Position and Velocity Estimation for Two-Inertia System with Nonlinear Stiffness Based on Acceleration Sensor

Abstract

:1. Introduction

2. Problem Formulation

3. Main Results

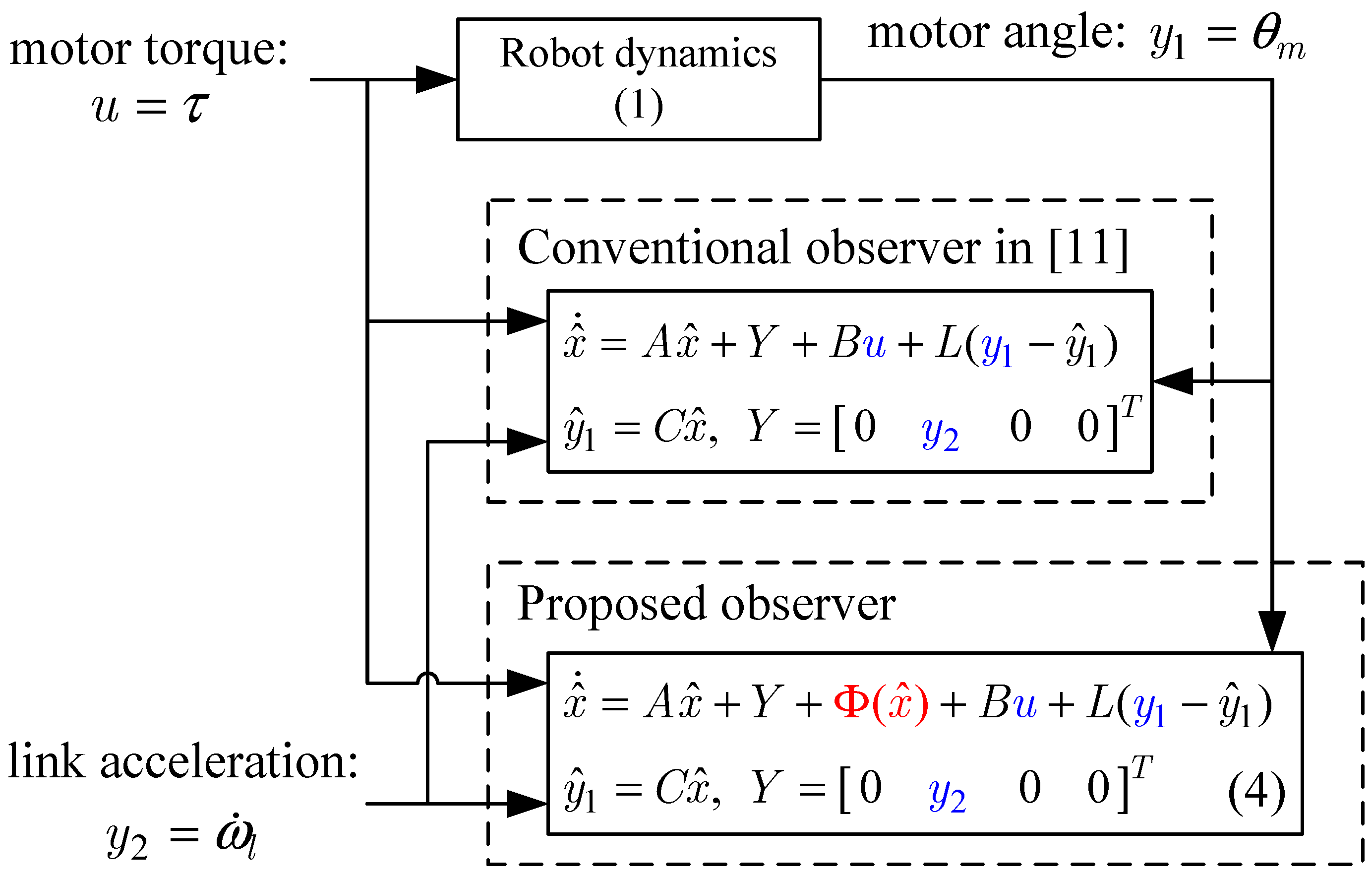

3.1. Observer Design

3.2. Coordinate Transformation

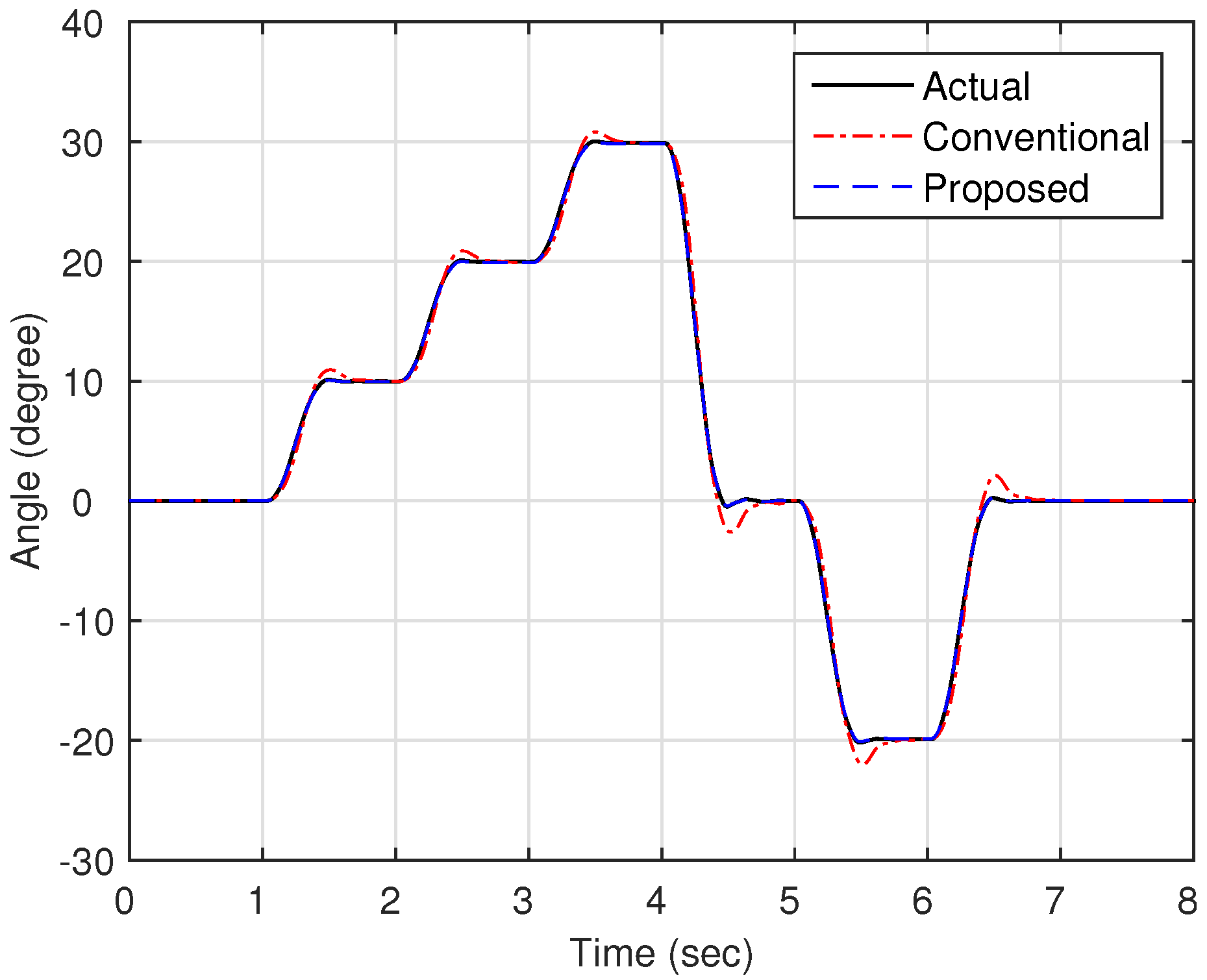

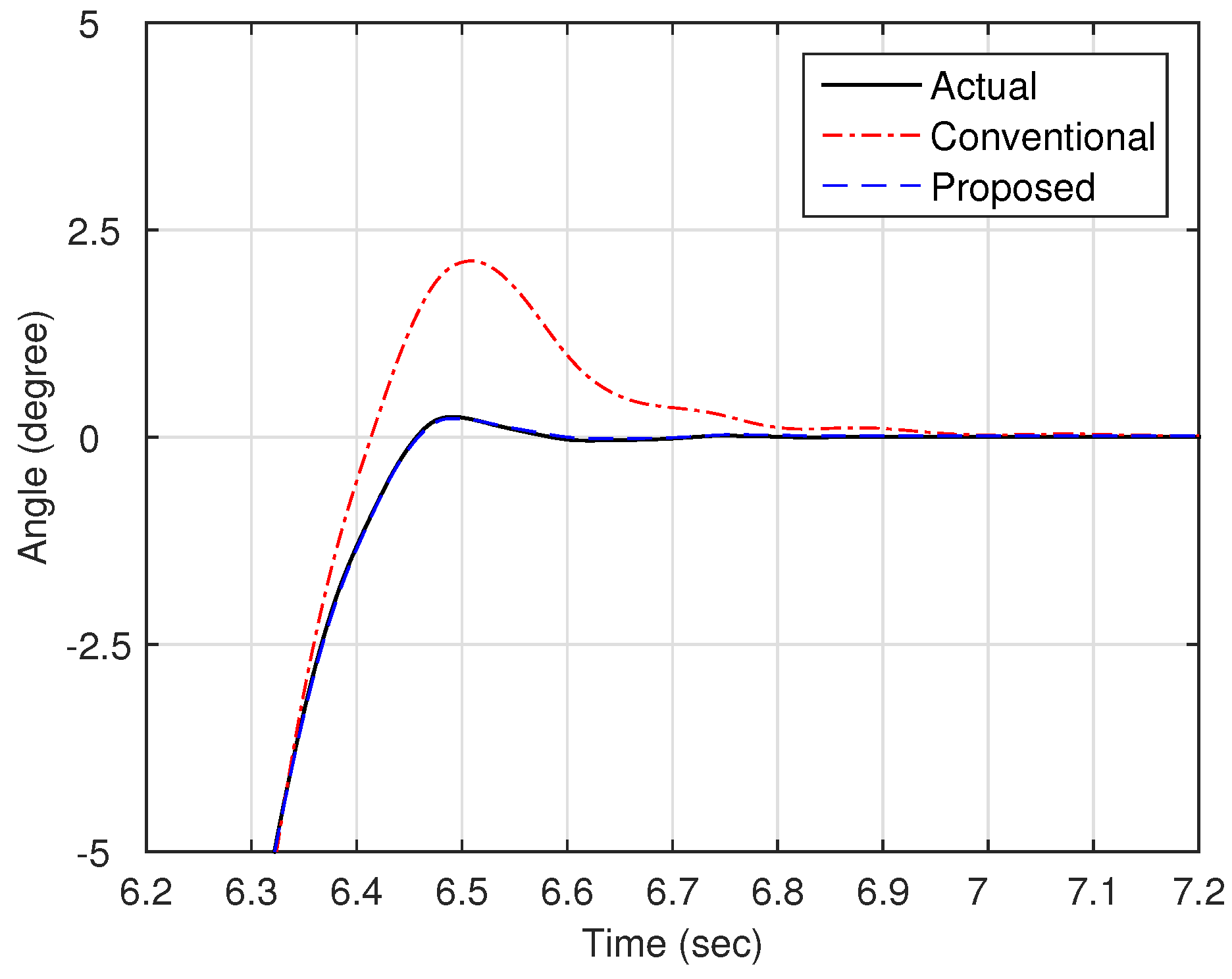

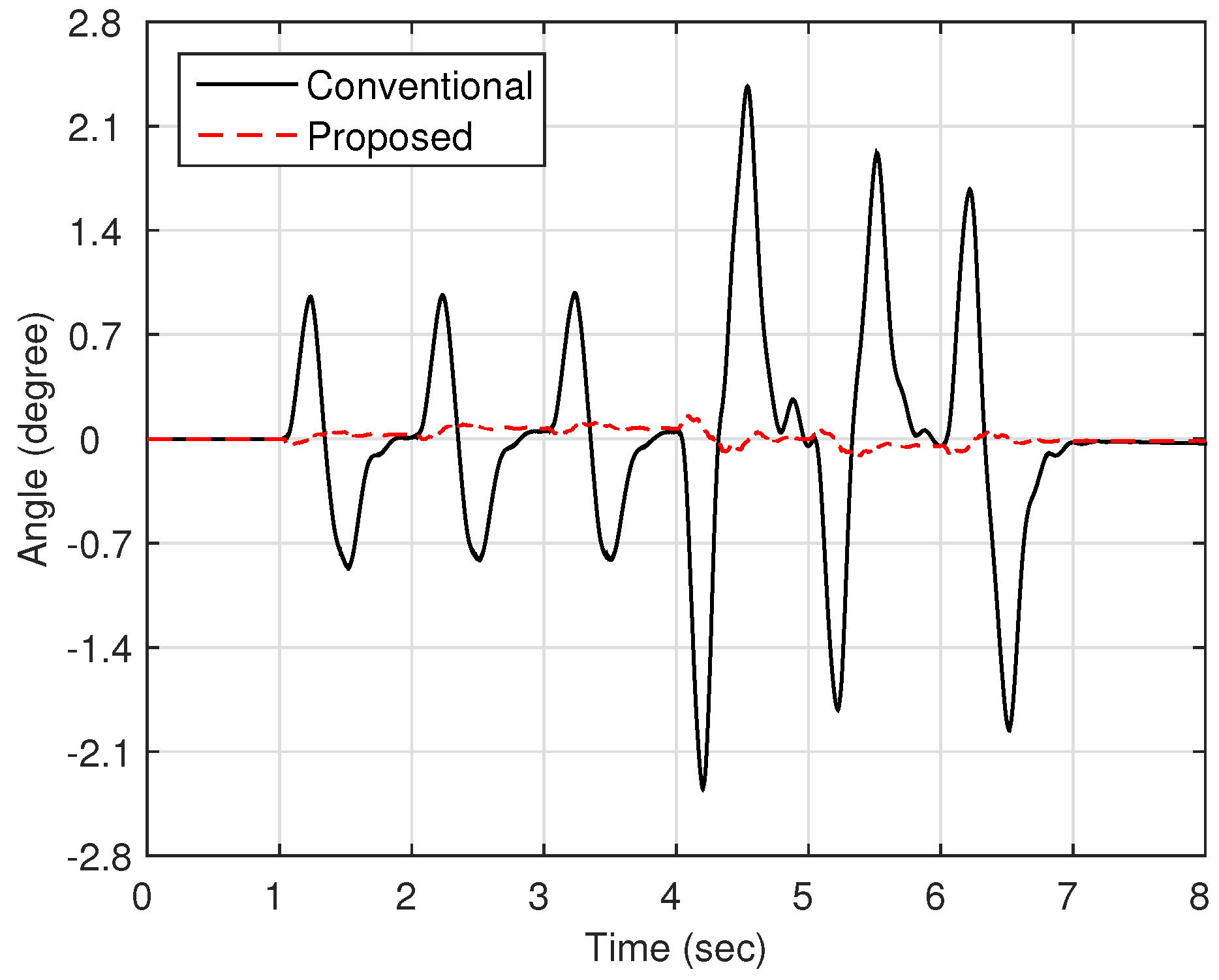

4. Experimental Results

| Parameter | Value | Unit |

|---|---|---|

| motor inertia () | 0.001027 | kg· m |

| damping (D) | 600 | Nm·s/rad |

| 1.5 | Nm/rad | |

| 9.85 | Nm/rad | |

| 2 | arcmin | |

| gear ratio | 144 |

| Parameter | Value |

|---|---|

| observer gain (L) | |

| ϵ | |

