A THz Receiver with Novel Features and Functionality

Abstract

1. Introduction

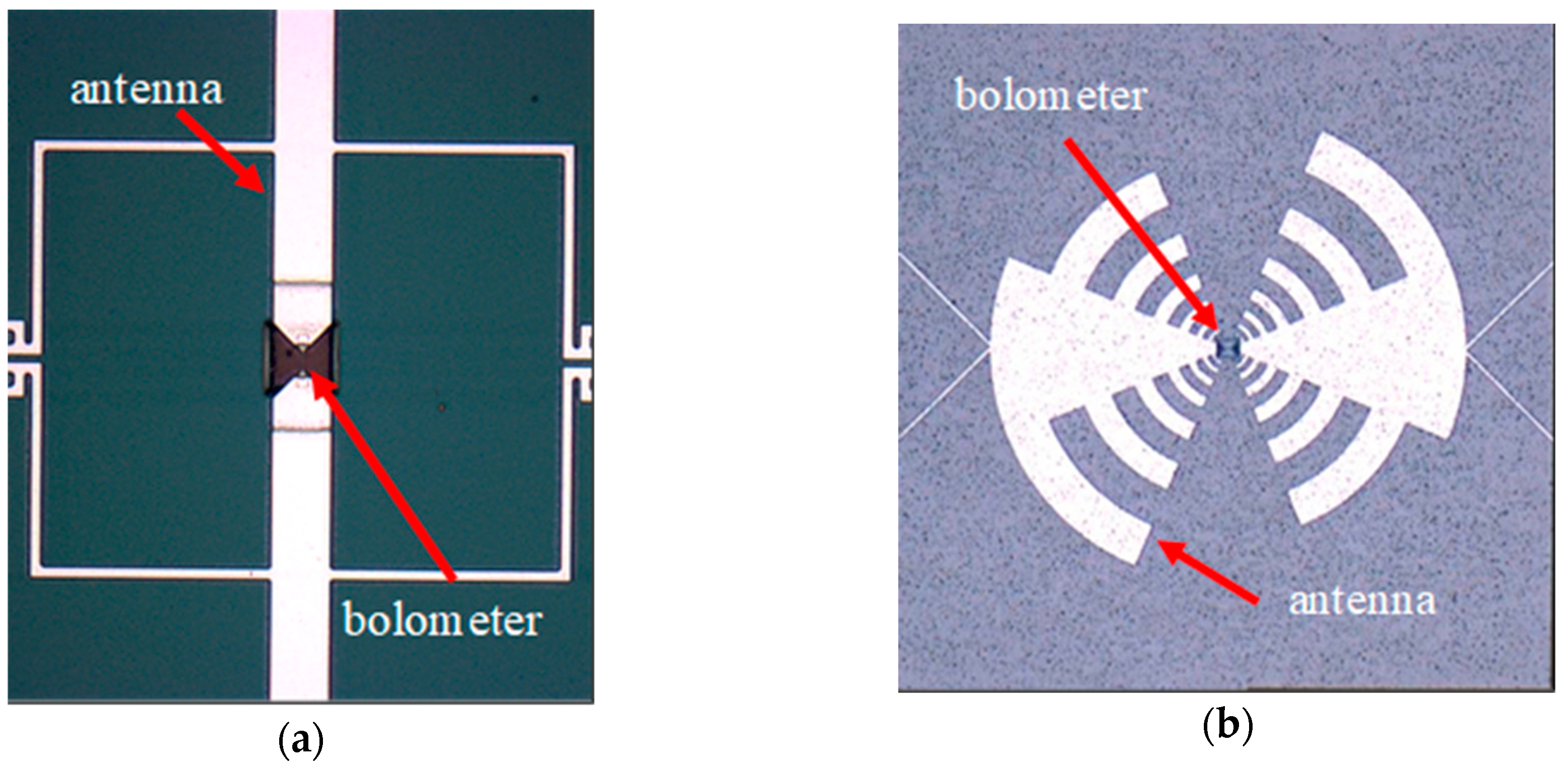

Coupled Antenna as Radiation Receiver

2. New Method for Micro-Bolometer Sensitivity Measurement

New Method for Sensitivity Measurement and Calculation

3. Results

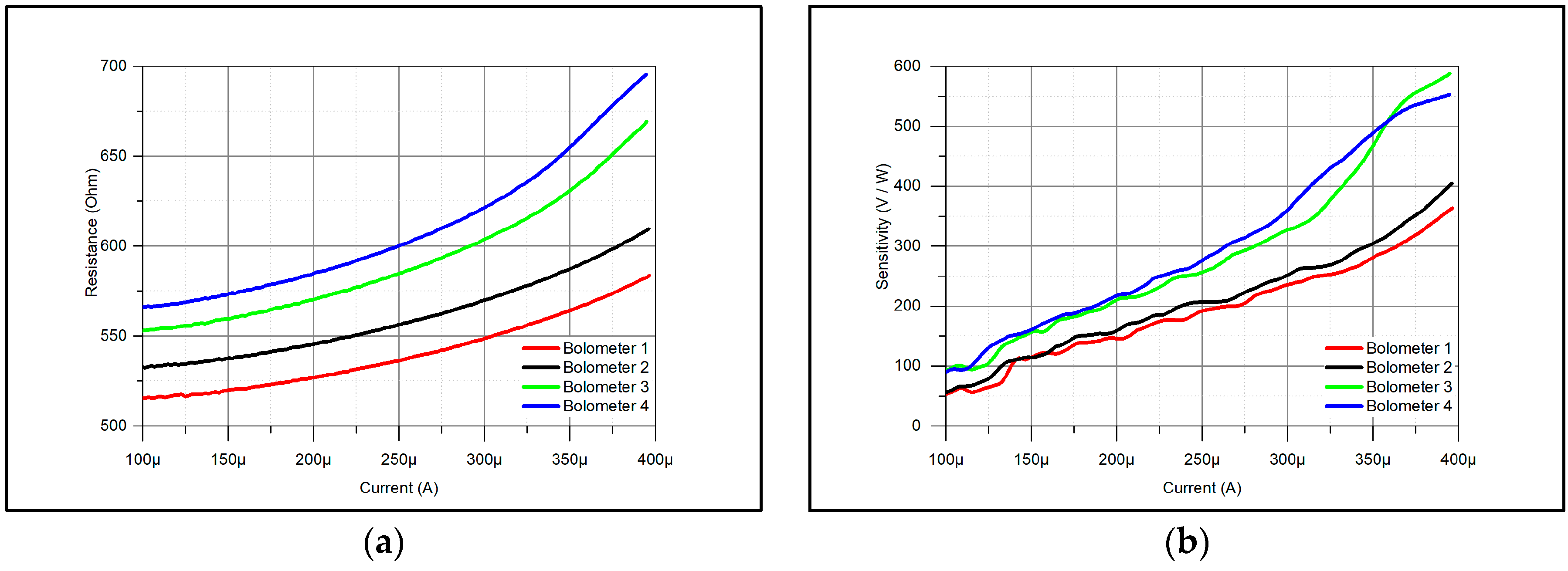

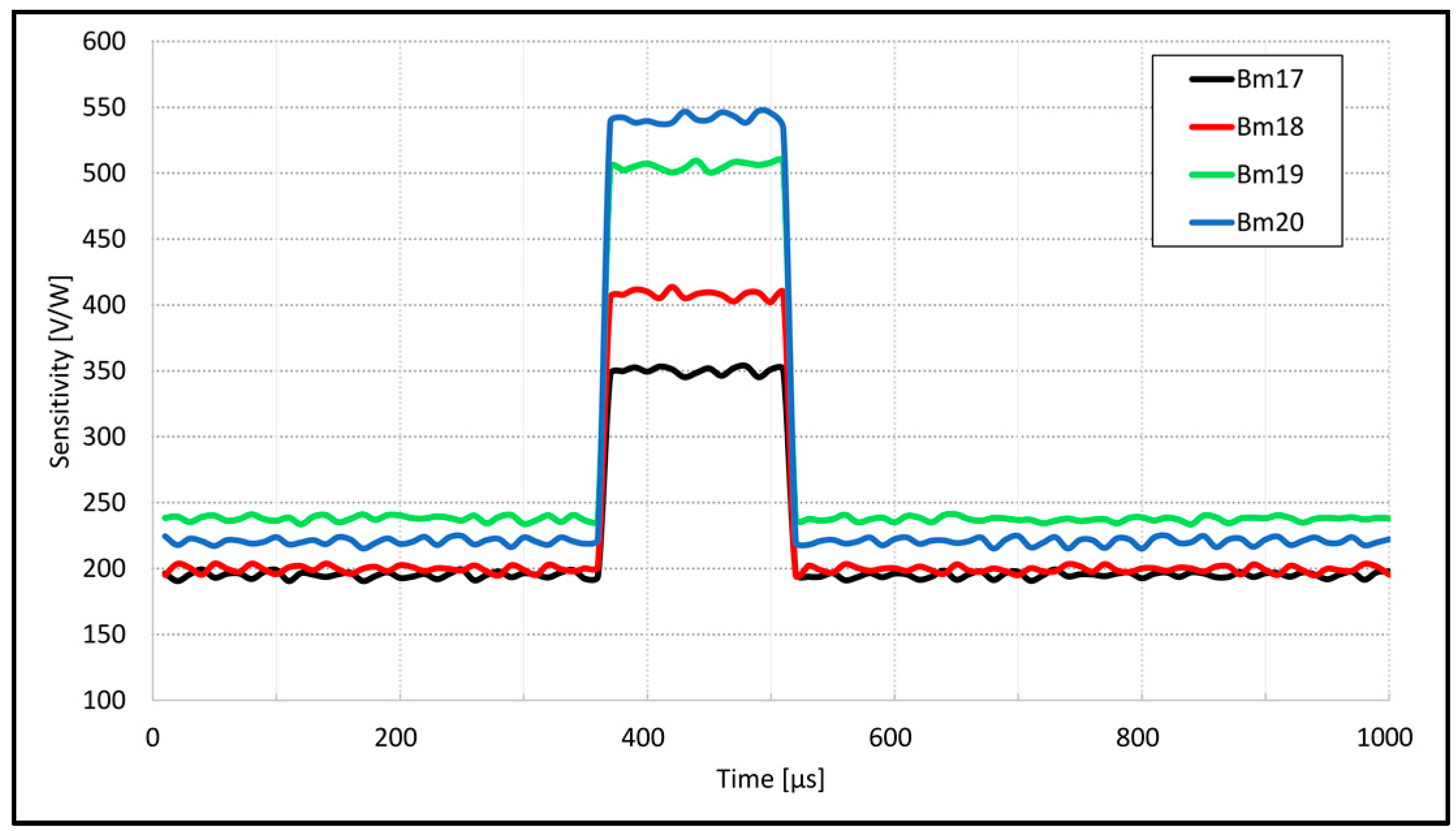

3.1. Measurement of Micro-Bolometer Sensitivity

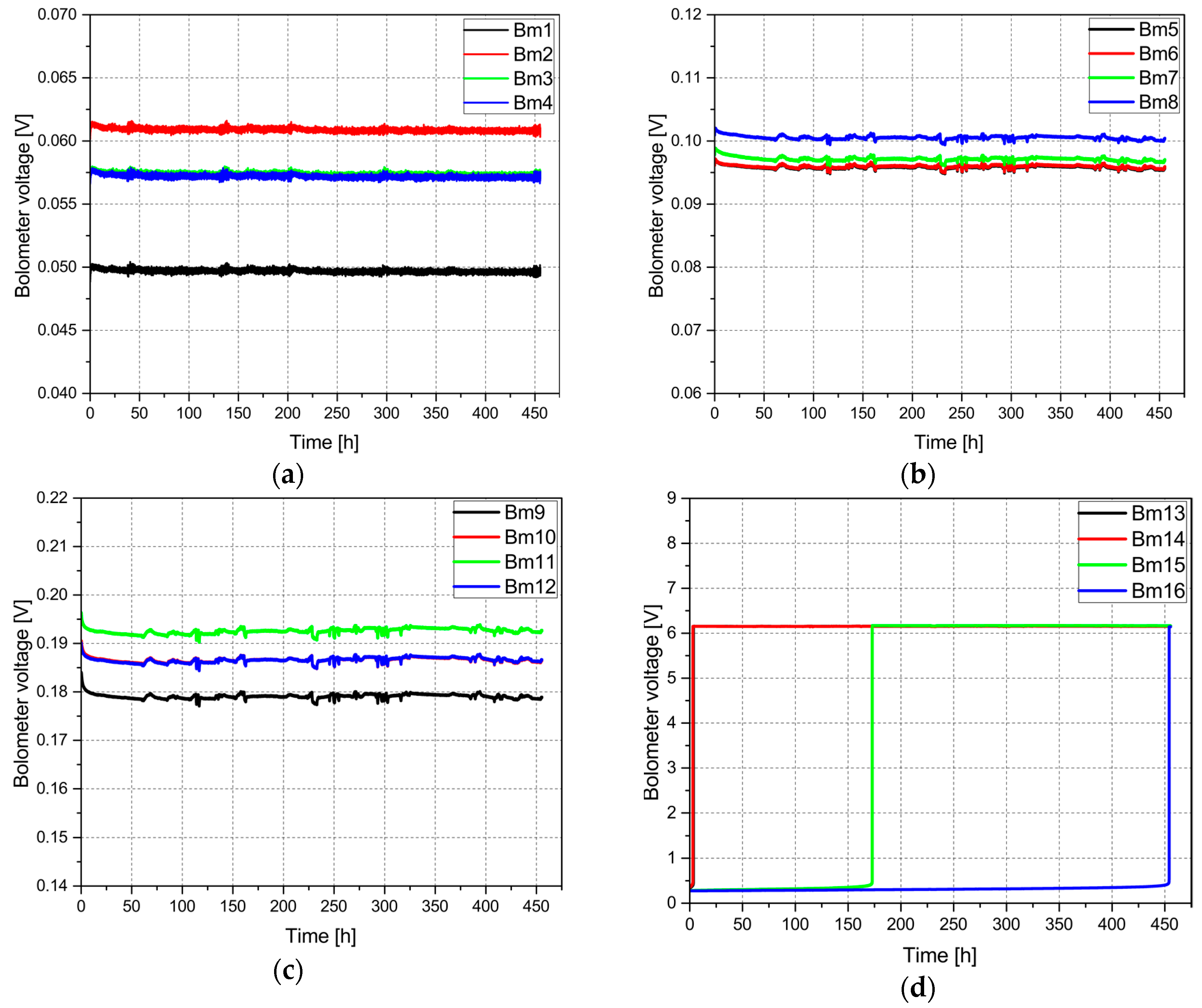

3.2. Micro-Bolometer Lifetime Measurements

3.3. Sensitivity Boosting Method

