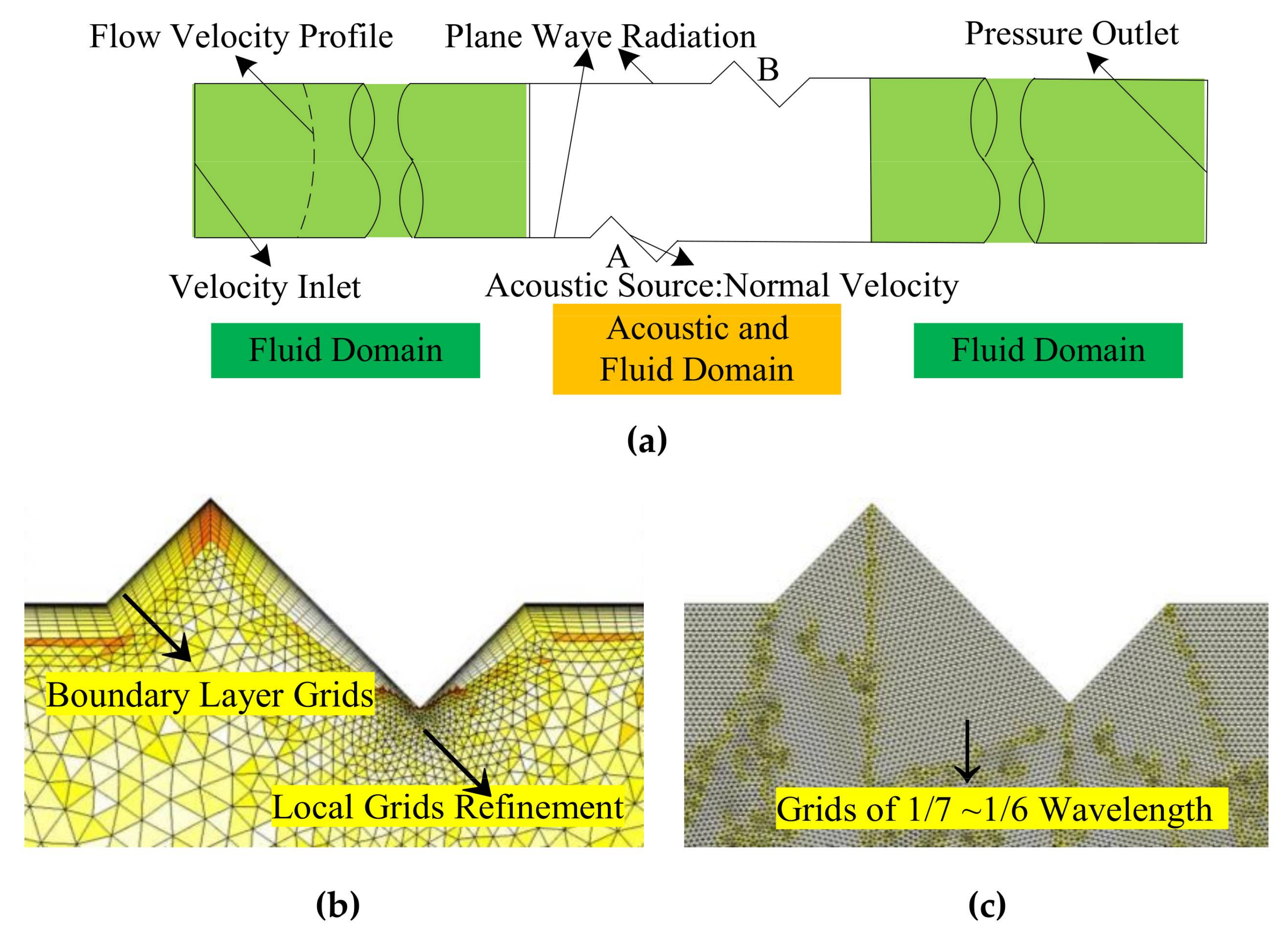

2.3. Numerical Method

2.4. Verification of the Numerical Method

3. Results and Discussion

3.1. Step-By-Step Approach for Flow-Acoustic Coupling Analysis inside the Sensor

3.1.1. Flow Field Obtained Only by CFD and Comparison

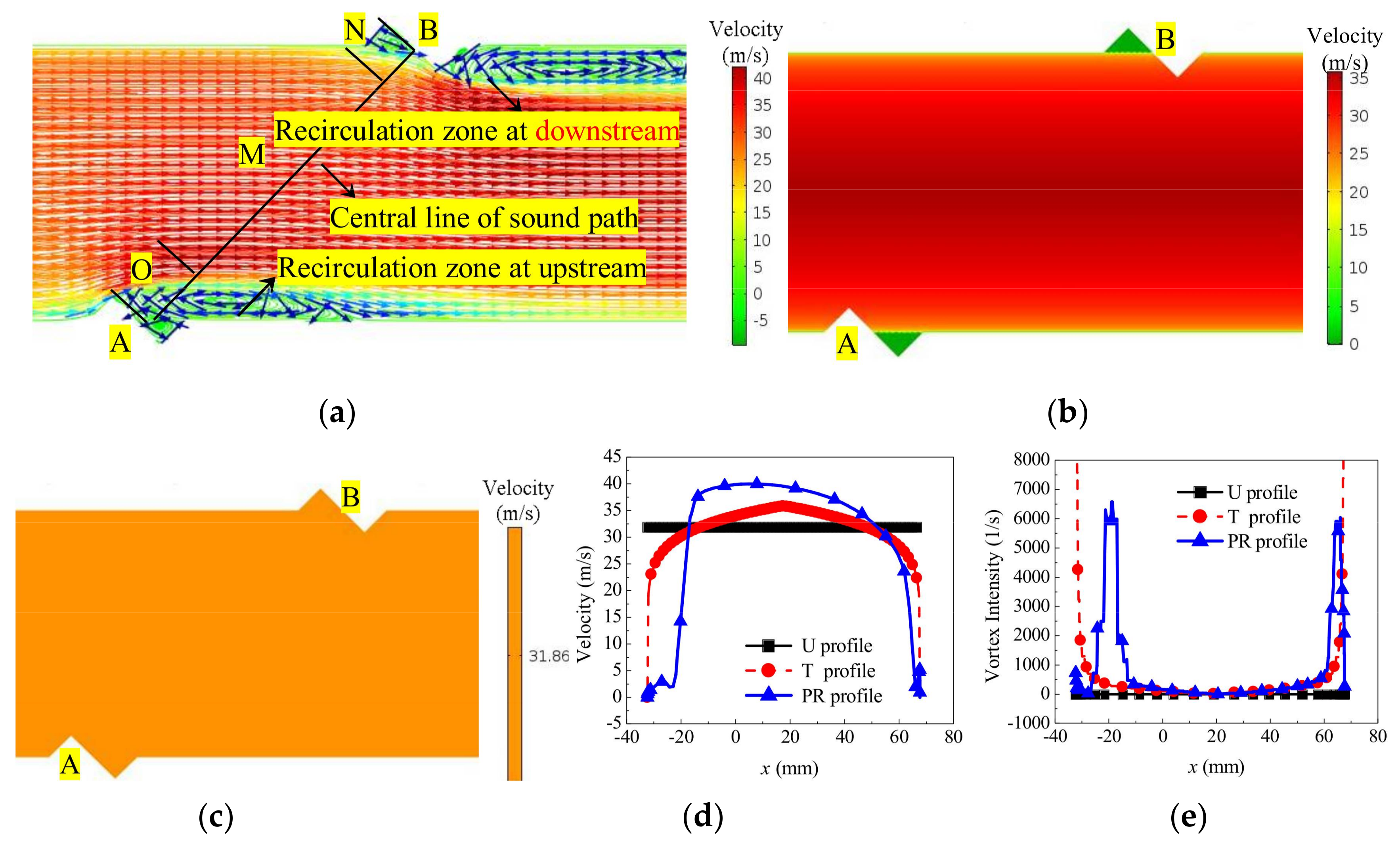

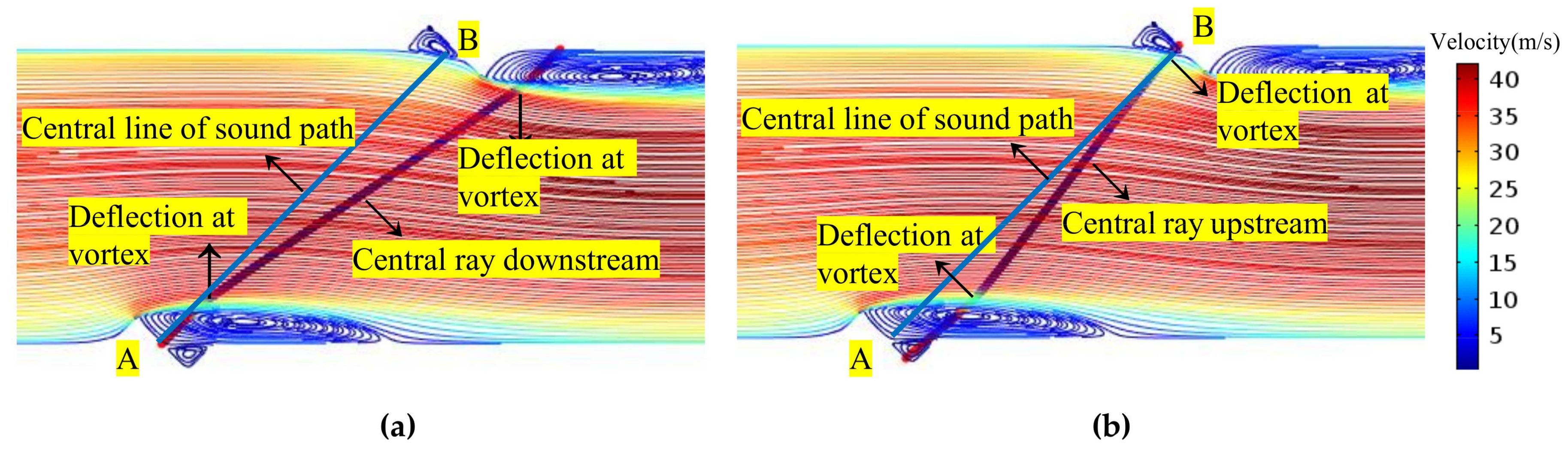

- When the fluid is flowing through the transducer, similar to the backward-facing step flow, the vortex and recirculation zone are generated due to the throttling effect caused by the transducer. In the backflow zone, a negative velocity appears near the transducer, which is an important factor affecting the performance measure.

- The vortex intensity is used to describe the velocity profile containing the vortex, as shown in (7).where is the fluid element, and is the normal component of the rotating angular velocity for the fluid element.

- According to the vortex intensity and velocity distribution on line , three zones are formed (Figure 4a), including the upstream O, central M, and downstream N zones. The lengths of the three zones on the line are not sensitive to the velocity change by the velocity or vortex intensity statistics in the range of 0.55 m/s–52.95 m/s. For the PR profile, the