Behaviour of Hybrid Steel and FRP-Reinforced Concrete—ECC Composite Columns under Reversed Cyclic Loading

Abstract

:1. Introduction

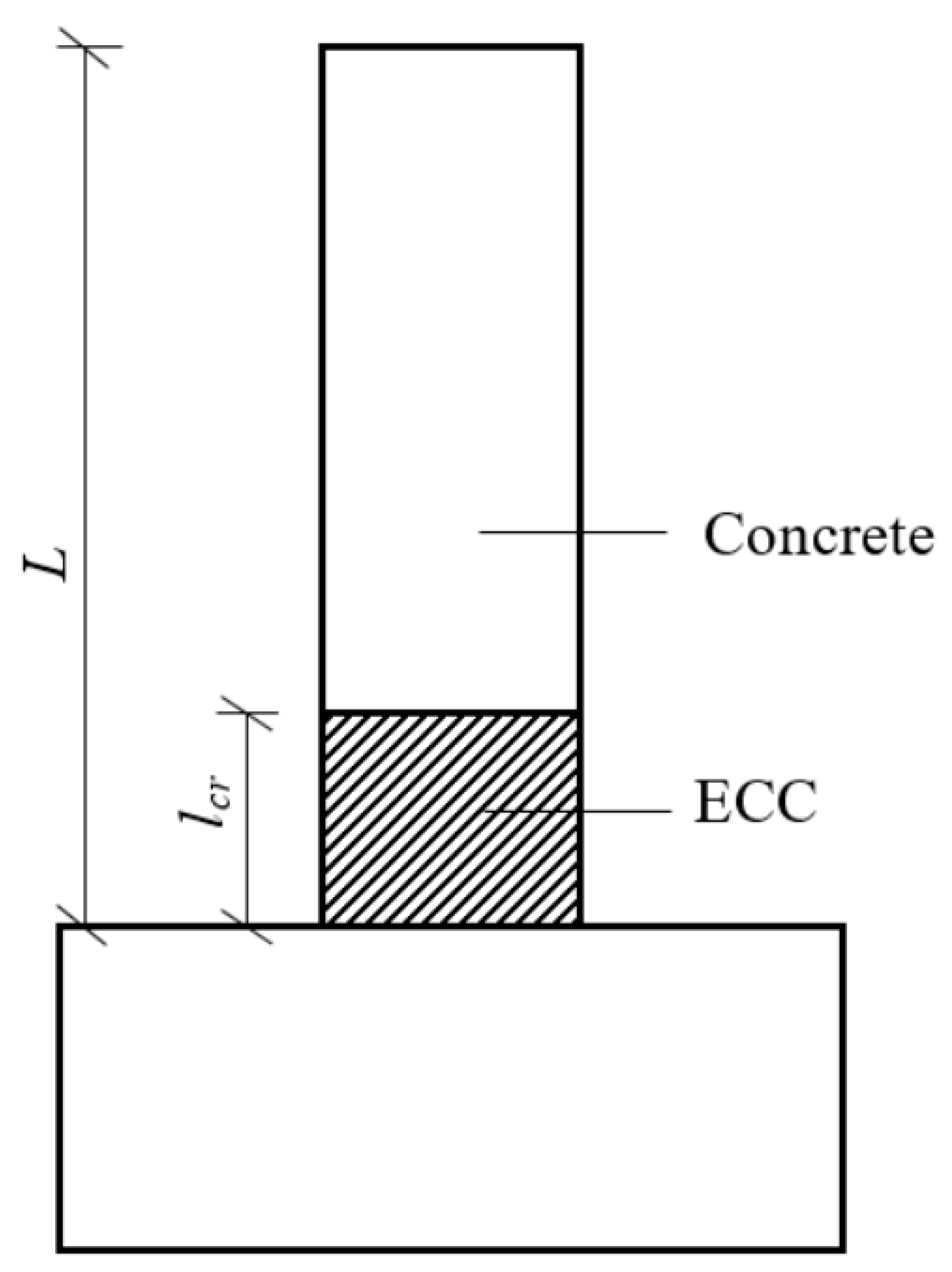

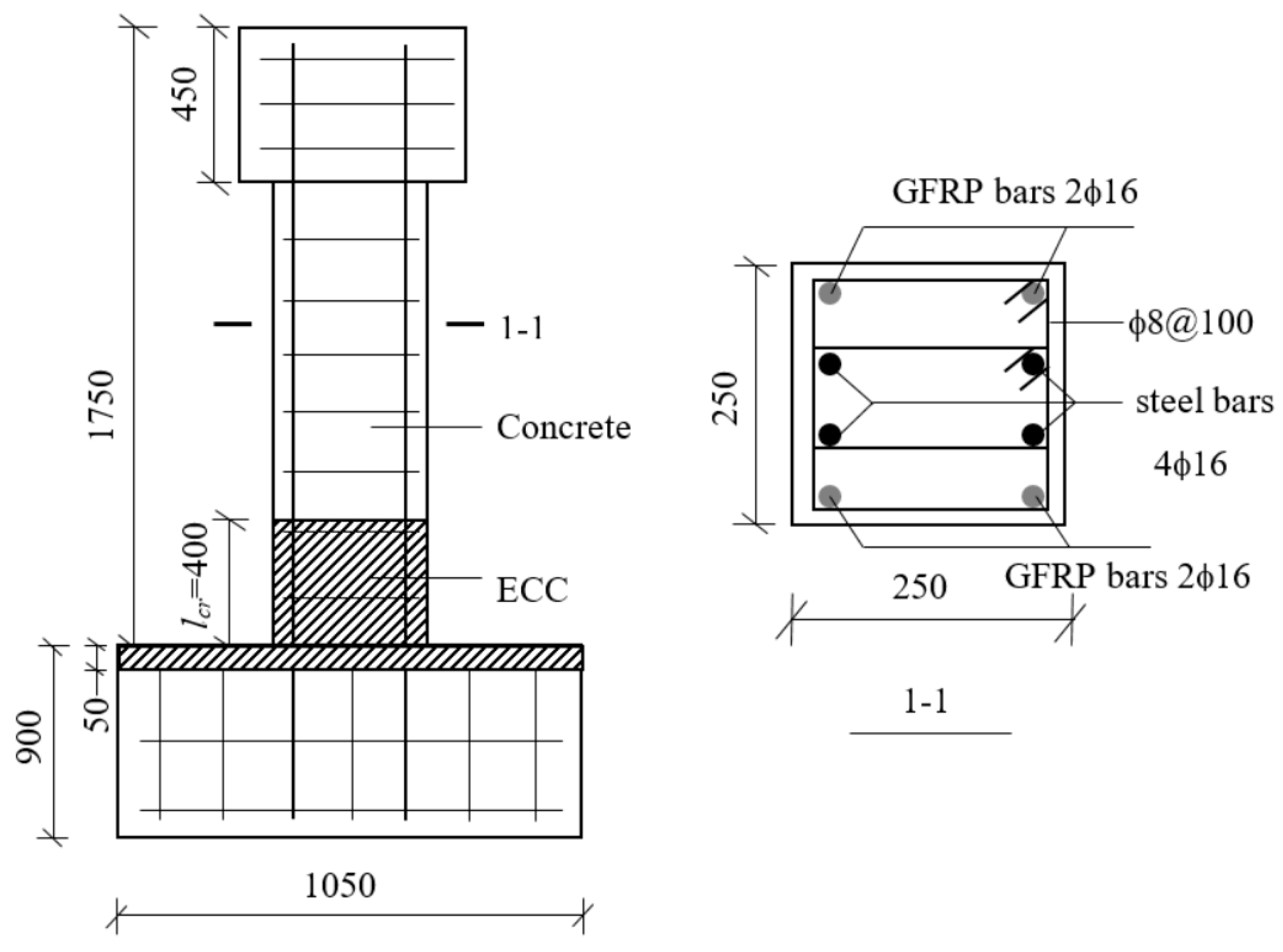

2. Design Philosophy

3. Experimental Program

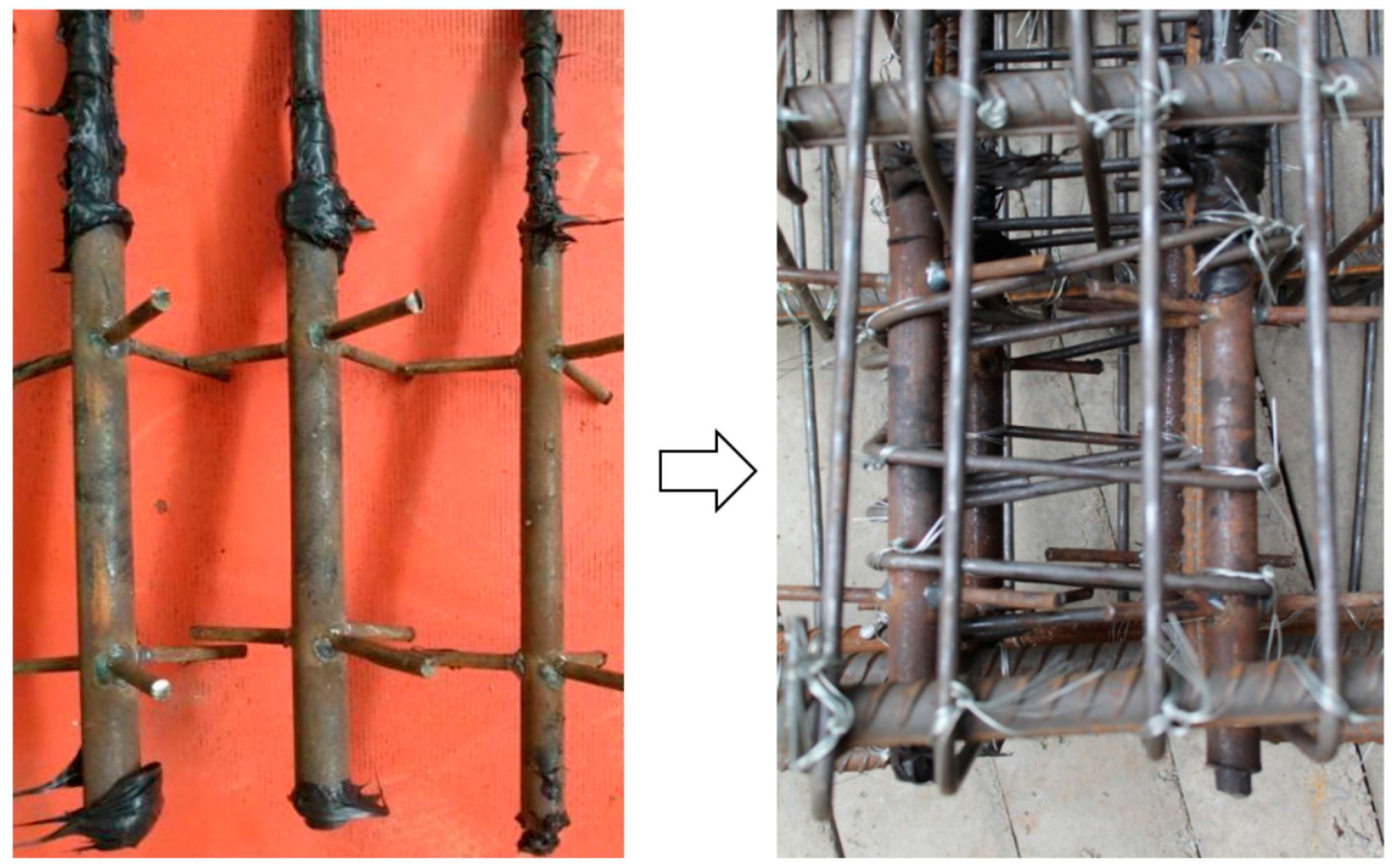

3.1. Specimen Preparation

3.2. Material Properties

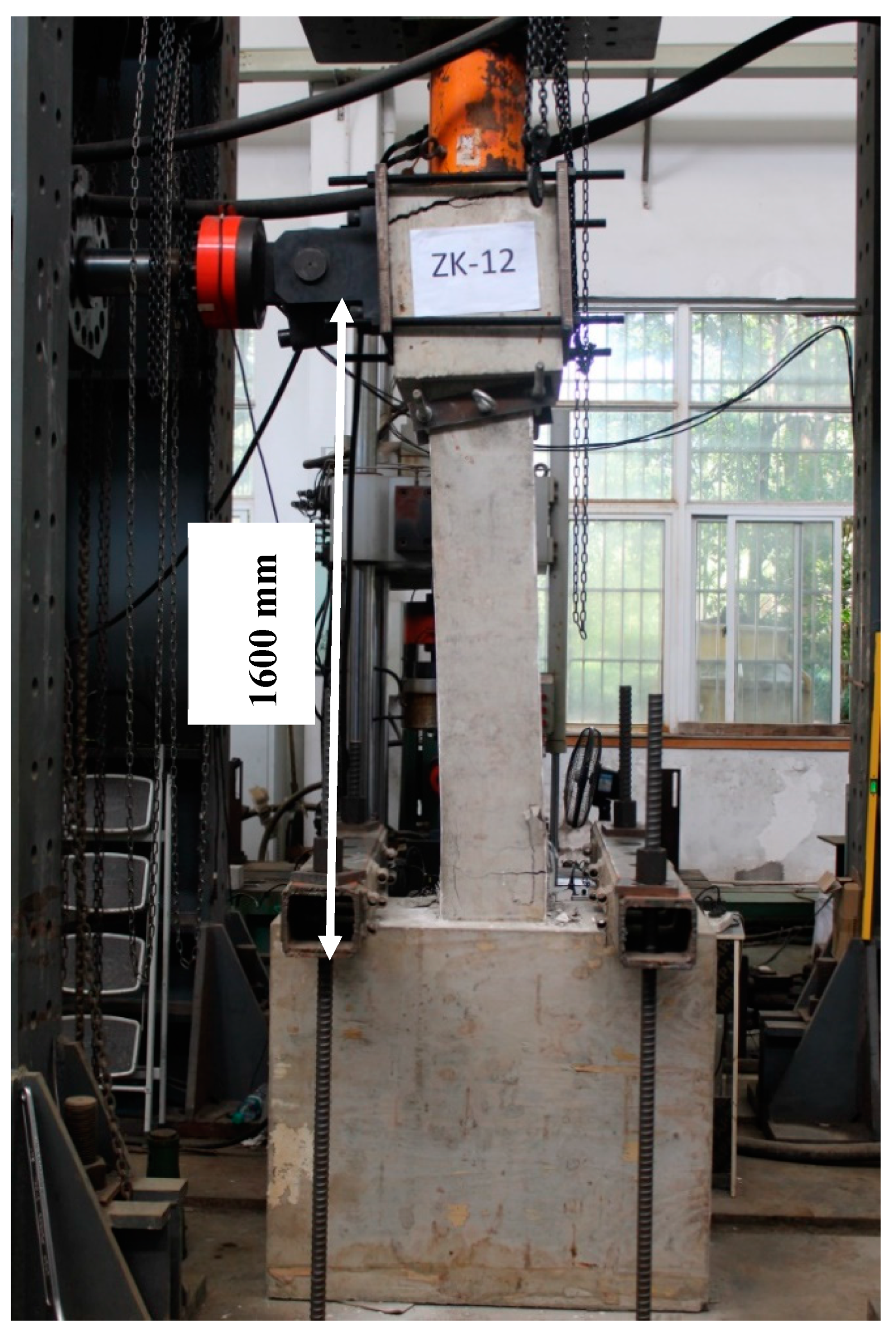

