Discontinuity Detection in the Shield Metal Arc Welding Process

Abstract

:1. Introduction

2. Materials and Methods

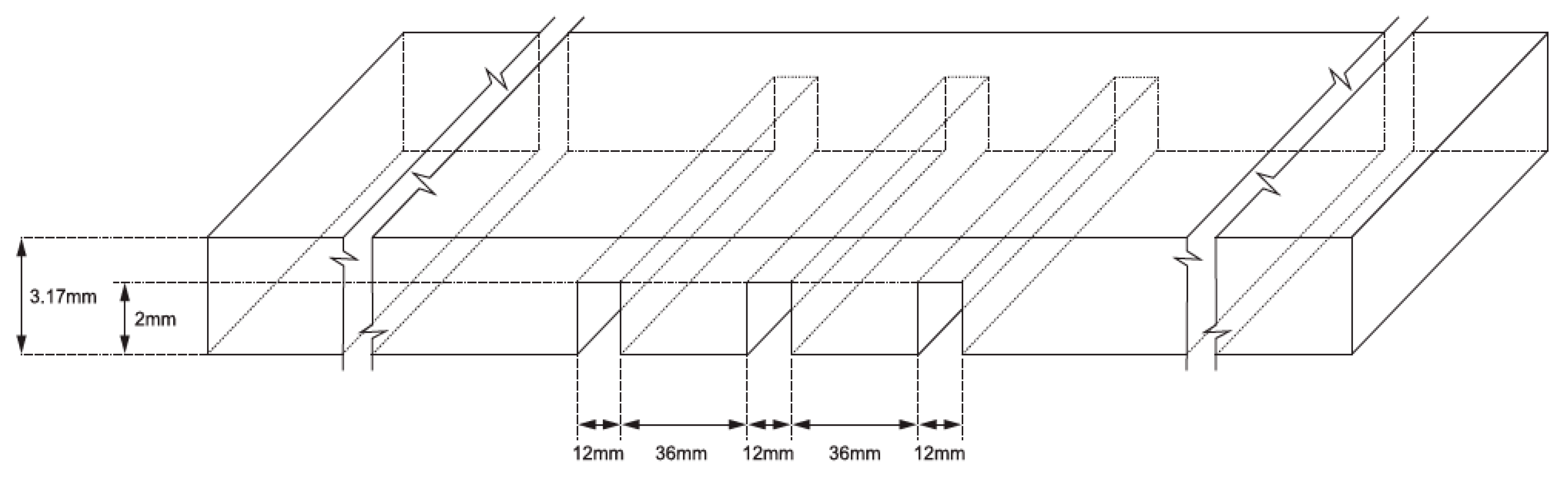

2.1. Experimental Setup

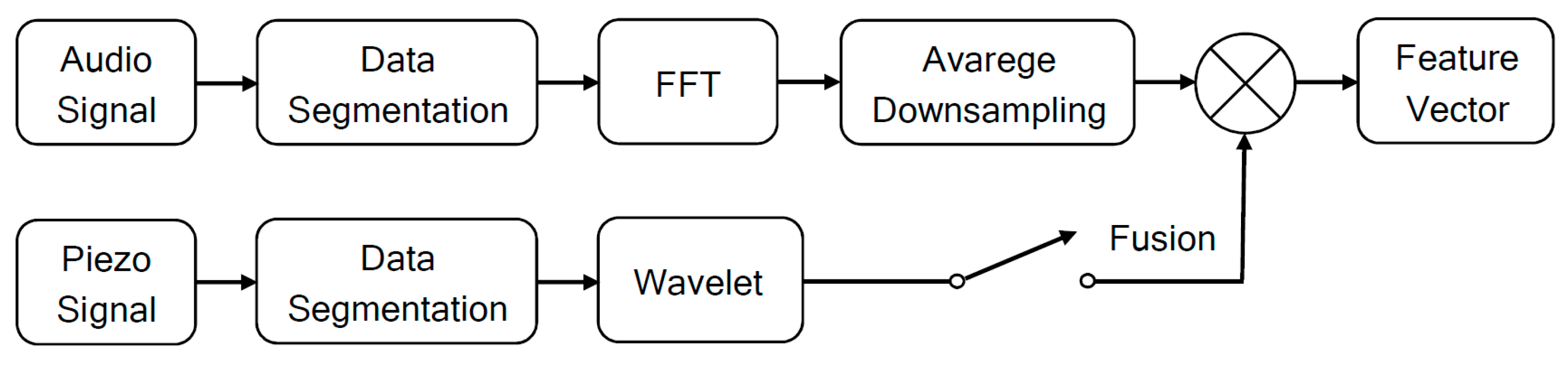

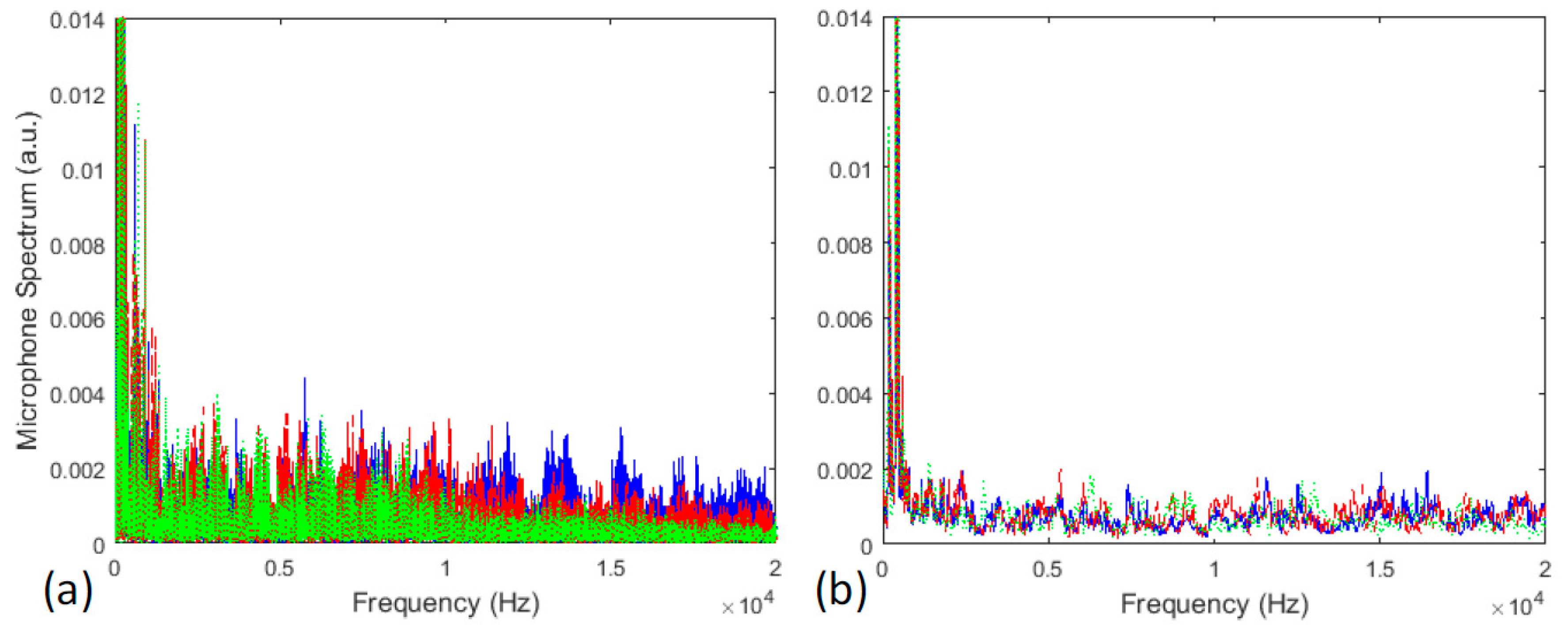

