A T-Type Capacitive Sensor Capable of Measuring5-DOF Error Motions of Precision Spindles

Abstract

:1. Introduction

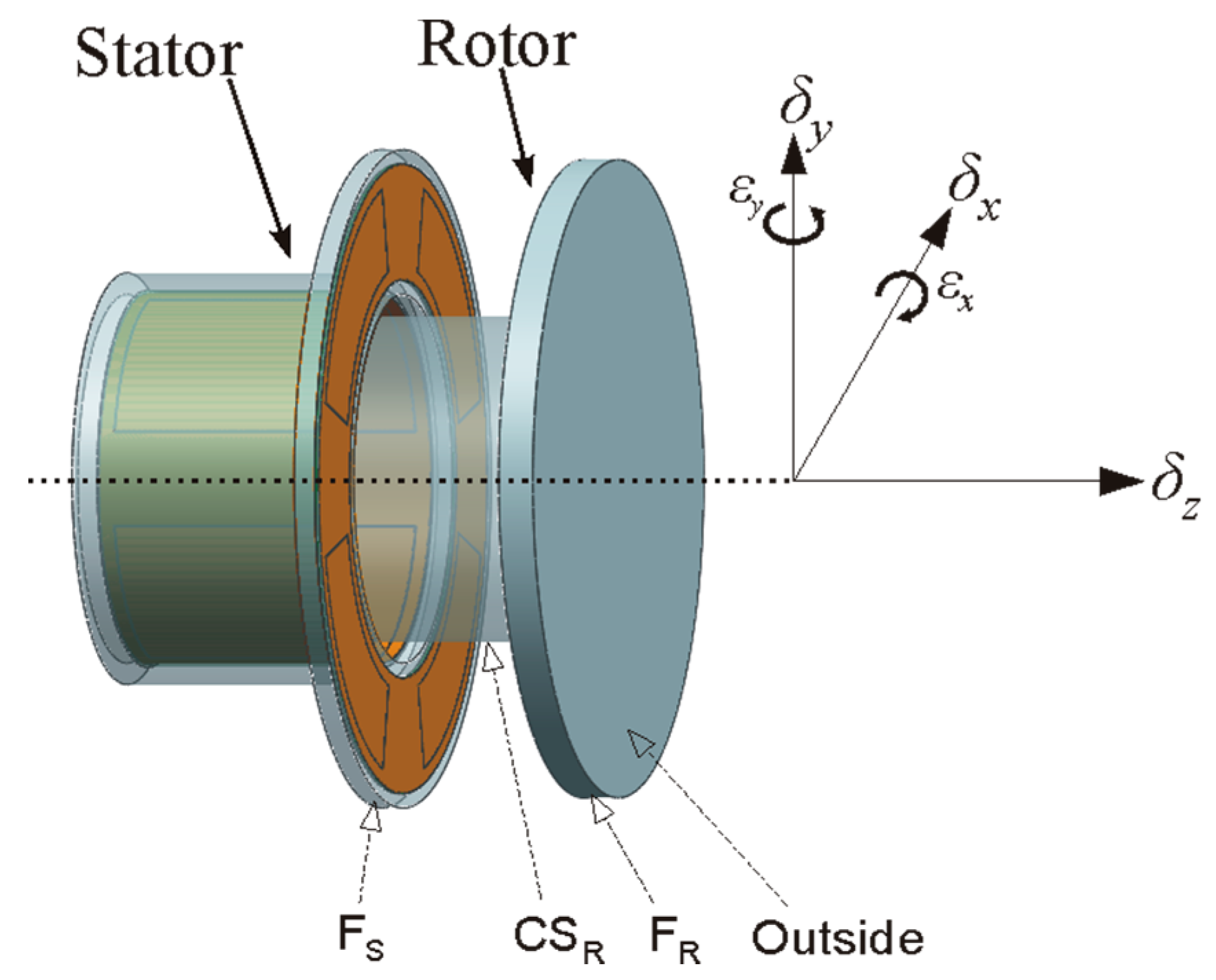

2. Measurement Principle

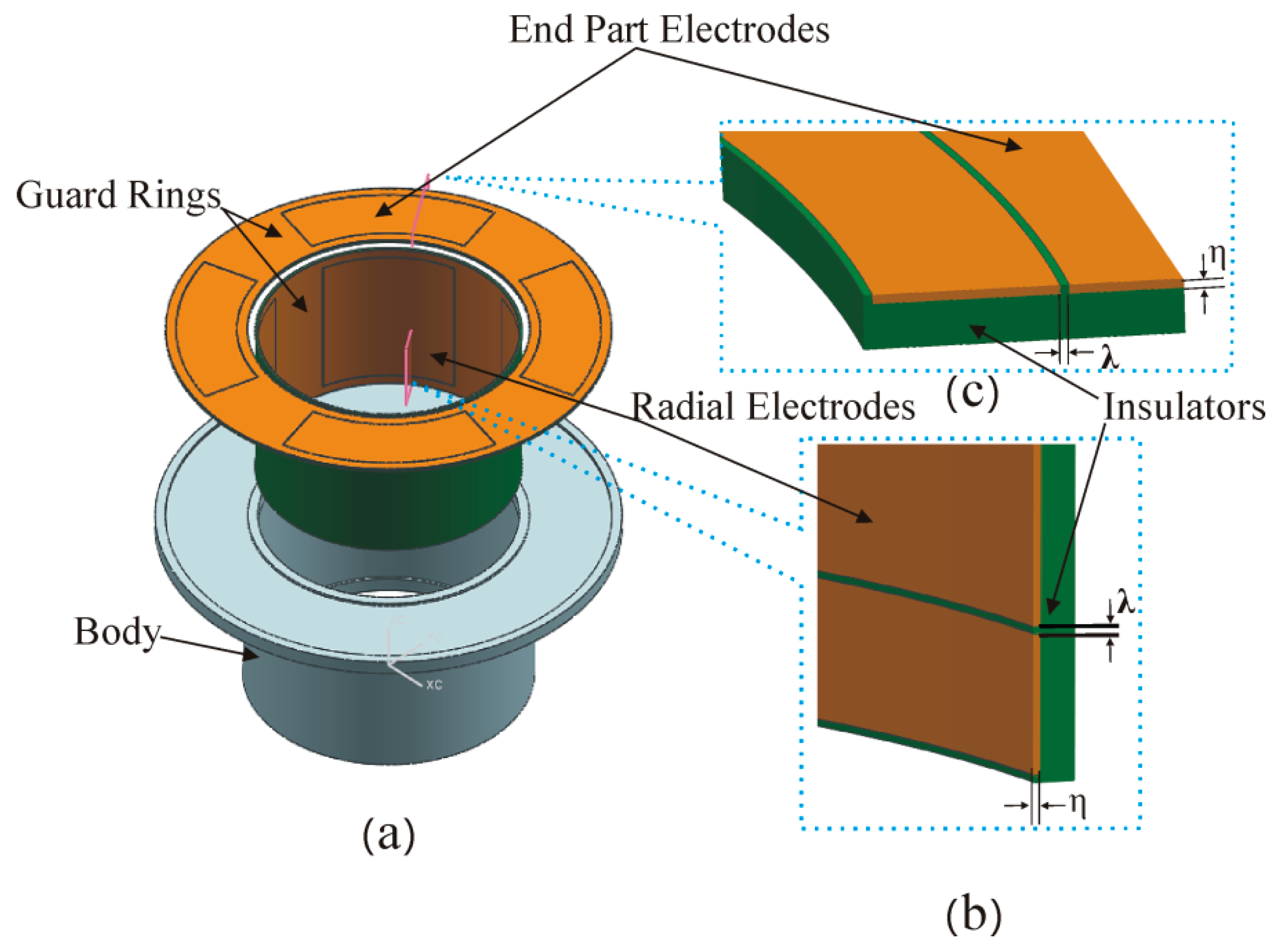

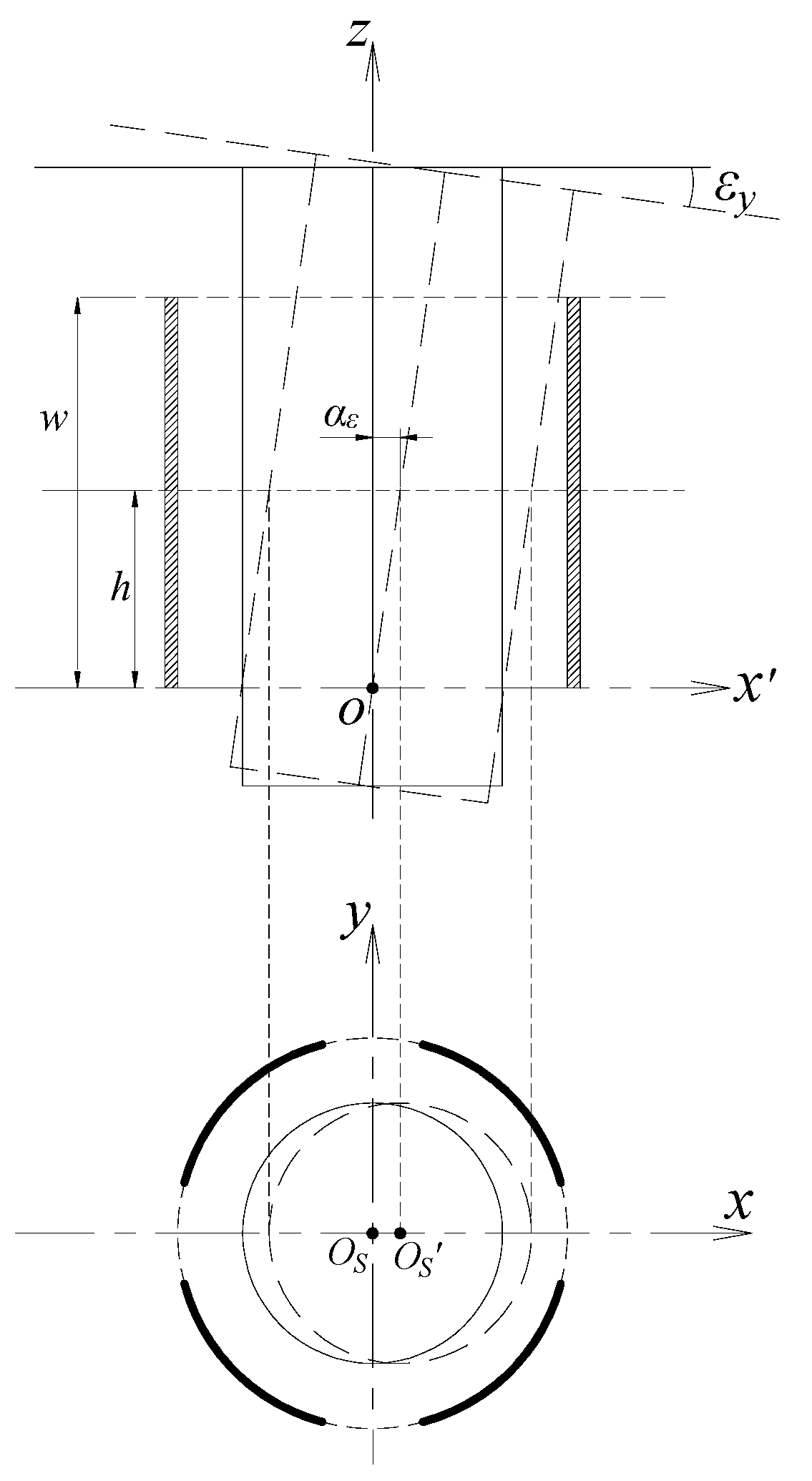