3.3. Test Setup

4. Results and Discussion

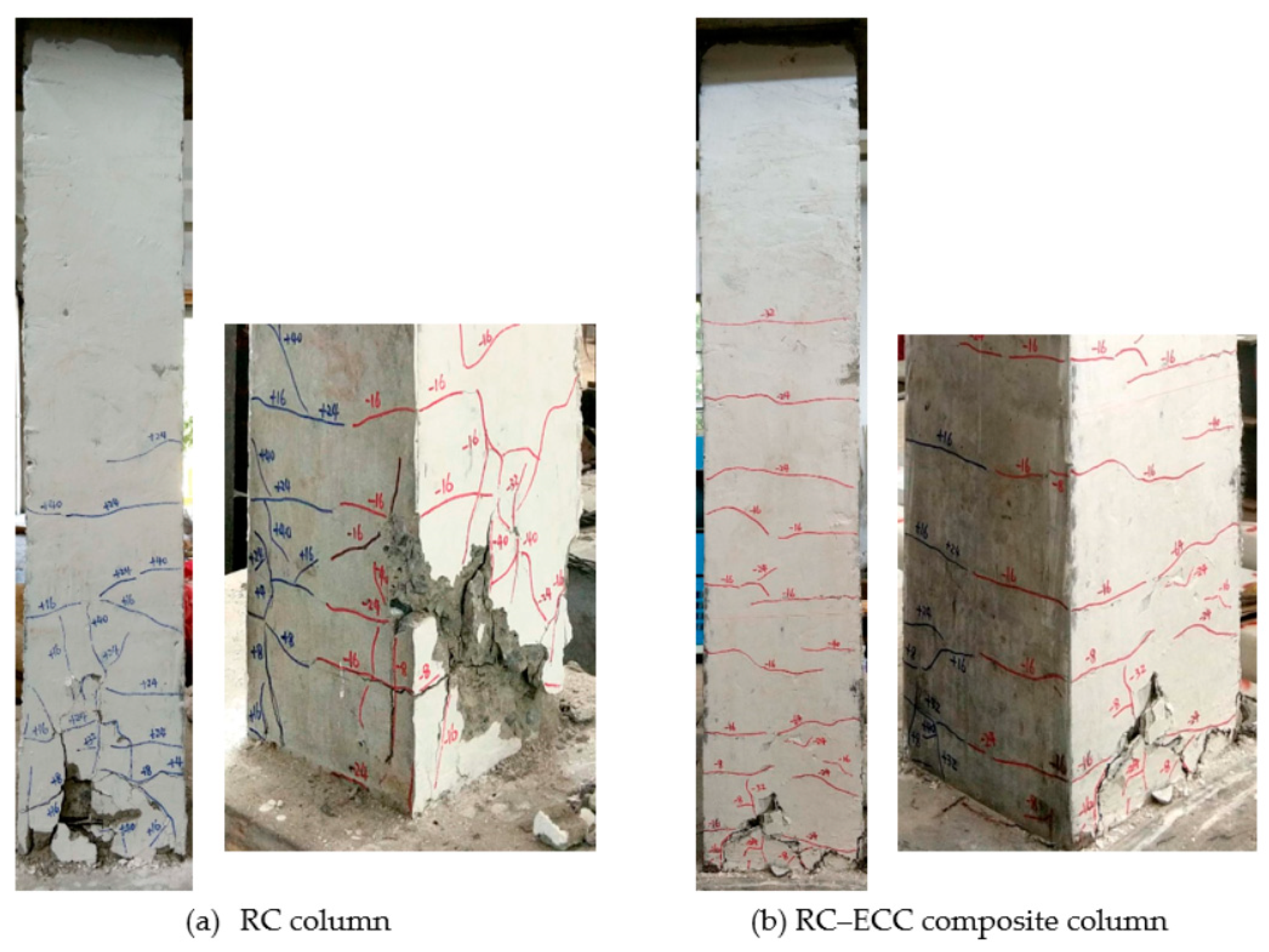

4.1. Failure Modes and Crack Patterns

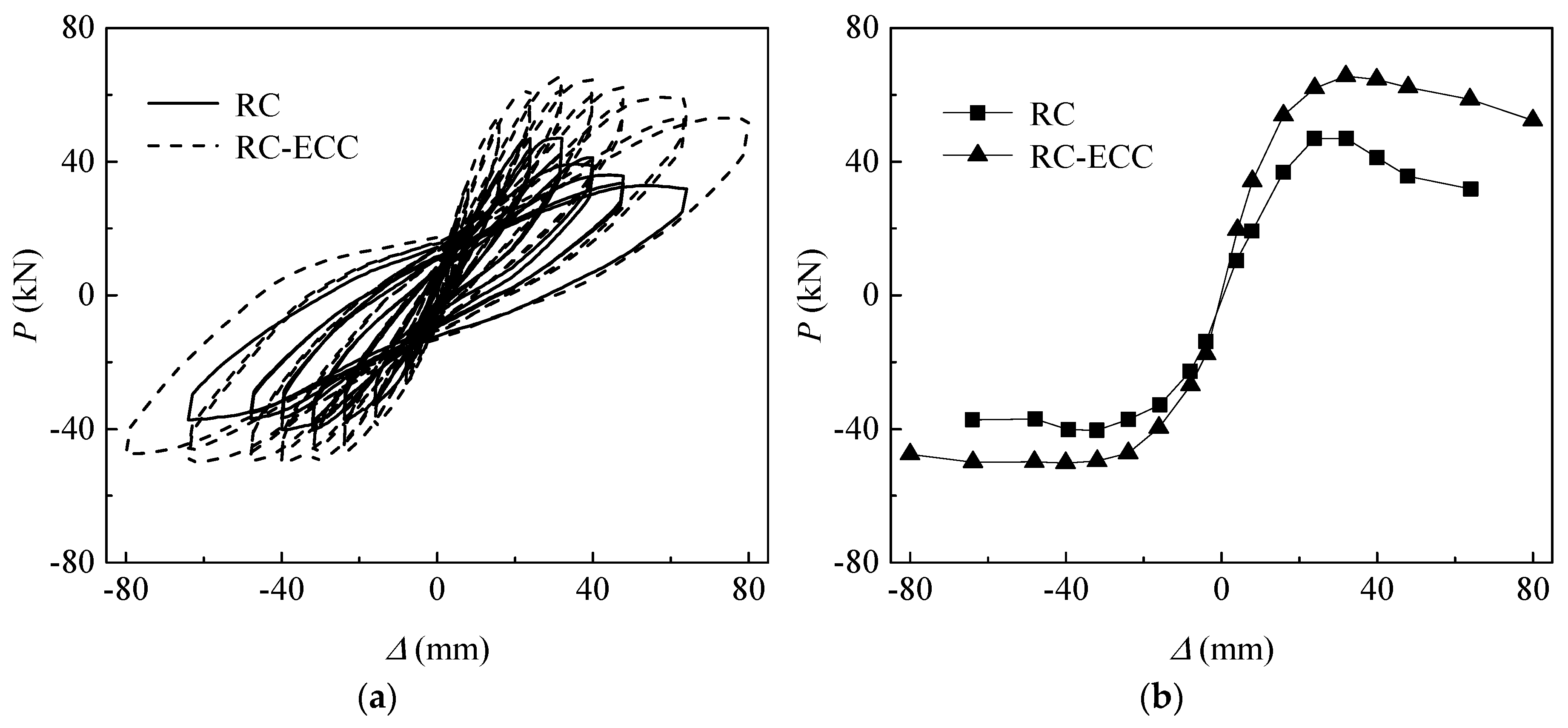

4.2. Load Versus Deformation Responses

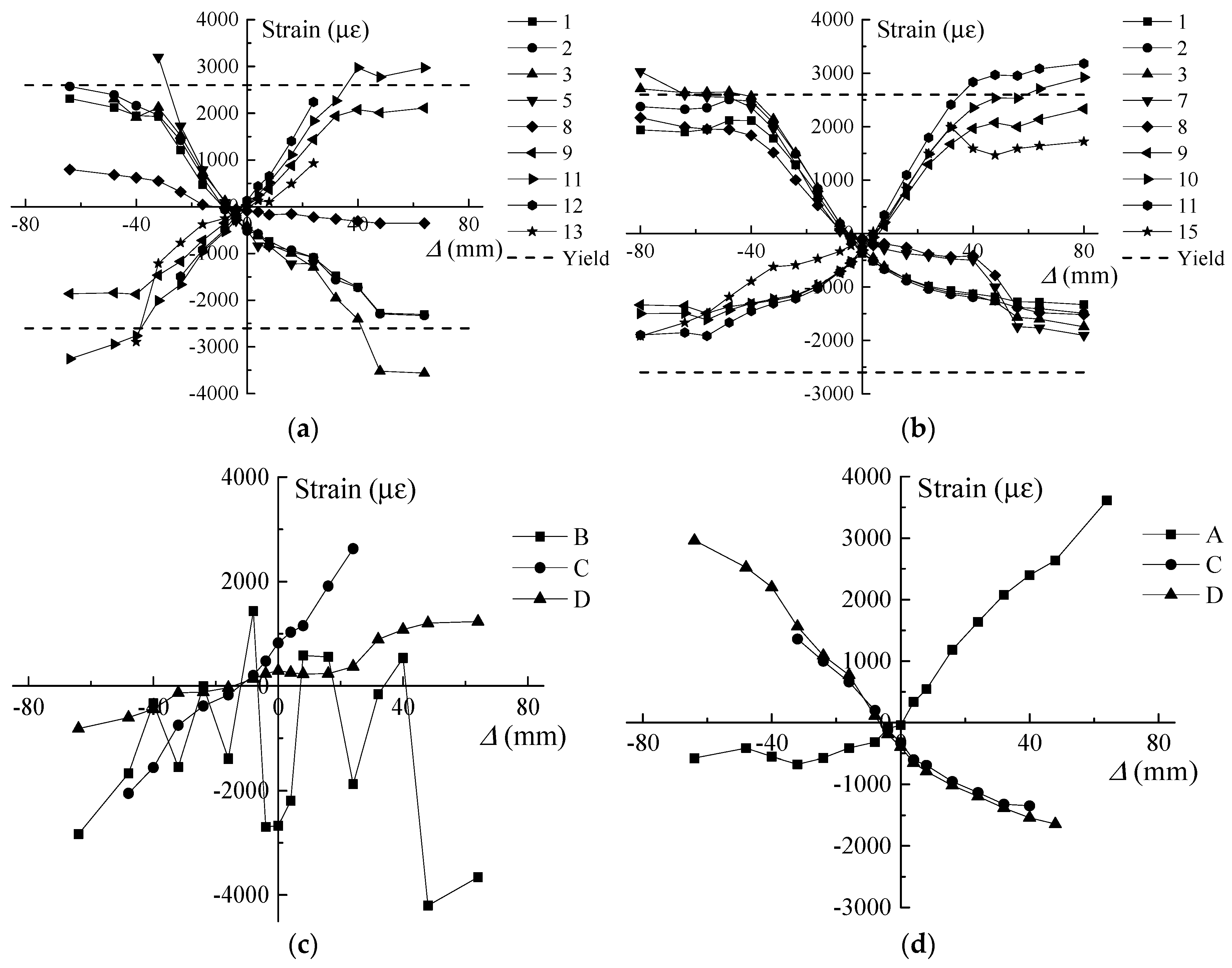

4.3. Strain Analysis

4.4. Ductility and Energy Dissipation

5. Conclusions

- The failure mode hybrid steel—FRP-reinforced concrete—ECC composite column was different