A Thermal Performance Analysis and Comparison of Fiber Coils with the D-CYL Winding and QAD Winding Methods

Abstract

:1. Introduction

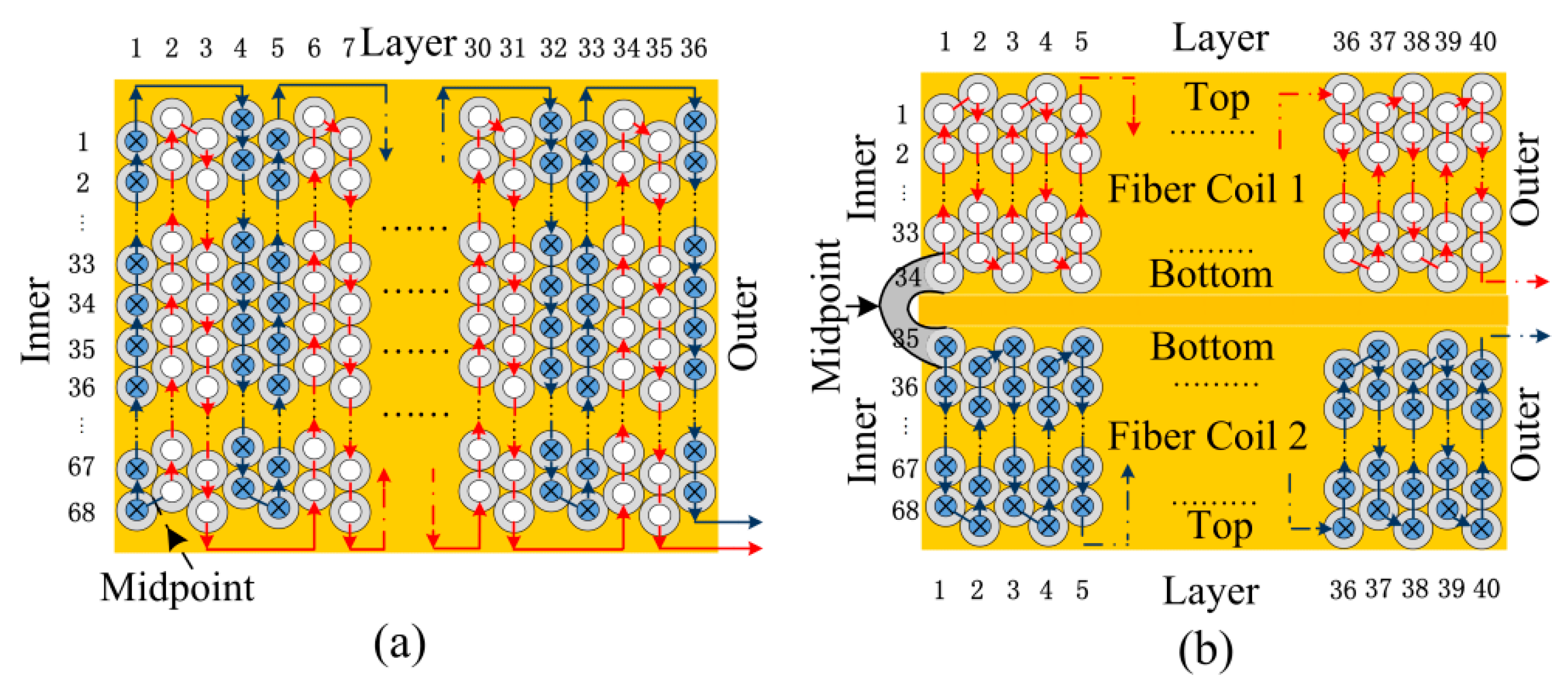