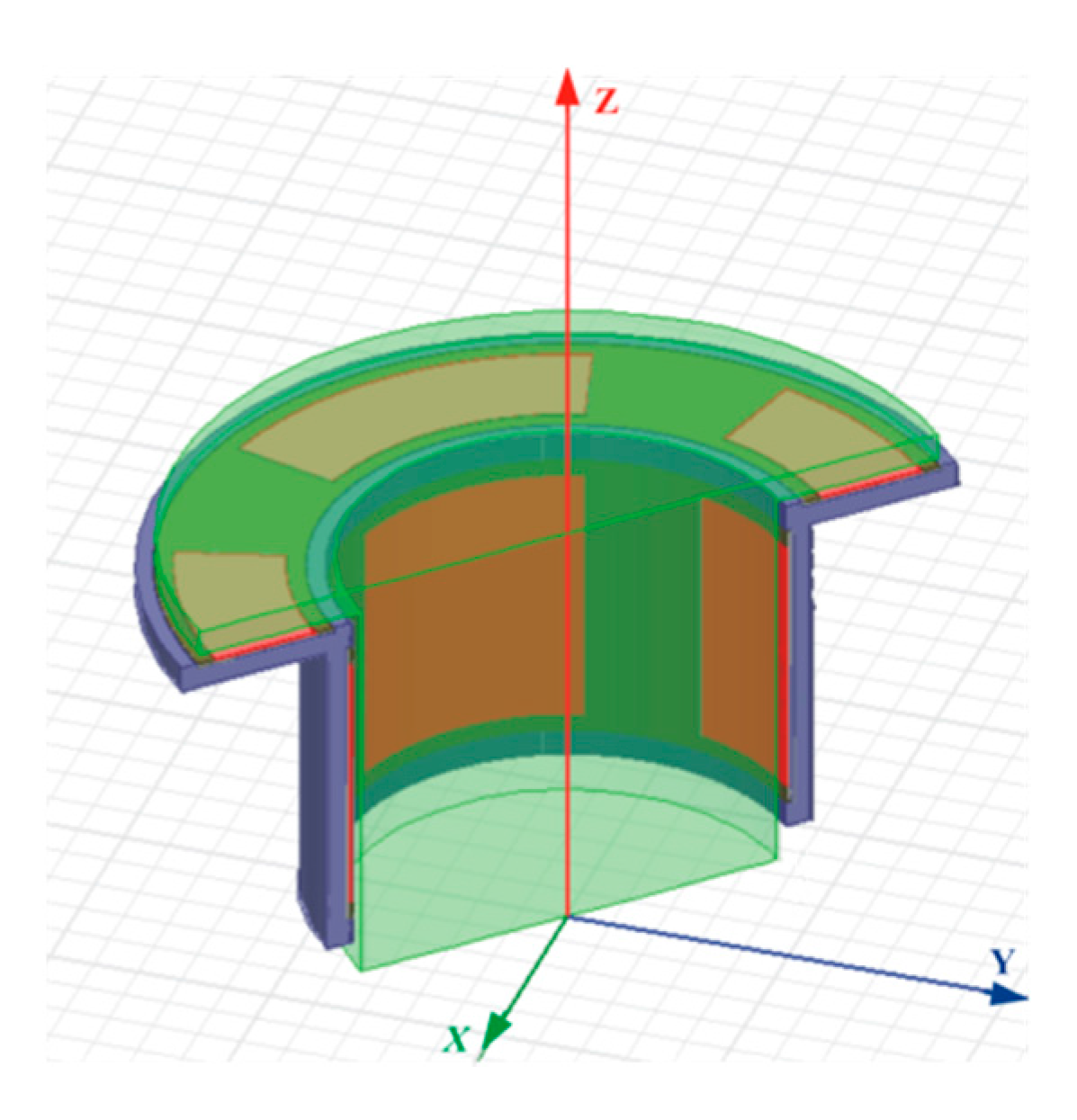

2.1. The Structure Model of T-Type CS

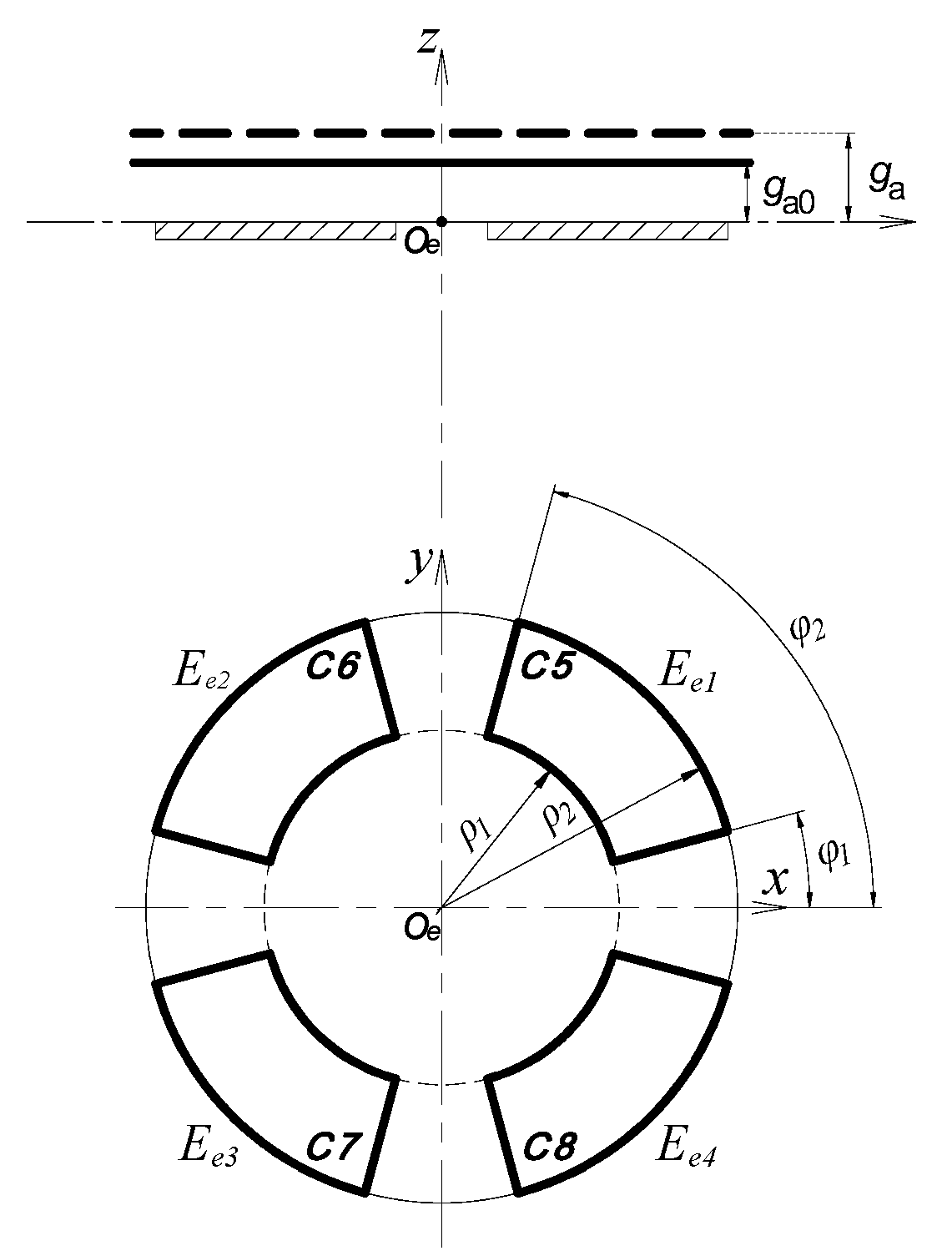

2.2. Radial Error Motion Measurement

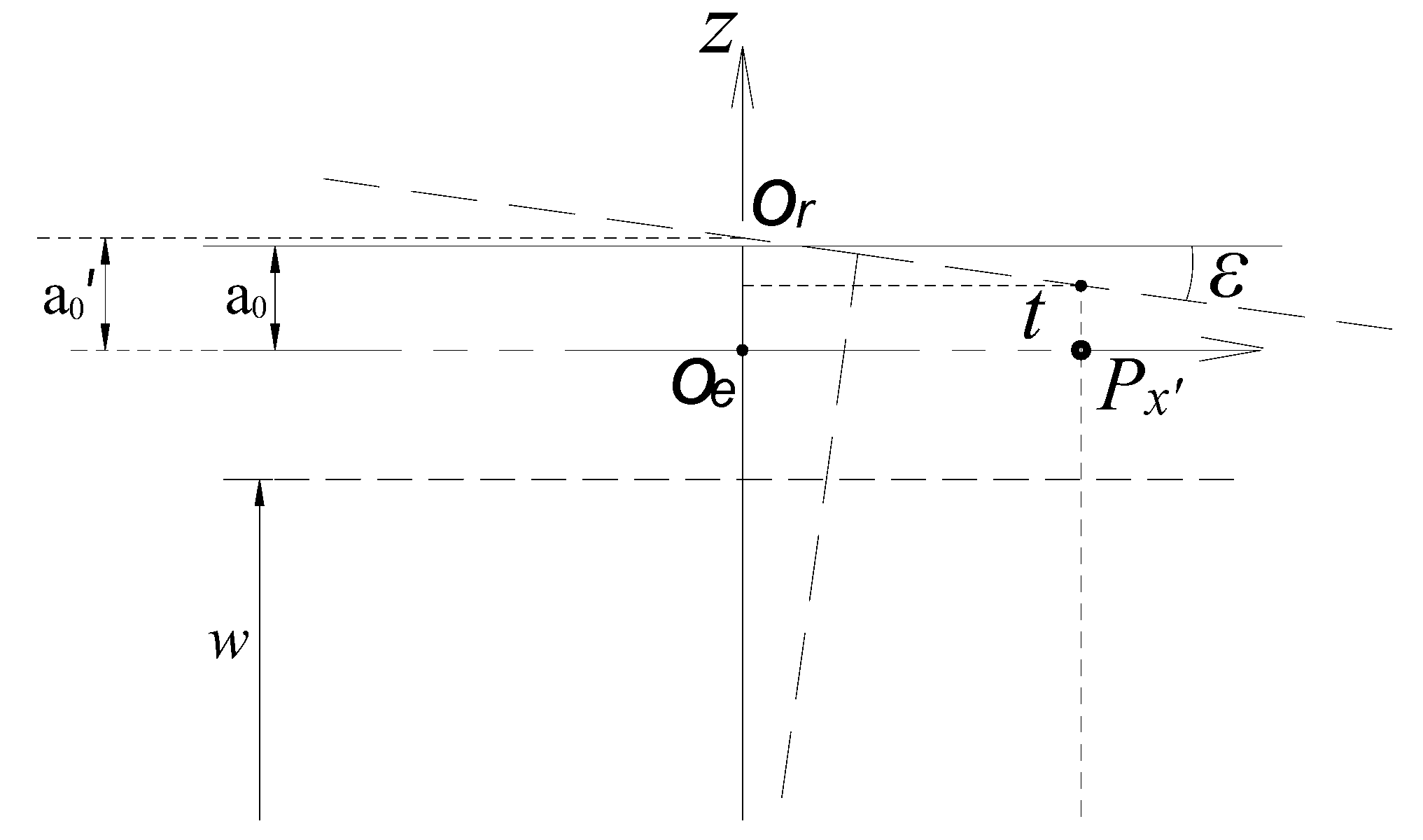

2.3. Axial Error Motion Measurement

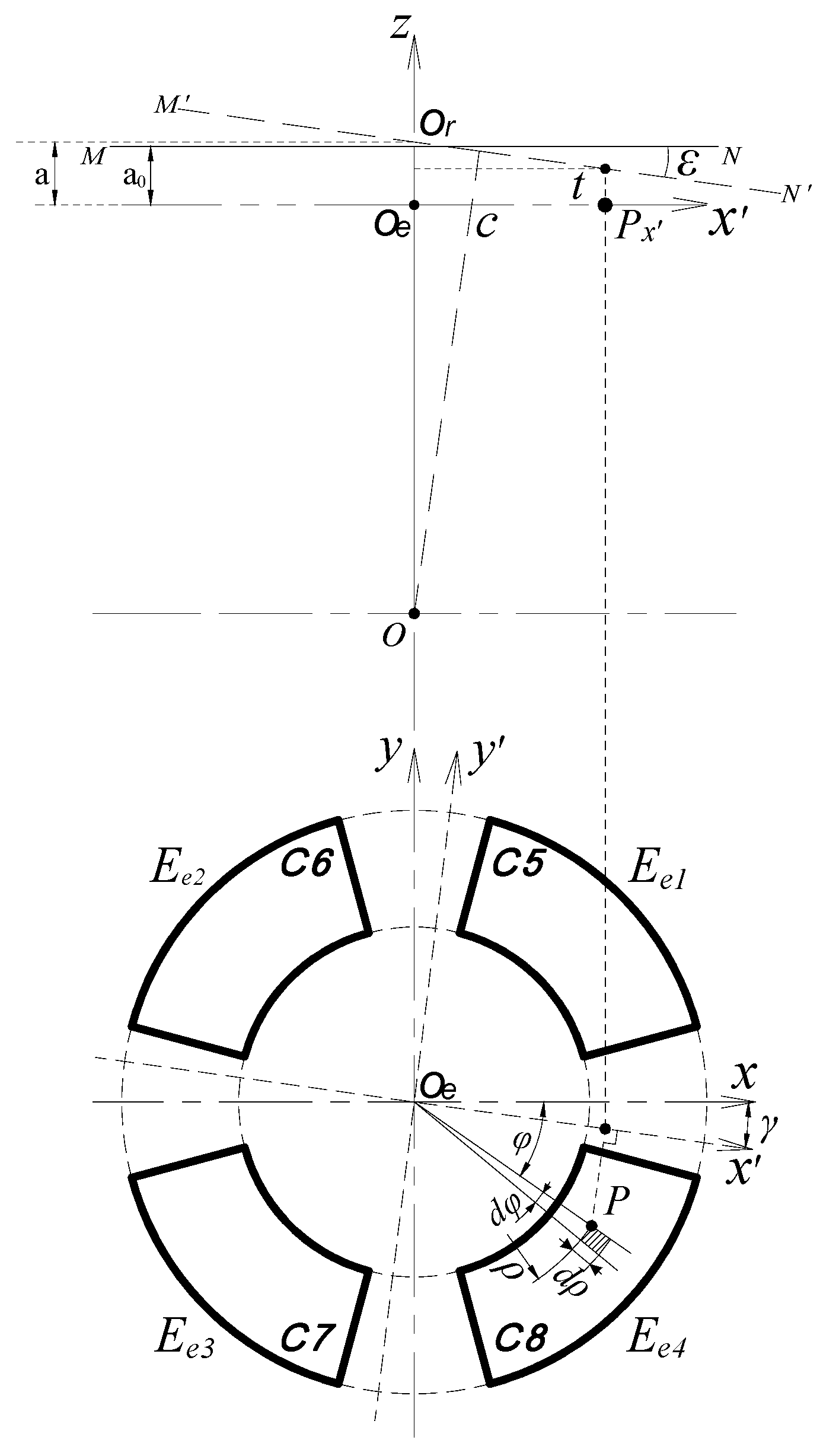

