Measurement of Moisture in Wood for Application in the Restoration of Old Buildings

Abstract

:1. Introduction

2. Materials and Methods

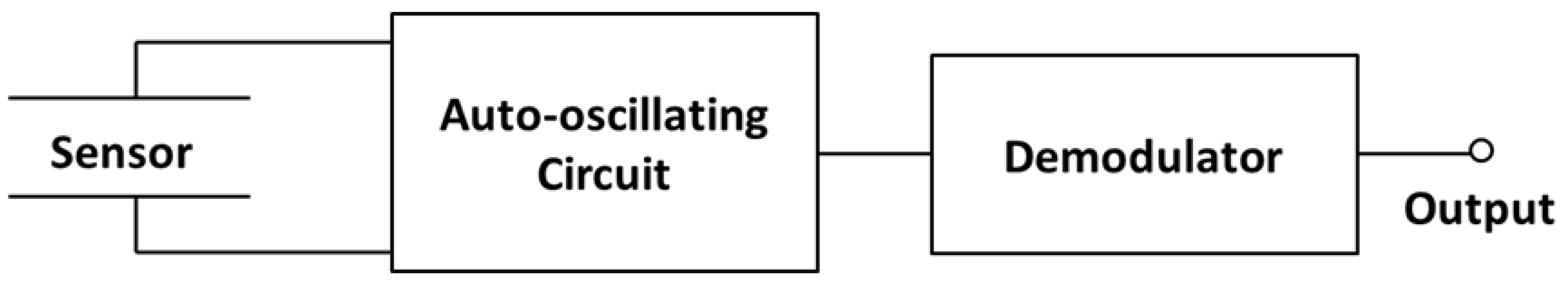

2.1. Measurement Equipment

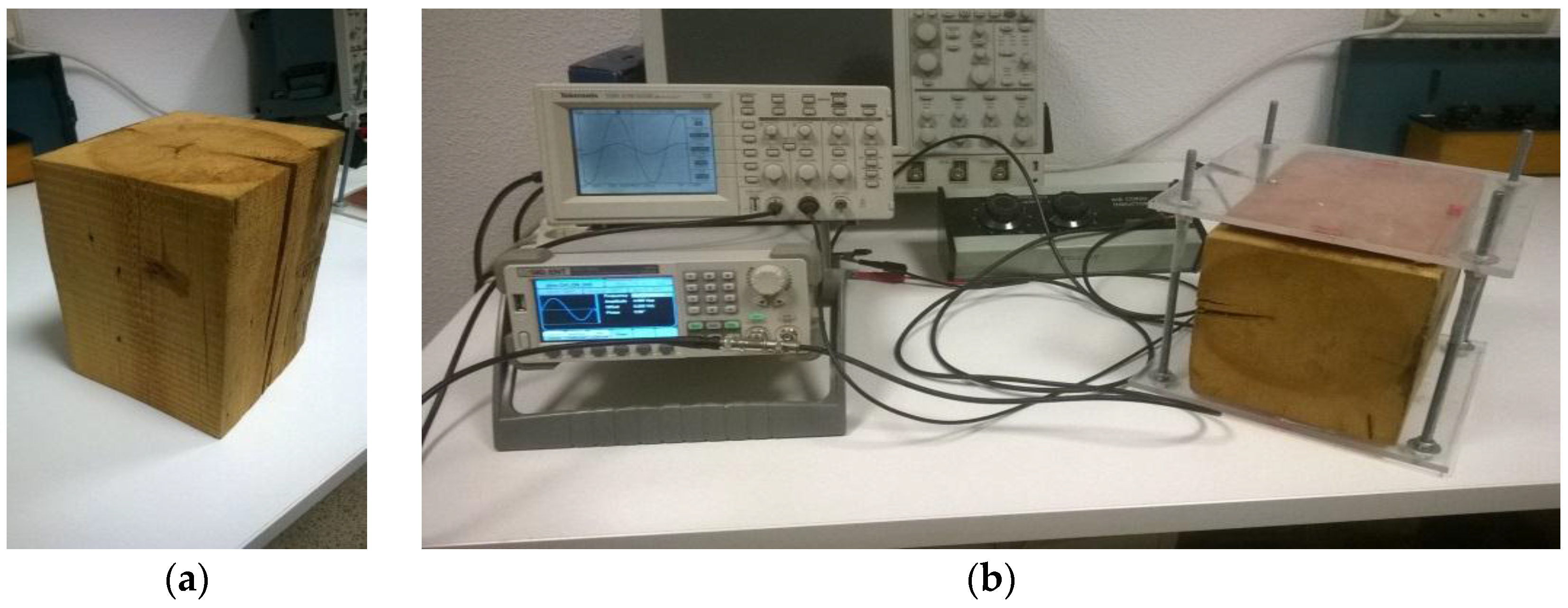

2.2. Conditioning of Wood Samples

2.3. Measures and Moisture Measurement

