Synthesis of Bio-Based Polyurethanes from Functionalized Sunflower Seed Oil

Abstract

1. Introduction

2. Results and Discussion

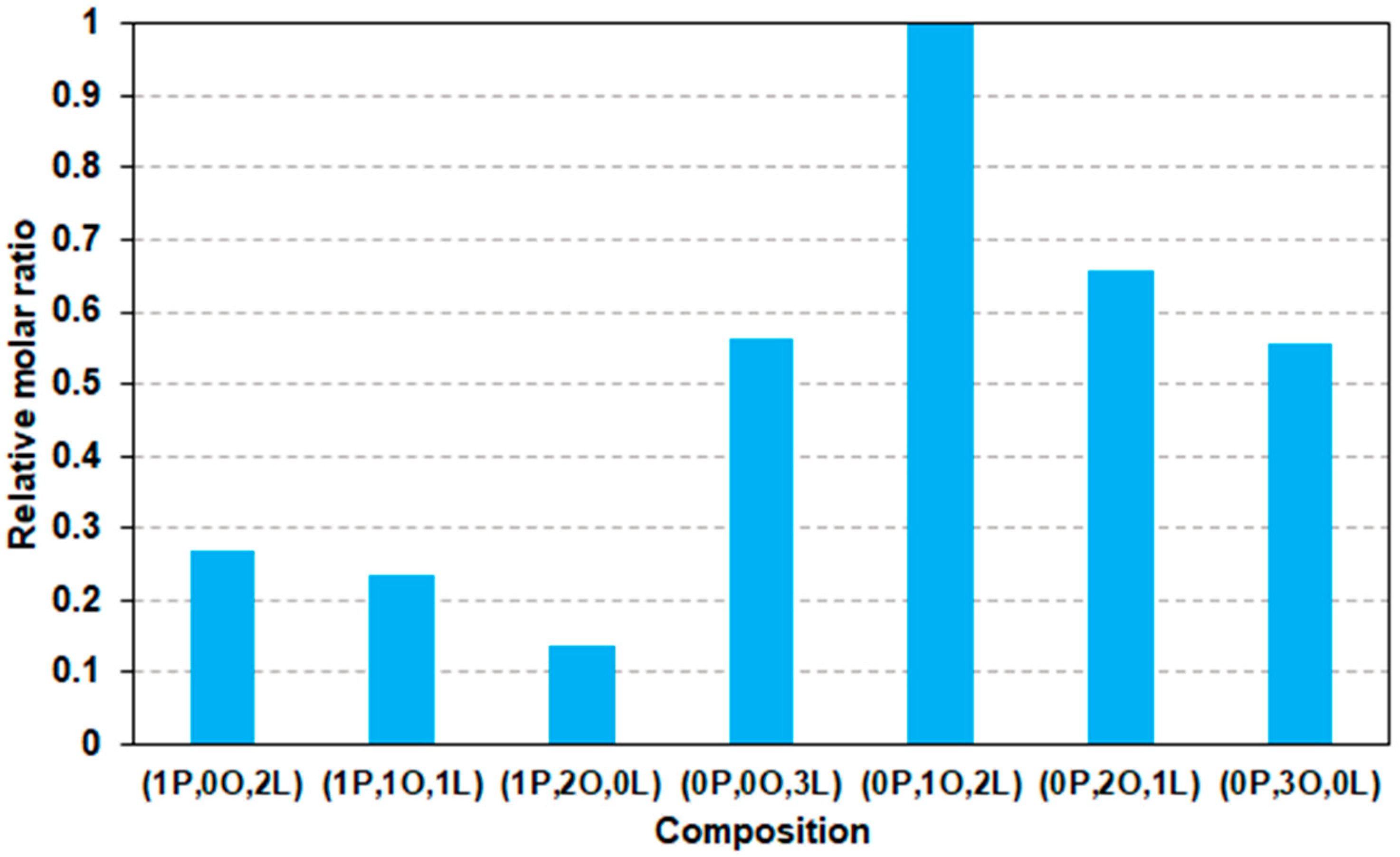

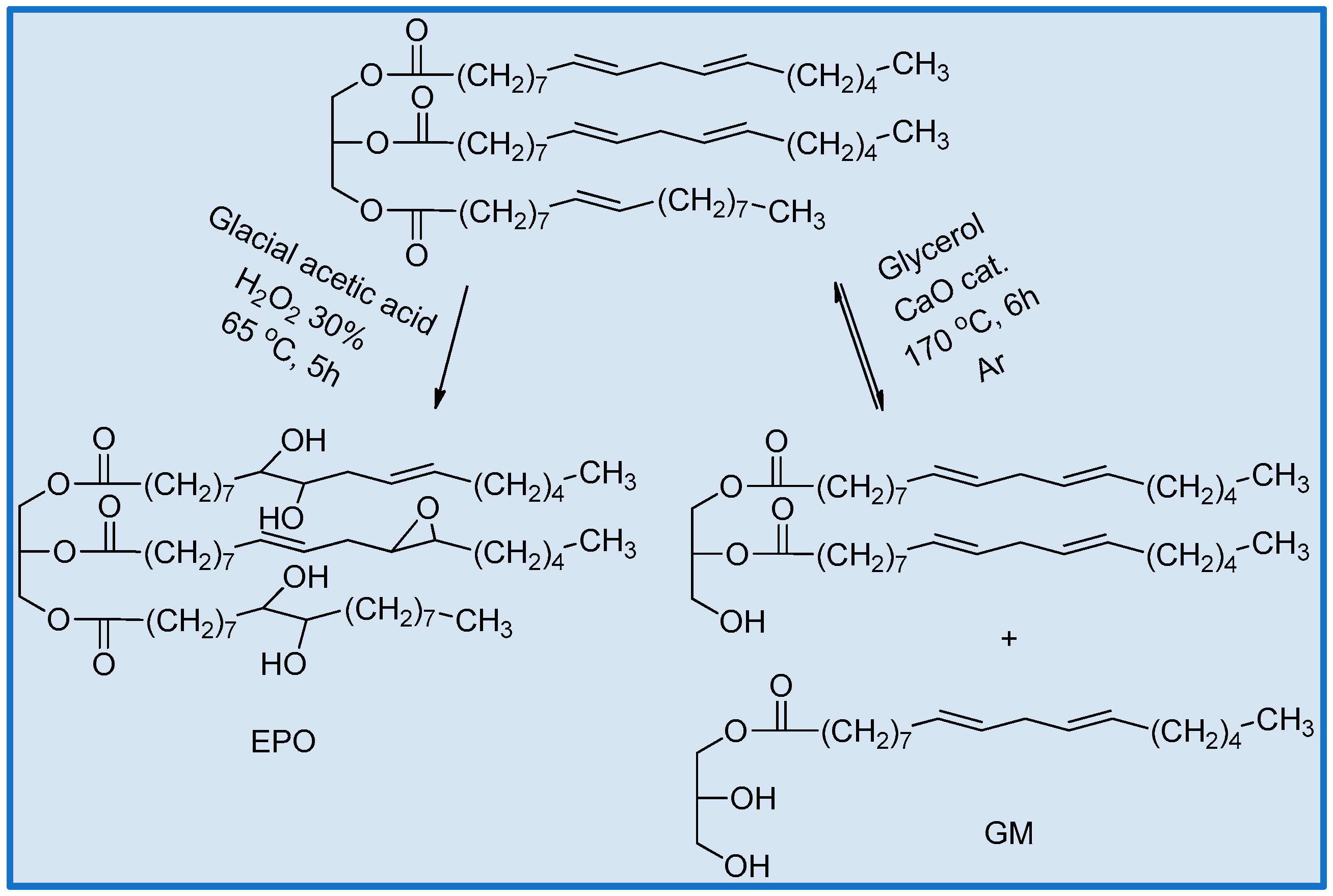

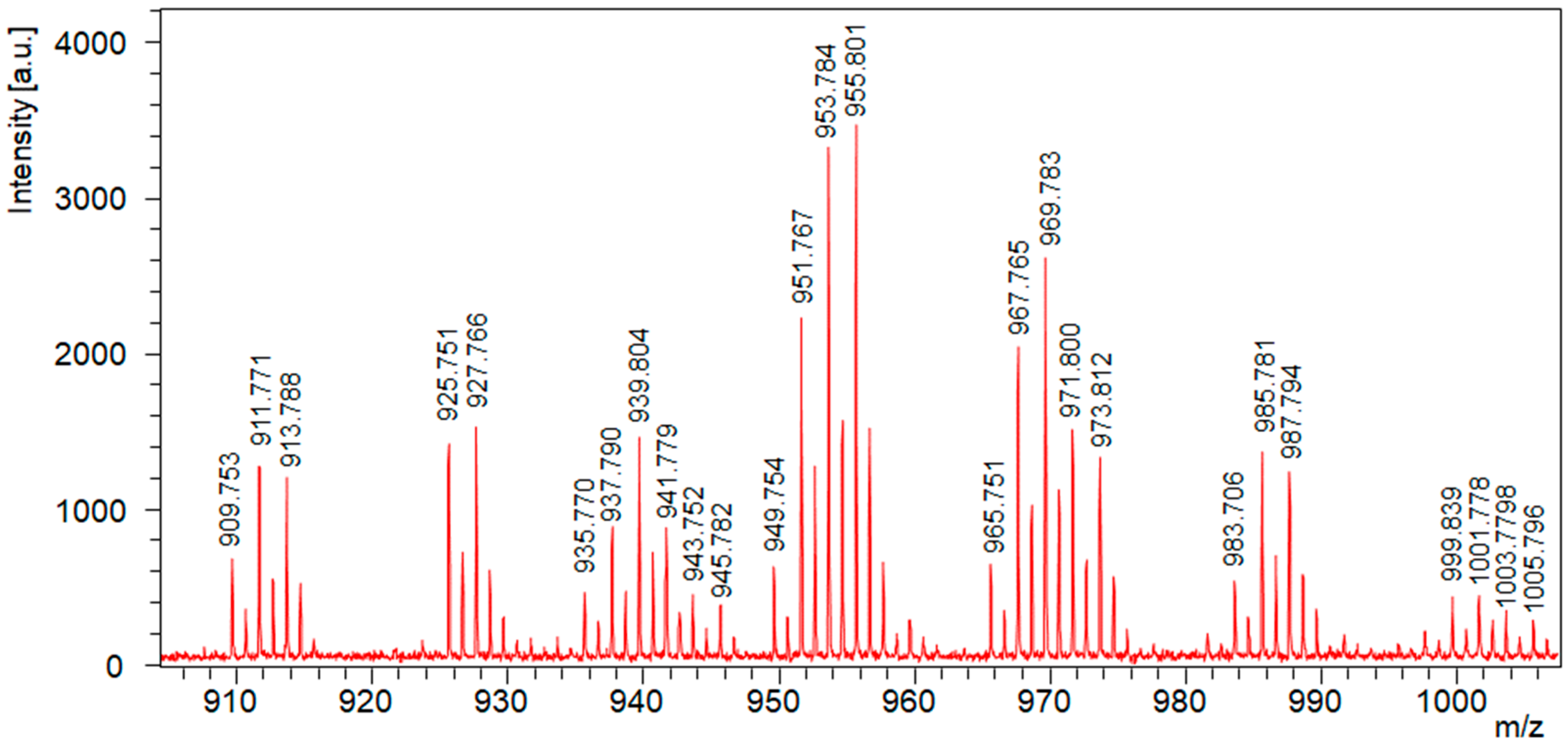

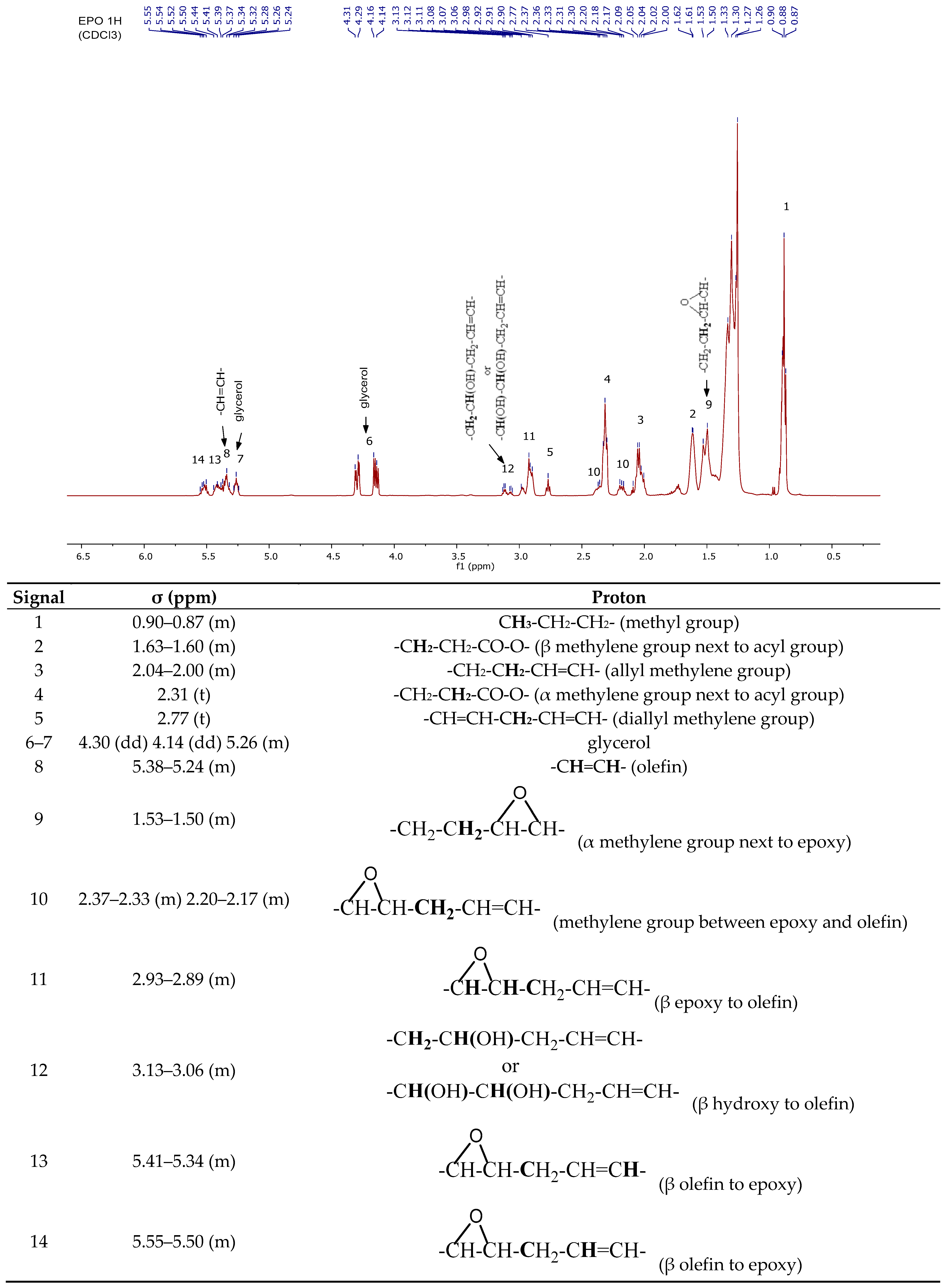

2.1. Chemical Transformation of Sunflower Oil