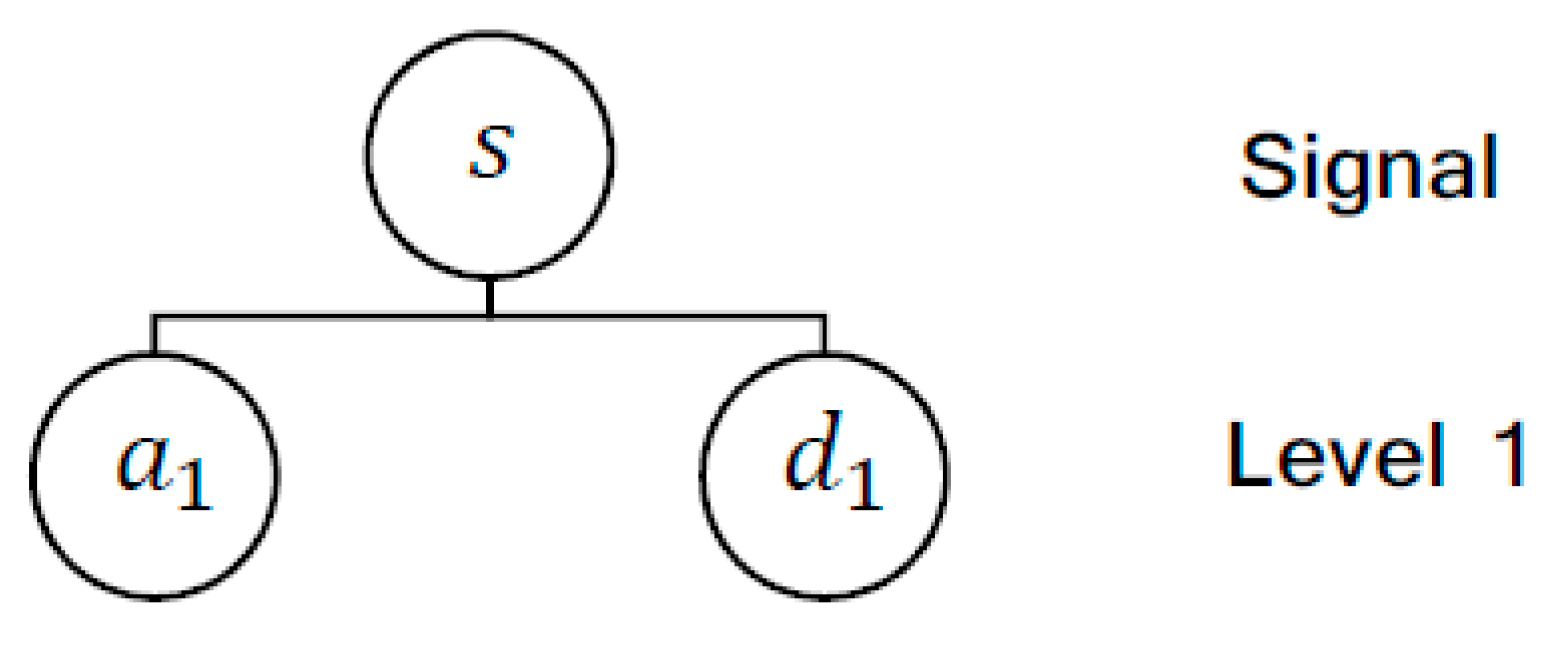

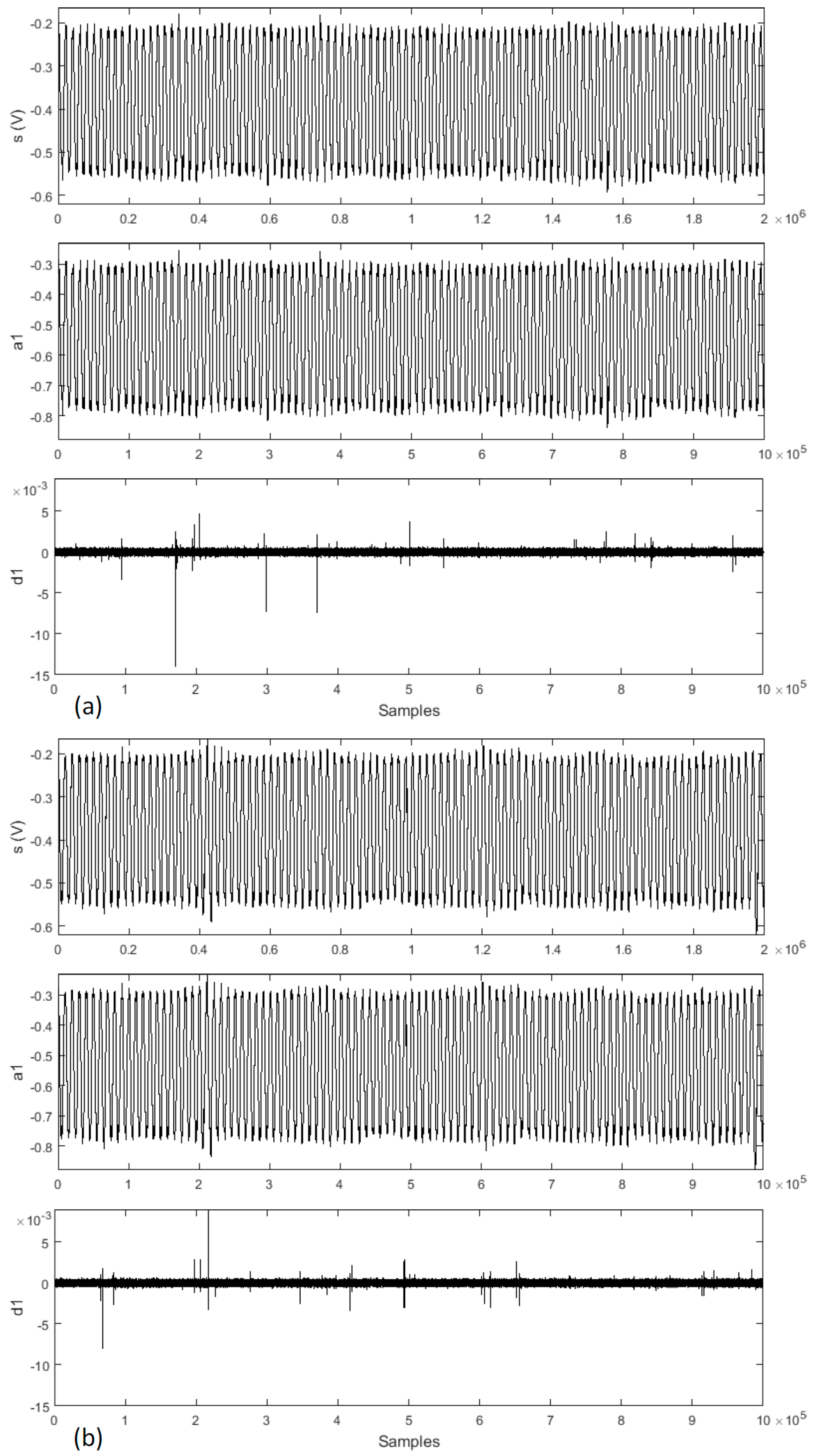

2.2. Feature Extraction

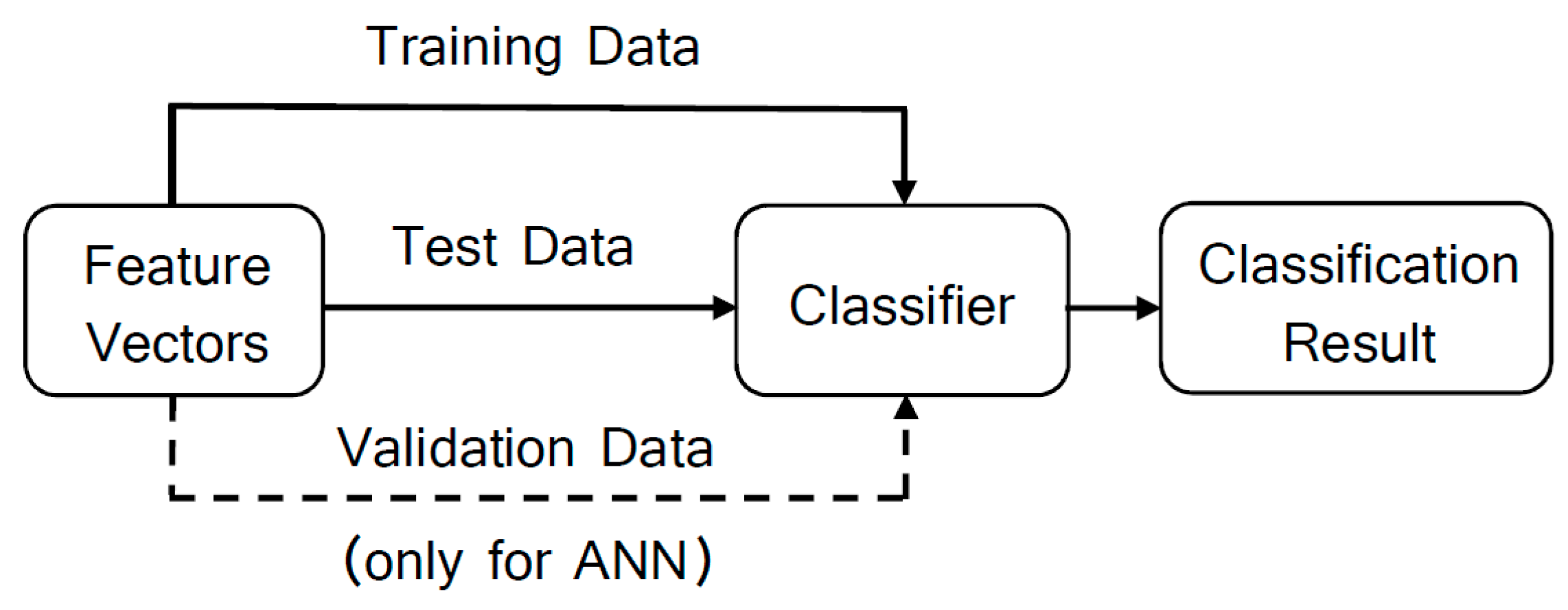

2.3. Classifiers

2.3.1. Support Vector Machine

2.3.2. Artificial Neural Networks

3. Results and Discussion

