Simultaneous Moisture Content and Mass Flow Measurements in Wood Chip Flows Using Coupled Dielectric and Impact Sensors

Abstract

:1. Introduction

2. Experimental Section

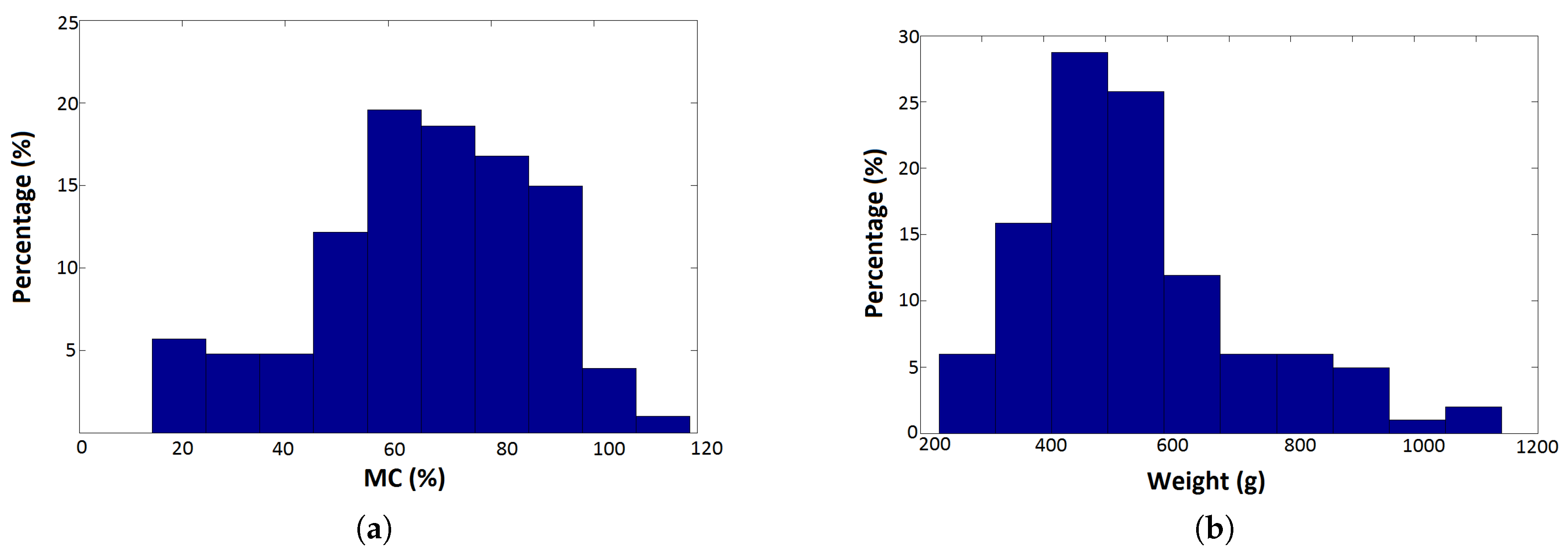

2.1. Biomass Samples

2.2. Experimental Methods

2.3. Experimental Procedures

2.4. Mass Estimation Procedures

2.4.1. Impact Method

2.4.2. ECT Method

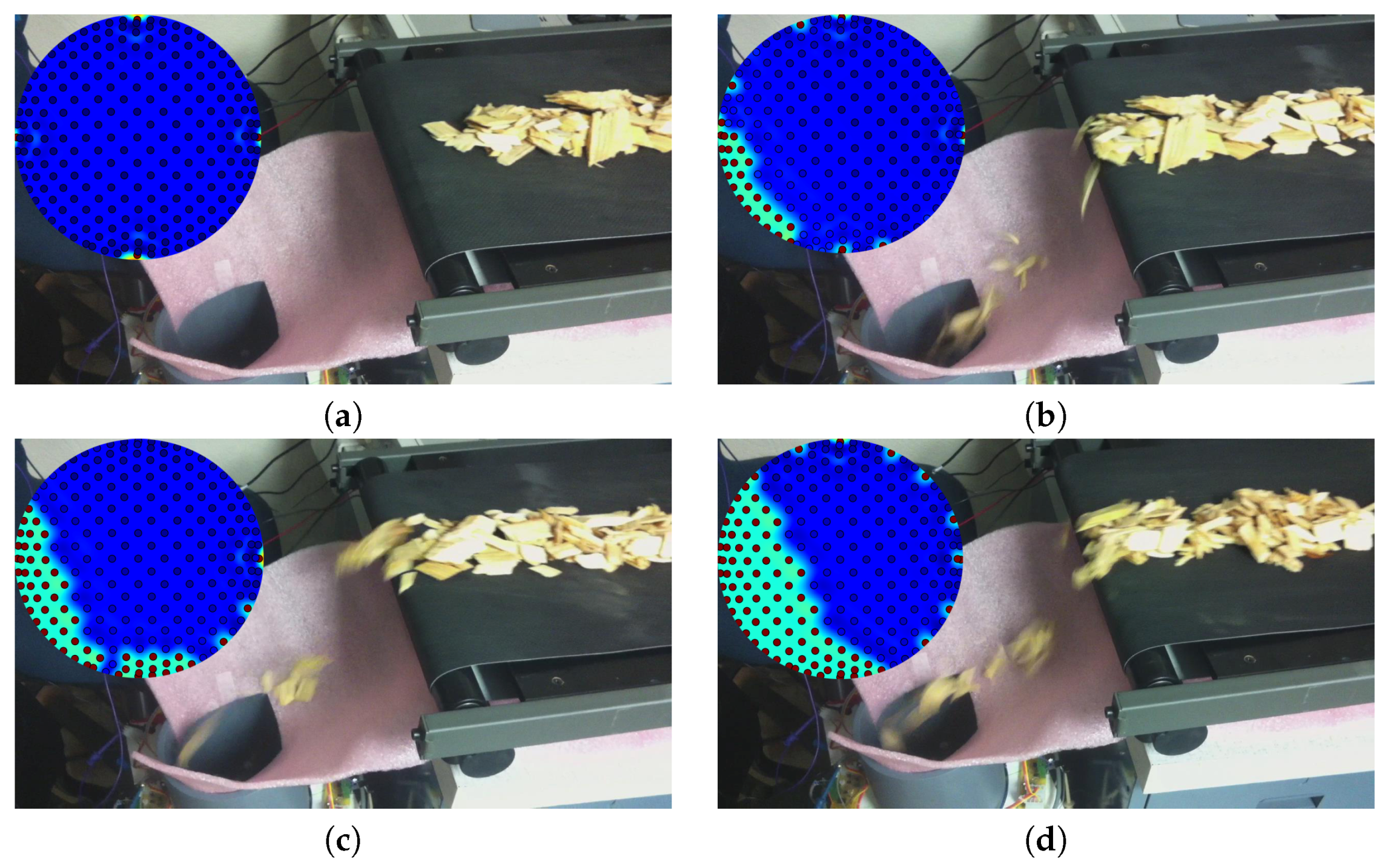

- thresholding ECT images to separate biomass from background regions;

- summing the estimated areas over time and correlating the summed areas with measured sample dry mass D.

- A digital camera installed above the capacitance sensor captured a sequence of grayscale images as the wood chip traveled through the sensing area. These image data were first binarized, then a noise removal process (open/close) employed, to arrive at a threshold gray value resulting in a binary image that closely matched a visual assessment of chip area. Once binarized, the ratio of chip to enclosure area was calculated.

- The ECT approach was used to simultaneously calculate the dielectric constant distribution as the chip fell through the sensor. This process also resulted in a sequence of grayscale images.

- A single desktop computer recorded both camera and capacitance sensor data during the chip descent. Image data between the two were matched in time using the CPU clock.

- The visible binary image of the chip closest in time to the a given ECT image was then selected. A properly thresholded reconstructed permittivity image was assumed to have the same area ratio as that observed in the visible image. The threshold value most closely matching the area ratios in the ECT and visible images was calculated.

- The global threshold value was taken to be the average of all observed thresholds calculated for images collected during five tests as outlined above.