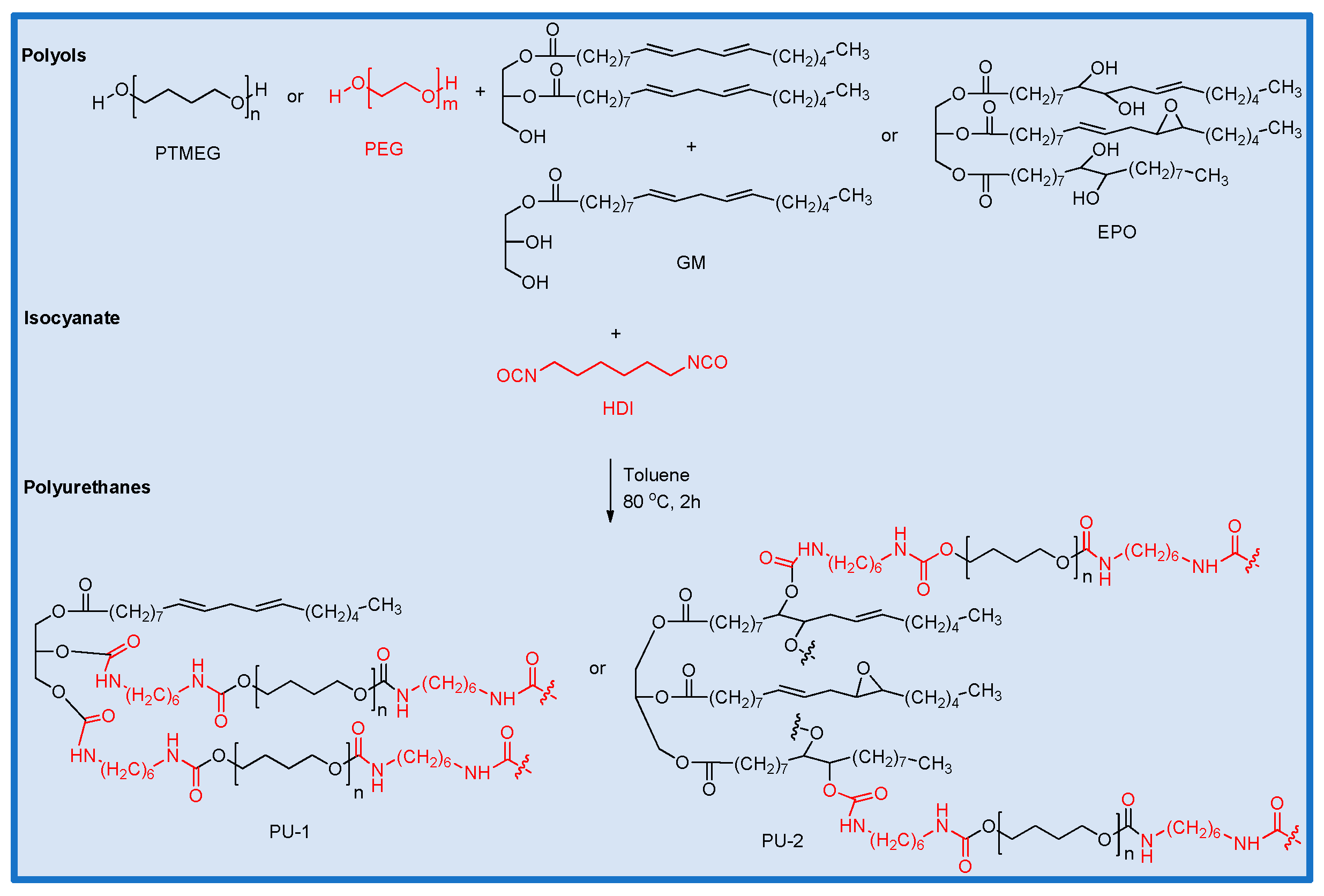

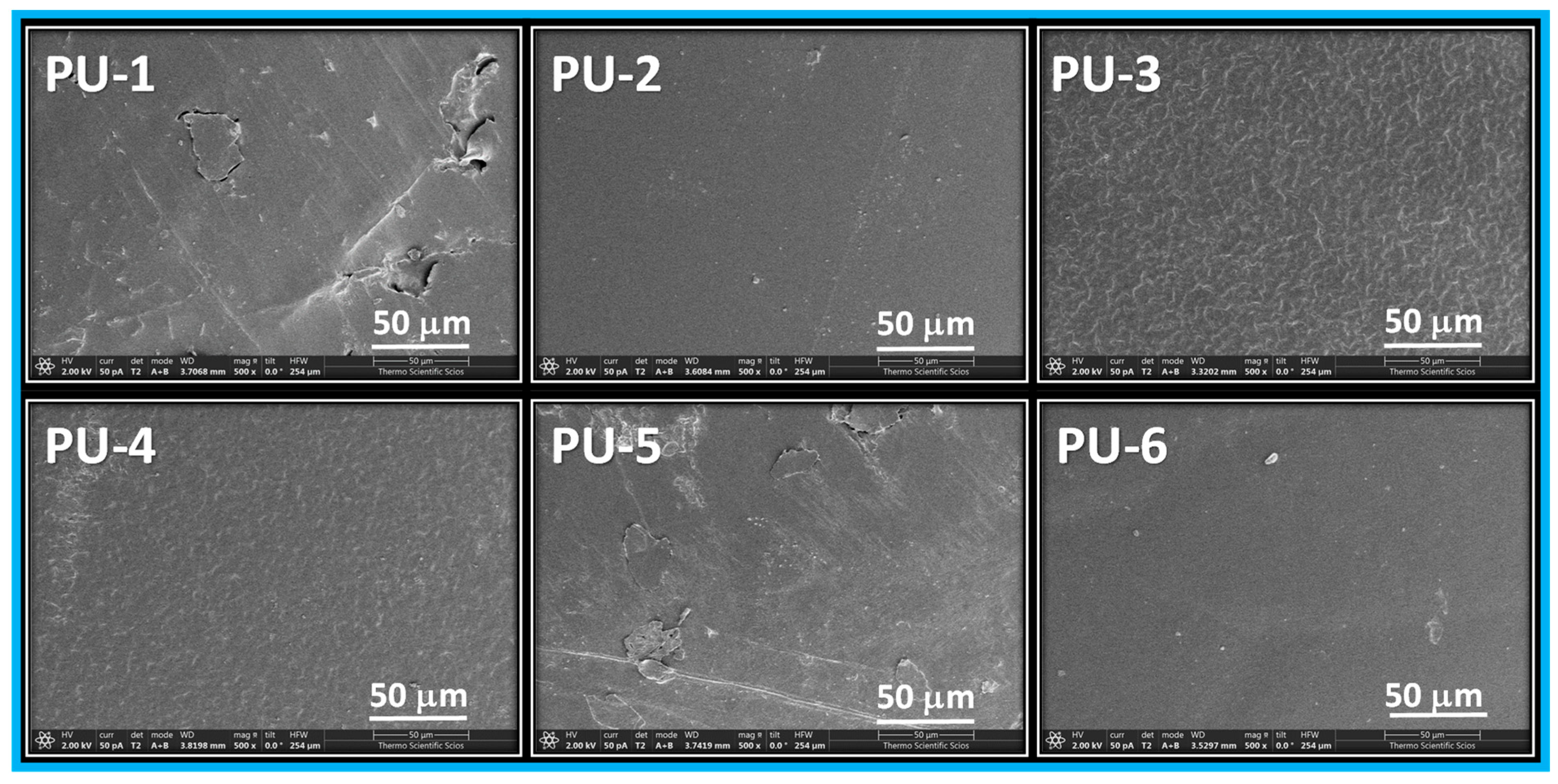

2.2. Synthesis of Polyurethanes

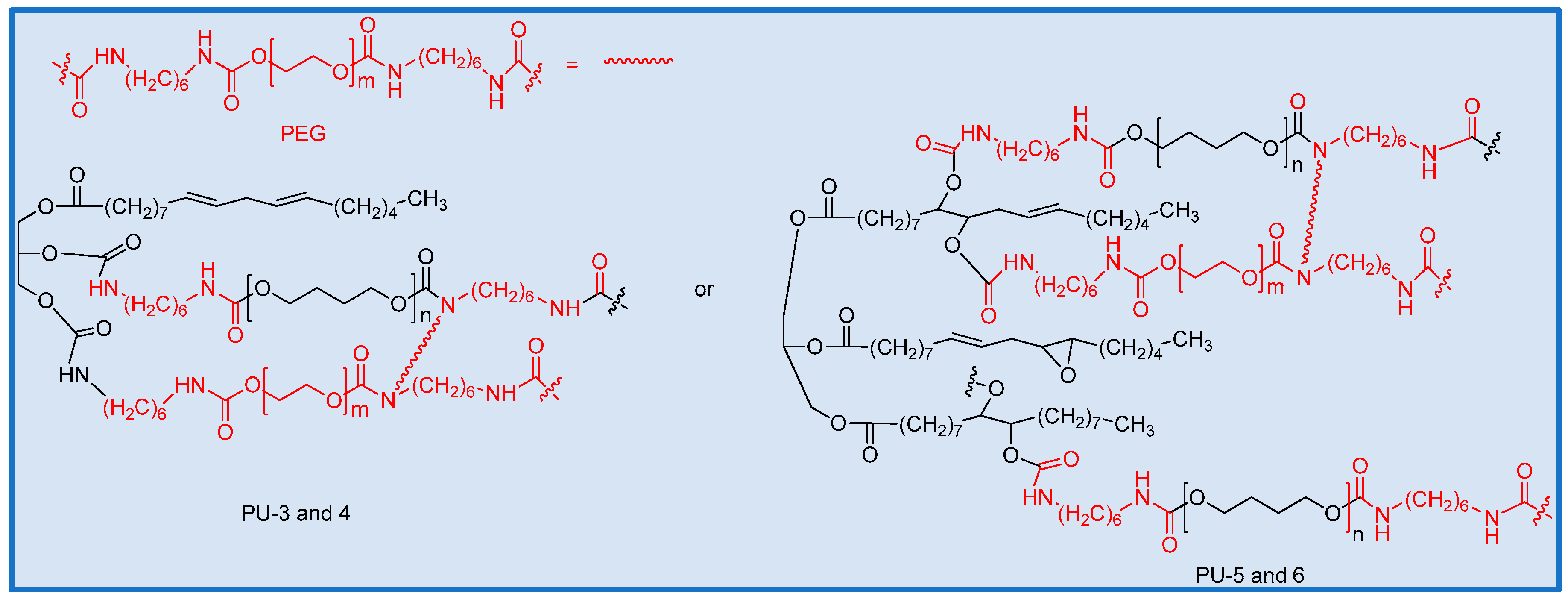

2.3. Infrared Spectroscopy

2.4. Swelling Test

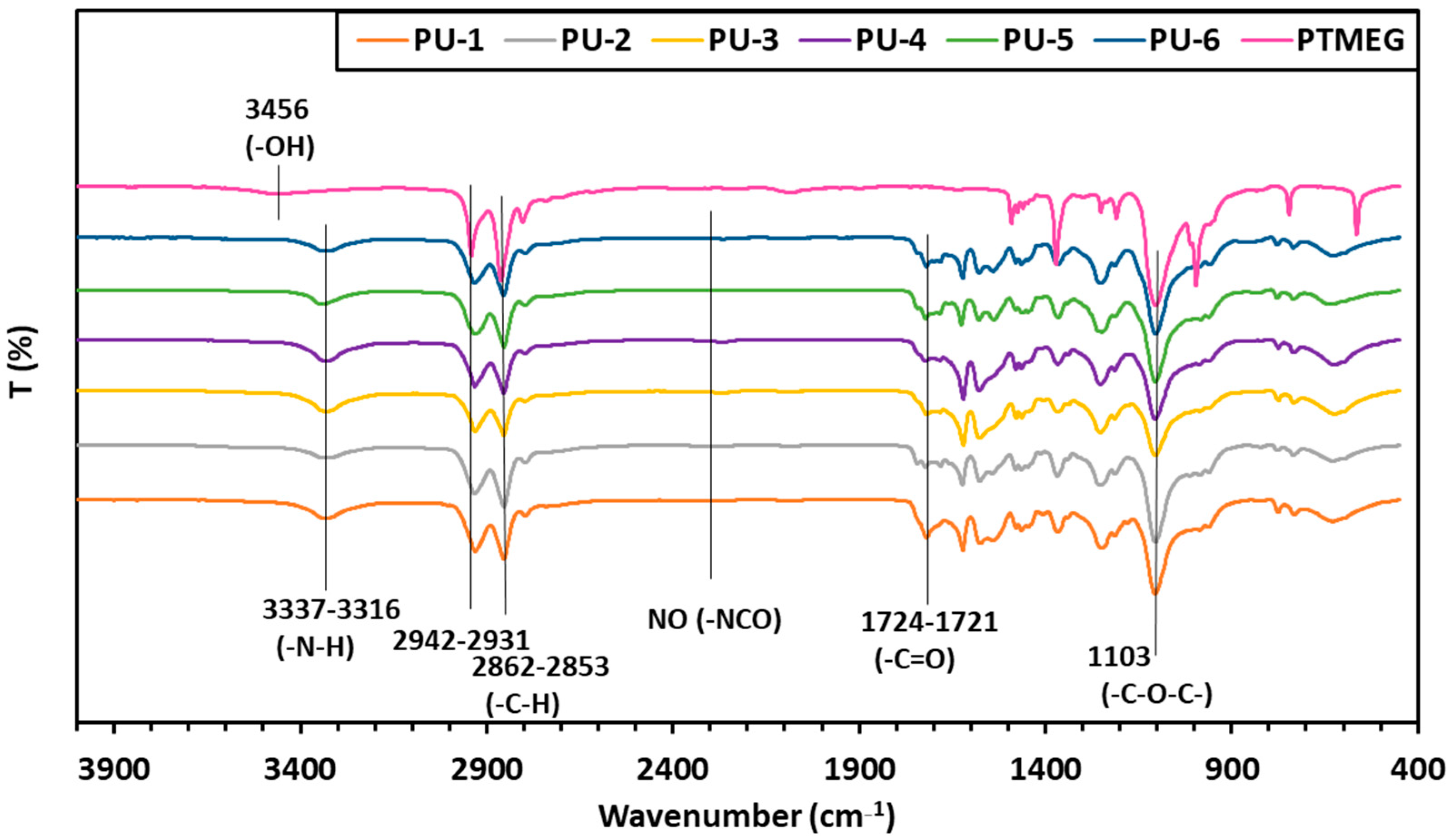

2.5. Morphology

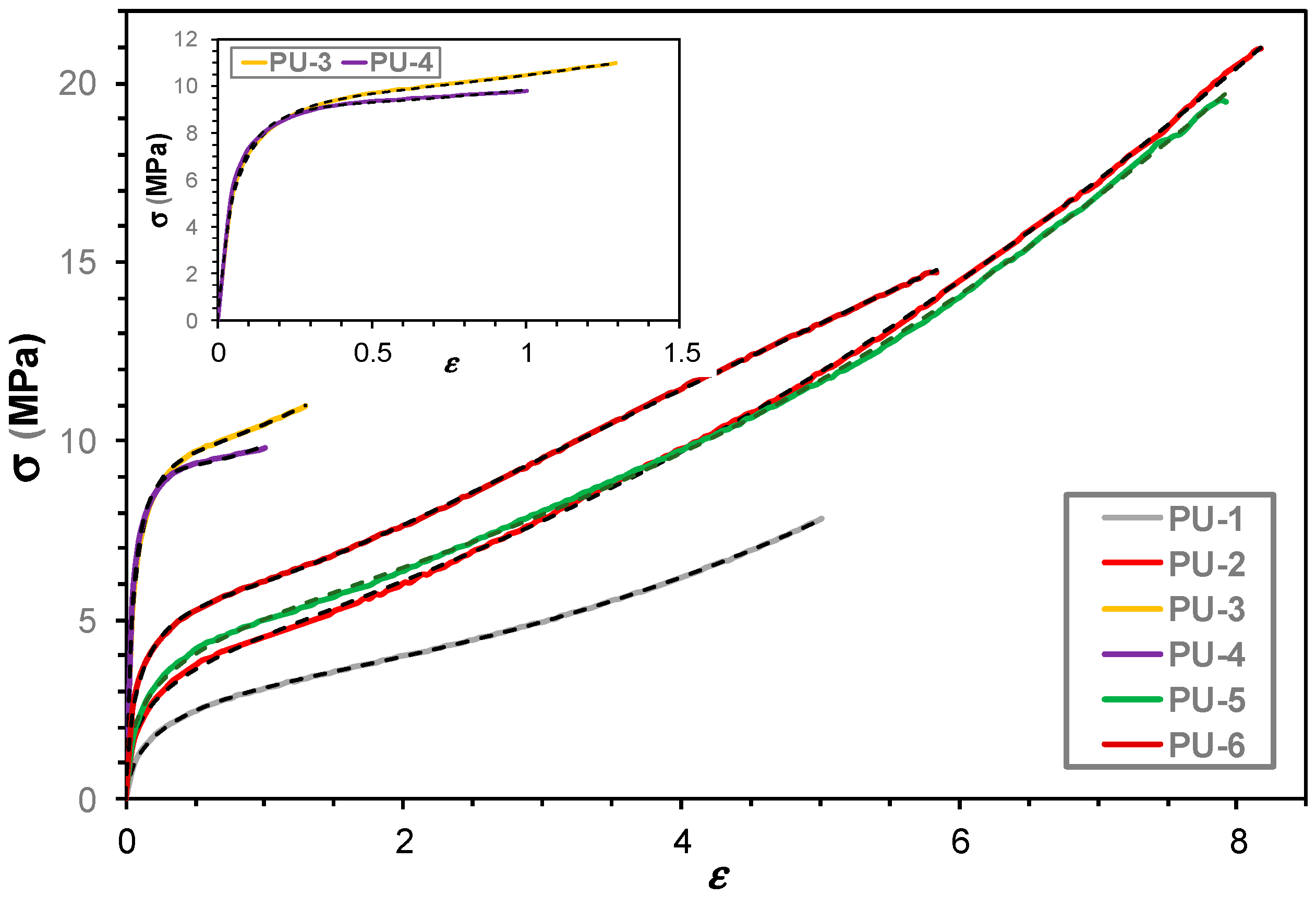