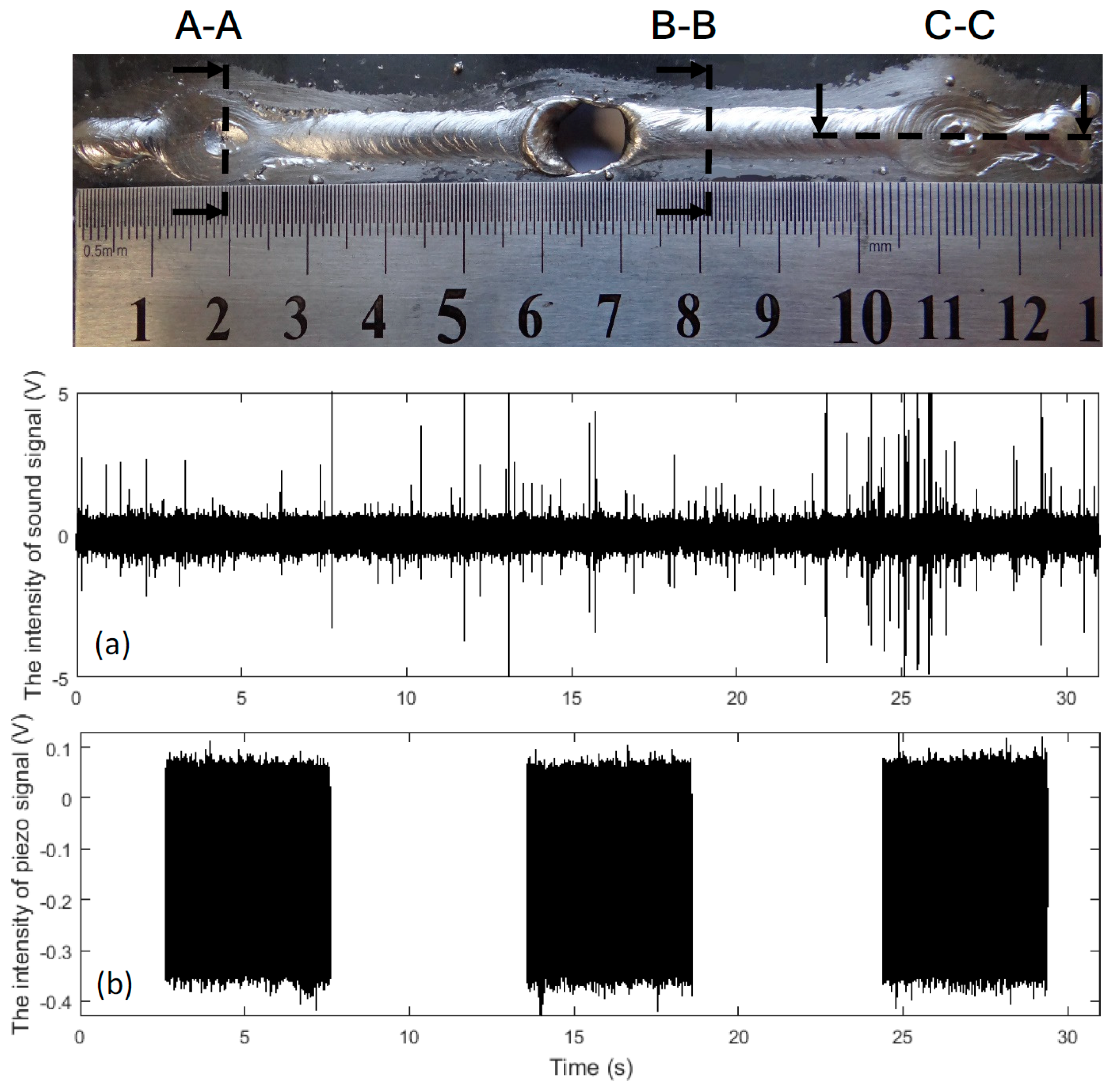

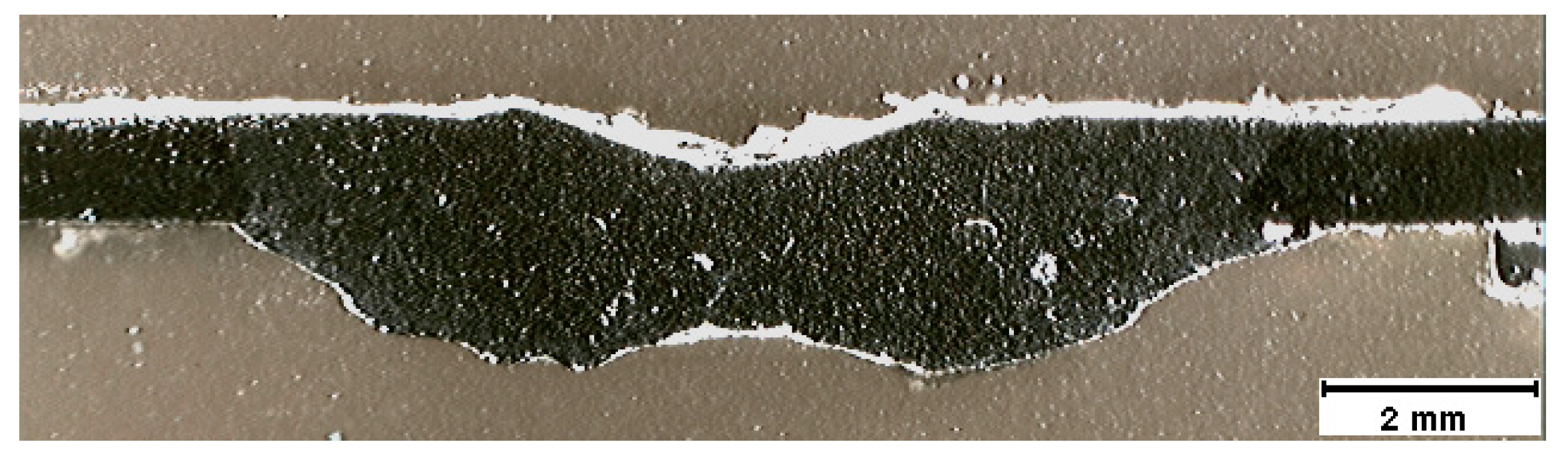

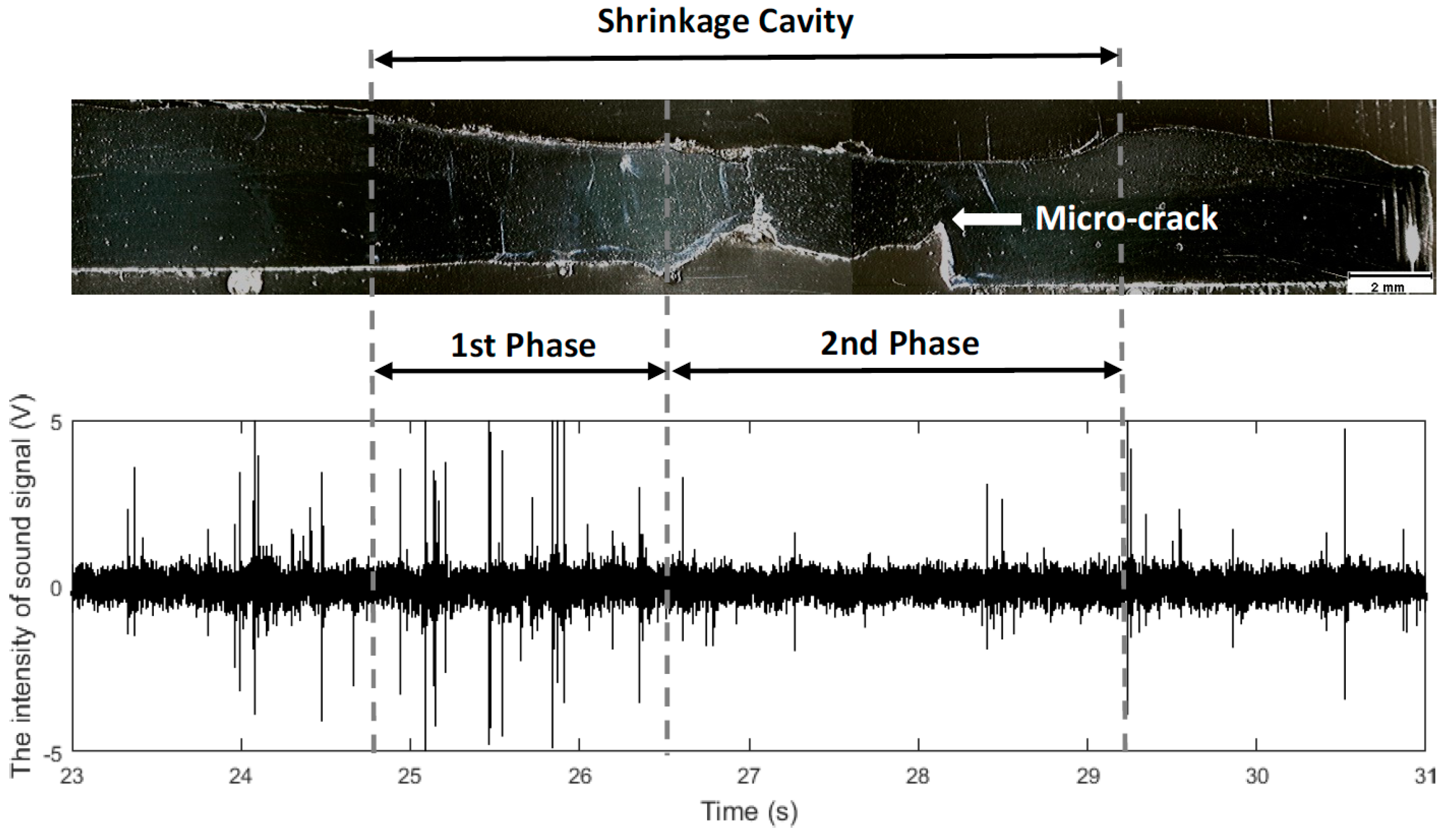

3.1. Weld Bead Characteristics

3.2. Classification

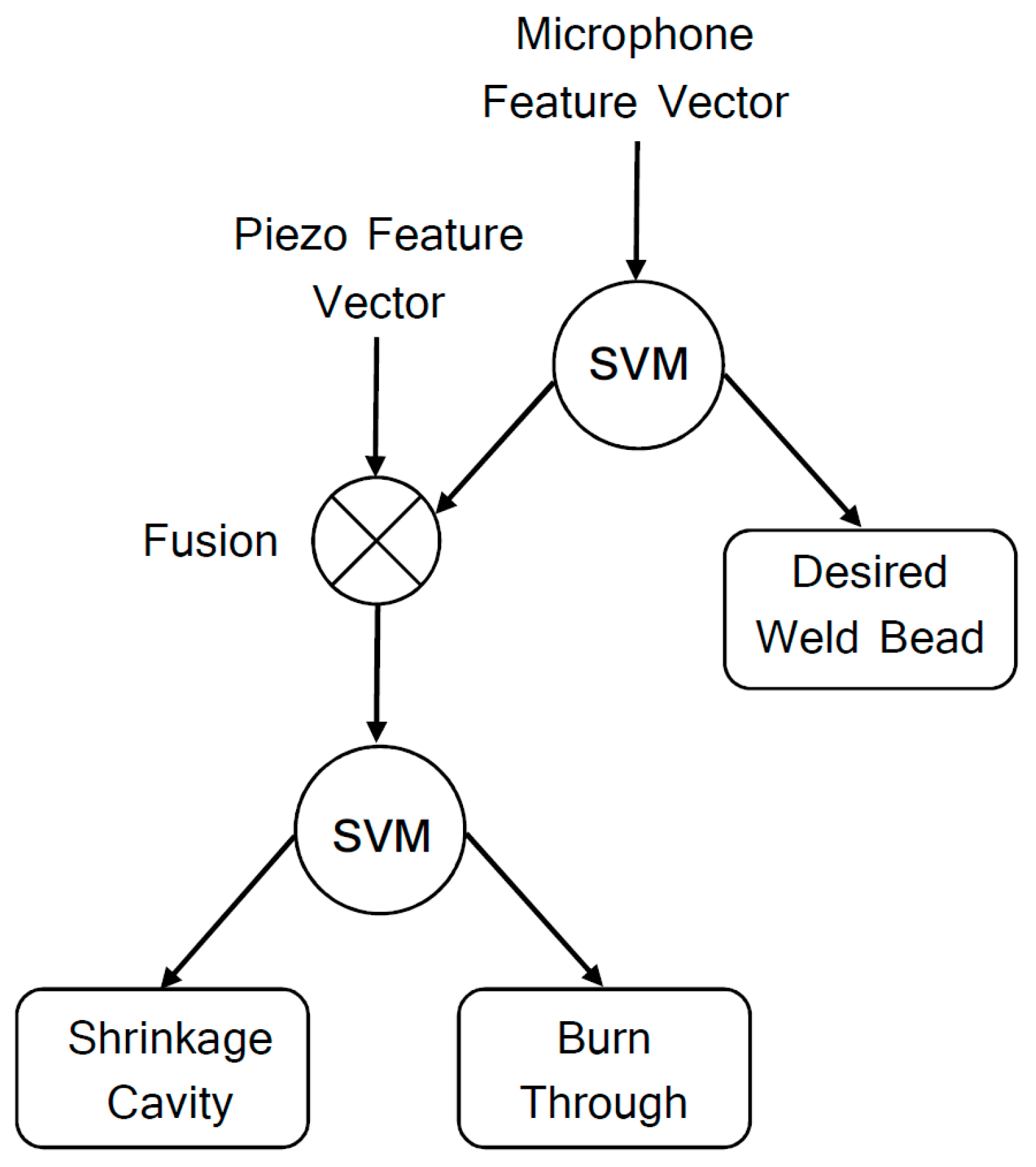

3.2.1. Support Vector Machine

3.2.2. Artificial Neural Networks

3.2.3. Classification Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- O’Brien, A. (Ed.) AWS Welding Handbook, 9th ed.; American Welding Society: Doral, FL, USA, 2004; Volume 2, p. 52. [Google Scholar]

- Paul, A.K. Robust Product Design Using SOSM for Control of Shielded Metal Arc-Welding (SMAW) Process. IEEE Trans. Ind. Electron. 2016, 63, 3717–3724. [Google Scholar] [CrossRef]

- Lima, E.J., II; Bracarense, A.Q. Robotic Shielded Metal Arc Welding. Weld. J. 2010, 89, 166–171. [Google Scholar]

- Paul, A.K. Sliding Surface in 1-Sliding Boosts Multi-objective Optimization Program of Shielded Metal Arc Welding Process. In Proceedings of the International Conference on Advanced Electronic Systems, Pilani, India, 21–23 September 2013; IEEE: Danvers, MA, USA, 2013; pp. 39–44. [Google Scholar]

