A Smart Eddy Current Sensor Dedicated to the Nondestructive Evaluation of Carbon Fibers Reinforced Polymers

Abstract

:1. Introduction

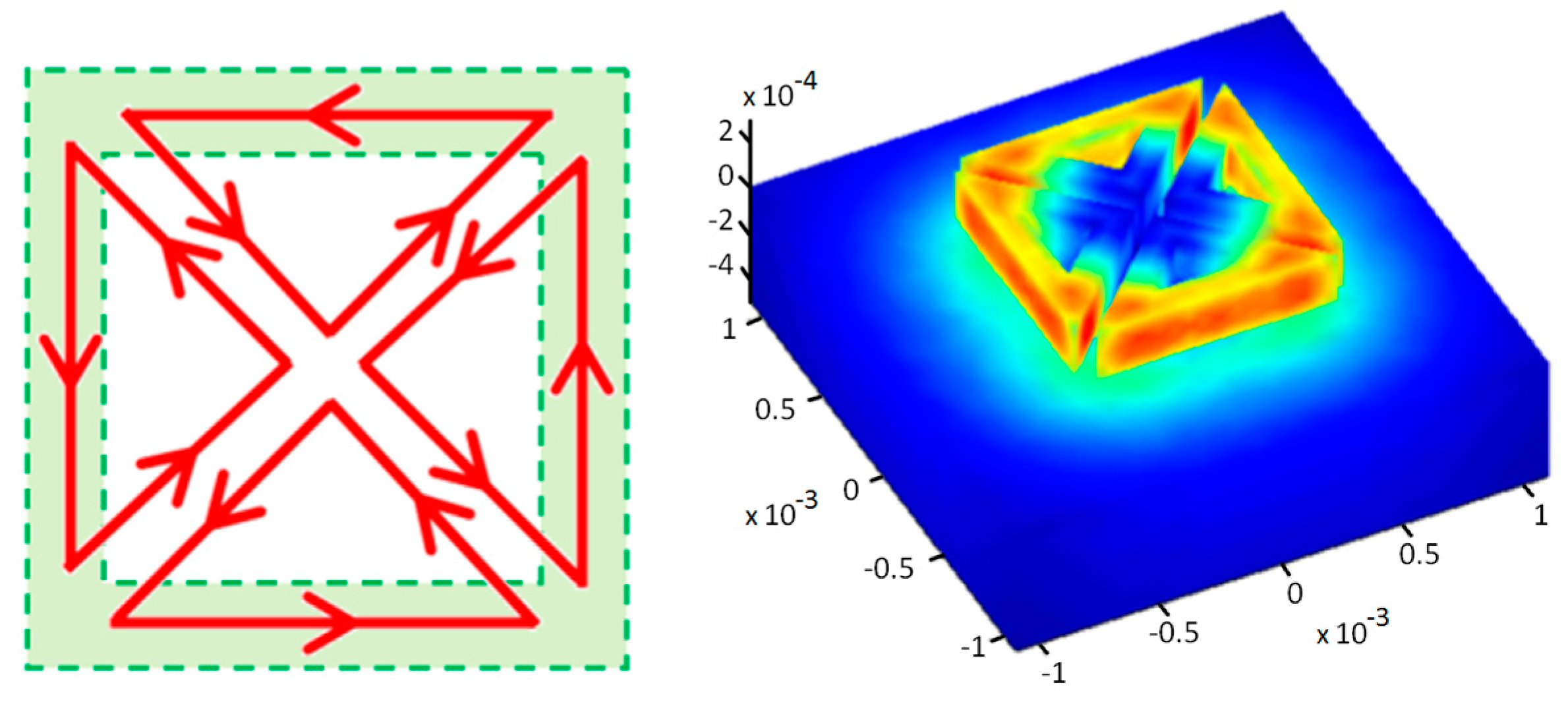

2. Conception

3. Sensor Characteristics

3.1. Geometrical Characterization

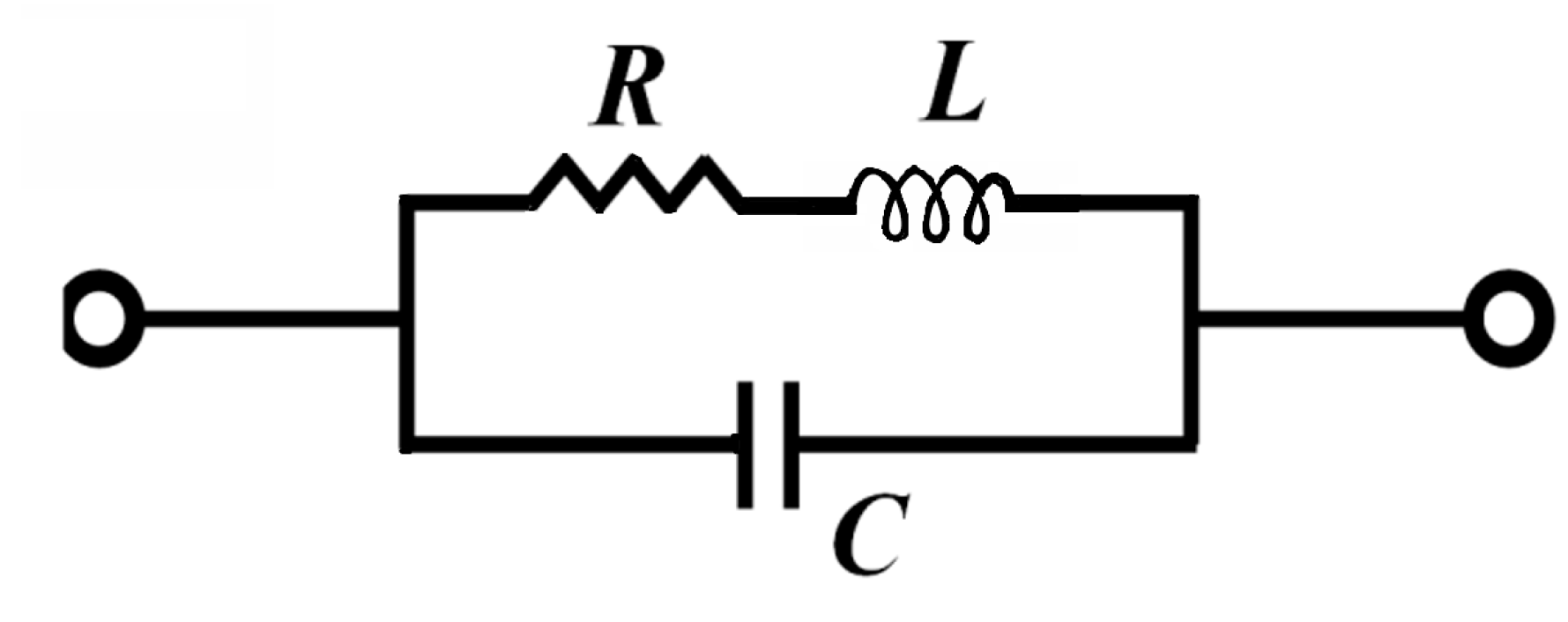

3.2. Electrical Characterization

3.3. Physical Characterization

- ■

- According to Faraday-Lenz’s law, at a frequency f, the sensitivity of a coil is:where dV is the voltage variation provoked by a variation in the received magnetic induction dB.

- ■

- The noise of a coil when it is not carrying current is only a thermal agitation noise. This effective voltage vb at a temperature T and in measuring frequency range Δf is given by;where K is Boltzmann’s constant.