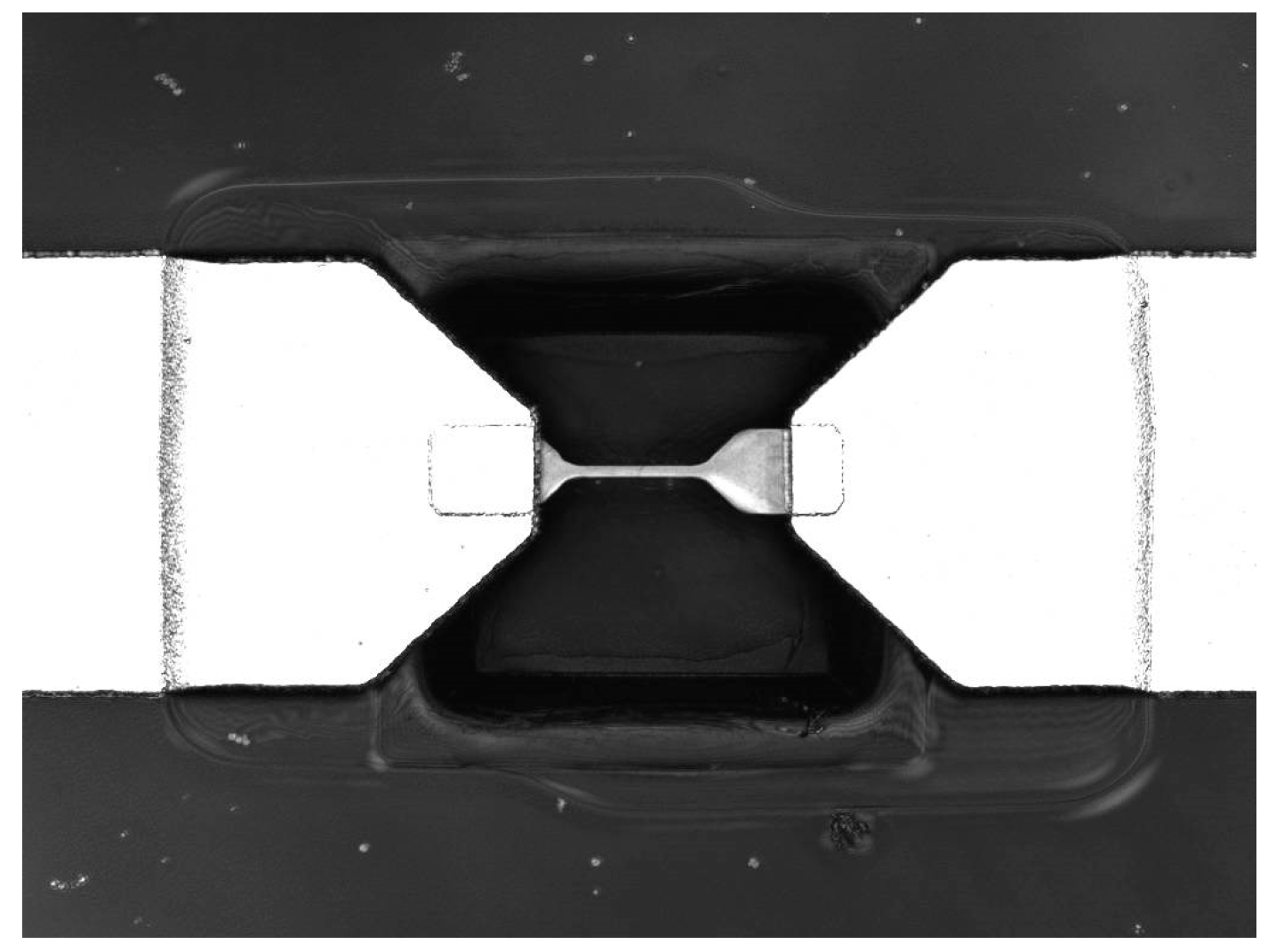

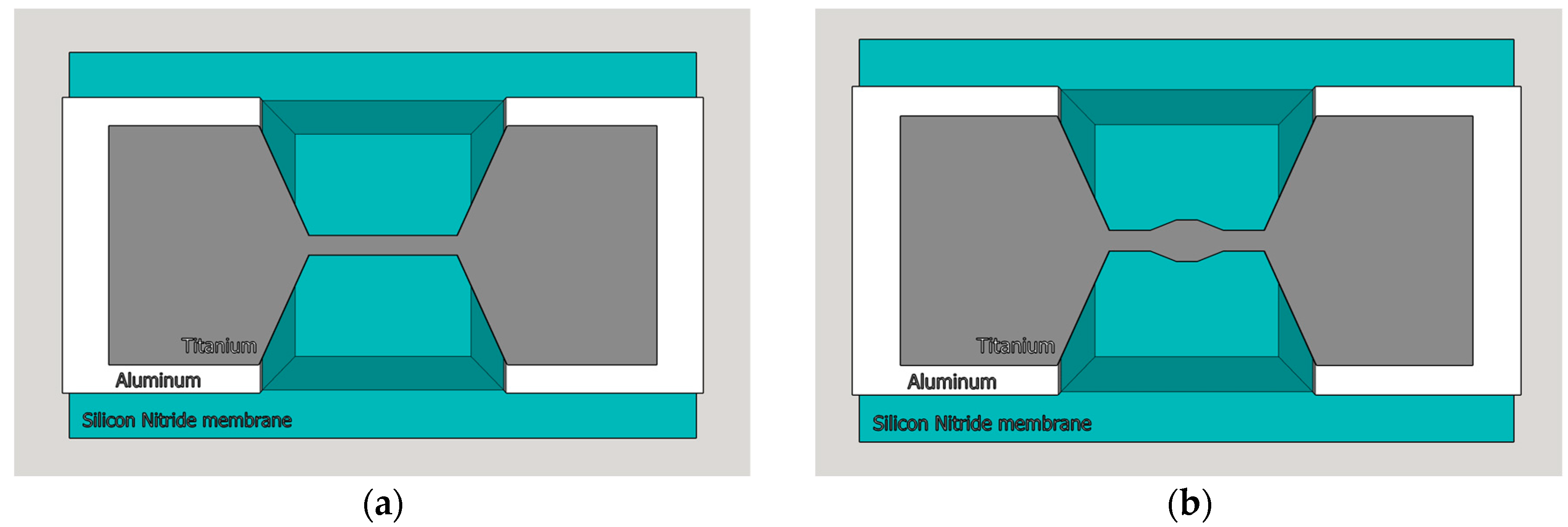

3.4. New Micro-Bolometer Design

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Armstrong, C.M. The Truth about Terahertz. Available online: https://spectrum.ieee.org/aerospace/military/the-truth-about-terahertz (accessed on 19 June 2018).

- Petkie, D.T.; Casto, C.; De Lucia, F.C.; Murrill, S.R.; Redman, B.; Espinola, R.L.; Franck, C.C.; Jacobs, E.L.; Griffin, S.T.; Halford, C.E.; et al. Active and passive imaging in the THz spectral region: phenomenology, dynamic range, modes, and illumination. J. Opt. Soc. Am. B: Opt. Phys. 2008, 25, 1523–1531. [Google Scholar] [CrossRef]

- Siegel, P.H. Terahertz technology. IEEE Trans. Microw. Theory Tech. 2002, 50, 910–928. [Google Scholar] [CrossRef]

- Woolard, D.L.; Loerop, W.R.; Shur, M. Terahertz Sensing Technology: Emerging Scientific Applications & Novel Device Concepts; World Scientific: Singapore, 2003; Volume 2. [Google Scholar]

- Sešek, A.; Kašalynas, I.; Žemva, A.; Trontelj, J. Antenna-coupled Ti-microbolometers for High-sensitivity Terahertz Imaging. Sens. Actuators A 2017, 268, 133–140. [Google Scholar] [CrossRef]

- Svetlitza, A.; Brouk, I.; Bar-Lev, S.; Stolyarova, S.; Nemirovsky, Y. The TeraMOS sensing pixel for monolithic passive uncooled THz imagers. In Proceedings of the 2012 International Conference on Optical MEMS and Nanophotonics, Banff, AB, Canada, 6–9 August 2012; pp. 123–124. [Google Scholar]

- Urbanowicz, A.; Pačebutas, V.; Geižutis, A.; Stanionytė, S.; Krotkus, A. Terahertz time-domain-spectroscopy system based on 1.55 μm fiber laser