- Shi, Y.; Zhang, G.; Ma, X.J.; Gu, Y.F.; Huang, J.K.; Fan, D. Laser-Vision-Based Measurement and Analysis of Weld Pool Oscillation Frequency in GTAW-P. Weld. J. 2015, 94, 176–186. [Google Scholar]

- Krolczyk, G.M.; Nieslony, P; Krolczyk, J.B.; Samardzic, I.; Legutko, S.; Hloch, S. Influence of Argon Pollution on the Weld Surface Morphology. Measurement 2015, 70, 203–213. [Google Scholar] [CrossRef]

- You, D.; Gao, X.; Katayama, S. Multisensor Fusion System for Monitoring High-Power Disk Laser Welding Using Support Vector Machine. IEEE Trans. Ind. Inform. 2014, 10, 1285–1295. [Google Scholar]

- Ao, S.; Luo, Z.; Zhao, N.; Wang, R. Blind Source Separation based on Principal Component Analysis—Independent Component Analysis for Acoustic Signal during Laser Welding Process. In Proceedings of the International Conference on Digital Manufacturing and Automation, ChangSha, China, 18–20 December 2010; IEEE: Danvers, MA, USA, 2010; pp. 39–44. [Google Scholar]

- Alfaro, S.C.A.; Cayo, E.H. Sensoring Fusion Data from the Optic and Acoustic Emissions of Electric Arcs in the GMAW-S Process for Welding Quality Assessment. Sensors 2012, 12, 6953–6966. [Google Scholar] [CrossRef] [PubMed]

- Apasov, A.M.; Apasov, A.A. Acoustic Emission Diagnostics of Fault Fusion in Welding. In Proceedings of the International Forum on Strategic Technology, Tomsk, Russia, 18–21 September 2012; IEEE: Danvers, MA, USA, 2012; pp. 1–5. [Google Scholar]

- Manjula, K.; Vijayarekha, K.; Venkatraman, B.; Karthik, D. Ultrasonic Time of Flight Diffraction Technique for Weld Defects: A Review. Res. J. Appl. Sci. Eng. Technol. 2012, 24, 5525–5533. [Google Scholar]

- Andersen, K.; Cook, G.E.; Karsai, G.; Ramaswamy, K. Artificial Neural Networks Applied to Arc Welding Process Modeling and Control. IEEE Trans. Ind. Appl. 1990, 26, 824–830. [Google Scholar] [CrossRef]

- Cook, G.E.; Barnett, R.J.; Andersen, K.; Strauss, A.M. Weld Modeling and Control Using Artificial Neural Networks. IEEE Trans. Ind. Appl. 1995, 31, 1484–1491. [Google Scholar] [CrossRef]

- Nagesh, D.S.; Datta, G.L. Prediction of Weld Bead Geometry and Penetration in Shielded Metal-Arc Welding Using Artificial Neural Networks. J. Mater. Proc. Tech. 2002, 123, 303–312. [Google Scholar] [CrossRef]

- Sterjovski, Z.; Pitrun, M.; Nolan, D.; Dunne, D.; Norrish, J. Artificial Neural Networks for Predicting Diffusible Hydrogen Content and Cracking Susceptibility in Rutile Flux-cored Arc Welds. J. Mater. Proc. Tech. 2007, 184, 420–427. [Google Scholar]

- Mirapeix, J.; García-Allende, P.B.; Cobo, A.; Conde, O.M.; Lopez-Higuera, J.M. Real-time Arc-welding Defect Detection and Classification with Principal Component Analysis and Artificial Neural Networks. NDT E Int. 2007, 40, 315–323. [Google Scholar] [CrossRef]

- Garcia-Allende, P.B.; Mirapeix, J.; Conde, O.M.; Cobo, A.; Lopez-Higuera, J.M. Arc-Welding Spectroscopic Monitoring based on Feature Selection and Neural Networks. Sensors 2008, 8, 6496–6506. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Chandrasekhar, N.; Albert, S.K.; Jayapandian, J. Analysis of Arc Welding Process Using Digital Storage Oscilloscope. Measurement 2016, 81, 1–12. [Google Scholar] [CrossRef]

- Ancona, A.; Maggipinto, T.; Spagnolo, V.; Ferrara, M.; Lugara, P.M. Optical Sensor for Real Time Weld Defects Detection. Proc. SPIE 2002, 4669, 217–226. [Google Scholar]

- Mirapeix, J.; Cobo, A.; Fuentes, J.; Davila, M.; Etayo, J.M.; Lopez-Higuera, J.M. Use of the Plasma Spectrum RMS Signal for Arc-Welding Diagnostics. Sensors 2009, 9, 5263–5276. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wu, D.; Zhang, Z.; Chen, H.; Chen, S. EMD-based pulsed TIG welding process porosity defect detection and defect diagnosis using GA-SVM. J. Mater. Proc. Tech. 2017, 239, 92–102. [Google Scholar] [CrossRef]

- Rocha, F.A.S.; Serrantola, W.G.; Lopez, G.N.; Torga, D.S.; de Carvalho, M.A.; de Souza, G.P.; Cocota, J.A.N., Jr.; Rêgo Segundo, A.K. Retrofitting of a XY Table. In Proceedings of the XII Brazilian Symposium on Intelligent Automation, Natal, Brazil, 25–28 October 2015; pp. 1931–1936. [Google Scholar]

- Kumar, G.S.; Natarajan, U.; Veerarajan, T.; Ananthan, S.S. Quality Level Assessment for Imperfections in GMAW. Weld. J. 2014, 93, 85–97. [Google Scholar]