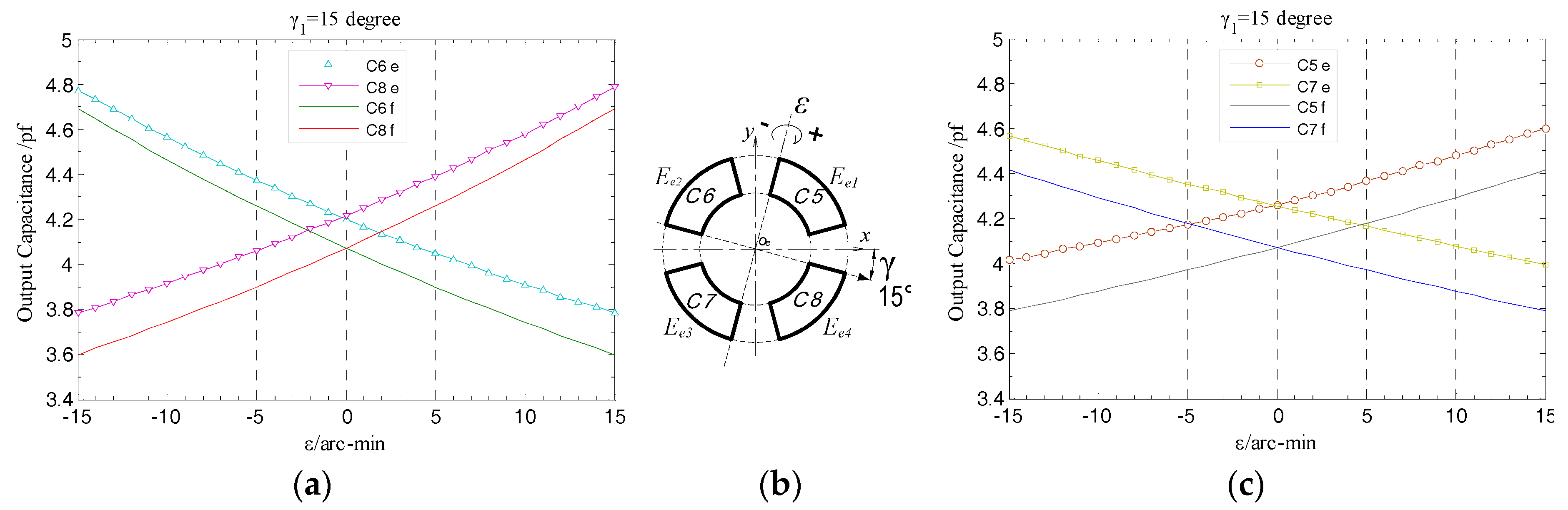

2.4. Tilt Error Motion Measurement

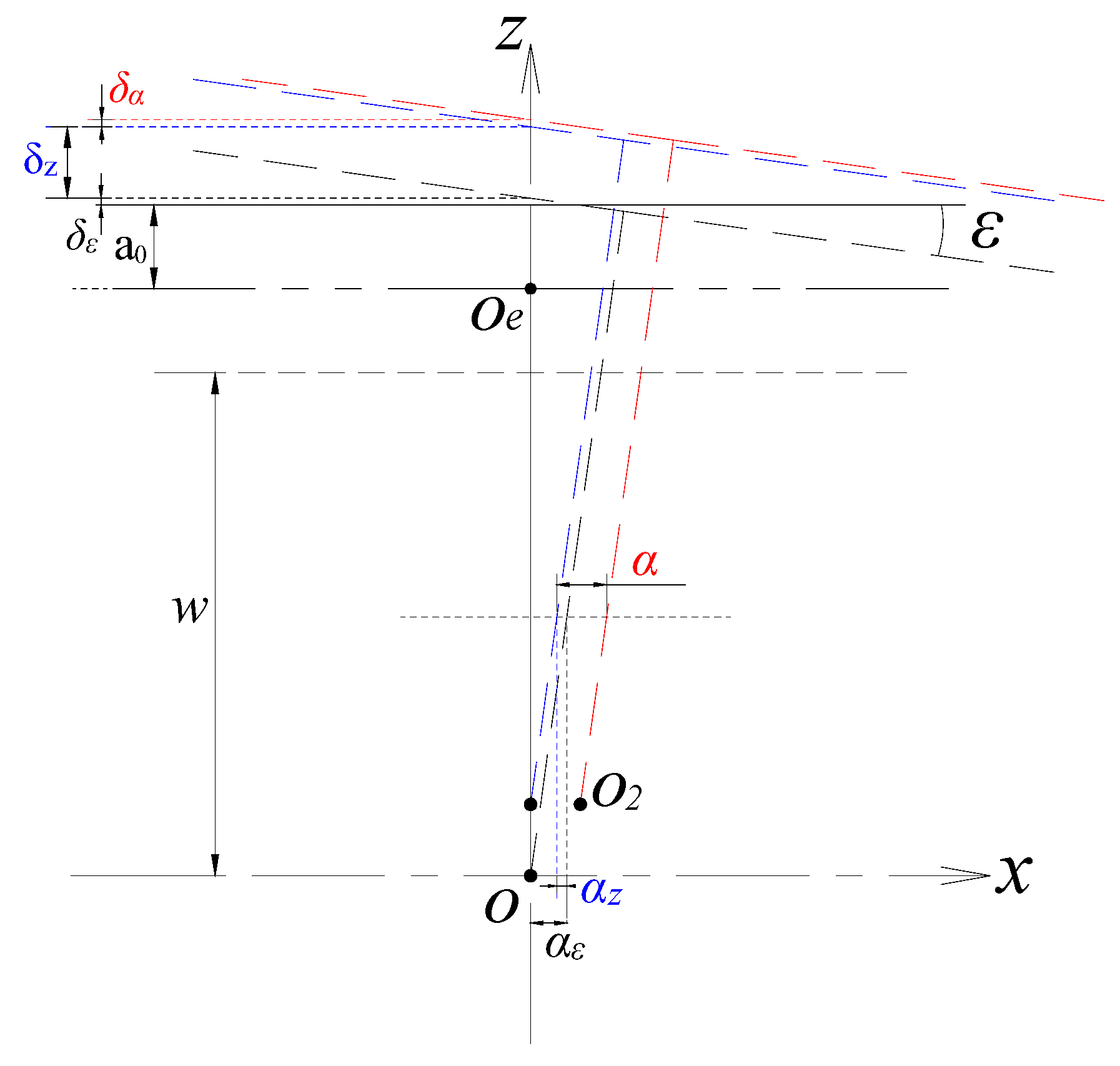

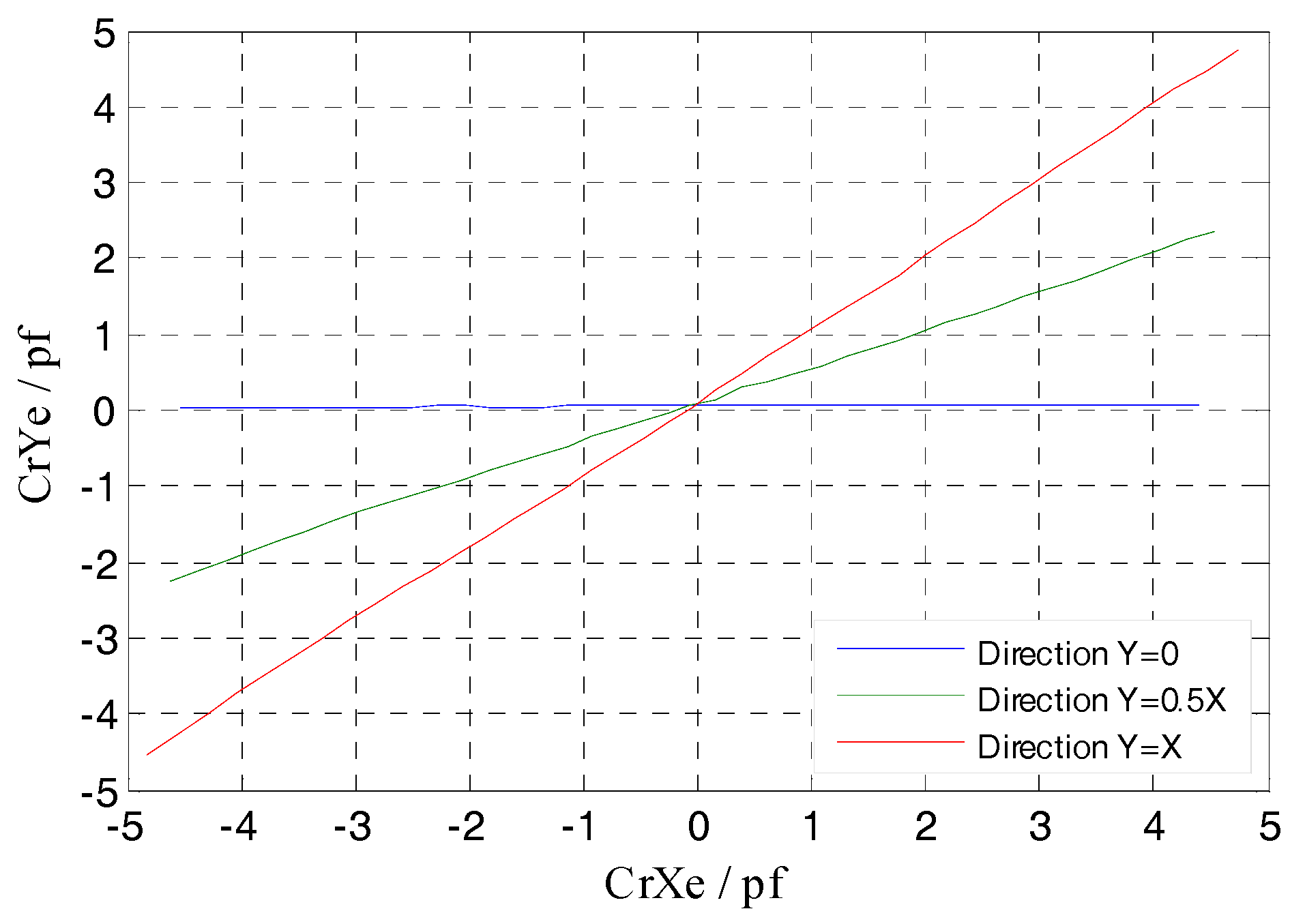

2.5. Coupling Effect Analysis for the Multi-DOF Error Motions

2.5.1. Effect of Tilt Motion on the Output of Radial Cylindrical Electrode