from that of the hybrid steel—FRP-reinforced concrete column. Severe matrix spalling and local buckling of FRP bar were observed in the reinforced concrete column, but did not appear in the composite column. ECC can provide a more stable confinement on the GFRP bars than that of concrete.

- The anchoring scheme in the present study could present the bond-slip failure between GFRP bars and concrete effectively.

- With the substitution of ECC with concrete in the plastic hinge region, the load carrying capacity, ductility, and energy dissipation capacity of the hybrid steel—FRP-reinforced column increased by 39.62%, 73.44%, and 72.46%, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Benmokrane, B.; Masmoudi, R. Flexural response of concrete beams reinforced with FRP reinforcing bars. Struct. J. 1996, 93, 46–55. [Google Scholar]

- Uomoto, T. Recommendation for Design and Construction of Concrete Structures Using Continuous Fiber Reinforcing Materials; Machida, A., Ed.; Japan Society of Civil Engineers: Tokyo, Japan, 1997. [Google Scholar]

- Benmokrane, B.; Rahman, H. Durability of fiber reinforced polymer (FRP) composites for construction. In Proceedings of the First International Conference on Composite for Construction, Sherbrooke, QC, Canada, 5–7 August 1998. [Google Scholar]

- GangaRao, H.V.; Taly, N.; Vijay, P.V. Reinforced Concrete Design with FRP Composites; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2006. [Google Scholar]

- Vijay, P.V.; GangaRao, H.V. Bending behavior and deformability of glass fiber-reinforced polymer reinforced concrete members. Struct. J. 2001, 98, 834–842. [Google Scholar]