- Giannakopoulos, T.; Pikrakis, A. Introduction to Audio Analysi, 1st ed.; Academic Press: San Diego, CA, USA, 2014; pp. 59–148. [Google Scholar]

- Wersborg, I.S.G.; Bautze, T.; Born, F.; Diepold, K. A cognitive approach for a robotic welding system that can learn how to weld from acoustic data. In Proceedings of the International Conference on Computational Intelligence in Robotics and Automation, Daejeon, Korea, 15–18 December 2009; IEEE: Danvers, MA, USA, 2009; pp. 1–6. [Google Scholar]

- Sibillano, T.; Ancona, A.; Rizzi, D.; Lupo, V.; Tricarico, L. Plasma Plume Oscillations Monitoring during Laser Welding of Stainless Steel by Discrete Wavelet Transform Application. Sensors 2010, 10, 3549–3561. [Google Scholar] [CrossRef] [PubMed]

- You, D.; Gao, X.; Katayama, S. PD-PCA-Based Laser Welding Process Monitoring and Defects Diagnosis by Using FNN and SVM. IEEE Trans. Ind. Electron. 2015, 62, 628–636. [Google Scholar] [CrossRef]

- Li, X.R.; Shao, Z.; Zhang, Y.M.; Kvidahl, L. Monitoring and Control of Penetration in GTAW and Pipe Welding. Weld. J. 2013, 92, 190–196. [Google Scholar]

- Kannatey-Asibu, E., Jr. Principles of Laser Materials Processing, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2009; pp. 281–327. [Google Scholar]

- Molino, A.; Martina, M.; Vacca, F.; Masera, G.; Terreno, A.; Pasquettaz, G.; D’Angelo, G. FPGA implementation of time-frequency analysis algorithms for laser welding monitoring. J. Microprocess. Microsyst. 2009, 33, 179–190. [Google Scholar] [CrossRef]

| Class No. | Description | Number of Feature Vectors | |

|---|---|---|---|

| Microphone | Piezo | ||

| 1 | Desirable weld | 110 | * |

| 2 | Shrinkage cavity | 56 | 56 |

| 3 | Burn through | 30 | 30 |

| Class No. | Description | Classified as # 1 | Classified as # 2 | Classified as # 3 | Correct (%) | Incorrect (%) |

|---|---|---|---|---|---|---|

| 1 | Desirable weld | 32 | 2 | 0 | 32 (94.2) | 2 (5.8) |

| 2 | Shrinkage cavity | 1 | 16 | 0 | 16 (94.2) | 1 (5.8) |

| 3 | Burn through | 0 | 0 | 10 | 10 (100) | 0 (0) |

| Class No. | Description | Classified as # 1 | Classified as # 2&3 | Correct (%) | Incorrect (%) |

|---|---|---|---|---|---|

| 1 | Desirable weld | 33 | 1 | 33 (97.1) | 1 (2.9) |

| 2&3 | Discontinuity | 1 | 26 | 26 (96.3) | 1 (3.7) |

| Class No. | Description | Classified as # 2 | Classified as # 3 | Correct (%) | Incorrect (%) |

|---|---|---|---|---|---|

| 2 | Shrinkage cavity | 16 | 0 | 16 (100) | 0 (0) |

| 3 | Burn through | 1 | 9 | 9 (90) | 1 (10) |

| Class No. | Description | Classified as # 1 | Classified as # 2 | Classified as # 3 | Correct (%) | Incorrect (%) |

|---|---|---|---|---|---|---|

| 1 | Desirable weld | 22 | 0 | 0 | 26 (100) | 0 (0) |

| 2 | Shrinkage cavity | 0 | 11 | 1 | 11 (91.7) | 1 (8.3) |

| 3 | Burn through | 0 | 0 | 6 | 6 (100) | 0 (0) |

| Classifier | Mean Run-Time for Each Segmented Database | Overall Accuracy (%) | Overall Accuracy Median (%) | ||

|---|---|---|---|---|---|

| Feature Extraction | Training | Classification | |||

| ANN | 81 | 20.8 | 0.9 | 97.5 | 83.8 |

| SVM | 81 | 24.8 | 0.6 | 95.1 | 86.9 |

| HSVM | 325 * | 156.9 * | 2.4 * | 96.6 | 91.8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cocota, J.A.N.; Garcia, G.C.; Da Costa, A.R.; De Lima, M.S.F.; Rocha, F.A.S.; Freitas, G.M. Discontinuity Detection in the Shield Metal Arc Welding Process. Sensors 2017, 17, 1082. https://doi.org/10.3390/s17051082

Cocota JAN, Garcia GC, Da Costa AR, De Lima MSF, Rocha FAS, Freitas GM. Discontinuity Detection in the Shield Metal Arc Welding Process. Sensors. 2017; 17(5):1082. https://doi.org/10.3390/s17051082

Chicago/Turabian StyleCocota, José Alberto Naves, Gabriel Carvalho Garcia, Adilson Rodrigues Da Costa, Milton Sérgio Fernandes De Lima, Filipe Augusto Santos Rocha, and Gustavo Medeiros Freitas. 2017. "Discontinuity Detection in the Shield Metal Arc Welding Process" Sensors 17, no. 5: 1082. https://doi.org/10.3390/s17051082

APA StyleCocota, J. A. N., Garcia, G. C., Da Costa, A. R., De Lima, M. S. F., Rocha, F. A. S., & Freitas, G. M. (2017). Discontinuity Detection in the Shield Metal Arc Welding Process. Sensors, 17(5), 1082. https://doi.org/10.3390/s17051082