The Development of an IMU Integrated Clothes for Postural Monitoring Using Conductive Yarn and Interconnecting Technology

Abstract

:1. Introduction

2. Methods

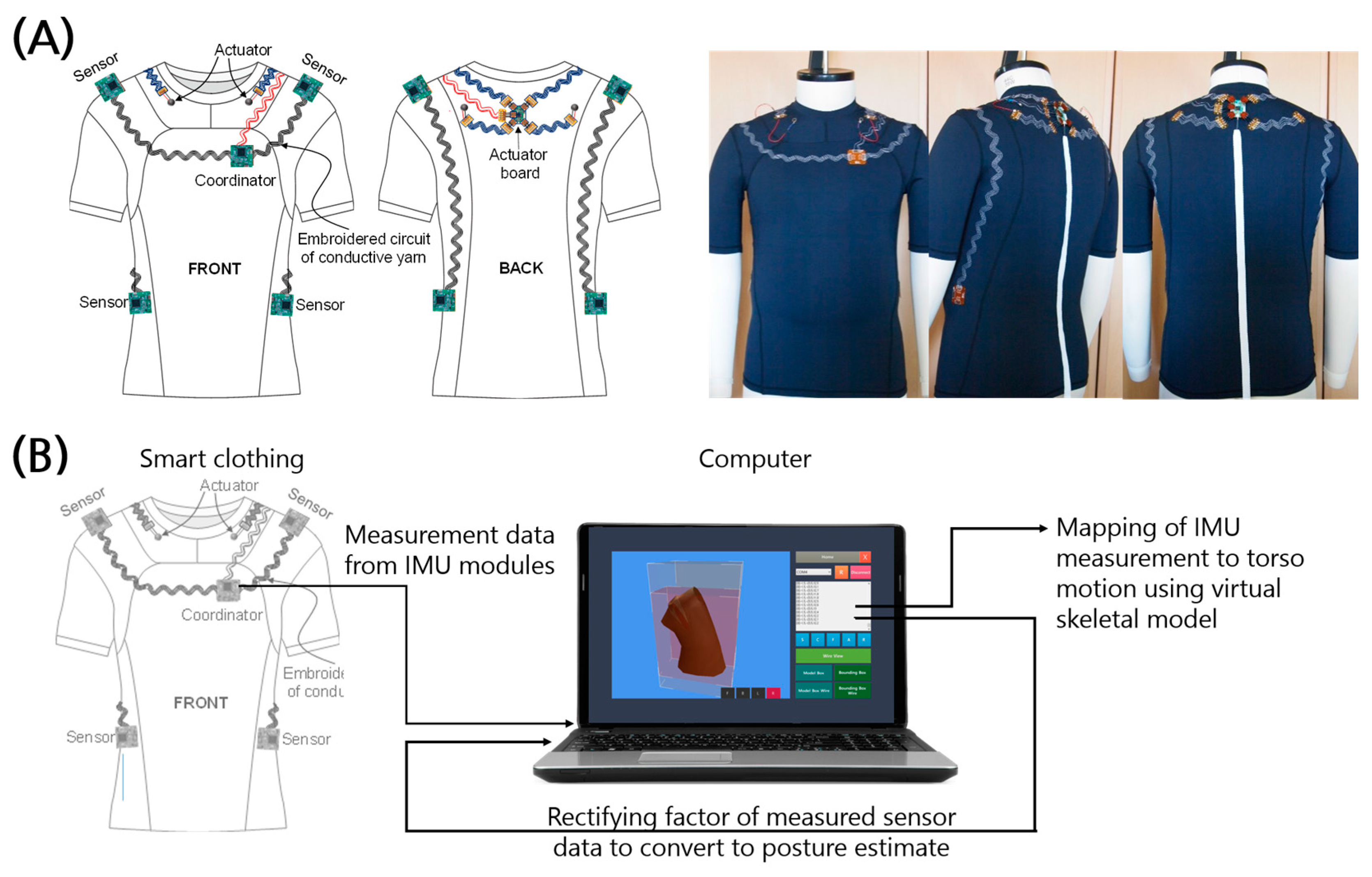

2.1. Motion Monitoring Process of Smart Clothing

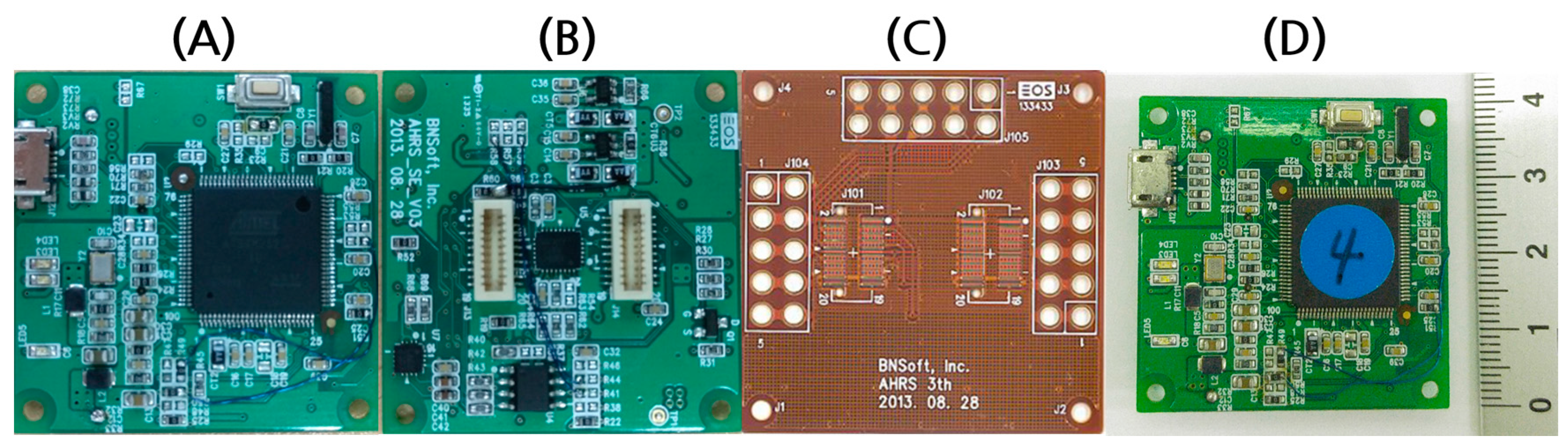

2.2. Sensors and Actuators

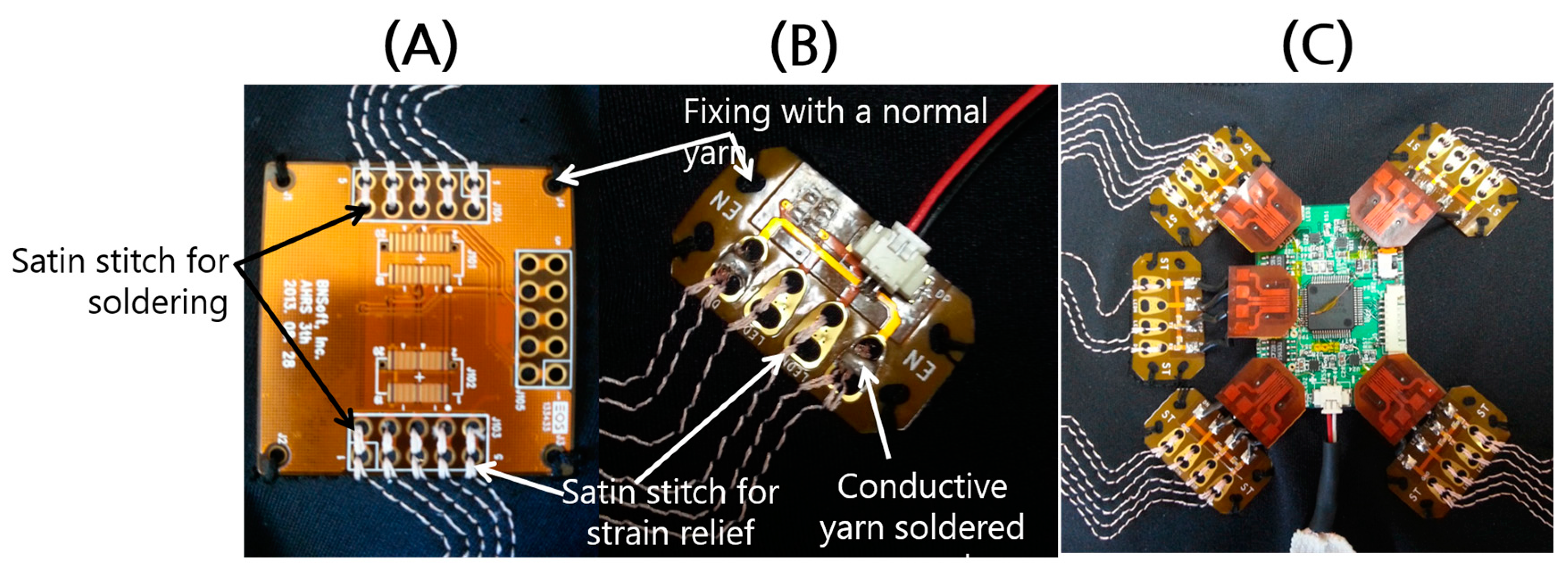