approximate scope of the O, M and N on line are −36 mm–10 mm, −10 mm–60 mm, and 60 mm–70 mm, respectively, based on the x coordinate (Figure 4d,e). In the O and N zones, for the PR profile, sudden changes of flow velocity and vortex intensity are exhibited, and the trend and value are different. In the M zone, the velocity distributions of the three profiles are significantly different. The descending order of velocity is as follows: PR, T, and U profiles. Besides, the vortex intensity tends to zero in the M zone, and the sudden change is not shown.

- In addition, the velocity and vortex intensity distribution on the sensor cross-section are different. Compared with the U and T profile (without the recirculation zone), the asymmetry feature appears on the PR profile due to the recirculation zone.

3.1.2. Combination of CFD and Ray Acoustics

3.1.3. Combination of CFD, Ray Acoustics, and Wave Acoustics

3.1.4. Analytical Method for the Central Ray and the Fastest Ray

3.2. Acoustic Propagation Features Influenced by the Flow Field inside the Sensor

3.2.1. Propagation Features Obtained by the Central Ray

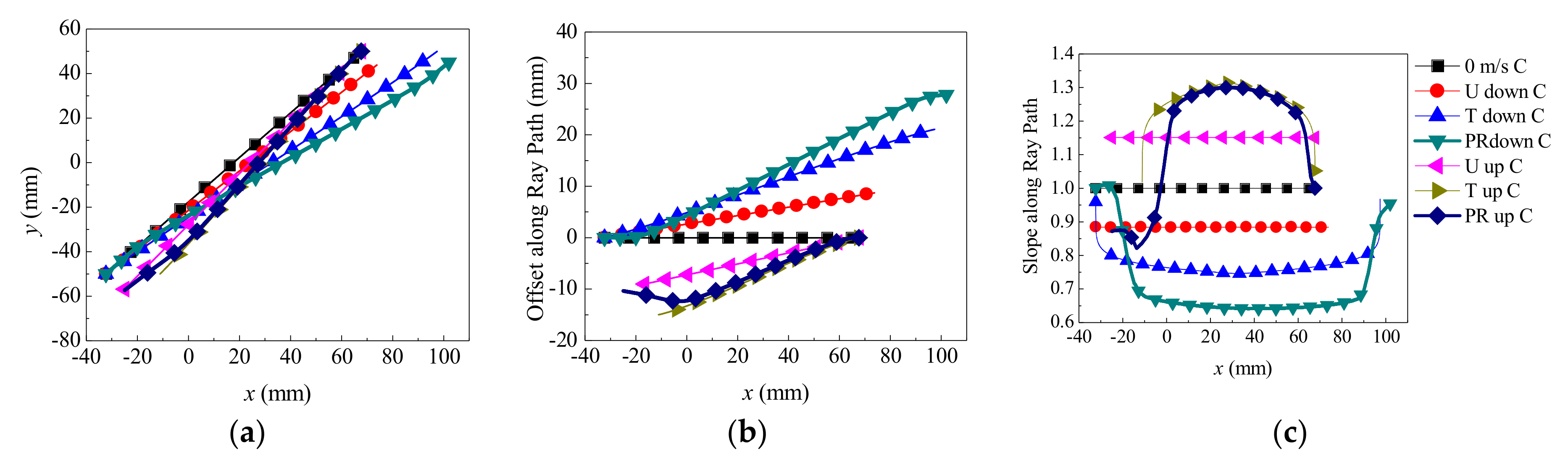

- When = 0 m/s, the ray trajectory upstream (or downstream) is overlapped with the line . = 0, = 1.

