Development of Embedded EM Sensors for Estimating Tensile Forces of PSC Girder Bridges

Abstract

:1. Introduction

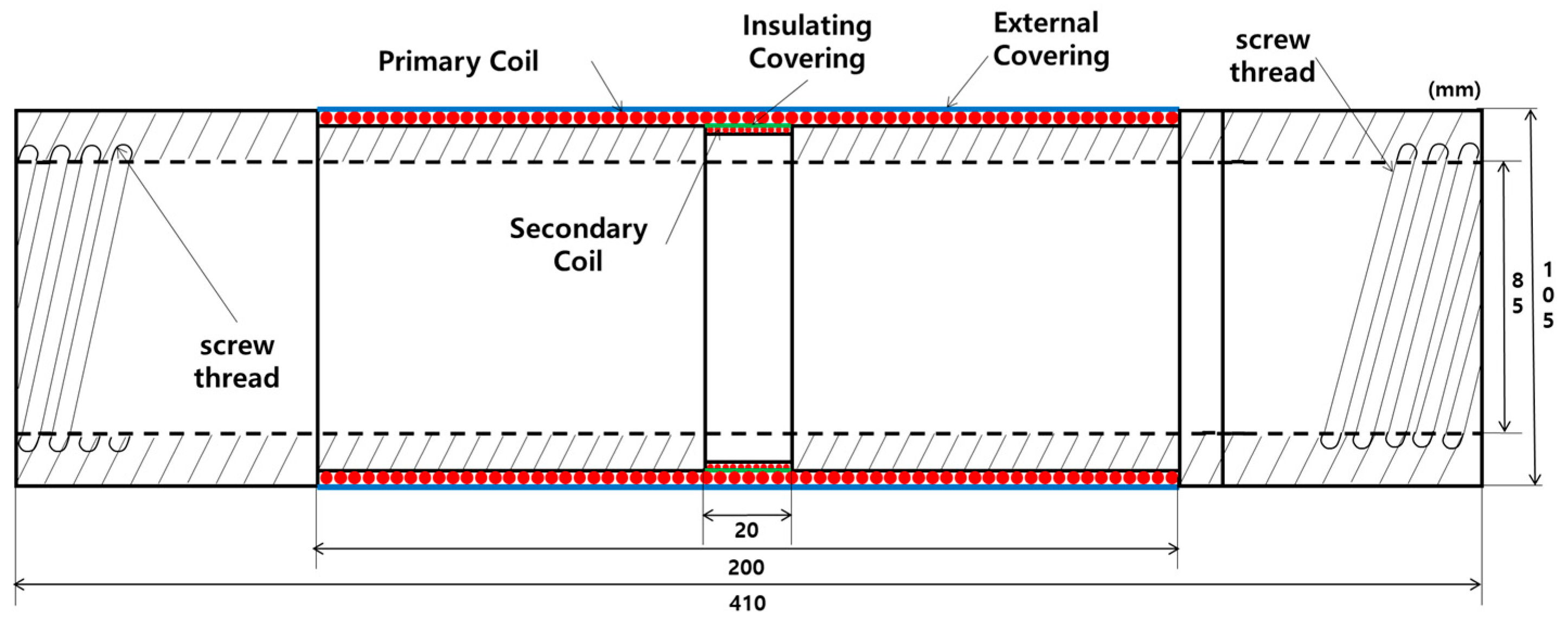

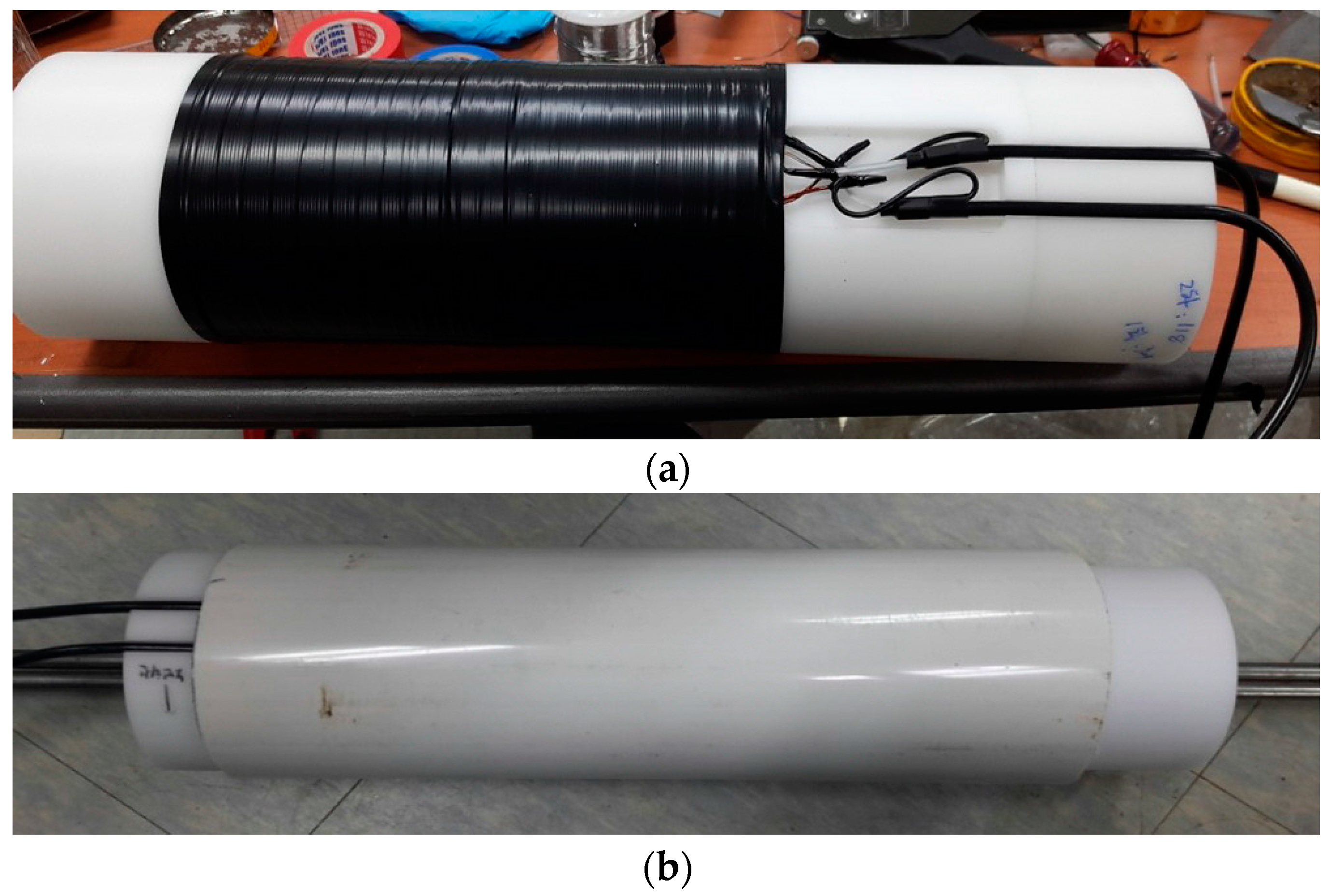

2. Development of the Embedded EM Sensor

3. Experimental Study

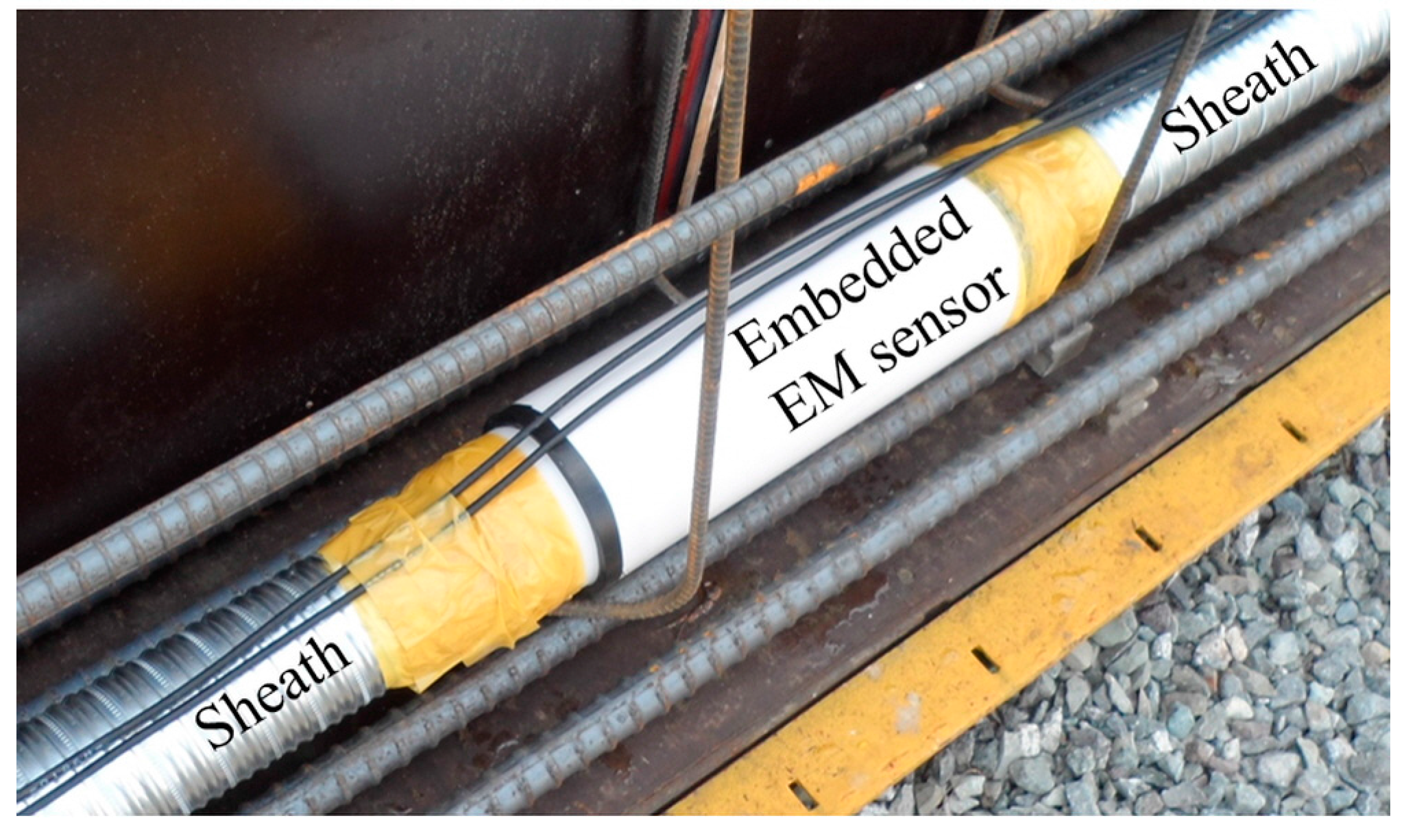

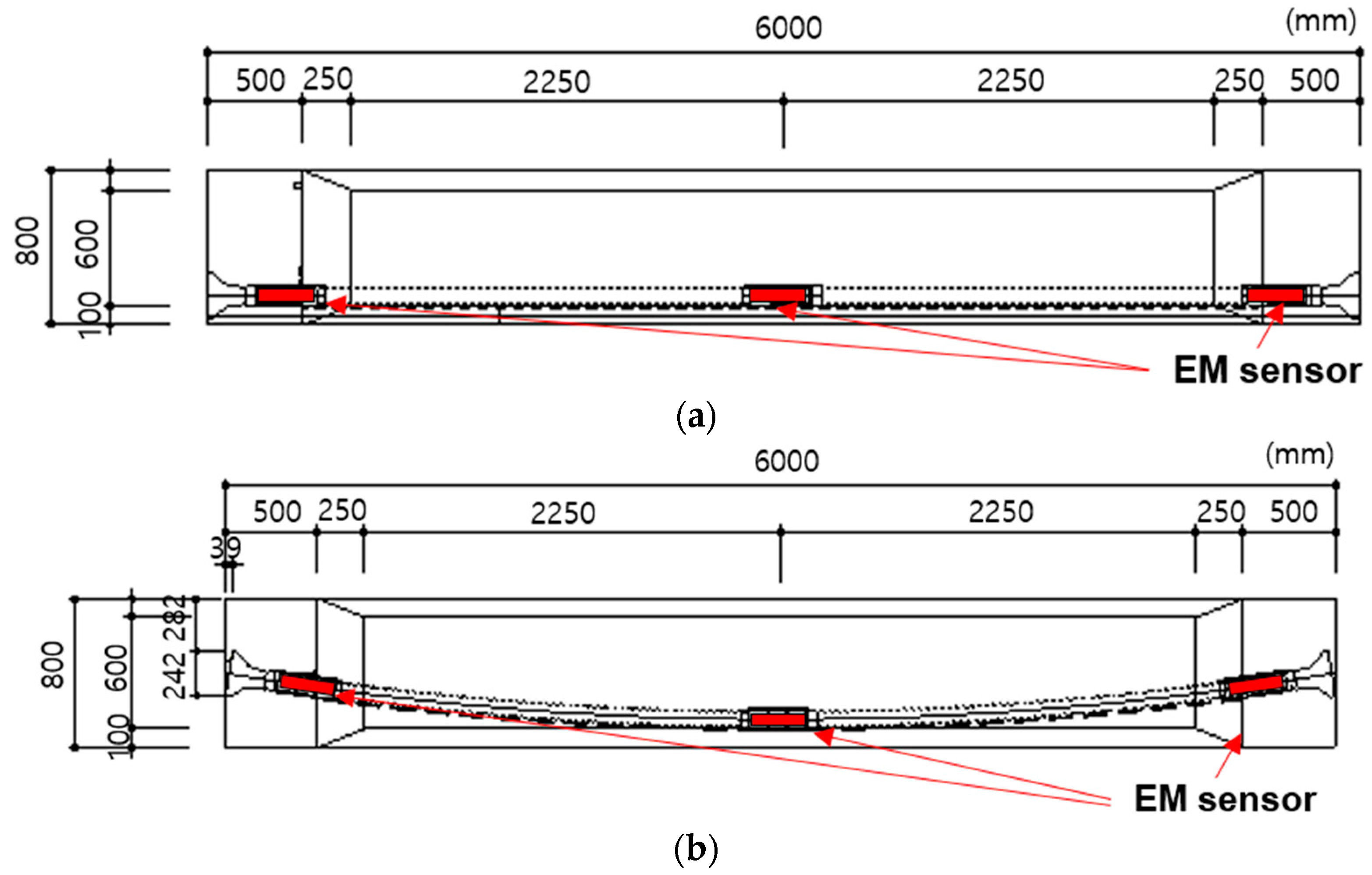

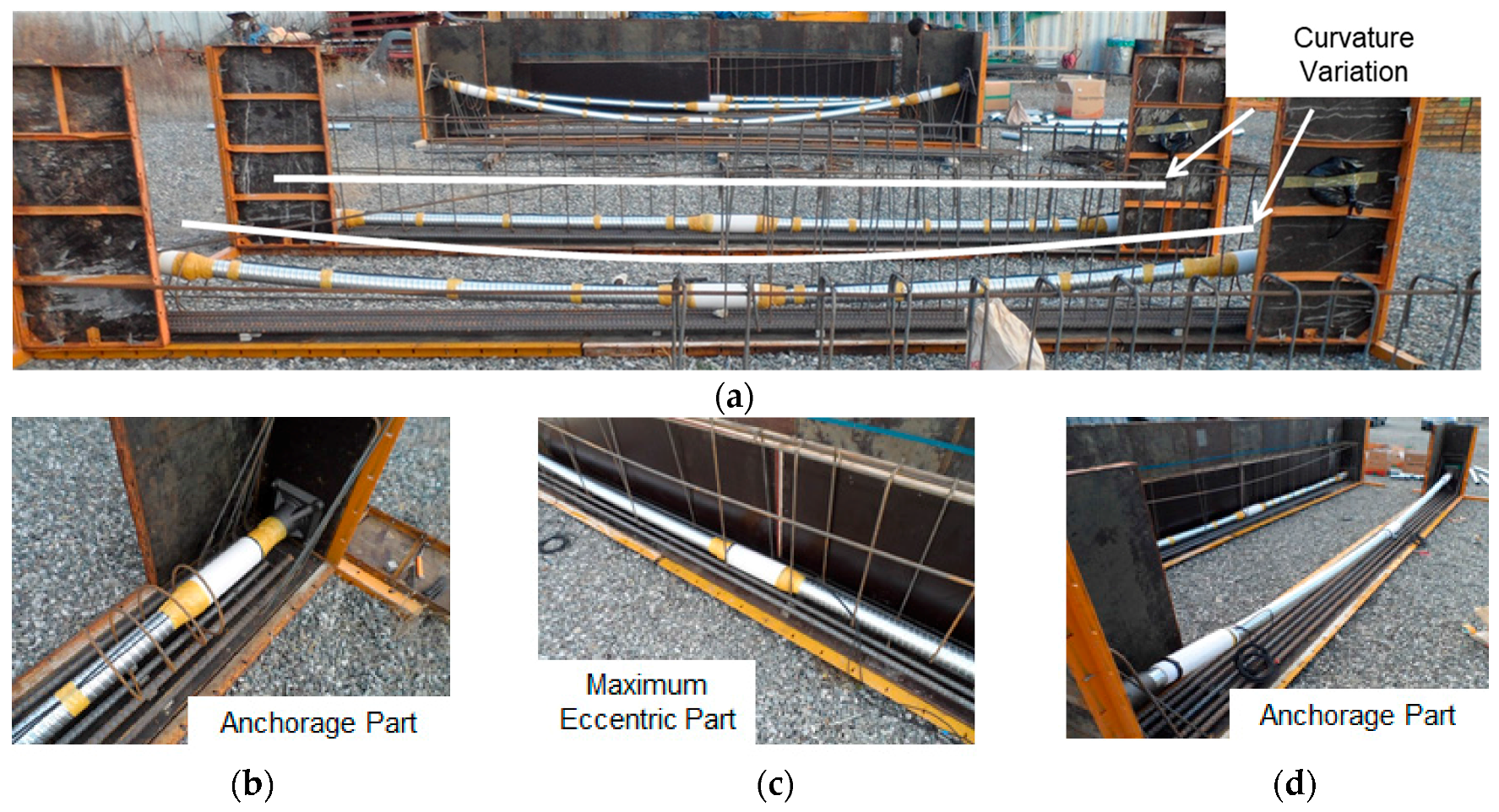