2.3. Design and Prototype of Smart Clothing

2.4. Feasibility Test of Prototype for Posture Monitoring

3. Results and Discussion

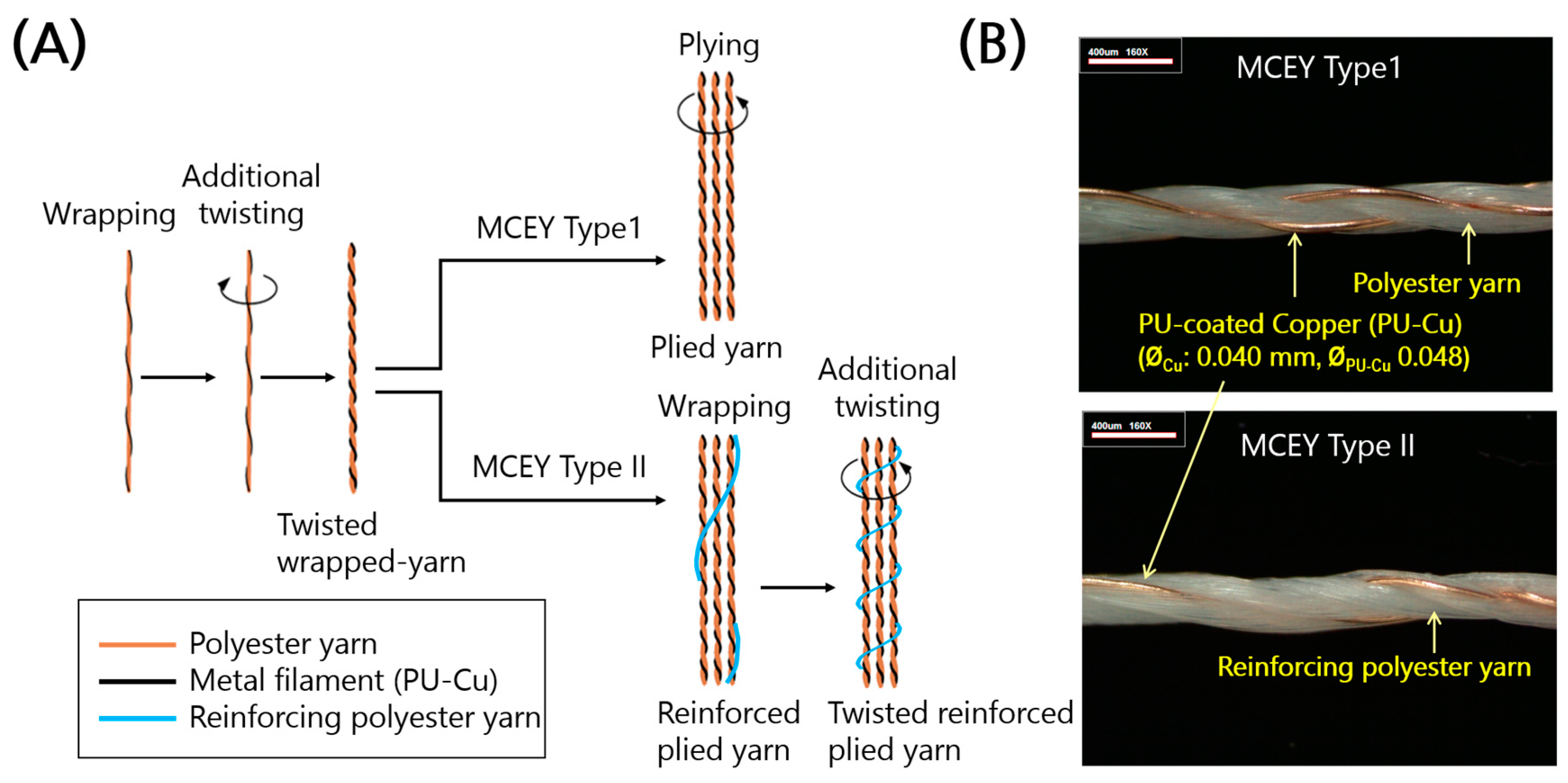