- ■

- The emissive ability Pe is the ratio between the emitted field “B” and the current “I” necessary for its emission:

3.4. Optimization of the Coil

4. Modeling

5. Results

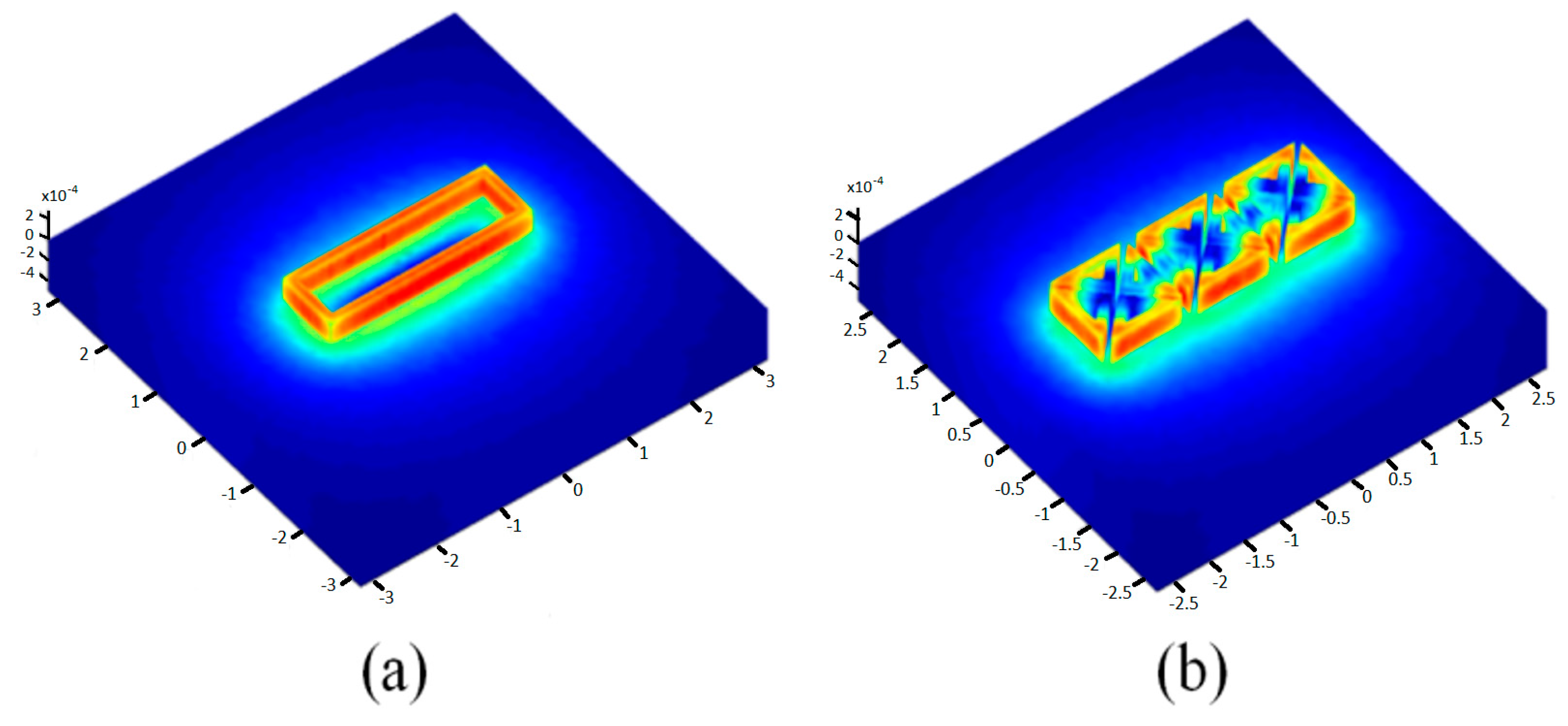

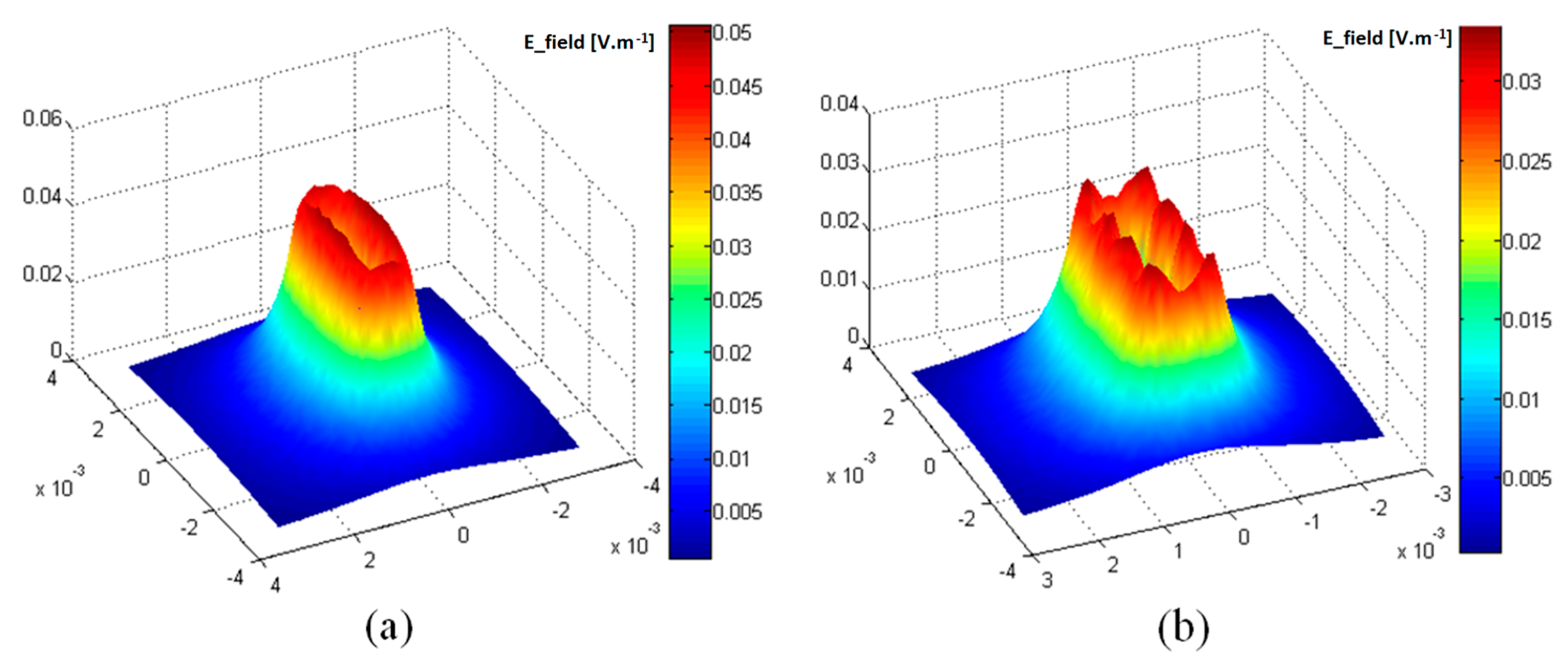

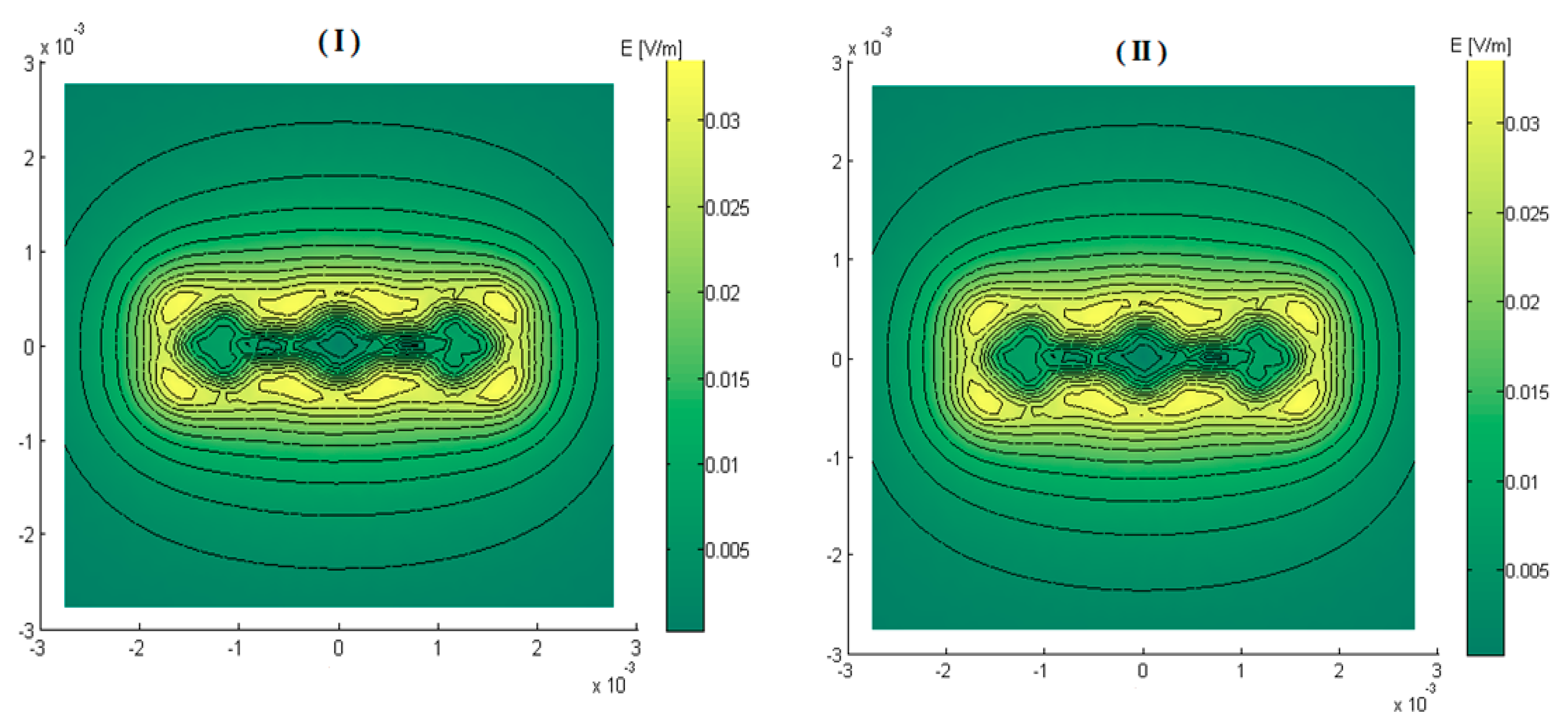

5.1. Sensor and EM Field