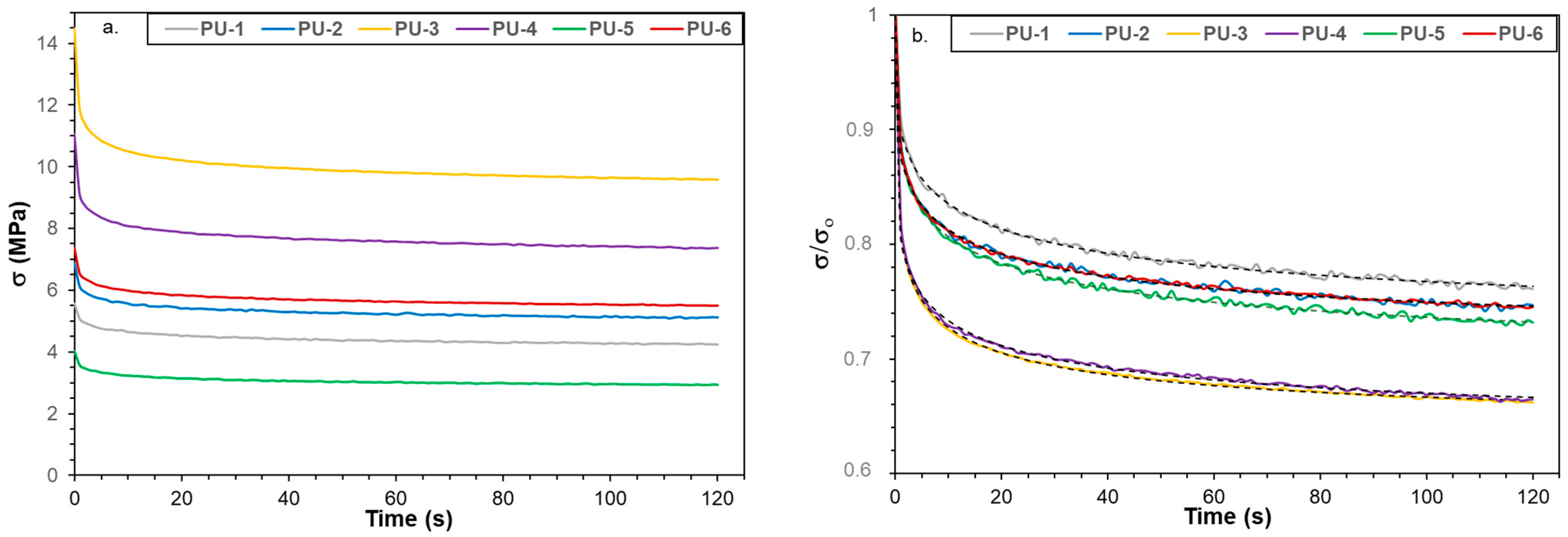

2.6. Tensile and Relaxation Tests

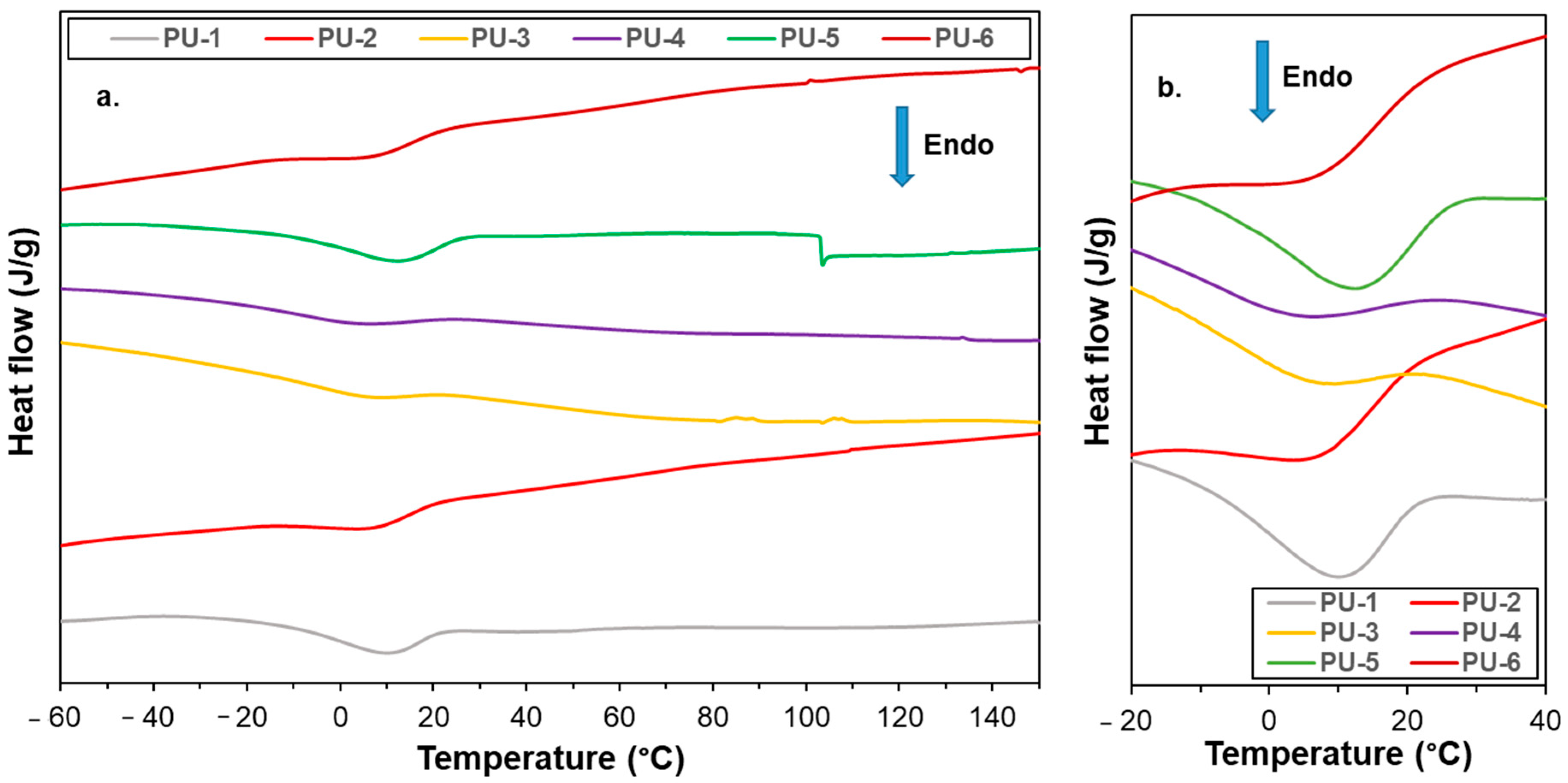

2.7. Thermal Properties

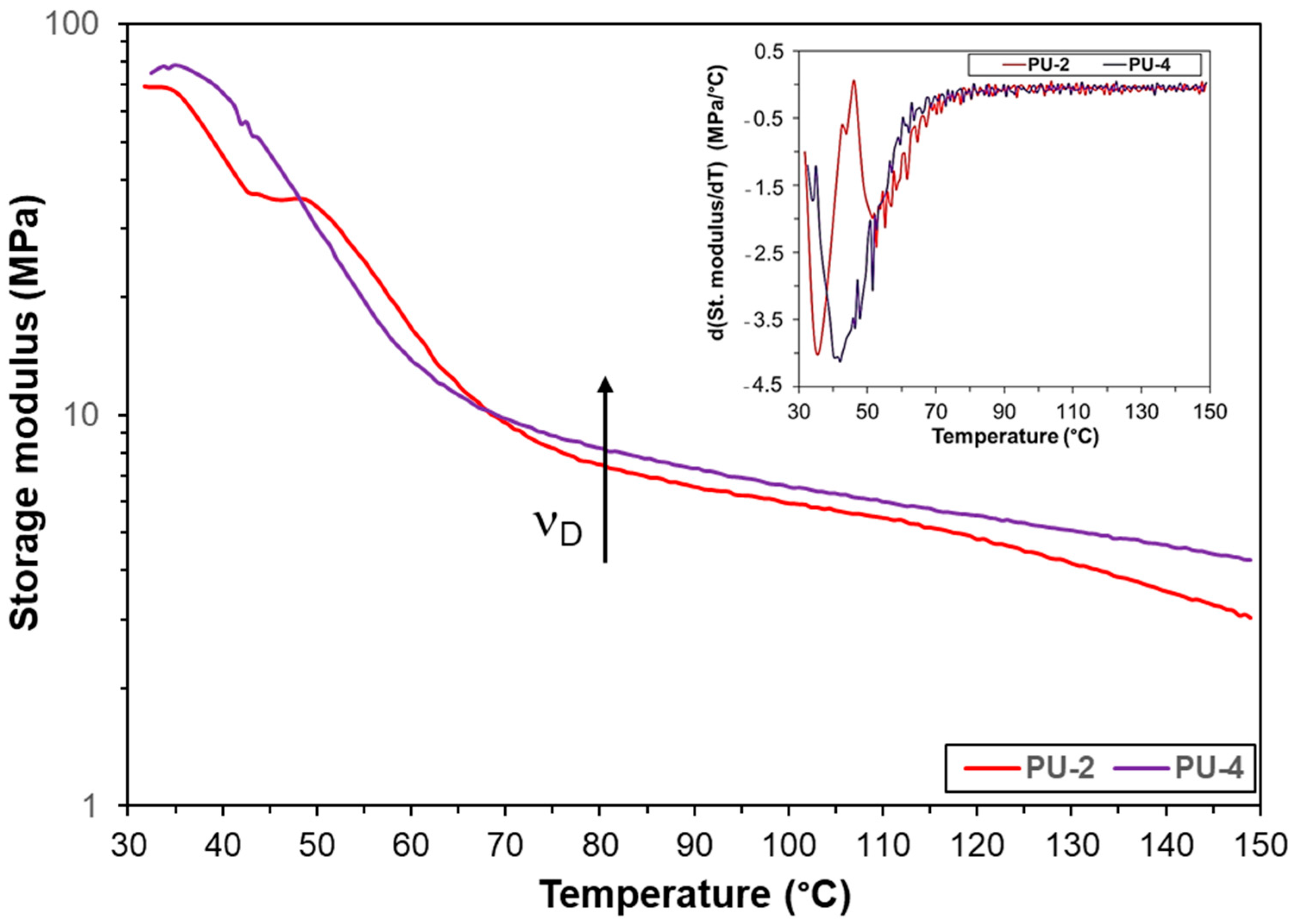

2.8. Thermomechanical Properties

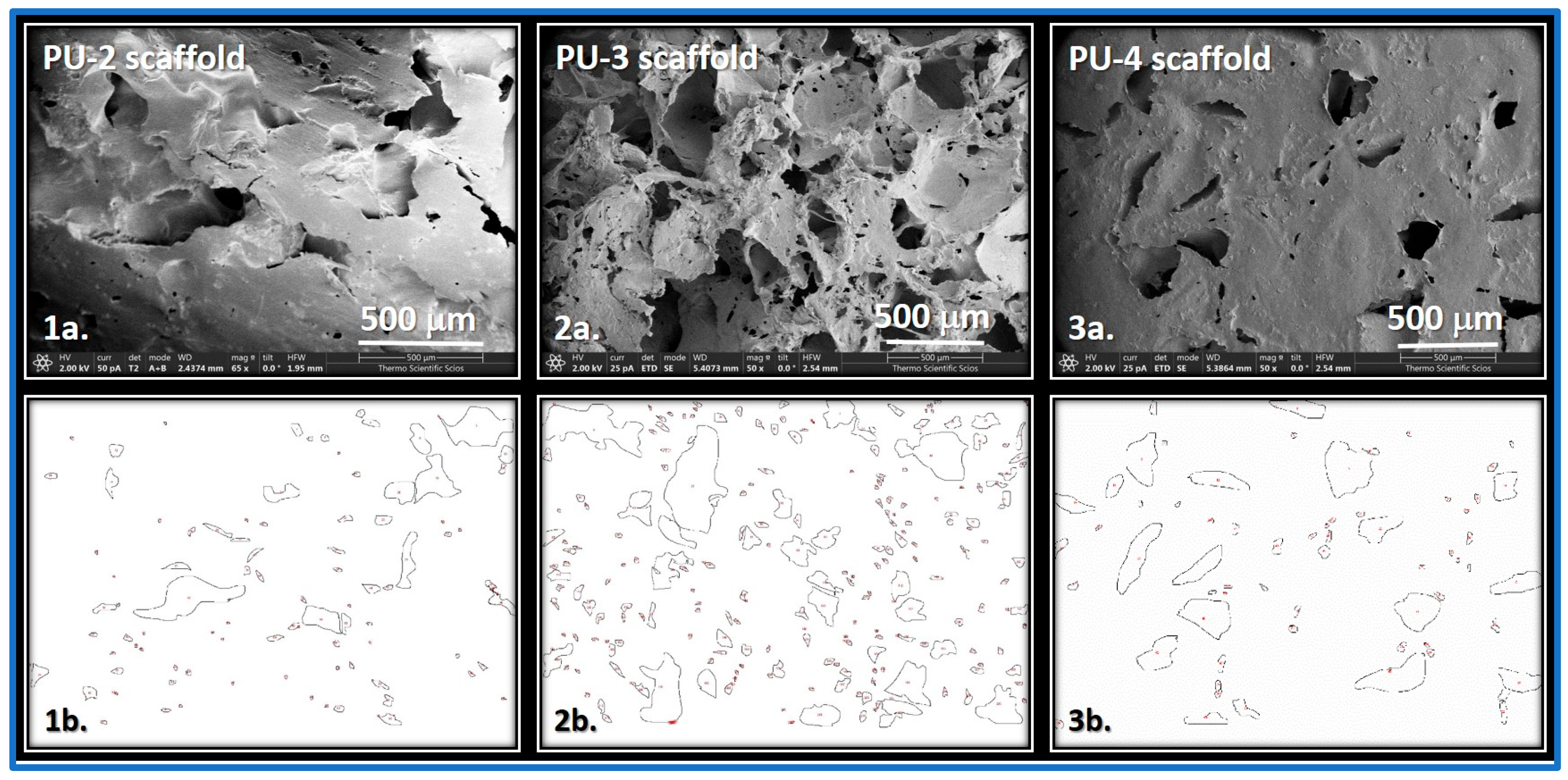

2.9. Scaffolds from PUs 2–4

3. Materials and Methods

3.1. Materials

3.2. Transesterification of Sunflower Oil

3.3. Epoxidation of Sunflower Oil

3.4. Synthesis of PUs

3.5. Preparation of Scaffolds

3.6. Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maamoun, A.A.; Arafa, M.; Esawi, A.M.K. Flexible polyurethane foam: Materials, synthesis, recycling, and applications in energy harvesting—A review. Mater. Adv. 2025, 6, 1842–1858. [Google Scholar] [CrossRef]

- Sawpan, A.M. Polyurethanes from vegetable oils and applications: A review. J. Polym. Res. 2018, 25, 184. [Google Scholar] [CrossRef]

- Maamoun, A.A.; Abouomar, R.M.; El--Basheer, T.M.; Azab, M.A.; Zaki, E.G.; Elsaeed, S.M.; Elkhateeb, A. Improving the acoustic performance of flexible polyurethane foam using biochar modified by (3-aminopropyl)trimethoxysilane coupling agent. Sci. Rep. 2024, 14, 18382. [Google Scholar] [CrossRef] [PubMed]

- Pfister, D.P.; Xia, Y.; Larock, R.C. Recent Advances in Vegetable Oil-Based Polyurethanes. ChemSusChem 2011, 4, 703–717. [Google Scholar] [CrossRef]

