Fabrication of Silane-Grafted Cellulose Nanocrystals and Their Effects on the Structural, Thermal, Mechanical, and Hysteretic Behavior of Thermoplastic Polyurethane

Abstract

1. Introduction

2. Results and Discussion

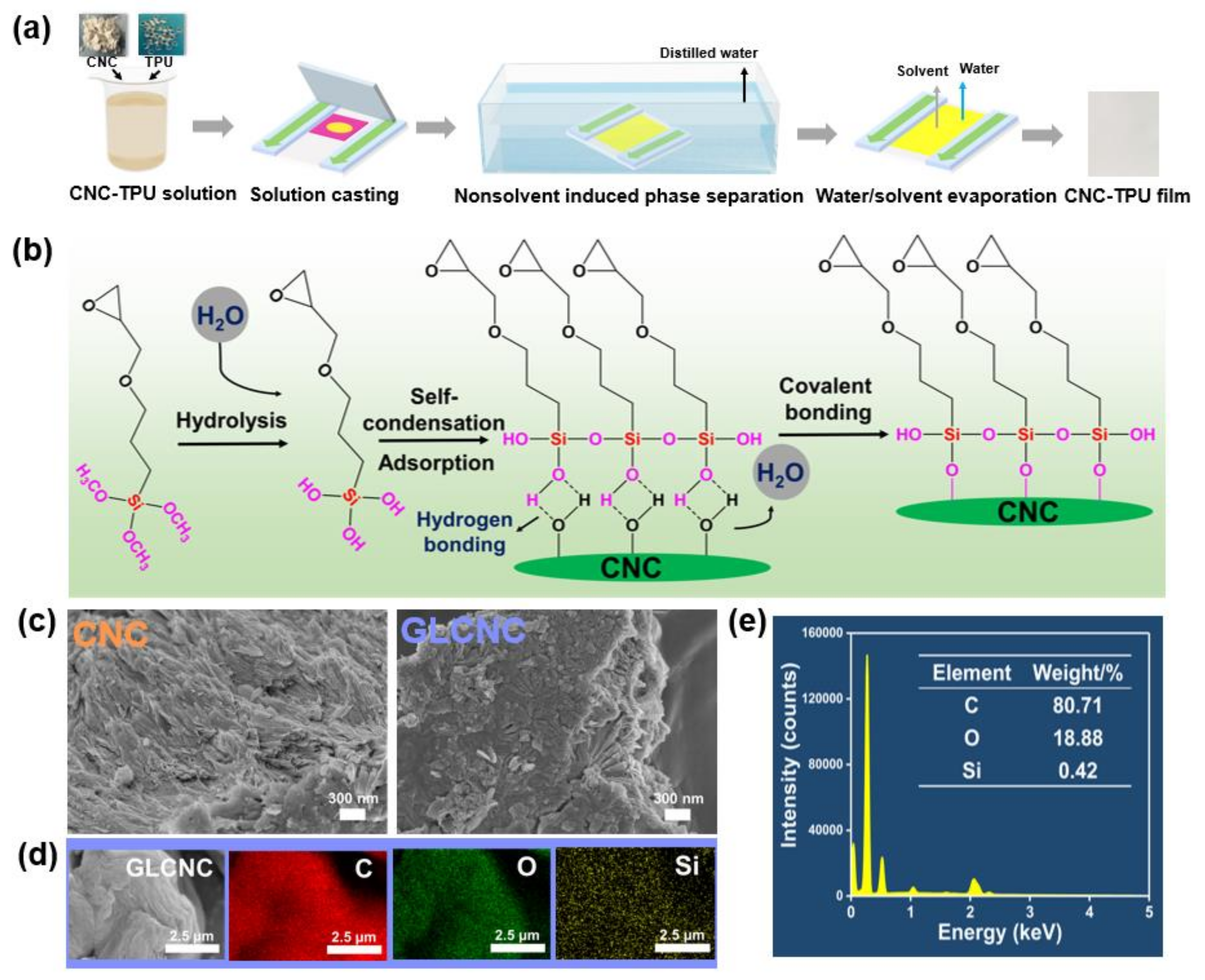

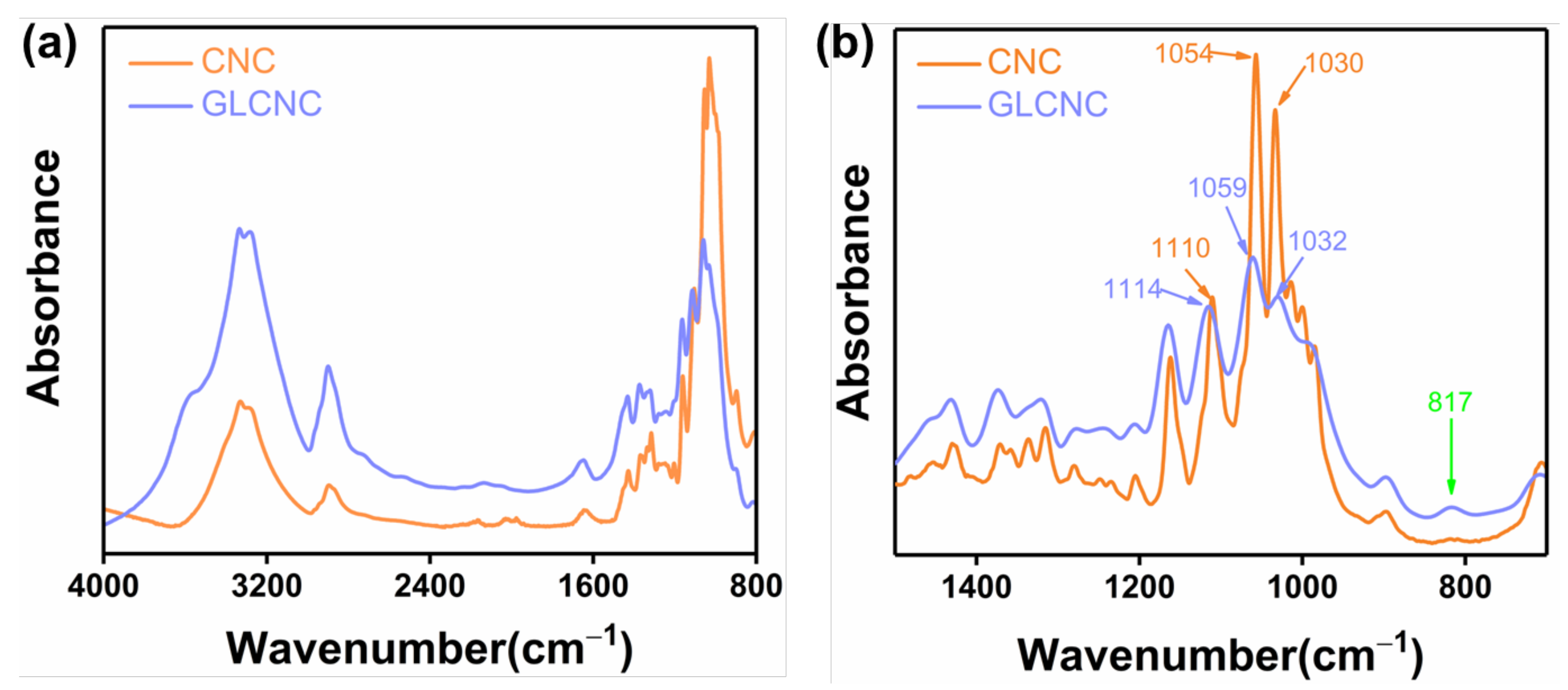

2.1. GL Modification of CNCs

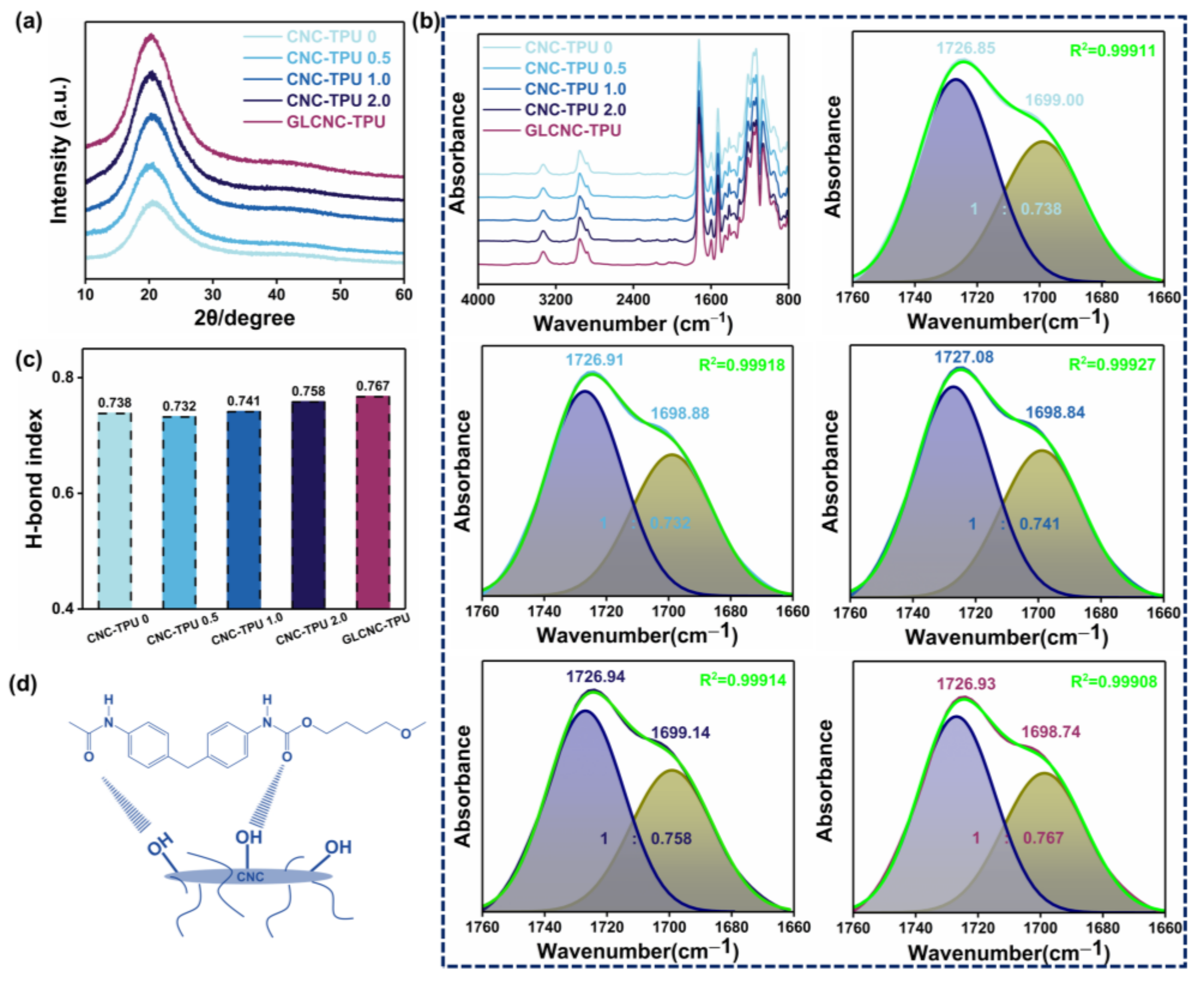

2.2. Structure of CNC/TPU Composite Films

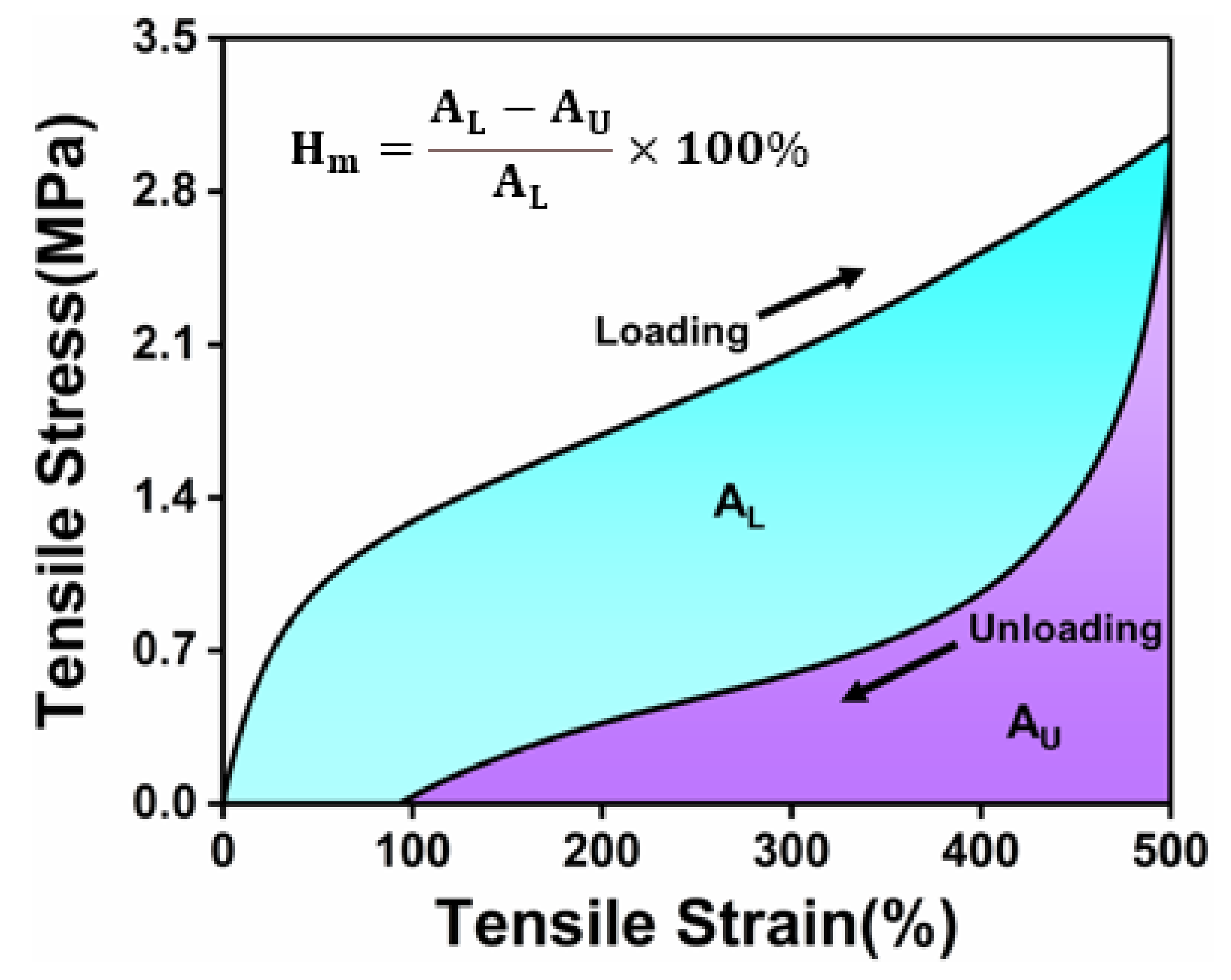

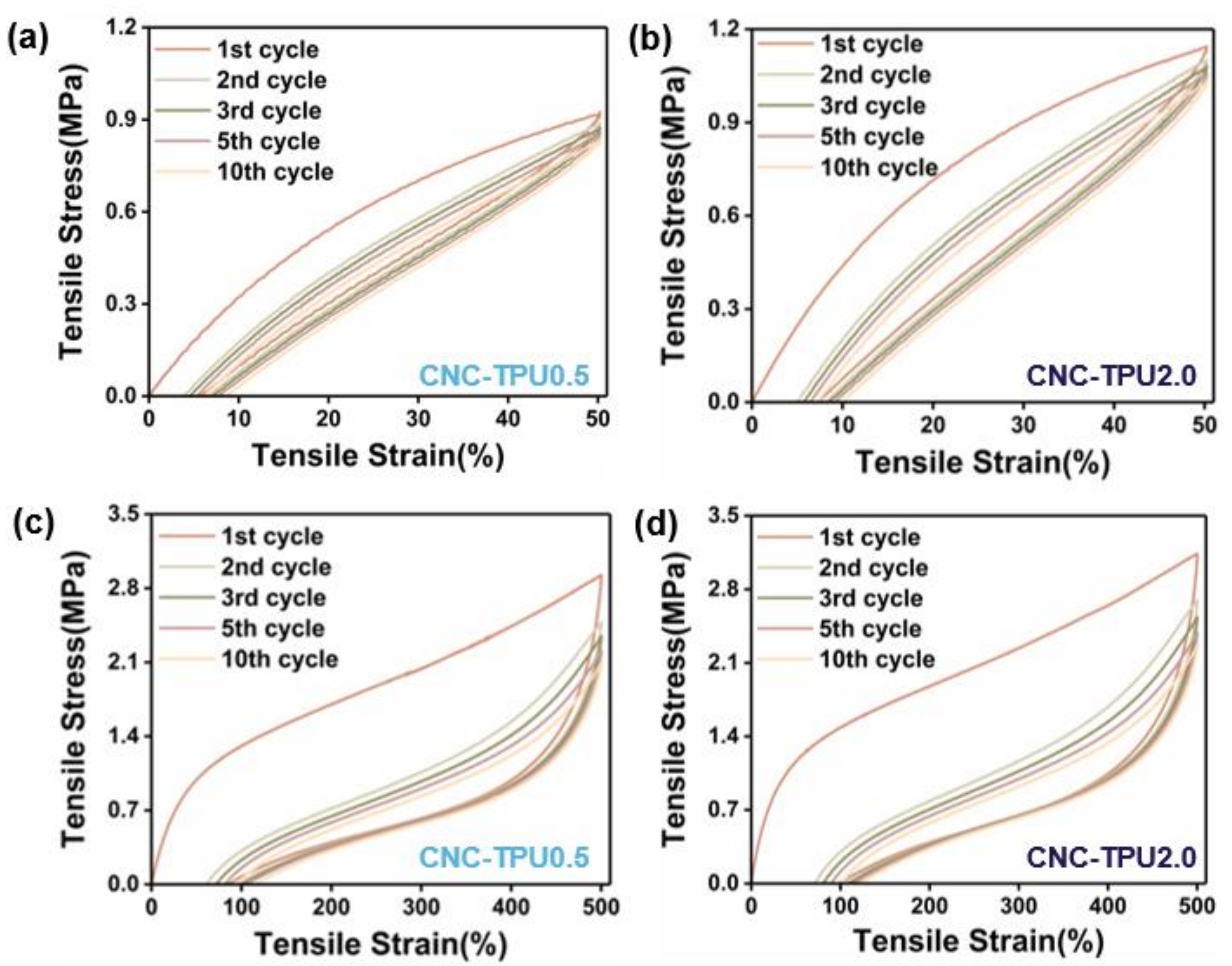