3.1. Mechanical and Electrical Properties of MCEY (PU-Cu)

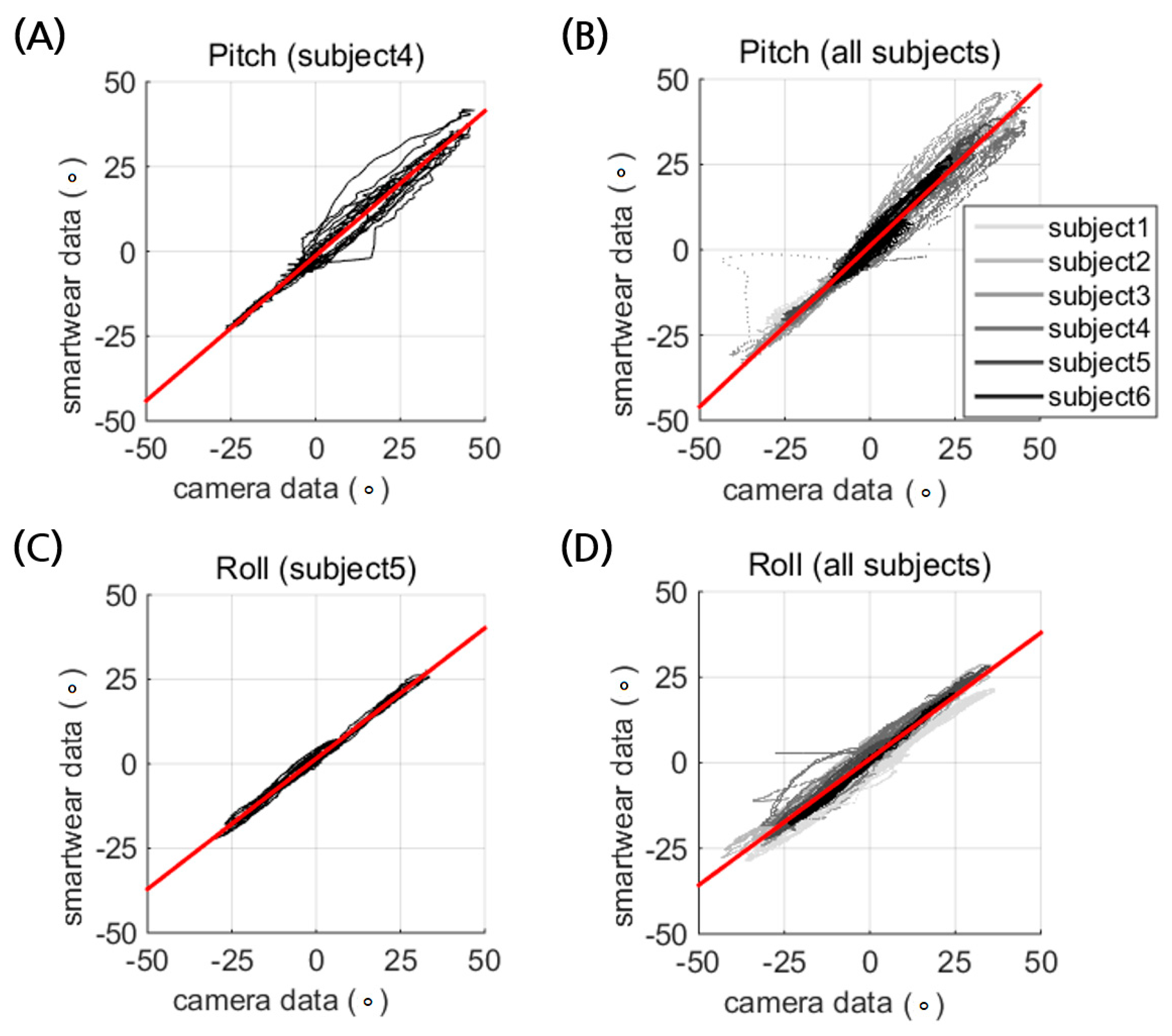

3.2. Calibration of the Prototype

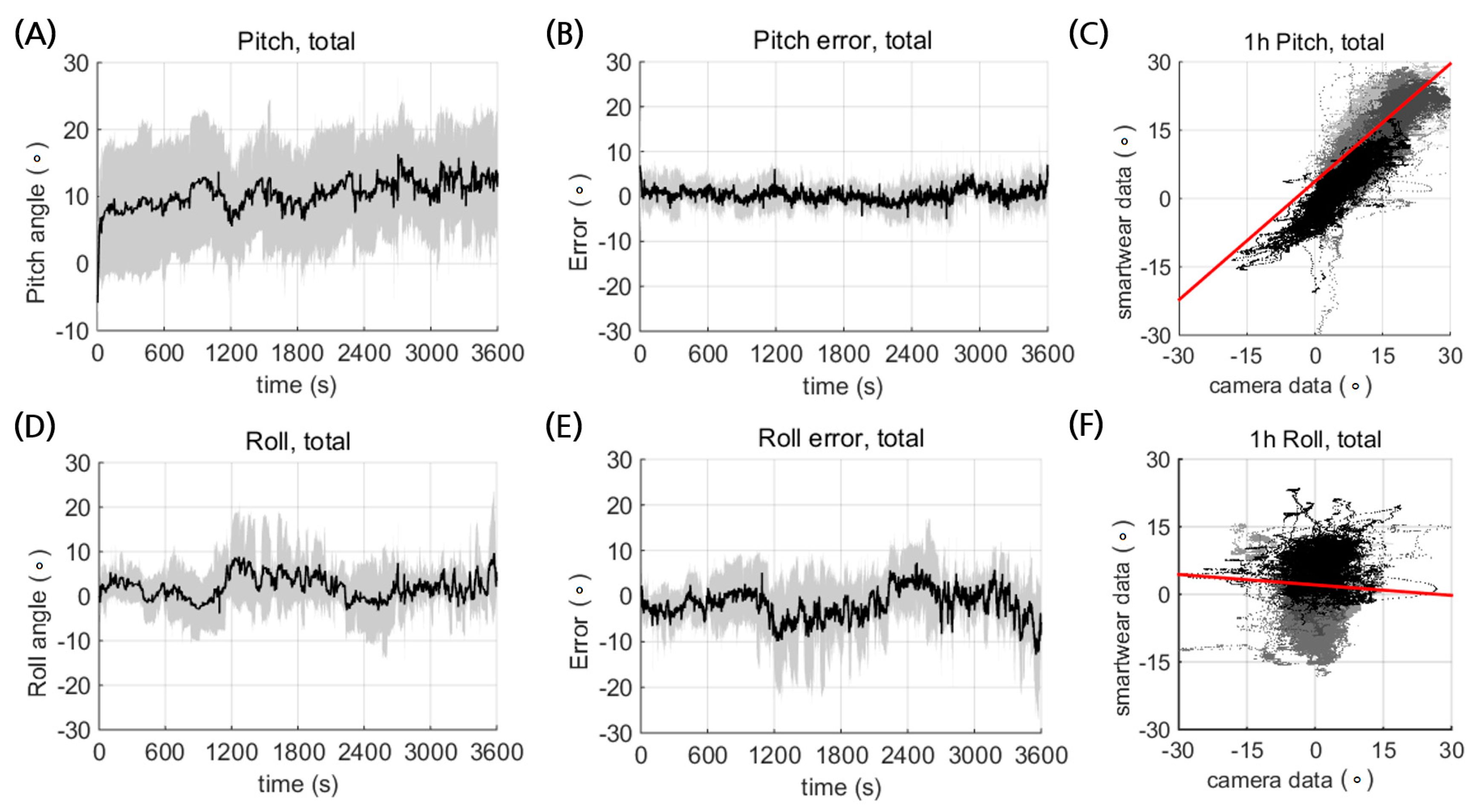