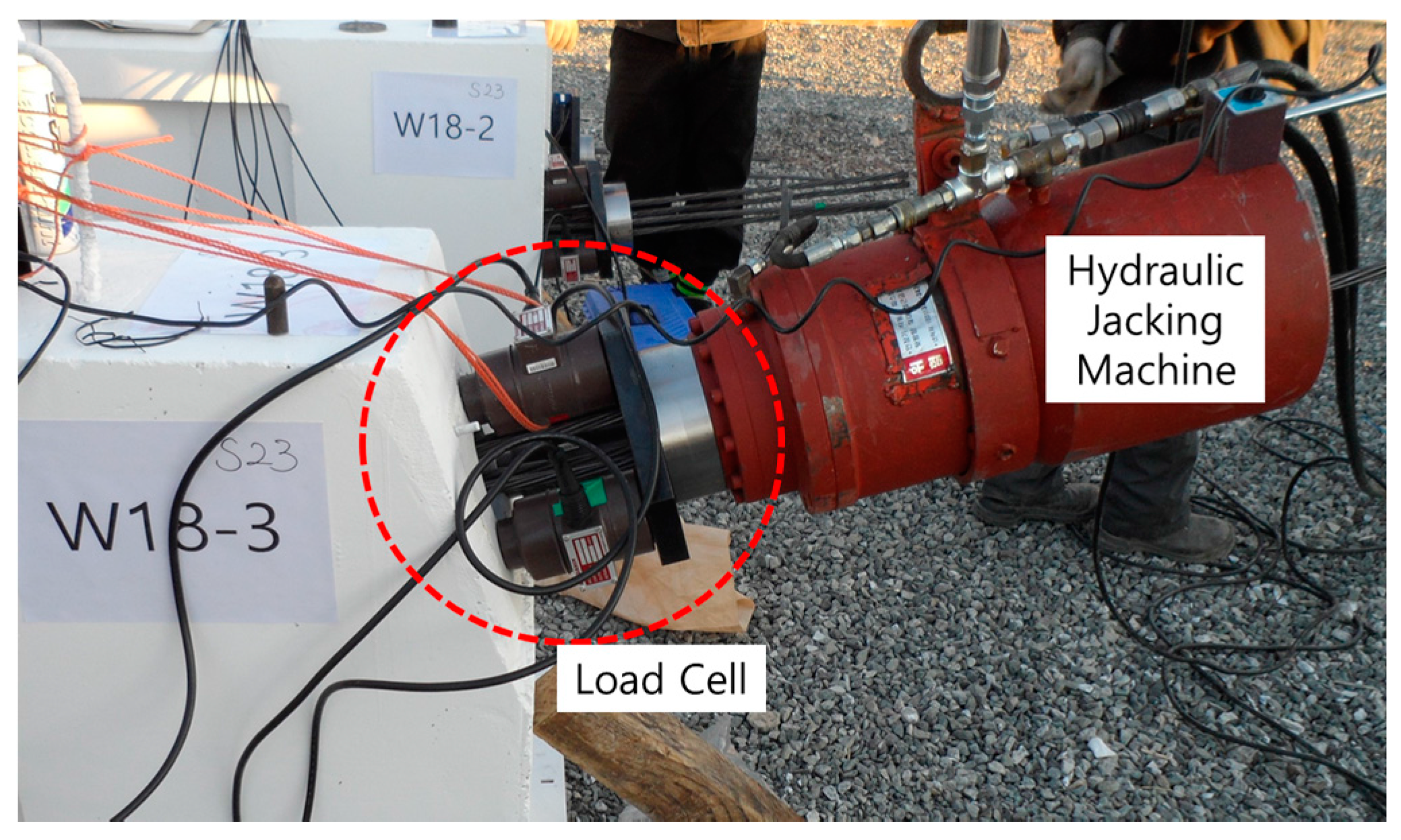

3.1. Experimental Setup and Test Procedure

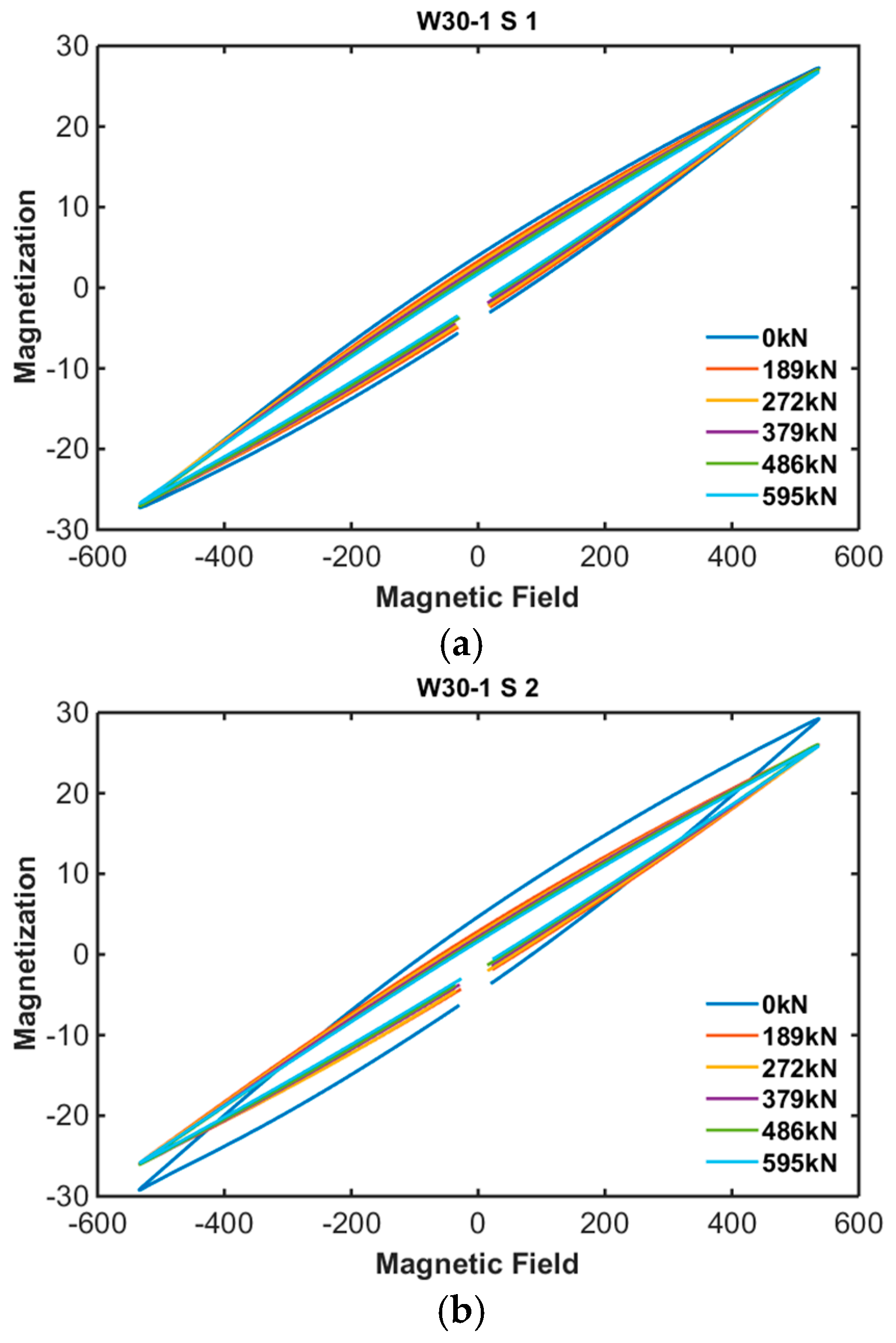

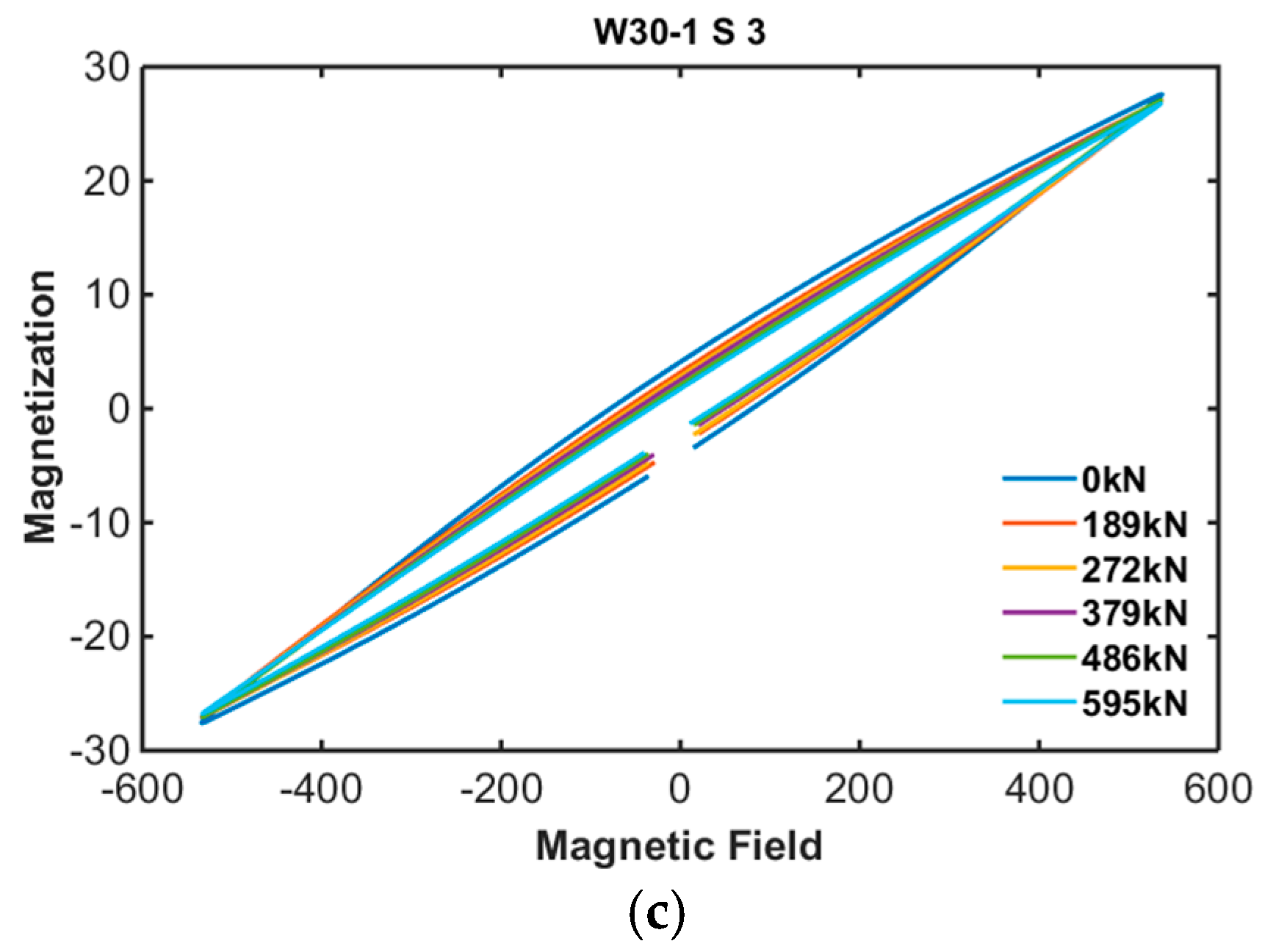

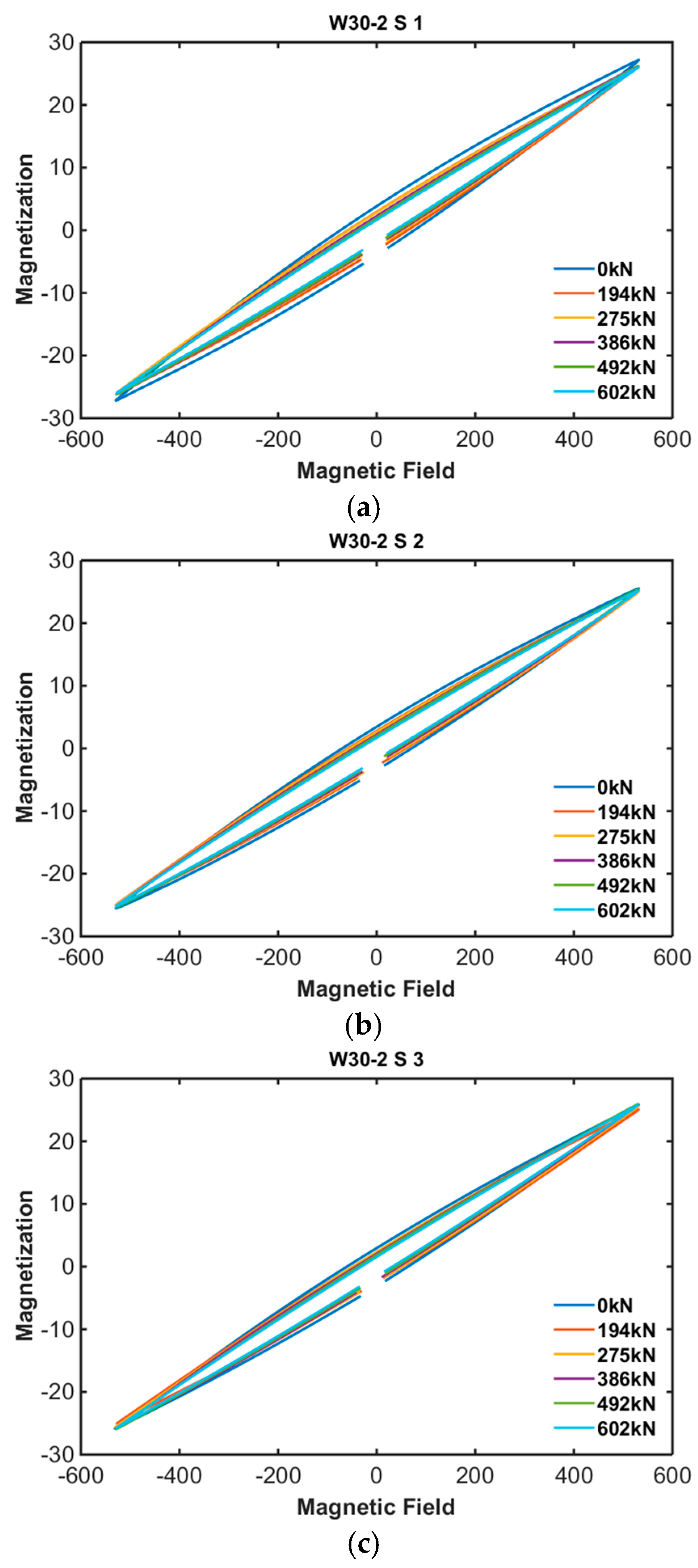

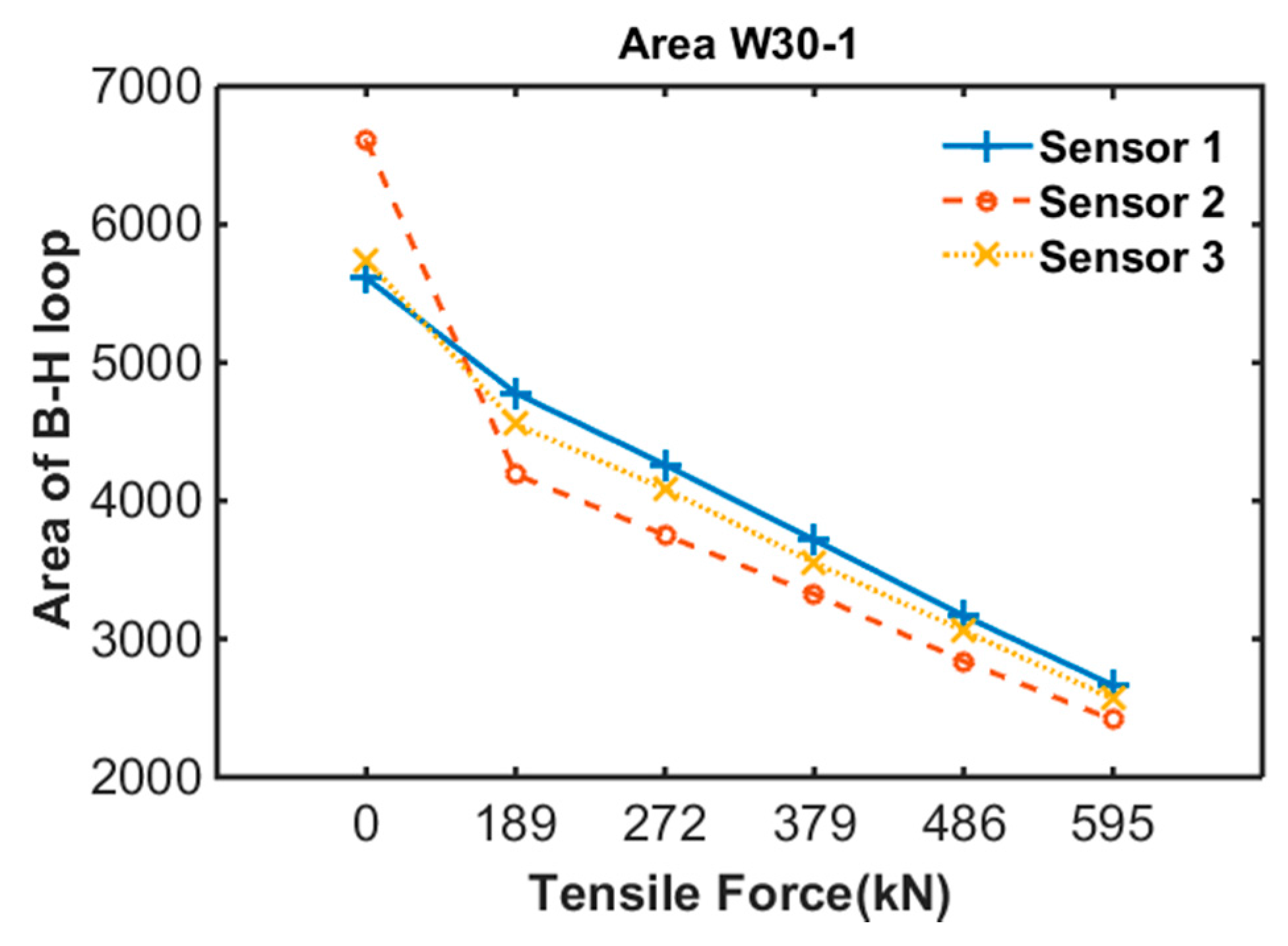

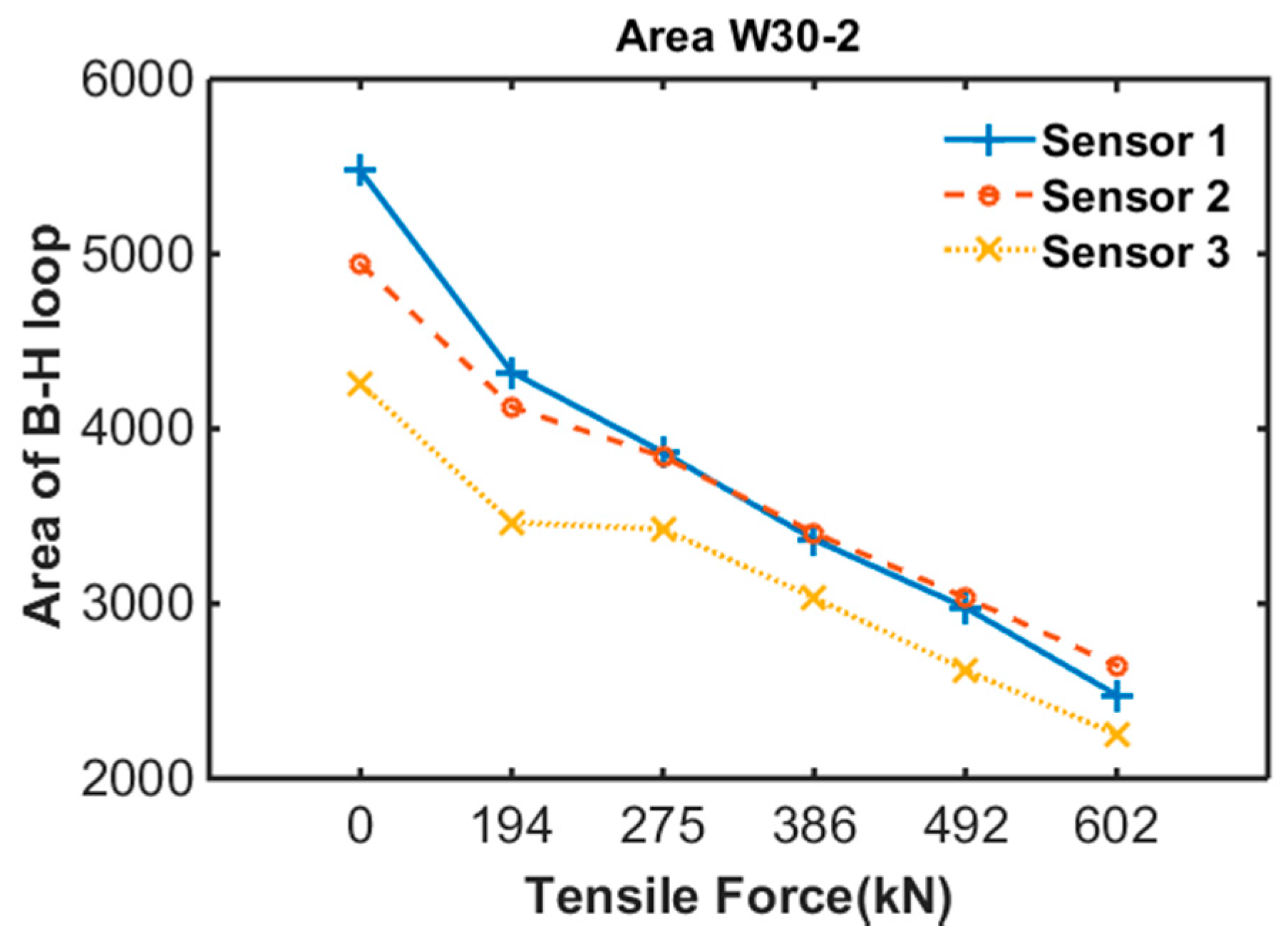

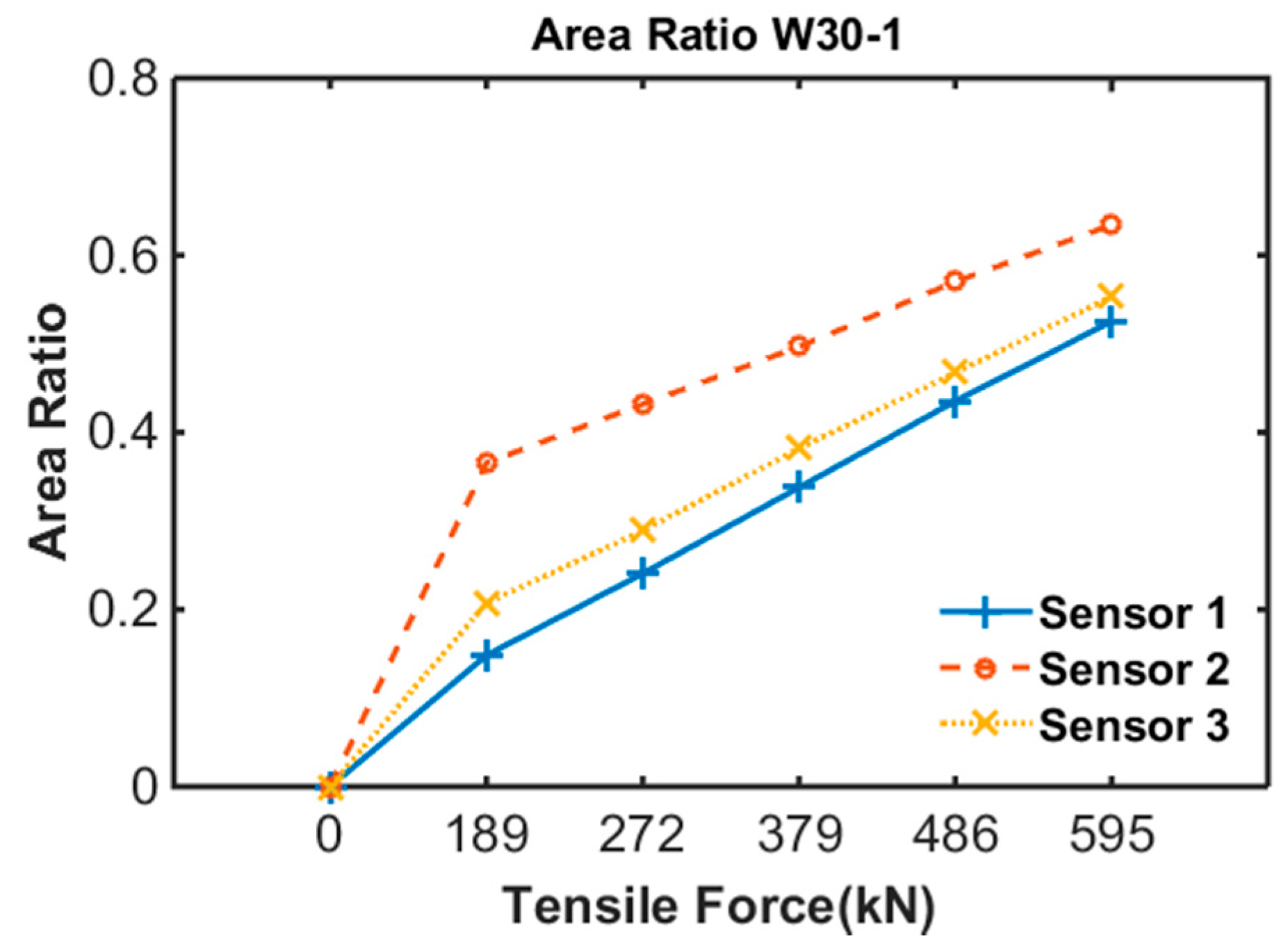

3.2. Results of EM Measurement