- When increases, the central rays for all velocity profiles deviate from the line , and are moved toward the flow direction. The and are increased as the increases. Downstream, > 0 and < 1, whereas upstream, < 0 and > 1.

- When is equal, the and are different for each flow velocity profile.

- The vortex near the transducer plays a big role in the ray deflection. When the central ray comes out of the vortex zone upstream, apparent deflection occurs. After entering into the central zone, deflection is mitigated. Finally, when passing through the vortex zone downstream, an obvious deflection appears again.

- The ray deflection degree (change of and ) in the vortex upstream is greater than that in the downstream section. The deflection degree is proportional to the vortex intensity in the flow field where the ray passes through.

- The propagation features of the central ray in the PR profile is significantly different from the U and T profiles, because of the vortex near the transducer.

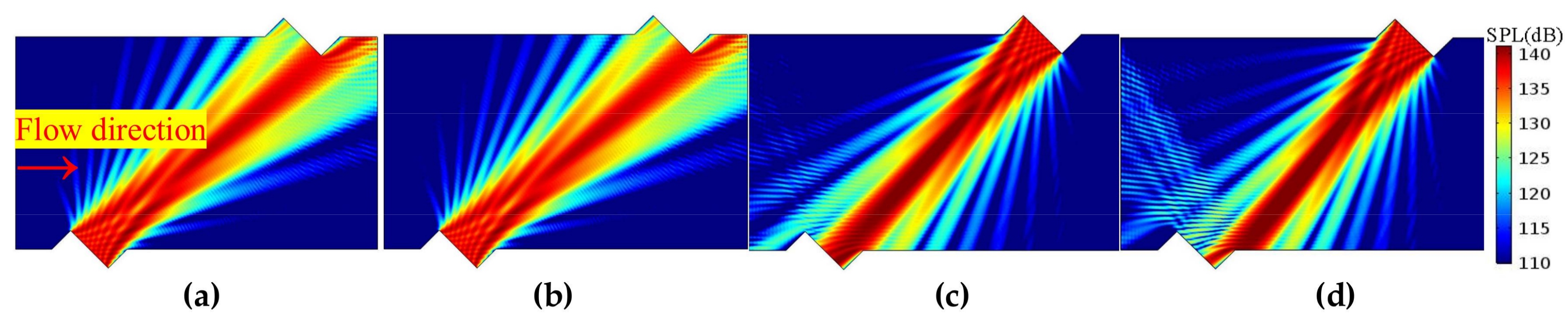

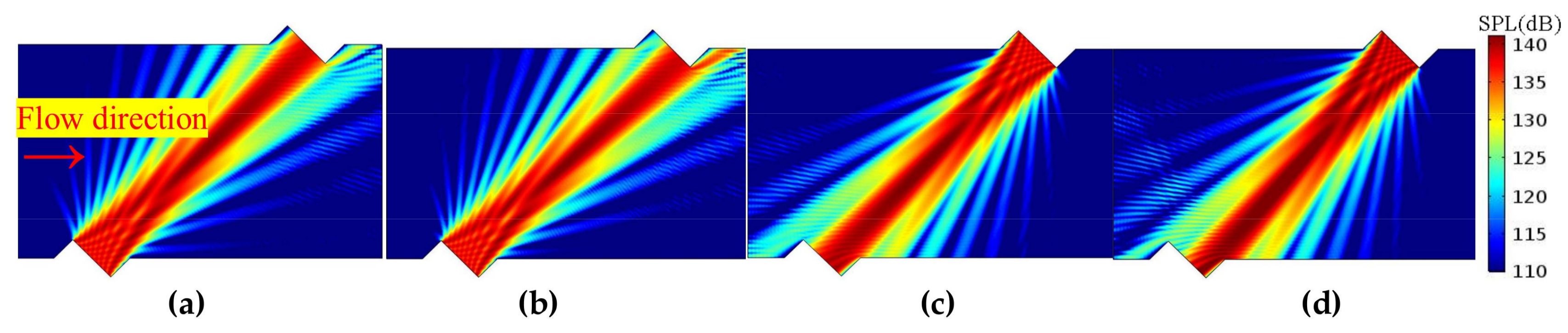

3.2.2. Propagation Features Obtained by the Acoustic Beam

- When increases, at the downstream (or upstream) situation, the sound beam is deflected to the flow direction for each profile. As a result, the main lobe having the most energy deviates from the center of the receiver, whereas the side lobe is gradually moved to the receiver.

- When is equal, the acoustic beams downstream and upstream are different for the same profile. Moreover, the acoustic beams downstream (or upstream) are also different for different profiles.

- When increases (e.g., > 22.35 m/s), compared with the profiles with non-recirculation, the acoustic beam deflects (or bends) more significantly due to the recirculation zone.

