Design and Development of a Three-Component Force Sensor for Milling Process Monitoring

Abstract

:1. Introduction

2. Sensor Design and Fabrication

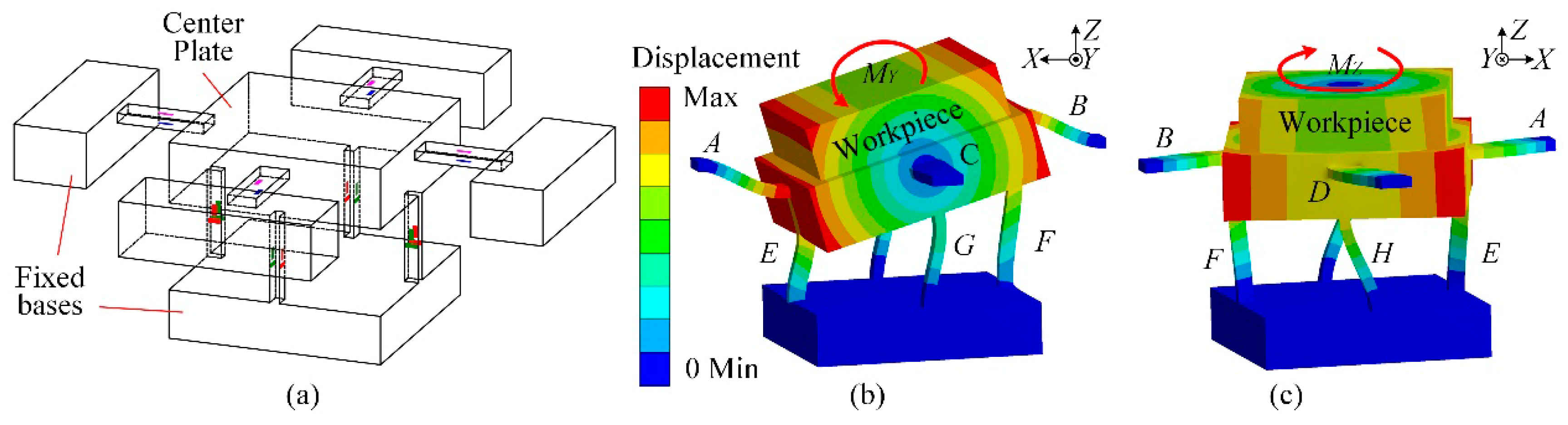

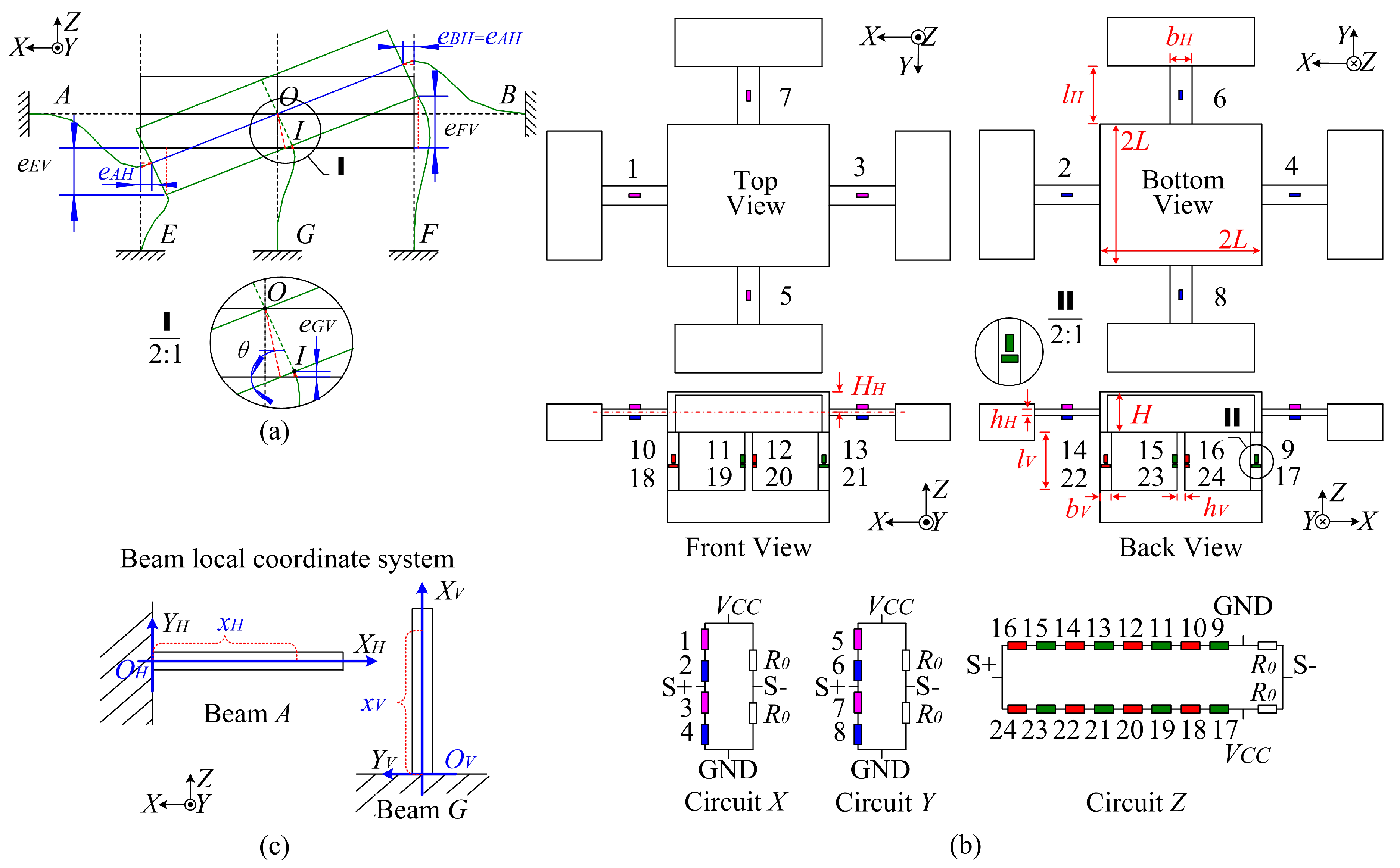

2.1. Sensor Structure Design