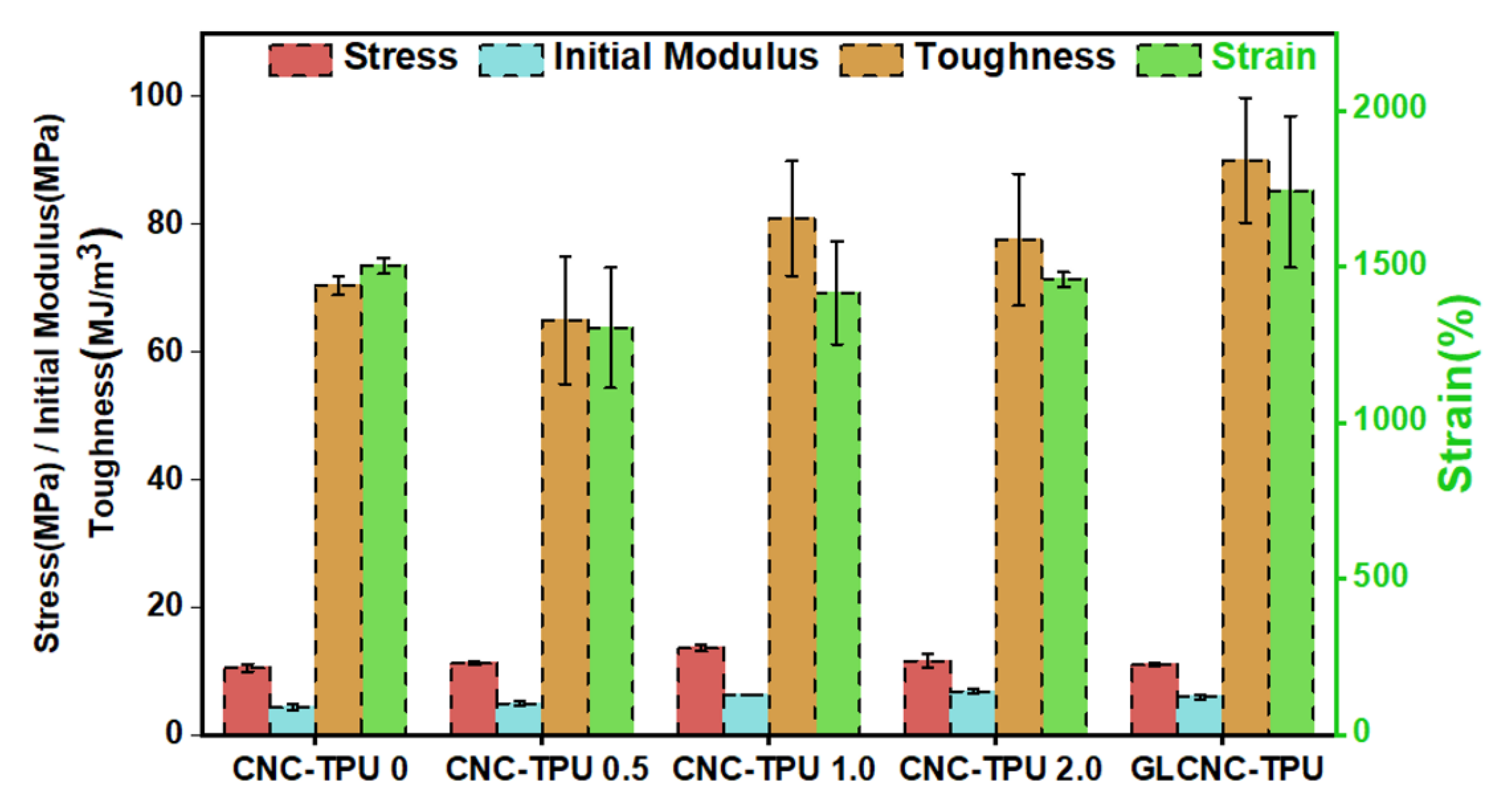

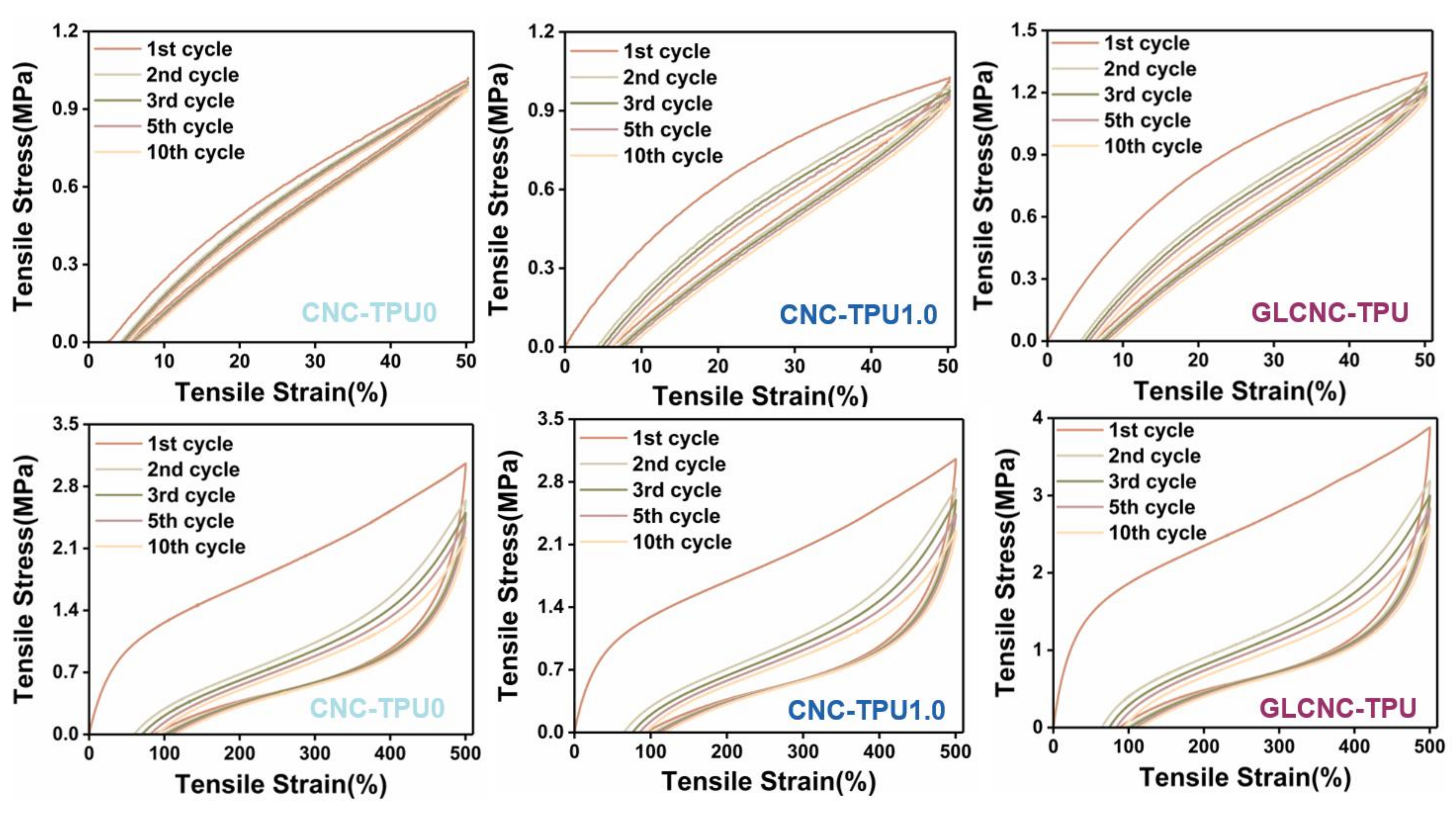

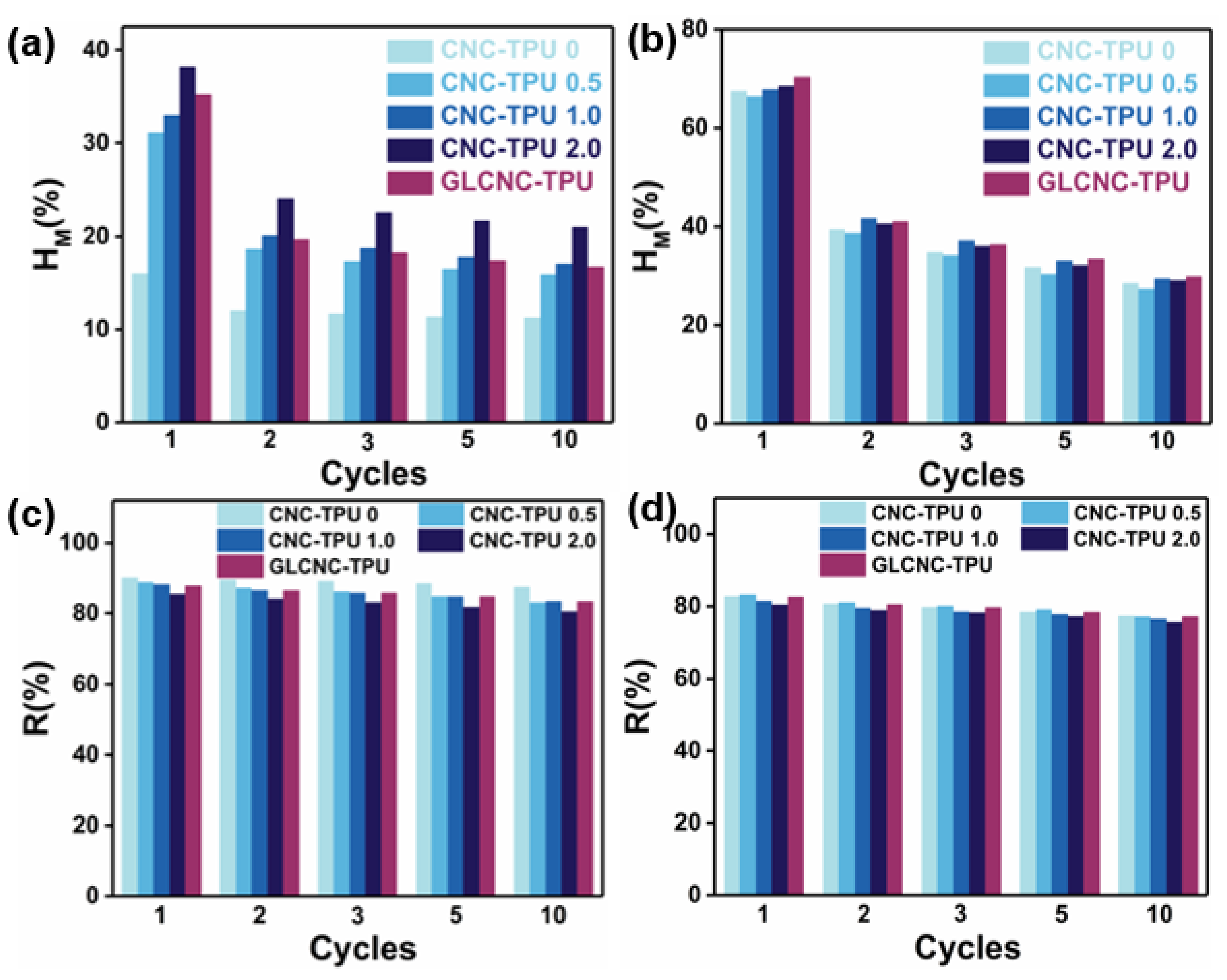

2.3. Mechanical Properties of CNC/TPU Composite Films

2.4. Thermal Degradation Behavior of CNC/TPU Composite Films

2.5. Wettability of CNC/TPU Composite Films

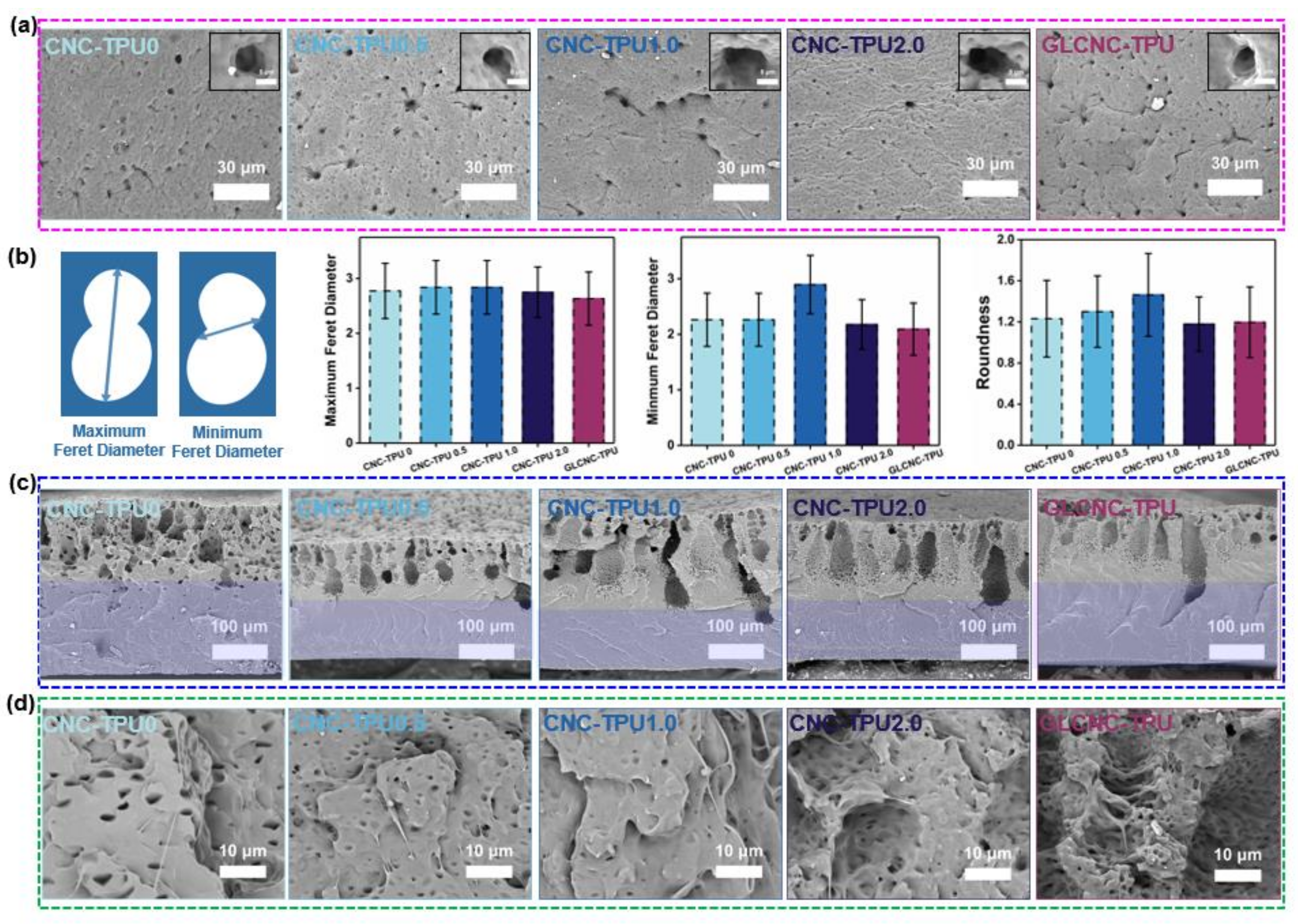

2.6. Morphologies of CNC/TPU Composite Films

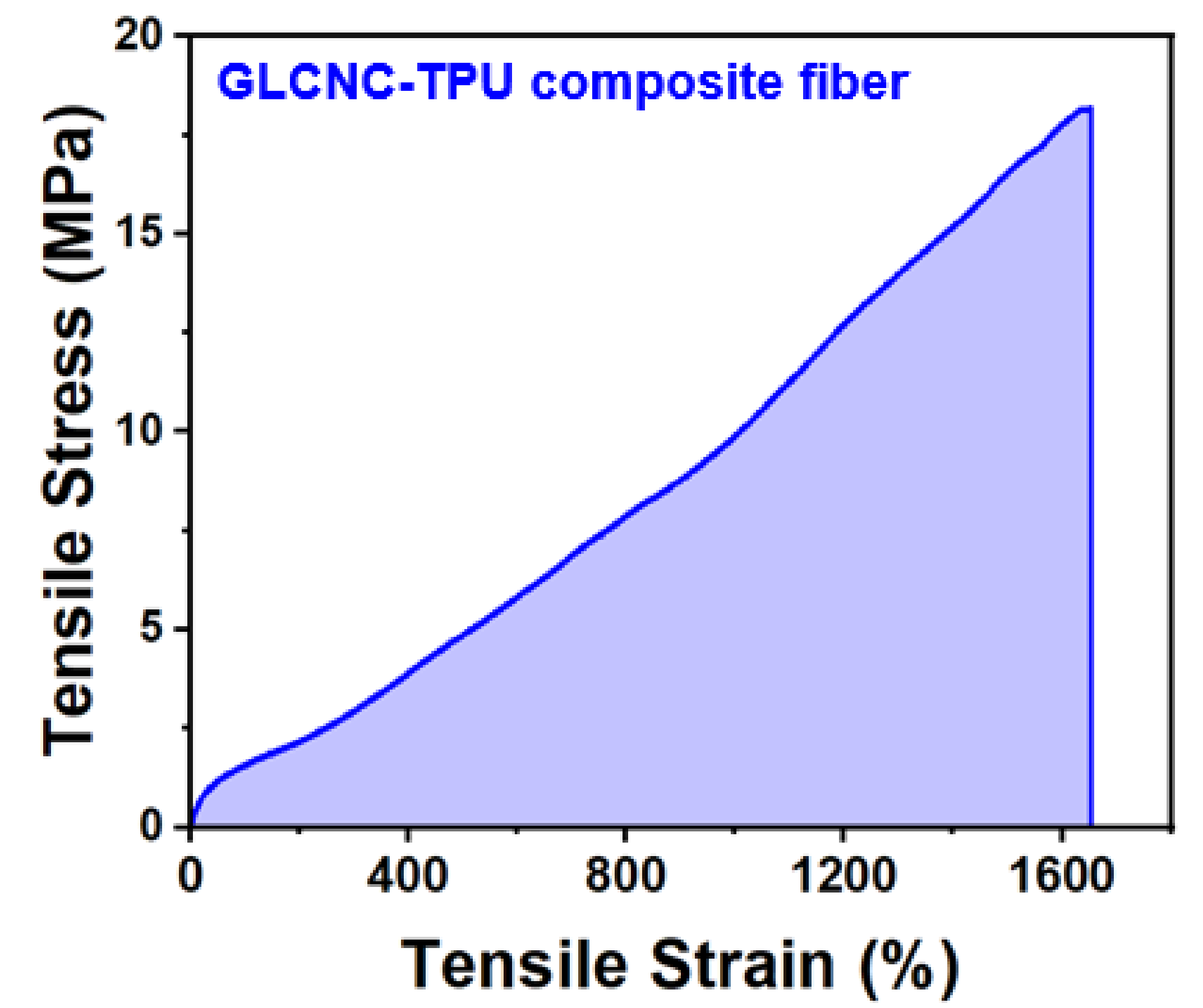

2.7. Mechanical Properties of GLCNC-TPU Composite Fiber

3. Materials and Methods