2.5.2. Effect of Tilt Motion on the Measurement of Axial Error Motion

2.5.3. Coupling Effect of Radial and Axial Error Motion under Tilt Displacement

3. Finite Element Simulation and Analysis

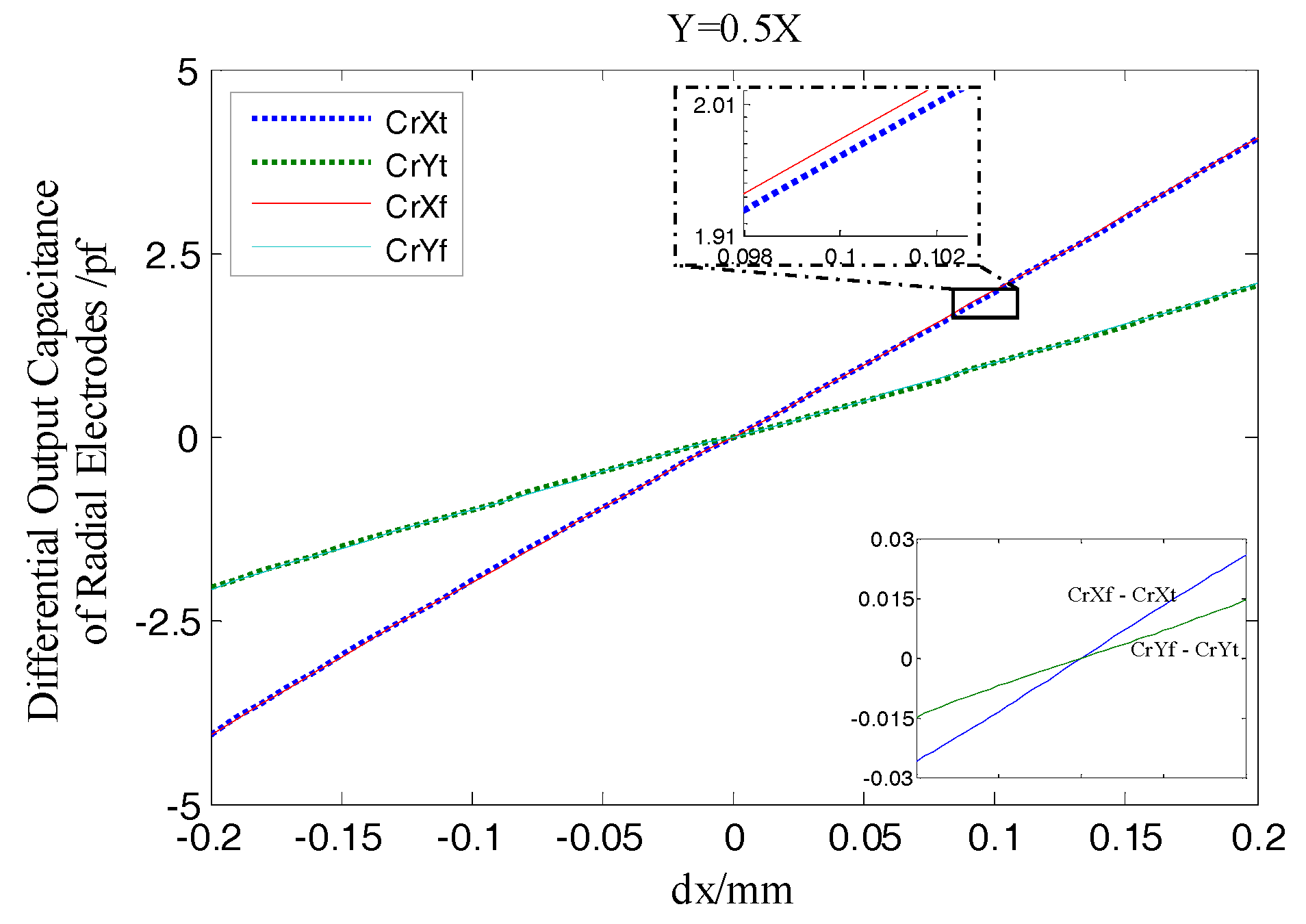

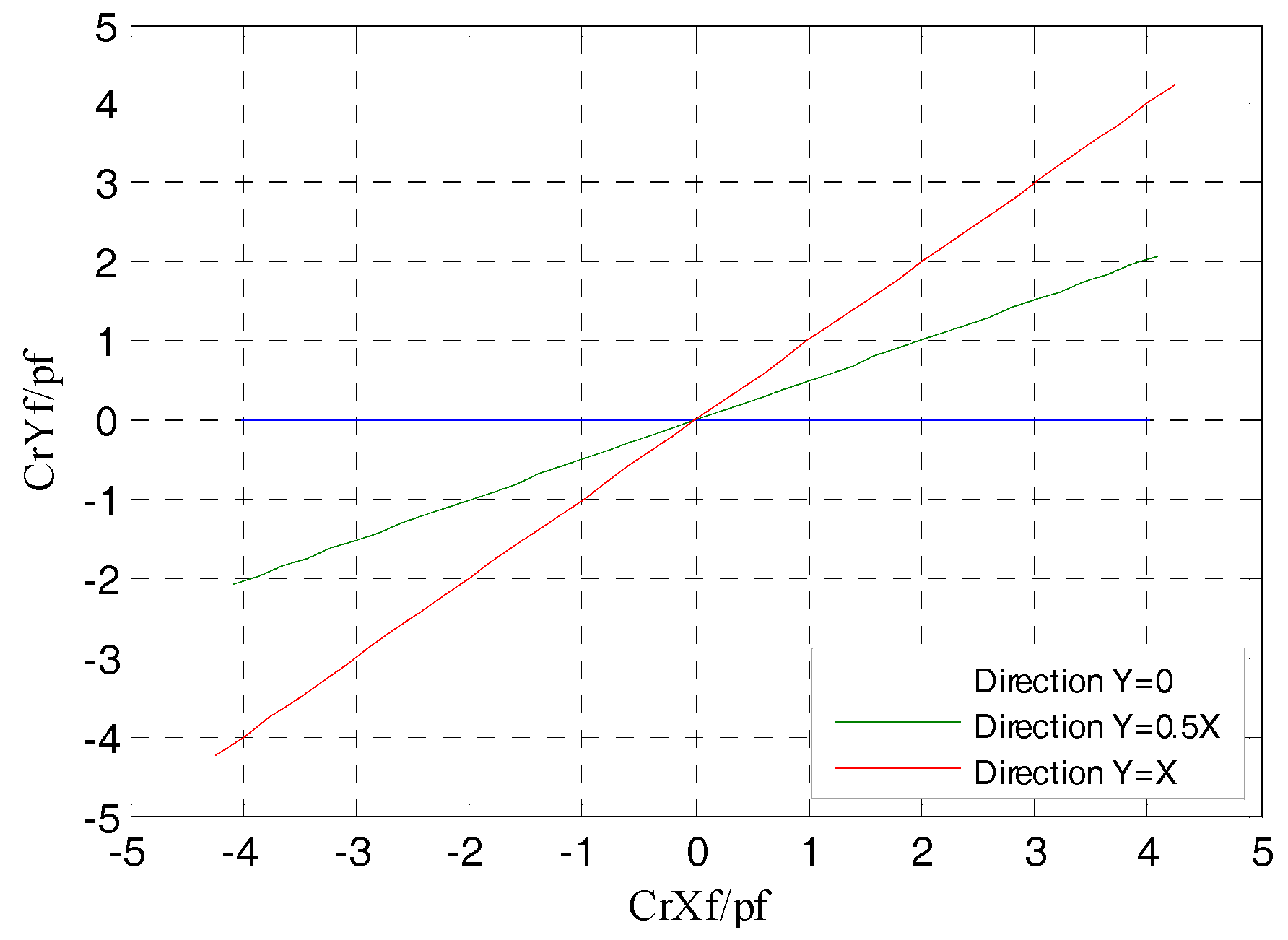