2.1.1. The Initial Model for Sensor Structural Design

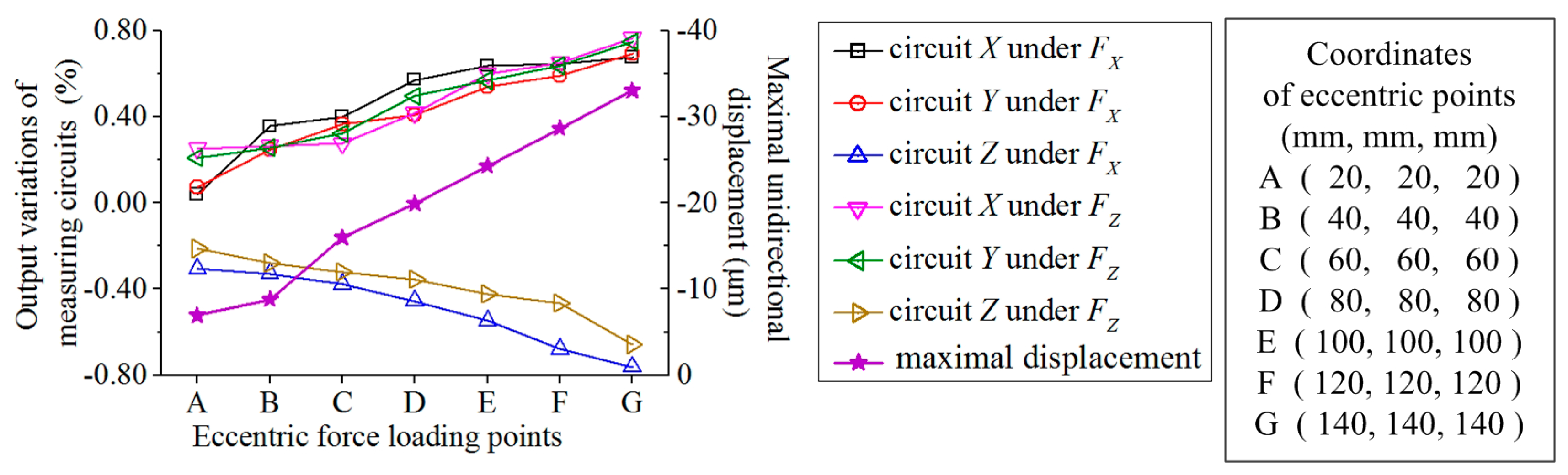

2.1.2. Sensor Output under Additional Moment

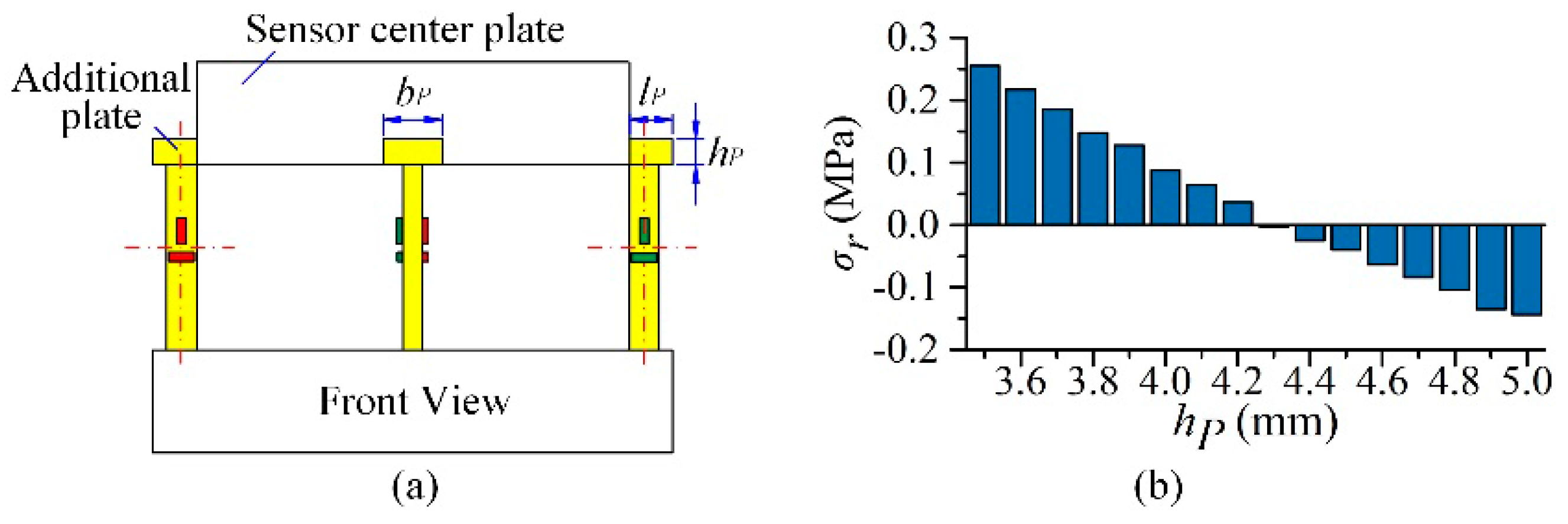

2.1.3. Beam Structural Adjustment Based on MY