2. Theory

3. Simulations and Experiments

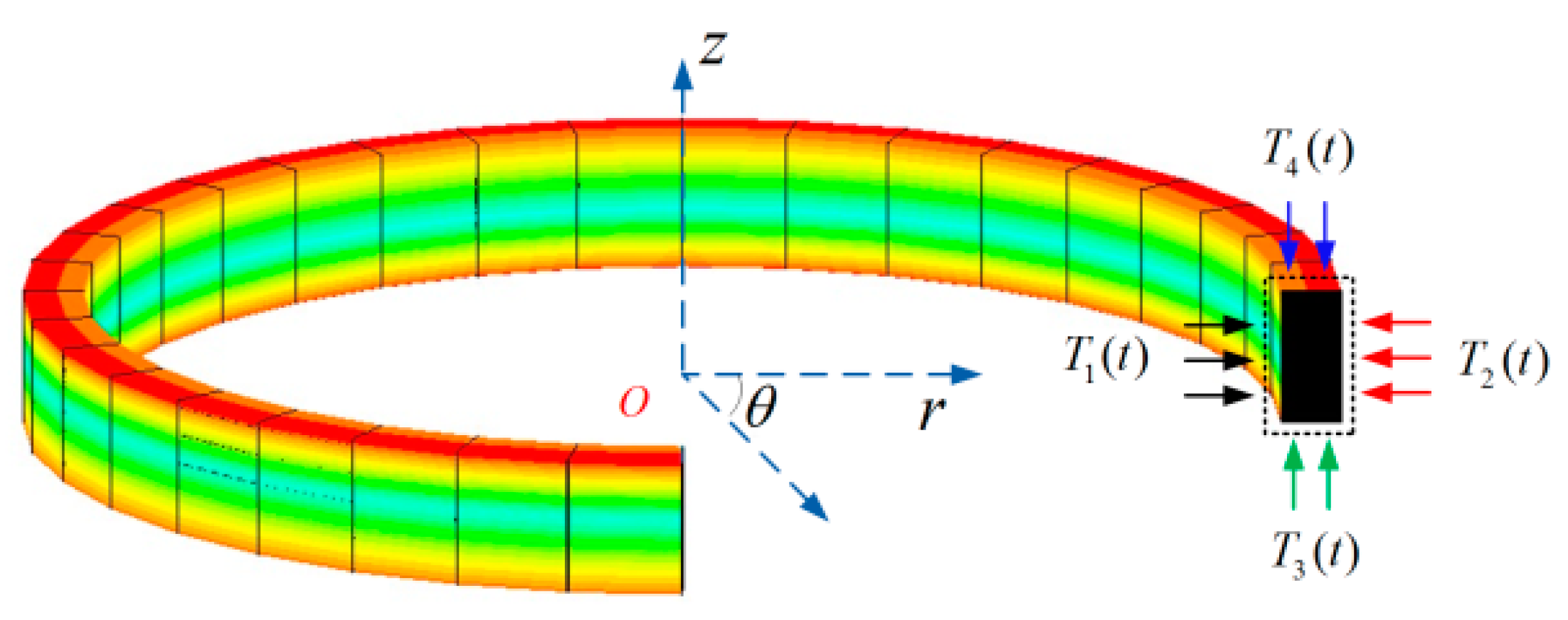

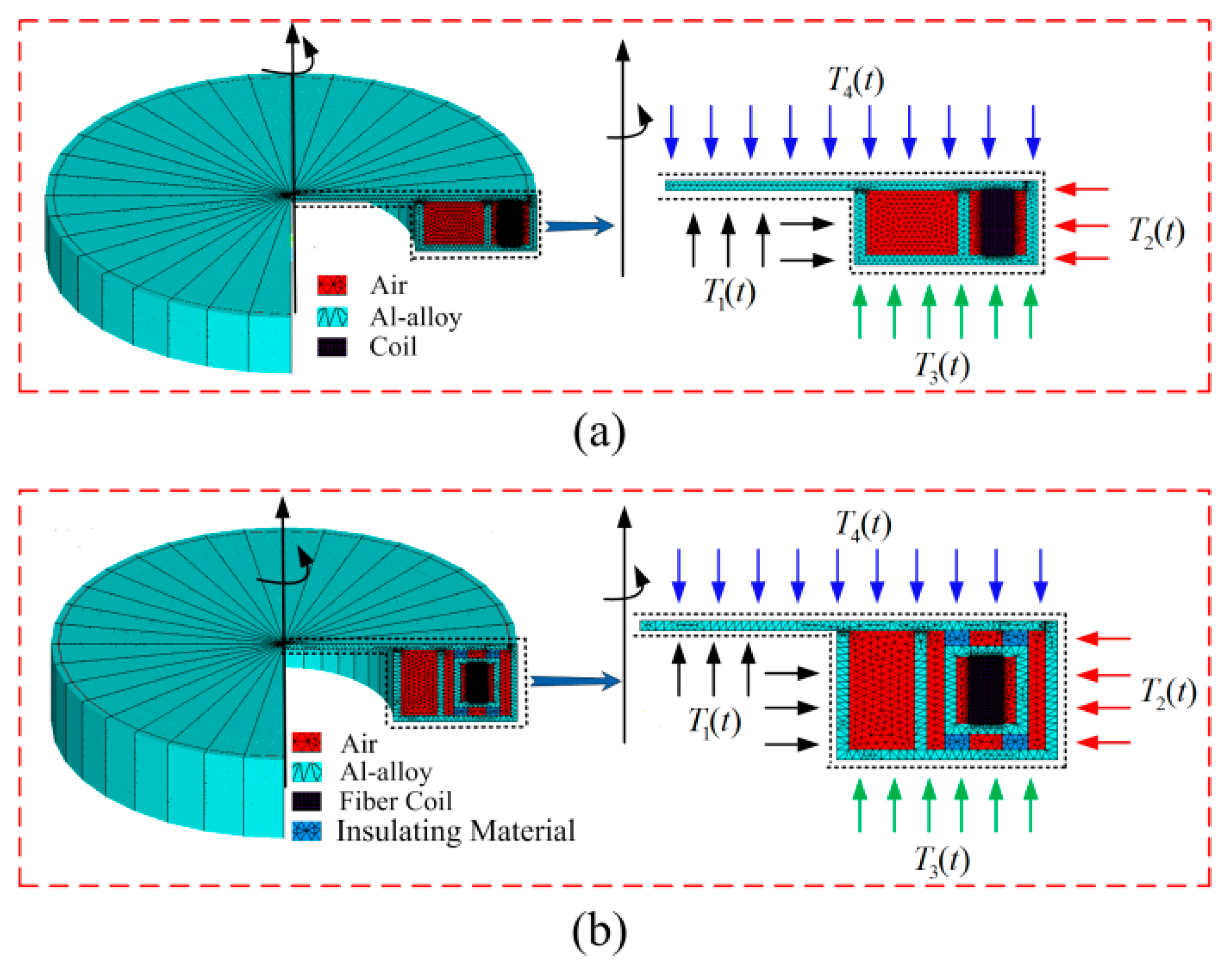

3.1. Finite Element Model

