Planar Indium Tin Oxide Heater for Improved Thermal Distribution for Metal Oxide Micromachined Gas Sensors

Abstract

:1. Introduction

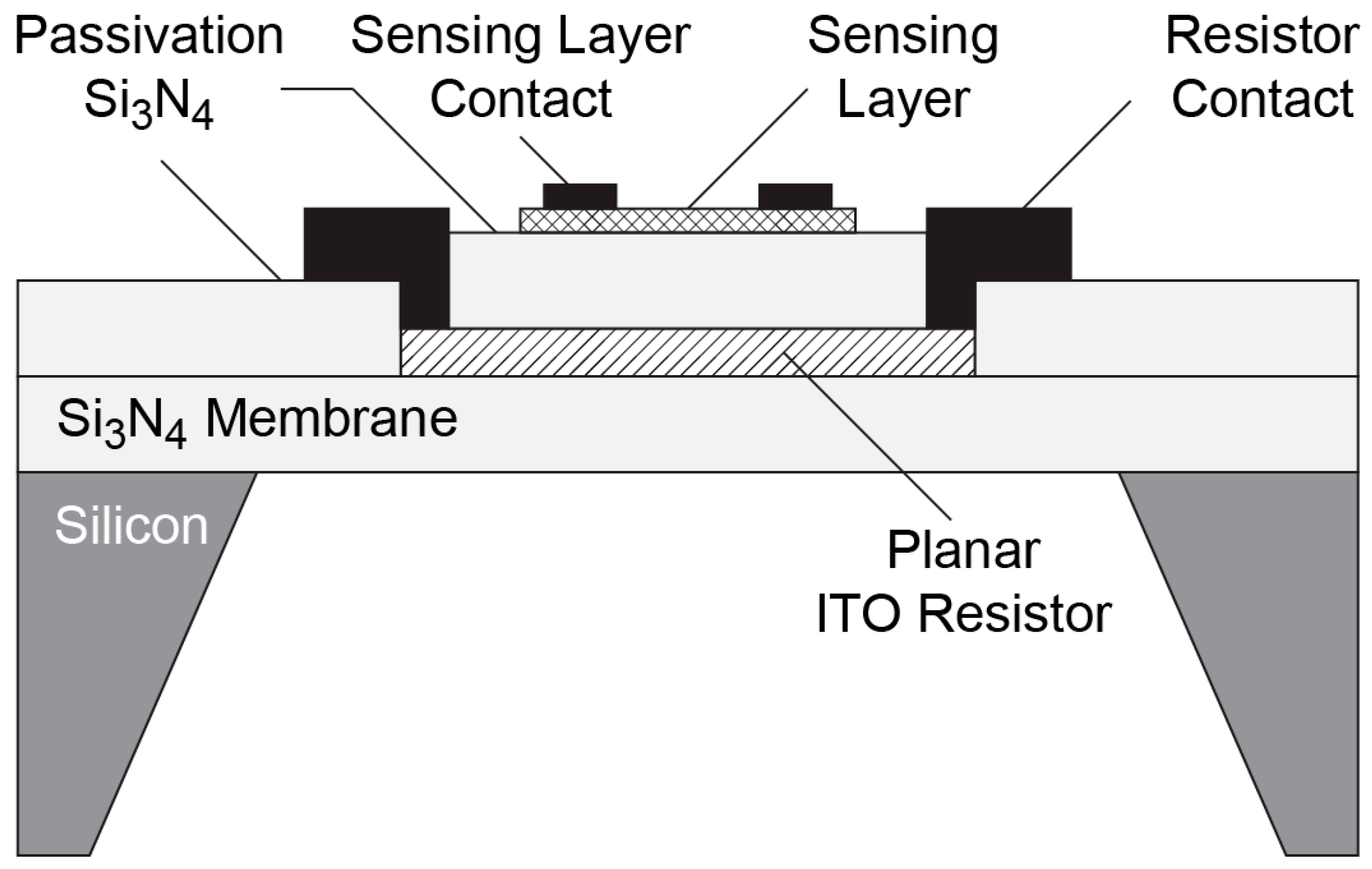

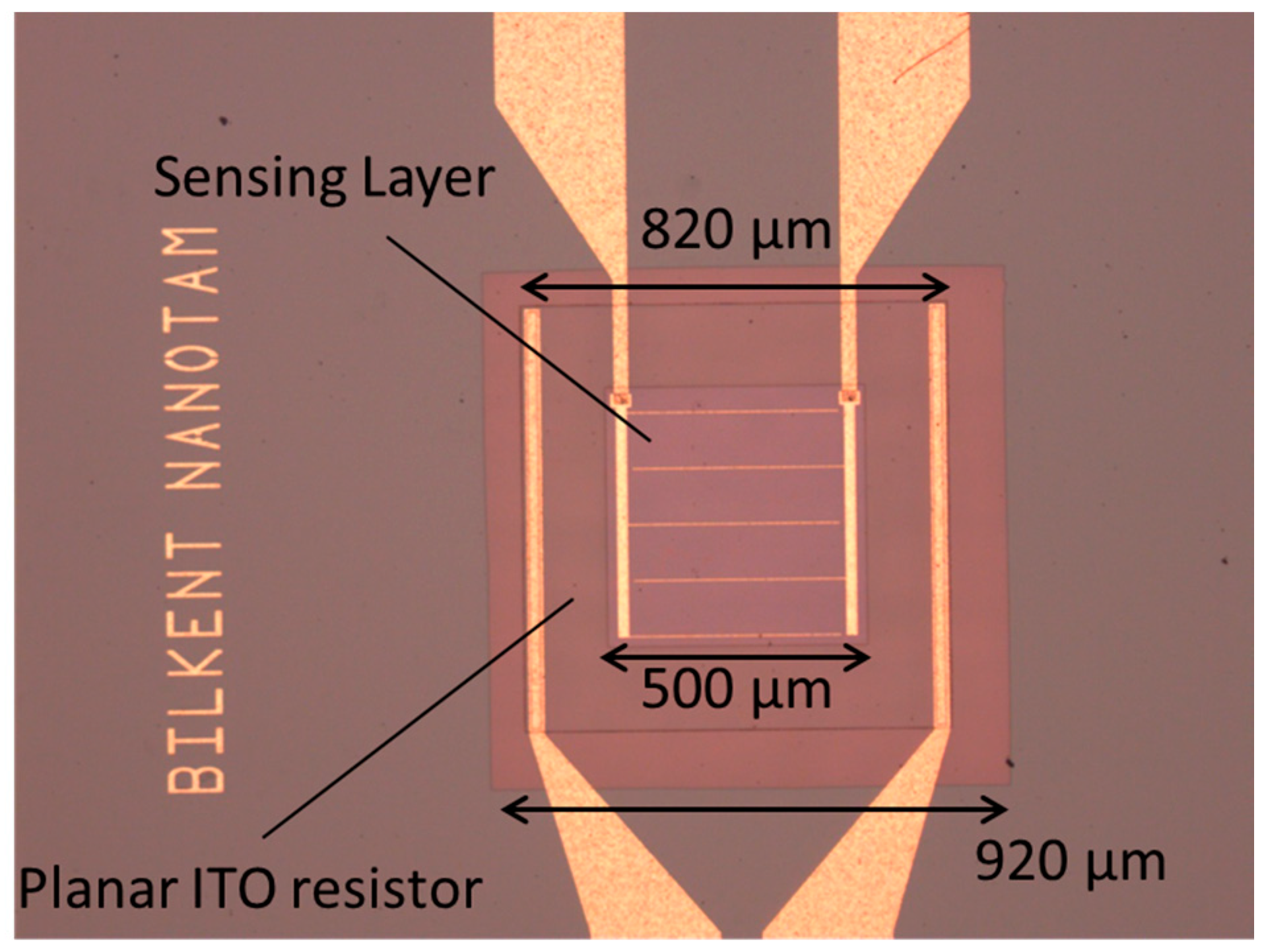