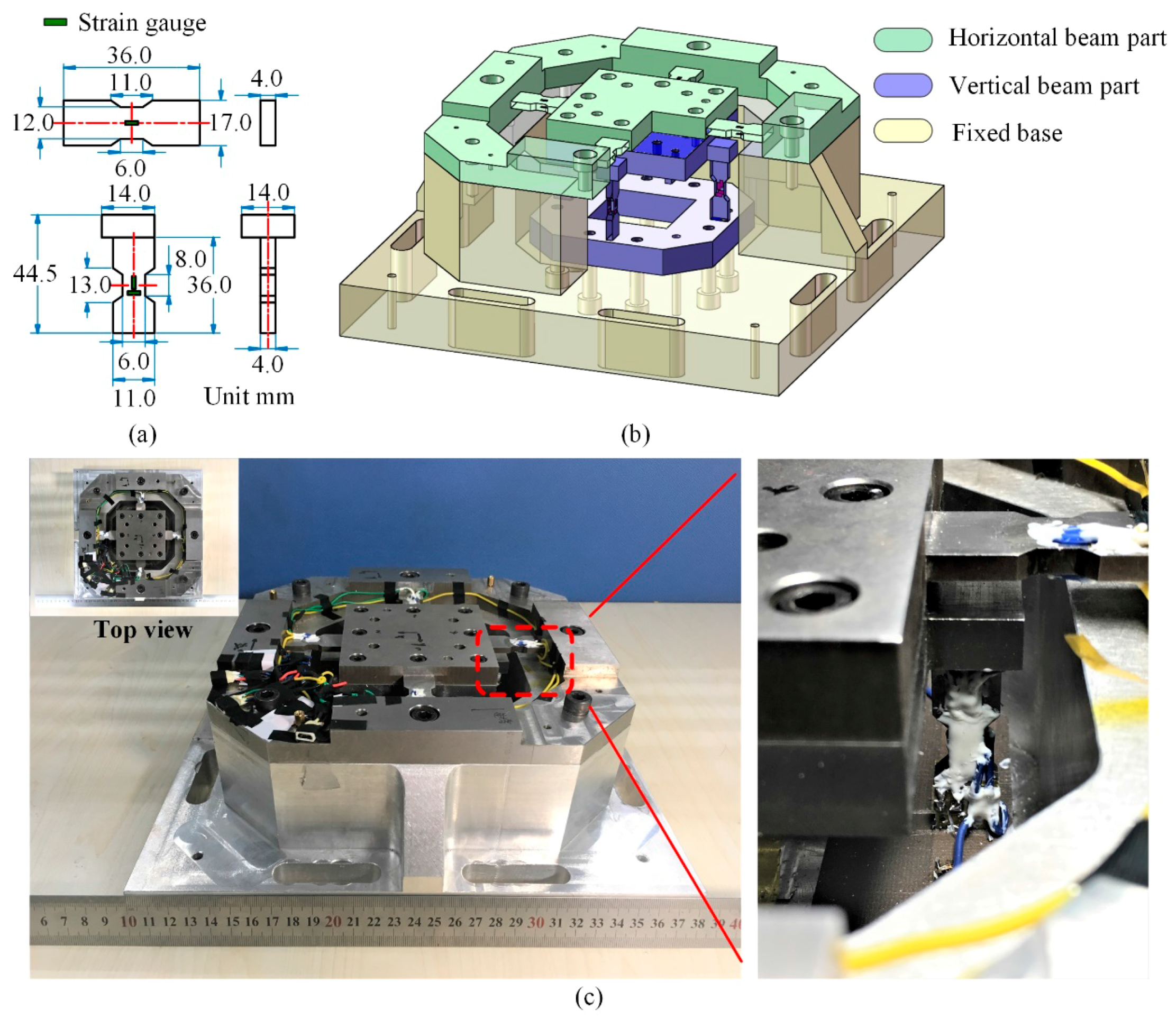

2.2. Sensor Fabrication

3. Experimental Results and Discussion

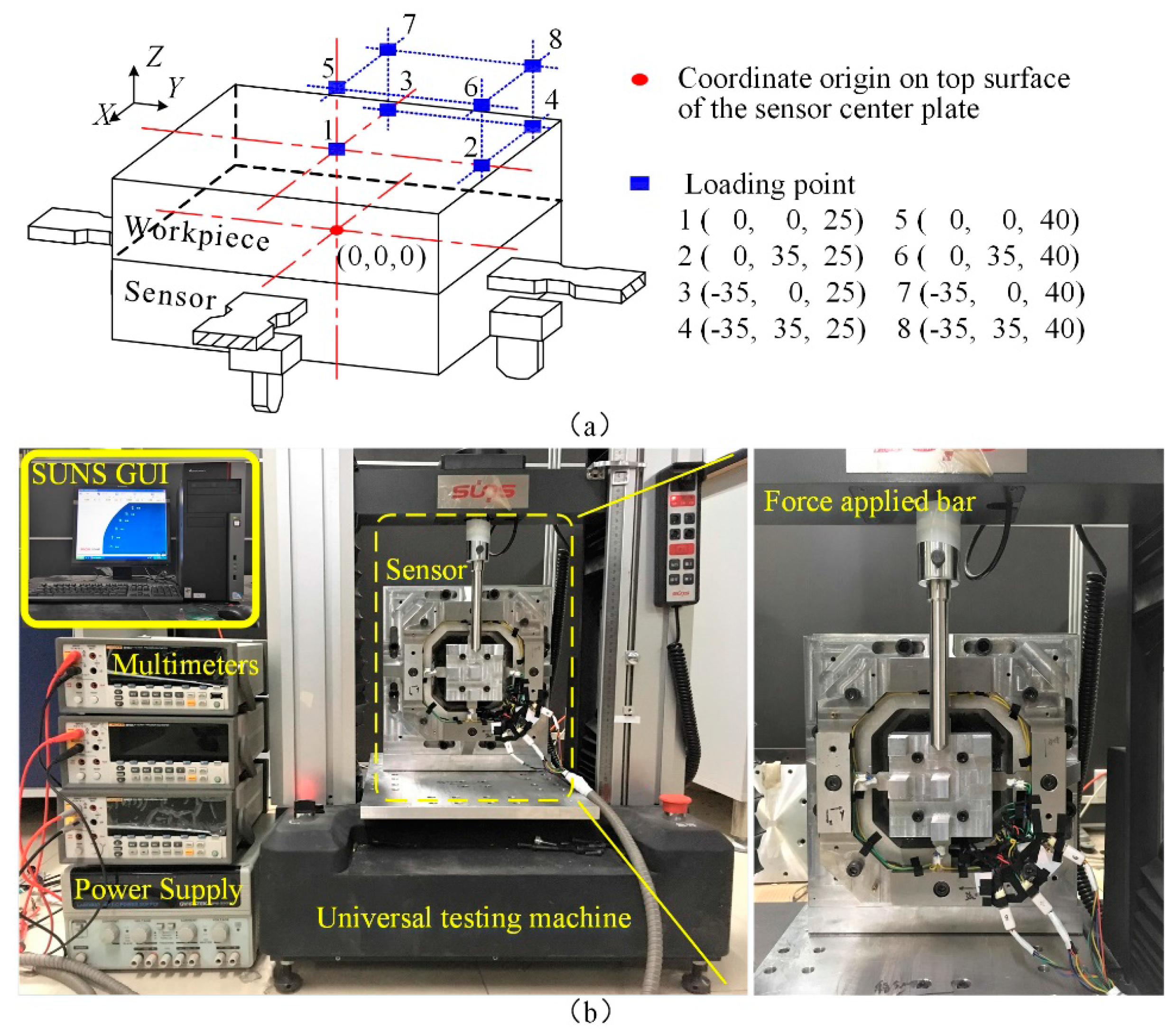

3.1. Static Calibration Test

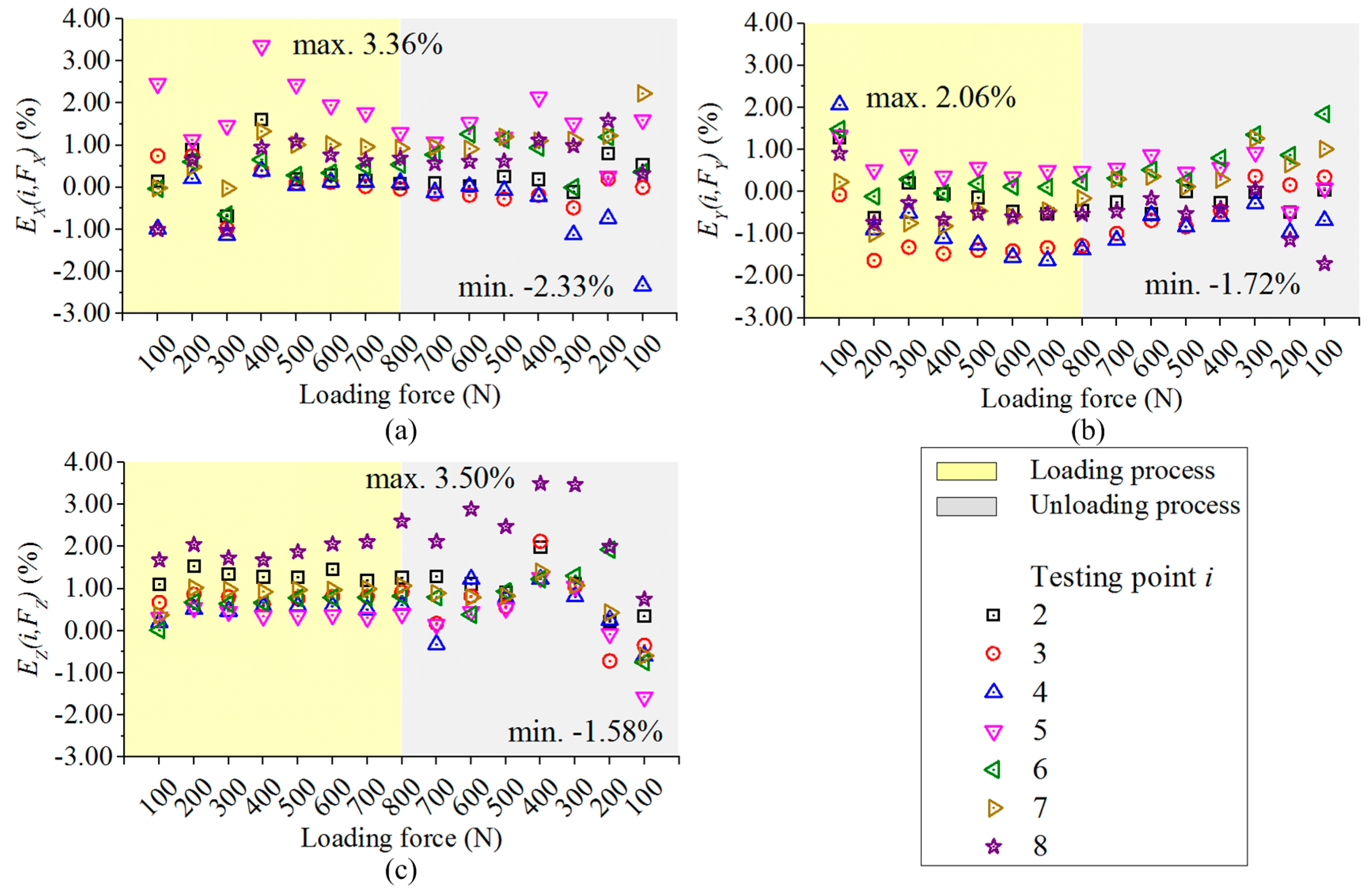

3.1.1. Output Errors of the Principal Components in Each Circuit