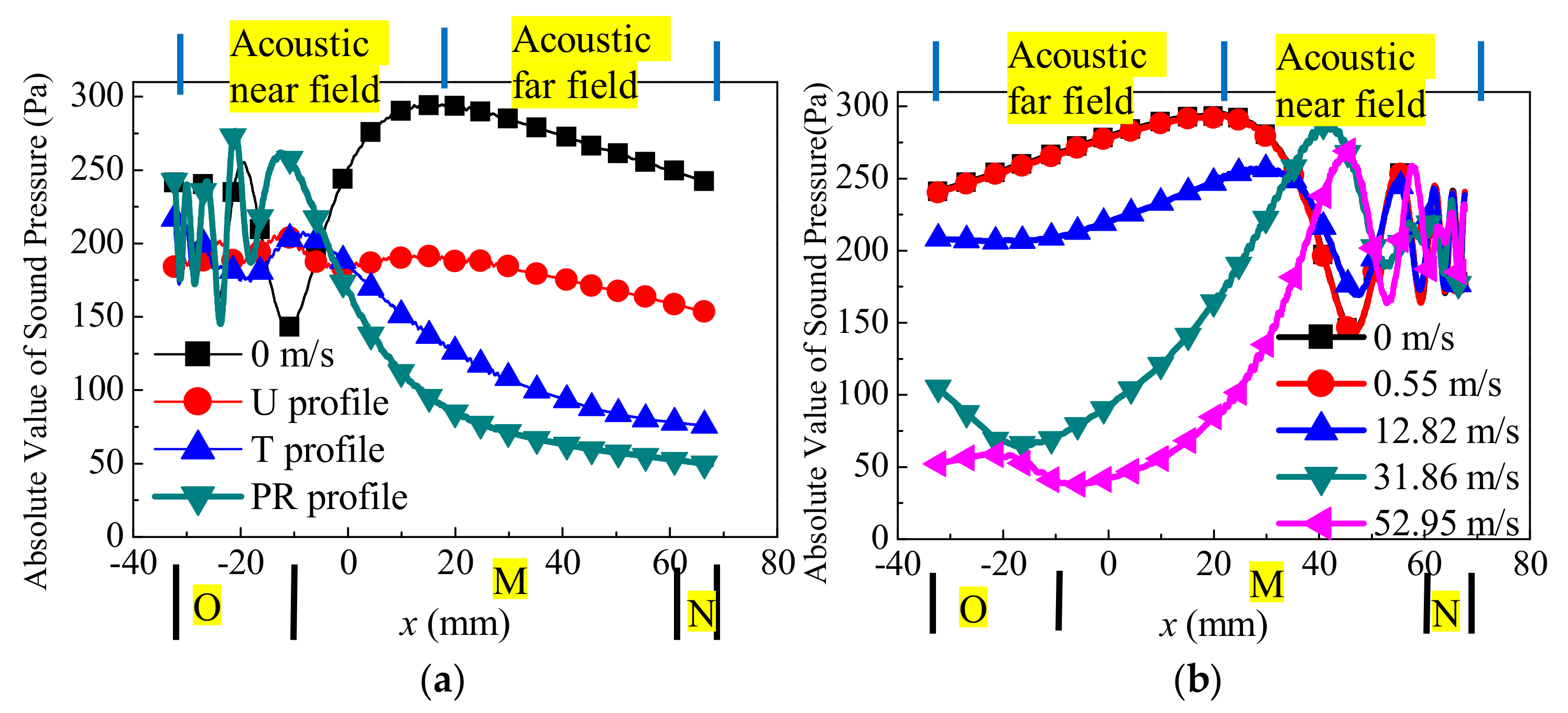

- The O zone and acoustic near field. The far-near field demarcation of the piston transducer is shown in (9).Here, is the acoustic wave length. It can be seen that the near field is located within a distance of 55mm on line . The undulations of the acoustic pressure amplitude are observed in the near field. When increases, the near field is “shortened” compared with the “ = 0 m/s” case. This is because the center axis of the acoustic beam shifts away from the line and deflects to the flow direction.

- The M zone and acoustic near field (or acoustic far field). The distance within 55 mm is the near field, and the rest is the far field. In the far field, the sound pressure amplitude decreases as the distance increases. The sound pressure is different for each profile. The sound pressure also decreases as the velocity increases.

- The N zone and acoustic far field. The phenomena appearing in this zone are similar to that of the “M zone and acoustic far field” described above.

- The O and N zones. In the upstream situation (contrary to the downstream), the acoustic beam passes successively through the N, M, and O zones. The sound pressure distribution in the N zone upstream is similar to that of the O zone downstream. Note that, in the O zone, the sound pressure abnormally increases with increasing distance due to the vortex near the transducer (Figure 4).

- The M zone and acoustic far field. In the M zone that overlaps with the acoustic far field, there are two main features for sound pressure distribution. When is equal, sound pressure decreases as the distance increases. On the other hand, when the distance is equal, sound pressure decreases as the flow velocity increases.