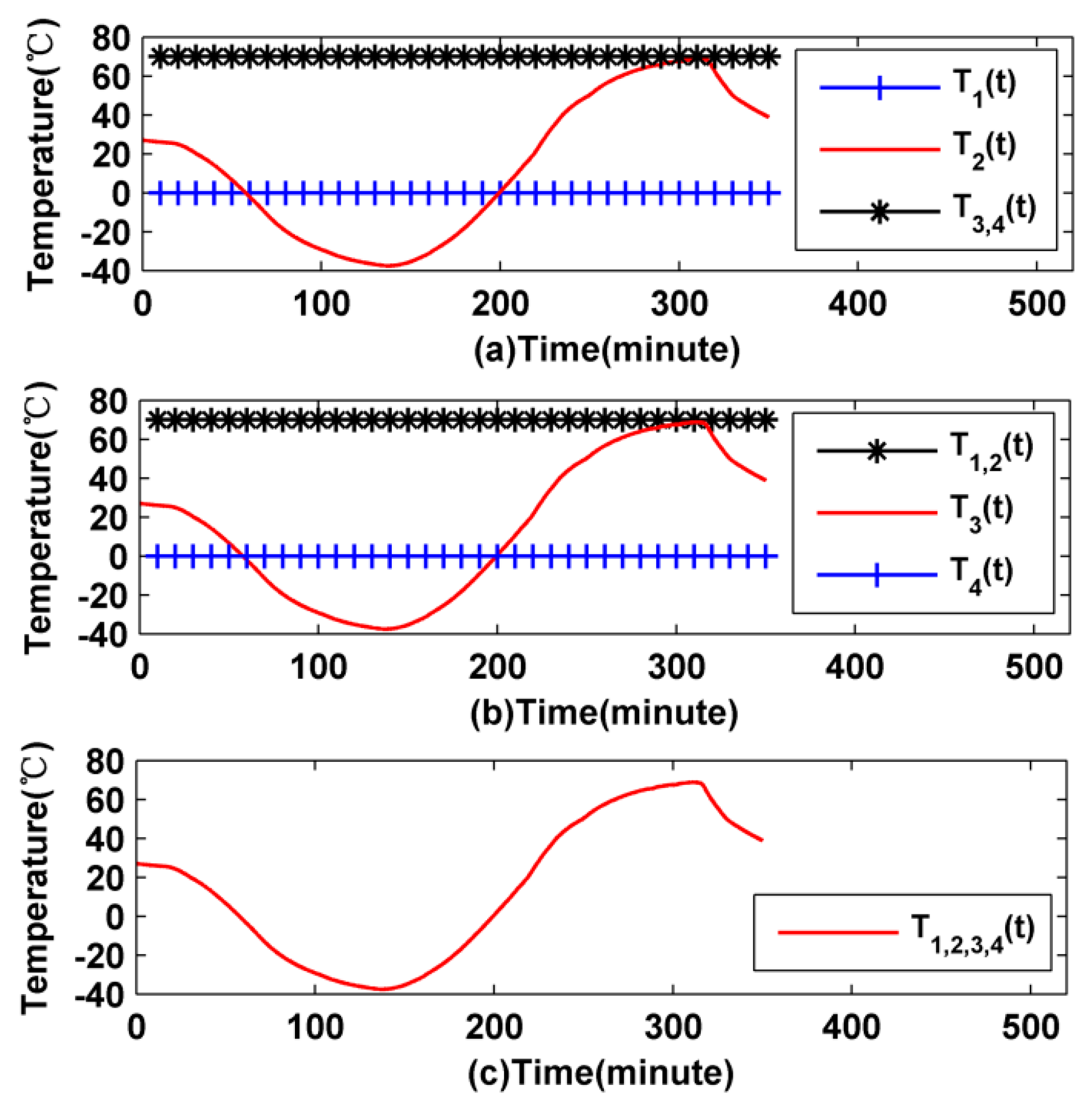

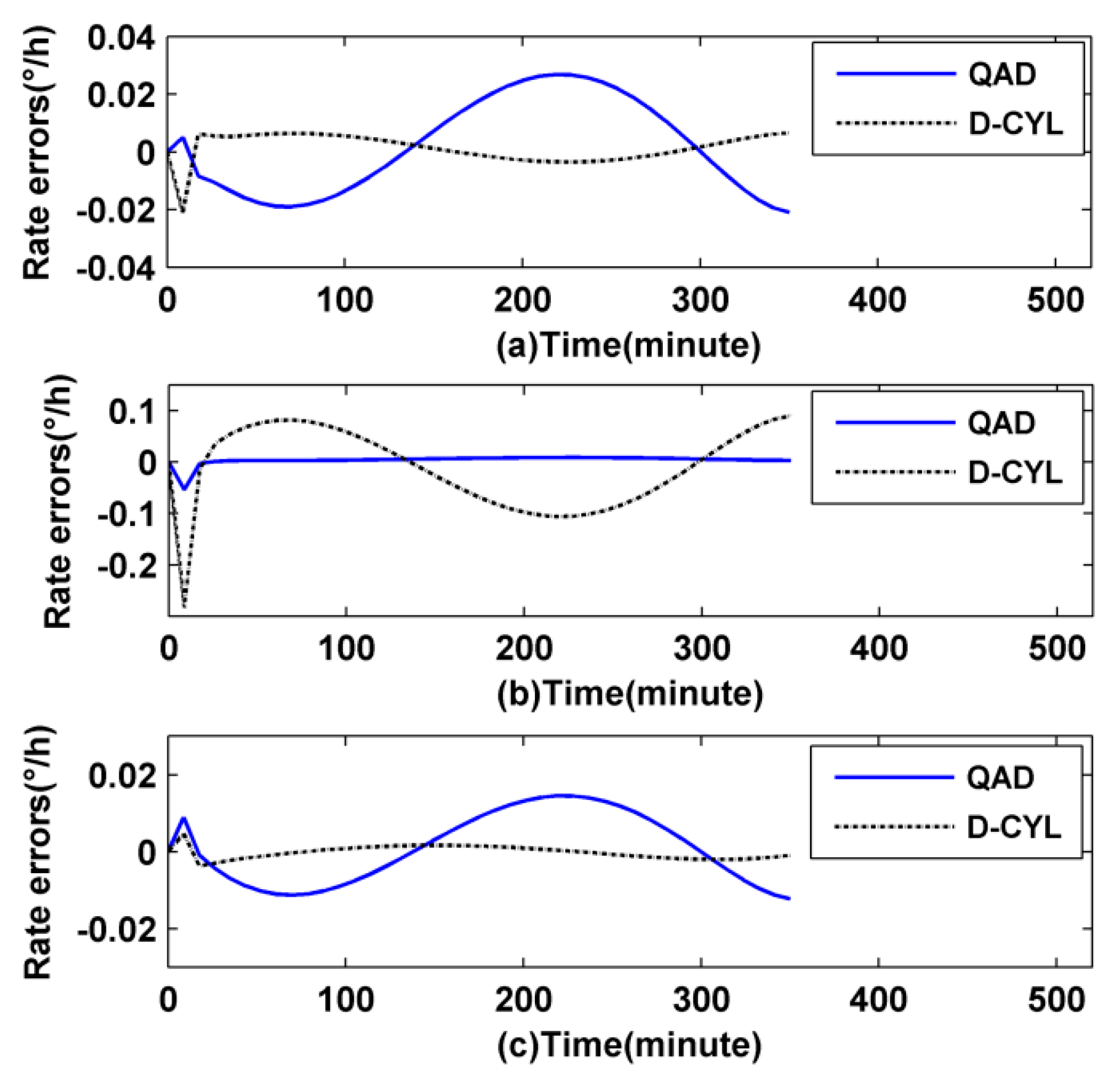

3.2. Simulation without Spool

3.3. Simulation with Spool

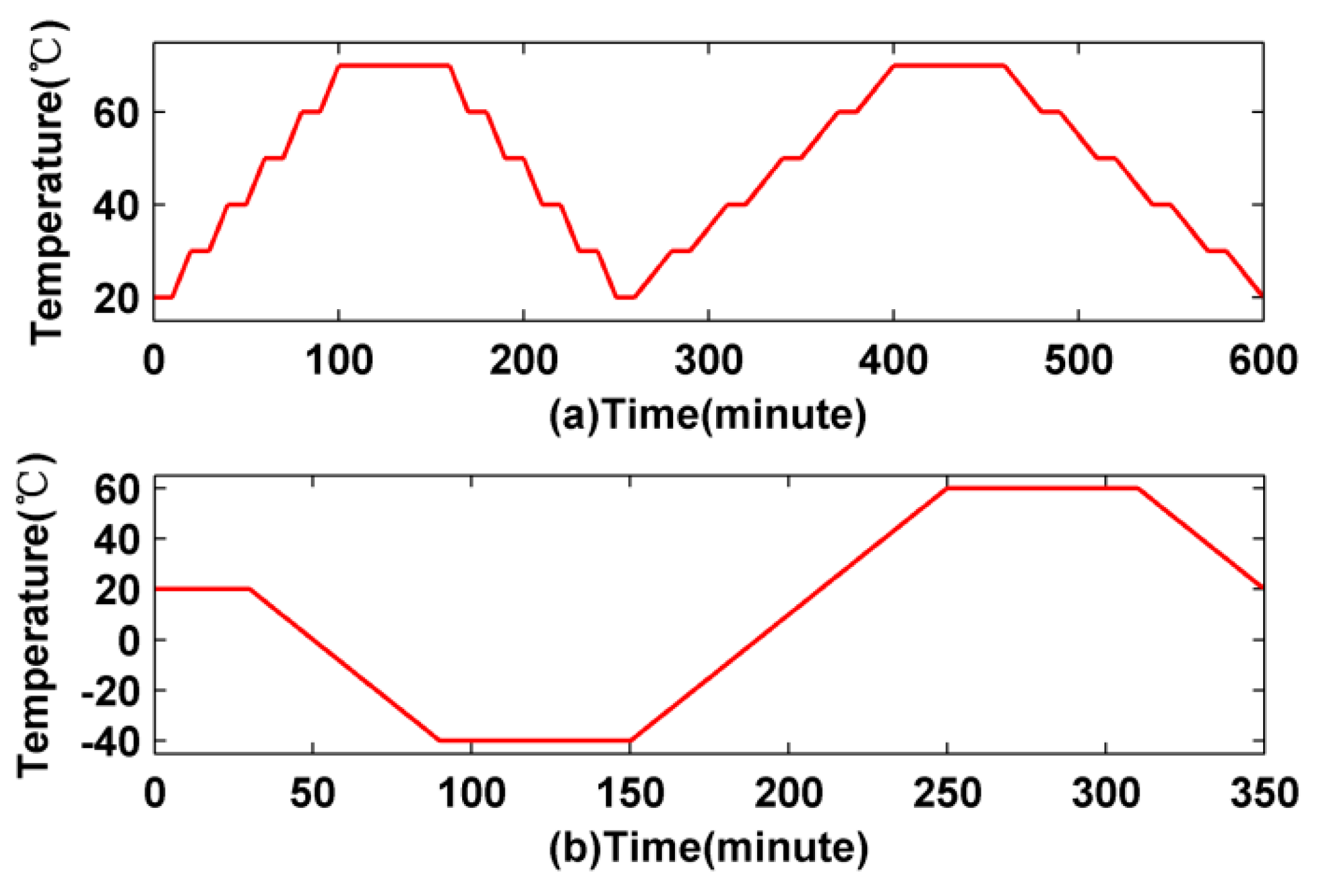