3. Results and Discussion

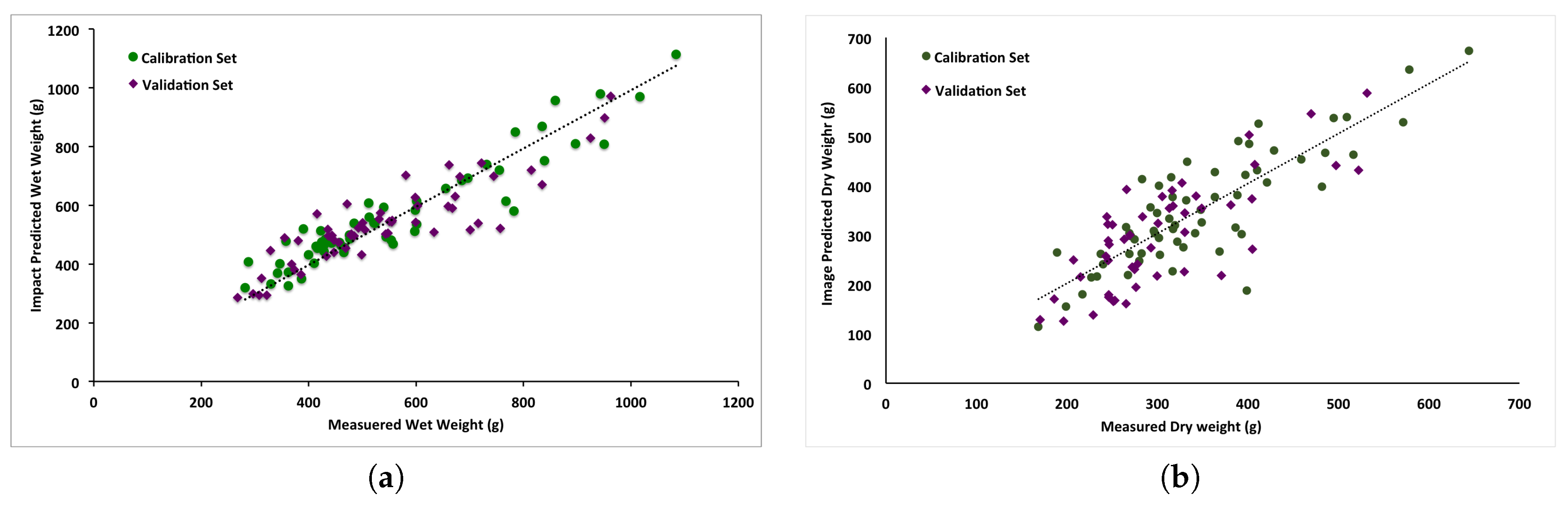

3.1. Mass Flow Estimation

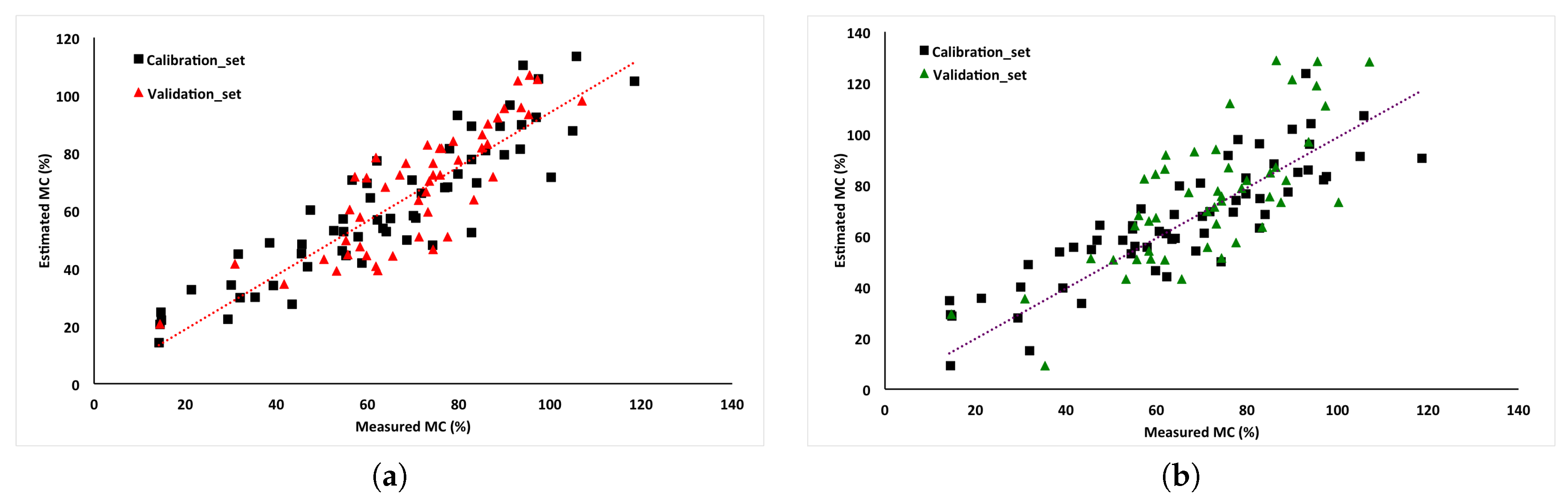

3.2. Moisture Content Estimation

3.3. Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dai, G.; Ahmet, K. Long-term monitoring of timber moisture content below the fiber saturation point using wood resistance sensors. For. Prod. J. 2001, 51, 52–58. [Google Scholar]