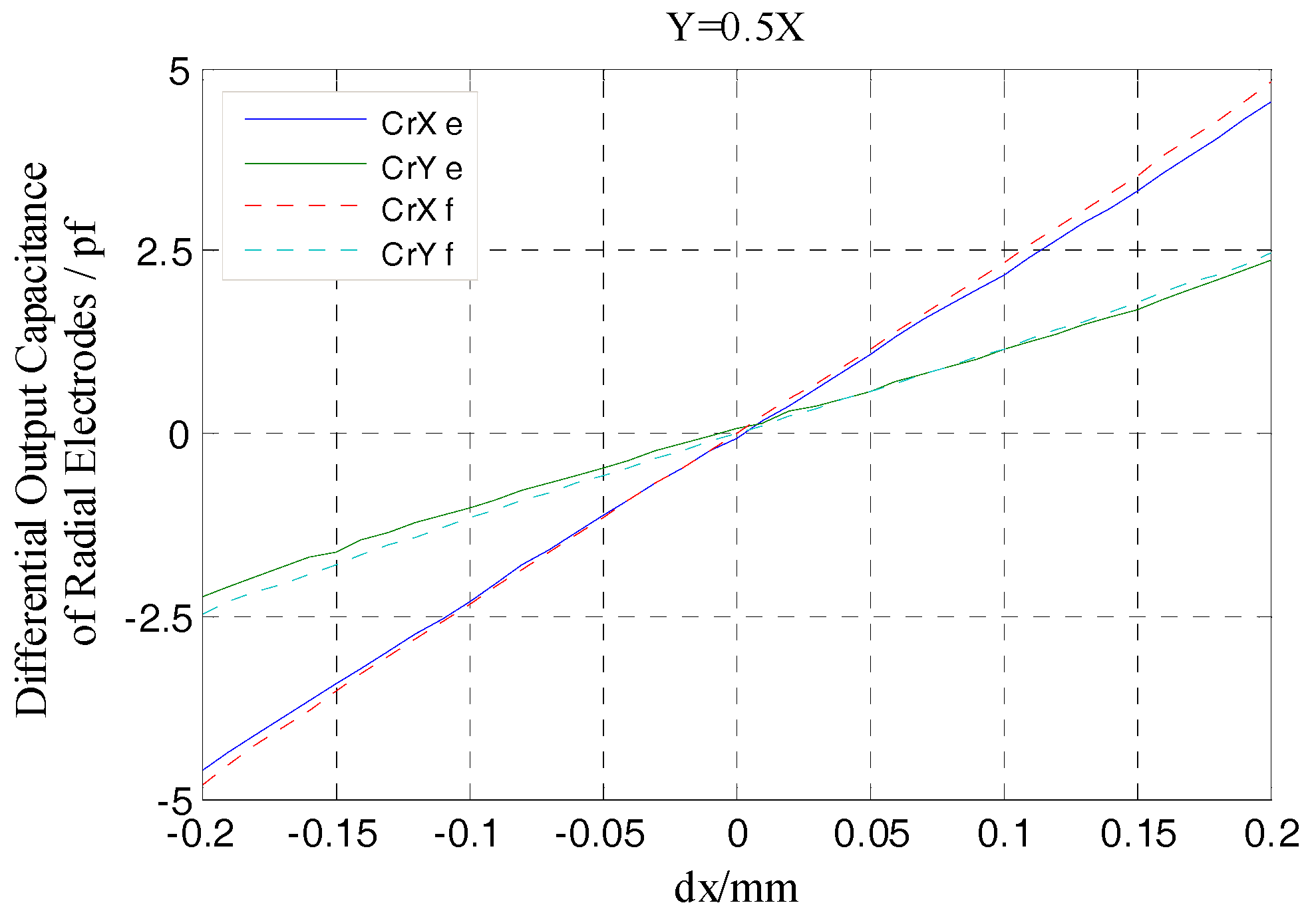

3.1. Radial Error Motions Simulation

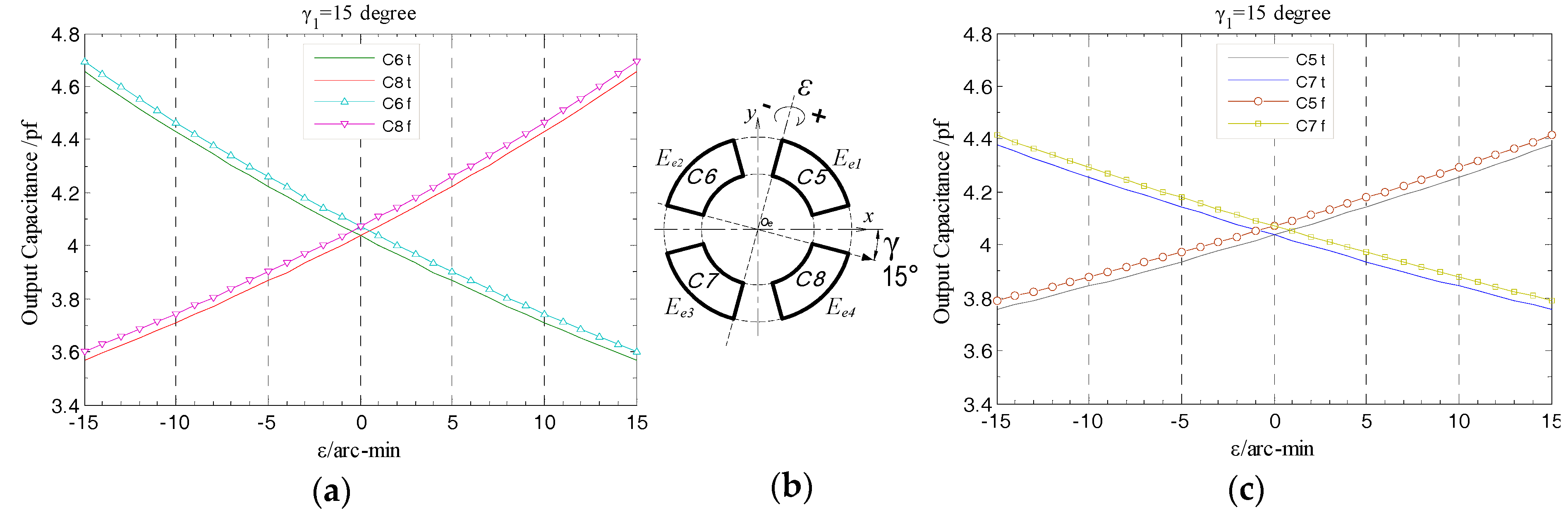

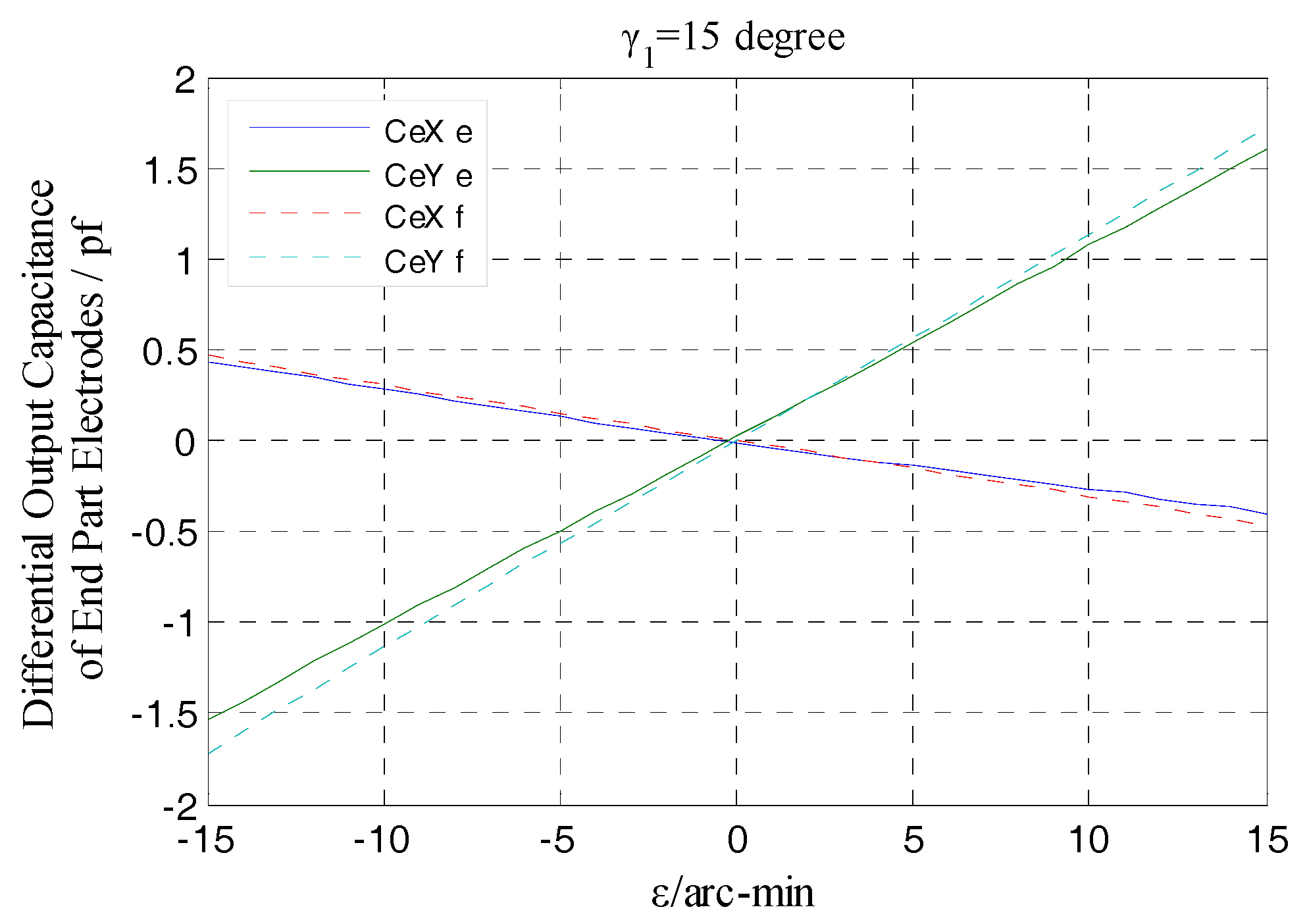

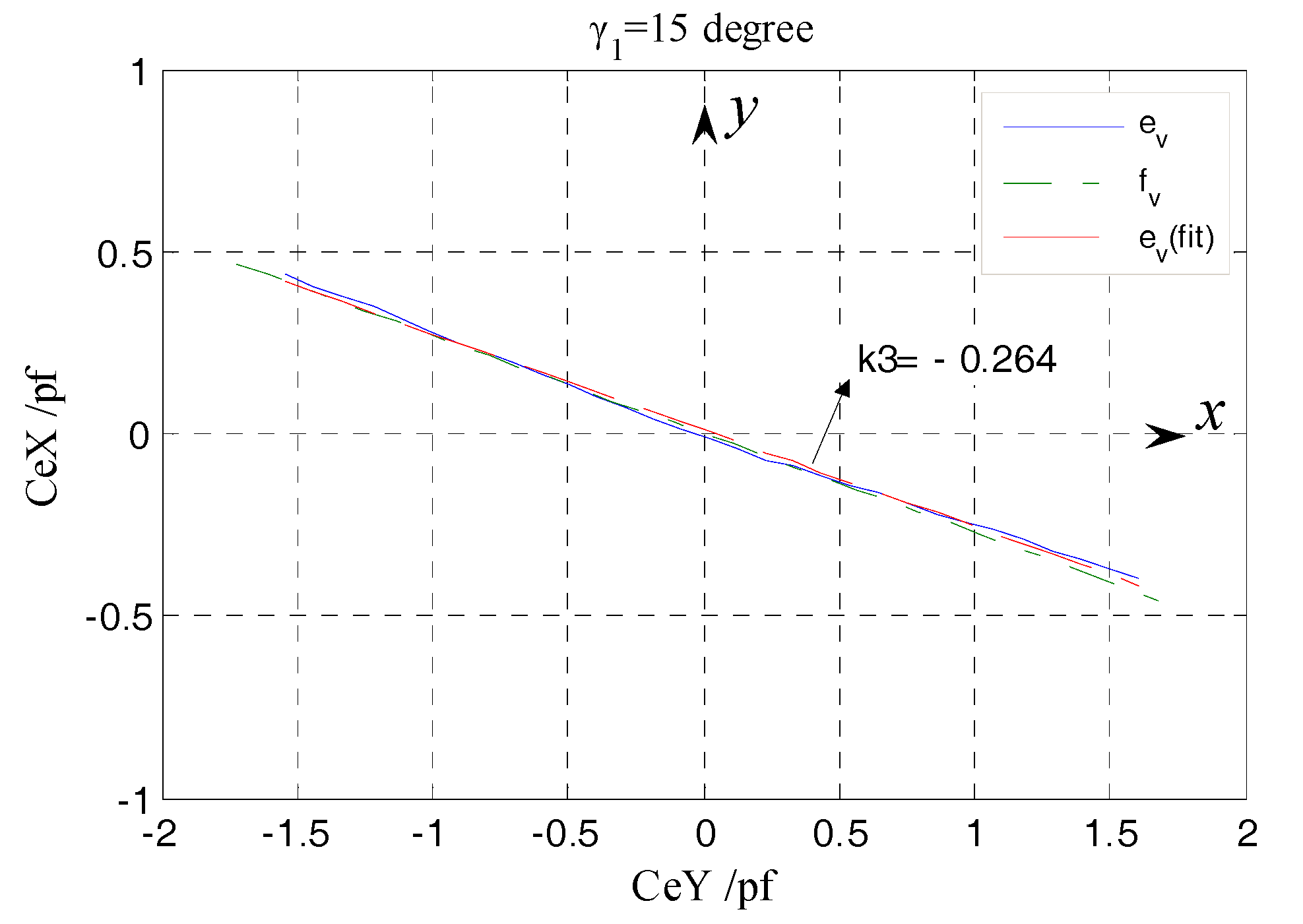

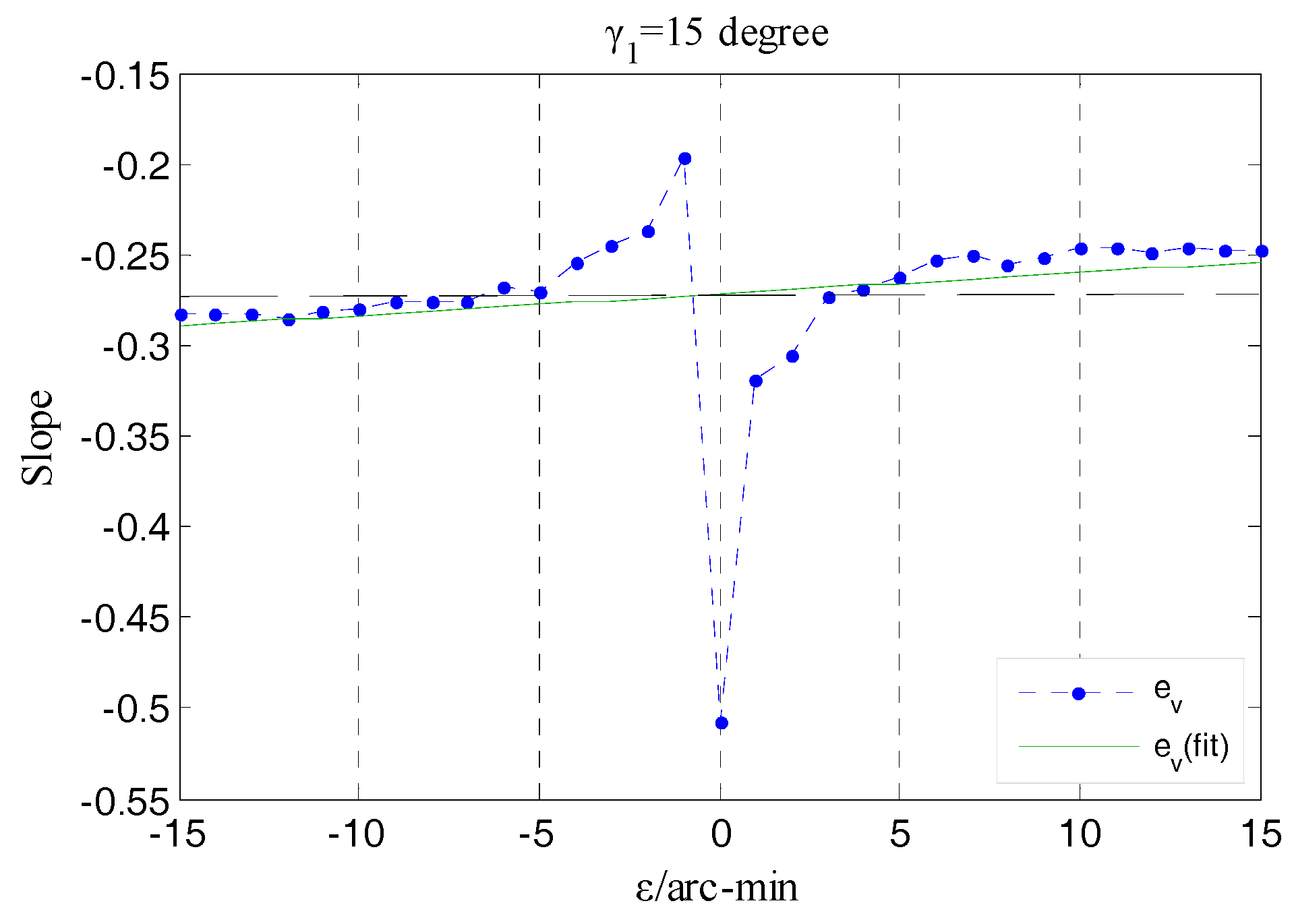

3.2. Tilt Error Motions Simulation