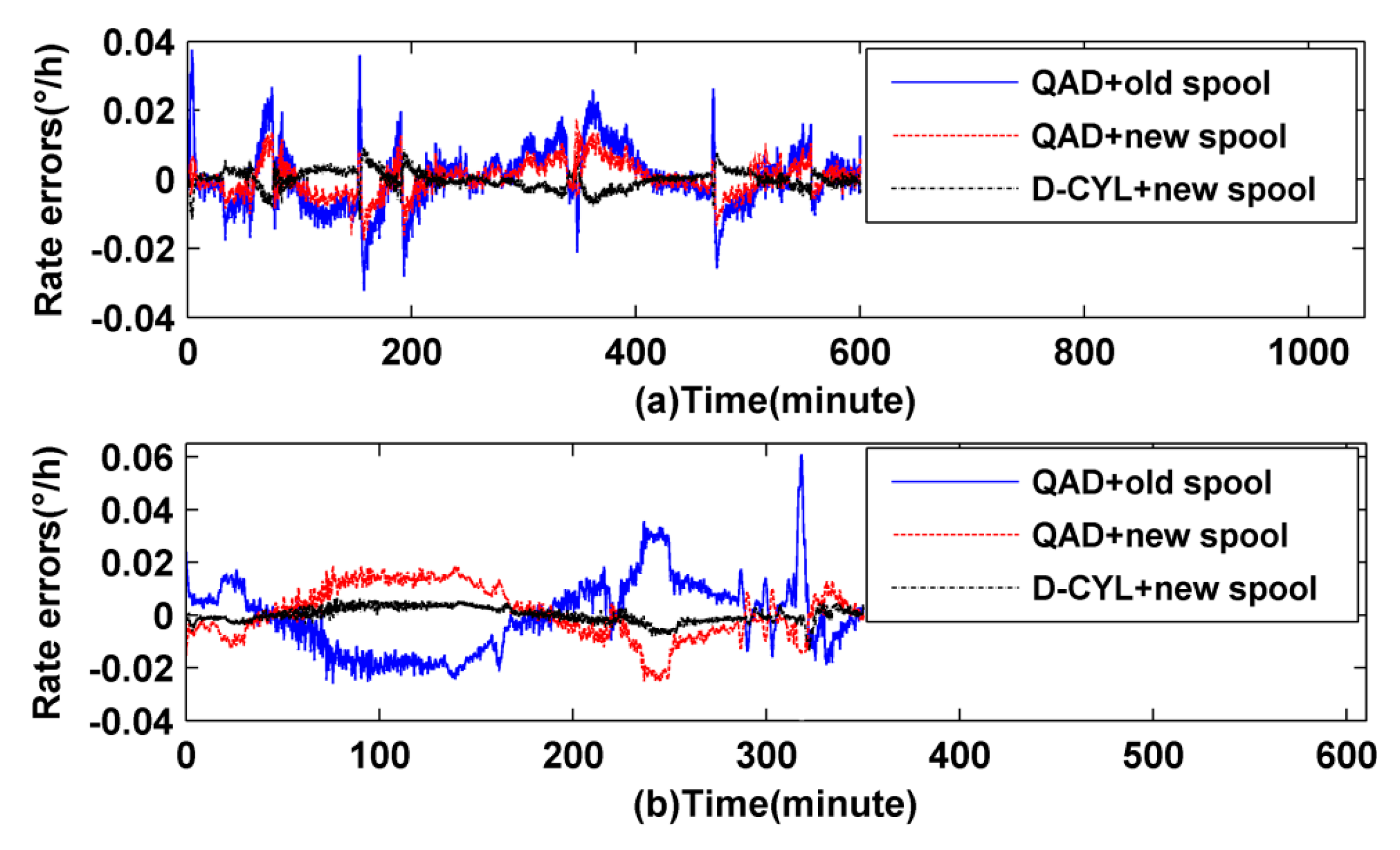

3.4. Experiment Section

4. Analysis and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shupe, D. Thermally induced nonreciprocity in the fiber-optic interferometer. Appl. Opt. 1980, 19, 654–655. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ren, L.; Xu, J.; Liang, J.; Kang, M.; Ren, K.; Shi, N. The compensation of Y waveguide temperature drifts in FOG with the thermal resistor. Adv. Mater. Res. 2014, 924, 336–342. [Google Scholar] [CrossRef]