3.3. Acoustic Receiving Features Influenced by the Flow Field inside the Sensor

3.3.1. Receiving Features Obtained by the Central Ray

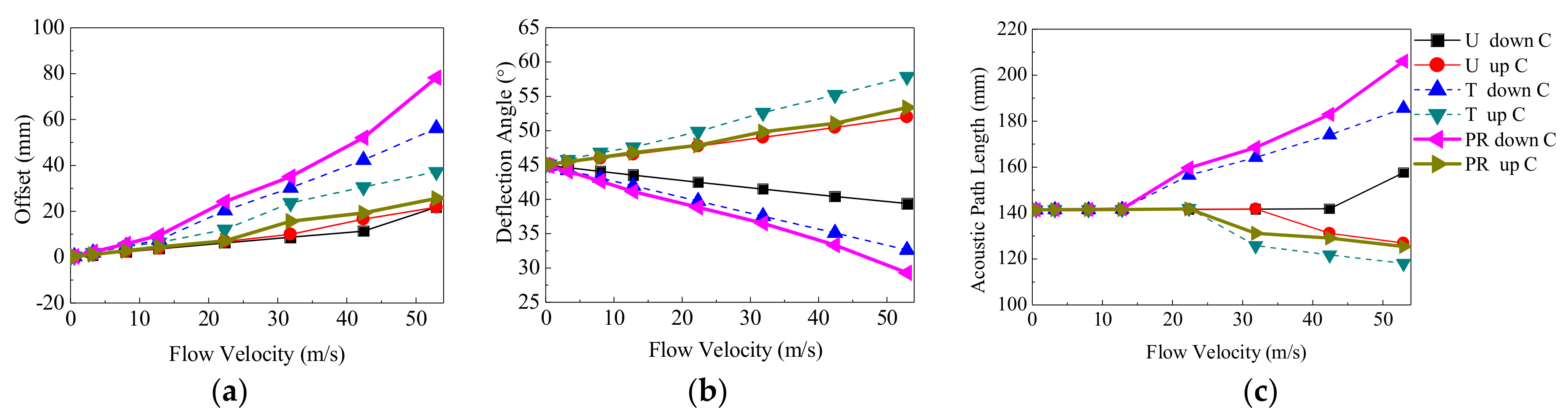

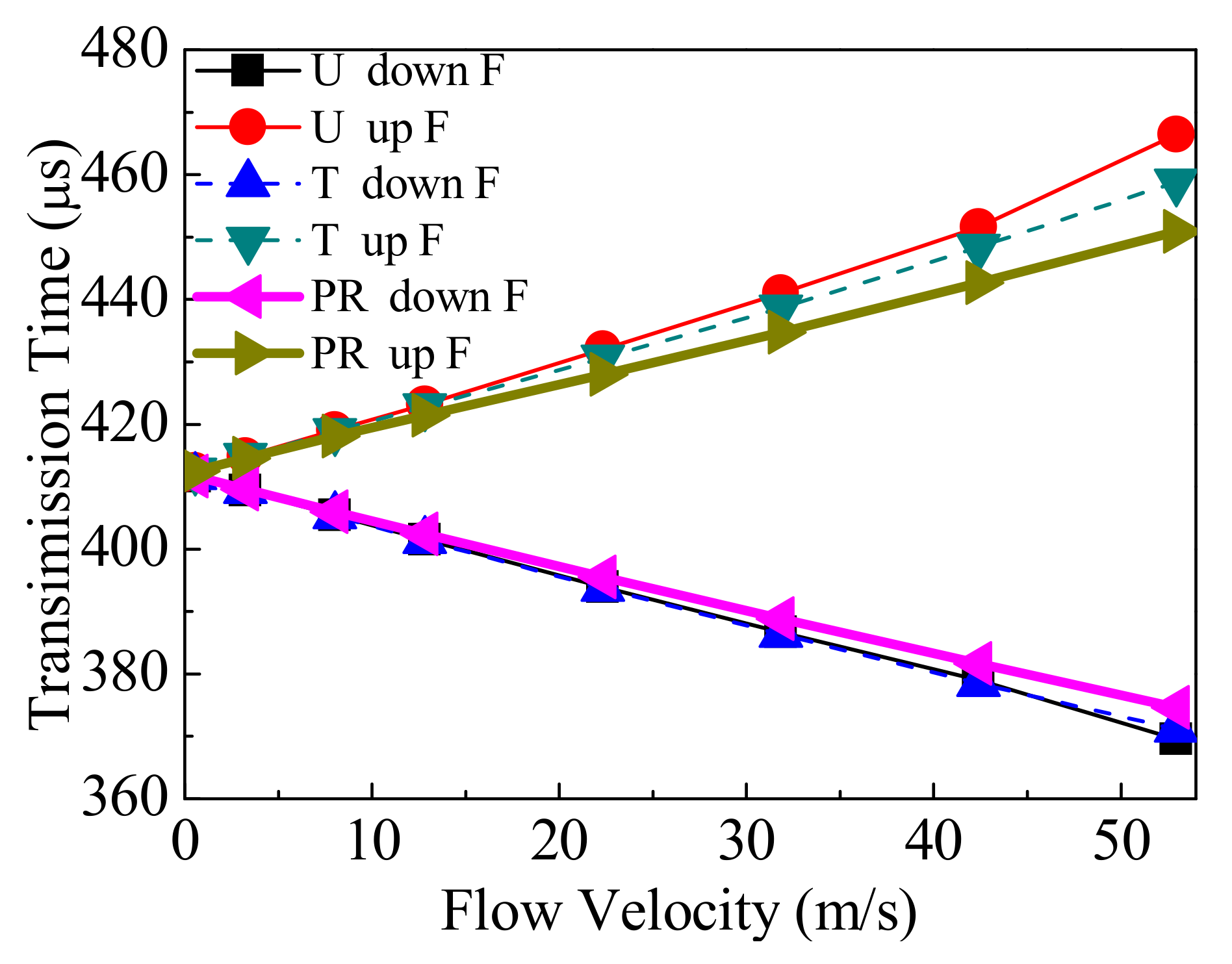

- When increases, for all velocity profiles, the parameters of , , , , and increase, whereas decreases.

- When is equal, > for the PR and T profiles. < , and > for all profiles.

- When is equal, for parameters of , , and , the sequence of the three velocity profiles are as follows: PR > T > U for and ; T > PR > U for and ; U > T > PR for ; U > PR > T for .

3.3.2. Receiving Features Obtained by the Acoustic Beam

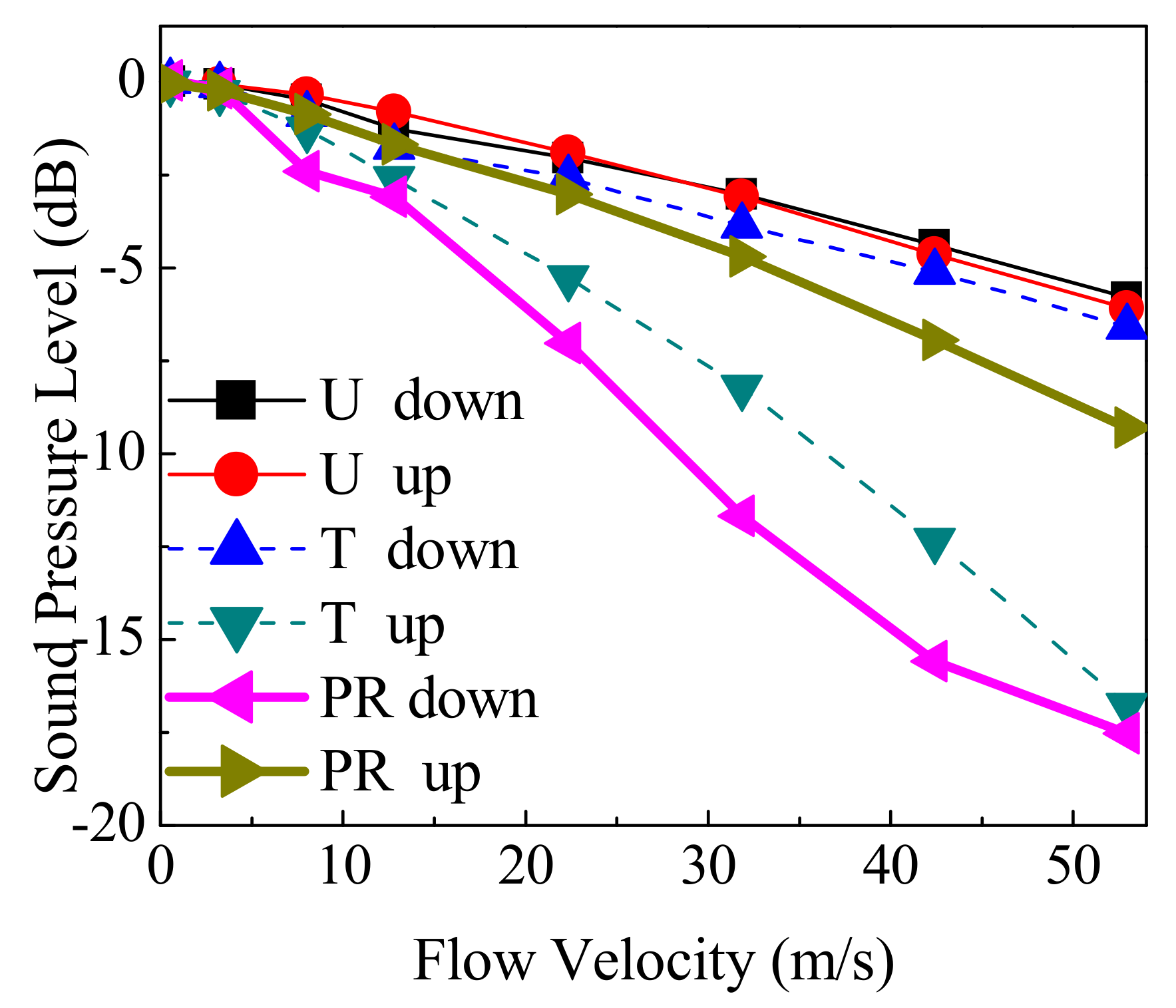

- When is small (such as 0.55 m/s < < 12.82 m/s), the flow velocity and velocity profile have little effect on the sound pressure of the sound path. The of the three profiles is close, and the is less than 3%.

- When increases (for example, 12.82 m/s < < 52.95 m/s), decreases. The also increases, and the maximum deviation is 17%.

- When is equal, for the downstream situation, the in descending order is U, T, and PR profiles. For the upstream situation, the sequence follows the order of U, PR, and T profiles. Both “the U and T profiles in the downstream section” and “the U and PR profiles in the upstream section” have the smallest deviations.