- Zlatanić, A.; Lava, C.; Zhang, W.; Petrović, Z.S. Effect of Structure on Properties of Polyols and Polyurethanes Based on Different Vegetable Oils. J. Polym. Sci. Part B Polym. Phys. 2004, 42, 809–819. [Google Scholar] [CrossRef]

- Shen, Y.; He, J.; Xie, Z.; Zhou, X.; Fang, C.; Zhang, C. Synthesis and characterization of vegetable oil based polyurethanes with tunable thermomechanical performance. Ind. Crop. Prod. 2019, 140, 111711. [Google Scholar] [CrossRef]

- Oh, J.; Kim, Y.K.; Hwang, S.-H.; Kim, H.-C.; Jung, J.-H.; Jeon, C.-H.; Lim, S.K. Synthesis and characterization of improved bio-based carbon content thermoplastic polyurethane with bio-aliphatic and petro-aromatic diisocyanate. J. Appl. Polym. Sci. 2023, 140, 54088. [Google Scholar] [CrossRef]

- Zeng, J.; Yang, Y.; Tang, Y.; Xu, X.; Chen, X.; Li, G.; Chen, K.; Li, H.; Ouyang, P.; Tan, W.; et al. Synthesis, Monomer Removal, Modification, and Coating Performances of Biobased Pentamethylene Diisocyanate Isocyanurate Trimers. Ind. Eng. Chem. Res. 2022, 61, 2403–2416. [Google Scholar] [CrossRef]

- Asensio, M.; Ferrer, J.-F.; Nohales, A.; Culebras, M.; Gómez, C.M. The Role of Diisocyanate Structure to Modify Properties of Segmented Polyurethanes. Materials 2023, 16, 1633. [Google Scholar] [CrossRef]

- Lligadas, G.; Ronda, C.J.; Galia, M.; Biermann, U.; Metzger, O. Synthesis and Characterization of Polyurethanes from Epoxidized Methyl Oleate Based Polyether Polyols as Renewable Resources. J. Polym. Sci. Part A Polym. Chem. 2006, 44, 634–645. [Google Scholar] [CrossRef]

- Oprea, S. Synthesis and Properties of Polyurethane Elastomers with Castor Oil as Crosslinker. J. Am. Oil Chem. Soc. 2010, 87, 313–320. [Google Scholar] [CrossRef]

- Dutta, N.; Karak, N.; Dolui, S.K. Synthesis and characterization of polyester resins based on Nahar seed oil. Prog. Org. Coat. 2004, 49, 146–152. [Google Scholar] [CrossRef]

- Kalita, H.; Karak, N. Biobased Hyperbranched Shape-Memory Polyurethanes: Effect of Different Vegetable Oils. J. Appl. Polym. Sci. 2014, 131, 39579. [Google Scholar] [CrossRef]

- Cuong, D.T.; Le, Q.D.; Hoang, P.H. Preparation of bio-based porous material with high oil adsorption capacity from bio-polyurethane and sugarcane bagasse. RSC Adv. 2024, 14, 6938–6947. [Google Scholar] [CrossRef] [PubMed]

- Suthar, V.; Asare, M.A.; Sahu, P.; Gupta, K.R. Sunflower oil-based polyurethane/graphene composite: Synthesis and properties. J. Thermoplast. Compos. Mater 2024, 37, 1667–1689. [Google Scholar] [CrossRef]

- Campanella, A.; Rustoy, E.; Baldessari, A.; Baltanás, M.A. Lubricants from chemically modified vegetable oils. Bioresour. Technol. 2010, 101, 245–254. [Google Scholar] [CrossRef]

- Dhiraj, S.; Kaikade, D.S.; Sabnis, A.S. Polyurethane foams from vegetable oil-based polyols: A review. Polym. Bull. 2023, 80, 2239–2261. [Google Scholar]

- Bashiri, S.; Ghobadian, B.; Soufi, M.D.; Gorjian, S. Chemical modification of sunflower waste cooking oil for biolubricant production through epoxidation reaction. Mater. Sci. Energy Technol. 2021, 4, 119–127. [Google Scholar] [CrossRef]

- Yelwa, J.M.; Abdullahi, S. Epoxidation and Hydroxylation of Sunflower Seed Oil. IJSRCH 2019, 4, 2456–8457. [Google Scholar]

- Benaniba, T.M.; Belhaneche-Bensemra, N.; Gelbard, G. Epoxidation of sunflower oil with peroxoacetic acid in presence of ion exchange resin by various processes. Energ. Ed. Sci. Technol. 2008, 21, 71–82. [Google Scholar]

- Asare, M.A.; Kote, P.; Chaudhary, S.; de Souza, F.M.; Gupta, R.K. Sunflower Oil as a Renewable Resource for Polyurethane Foams: Effects of Flame-Retardants. Polymers 2022, 14, 5282. [Google Scholar] [CrossRef]

- Zhang, C.Q.; Madbouly, S.A.; Kessler, M.R. Biobased Polyurethanes Prepared from Different Vegetable Oils. ACS Appl. Mater. Interfaces 2015, 7, 1226–1233. [Google Scholar] [CrossRef]

- Zhu, Y.; Yang, J.; Mei, F.; Li, X.; Zhao, C. Bio-based 1,4-butanediol and tetrahydrofuran synthesis: Perspective. Green Chem. 2022, 24, 6450–6466. [Google Scholar] [CrossRef]

- Czifrák, K.; Lakatos, C.; Cserháti, C.; Vecsei, G.; Zsuga, M.; Kéki, S. Bio-based Polyurethane Networks Containing Sunflower Oil Based Polyols. Int. J. Mol. Sci. 2024, 25, 7300. [Google Scholar] [CrossRef] [PubMed]

- Yücedag, F.; Atalay-Oral, C.; Erkal, S.; Sirkecioglu, A.; Karasartova, D.; Sahin, F.; Tantekin-Ersolmaz, B.S.; Güner, F.S. Antibacterial Oil-Based Polyurethane Films for Wound Dressing Applications. J. Appl. Polym. Sci. 2010, 115, 1347–1357. [Google Scholar] [CrossRef]

- Sharmin, E.; Ashraf, M.S.; Ahmad, S. Synthesis, characterization, antibacterial and corrosion protective properties of epoxies, epoxy-polyols and epoxy-polyurethane coatings from linseed and Pongamia glabra seed oils. Int. J. Biol. Macromol. 2007, 40, 407–422. [Google Scholar] [CrossRef]

- Hazmia, A.S.A.; Aung, M.M.; Abdullah, L.C.; Salleh, M.Z.; Mahmood, M.H. Producing Jatropha oil-based polyol via epoxidation and ring opening. Ind. Crops Prod. 2013, 50, 563–567. [Google Scholar] [CrossRef]

- Cai, C.; Dai, H.; Chen, R.; Su, C.; Xu, X.; Zhang, S.; Yang, L. Studies on the kinetics of in situ epoxidation of vegetable oils. Eur. J. Lipid Sci. Technol. 2008, 110, 341–346. [Google Scholar] [CrossRef]

- Xu, H.; Xue, R.; Zhang, M.; Wang, X.; Hu, G.-H.; Du, J.; Zhang, S.-M.; Liao, G.; Zhao, H. Bioinspired photonic polyurethane: Uniting self-healing and flexibility for multiple sensing. Sci. China Mater. 2025, 1–9. [Google Scholar] [CrossRef]

- Li, C.; Xiao, H.; Wang, X.; Zhao, T. Development of green waterborne UV-curable vegetable oil-based urethane acrylate pigment prints adhesive: Preparation and application. J. Clean. Prod. 2018, 180, 272–279. [Google Scholar] [CrossRef]

- Kong, X.; Narine, S.S. Sequential Interpenetrating Polymer Networks Produced from Vegetable Oil Based Polyurethane and Poly(methylmethacrylate). Biomacromolecules 2008, 9, 2221–2229. [Google Scholar] [CrossRef]

- Zhang, W.; Deng, H.; Xia, L.; Shen, L.; Zhang, C.; Lu, Q.; Sun, S. Semi-interpenetrating polymer networks prepared from castor oil-based waterborne polyurethanes and carboxymethyl chitosan. Carbohydr. Polym. 2021, 256, 117507. [Google Scholar] [CrossRef]