3. Results and Discussion

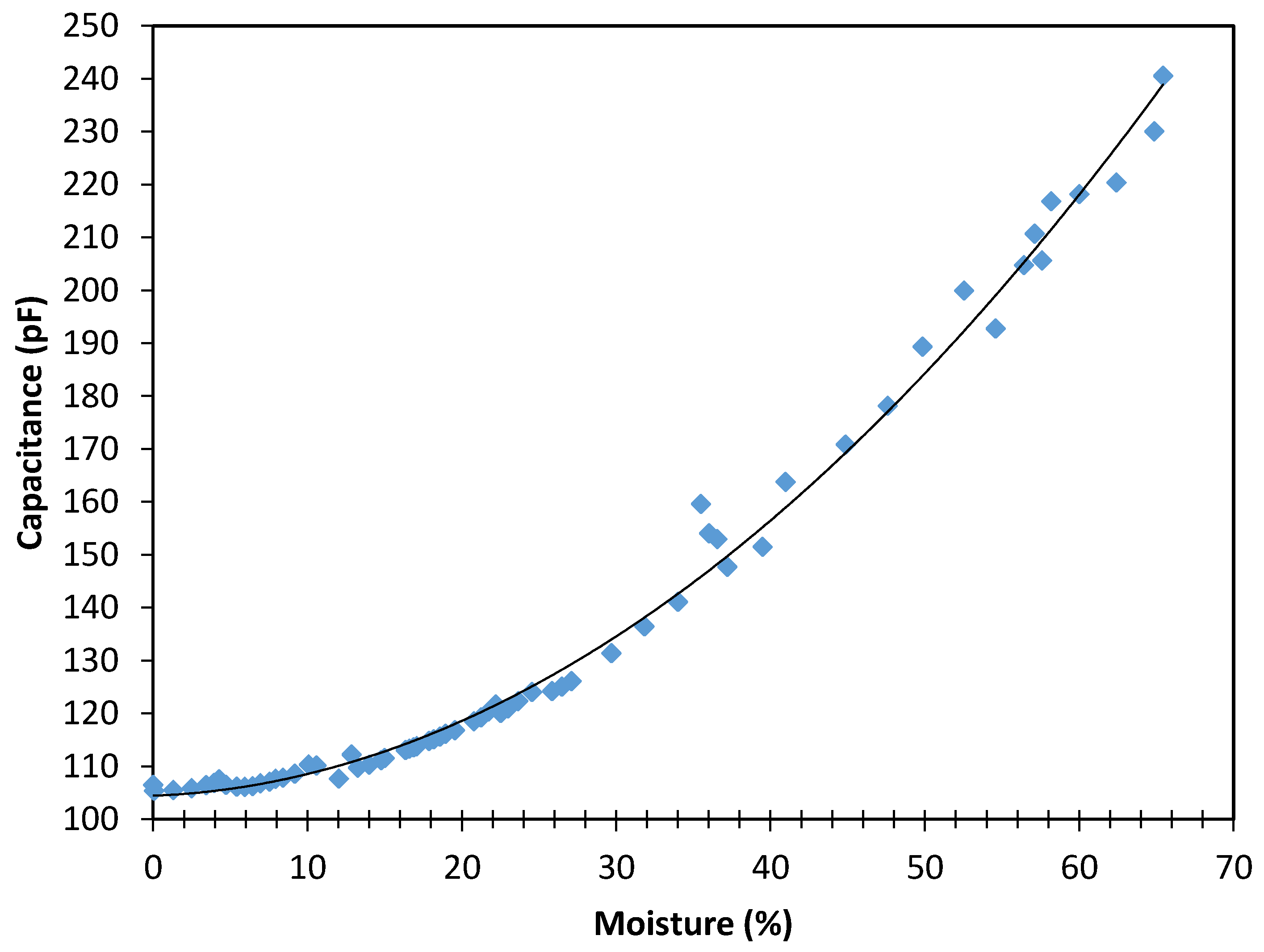

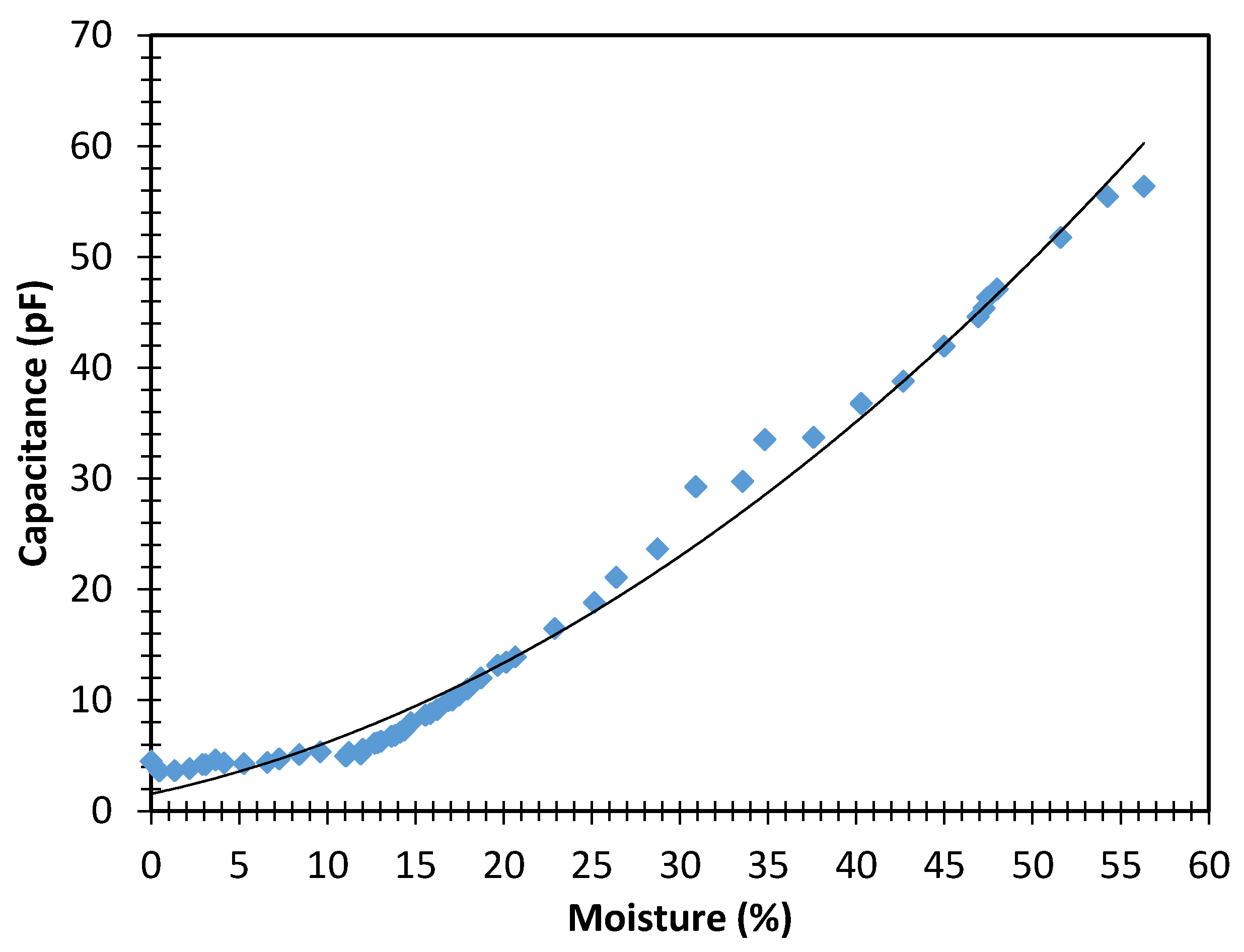

3.1. Capacitance in Relation to Wood Moisture

3.1.1. Capacitance in Relation to Moisture of Wood Samples from a Building under Restoration

3.1.2. Capacitance in Relation to Moisture of a Fresh Wood Sample

3.2. Relationship between Capacitance and Moisture

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| FSP | Fibre Saturation Point |

| GPR | Ground Penetrating Radar |

| TDR | Time Domain Reflectometry |

References

- Nilsson, T.; Rowell, R. Historical wood—Structure and properties. J. Cult. Herit. 2012, 13S, S5–S9. [Google Scholar] [CrossRef]