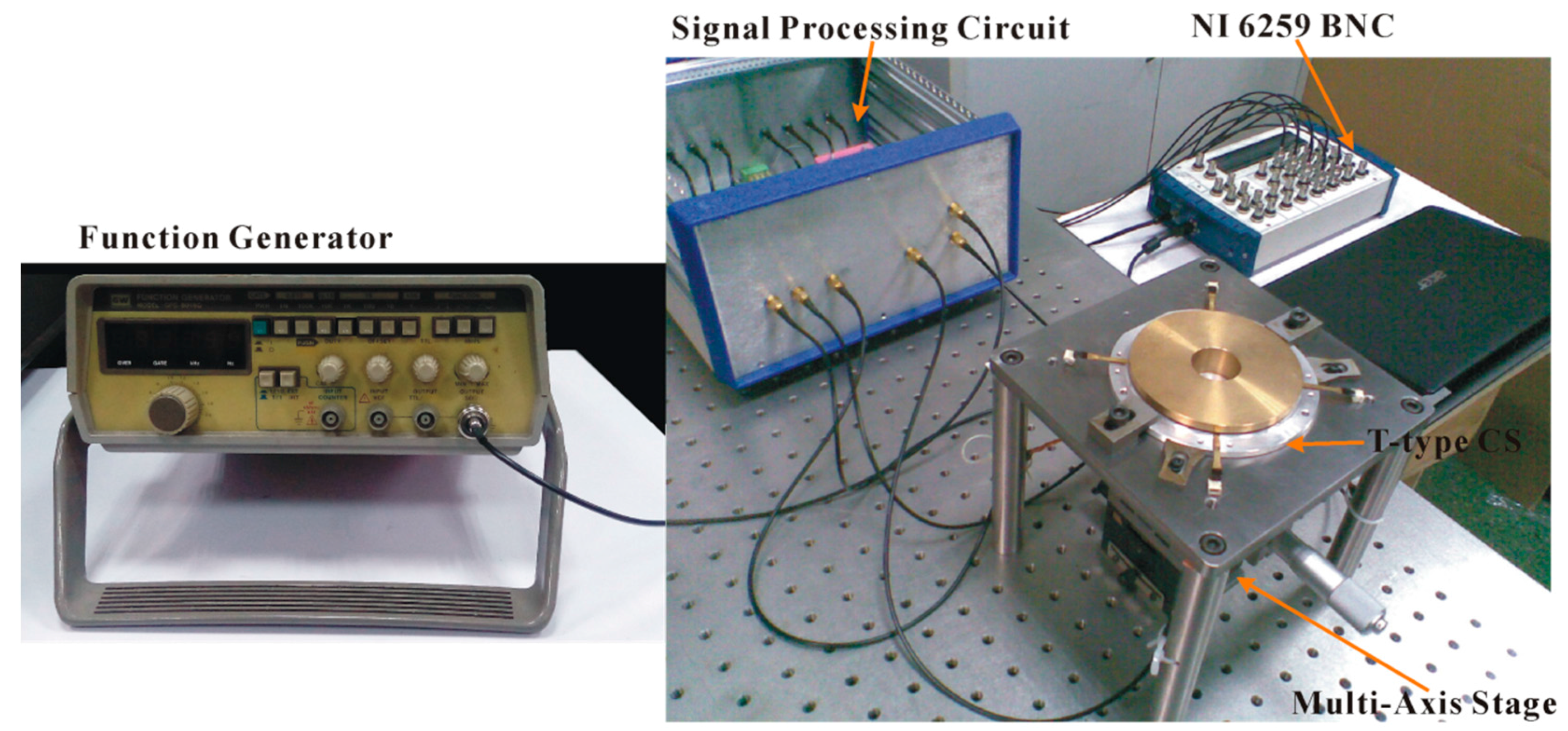

4. Experimental Validation

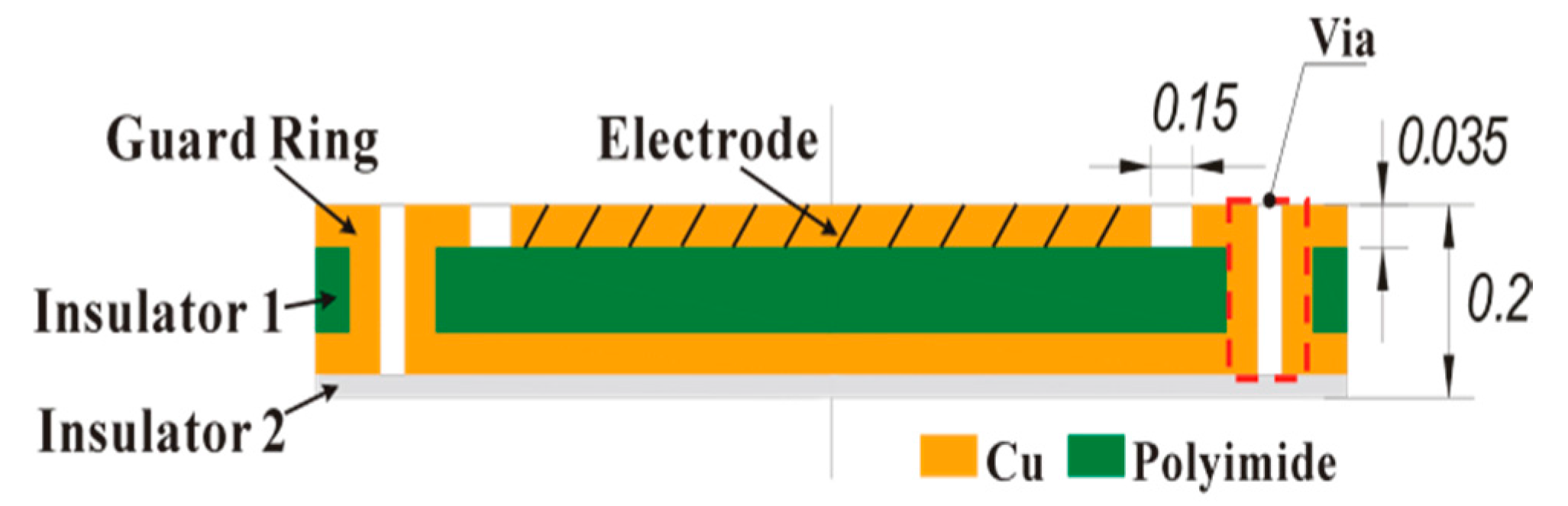

4.1. Sensor Fabrication

4.2. Signal Processing Circuit

4.3. Measurement Experiments

4.3.1. Radial Error Motions Measurement

4.3.2. Tilt Error Motions Measurement

5. Conclusions

- The simulation and experimental results indicate that the mathematical models which are established based on the integrated structural model can accurately predict the variation relationship between the inputted displacements (simulating the error motions) and the output capacitance.