- Tang, Y.; Wu, Z. Distributed long-gauge optical fiber sensors based self-sensing FRP bar for concrete structure. Sensors 2016, 16, 286. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.T.; Wu, G.; Pang, Y.Y. Theoretical and Numerical Study on Stress Intensity Factors for FRP-Strengthened Steel Plates with Double-Edged Cracks. Sensors 2018, 18, 2356. [Google Scholar] [CrossRef] [PubMed]

- Hawileh, R.A.; Naser, M.Z. Thermal-stress analysis of RC beams reinforced with GFRP bars. Compos. Part B-Eng. 2012, 43, 2135–2142. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.F.; Dai, M.J. Degradation of steel-to-concrete bond due to corrosion. Constr. Build. Mater. 2018, 158, 1073–1080. [Google Scholar] [CrossRef]

- Fraternali, F.; Spadea, S.; Berardi, V.P. Effects of recycled PET fibres on the mechanical properties and seawater curing of Portland cement-based concretes. Constr. Build. Mater. 2014, 61, 293–302. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Berardi, V.P.; Dentale, F.; Fraternali, F. Energy dissipation capacity of concretes reinforced with recycled PET fibers. Ing. Sismica 2014, 31, 61–70. [Google Scholar]

- Wan, B.; Jiang, C.; Wu, Y.F. Effect of defects in externally bonded FRP reinforced concrete. Constr. Build. Mater. 2018, 172, 63–76. [Google Scholar] [CrossRef]

- Nanni, A. Flexural behavior and design of RC members using FRP reinforcement. J. Struct. Eng. 1993, 119, 3344–3359. [Google Scholar] [CrossRef]

- GangaRao, H.V.S.; Vijay, P.V. Design of concrete members reinforced with GFRP bars. In Proceedings of the 3rd International Symposium, Fiber Reinforced Polymer Reinforcement for Reinforced Concrete Structures, Sapporo, Japan, 14–16 October 1997; pp. 143–150. [Google Scholar]

- Jaejer, L.G.; Mufti, A.A.; Tadros, G. The concept of the overall performance factor in rectangular-section reinforced concrete beams. In Proceedings of the 3rd International Symposium on Non-Metallic (FRP) Reinforcement for Concrete Structures, Sapporo, Japan, 14–16 October 1997; pp. 551–558. [Google Scholar]

- Qu, W.; Zhang, X.; Huang, H. Flexural behavior of concrete beams reinforced with hybrid (GFRP and steel) bars. J. Compos. Constr. 2009, 13, 350–359. [Google Scholar] [CrossRef]

- Nanni, A.; Henneke, M.J.; Okamoto, T. Behaviour of concrete beams with hybrid reinforcement. Constr. Build. Mater. 1994, 8, 89–95. [Google Scholar] [CrossRef]

- Tan, K.H. Behaviour of hybrid FRP-steel reinforced concrete beams. In Proceedings of the 3rd International Symposium, FRPRCS, Sapporo, Japan, 14–16 October 1997; pp. 487–494. [Google Scholar]

- Newhook, J.P. Design of under-reinforced concrete T-sections with GFRP reinforcement. In Proceedings of the 3rd International Conference on Advanced Composite Materials in Bridges and Structures; Canadian Society for Civil Engineering: Montreal, QC, Canada, 2000; pp. 153–160. [Google Scholar]

- Bakis, C.E.; Nanni, A.; Terosky, J.A.; Koehler, S.W. Self-monitoring, pseudo-ductile, hybrid FRP reinforcement rods for concrete applications. Compos. Sci. Technol. 2001, 61, 815–823. [Google Scholar] [CrossRef]

- Aiello, M.A.; Ombres, L. Structural performances of concrete beams with hybrid (fiber-reinforced polymer-steel) reinforcements. J. Compos. Constr. 2002, 6, 133–140. [Google Scholar] [CrossRef]

- Jo, B.W.; Tae, G.H.; Kwon, B.Y. Ductility evaluation of prestressed concrete beams with CFRP tendons. J. Reinf. Plast. Compos. 2004, 23, 843–859. [Google Scholar] [CrossRef]

- Lau, D.; Pam, H.J. Experimental study of hybrid FRP reinforced concrete beams. Eng. Struct. 2010, 32, 3857–3865. [Google Scholar] [CrossRef]

- Ge, W.; Zhang, J.; Cao, D.; Tu, Y. Flexural behaviors of hybrid concrete beams reinforced with BFRP bars and steel bars. Constr. Build. Mater. 2015, 87, 28–37. [Google Scholar] [CrossRef]

- Qin, R.; Zhou, A.; Lau, D. Effect of reinforcement ratio on the flexural performance of hybrid FRP reinforced concrete beams. Compos. Part B-Eng. 2017, 108, 200–209. [Google Scholar] [CrossRef]

- Yuan, F.; Chen, M.C. Numerical sensing of plastic hinge regions in concrete beams with hybrid (FRP and steel) bars. Sensors 2018, 18, 3255. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K.Y. Steady state and multiple cracking of short random fiber composites. ASCE J. Eng. Mech. 1992, 188, 2246–2264. [Google Scholar] [CrossRef]