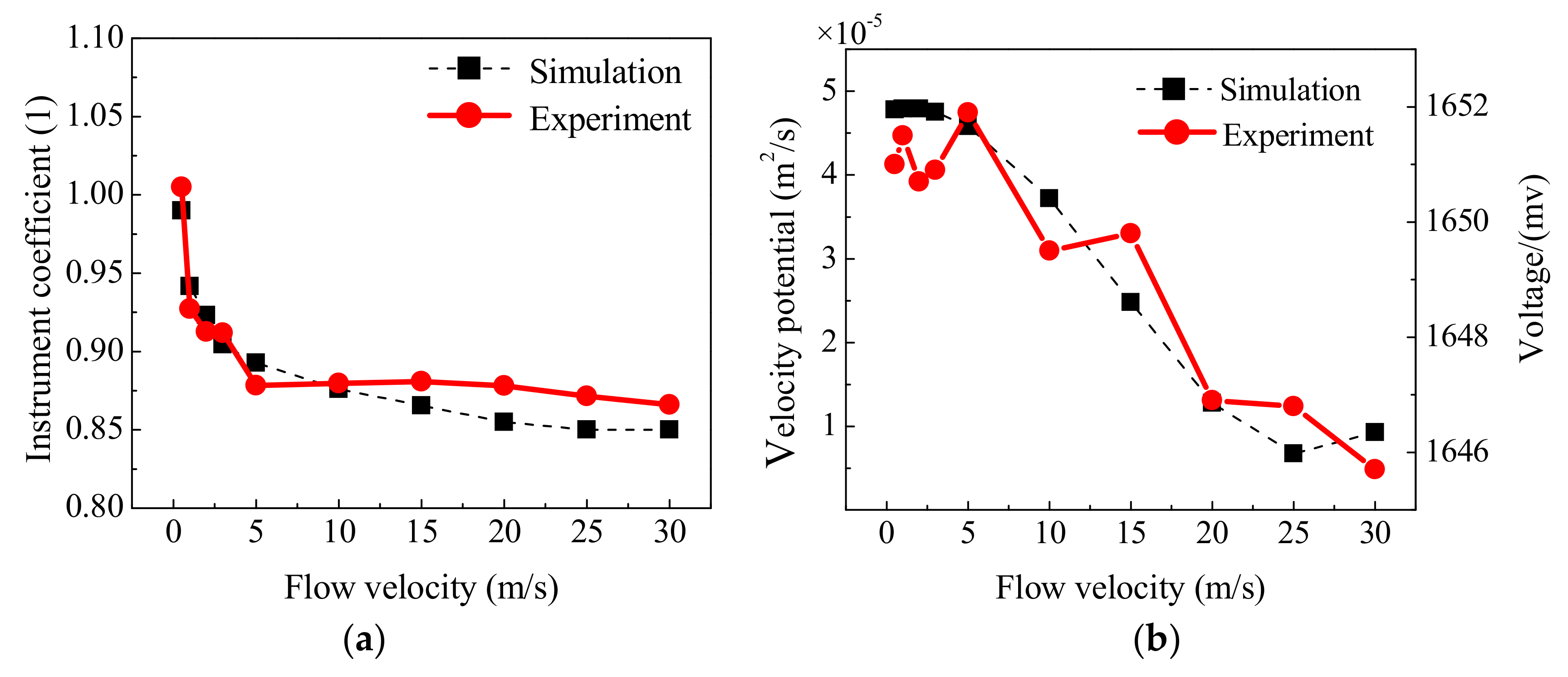

3.4. Flowmeter Performance Influenced by the Flow Field Using the Fastest Ray

- Firstly, in the range of 0.55~52.95 m/s for the T and PR profiles, the instrument coefficient decreases as the increases. When is equal, the descending order of for each profile is U > T > PR. Compared with the U profile, the PR profile is closer to the T profile.

- Secondly, compared with the inlet velocity (used as a theoretical value), the maximum relative deviation of U, T, and SP profiles are 2%, −11%, and −17%, respectively.

- Thirdly, the deviation of the U profile between simulation and theoretical values is small, so the simulation scheme is feasible.

- Lastly, for the T and PR profiles (with a vortex near the transducer), the deviation is large between the simulation and theoretical values. That is a very important reason found in this work for many scholar seeking to improve the flowmeter performance by using various methods, including improving the velocity integral methods, waveform signal processing, and optimal arrangement of the multichannel, etc.