| β |

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Spong, M.W.; Hutchinson, S.; Vidyasagar, M. Robot Modeling and Control; Wiley: New York, NY, USA, 2006. [Google Scholar]

- Bang, J.S.; Shim, H.; Park, S.K.; Seo, J.H. Robust tracking and vibration suppression for a two-inertia system by combining backstepping approach with disturbance observer. IEEE Trans. Ind. Electron. 2010, 11, 618–623. [Google Scholar]

- Tomei, P. A simple pd controller for robots with elastic joints. IEEE Trans. Autom. Control 1991, 36, 1208–1213. [Google Scholar] [CrossRef]

- Jankovic, M. Observer based control for elastic joint robots. IEEE Trans. Robot. Autom. 1995, 11, 618–623. [Google Scholar] [CrossRef]

- Choi, C.H.; Kwak, N. Robust control of robot manipulator by model-based disturbance attennuation. IEEE ASME Trans. Mechatron. 2003, 8, 511–513. [Google Scholar] [CrossRef]

- Islam, S.; Liu, P.X. Pd output feedback control design for industrial robotic manipulators. IEEE ASME Trans. Mechatron. 2011, 18, 187–197. [Google Scholar] [CrossRef]

- Kostarigka, A.K.; Doulgeri, Z.; Rovithakis, G.A. Prescribed performance tracking for flexible joint robots with unknown dynamics and variable elasticity. Automatica 2013, 49, 1137–1147. [Google Scholar] [CrossRef]

- Yun, J.N.; Su, J.B. Design of a disturbance ovserver for a tow-link manipulator with flexible joints. IEEE Trans. Control Syst. Technol. 2014, 22, 809–815. [Google Scholar] [CrossRef]

- Lotfi, N.; Namvar, M. Global adaptive estimation of joint velocities in robotic manipulators. IET Control Theory Appl. 2010, 4, 2672–2681. [Google Scholar] [CrossRef]

- Cantelli, L.; Muscato, G.; Nunnari, M.; Spina, D. A joint-angle estimation method for industrial manipulators using inertial sensors. IEEE ASME Trans. Mechatron. 2015, 20, 2486–2495. [Google Scholar] [CrossRef]

- Luca, A.E.; Schroder, D.; Thummel, M.; Spina, D. An acceleration-based state observer for robot manipulators with elastic joints. In Proceedings of the IEEE International Conference on Robotics and Automation, Roma, Italy, 10–14 April 2007; pp. 3817–3823.