- Hunt, D. Properties of wood in the conservation of historical wooden artifacts. J. Cult. Herit. 2012, 13S, S10–S15. [Google Scholar] [CrossRef]

- Kozlov, V.; Kisternaya, M. Sorption properties of historic and recent pine wood. Int. Biodeterior. Biodegradation 2014, 86, 153–157. [Google Scholar] [CrossRef]

- Blanchette, R.A. A review of microbial deterioration found in archaeological wood from different environments. Int. Biodeterior. Biodegrad. 2000, 46, 189–204. [Google Scholar] [CrossRef]

- Schmidt, O. Wood and Tree Fungi. Biology, Damage, Protection and Use; Springer-Verlag: Berlin, Germany, 2006. [Google Scholar]

- Johansson, P.; Svensson, T.; Ekstrand-Tobin, A. Validation of critical moisture conditions for mould growth on building materials. Build. Environ. 2013, 62, 201–209. [Google Scholar] [CrossRef]

- Rodríguez Barreal, J.A. Patología de la Madera; Fundación Conde del Valle de Salazar: Madrid, Spain, 1998. [Google Scholar]

- Peraza Sánchez, F. Protección Preventiva de la Madera; AITIM: Madrid, Spain, 2001. [Google Scholar]

- Dubois, F.; Husson, J.M.; Sauvat, N.; Manfoumbi, N. Modeling of the viscoelastic mechano-sorptive behavior in wood. Mech. Time-Depend Mater. 2012, 16, 439–460. [Google Scholar] [CrossRef]

- Svensson, S.; Toratti, T. Mechanical response of wood perpendicular to grain when subjected to changes of humidity. Wood Sci. Technol. 2002, 36, 145–156. [Google Scholar] [CrossRef]

- Klaassen, R.K.W.M. Bacterial decay in wooden foundation piles—Patterns and causes: A study of historical pile foundations in the Netherlands. Int. Biodeterior. Biodegrad. 2008, 61, 45–60. [Google Scholar] [CrossRef]

- Klaassen, R.K.W.M.; Creemers, J.G.M. Wooden foundation piles and its underestimated relevance for cultural heritage. J. Cult. Heritage 2012, 13S, S123–S128. [Google Scholar] [CrossRef]

- Conde, M.J.M.; Liñán, C.R.; de Hita, P.R. Use of ultrasound as a nondestructive evaluation technique for sustainable interventions on wooden structures. Build. Environ. 2014, 82, 247–257. [Google Scholar] [CrossRef]

- Palanti, S.; Macchioni, N.; Paoli, R.; Feci, E.; Scarpino, F. A case study: The evaluation of biological decay of a historical hayloft in Rendena Valley, Trento, Italy. Int. Biodeterior. Biodegrad. 2014, 86, 179–187. [Google Scholar] [CrossRef]

- Korizóg, A.; Otlewska, A.; Piotrowska, M.; Rajkowska, K.; Nowicka-Krawczyk, P.; Hachułka, M.; Wolski, G.J.; Gutarowska, B.; Kunicka-Styczyńska, A.; Libudzisz, Z.; et al. Colonising organism as a biodegradation factor affecting historical wood materials at the former concentration camp of Auschwitz II–Bikernau. Int. Biodeterior. Biodegrad. 2014, 86, 171–178. [Google Scholar]

- D’Orazio, M.; Quagliarini, E. Study on some sorption properties of treated bentonites for their potential use as a moisture regulating system for the preservation of historical wooden elements. J. Cult. Heritage 2010, 11, 185–195. [Google Scholar] [CrossRef]

- Papez, J.; Kic, P. Wood moisture of rural timber construction. Agron. Res. 2013, 11, 505–512. [Google Scholar]

- Hervé, V.; Mothe, F.; Freyburger, C.; Gelhaye, E.; Frey-Klett, P. Density mapping of decaying wood using X-ray computed tomography. Int. Biodeterior. Biodegrad. 2014, 86, 358–363. [Google Scholar] [CrossRef]