2. Design and Fabrication

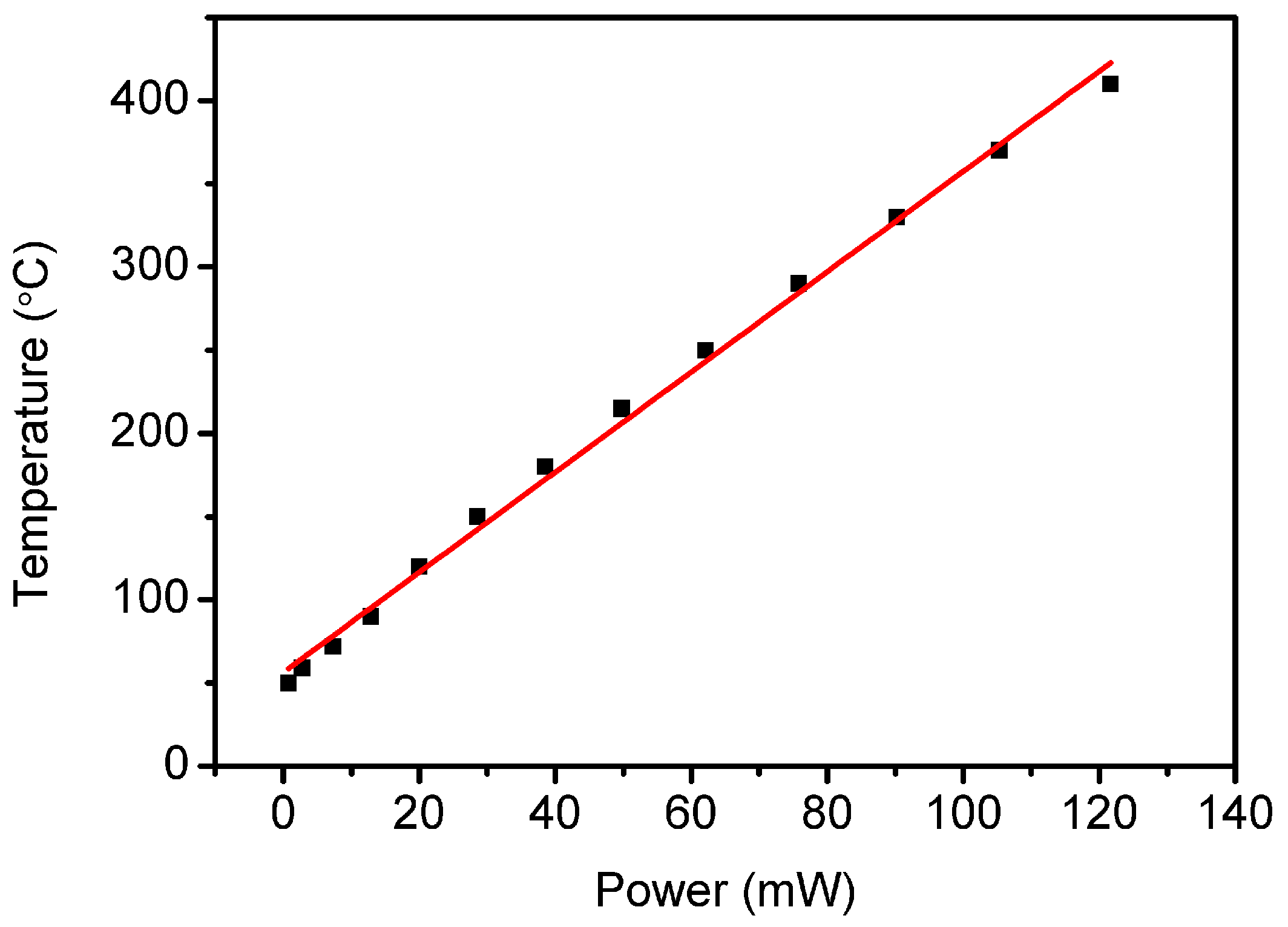

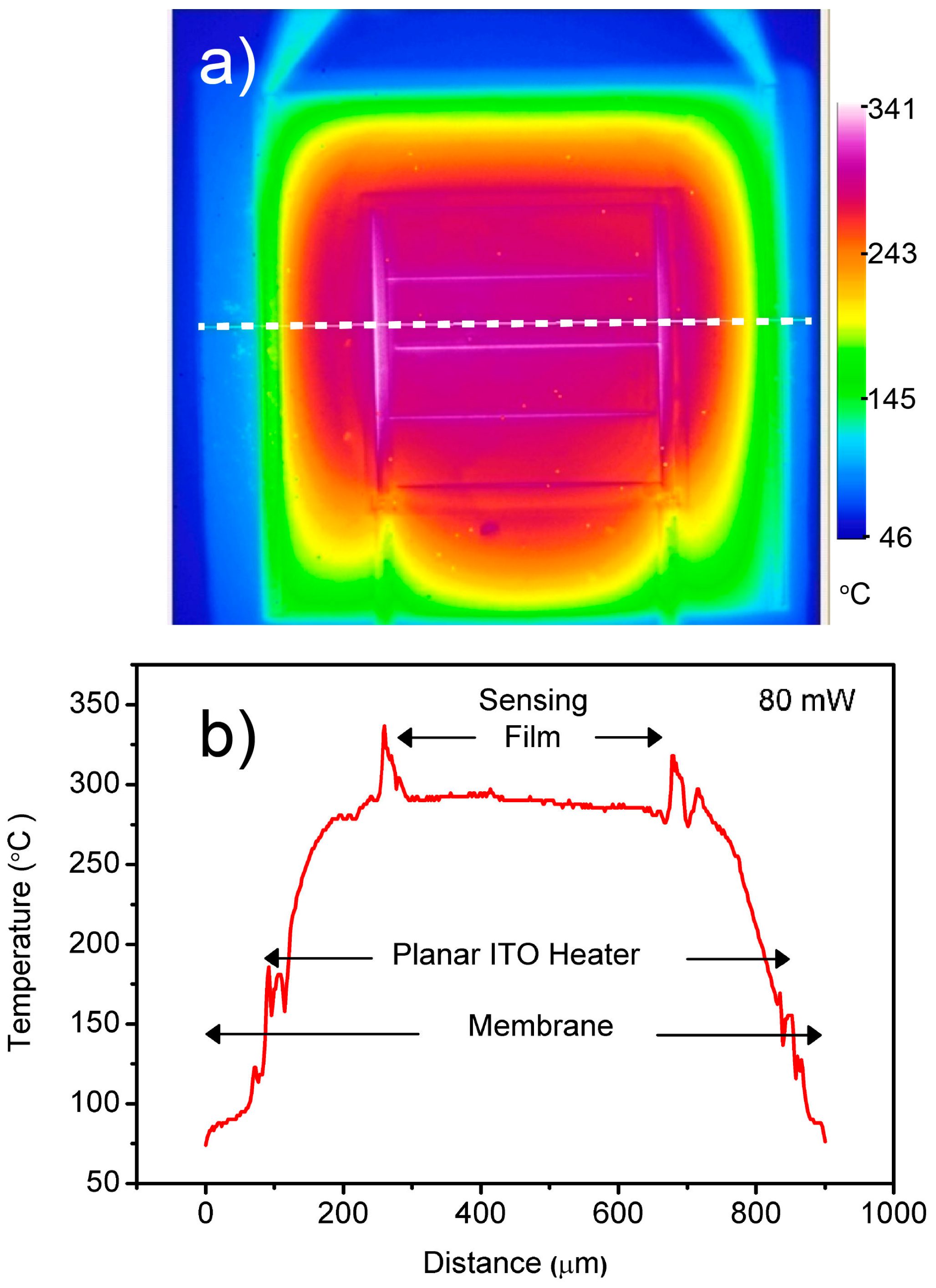

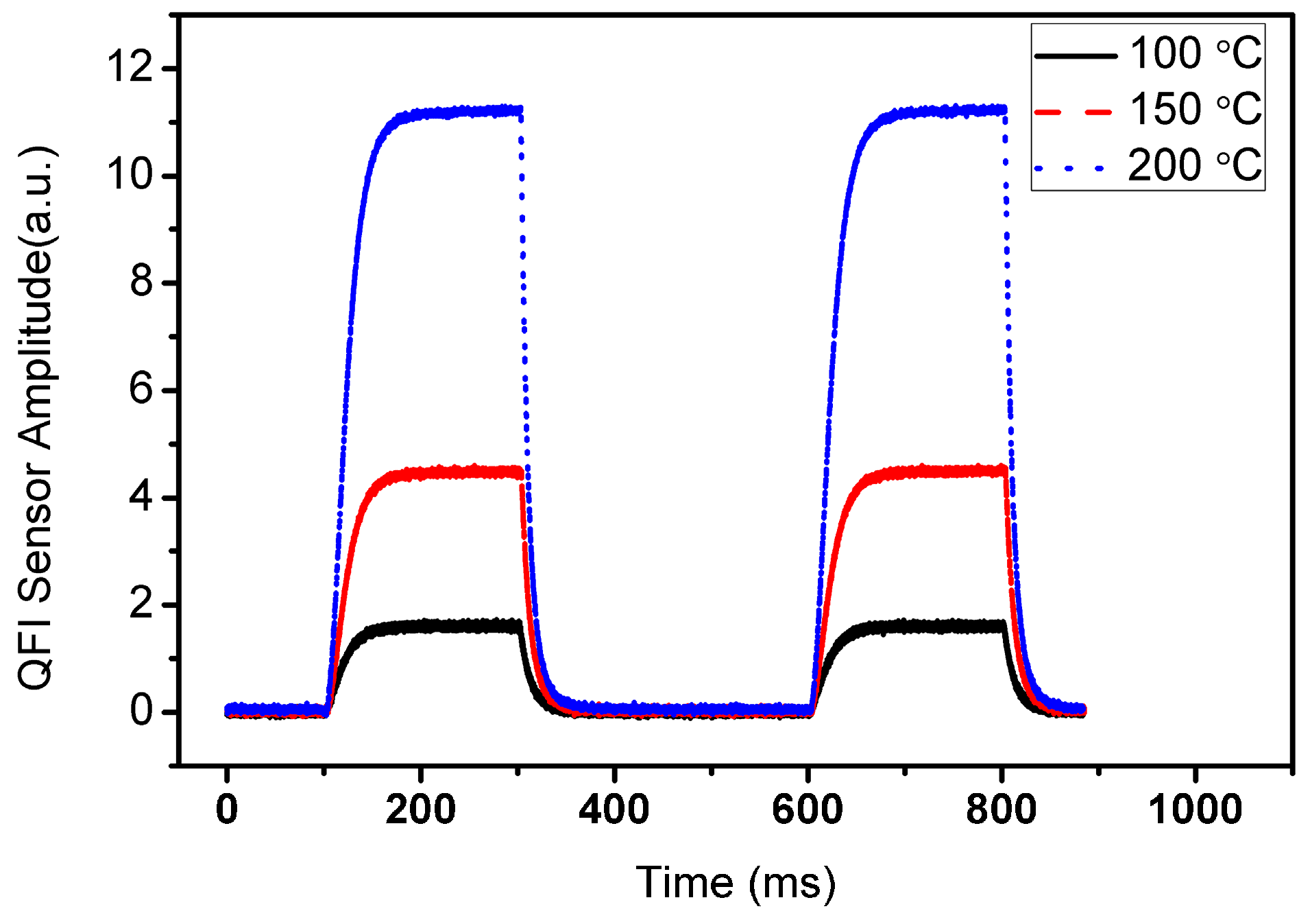

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, C. Metal Oxide Gas Sensors: Sensitivity and Influencing Factors. Sensors 2010, 10, 2088–2106. [Google Scholar] [CrossRef] [PubMed]

- Çalışkan, D.; Bütün, B.; Çakır, M.C.; Özcan, Ş.; Özbay, E. Low dark current and high speed ZnO metal–semiconductor–metal photodetector on SiO2/Si substrate. Appl. Phys. Lett. 2014, 105, 161108. [Google Scholar] [CrossRef]

- Razeghi, M.; Rogalski, A. Semiconductor ultraviolet detectors. J. Appl. Phys. 1996, 79, 7433–7473. [Google Scholar] [CrossRef]

- Hwang, W.; Shin, K.; Roh, J.; Lee, D.; Choa, S. Development of Micro-Heaters with Optimized Temperature Compensation Design for Gas Sensors. Sensors 2010, 11, 2580–2591. [Google Scholar] [CrossRef] [PubMed]