- Staufer, P.; Gattringer, H. State estimation on flexible robots using accelerometers and angular rate sensors. Mechatronics 2012, 22, 1043–1049. [Google Scholar] [CrossRef]

- Axelsson, P.; Karlssn, R.; Norrlof, M. Bayesian state estimation of a flexible industrial robot. Mechatronics 2012, 20, 1220–1228. [Google Scholar] [CrossRef]

- Chen, W.; Tomizuka, M. Load side state estimation in robot with joint elasticity. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Kachsiung, Taiwan, 11–14 July 2012; pp. 598–603.

- Chen, W.; Tomizuka, M. Direct joint space state estimation in robots with multiple elastic joints. IEEE ASME Trans. Mechatron. 2014, 19, 697–706. [Google Scholar] [CrossRef]

- Moberg, S.; Öhr, J.; Gunnarsson, S. A benchmark problem for robust control of a multivariable nonlinear flexible manipulator. In Proceedings of the 17th IFAC World Congress, Seoul, Korea, 6–11 July 2008; pp. 1206–1211.

- Moberg, S.; Öhr, J.; Gunnarsson, S. A benchmark problem for robust control of a multivariable nonlinear flexible manipulator. IEEE Trans. Control Syst. Technol. 2009, 17, 1398–1405. [Google Scholar] [CrossRef]

- Moberg, S.; Wernholt, E.; Hanssen, S.; Brongardh, T. Modeling and parameter estimation of robot manipulators using extended flexible joint models. J. Dyn. Syst. Meas. Control 2014, 136, 1–13. [Google Scholar] [CrossRef]

- Raghavan, S.; Hedrick, J.K. Observer design for a class of nonlinear systems. Asian J. Control 1994, 59, 515–528. [Google Scholar] [CrossRef]

- Sugiura, K.; Hori, Y. Vibration suppression in 2- and 3-mass system based on the feedback of imperfect derivative of the estimated torsional torque. IEEE Trans. Ind. Electron. 1996, 43, 56–64. [Google Scholar] [CrossRef]

- Song, B.; Hedrick, J.K. Nonlinear observer design for lipschitz nonlinear systems. In Proceedings of the American Control Conference (ACC), San Francisco, CA, USA, 29 June–1 July 2011; pp. 2578–2583.

- Khalil, H. Nonlinear Systems, 3rd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Farza, M.; M’Saad, M.; Rossignol, L. Observer design for a class of MIMO nonlinear systems. Automatica 2004, 40, 135–143. [Google Scholar] [CrossRef]

- Ni, M.-L. Existence condition on solutions to the algebraic riccati equation. Acta Autom. Sin. 2008, 34, 85–87. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nam, K.-T.; Lee, S.-J.; Kuc, T.-Y.; Kim, H. Position and Velocity Estimation for Two-Inertia System with Nonlinear Stiffness Based on Acceleration Sensor. Sensors 2016, 16, 49. https://doi.org/10.3390/s16010049

Nam K-T, Lee S-J, Kuc T-Y, Kim H. Position and Velocity Estimation for Two-Inertia System with Nonlinear Stiffness Based on Acceleration Sensor. Sensors. 2016; 16(1):49. https://doi.org/10.3390/s16010049

Chicago/Turabian StyleNam, Kyung-Tae, Seung-Joon Lee, Tae-Yong Kuc, and Hyungjong Kim. 2016. "Position and Velocity Estimation for Two-Inertia System with Nonlinear Stiffness Based on Acceleration Sensor" Sensors 16, no. 1: 49. https://doi.org/10.3390/s16010049

APA StyleNam, K.-T., Lee, S.-J., Kuc, T.-Y., & Kim, H. (2016). Position and Velocity Estimation for Two-Inertia System with Nonlinear Stiffness Based on Acceleration Sensor. Sensors, 16(1), 49. https://doi.org/10.3390/s16010049