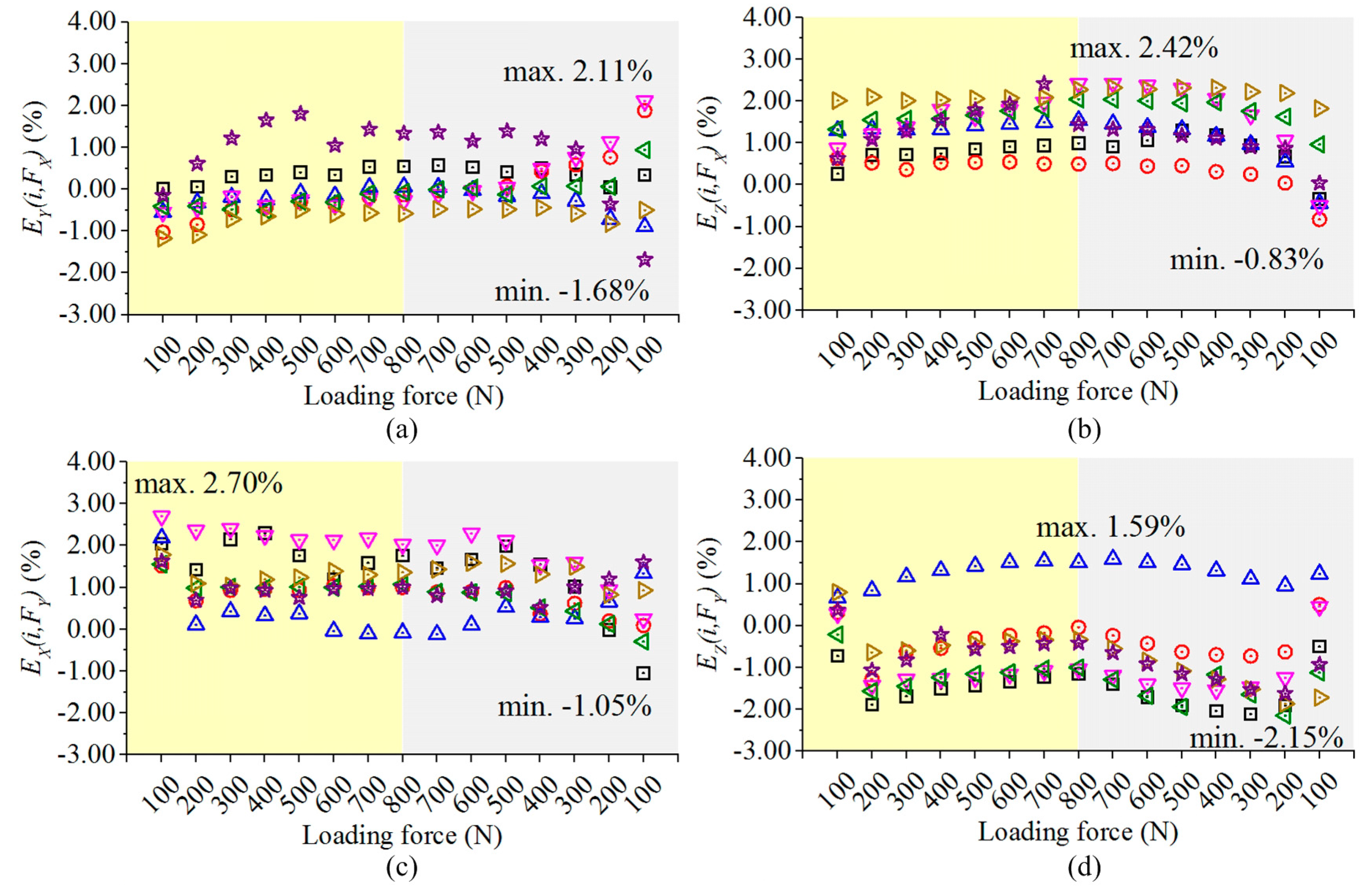

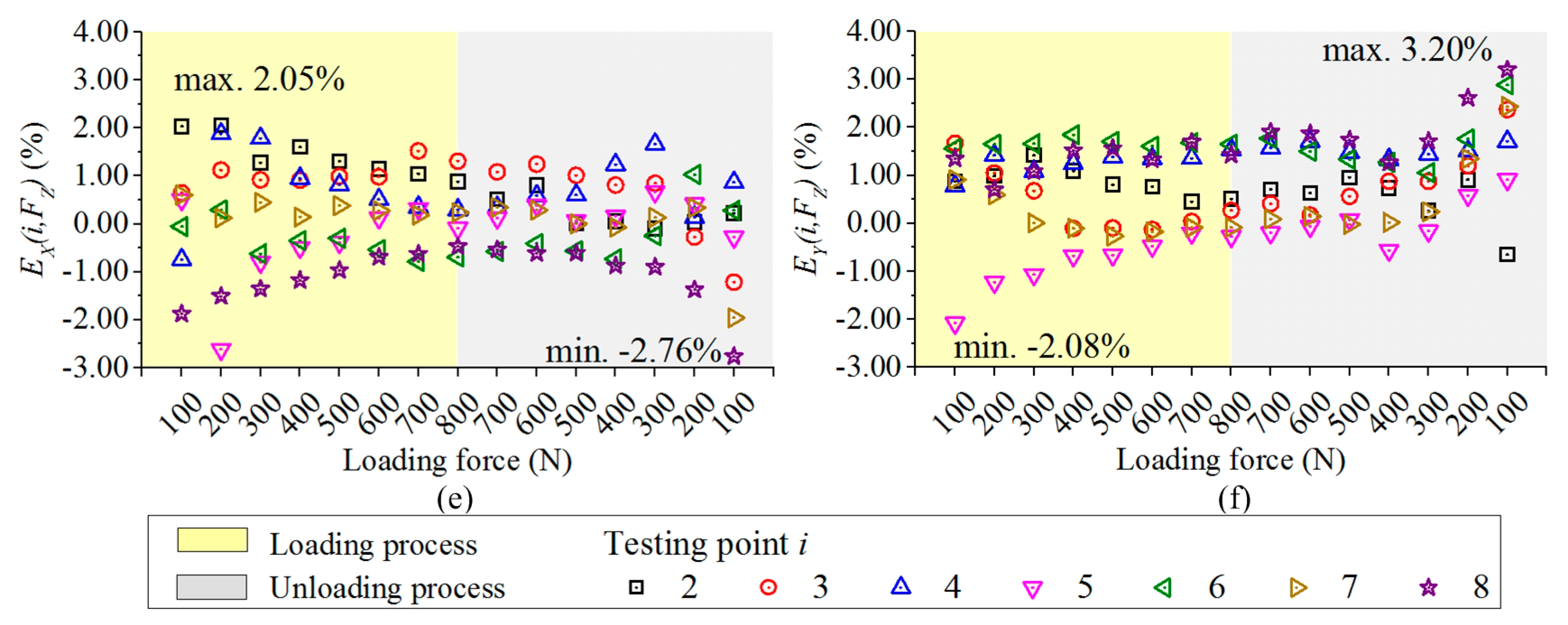

3.1.2. Output Errors of the Cross Couplings in Each Circuit

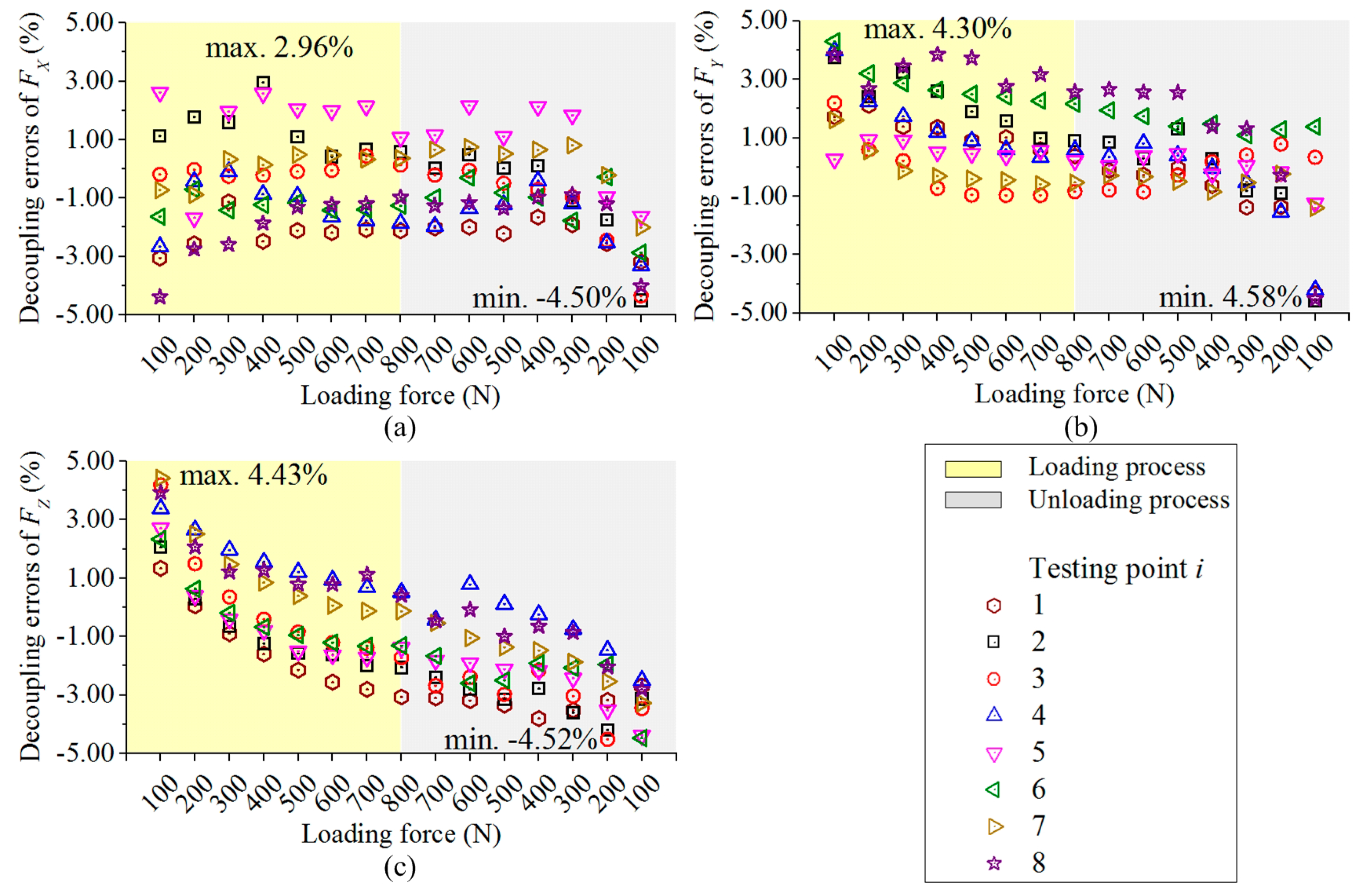

3.1.3. Static Force Decoupling