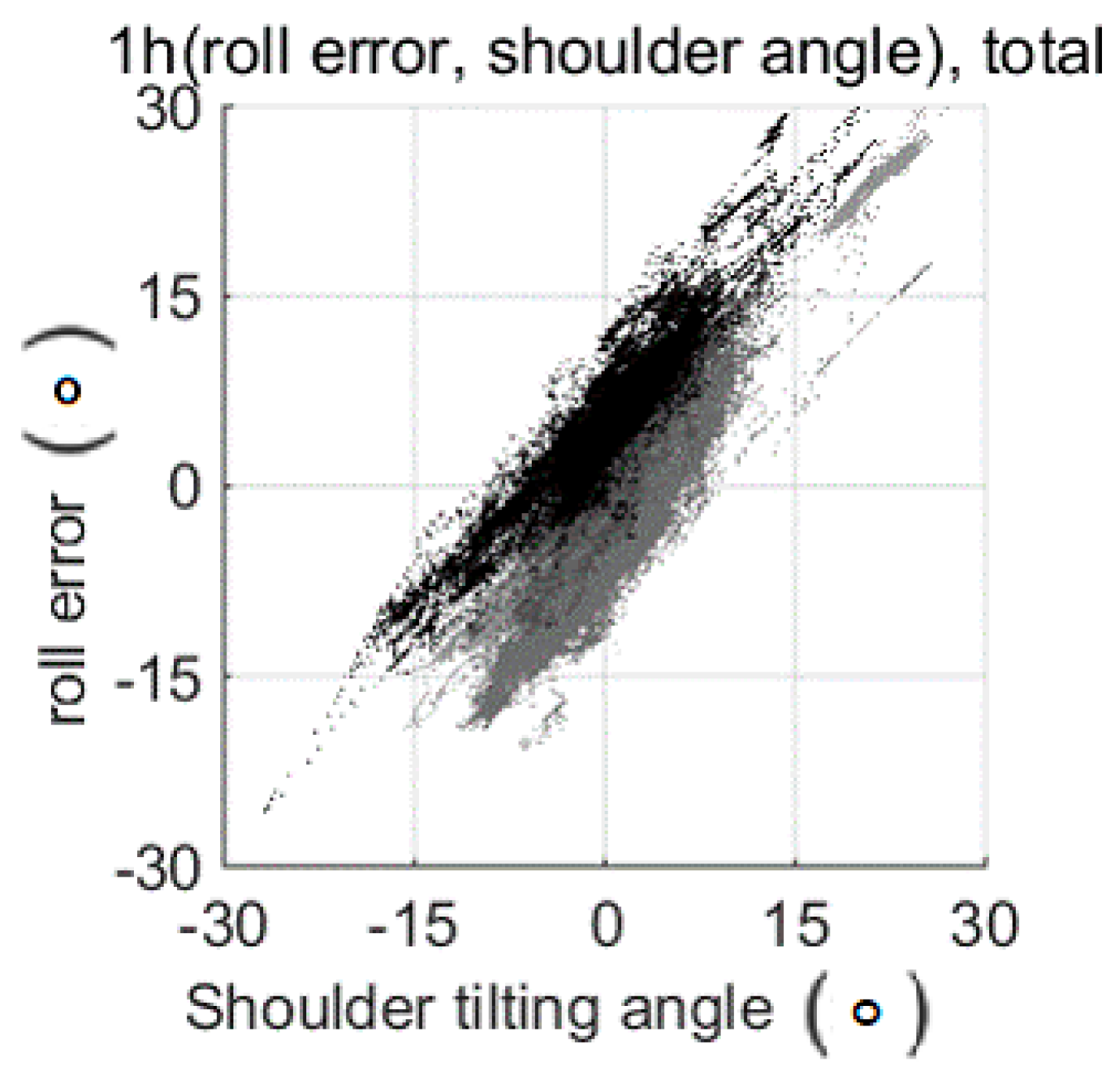

3.3. System Verification under Free Movement

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gopalai, A.A.; Senanayake, S.A.A. A wearable real-time intelligent posture corrective system using vibrotactile feedback. IEEE/ASME Trans. Mechatron. 2011, 16, 827–834. [Google Scholar] [CrossRef]