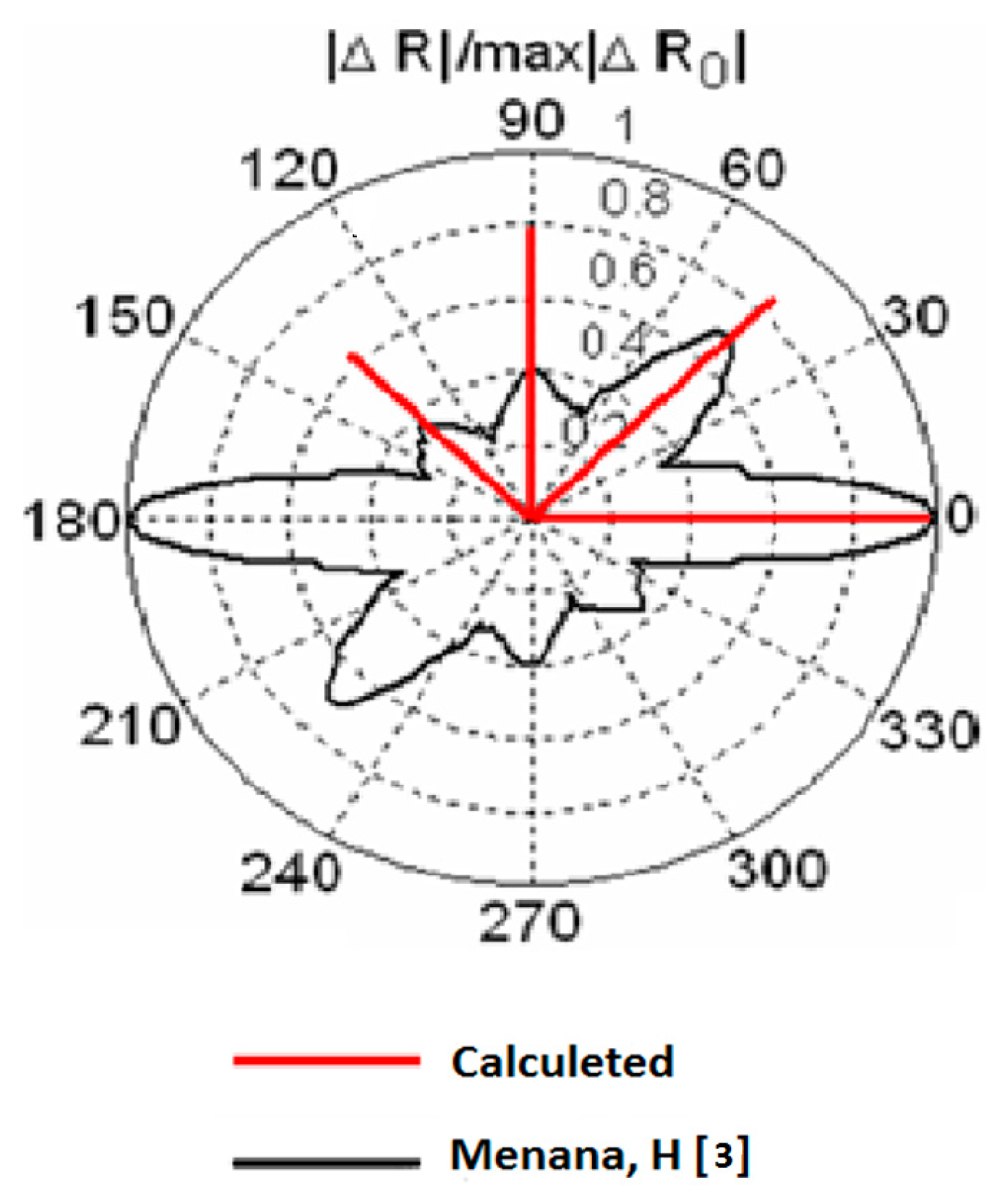

5.2. Application to CFRP

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

Appendix A.1. Calculation of the Developed Length of the Coil

Appendix A.2. Calculation of the Total Area

References

- Heuer, H.; Schulze, M.; Pooch, M.; Gäbler, S.; Nocke, A.; Bardl, G.; Cherif, C.; Klein, M.; Kupke, R.; Vetter, R.; et al. Review on quality assurance along the CFRP value chain—Non-destructive testing of fabrics, preforms and CFRP by HF radio wave techniques. Compos. Part B Eng. 2015, 77, 494–501. [Google Scholar] [CrossRef]

- Mook, G.; Lange, R.; Koeser, O. Non-destructive characterization of carbon-fiber reinforced plastics by means of eddy currents. Compos. Sci. Technol. 2001, 61, 865–873. [Google Scholar] [CrossRef]

- Menana, H.; Feliachi, M. Non destructive evaluation of the conductivity tensor of a CFRP plate using a rotating eddy current sensor. In Proceedings of the XIV International Symposium on Electromagnetic Fields, Arras, France, 10–12 September 2009. [Google Scholar]