- Tamme, V.; Muiste, P.; Tamme, H. Experimental study of resistance type wood moisture sensors for monitoring wood drying process above fibre saturation point. For. Stud. 2013, 59, 28–44. [Google Scholar]

- Brashaw, B.K.; Wang, X.; Ross, R.J.; Pellerin, R.F. Relationship between stress wave velocities of green and dry veneer. For. Prod. J. 2004, 54, 85–89. [Google Scholar]

- Chan, J.M.; Walker, J.C.; Raymond, A.A. Effects of moisture content and temperature on acoustic velocity and dynamic MOE of radiata pine sapwood boards. Wood Sci. Technol. 2011, 45, 609–626. [Google Scholar] [CrossRef]

- Lundgren, N.; Hagman, O.; Johansson, J. Predicting moisture content and density distribution of Scots pine by microwave scanning of sawn timber II: Evaluation of models generated on a pixel level. J. Wood Sci. 2006, 52, 39–43. [Google Scholar] [CrossRef]

- Moschler, W.W.; Hanson, G.R.; Gee, T.F.; Killough, S.M.; Wilgen, J.B. Microwave moisture measurement system for lumber drying. For. Prod. J. 2007, 57, 69–74. [Google Scholar] [CrossRef]

- Jones, P.D.; Schimleck, L.R.; Peter, G.F.; Daniels, R.F.; Clark, A., III. Nondestructive estimation of Pinus taeda L. wood properties for samples from a wide range of sites in Georgia. Can. J. For. Res. 2005, 35, 85–92. [Google Scholar] [CrossRef]

- Schimleck, L.R.; Evans, R.; Matheson, A.C. Estimation of Pinus radiata D. Don clear wood properties by near-infrared spectroscopy. J. Wood Sci. 2002, 48, 132–137. [Google Scholar] [CrossRef]

- Tomppo, L.; Tiitta, M.; Laakso, T.; Harju, A.; Venalainen, M.; Lappalainen, R. Dielectric spectroscopy of Scots pine. Wood Sci. Technol. 2009, 43, 653–667. [Google Scholar] [CrossRef]

- Wullschleger, S.D.; Hanson, P.J.; Todd, D.E. Measuring stem water content in four deciduous hardwoods with a time-domain reflectometer. Tree Physiol. 1996, 16, 809–815. [Google Scholar] [CrossRef] [PubMed]

- Woodhead, I.M.; Buchan, G.D.; Christie, J.H.; Irie, K. A general dielectric model for time domain reflectometry. Biosyst. Eng. 2003, 86, 207–216. [Google Scholar] [CrossRef]

- Jazayeri, S.; Ahmet, K. Detection of transverse moisture gradients in timber by measurements of capacitance using a multiple-electrode arrangement. For. Prod. J. 2000, 50, 27–32. [Google Scholar]

- Xinguang, L.; Mingying, X. Applied research on moisture content measurement: One sided capacitance sensors. Meas. Control 2009, 42, 84–86. [Google Scholar] [CrossRef]

- Jensen, P.D.; Hartmann, H.; Böhm, T.; Temmerman, M.; Rabier, F.; Morsing, M. Moisture content determination in solid biofuels by dielectric and NIR reflection methods. Biomass Bioenergy 2006, 30, 935–943. [Google Scholar] [CrossRef]

- Huang, S.M.; Plaskowski, A.B.; Xie, C.G.; Beck, M.S. Capacitance-based tomographic flow imaging system. Electron. Lett. 1988, 24, 418–419. [Google Scholar] [CrossRef]

- Sobue, N.; Woodhead, I. Improvement of simple impedance tomography method in RF range for estimating moisture distribution in squared timbers. J. Wood Sci. 2010, 56, 366–370. [Google Scholar] [CrossRef]

- Niu, G.; Jia, Z.; Wang, J. Void fraction measurement in oil-gas transportation pipeline using an improved electrical capacitance tomography system. Chin. J. Chem. Eng. 2004, 12, 476–481. [Google Scholar]