- Manginell, R.P.; Smith, J.H.; Ricco, A.J. An overview of micromachined platforms for thermal sensing and gas detection. Proc. SPIE 1997, 3046. [Google Scholar] [CrossRef]

- Semancik, S.; Cavicchia, R.E.; Wheelera, M.C.; Tiffanya, J.E.; Poiriera, G.E.; Walton, R.M.; Suehlea, J.S.; Panchapakesanb, B.; DeVoeb, D.L. Microhotplate platforms for chemical sensor research. Sens. Actuators B Chem. 2010, 77, 579–591. [Google Scholar] [CrossRef]

- Min, Y. Properties and Sensor Performance of Zinc Oxide Thin Films. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2003. [Google Scholar]

- Semancik, S.; Cavicchi, R. Kinetically controlled chemical sensing using micromachined stuctures. Acc. Chem. Res. 1998, 31, 279–287. [Google Scholar] [CrossRef]

- Steffes, H.; Imawan, C.; Solzbacher, F.; Obermeier, E. Enhancement of NO2 sensing properties of In2O3-based thin films using an Au or Ti surface modification. Sens. Actuators B Chem. 2001, 78, 106–112. [Google Scholar] [CrossRef]

- Kolmakov, A.; Klenov, D.O.; Lilach, Y.; Stemmer, S.; Moskovits, M. Enhanced Gas Sensing by Individual SnO2 Nanowires and Nanobelts Functionalized with Pd Catalyst Particles. Nano Lett. 2005, 5, 667–673. [Google Scholar] [CrossRef] [PubMed]

- Jing, Z.; Zhan, J. Fabrication and Gas-Sensing Properties of Porous ZnO Nanoplates. Adv. Mater. 2008, 20, 4547–4551. [Google Scholar] [CrossRef]

- Sidek, O.; Ishak, M.Z.; Khalid, M.A.; Abu Bakar, M.Z.; Miskam, M.A. Effect of heater geometry on the high temperature distribution on a MEMS micro-hotplate. In Proceedings of the 3rd Asia Symposium on Quality Electronic Design (ASQED), Kuala Lumpur, Malaysia, 19–20 July 2011; pp. 100–104.

- Martinelli, E. Self-adapted temperature modulation in metal-oxide semiconductor gas sensors. Sens. Actuators B Chem. 2010, 161, 534–541. [Google Scholar] [CrossRef]

- Briand, D.; Heimgartner, S.; Gétillat, M.-A.; van der Schoot, B.; de Rooij, N.F. Thermal optimization of micro-hotplates that have a silicon island. J. Micromech. Microeng. 2002, 12, 971–978. [Google Scholar] [CrossRef]

- Guha, P.K.; Ali, S.Z.; Lee, C.C.C.; Udrea, F.; Milne, W.I.; Iwaki, T.; Covington, J.A.; Gardner, J.W. Novel design and characterization of SOI CMOS micro-hotplates for high temperature gas sensors. Sens. Actuators B Chem. 2007, 127, 260–266. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Çakır, M.C.; Çalışkan, D.; Bütün, B.; Özbay, E. Planar Indium Tin Oxide Heater for Improved Thermal Distribution for Metal Oxide Micromachined Gas Sensors. Sensors 2016, 16, 1612. https://doi.org/10.3390/s16101612

Çakır MC, Çalışkan D, Bütün B, Özbay E. Planar Indium Tin Oxide Heater for Improved Thermal Distribution for Metal Oxide Micromachined Gas Sensors. Sensors. 2016; 16(10):1612. https://doi.org/10.3390/s16101612

Chicago/Turabian StyleÇakır, M. Cihan, Deniz Çalışkan, Bayram Bütün, and Ekmel Özbay. 2016. "Planar Indium Tin Oxide Heater for Improved Thermal Distribution for Metal Oxide Micromachined Gas Sensors" Sensors 16, no. 10: 1612. https://doi.org/10.3390/s16101612

APA StyleÇakır, M. C., Çalışkan, D., Bütün, B., & Özbay, E. (2016). Planar Indium Tin Oxide Heater for Improved Thermal Distribution for Metal Oxide Micromachined Gas Sensors. Sensors, 16(10), 1612. https://doi.org/10.3390/s16101612