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rens, K.L.; Wipf, T.J.; Klaiber, F.W. Review of nondestructive evaluation techniques of civil infrastructure. J. Perform. Const. Facil. 1997, 11, 152–160. [Google Scholar] [CrossRef]

- Kim, J.W.; Kim, J.; Park, S.; Oh, T.K. Integrating embedded piezoelectric sensors with continuous wavelet transforms for real-time concrete curing strength monitoring. Struct. Infrastruct. E 2015, 11, 897–903. [Google Scholar] [CrossRef]

- Lee, C.; Kim, J.; Park, S.; Kim, D.H. Advanced Fatigue Crack Detection using Nonlinear Self-Sensing Impedance Technique for Automated NDE of Metallic Structures. Res. Nondestruct. Eval. 2015, 26, 107–121. [Google Scholar] [CrossRef]

- Lee, C.; Park, S. Damage visualization of pipeline structures using laser-induced ultrasonic waves. Struct. Health Monit. 2015, 14, 475–488. [Google Scholar] [CrossRef]

- Lee, C.; Park, S. Flaw Imaging Technique for Plate-Like Structures Using Scanning Laser Source Actuation. Shock Vib. 2014, 725030. [Google Scholar] [CrossRef]

- Lee, C.; Kang, D.; Park, S. Visualization of Fatigue Cracks at Structural Members using a Pulsed Laser Scanning System. Res. Nondestruct. Eval. 2015, 26, 123–132. [Google Scholar] [CrossRef]

- Park, S.; Kim, J.W.; Lee, C.; Lee, J.J. Magnetic Flux Leakage Sensing-Based Steel Cable NDE Technique. Shock Vib. 2014, 929341. [Google Scholar] [CrossRef]

- Weiher, H.; Zilch, K. Condition of post-tensioned concrete bridges-assessment of the German stock by a spot survey of damages. In Proceedings of the First International Conference on Advances in Bridge Engineering, London, UK, 26–28 June 2006; Brunel University: London, UK, 2006; pp. 26–28. [Google Scholar]

- Youn, S.G.; Kim, E.K. Deterioration of bonded post-tensioned concrete bridges and research topics on the strength evaluation in ISARC. In Proceedings of the JSCE-KSCE Joint Seminar on Maintenance and Management Strategy of Infrastructure in Japan and Korea, Shiga, Japan, 20 September 2006; Sakai, K., Ed.; JSCE: Tokyo, Japan, 2006; pp. 49–63. [Google Scholar]