3.1. Materials

3.2. Synthesis of GL Modified CNC (GLCNC)

3.3. Fabrication of CNC/TPU Composite Films

3.4. Fabrication of GLCNC-TPU Composite Fiber

3.5. Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Yang, X.; Biswas, S.K.; Han, J.; Tanpichai, S.; Li, M.C.; Chen, C.; Zhu, S.; Das, A.K.; Yano, H. Surface and Interface Engineering for Nanocellulosic Advanced Materials. Adv. Mater. 2020, 33, 2002264. [Google Scholar] [CrossRef] [PubMed]

- Mohd Amin, K.N.; Chaleat, C.; Edwards, G.; Martin, D.J.; Annamalai, P.K. A cleaner processing approach for cellulose reinforced thermoplastic polyurethane nanocomposites. Polym. Eng. Sci. 2022, 62, 949–961. [Google Scholar] [CrossRef]

- Meng, L.; Li, J.; Fan, X.; Wang, Y.; Xiao, Z.; Wang, H.; Liang, D.; Xie, Y. Improved mechanical and antibacterial properties of polyvinyl alcohol composite films using quaternized cellulose nanocrystals as nanofillers. Compos. Sci. Technol. 2023, 23, 109885. [Google Scholar] [CrossRef]

- Mohammadi, M.; Heuzey, M.-C.; Carreau, P.J.; Taguet, A. Interfacial localization of CNCs in PLA/PBAT blends and its effect on rheological, thermal, and mechanical properties. Polymer 2021, 233, 124229. [Google Scholar] [CrossRef]

- Vadillo, J.; Larraza, I.; Calvo-Correas, T.; Martin, L.; Derail, C.; Eceiza, A. Enhancing the Mechanical Properties of 3D-Printed Waterborne Polyurethane-Urea and Cellulose Nanocrystal Scaffolds through Crosslinking. Polymers 2022, 14, 4999. [Google Scholar] [CrossRef] [PubMed]

- Prataviera, R.; Pollet, E.; Bretas, R.E.S.; Avérous, L.; Lucas, A.A. Nanocomposites based on renewable thermoplastic polyu-rethane and chemically modified cellulose nanocrystals with improved mechanical properties. J. Appl. Polym. Sci. 2018, 135, 46736. [Google Scholar] [CrossRef]

- Zhou, L.; Ke, K.; Yang, M.-B.; Yang, W. Recent progress on chemical modification of cellulose for high mechanical-performance Poly(lactic acid)/Cellulose composite: A review. Compos. Commun. 2021, 23, 100548. [Google Scholar] [CrossRef]

- Yang, F.; Liang, S.; Wu, H.; Yue, C.; Yan, H.; Wu, H.; Chen, X.; Zhang, J.; Yan, S.; Duan, Y. Upgrading the Pyrolysis Carbon Black from Waste Tire by Hybridization with Cellulose. Ind. Eng. Chem. Res. 2022, 61, 6512–6520. [Google Scholar] [CrossRef]

- Raza, M.; Abu-Jdayil, B. Cellulose nanocrystals from lignocellulosic feedstock: A review of production technology and surface chemistry modification. Cellulose 2022, 29, 685–722. [Google Scholar] [CrossRef]