3.2. Milling Experiment

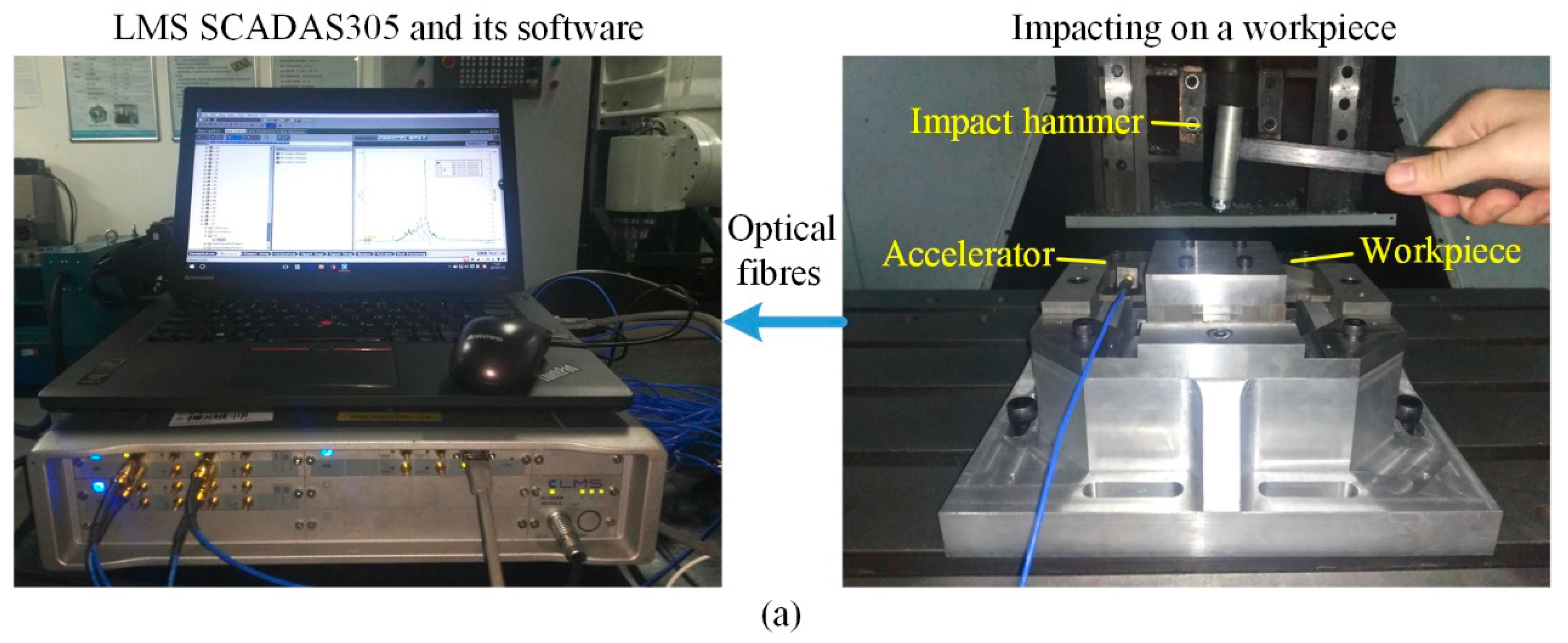

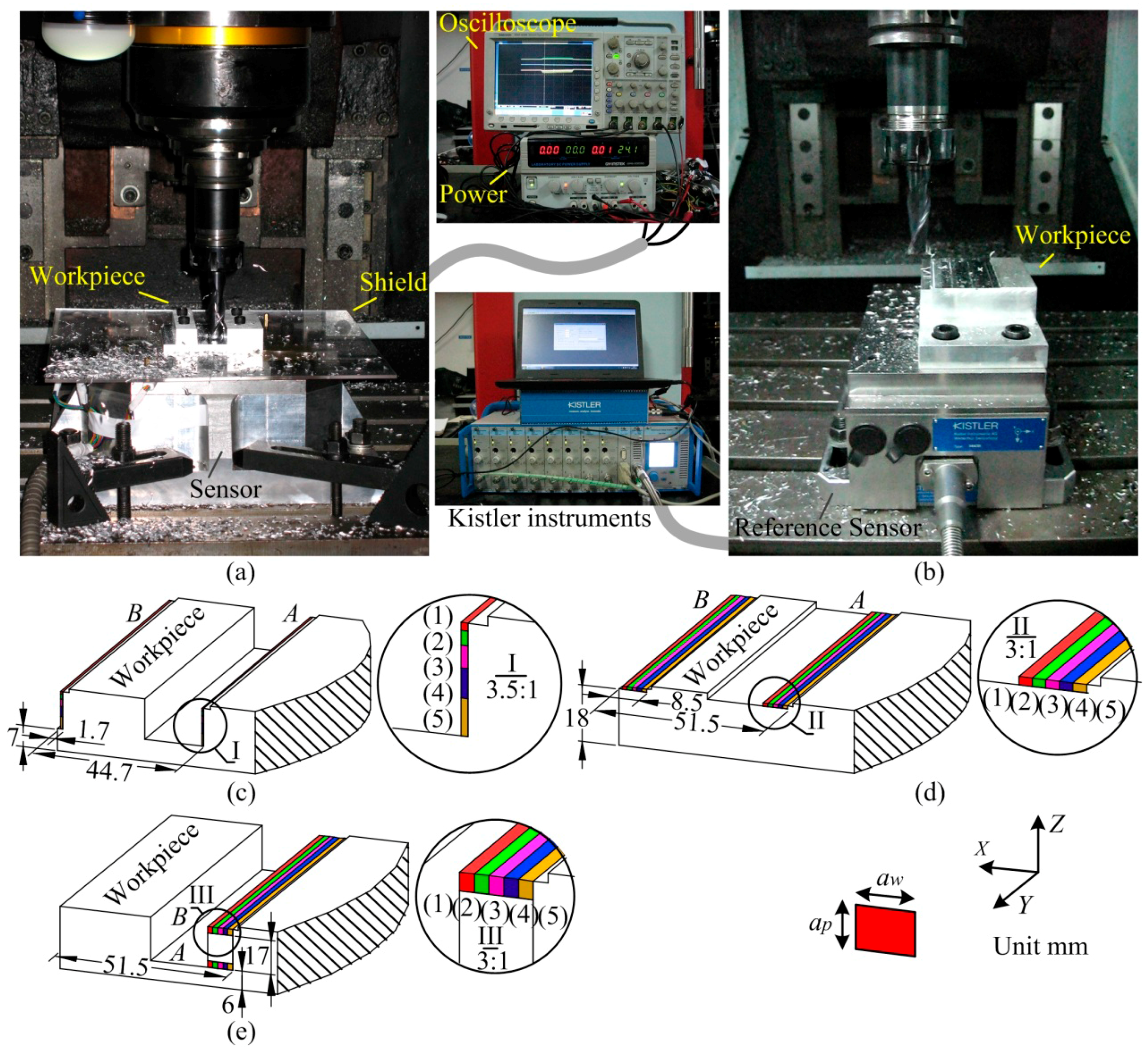

3.2.1. Resonant Frequency Identification

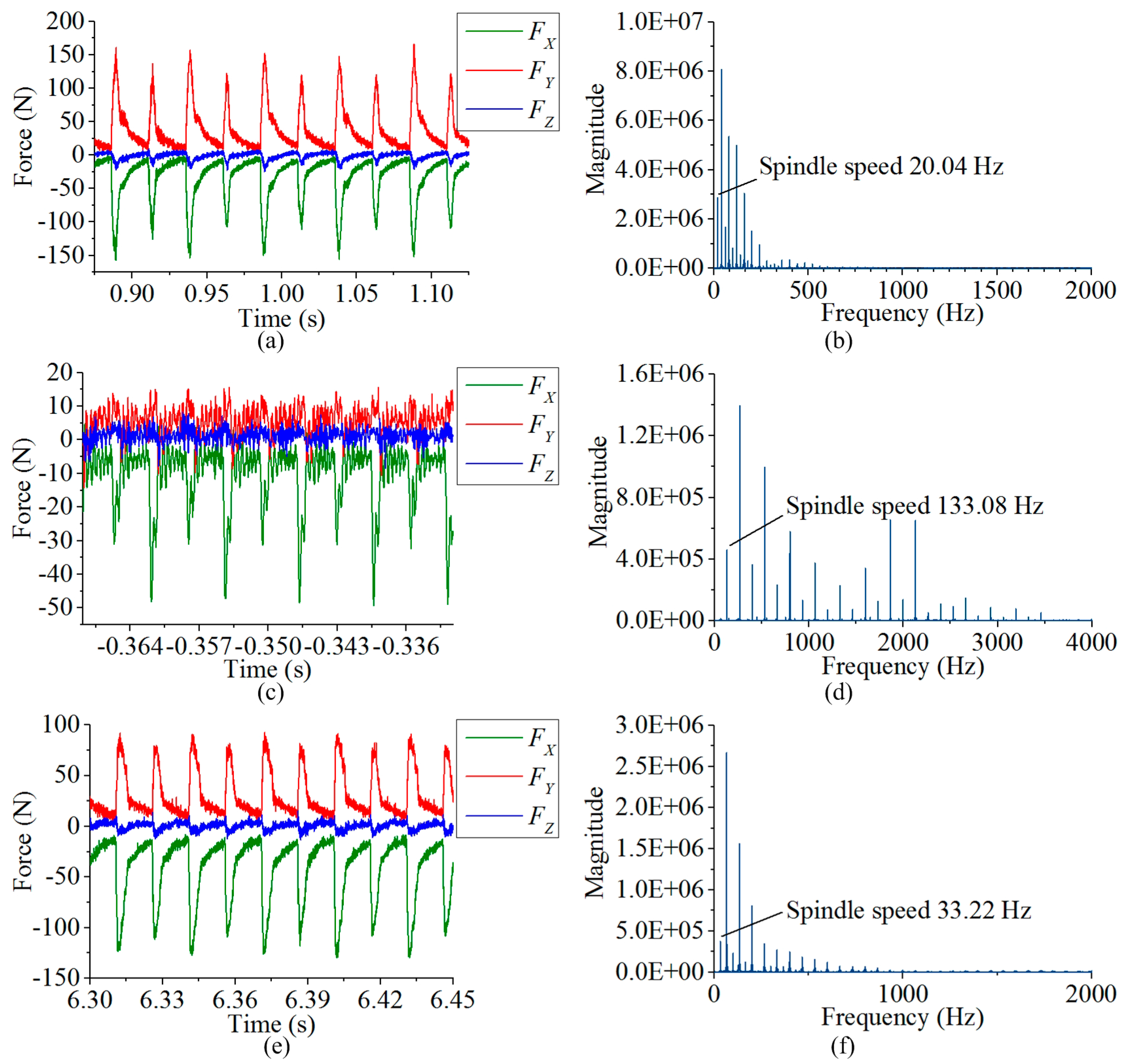

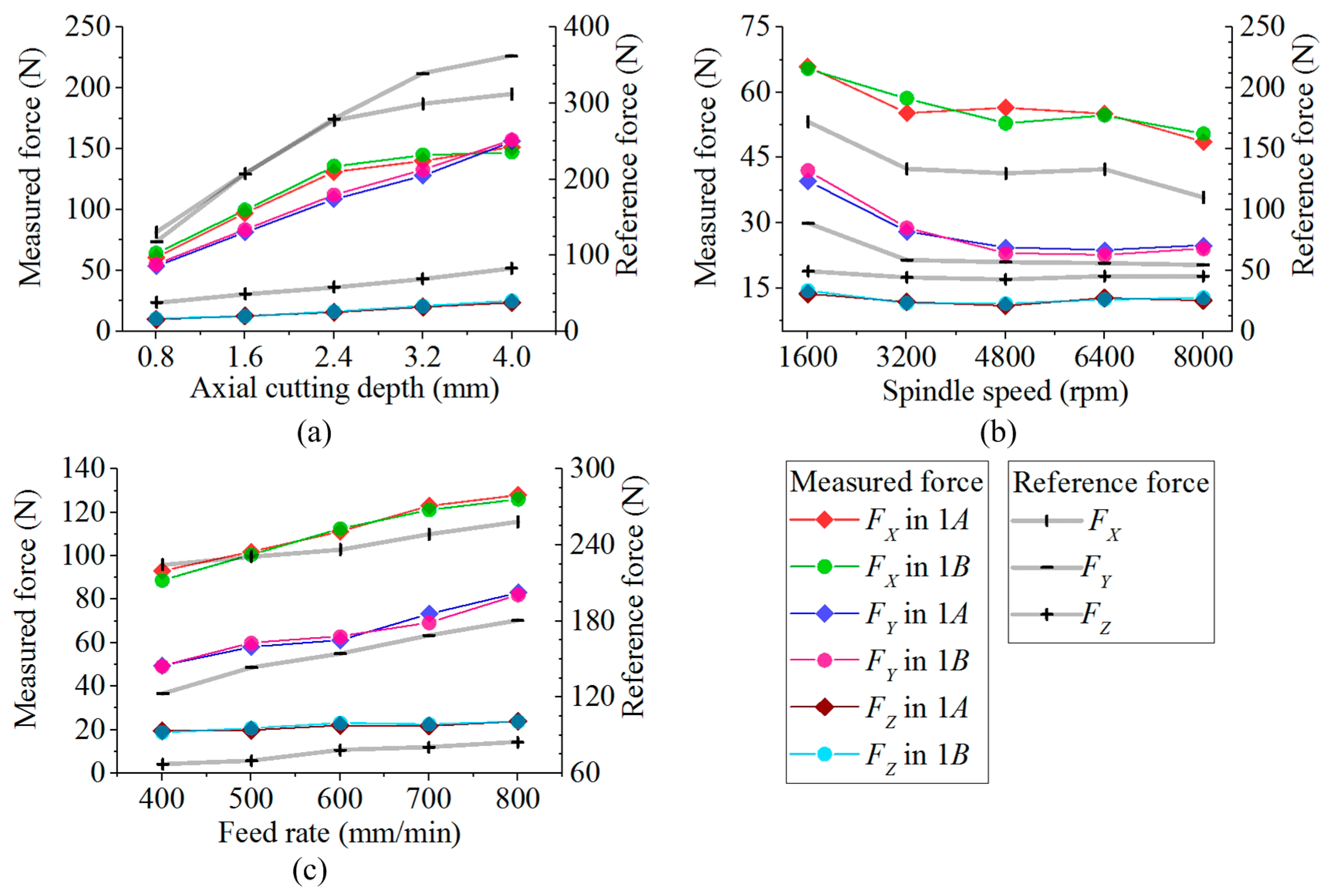

3.2.2. Milling Test and Results

3.3. Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lauro, C.H.; Brandão, L.C.; Baldo, D.; Reis, R.A.; Davim, J.P. Monitoring and processing signal applied in machining processes—A review. Measurement 2014, 58, 73–86. [Google Scholar] [CrossRef]