- Dranitsyna, E.; Egorov, D.; Untilov, A.; Deineka, G.; Sharkov, I.; Deineka, I. Reducing the effect of temperature variations on FOG output signal. Gyroscopy Navig. 2013, 4, 92–98. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Yu, Q. Four-state modulation in fiber optic gyro. In Proceedings of the IEEE International on Conference on Mechatronics and Automation, Takamatsu, Japan, 5–8 August 2008.

- Her, S.; Huang, C. Thermal strain analysis of optic fiber sensors. Sensors 2013, 13, 1846–1855. [Google Scholar] [CrossRef] [PubMed]

- Ling, W.; Li, X.; Xu, Z.; Zhang, Z.; Wei, Y. Thermal effects of fiber sensing coils in different winding pattern considering both thermal gradient and thermal stress. Opt. Commun. 2015, 356, 290–295. [Google Scholar] [CrossRef]

- Li, X.; Ling, W.; Wei, Y.; Xu, Z. Three-dimensional model of thermal-induced optical phase shifts in rotation sensing. Chin. Opt. Lett. 2015, 13, 090603. [Google Scholar]

- Kim, H.; Digonnet, M.; Kino, G. Air-core photonic-bandgap fiber-optic gyroscope. J. Lightwave Technol. 2006, 24, 3169–3174. [Google Scholar]

- Digonnet, M.; Blin, S.; Kim, H.; Dangui, V.; Kino, G. Sensitivity and stability of an air-core fibre-optic gyroscope. Meas. Sci. Technol. 2007, 18, 2089–3097. [Google Scholar] [CrossRef]

- Bi, C.; Sun, G.; Wu, Y.; Zhao, K. Potted fiber optic sensor coil by novel adhesives for high-stability FOG. SPIE 2011. [Google Scholar] [CrossRef]

- Li, X.; Ling, W.; Xu, Z.; Wei, Y. Design of a new spool for fiber coil based on cross winding pattern. Acta Opt. Sin. 2015. [Google Scholar] [CrossRef]

- Li, Z.; Meng, Z.; Gen, T.; Yao, X. A novel method for determining and improving the quality of a quadrupolar fiber gyro coil under temperature variations. Opt. Express 2013, 21, 2521–2530. [Google Scholar] [CrossRef] [PubMed]

- Dyott, R. Reduction of the shupe effect in fiber optic gyros; the radom-wound coil. Electron. Lett. 1996, 32, 2177–2178. [Google Scholar] [CrossRef]

- Mohr, F. Thermooptically induced bias drift in fiber optical sagnac interferometers. J. Lightwave Technol. 1996, 14, 27–41. [Google Scholar] [CrossRef]

- Malvern, N. Optical Fiber Gyroscope Sensing Coil Having a Reduced Sensitivity to Temperature Variations Occurring Therein. U.S. Patent 546,5150, 7 November 1995. [Google Scholar]

- Yu, Y.; Wang, Y.; Ma, L. Temperature transient model in FOG fiber coil with cross winding. J. Chin. Inert. Technol. 2013, 21, 687–691. [Google Scholar]

- Du, S.; Guan, Y.; Jin, J.; Zhang, C. Finite element model of thermal transient effect for crossover-free fiber optic gyros. Optik 2012, 123, 748–751. [Google Scholar] [CrossRef]

- Ling, W.; Li, X.; Xu, Z.; Wei, Y. A dicylinc method for suppressing the thermal-induced bias drift of I-FOGs. IEEE Photon. Technol. Lett. 2016, 28, 272–275. [Google Scholar] [CrossRef]

- Ling, W.; Li, X.; Yang, H.; Liu, P.; Xu, Z.; Wei, Y. Reduction of the shupe effect in interferometric fiber optic gyroscopes: The double cylinder-wound coil. Opt. Commun. 2016, 370, 62–67. [Google Scholar] [CrossRef]

- Cheng, J.; Qi, B.; Chen, D.; Landry, R. Modification of an RBF ANN-based temperature compensation model of interferometric fiber optical gyroscopes. Sensors 2015, 15, 11189–11207. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yang, G.; Li, S. Application of BP-AdaBoost model in temperature compensation for fiber optic gyroscope bias. J. Beijing Univ. Aeronaut. Astronaut. 2014, 40, 235–239. [Google Scholar]