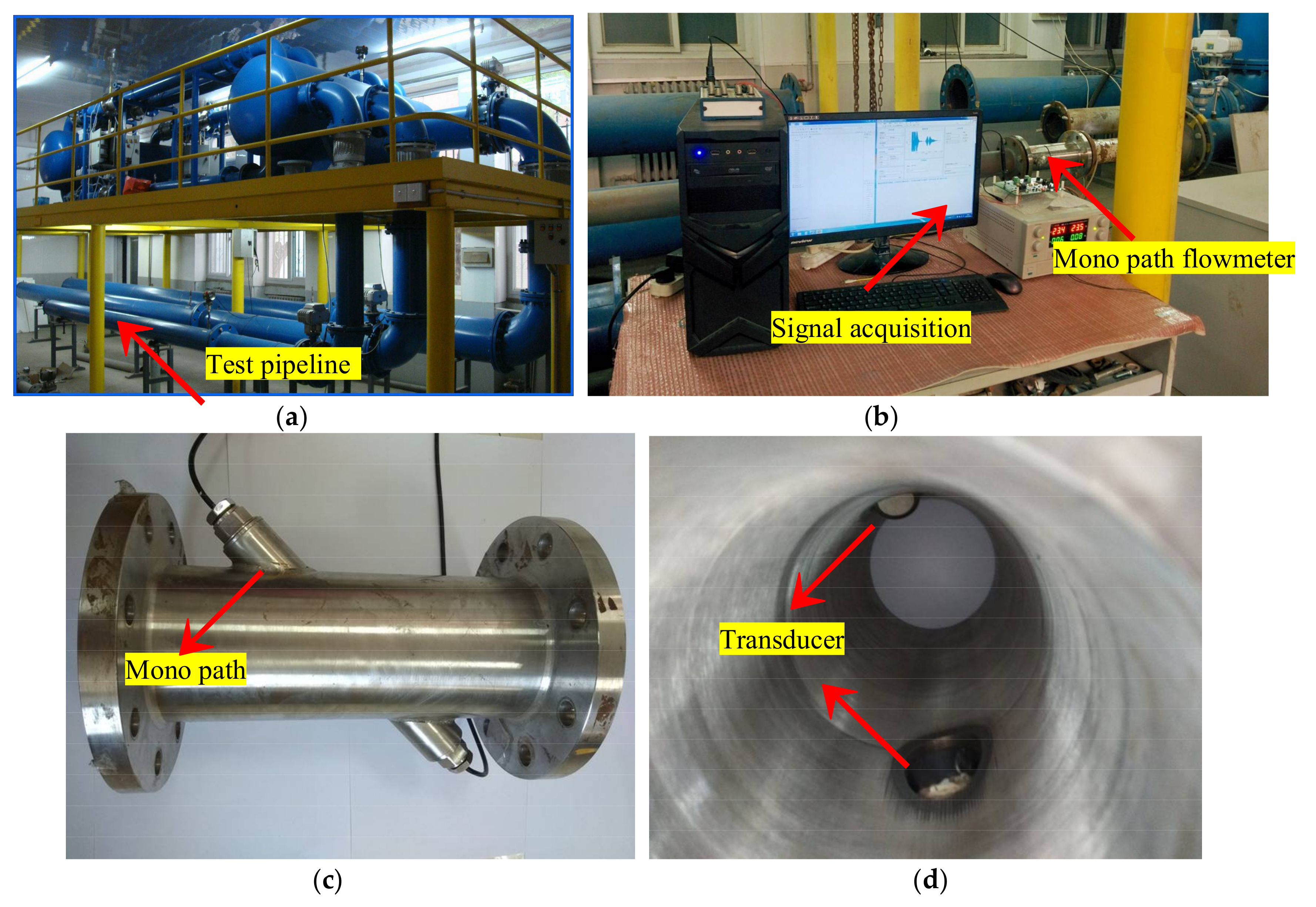

4. Validation by Experiment

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CFD | Computational Fluid Dynamics |

| FEM | Finite Element Method |

| PR | Protrusion and Recess (of the transducer) flow velocity profile |

| SPL | Sound Pressure Level |

| T | Turbulent flow velocity profile |

| U | Uniform flow velocity profile |

| Symbols | |

| A | Transducer at the upstream section |

| Radiation surface radius of circular piston | |

| B | Transducer at the downstream section |

| Central ray, subscript | |

| Sound speed | |

| D | Pipe diameter |

| Downstream, subscript | |

| Fluid element | |

| Fastest ray, subscript | |

| Frequency | |

| Vortex intensity | |

| Instrument coefficient | |

| Wave vector | |

| Wave number | |

| First component of wave number | |

| Second component of wave number | |

| Length of receiver | |

| Ray direction vector | |

| Average sound pressure level on receiver | |

| Average sound pressure level of stationary profile used as a benchmark | |

| Sound pressure level on receiver | |

| Sound pressure level of analytical | |

| Sound pressure level of simulation | |

| Sound path length | |

| Central line of acoustic path | |

| Straight line between A and C | |

| Straight line between A and F | |

| Length of central ray | |

| Length of fastest ray | |

| Last discrete point number on ray trajectory | |

| Ray position vector | |

| Radius of point source | |

| Sound propagation distance | |

| Slope of line | |

| Slope of line | |

| Transit time | |

| Upstream, subscript | |

| Vibration velocity amplitude | |

| Flow velocity vector | |

| Flow velocity | |

| Flow velocity obtained by fastest ray | |

| Far-near field demarcation of piston transducer | |

| Axial coordinates on transducer axis | |

| Sound path angle (the angle between the acoustic path and the pipeline axis) | |

| Coefficient, = 1 | |

| Offset at receiving position | |

| Offset al.ong ray trajectory | |

| Slope along ray trajectory | |

| Relative deviation between the and the | |

| Relative error between simulation and analytical value | |

| Coefficient, = −0.018 | |

| Coefficient, = −1 | |

| Angle between the direction of and “the link line of the point source and the sound field point” | |

| Acoustic wavelength | |

| Fluid density | |

| Acoustic velocity potential | |

| Normal component of rotating angular velocity for fluid element | |

| Acoustic angular frequency | |

References

- Lynnworth, L.C.; Liu, Y. Ultrasonic flowmeters: Half-century progress report, 1955–2005. Ultrasonics 2006, 44, 1371–1378. [Google Scholar] [CrossRef] [PubMed]

- Rajita, G.; Mandal, N. Review on transit time ultrasonic flowmeter. In Proceedings of the International Conference on Control, Instrumentation, Energy & Communication, Kolkata, India, 28–30 January 2016; pp. 88–92. [Google Scholar]

- Lansing, J. Measurement of Gas by Multipath Ultrasonic Meters; Tech. Rep. 9; AGA: Arlington, VA, USA, 1998. [Google Scholar]

- Mandard, E.; Kouame, D.; Battault, R.; Remenieras, J.P.; Patat, F. Transit time ultrasonic flowmeter: velocity profile estimation. In Proceedings of the IEEE Ultrasonics Symposium, Rotterdam, The Netherlands, 18–21 September 2005; pp. 763–766. [Google Scholar]

- Peng, L.H.; Zhang, B.W.; Zhao, H.C.; Stephane, S.A.; Ishikawa, H.; Shimizu, K. Data integration method for multipath ultrasonic flowmeter. IEEE Sens. J. 2012, 12, 2866–2874. [Google Scholar] [CrossRef]

- Marushchenko, S.; Gruber, P.; Staubli, T. Approach for acoustic transit time flow measurement in sections of varying shape: Theoretical fundamentals and implementation in practice. Flow Meas. Instrum. 2016, 49, 8–17. [Google Scholar] [CrossRef]

- Hu, L.; Qin, L.H.; Mao, K.; Chen, W.Y.; Fu, X. Optimization of neural network by genetic algorithm for flowrate determination in multipath ultrasonic gas flowmeter. IEEE Sens. J. 2016, 16, 1158–1167. [Google Scholar] [CrossRef]

- Birkhofer, B.; Meile, T.; De Cesare, G.; Jeelani, S.A.K.; Windhab, E.J. Use of gas bubbles for ultrasound doppler flow velocity profile measurement. Flow Meas. Instrum. 2016, 52, 233–239. [Google Scholar] [CrossRef]

- ASME PTC18-2011. Hydraulic Turbines and Pump Turbines Performance Test Codes; American Society of Mechanical Engineers: New York, NY, USA, 2011. [Google Scholar]

- Voser, A. CFD-Calculations of Protrusion Effects and Impact on the Acoustic Discharge Measurement Accuracy. Available online: http://www.ighem.org/Paper1996/GHEM1996_35.pdf (accessed on 28 June 1996).

- Lowell, F.; Schafer, S.; Walsh, J. Acoustic Flowmeters in circular Pipes: Acoustic Transducer Conduit Protrusion Effects in Discharge Measurement. Available online: http://www.ighem.org/Paper1998/IQHEM1998_05.pdf (accessed on 20 August 1998).