- Huang, S.N.; Tan, K.K.; Wong, Y.S.; de Silva, C.W.; Goh, H.L.; Tan, W.W. Tool wear detection and fault diagnosis based on cutting force monitoring. Int. J. Mach. Tools Manuf. 2007, 47, 444–451. [Google Scholar] [CrossRef]

- Segreto, T.; Simeone, A.; Teti, R. Chip form classification in carbon steel turning through cutting force measurement and principal components analysis. Proc. CIRP 2012, 2, 49–54. [Google Scholar] [CrossRef]

- Wu, H.; Chen, H.J.; Meng, P.; Yang, J.G. Modelling and real-time compensation of cutting-force-induced error on a numerical control twin-spindle lathe. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 567–577. [Google Scholar] [CrossRef]

- Antonialli, A.Í.S.; Diniz, A.E.; Pederiva, R. Vibration analysis of cutting force in titanium alloy milling. Int. J. Mach. Tools Manuf. 2010, 50, 65–74. [Google Scholar] [CrossRef]

- Liang, Q.; Zhang, D.; Wu, W.; Zhou, K. Methods and Research for Multi-Component Cutting Force Sensing Devices and Approaches in Machining. Sensors 2016, 16, 1926. [Google Scholar] [CrossRef] [PubMed]

- Hoffmann, P.; Scheer, C.; Kirchheim, A.; Schaffner, G. Spindle-integrated force sensors for monitoring drilling and milling. Processings of the 9th International Trade Fair and Conference for Sensors Transducers & Systems, Nürnberg, Germany, 18–20 May 1999; pp. 1–8. Available online: http://www.yumpu.com/en/document/view/4212100/spindle-integrated-force-sensors-kistler/3 (accessed on 24 April 2017).

- Totis, G.; Adams, O.; Sortino, M.; Veselovac, D.; Klocke, F. Development of an innovative plate dynamometer for advanced milling and drilling applications. Measurement 2014, 49, 164–181. [Google Scholar] [CrossRef]

- Rizal, M.; Ghani, J.A.; Nuawi, M.Z.; Che, H.C.H. Development and testing of an integrated rotating dynamometer on tool holder for milling process. Mech. Syst. Signal Process. 2015, 52–53, 559–576. [Google Scholar] [CrossRef]

- Qin, Y.; Zhao, Y.; Li, Y.; Zhao, Y.; Wang, P. A high performance torque sensor for milling based on a piezoresistive MEMS strain gauge. Sensors 2016, 16, 513. [Google Scholar] [CrossRef] [PubMed]

- Liang, Q.; Zhang, D.; Coppola, G.; Mao, J.; Sun, W.; Wang, Y.; Ge, Y. Design and Analysis of a Sensor System for Cutting Force Measurement in Machining Processes. Sensors 2016, 16, 70. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Sastry, C.R. Passive RF Energy Harvesting Scheme for Wireless Sensor. US Patent, US8552597, B2, 8 October 2013. [Google Scholar]

- Albertelli, P.; Goletti, M.; Torta, M.; Salehi, M.; Monno, M. Model-based broadband estimation of cutting forces and tool vibration in milling through in-process indirect multiple-sensors measurements. Int. J. Adv. Manuf. Technol. 2016, 82, 779–796. [Google Scholar] [CrossRef]

- Shaw, M.C. Metal Cutting Principles, 3rd ed.; MIT Press: Cambridge, MA, USA, 1960; pp. 4-1–4-2. [Google Scholar]

- Yaldız, S.; Ünsaçar, F.; Sağlam, H.; Işık, H. Design, development and testing of a four-component milling dynamometer for the measurement of cutting force and torque. Mech. Syst. Signal Process. 2007, 21, 1499–1511. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Y.; Fei, J.; Zhao, Y.; Li, X.; Gao, Y. Development of a tri-axial cutting force sensor for the milling process. Sensors 2016, 16, 405. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Zhao, W.; He, N.; Li, L. Design of high frequency three-dimensional dynamic milling force test platform. J. Nanjing Univ. Aeronaut. Astronaut. 2012, S1, 154–156. [Google Scholar]

- Huang, Z.; Zhao, W. Theoretical calculation and experimental analyses of natural frequency for high frequency dynamometer. China Mech. Eng. 2015, 26, 7–11. [Google Scholar]

- Huang, Z. Structure Design and Experimental Study of High Frequency Dynamometer. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2014; pp. 30–37. Available online: http://cdmd.cnki.com.cn/Article/CDMD-10287-1014061417.htm (accessed on 24 April 2017). (In Chinese).

- Wang, W.; Zhao, Y.; Lin, Q.; Yuan, G. A three-axial micro-force sensor based on MEMS technology. Int. J. Appl. Electromagn. Mech. 2010, 33, 991–999. [Google Scholar]

- Zhao, Y.; Zhao, Y.; Liang, S.; Zhou, G. A high performance sensor for triaxial cutting force measurement in turning. Sensors 2015, 15, 7969–7984. [Google Scholar] [CrossRef] [PubMed]

| Additional Moment M | ||||||

|---|---|---|---|---|---|---|

| Moment decomposition | MX | MY | MZ | |||

| Applied force component | FY | FZ | FX | FZ | FX | FY |

| Force bearing point moving direction | Z | Y | Z | X | Y | X |

| Material | Structural Steel | Finite Element Type | Solid 186 | Mesh Size | 2 mm |

|---|---|---|---|---|---|

| MY = 28 Nm | Supposing FZ 800 N, force bearing point moves 35 mm in X direction. | ||||

| Dimensions (mm3) | Sensor center plate | 88 × 88 × 25 | |||

| Horizontal beams | 12 × 4 × 36 | Vertical bemas | 6 × 4 × 36 | ||

| Distance between the axis of the horizontal beam and the top surface of the workpiece (HH) | 13 mm | ||||

| HH (mm) | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 17 | 19 | 21 | 23 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| θ (10−30) | 4.459 | 4.481 | 4.495 | 4.507 | 4.516 | 4.525 | 4.533 | 4.539 | 4.541 | 4.539 | 4.530 |

| σr (10−1 MPa) | 8.026 | 8.004 | 7.796 | 7.534 | 7.256 | 6.996 | 6.741 | 6.576 | 6.548 | 6.655 | 7.439 |

| Loading Point | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

| FX | Linearity error (%) | −0.73 | −0.64 | −0.77 | −0.65 | 0.96 | −0.19 | 0.26 | 0.19 |

| Hysteresis error (%) | 0.26 | 0.23 | 0.27 | 0.24 | 0.35 | 0.17 | 0.09 | 0.17 | |

| Repeatability error (%) | 0.76 | 0.40 | 0.39 | 0.25 | 0.60 | 0.71 | 0.52 | 0.81 | |

| FY | Linearity error (%) | 0.57 | 0.31 | −0.72 | −0.82 | 1.05 | 0.80 | 0.41 | −0.34 |

| Hysteresis error (%) | 0.21 | 0.11 | 0.26 | 0.30 | 0.38 | 0.29 | 0.15 | 0.38 | |