- Sardini, E.; Serpelloni, M.; Pasqui, V. Daylong sitting posture measurement with a new wearable system for at home body movement monitoring. In Proceedings of the 2015 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Pisa, Italy, 11–14 May 2015; pp. 652–657. [Google Scholar]

- Mattmann, C.; Amft, O.; Harms, H.; Troster, G.; Clemens, F. Recognizing Upper Body Posture using Textile Strain Sensors. In Proceedings of the 2007 11th IEEE International Symposium on Wearable Computers, Boston, MA, USA, 11–13 October 2007. [Google Scholar]

- Dunne, L.E.; Walsh, P.; Smyth, B.; Caulfield, B. Design and Evaluation of a Wearable Optical Sensor for Monitoring Seated Spinal Posture. In Proceedings of the 2006 10th IEEE International Symposium on Wearable Computers, Montreux, Switzerland, 11–14 October 2006. [Google Scholar]

- Roh, J.-S. Textile touch sensors for wearable and ubiquitous interfaces. Text. Res. J. 2014, 84, 739–750. [Google Scholar] [CrossRef]

- Bae, S.-H.; Lee, Y.; Sharma, B.K.; Lee, H.-J.; Kim, J.-H.; Ahn, J.-H. Graphene-based transparent strain sensor. Carbon 2013, 51, 236–242. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef] [PubMed]

- Fujimori, Y.; Ohmura, Y.; Harada, T.; Kuniyoshi, Y. Wearable motion capture suit with full-body tactile sensors, Robotics and Automation. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 3186–3193. [Google Scholar]

- Mengüç, Y.; Park, Y.-L.; Martinez-Villalpando, E.; Aubin, P.; Zisook, M.; Stirling, L.; Wood, R.J.; Walsh, C.J. Soft wearable motion sensing suit for lower limb biomechanics measurements. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 5309–5316. [Google Scholar]

- Alagirusamy, R.; Eichhoff, J.; Gries, T.; Jockenhoevel, S. Coating of conductive yarns for electro-textile applications. J. Text. Inst. 2013, 104, 270–277. [Google Scholar] [CrossRef]

- Roh, J.-S.; Chi, Y.-S.; Lee, J.-H.; Nam, S.; Kang, T.J. Characterization of embroidered inductors. Smart Mater. Struct. 2010, 19. [Google Scholar] [CrossRef]

- Roh, J.-S. All-fabric interconnection and one-stop production process for electronic textile sensors. Text. Res. J. 2016. [Google Scholar] [CrossRef]

- Ashayer-Soltani, R.; Hunt, C.; Thomas, O. Fabrication of highly conductive stretchable textile with silver nanoparticles. Text. Res. J. 2016, 86, 1041–1049. [Google Scholar] [CrossRef]

- Roh, J.-S.; Kim, S. All-fabric intelligent temperature regulation system for smart clothing applications. J. Intell. Mater. Syst. Struct. 2016, 27, 1165–1175. [Google Scholar] [CrossRef]

- Beate Ziegert, G.K. Stretch fabric interaction with action wearables: Defining a body contouring pattern system. Cloth. Text. Res. J. 1988, 6, 54–64. [Google Scholar] [CrossRef]

| Range | Resolution | Sample Rate | Noise | |

|---|---|---|---|---|

| Our system | ||||

| Accelerometer | ±16 g | 13 bits | 6.25–3200 Hz | 28.6 mg |

| Gyroscope | ±2000 deg/s | 14 bits | 100–800 Hz | 0.03 deg/s |

| Magnetometer | ±8 Gauss | 14 bits | 0.75–75 Hz | 2 mGauss |

| APDM | ||||

| Accelerometer | ±16 g | 14 bits | 20–200 Hz | 120 μg |

| Gyroscope | ±2000 deg/s | 16 bits | 20–200 Hz | 0.025 deg/s |

| Magnetometer | ±8 Gauss | 12 bits | 20–200 Hz | 2 mGauss |

| Shimmer3 | ||||

| Accelerometer | ±16 g | 16 bits | 512 Hz | 2.80 mg |

| Gyroscope | ±2000 deg/s | 16 bits | 512 Hz | 0.048 deg/s |

| Magnetometer | ±8.1 Gauss | 16 bits | 512 Hz | 8 mGauss |

| Yarn Type | Composition (wt % of PU-Cu:Polyester) | Resistance (Ω/cm) | Linear Density (Denier) | Load at Yield (Offset 0.2%) (N) | Max. Load (N) | Strain (%) |