- Li, V.C. On engineered cementitious composites (ECC)—A review of the material and its applications. J. Adv. Concr. Technol. 2003, 1, 215–229. [Google Scholar] [CrossRef]

- Zhou, J.J.; Pan, J.L.; Leung, C.K.Y. Mechanical behavior of fiber-reinforced engineered cementitious composites in uniaxial compression. J. Mater. Civ. Eng. 2015, 27, 04014111. [Google Scholar] [CrossRef]

- Yuan, F.; Chen, M.C.; Zhou, F.L.; Yang, C. Behaviors of steel-reinforced ECC columns under eccentric compression. Constr. Build. Mater. 2018, 185, 402–413. [Google Scholar] [CrossRef]

- Fischer, G.; Li, V.C. Deformation behavior of fiber-reinforced polymer reinforced engineered cementitious composite (ECC) flexural members under reversed cyclic loading conditions. ACI Struct. J. 2003, 100, 25–35. [Google Scholar]

- Yuan, F.; Pan, J.L.; Xu, Z.; Leung, C.K.Y. A comparison of engineered cementitious composites versus normal concrete in beam-column joints under reversed cyclic loading. Mater. Struct. 2013, 46, 145–159. [Google Scholar] [CrossRef]

- Yuan, F.; Pan, J.L.; Dong, L.T.; Leung, C.K.Y. Mechanical behaviors of steel reinforced ECC or ECC/concrete composite beams under reversed cyclic loading. J. Mater. Civ. Eng. 2014, 26, 04014047. [Google Scholar] [CrossRef]

- Ge, W.J.; Ashour, A.F.; Yu, J.M.; Gao, P.Q.; Cao, D.F.; Cai, C.; Ji, X. Flexural Behavior of ECC–Concrete Hybrid Composite Beams Reinforced with FRP and Steel Bars. J. Compo. Constr. 2019, 23, 04018069. [Google Scholar] [CrossRef]

| Matrix Designation | Cement | Fly Ash | Sand | Coarse Aggregate | Water | High-Range Water-Reducing Admixture, % | PVA Fiber Volume Fraction, % |

|---|---|---|---|---|---|---|---|

| ECC | 0.2 | 0.8 | 0.2 | --- | 0.22 | 0.8 | 2.0 |

| Concrete | 1.0 | --- | 1.5 | 2.5 | 0.35 | 0.3 | --- |

| Length (mm) | Diameter (µm) | Tensile Strength (MPa) | Elongation (%) | Elastic Modulus (GPa) | Density (g/cm3) |

|---|---|---|---|---|---|

| 12 | 39 | 1620 | 7 | 42.8 | 1.3 |

| Specimen ID | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Mean Value | Standard Deviation |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressive strength of ECC (MPa) | 46.0 | 46.6 | 46.9 | 46.4 | 46.5 | 46.6 | 50.1 | 49.8 | 47.2 | 47.3 | 3% |

| Compressive strength of concrete (MPa) | 37.4 | 36.8 | 36.4 | 34.9 | 36.7 | 35.2 | 35.4 | 36.9 | 32.7 | 35.8 | 3.82% |

| Elastic modulus of GFRP bars (MPa) | 42 | 43.5 | 41.4 | -- | -- | -- | -- | -- | -- | -- | 2.01% |

| Tensile strength of GFRP bars (MPa) | 746 | 749 | 761 | -- | -- | -- | -- | -- | -- | -- | 0.86% |

| Diameter (mm) | Yield Strength fy (MPa) | Ultimate Strength fsu (MPa) | Elasticity Modulus es (GPa) |

|---|---|---|---|

| 8 | 366 | 524 | 193 |

| 16 | 528 | 635 | 203 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, F.; Chen, L.; Chen, M.; Xu, K. Behaviour of Hybrid Steel and FRP-Reinforced Concrete—ECC Composite Columns under Reversed Cyclic Loading. Sensors 2018, 18, 4231. https://doi.org/10.3390/s18124231

Yuan F, Chen L, Chen M, Xu K. Behaviour of Hybrid Steel and FRP-Reinforced Concrete—ECC Composite Columns under Reversed Cyclic Loading. Sensors. 2018; 18(12):4231. https://doi.org/10.3390/s18124231

Chicago/Turabian StyleYuan, Fang, Liping Chen, Mengcheng Chen, and Kaicheng Xu. 2018. "Behaviour of Hybrid Steel and FRP-Reinforced Concrete—ECC Composite Columns under Reversed Cyclic Loading" Sensors 18, no. 12: 4231. https://doi.org/10.3390/s18124231

APA StyleYuan, F., Chen, L., Chen, M., & Xu, K. (2018). Behaviour of Hybrid Steel and FRP-Reinforced Concrete—ECC Composite Columns under Reversed Cyclic Loading. Sensors, 18(12), 4231. https://doi.org/10.3390/s18124231