- The differential measurement configuration adopted is identically applicable for the sensing electrode groups which have different electrode geometry (curved cylindrical face/planar sector) and different measurement purposes (linear translation/tilt displacement), by which the T-type CS has near-linear output response to the variation of the rotor displacements.

- The feasibility of the proposed fabrication and assembly methods of the sensing electrode group was verified by the measurement results. By using these methods, the additional output capacitance introduced by fringe effects is significantly reduced and the decreasing amplitude is about 90%; the sensing electrode group could be obtained by once machining which makes the electrodes in it have a high geometric precision.

- Based on the constructed signal processing circuit, the actual measured differential output capacitance is up to 93% of the simulation values; furthermore, the T-type CS could achieve consistent and stable measurement output for the inputted displacements.

- The T-type CS only needs to be mounted once times in the measurement process which could effectively avoid the impact of accumulative installation errors on the measurement accuracy.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Marsh, E.R. Precision Spindle Metrology, 2nd ed.; DEStech Publications: Lancaster, PA, USA, 2010. [Google Scholar]

- Martin, D.L.; Tabenkin, A.N.; Parsons, F.G. Precision Spindle and Bearing Error Analysis. Int. J. Mach. Tools Manuf. 1995, 35, 187–193. [Google Scholar] [CrossRef]

- Gao, W.; Kiyono, S.; Satoh, E.; Sata, T. Precision Measurement of Multi-Degree-of-Freedom Spindle Errors Using Two-dimensional Slope Sensors. CIRP Ann.-Manuf. Technol. 2002, 51, 447–450. [Google Scholar] [CrossRef]

- Liu, C.H.; Jywe, W.Y.; Lee, H.W. Development of a Simple Test Device for Spindle Error Measurement Using a Position Sensitive Detector. Meas. Sci. Technol. 2004, 15, 1733–1741. [Google Scholar] [CrossRef]

- Castro, H.F.F. A Method for Evaluating Spindle Rotation Errors of Machine Tools Using a Laser Interferometer. Measurement 2008, 41, 526–537. [Google Scholar] [CrossRef]

- Madden, M.; Aketagawa, M.; Kumagai, T.; Maeda, Y.; Okuyama, E. Concurrent Measurement Method of Spindle Radial, Axial and Angular Motions Using Concentric Circle Grating and Phase Modulation Interferometers. Meas. Sci. Technol. 2014, 25, 094005. [Google Scholar] [CrossRef]

- Grejda, R.; Marsh, E.; Vallance, R. Techniques for Calibrating Spindles with Nanometer Error Motion. Precis. Eng. 2005, 29, 113–123. [Google Scholar] [CrossRef]

- Ma, P.; Zhao, C.; Lu, X.; Gong, C.; Niu, X. Rotation Error Measurement Technology and Experimentation Research of High-Precision Hydrostatic Spindle. Int. J. Adv. Manuf. Technol. 2014, 73, 1313–1320. [Google Scholar] [CrossRef]

- Fleming, A.J. A Review of Nanometer Resolution Position Sensors: Operation and Performance. Sens. Actuators A Phys. 2013, 190, 106–126. [Google Scholar] [CrossRef]

- Gao, W.; Kiyono, S. On-Machine Roundness Measurement of Cylindrical Workpieces by the Combined Three-Point Method. Measurement 1997, 21, 147–156. [Google Scholar] [CrossRef]

- Tu, J.F.; Bossmanns, B.; Hung, S.C. Modeling and Error Analysis for Assessing Spindle Radial Error Motions. Precis. Eng. 1997, 21, 90–101. [Google Scholar] [CrossRef]

- Vallance, R.R.; Marsh, E.R.; Smith, P.T. Effects of Spherical Targets on Capacitive Displacement Measurements. J. Manuf. Sci. Eng. 2004, 126, 822–829. [Google Scholar] [CrossRef]

- Chapman, P.D. A Capacitance Based Ultra-Precision Spindle Error Analyser. Precis. Eng. 1985, 7, 129–137. [Google Scholar] [CrossRef]

- Jeon, S.; Ahn, H.J.; Han, D.C.; Chang, I.B. New Design of Cylindrical Capacitive Sensor for On-Line Precision Control of AMB Spindle. IEEE Trans. Instrum. Meas. 2001, 50, 757–763. [Google Scholar] [CrossRef]

- Ahn, H.J.; Han, D.C.; Hwang, I.S. A Built-In Bearing Sensor to Measure the Shaft Motion of a Small Rotary Compressor for Air Conditioning. Tribol. Int. 2003, 36, 561–572. [Google Scholar] [CrossRef]

- Kim, J.H.; Chang, H.K.; Han, D.C.; Jang, D.Y.; Oh, S.I. Cutting Force Estimation by Measuring Spindle Displacement in Milling Process. CIRP Ann.-Manuf. Technol. 2005, 54, 67–70. [Google Scholar] [CrossRef]

- Wang, W.; Wen, Y.; Yu, J.; Chen, Z. Impact of Fringe Effect on Measuring Accuracy of Planar Capacitive Sensors. Sens. Lett. 2011, 9, 1458–1461. [Google Scholar] [CrossRef]

- Xiang, K.; Wang, W.; Zhang, M.; Lu, K.; Fan, Z.; Chen, Z. Nonlinear Analysis of Cylindrical Capacitive Sensor Used for Measuring High Precision Spindle Rotation Errors. In Proceedings of the 2014 SPIE International Symposium on Precision Engineering Measurement and Instrumentation (ISPEMI), Changsha, China, 9–13 August 2014; p. 94461S. [Google Scholar]

- Peng, J.Y.; Lu, M.S.C. A Flexible Capacitive Tactile Sensor Array with Cmos Readout Circuits for Pulse Diagnosis. IEEE Sens. J. 2015, 15, 1170–1177. [Google Scholar] [CrossRef]

- Chen, X.; Ding, T. Flexible Eddy Current Sensor Array for Proximity Sensing. Sens. Actuators A Phys. 2007, 135, 126–130. [Google Scholar] [CrossRef]

- Hammond, J.L.; Glidewell, S.R. Design of Algorithms to Extract Data from Capacitance Sensors to Measure Fastener Hole Profiles. IEEE Trans. Instrum. Meas. 1983, 32, 343–349. [Google Scholar] [CrossRef]

- Ahn, H.J.; Jeon, S.; Han, D.C. Error Analysis of the Cylindrical Capacitive Sensor for Active Magnetic Bearing Spindles. J. Dyn. Sys. Meas. Control 2000, 122, 102–107. [Google Scholar] [CrossRef]

- Baxter, L.K. Capacitive Sensors: Design and Applications; IEEE Press: New York, NY, USA, 1997. [Google Scholar]

- Meade, M.L. Lock-In Amplifiers: Principles and Applications; IEEE Press: London, UK, 1983. [Google Scholar]

| Model Geometry Parameters | Symbol | Value | Unit | |

|---|---|---|---|---|

| Radial cylindrical electrode (Sensing electrode) | Start angle, stop angle (The first quadrant) | ζ1, ζ2 | π/12, 5π/12 | rad mm |

| Inside radius | R | 26 | ||

| Axial width | w | 30 | ||

| Thickness | ηr | 0.1 | ||

| End part fan-shaped electrode (Sensing electrode) | Start angle, stop angle (The first quadrant) | ϕ1, ϕ2 | π/12, 5π/12 | rad mm |

| Inside radius | ρ1 | 30.2 | ||

| Outside radius | ρ2 | 42.2 | ||

| Thickness | ηe | 0.1 | ||

| Rotor (Excitation electrode) | CSR radius | RCS | 25 | mm |

| Flange radius | RF | 44.2 | ||

| Equipotential guard ring | Gap with the sensing electrode | λ | 0.1 | mm |

| Thickness | ηgr | 0.1 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, K.; Wang, W.; Qiu, R.; Mei, D.; Chen, Z. A T-Type Capacitive Sensor Capable of Measuring5-DOF Error Motions of Precision Spindles. Sensors 2017, 17, 1975. https://doi.org/10.3390/s17091975

Xiang K, Wang W, Qiu R, Mei D, Chen Z. A T-Type Capacitive Sensor Capable of Measuring5-DOF Error Motions of Precision Spindles. Sensors. 2017; 17(9):1975. https://doi.org/10.3390/s17091975

Chicago/Turabian StyleXiang, Kui, Wen Wang, Rongbo Qiu, Deqing Mei, and Zichen Chen. 2017. "A T-Type Capacitive Sensor Capable of Measuring5-DOF Error Motions of Precision Spindles" Sensors 17, no. 9: 1975. https://doi.org/10.3390/s17091975

APA StyleXiang, K., Wang, W., Qiu, R., Mei, D., & Chen, Z. (2017). A T-Type Capacitive Sensor Capable of Measuring5-DOF Error Motions of Precision Spindles. Sensors, 17(9), 1975. https://doi.org/10.3390/s17091975