- Lofts, C.; Ruffin, P.; Parker, M.; Sung, C. Investigation of the effects of temporal thermal gradients in fiber optic gyroscope sensing coils. Opt. Eng. 1995, 34, 2856–2863. [Google Scholar] [CrossRef]

- Mohr, F.; Schadt, F. Rigorous treatment of fiber-environmental interactions in fiber gyroscopes. In Proceedings of the IEEE Region 8 International Conference on Computational Technologies in Electrical and Electronics Engineering, Novosibirsk, Russia, 21–25 July 2008; pp. 372–375.

- Tirat, O.; Euverte, J. Finite element model of thermal transient effect in fiber optic gyro. Proc. SPIE 1996, 2837, 230–238. [Google Scholar]

- Webber, M.; Willig, R.; Raczkowski, H.; Dineen, A. Modeling of rate error in interferometric fiber-optic gyroscopes due to stress induced by moisture diffusion. J. Lightwave Technol. 2012, 30, 2356–2362. [Google Scholar] [CrossRef]

| i | M | N | li/m | dli/m |

|---|---|---|---|---|

| 1 | 40 | 1 | 0 | 0.379652746 m |

| 2 | 40 | 2 | 0.379652746 m | 0.379652746 m |

| 33 | 40 | 33 | 12.148887872 m | 0.379652746 m |

| 34 | 40 | 34 | 12.528540618 m | 0.379652746 m |

| 1360 | 1 | 34 | 496.09269035 m | 0.346055 m |

| 1361 | 1 | 35 | 496.438754035 m | 0.346055 m |

| 2687 | 40 | 35 | 979.969314717 m | 0.379652746 m |

| 2688 | 40 | 36 | 980.348967473 m | 0.379652746 m |

| 2719 | 40 | 67 | 992.118202589 m | 0.379652746 m |

| 2720 | 40 | 68 | 992.497855335 m | 0.379652746 m |

| i | M | N | li/m | dli/m |

|---|---|---|---|---|

| 1 | 40 | 68 | 0 | 0.379652746 m |

| 2 | 40 | 67 | 0.379652746 m | 0.379652746 m |

| 67 | 40 | 2 | 25.057081236 m | 0.379652746 m |

| 68 | 40 | 1 | 25.436733982 m | 0.379652746 m |

| 1360 | 1 | 68 | 496.147583754 m | 0.346055 m |

| 1361 | 2 | 68 | 496.493638754 m | 0.347168 m |

| 2653 | 39 | 1 | 967.126383888 m | 0.378693 m |

| 2654 | 39 | 2 | 967.505076888 m | 0.378693 m |

| 2719 | 39 | 67 | 992.120121888 m | 0.378693 m |

| 2720 | 39 | 68 | 992.498814888 m | 0.378693 m |

| Parameters | Al-Alloy | Core | Coating | Glue | Insulating Material |

|---|---|---|---|---|---|

| Density ρ kg/m3 | 2740 | 2203 | 1190 | 970 | 2520 |

| Specific heat c J/(kg·K) | 896 | 703 | 1400 | 1600 | 2000 |

| Thermal conductivity λ W/(K·m) | 221 | 1.38 | 0.21 | 0.21 | 1.6 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Ling, W.; He, K.; Xu, Z.; Du, S. A Thermal Performance Analysis and Comparison of Fiber Coils with the D-CYL Winding and QAD Winding Methods. Sensors 2016, 16, 900. https://doi.org/10.3390/s16060900

Li X, Ling W, He K, Xu Z, Du S. A Thermal Performance Analysis and Comparison of Fiber Coils with the D-CYL Winding and QAD Winding Methods. Sensors. 2016; 16(6):900. https://doi.org/10.3390/s16060900

Chicago/Turabian StyleLi, Xuyou, Weiwei Ling, Kunpeng He, Zhenlong Xu, and Shitong Du. 2016. "A Thermal Performance Analysis and Comparison of Fiber Coils with the D-CYL Winding and QAD Winding Methods" Sensors 16, no. 6: 900. https://doi.org/10.3390/s16060900

APA StyleLi, X., Ling, W., He, K., Xu, Z., & Du, S. (2016). A Thermal Performance Analysis and Comparison of Fiber Coils with the D-CYL Winding and QAD Winding Methods. Sensors, 16(6), 900. https://doi.org/10.3390/s16060900