| Repeatability error (%) | 0.67 | 0.65 | 0.63 | 0.82 | 0.61 | 0.28 | 0.34 | 0.37 | |

| FZ | Linearity error (%) | −1.55 | −0.48 | −0.95 | −1.30 | −1.18 | −0.84 | −0.62 | 1.01 |

| Hysteresis error (%) | 0.58 | 0.18 | 0.36 | 0.49 | 0.44 | 0.31 | 0.23 | 0.38 | |

| Repeatability error (%) | 0.66 | 0.62 | 0.46 | 0.81 | 0.43 | 0.60 | 0.56 | 0.61 |

| Test Groups | Test Series | Subtests | ap (mm) | aw (mm) | vf (mm/min) | n (rpm) | Workpiece Sizes (mm3) | Cutting Material |

|---|---|---|---|---|---|---|---|---|

| 1 | (1) | A and B | 0.8 | 0.7 | 200 | 1200 | 88 × 88 × 20 | AISI 1045 |

| (2) | A and B | 1.6 | 0.7 | 200 | 1200 | |||

| (3) | A and B | 2.4 | 0.7 | 200 | 1200 | |||

| (4) | A and B | 3.2 | 0.7 | 200 | 1200 | |||

| (5) | A and B | 4.0 | 0.7 | 200 | 1200 | |||

| 2 | (1) | A and B | 1 | 1.5 | 400 | 1600 | 88 × 88 × 20 | Aluminum alloy 6061 |

| (2) | A and B | 1 | 1.5 | 400 | 3200 | |||

| (3) | A and B | 1 | 1.5 | 400 | 4800 | |||

| (4) | A and B | 1 | 1.5 | 400 | 6400 | |||

| (5) | A and B | 1 | 1.5 | 400 | 8000 | |||

| 3 | (1) | A and B | 2 | 1.5 | 400 | 2000 | 88 × 88 × 20 | Aluminum alloy 6061 |

| (2) | A and B | 2 | 1.5 | 500 | 2000 | |||

| (3) | A and B | 2 | 1.5 | 600 | 2000 | |||

| (4) | A and B | 2 | 1.5 | 700 | 2000 | |||

| (5) | A and B | 2 | 1.5 | 800 | 2000 |

| Test Group 1 | Test Group 2 | Test Group 3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| FX | FY | FZ | FX | FY | FZ | FX | FY | FZ | ||

| R | Subtest A | 0.9986 | 0.9823 | 0.9964 | 0.9865 | 0.9819 | 0.9569 | 0.9816 | 0.9780 | 0.9711 |

| Subtest B | 0.9986 | 0.9878 | 0.9927 | 0.9511 | 0.9693 | 0.9666 | 0.9573 | 0.9763 | 0.9505 | |

| Test Series | Test Group 1 | Test Group 2 | Test Group 3 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| FX | FY | FZ | FX | FY | FZ | FX | FY | FZ | ||

| Differences (%) | (1) | 5.86 | 2.87 | 5.49 | 0.06 | 6.03 | 5.53 | −4.76 | −0.07 | −3.68 |

| (2) | 2.73 | 2.27 | −2.26 | 6.14 | 3.27 | −2.46 | −1.36 | 2.97 | 4.46 | |

| (3) | 3.55 | 3.12 | 4.23 | −6.29 | −5.09 | 4.35 | 1.08 | 2.60 | 5.28 | |

| (4) | 3.70 | 3.66 | 3.59 | −0.06 | −4.51 | −2.70 | −1.46 | −5.73 | 3.65 | |

| (5) | −2.79 | 0.08 | 6.21 | 3.77 | −2.83 | 5.14 | −1.44 | −1.32 | −0.05 | |

| Related Researches | Forces | Decoupling Performances | |||||

|---|---|---|---|---|---|---|---|

| Principal Components | Decoupling Components | Decoupling Results | |||||

| Eccentric Range (LX, LY, LZ) (mm) | Output Error (%) | Eccentric Range (LX, LY, LZ) (mm) | Output Error (%) | Eccentric Range (LX, LY, LZ) (mm) | Meaured Error (%) | ||

| [15] | FX | (50, 50, 50) | 0.18 | / | / | / | / |

| FY | 0.18 | ||||||

| FZ | 1.28 | ||||||

| F1 | / | / | / | / | (0, 0, 0) | 1.49 (static test) | |

| [21] | FX | / | / | (8, 12, 31) | 4.74, 4.09,2 | / | / |

| FY | 2.58, 5.38 | ||||||

| FZ | 7.33,10.51 | ||||||

| [17,18,19] | FX | / | / | / | / | (10, 10, <20) | 8–9,3 |

| FY | 20–35 | ||||||

| FZ | 60–90 (milling test) | ||||||

| [16] | FX | (35, 35, 15) | ≤5.2 | (35, 35, 15) | ≤3.94 | (35, 35, 15) | ≤4.80 |

| FY | ≤5.6 | ≤2.98 | ≤4.58 | ||||

| FZ | ≤4.8 | ≤3.48 | ≤4.87 (static test) | ||||

| This work | FX | (35, 35, 15) | ≤3.36 | (35, 35, 15) | ≤2.42 | (35, 35, 15) | ≤4.50 |

| FY | ≤2.06 | ≤2.70 | ≤4.58 | ||||

| FZ | ≤3.50 | ≤3.20 | ≤4.52 (static test) | ||||

| F | / | / | / | / | (35, 35, 15) | ≤4.07 | |

| Elastic Beams | [15] | [21] | [17,18,19] | [16] | |

|---|---|---|---|---|---|

| Structure | Octagonal rings | Parallel vertical beams | Cross beam | This work | |

| Material | AISI 4140 | AISI 1045 | 6061 | AISI 630 | |

| Sensor type | Milling table sensor | Turning sensor | Milling table sensor | ||

| Sensor resonance frequency | |||||

| Upper plate | |||||

| size (mm3) | 245 × 270 × 25 | / | 48 × 48 × 4 | 88 × 88 × 20 | 88 × 88 × 25 |

| Material | Unknown | / | 6061 | AISI 630 | AISI 630 |

| Clamp | |||||

| Dimensions (mm3) | / | 16 ×16 ×100 (turning tool) | / | 88 × 88 × 15 (workpiece) | 88 × 88 × 20 (workpiece) |

| Material | / | Steel | / | AISI 1045 | AISI 1045 |

| Resonance frequency (Hz) | ≥1200 | ≥1122 | ≥9106 | ≥680 | ≥1663.5 |

| Sensor sensitivity | |||||

| Circuit amplification | Unknown | 1 | 1 | 1 | 1 |

| Output sensitivity FX, FY, FZ (10-3 mV/N/V) | 3.61 | 1.06 | 0.088 | 1.72 | 2.68 |

| 3.47 | 1.14 | 0.154 | 1.71 | 2.67 | |

| 1.81 (Static test) | 0.18 (Static test) | 0.105 (Dynamic test) | 12.50 (Static test) | 2.16 (Static test) | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhao, Y.; Fei, J.; Qin, Y.; Zhao, Y.; Cai, A.; Gao, S. Design and Development of a Three-Component Force Sensor for Milling Process Monitoring. Sensors 2017, 17, 949. https://doi.org/10.3390/s17050949

Li Y, Zhao Y, Fei J, Qin Y, Zhao Y, Cai A, Gao S. Design and Development of a Three-Component Force Sensor for Milling Process Monitoring. Sensors. 2017; 17(5):949. https://doi.org/10.3390/s17050949

Chicago/Turabian StyleLi, Yingxue, Yulong Zhao, Jiyou Fei, Yafei Qin, You Zhao, Anjiang Cai, and Song Gao. 2017. "Design and Development of a Three-Component Force Sensor for Milling Process Monitoring" Sensors 17, no. 5: 949. https://doi.org/10.3390/s17050949

APA StyleLi, Y., Zhao, Y., Fei, J., Qin, Y., Zhao, Y., Cai, A., & Gao, S. (2017). Design and Development of a Three-Component Force Sensor for Milling Process Monitoring. Sensors, 17(5), 949. https://doi.org/10.3390/s17050949