- Savin, A.R.; Grimberg, R.; Chifan, S. Evaluation of delamination in Carbon Fiber Composites Using the Eddy Current Method. In Proceedings of the 15th World Conference on Non-Destructive Testing, Roma, Italy, 15–21 October 2000. [Google Scholar]

- Grimberg, R.; Savin, A.; Steigmann, R.; Bruma, A. Eddy current examination of carbon fibres in carbon-epoxy composites and Kevlar. In Proceedings of the 8th International Conference of the Slovenian Society for Non-Destructive Testing, Portorož, Slovenia, 1–3 September 2005; pp. 223–228. [Google Scholar]

- Ravat, C. Conception de Multicapteurs à Courants de Foucault et Inversion des Signaux Associés Pour le Contrôle non Destructif. Ph.D. Thesis, Sciences and Technologys of Information and telecommunications Systems, University of Paris-Sud, Paris, France, 2008. [Google Scholar]

- Helifa, B. Contribution à la Simulation du CND par Courants de Foucault en vue de la Caractérisation des Fissures Débouchantes. Ph.D. Thesis, Computer and Mathematical Sciences and Technologies, Nantes University, Nantes, France, 2012. [Google Scholar]

| Parameter | Numerical Value | Unit | |

|---|---|---|---|

| Coil dimensions | external length D | 1 | [mm] |

| line width lp | 6 | [µm] | |

| inter-line space Ep | 3 | [µm] | |

| number of turns n | 33 | ||

| Electrical parameters | resistance R | 4.24 | [ohm] |

| inductance L | 1.44 | [µH] | |

| capacity C | 3.5 | [fF] | |

| sensitivity S | 35 | [V/T] | |

| noise voltage vb | 0.83 | [µV] | |

| emissive ability Pe | 254 | [mT/A] |

| Parameter | Numerical Values | Unit | |

|---|---|---|---|

| Laminate | Number of plies | 4 | |

| Fibers orientation | 0°, 45°, 90° and −45° | [°] | |

| Conductivity (σ//, σ⊥, σzz) | (104, 2 × 102, 10) | [S/m] | |

| Ply thickness | 125 | [µm] | |

| Sensor | Number of coils | 36 | |

| Gap inter-coils | 0.08 | [mm] | |

| Lift-off | 0.125 | [mm] | |

| Current intensity | 20 | [mA] | |

| Frequency | 1 | [MHz] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naidjate, M.; Helifa, B.; Feliachi, M.; Lefkaier, I.-K.; Heuer, H.; Schulze, M. A Smart Eddy Current Sensor Dedicated to the Nondestructive Evaluation of Carbon Fibers Reinforced Polymers. Sensors 2017, 17, 1996. https://doi.org/10.3390/s17091996

Naidjate M, Helifa B, Feliachi M, Lefkaier I-K, Heuer H, Schulze M. A Smart Eddy Current Sensor Dedicated to the Nondestructive Evaluation of Carbon Fibers Reinforced Polymers. Sensors. 2017; 17(9):1996. https://doi.org/10.3390/s17091996

Chicago/Turabian StyleNaidjate, Mohammed, Bachir Helifa, Mouloud Feliachi, Iben-Khaldoun Lefkaier, Henning Heuer, and Martin Schulze. 2017. "A Smart Eddy Current Sensor Dedicated to the Nondestructive Evaluation of Carbon Fibers Reinforced Polymers" Sensors 17, no. 9: 1996. https://doi.org/10.3390/s17091996

APA StyleNaidjate, M., Helifa, B., Feliachi, M., Lefkaier, I.-K., Heuer, H., & Schulze, M. (2017). A Smart Eddy Current Sensor Dedicated to the Nondestructive Evaluation of Carbon Fibers Reinforced Polymers. Sensors, 17(9), 1996. https://doi.org/10.3390/s17091996