and photoconductive antennas from dilute bismides. AIP Adv. 2016, 6, 025218. [Google Scholar] [CrossRef]

- Lewis, R.A. A review of terahertz sources. J. Phys. D Appl. Phys. 2014, 47, 374001. [Google Scholar] [CrossRef]

- Virginia Diodes, Inc.—Your Source for Terahertz and mm-Wave Products. Available online: https://www.vadiodes.com/en/ (accessed on 19 June 2018).

- Home Page | MM-Wave Technology. Spacek Labs | MM-Wave Technology. Available online: http://spaceklabs.com/ (accessed on 19 June 2018).

- Terahertz Equipment for THz Imaging | TeraSense. Available online: http://terasense.com/ (accessed on 19 June 2018).

- Zhang, Y.; Zhang, X.; Li, S.; Gu, J.; Li, Y.; Tian, Z.; Ouyang, C.; He, M.; Han, J.; Zhang, W. A Broadband THz-TDS System Based on DSTMS Emitter and LTG InGaAs/InAlAs Photoconductive Antenna Detector. Sci. Rep. 2016, 6, 26949. [Google Scholar] [CrossRef] [PubMed]

- Wood, R.A. Uncooled Microbolometer Infrared Sensor Arrays. In Infrared Detectors and Emitters: Materials and Devices; Springer: Boston, MA, USA, 2001; pp. 149–175. [Google Scholar]