- Raišutis, R. Investigation of the flow velocity profile in a metering section of an invasive ultrasonic flowmeter. Flow Meas. Instrum. 2006, 17, 201–206. [Google Scholar] [CrossRef]

- Zheng, D.D.; Zhang, P.Y.; Xu, T.S. Study of acoustic transducer protrusion and recess effects on ultrasonic flowmeter measurement by numerical simulation. Flow Meas. Instrum. 2011, 22, 488–493. [Google Scholar] [CrossRef]

- Guo, L.; Sun, Y.; Liu, L.; Shen, Z.; Gao, R.; Zhao, K. The flow field analysis and flow calculation of ultrasonic flowmeter based on the fluent software. Abstr. Appl. Anal. 2014, 2014, 528–602. [Google Scholar] [CrossRef]

- Koechner, H.; Melling, A. Numerical simulation of ultrasonic flowmeters. Acta Acust. United Acust. 2000, 86, 39–48. [Google Scholar]

- Bezdek, M.; Landes, H.; Rieder, A.; Lerch, R. A coupled finite-element, boundary-integral method for simulating ultrasonic flowmeters. IEEE Trans. Ultrason. Ferr. 2007, 54, 636–646. [Google Scholar] [CrossRef]

- Tezuka, K.; Mori, M.; Wada, S.; Aritomi, M.; Kikura, H.; Sakai, Y. Analysis of ultrasound propagation in high-temperature nuclear reactor feedwater to investigate a clamp-on ultrasonic pulse doppler flowmeter. J. Nucl. Sci. Technol. 2008, 45, 752–762. [Google Scholar] [CrossRef]

- Ioos, B.; Lhuillier, C.; Jeanneau, H. Numerical simulation of transit-time ultrasonic flowmeters: Uncertainties due to flow profile and fluid turbulence. Ultrasonics 2002, 40, 1009–1015. [Google Scholar] [CrossRef]

- Kupnik, M.; O’Leary, P.; Schröder, A.; Rungger, I. Numerical simulation of ultrasonic transit-time flowmeters performance in high temperature gas flows. In Proceedings of the IEEE Ultrasonics Symposium, Honolulu, HI, USA, 5–8 October 2003; pp. 1354–1359. [Google Scholar]

- Li, Y.Z.; Wu, J.T.; Hu, K.M. Numerical simulating nonlinear effects of ultrasonic propagation on high-speed ultrasonic gas flow measurement. Appl. Math. Inf. Sci. 2013, 7, 1963–1967. [Google Scholar]

- Zheng, D.D.; Mei, J.Q.; Wang, M. Improvement of gas ultrasonic flowmeter measurement non-linearity based on ray tracing method. IET Sci. Meas. Technol. 2016, 10, 602–606. [Google Scholar] [CrossRef]

- Eccardt, P.C.; Landes, H.; Lerch, R. Finite element simulation of acoustic wave propagation within flowing media. In Proceedings of the IEEE Ultrasonics Symposium, Sab Antonio, TX, USA, 3–6 November 1996; pp. 991–994. [Google Scholar]

- Willatzen, M. Flow acoustics modelling and implications for ultrasonic flow measurement based on the transit-time method. Ultrasonics 2004, 41, 805–810. [Google Scholar] [CrossRef] [PubMed]

- Willatzen, M. Ultrasonic flowmeters: Temperature gradients and transducer geometry effects. Ultrasonics 2003, 41, 105–114. [Google Scholar] [CrossRef]

- Willatzen, M.; Kamath, H. Nonlinearities in ultrasonic flow measurement. Flow Meas. Instrum. 2008, 19, 79–84. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, Y.Y.; Chen, X.Q. Acoustic propagation in viscous fluid with uniform flow and a novel design methodology for ultrasonic flow meter. Ultrasonics 2013, 53, 595–606. [Google Scholar] [CrossRef] [PubMed]

- Luca, A.; Fodil, K.; Zerarka, A. Full-wave numerical simulation of ultrasonic transit-time gas flowmeters. In Proceedings of the IEEE Ultrasonics Symposium, Tours, France, 18–21 September 2016; pp. 1–4. [Google Scholar]

- Luca, A.; Marchiano, R.; Chassaing, J.C. Numerical simulation of transit-time ultrasonic flowmeters by a direct approach. IEEE Trans. Ultrason. Ferr. 2016, 63, 886–897. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Wang, Y.F.; Li, Q.; Liu, Z.W. A 3D CFD simulation and analysis of flow-induced forces on polymer piezoelectric sensors in a Chinese liquors identification e-nose. Sensors 2016, 16, 1738. [Google Scholar] [CrossRef] [PubMed]

- Ruhala, R.J.; Swanson, D.C. Planar near-field acoustical holography in a moving medium. J. Acoust. Soc. Am. 2002, 112, 420–429. [Google Scholar] [CrossRef] [PubMed]

- Du, G.H.; Zhu, Z.M.; Gong, X.F. Acoustics Foundation, 3nd ed.; Nanjing University Press: Nanjing, China, 2012; p. 235. [Google Scholar]

- Li, X.; Song, Z.X. An ultrasound-based liquid pressure measurement method in small diameter pipelines considering the installation and temperature. Sensors 2015, 15, 8253–8265. [Google Scholar] [CrossRef] [PubMed]

- Raine, A.B.; Aslam, N.; Underwood, C.P.; Danaher, S. Development of an ultrasonic airflow measurement device for ducted air. Sensors 2015, 15, 10705–10722. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, K.A.; Raisutis, R.; Samaitis, V. Hybrid signal processing technique to improve the defect estimation in ultrasonic non-destructive testing of composite structures. Sensors 2017, 17, 2858. [Google Scholar] [CrossRef] [PubMed]

| (m/s) | Downstream (%) | Upstream (%) | ||||

|---|---|---|---|---|---|---|

| PR | T | U | PR | T | U | |

| 0.55 | 0.03 | 0.02 | 0 | −0.05 | −0.04 | −0.01 |

| 12.82 | −3.1 | −1.75 | −1.26 | −1.68 | −2.61 | −0.81 |

| 31.86 | −11.68 | −3.88 | −3.02 | −4.7 | −8.21 | −3.1 |

| 52.95 | −15.03 | −6.6 | −5.2 | −9.3 | −16.77 | −6.7 |

| (m/s) | U | T | PR |

|---|---|---|---|

| 0.55 | 1.00 | 1.00 | 0.95 |

| 3.24 | 1.00 | 1.00 | 0.90 |

| 8.04 | 1.00 | 0.99 | 0.88 |

| 12.82 | 1.00 | 0.98 | 0.87 |

| 22.35 | 1.00 | 0.97 | 0.85 |

| 31.86 | 1.00 | 0.94 | 0.85 |

| 42.41 | 1.01 | 0.93 | 0.84 |

| 52.95 | 1.02 | 0.89 | 0.83 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Zhang, T.; Zheng, D. New Analysis Scheme of Flow-Acoustic Coupling for Gas Ultrasonic Flowmeter with Vortex near the Transducer. Sensors 2018, 18, 1151. https://doi.org/10.3390/s18041151

Sun Y, Zhang T, Zheng D. New Analysis Scheme of Flow-Acoustic Coupling for Gas Ultrasonic Flowmeter with Vortex near the Transducer. Sensors. 2018; 18(4):1151. https://doi.org/10.3390/s18041151

Chicago/Turabian StyleSun, Yanzhao, Tao Zhang, and Dandan Zheng. 2018. "New Analysis Scheme of Flow-Acoustic Coupling for Gas Ultrasonic Flowmeter with Vortex near the Transducer" Sensors 18, no. 4: 1151. https://doi.org/10.3390/s18041151

APA StyleSun, Y., Zhang, T., & Zheng, D. (2018). New Analysis Scheme of Flow-Acoustic Coupling for Gas Ultrasonic Flowmeter with Vortex near the Transducer. Sensors, 18(4), 1151. https://doi.org/10.3390/s18041151