- Riggio, M.; Sandak, J.; Franke, S. Application of imaging techniques for detection of defects, damage and decay in timber structures on-site. Constr. Build. Mater. 2015, 101, 1241–1252. [Google Scholar] [CrossRef]

- Rodriguez-Abad, I.; Martinez-Sala, R.; Capuz Lladro, R.; Diez Barra, R.; Garcia-Garcia, F. Estudio de la variacion del contenido de humedad en el Pinus pinaster Ait por medio de la tecnica no destructiva del georradar. Mater. Construcc. 2011, 61, 143–156. (In Spanish) [Google Scholar] [CrossRef]

- Hans, G.; Redman, D.; Leblon, B.; Nader, J.; La Rocque, A. Determination of log moisture content using ground penetrating radar (GPR). Part 2. Propagation velocity (PV) method. Holzforschung 2015, 69, 1125–1132. [Google Scholar] [CrossRef]

- Schajer, G.S.; Orhan, F.B. Measurement of wood grain angle, moisture content and density using microwaves. Holz Roh Werkst 2006, 64, 483–490. [Google Scholar] [CrossRef]

- Denzler, J.K.; Lux, C.; Arthaber, H. Contactless moisture content and density evaluation of sawn timber using microwave transmission. Int. Wood Prod. J. 2014, 5, 200–206. [Google Scholar] [CrossRef]

- Ludwig, N.; Redaelli, V.; Rosina, E.; Augelli, F. Moisture detection in wood and plaster by IR thermography. Infrared. Phys. Technol. 2004, 46, 161–166. [Google Scholar] [CrossRef]

- Kandemir-Yucel, A.; Tavukcuoglu, A.; Caner-Saltik, E.N. In situ assessment of structural timber elements of a historic building by infrared thermography and ultrasonic velocity. Infrared. Phys. Technol. 2007, 49, 243–248. [Google Scholar] [CrossRef]

- Černý, R. Time-domain reflectometry method and its application for measuring moisture content in porous materials: A review. Measurement 2009, 42, 329–336. [Google Scholar] [CrossRef]

- Dahlen, J.; Antony, F.; Li, A.; Love-Myers, K.; Schimleck, L.; Schilling, E.B. Time-Domain Reflectometry for the Prediction of Loblolly Pine and Sweetgum Moisture Content. Bioresources 2015, 10, 4947–4960. [Google Scholar] [CrossRef]

- Mai, T.C.; Razafindratsima, S.; Sbartaï, Z.M.; Demontoux, F.; Bos, F. Non-destructive evaluation of moisture content of wood material at GPR frequency. Constr. Build. Mater. 2015, 77, 213–217. [Google Scholar] [CrossRef]

- Tiitta, M.; Kainulainen, P.; Harju, A.M.; Venäläinen, M.; Manninen, A.M.; Vuorinen, M.; Viitanen, H. Comparing the Effect of Chemical and Physical Properties on Complex Electrical Impedance of Scots Pine Wood. Holzforschung 2003, 57, 433–439. [Google Scholar] [CrossRef]

- Kol, H.S. Thermal and dielectric properties of pine wood in the transverse direction. Bioresources 2009, 4, 1663–1669. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moron, C.; Garcia-Fuentevilla, L.; Garcia, A.; Moron, A. Measurement of Moisture in Wood for Application in the Restoration of Old Buildings. Sensors 2016, 16, 697. https://doi.org/10.3390/s16050697

Moron C, Garcia-Fuentevilla L, Garcia A, Moron A. Measurement of Moisture in Wood for Application in the Restoration of Old Buildings. Sensors. 2016; 16(5):697. https://doi.org/10.3390/s16050697

Chicago/Turabian StyleMoron, Carlos, Luisa Garcia-Fuentevilla, Alfonso Garcia, and Alberto Moron. 2016. "Measurement of Moisture in Wood for Application in the Restoration of Old Buildings" Sensors 16, no. 5: 697. https://doi.org/10.3390/s16050697

APA StyleMoron, C., Garcia-Fuentevilla, L., Garcia, A., & Moron, A. (2016). Measurement of Moisture in Wood for Application in the Restoration of Old Buildings. Sensors, 16(5), 697. https://doi.org/10.3390/s16050697