- Zhou, J.W.; Farooqui, K.; Timbie, P.T.; Wilson, G.W.; Allen, C.A.; Moseley, S.H.; Mott, D.B. Monolithic silicon bolometers as sensitive MM-wave detectors. In Proceedings of the 1995 IEEE MTT-S International Microwave Symposium, Orlando, FL, USA, 16–20 May 1995; pp. 1347–1350. [Google Scholar]

- Desmet, Y.; Thomas, B.; Peytavit, E.; Pavanello, F.; Okada, E.; Lampin, E.; Walber, A.; Ceru, J.; Graux, F.; Ducatteau, D.; et al. Room temperature platinum nano-strip bolometer for mm submm-wave applications. In Proceedings of the 2016 Global Symposium on Millimeter Waves (GSMM) ESA Workshop on Millimetre-Wave Technology and Applications, Espoo, Finland, 6–8 June 2016; pp. 1–4. [Google Scholar]

- Trontelj, J.; Valušis, G.; Venckevičius, R.; Kašalynas, I.; Sešek, A.; Švigelj, A. A high performance room temperature THz sensor. In Proceedings of the Terahertz Emitters, Receivers, and Applications V, San Diego, CA, USA, 5 September 2004. [Google Scholar]

- Trontelj, J.; Maček, M.; Sešek, A. A Detection System and a Method of Making a Detection System. Patent Application GB 2513170(A), 22 October 2014. [Google Scholar]

- Sesek, A.; Zemva, A.; Trontelj, J. A Microbolometer System for Radiation Detection in the THz Frequency Range with a Resonating Cavity Fabricated in the CMOS Technology. Recent Pat. Nanotechnol. 2018, 12, 34–44. [Google Scholar] [CrossRef] [PubMed]

- Kašalynas, I.; Venckevičius, R.; Minkevičius, L.; Sešek, A.; Wahaia, F.; Tamošiūnas, V.; Voisiat, B.; Seliuta, D.; Valušis, G.; Švigelj, A.; et al. Spectroscopic Terahertz Imaging at Room Temperature Employing Microbolometer Terahertz Sensors and Its Application to the Study of Carcinoma Tissues. Sensors 2016, 16, 432. [Google Scholar] [CrossRef] [PubMed]

- Trontelj, J.; Sešek, A. Micro-machined millimeter wave sensor array for FM radar application. In Proceedings of the Millimetre Wave and Terahertz Sensors and Technology V, Edinburgh, UK, 26 October 2012; p. 85440G. [Google Scholar]

- Maček, M. THz micro-bolometer fabrication challenges. In Proceedings of the MIDEM, Bled, Slovenia, 23–25 September 2015; pp. 168–173. [Google Scholar]

- Podhraski, M.; Svigelj, A.; Macek, M.; Trontelj, J. Thermal Analysis of THz Microbolometer. Available online: https://plus.si.cobiss.net/opac7/bib/9418068 (accessed on 17 September 2018).

| Marking | Lot No. | R01 [Ω] | I0 [µA] | Gth [µW/K] | ℜe [V/W] |

|---|---|---|---|---|---|

| Bolometer 1 | A02 | 511 | 1038 | 0.69 | 264 |

| Bolometer 2 | A06 | 533 | 1066 | 0.76 | 257 |

| Bolometer 3 | A07 | 553 | 971 | 0.66 | 282 |

| Bolometer 4 | A09 | 567 | 875 | 0.54 | 313 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sešek, A.; Berčan, D.; Gradišek, M.; Švigelj, A.; Trontelj, J. A THz Receiver with Novel Features and Functionality. Sensors 2018, 18, 3793. https://doi.org/10.3390/s18113793

Sešek A, Berčan D, Gradišek M, Švigelj A, Trontelj J. A THz Receiver with Novel Features and Functionality. Sensors. 2018; 18(11):3793. https://doi.org/10.3390/s18113793

Chicago/Turabian StyleSešek, Aleksander, Damjan Berčan, Miha Gradišek, Andrej Švigelj, and Janez Trontelj. 2018. "A THz Receiver with Novel Features and Functionality" Sensors 18, no. 11: 3793. https://doi.org/10.3390/s18113793

APA StyleSešek, A., Berčan, D., Gradišek, M., Švigelj, A., & Trontelj, J. (2018). A THz Receiver with Novel Features and Functionality. Sensors, 18(11), 3793. https://doi.org/10.3390/s18113793