|---|---|---|---|---|---|---|

| 1 | 57.3:42.7 | 0.052 | 549 | 3.92 | 13.3 | 13.1 |

| 2 | 50.3:49.7 | 0.051 | 634 | 4.48 | 17.4 | 15.2 |

| Yarn Type | D1 Front-to-Back | D2 Left-to-Right | D3 Back-to-Front | D4 Right-to-Left |

|---|---|---|---|---|

| 1 | 0.766 ± 0.095 | 0.815 ± 0.017 | 0.727 ± 0.022 | 0.865 ± 0.039 |

| 2 | 0.966 ± 0.019 | 0.767 ± 0.015 | 0.726 ± 0.009 | 0.940 ± 0.019 |

| Subject | 1 | 2 | 3 | 4 | 5 | 6 | Average |

|---|---|---|---|---|---|---|---|

| a | 0.924 | 0.963 | 1.01 | 0.854 | 0.964 | 1.03 | 0.958 ± 0.063 |

| b | 1.43 | 0.643 | 3.04 | −1.31 | 1.72 | 0.871 | 1.07 ±1.44 |

| R2 | 0.975 | 0.983 | 0.970 | 0.979 | 0.987 | 0.942 | 0.973 ± 0.016 |

| Subject | 1 | 2 | 3 | 4 | 5 | 6 | Average |

|---|---|---|---|---|---|---|---|

| a | 0.721 | 0.723 | 0.763 | 0.727 | 0.772 | 0.808 | 0.752 ± 0.035 |

| b | −2.81 | 2.96 | 0.974 | 3.59 | 1.54 | 0.375 | 1.10 ± 2.27 |

| R2 | 0.987 | 0.985 | 0.975 | 0.902 | 0.992 | 0.996 | 0.973 ± 0.035 |

| Subject | 1 | 2 | 3 | 4 | 5 | 6 | Average | |

|---|---|---|---|---|---|---|---|---|

| Pitch RMSE | Cal. | 2.07 | 2.02 | 3.40 | 2.74 | 1.78 | 2.11 | 2.35 ± 0.604 |

| 1 h exp. | 2.33 | 5.64 | 3.62 | 4.67 | 2.89 | 3.62 | 3.80 ± 1.20 | |

| Roll RMSE | Cal. | 4.05 | 4.45 | 2.55 | 4.90 | 1.40 | 0.804 | 3.03 ± 1.70 |

| 1 h exp. | 2.07 | 6.36 | 6.72 | 15.2 | 4.98 | 6.76 | 7.02 ± 4.39 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.-W.; Choi, H.; Park, H.-I.; Choi, B.-G.; Im, H.; Shin, D.; Jung, Y.-G.; Lee, J.-Y.; Park, H.-W.; Park, S.; et al. The Development of an IMU Integrated Clothes for Postural Monitoring Using Conductive Yarn and Interconnecting Technology. Sensors 2017, 17, 2560. https://doi.org/10.3390/s17112560

Kang S-W, Choi H, Park H-I, Choi B-G, Im H, Shin D, Jung Y-G, Lee J-Y, Park H-W, Park S, et al. The Development of an IMU Integrated Clothes for Postural Monitoring Using Conductive Yarn and Interconnecting Technology. Sensors. 2017; 17(11):2560. https://doi.org/10.3390/s17112560

Chicago/Turabian StyleKang, Sung-Won, Hyeob Choi, Hyung-Il Park, Byoung-Gun Choi, Hyobin Im, Dongjun Shin, Young-Giu Jung, Jun-Young Lee, Hong-Won Park, Sukyung Park, and et al. 2017. "The Development of an IMU Integrated Clothes for Postural Monitoring Using Conductive Yarn and Interconnecting Technology" Sensors 17, no. 11: 2560. https://doi.org/10.3390/s17112560

APA StyleKang, S.-W., Choi, H., Park, H.-I., Choi, B.-G., Im, H., Shin, D., Jung, Y.-G., Lee, J.-Y., Park, H.-W., Park, S., & Roh, J.-S. (2017). The Development of an IMU Integrated Clothes for Postural Monitoring Using Conductive Yarn and Interconnecting Technology. Sensors, 17(11), 2560. https://doi.org/10.3390/s17112560