- Sun, M.; Liu, S.; Lei, J.; Li, Z.H. Mass flow measurement of pneumatically conveyed solids using electrical capacitance tomography. Meas. Sci. Technol. 2008, 19, 1–7. [Google Scholar] [CrossRef]

- Green, R.G.; Rahmat, M.F.; Dutton, K.; Evans, K.; Goude, A.; Henry, M. Velocity and mass flow rate profiles of dry powders in a gravity of drop conveyor using and electrodynamic tomography system. Meas. Sci. Technol. 1997, 8, 429–436. [Google Scholar] [CrossRef]

- Young, M.; Pickup, E.; Deloughry, R.; Hartley, T.; Nixon, S.A.; Barratt, L. Development of a variable density flow meter for an industrial application using tomographic imaging. IEE Colloq. Adv. Electr. Tomogr. 1996, 14, 1–3. [Google Scholar]

- Chen, J.; Liu, S.; Wu, D.; Han, Z.; Li, Z.; Lei, J.; Long, T. Decoupling the joint effect of moisture and mass in dense phase pneumatic conveying. Flow Meas. Instrum. 2013, 34, 168–176. [Google Scholar] [CrossRef]

- Pan, P.; McDonald, T.P.; Via, B.K.; Fulton, J.P.; Hung, J.Y. Predicting moisture content of chipped pine samples with a multi-electrode capacitance sensor. Biosyst. Eng. 2016, 145, 1–9. [Google Scholar] [CrossRef]

- Birrell, S.J.; Sudduth, K.A.; Borgelt, S.C. Comparison of sensors and techniques for crop yield mapping. Comput. Electron. Agric. 1996, 14, 215–233. [Google Scholar] [CrossRef]

- Xie, C.G.; Huang, S.M.; Hoyle, B.S.; Thorn, R.; Lenn, C.; Snowden, D.; Beck, M.S. Electrical capacitance tomography for flow imaging: System model for development of image reconstruction algorithms and design of primary sensors. Circuits Devices Syst. 1992, 139, 89–98. [Google Scholar] [CrossRef]

- Yang, W.Q.; York, T.A. New AC-based capacitance tomography system. IEE Proc. Sci. Meas. Technol. 1999, 146, 47–53. [Google Scholar] [CrossRef]

- Olmos, A.M.; Primicia, J.A.; Marron, J.L.F. Simulation design of electrical capacitance tomography sensors. IET Sci. Meas. Technol. 2007, 1, 216–223. [Google Scholar] [CrossRef]

| Method | Sample Set | Mean Sample Weight (g) | Absolute RMSE (g) | Relative RMSE |

|---|---|---|---|---|

| Impact | Calibration | 566.1 | 58.2 | 10.3 |

| Prediction | 530.5 | 71.2 | 13.4 | |

| ECT | Calibration | 346.3 | 62.5 | 18.1 |

| Prediction | 304.4 | 69.7 | 22.9 |

| Method | Sample Set | Relative RMSE (%) | |

|---|---|---|---|

| Impact | Calibration | 0.81 | 11.3 |

| Prediction | 0.71 | 11.9 | |

| ECT | Calibration | 0.71 | 19.1 |

| Prediction | 0.57 | 24.2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, P.; McDonald, T.; Fulton, J.; Via, B.; Hung, J. Simultaneous Moisture Content and Mass Flow Measurements in Wood Chip Flows Using Coupled Dielectric and Impact Sensors. Sensors 2017, 17, 20. https://doi.org/10.3390/s17010020

Pan P, McDonald T, Fulton J, Via B, Hung J. Simultaneous Moisture Content and Mass Flow Measurements in Wood Chip Flows Using Coupled Dielectric and Impact Sensors. Sensors. 2017; 17(1):20. https://doi.org/10.3390/s17010020

Chicago/Turabian StylePan, Pengmin, Timothy McDonald, John Fulton, Brian Via, and John Hung. 2017. "Simultaneous Moisture Content and Mass Flow Measurements in Wood Chip Flows Using Coupled Dielectric and Impact Sensors" Sensors 17, no. 1: 20. https://doi.org/10.3390/s17010020

APA StylePan, P., McDonald, T., Fulton, J., Via, B., & Hung, J. (2017). Simultaneous Moisture Content and Mass Flow Measurements in Wood Chip Flows Using Coupled Dielectric and Impact Sensors. Sensors, 17(1), 20. https://doi.org/10.3390/s17010020