- Bruce, S.M.; McCarten, P.S.; Freitag, S.A.; Hasson, L.M. Deterioration of prestressed concrete bridge beams. In Land Transport New Zealand Research Report; Land Transport New Zealand: Wellington, New Zealand, 2008; Volume 337, p. 72. [Google Scholar]

- Shenoy, C.V.; Frantz, G.C. Structural tests of 27-year-old prestressed concrete bridge beams. PCI J. 1991, 36, 80–90. [Google Scholar] [CrossRef]

- Aalami, B.O. Time-dependent analysis of post-tensioned concrete structures. Prog. Struct. Eng. Mater. 1998, 1, 384–391. [Google Scholar] [CrossRef]

- Pantelides, C.P.; Saxey, B.W.; Reaveley, L.D. Posttensioned tendon losses in a spliced-girder bridge, Part 1: Field measurements. PCI J. 2007, 52, 1–15. [Google Scholar]

- Lakshmanan, N.; Saibabu, S.; Murthy, A.R.C.; Ganapathi, S.C.; Jayaraman, R. Experimental, numerical and analytical studies on a novel external prestressing technique for concrete structural components. Comput. Concr. 2009, 6, 41–57. [Google Scholar] [CrossRef]

- Im, S.; Hurlebaus, S.; Trejo, D. Inspections of voids in external post-tensioned tendons. In Transportation Research Board; Business Office: Washington, DC, USA, 2010. [Google Scholar]

- Onyemelukwe, O.; Kunnath, S. Field Measurement and Evaluation of Time-Dependent Losses in Prestressed Concrete Bridges; Research Report: Project Number: WPI-0510735; Florida Department of Transportation: Tallahassee, FL, USA, 1997.

- Chen, H.L.; Wissawapaisal, K. Measurement of tensile forces in a seven-wire prestressing strands using stress waves. J. Eng. Mech. 2001, 127, 599–606. [Google Scholar] [CrossRef]

- Washer, G.A.; Green, R.E.; Pond, R.B. Velocity constants for ultrasonic stress measurement in prestressing tendons. Res. Nondestruct. Eval. 2002, 14, 81–94. [Google Scholar] [CrossRef]

- Kim, J.T.; Yun, C.B.; Ryu, Y.S.; Cho, H.M. Identification of prestress-loss in PSC beams using modal information. Struct. Eng. Mech. 2003, 17, 467–482. [Google Scholar] [CrossRef]

- Kim, J.T.; Park, J.H.; Hong, D.S.; Cho, H.M.; Na, W.B.; Yi, J.H. Vibration and impedance monitoring for prestress-loss prediction in PSC girder bridges. Smart Struct. Syst. 2009, 5, 81–94. [Google Scholar] [CrossRef]

- Kim, J.M.; Kim, H.W.; Park, Y.H.; Yang, I.H.; Kim, Y.S. FBG sensors encapsulated into 7-wire steel strand for tension monitoring of a prestressing tendon. Adv. Struct. Eng. 2012, 15, 907–917. [Google Scholar] [CrossRef]

- Lan, C.; Zhou, Z.; Ou, J. Monitoring of structural prestress loss in RC beams by inner distributed brillouin and fiber Bragg grating sensors on a single optical fiber. Struct. Control Health Monit. 2014, 21, 317–330. [Google Scholar] [CrossRef]

- Duan, Y.F.; Zhang, R.; Zhao, Y.; Or, S.W.; Fan, K.Q.; Tang, Z.F. Smart elasto-magneto-electric (EME) sensors for stress monitoring of steel structures in railway infrastructures. J. Zhejiang Univ.-Sci. A 2011, 12, 895–901. [Google Scholar] [CrossRef]

- Cho, S.; Yim, J.; Shin, S.W.; Jung, H.; Yun, C.; Wang, M.L. Comparative Field Study of Cable Tension Measurement for a Cable-Stayed Bridge. J. Bridg. Eng. 2012, 18, 748–757. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, M.L. Fast EM stress sensors for large steel cables. In Proceedings of the SPIE 6934, Nondestructive Characterization for Composite Materials, Aerospace Engineering, Civil Infrastructure, and Homeland Security 2008, San Diego, CA, USA, 9 March 2008. [Google Scholar]

- Wang, M.L.; Chen, Z.; Koontz, S.S.; Lloyd, G.D. Magneto-elastic permeability measurement for stress monitoring. In Proceedings of the SPIE 7th Annual Symposium on Smart Structures and Materials, Health Monitoring of the Highway Transportation Infrastructure, Newport Beach, CA, USA, 6–9 March 2000; Volume 3995, pp. 492–500. [Google Scholar]

- Holst, A.; Wichmann, H.-J.; Hariri, K.; Budelmann, H. Monitoring of tension members of civil structures—New concepts and testing. In Proceedings of the 3rd European workshop on SHM 2006, Granada, Spain, 5–7 July 2006; pp. 117–125. [Google Scholar]

- Joh, C.; Lee, J.W.; Kwahk, I. Feasibility study of stress measurement in prestressing tendons using Villari effect and induced magnetic field. Int. J. Distrib. Sens. Netw. 2013, 9, 1–8. [Google Scholar] [CrossRef]

- Duan, Y.F.; Zhang, R.; Zhao, Y.; Or, S.W.; Fan, K.Q. Steel stress monitoring sensor based on elasto-magnetic effect and using magneto-electric laminated composite. J. Appl. Phys. 2012, 111, 07E516. [Google Scholar] [CrossRef]

| Jacking Step | Tensile Force (kN) | |

|---|---|---|

| Specimen 1 (Straight Sheath) | Specimen 2 (Curved Sheath) | |

| 1 | 0 | 0 |

| 2 | 189 | 194 |

| 3 | 272 | 275 |

| 4 | 379 | 386 |

| 5 | 486 | 492 |

| 6 | 595 | 602 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Kim, J.-W.; Lee, C.; Park, S. Development of Embedded EM Sensors for Estimating Tensile Forces of PSC Girder Bridges. Sensors 2017, 17, 1989. https://doi.org/10.3390/s17091989

Kim J, Kim J-W, Lee C, Park S. Development of Embedded EM Sensors for Estimating Tensile Forces of PSC Girder Bridges. Sensors. 2017; 17(9):1989. https://doi.org/10.3390/s17091989

Chicago/Turabian StyleKim, Junkyeong, Ju-Won Kim, Chaggil Lee, and Seunghee Park. 2017. "Development of Embedded EM Sensors for Estimating Tensile Forces of PSC Girder Bridges" Sensors 17, no. 9: 1989. https://doi.org/10.3390/s17091989

APA StyleKim, J., Kim, J.-W., Lee, C., & Park, S. (2017). Development of Embedded EM Sensors for Estimating Tensile Forces of PSC Girder Bridges. Sensors, 17(9), 1989. https://doi.org/10.3390/s17091989