- Domínguez-Cartes, V.; Ramos-Cabeza, D.; de la Torre, M.L.; Salguero-Andújar, F. Complete Generalization of the Equations for the Stress–Strain Curves of Concrete under Uniaxial Compression. Materials 2023, 16, 3387. [Google Scholar] [CrossRef] [PubMed]

- Williams, G.; Watts, D.C. Non-Symmetrical Dielectric Relaxation Behavior Arising from a Simple Empirical Decay Function. Trans. Faraday Soc. 1970, 66, 80–85. [Google Scholar] [CrossRef]

- Fut, B.; Macknight, J.W. Structure-property relationships of segmented polyurethanes containing monodisperse 2,4-toluene diisocyanate butanediol hard segments. Rubber Chem. Technol. 1986, 5, 896–911. [Google Scholar] [CrossRef]

- Haeri, M.; Haeri, M. ImageJ Plugin for Analysis of Porous Scaffolds used in Tissue Engineering. J. Open Res. Software 2015, 3, e1. [Google Scholar] [CrossRef]

- Tariverdian, T.; Sefat, F.; Gelinsky, M.; Mozafari, M. Scaffold for bone tissue engineering. In Handbook of Tissue Engineering Scaffolds: Volume One; Elsevier Ltd.: Amsterdam, The Netherlands, 2019. [Google Scholar]

- MSZ 3633-81; Determination of the Acidity, Free Fatty Acid Content, Saponification Number and Ester Number in Fatty Acids. Hungarian Standard: Budapest, Hungary, 1981.

- MSZ 3634-80; Determination the Iodine Value of Oils and Fats. Hungarian Standard: Budapest, Hungary, 1980.

- MSZ 3629; Vegetable and Animal Fats and Oils—Quality Requirements and Test Methods. Hungarian Standard: Budapest, Hungary, 1993.

- MSZ EN ISO 3001:2000; Plastics-Epoxy Resins-Determination of Epoxy Equivalent. Hungarian Standard: Budapest, Hungarian, 2000.

- Kelch, S.; Steuer, S.; Schmidt, A.M.; Lendlein, A. Shape-Memory Polymer Networks from Oligo[(ε-hydroxycaproate)-co-glycolate]dimethacrylates and Butyl Acrylate with Adjustable Hydrolytic Degradation Rate. Biomacromolecules 2007, 8, 1018–1027. [Google Scholar] [CrossRef]

- Sekkar, V.; Gopalakrishnan, S.; Devi, K.A. Studies on allophanate–urethane networks based on hydroxyl terminated polybutadiene: Effect of isocyanate type on the network characteristics. Eur. Polym. J. 2003, 39, 1281–1290. [Google Scholar] [CrossRef]

- Castro, M.; Lu, J.; Bruzaud, S.; Kumar, B.; Feller, J.-F. Carbon nanotubes/poly(ε-caprolactone) composite vapour sensors. Carbon 2009, 47, 1930–1942. [Google Scholar] [CrossRef]

- ASTM D882-12; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. American Standard: Franklin, PA, USA, 2012.

- Kong, Y.; Hay, N.J. The measurement of the crystallinity of polymers by DSC. Polymer 2002, 43, 3873–3878. [Google Scholar] [CrossRef]

| Sample | Density (g/cm3) | Q | G (%) | νe (mol/cm3) |

|---|---|---|---|---|

| PU-1 | 1.09 | 2.6 | 90.2 | 7.5 × 10−4 |

| PU-2 | 0.94 | 2.1 | 88.8 | 2.3 × 10−3 |

| PU-3 | 1.06 | 1.4 | 94.0 | 5.3 × 10−3 |

| PU-4 | 1.07 | 1.5 | 93.6 | 4.8 × 10−3 |

| PU-5 | 1.08 | 2.1 | 84.0 | 1.8 × 10−3 |

| PU-6 | 0.97 | 2.0 | 85.8 | 2.8 × 10−3 |

| Sample | E (MPa) | εR (%) | σR (MPa) |

|---|---|---|---|

| PU-1 | 14.1 ± 1 | 429.1 ± 45 | 7.7 ± 1 |

| PU-2 | 4.2 ± 0.3 | 885 ± 34 | 23 ± 1.4 |

| PU-3 | 124 ± 13 | 268 ± 38 | 15.2 ± 1 |

| PU-4 | 142 ± 14 | 93 ± 11 | 9.8 ± 0.3 |

| PU-5 | 21.8 ± 3 | 694.2 ± 68 | 17.5 ± 3 |

| PU-6 | 38.2 ± 6 | 681.4 ± 51 | 18.2 ± 2 |

| Sample | ν(r) (mol/cm3) |

|---|---|

| PU-1 | 8.3 × 10−4 |

| PU-2 | 1.0 × 10−3 |

| PU-3 | 1.9 × 10−3 |

| PU-4 | 1.4 × 10−3 |

| PU-5 | 5.9 × 10−4 |

| PU-6 | 1.1 × 10−3 |

| Sample | PTMEG wt (%) | Tm (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|

| PTMEG2000 | 100 | 41 | 111 | 50 |

| PU-1 | 64 | 8 | 16.8 | 12 |

| PU-2 | 67 | 6 | 11 | 7 |

| PU-3 | 53 | 5 | 6.4 | 5 |

| PU-4 | 57 | 1 | 8.3 | 7 |

| PU-5 | 55 | 10 | 10.4 | 15 |

| PU-6 | 59 | 8 | 7.8 | 7 |

| Sample Name | PU-2 Scaffold | PU-3 Scaffold | PU-4 Scaffold |

|---|---|---|---|

| Count | 97 | 227 | 66 |

| Major diameter (μm) | 48 ± 25 | 60 ± 45 | 104 ± 39 |

| Minor diameter (µm) | 23 ± 16 | 31 ± 22 | 49 ± 20 |

| Ellipse angle | 95 ± 64 | 94 ± 59 | 78 ± 51 |

| Feret max (µm) | 55 ± 36 | 68 ± 45 | 111 ± 76 |

| Feret min (µm) | 26 ± 12 | 36 ± 19 | 55 ± 35 |

| Feret angle | 101 ± 55 | 106 ± 49 | 87 ± 48 |

| Sample | PTMEG (g) | PEG200 (g) | PEG600 (g) | GM (g) | EPO (g) | HDI (g) | SS (%) | HS (%) |

|---|---|---|---|---|---|---|---|---|

| PU-1 | 4 | 1 | 1.2 | 80.6 | 19.4 | |||

| PU-2 | 4 | 1 | 1 | 83.3 | 16.7 | |||

| PU-3 | 3.6 | 0.4 | 1 | 1.9 | 66.7 | 33.3 | ||

| PU-4 | 3.6 | 0.4 | 1 | 1.4 | 71.9 | 28.1 | ||

| PU-5 | 3.6 | 0.4 | 1 | 1.2 | 74.2 | 25.8 | ||

| PU-6 | 3.6 | 0.4 | 1 | 1.6 | 69.7 | 30.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lakatos, C.; Czifrák, K.; Cserháti, C.; Borsi-Gombos, R.; Nagy, L.; Zsuga, M.; Kéki, S. Synthesis of Bio-Based Polyurethanes from Functionalized Sunflower Seed Oil. Int. J. Mol. Sci. 2025, 26, 11380. https://doi.org/10.3390/ijms262311380

Lakatos C, Czifrák K, Cserháti C, Borsi-Gombos R, Nagy L, Zsuga M, Kéki S. Synthesis of Bio-Based Polyurethanes from Functionalized Sunflower Seed Oil. International Journal of Molecular Sciences. 2025; 26(23):11380. https://doi.org/10.3390/ijms262311380

Chicago/Turabian StyleLakatos, Csilla, Katalin Czifrák, Csaba Cserháti, Réka Borsi-Gombos, Lajos Nagy, Miklós Zsuga, and Sándor Kéki. 2025. "Synthesis of Bio-Based Polyurethanes from Functionalized Sunflower Seed Oil" International Journal of Molecular Sciences 26, no. 23: 11380. https://doi.org/10.3390/ijms262311380

APA StyleLakatos, C., Czifrák, K., Cserháti, C., Borsi-Gombos, R., Nagy, L., Zsuga, M., & Kéki, S. (2025). Synthesis of Bio-Based Polyurethanes from Functionalized Sunflower Seed Oil. International Journal of Molecular Sciences, 26(23), 11380. https://doi.org/10.3390/ijms262311380