- Muller, L.A.E.; Zingg, A.; Arcifa, A.; Zimmermann, T.; Nystrom, G.; Burgert, I.; Siqueira, G. Functionalized Cellulose Nano-crystals as Active Reinforcements for Light-Actuated 3D-Printed Structures. ACS Nano 2022, 16, 18210–18222. [Google Scholar] [CrossRef]

- Tom, C.; Sangitra, S.N.; Pujala, R.K. Rheological fingerprinting and applications of cellulose nanocrystal based composites: A review. J. Mol. Liq. 2023, 370, 121011. [Google Scholar] [CrossRef]

- Redondo, A.; Mortensen, N.; Djeghdi, K.; Jang, D.; Ortuso, R.D.; Weder, C.; Korley, L.T.J.; Steiner, U.; Gunkel, I. Comparing Percolation and Alignment of Cellulose Nanocrystals for the Reinforcement of Polyurethane Nanocomposites. ACS Appl. Mater. Interfaces 2022, 14, 7270–7282. [Google Scholar] [CrossRef]

- Lee, J.-E.; Kim, Y.E.; Lee, G.-H.; Kim, M.J.; Eom, Y.; Chae, H.G. The effect of cellulose nanocrystals (CNCs) on the microstructure of amorphous polyetherimide (PEI)-based nanocomposite fibers and its correlation with the mechanical properties. Compos. Sci. Technol. 2020, 200, 108452. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, J.; Liu, J.; Wang, Y.; Guo, J.; Zhong, Z.; Liu, X. High mechanical performance based on the alignment of cellulose nanocrystal/chitosan composite filaments through continuous coaxial wet spinning. Cellulose 2021, 28, 7995–8008. [Google Scholar] [CrossRef]

- Shrestha, S.; Montes, F.; Schueneman, G.T.; Snyder, J.F.; Youngblood, J.P. Effects of aspect ratio and crystal orientation of cellulose nanocrystals on properties of poly(vinyl alcohol) composite fibers. Compos. Sci. Technol. 2018, 167, 482–488. [Google Scholar] [CrossRef]

- Tatsumi, M.; Kimura, F.; Kimura, T.; Teramoto, Y.; Nishio, Y. Anisotropic Polymer Composites Synthesized by Immobilizing Cellulose Nanocrystal Suspensions Specifically Oriented under Magnetic Fields. Biomacromolecules 2014, 15, 4579–4589. [Google Scholar] [CrossRef]

- Zhang, C.; Lyu, P.; Xia, L.; Wang, Y.; Li, C.; Xiang, X.; Dai, F.; Xu, W.; Liu, X.; Deng, B. Regulation of pore morphologies of PU films and thereof water vapor permeability by varying tetrahydrofuran concentration in binary solvent. Polym. Test. 2018, 69, 32–38. [Google Scholar] [CrossRef]

- Zhang, C.; Xia, L.; Lyu, P.; Wang, Y.; Li, C.; Xiao, X.; Dai, F.; Xu, W.; Liu, X.; Deng, B. Is it possible to fabricate a nanocomposite with excellent mechanical property using unmodified inorganic nanoparticles directly? ACS Appl. Mater. Interfaces 2018, 10, 15357–15363. [Google Scholar] [CrossRef]

- Zhang, C.; Xia, L.; Deng, B.; Li, C.; Wang, Y.; Li, R.; Dai, F.; Liu, X.; Xu, W. Fabrication of a High-Toughness Polyurethane/Fibroin Composite without Interfacial Treatment and Its Toughening Mechanism. ACS Appl. Mater. Interfaces 2020, 12, 25409–25418. [Google Scholar] [CrossRef]

- Zhou, A.; Zhang, Y.; Qu, Q.; Li, F.; Lu, T.; Liu, K.; Huang, C. Well-defined multifunctional superhydrophobic green nanofiber membrane based-polyurethane with inherent antifouling, antiadhesive and photothermal bactericidal properties and its application in bacteria, living cells and zebra fish. Compos. Commun. 2021, 26, 100758. [Google Scholar] [CrossRef]

- Lin, W.; Hu, X.; You, X.; Sun, Y.; Wen, Y.; Yang, W.; Zhang, X.; Li, Y.; Chen, H. Hydrophobic Modification of Nanocellulose via a Two-Step Silanation Method. Polymers 2018, 10, 1035. [Google Scholar] [CrossRef] [PubMed]

- Tian, D.; Wang, F.; Yang, Z.; Niu, X.; Wu, Q.; Sun, P. High-performance polyurethane nanocomposites based on UPy-modified cellulose nanocrystals. Carbohydr. Polym. 2019, 219, 191–200. [Google Scholar] [CrossRef] [PubMed]

- Segal, L.; Greely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Pei, A.; Malho, J.-M.; Ruokolainen, J.; Zhou, Q.; Berglund, L.A. Strong Nanocomposite Reinforcement Effects in Polyurethane Elastomer with Low Volume Fraction of Cellulose Nanocrystals. Macromolecules 2011, 44, 4422–4427. [Google Scholar] [CrossRef]

- Fang, H.; Chen, X.; Wang, S.; Cheng, S.; Ding, Y. Enhanced mechanical and oxygen barrier performance in biodegradable polyurethanes by incorporating cellulose nanocrystals with interfacial polylactide stereocomplexation. Cellulose 2019, 26, 9751–9764. [Google Scholar] [CrossRef]

- Li, Z.; Xu, H.; Xia, X.; Song, Y.; Zheng, Q. Energy dissipation accompanying Mullins effect of nitrile butadiene rubber/carbon black nanocomposites. Polymer 2019, 171, 106–114. [Google Scholar] [CrossRef]

- Li, H.; Sun, J.; Wang, C.; Liu, S.; Yuan, D.; Zhou, X.; Tan, J.; Stubbs, L.; He, C. High modulus, strength, and toughness poly-urethane elastomer based on unmodified lignin. ACS Sustain. Chem. Eng. 2017, 5, 7942–7949. [Google Scholar] [CrossRef]

- Zeng, L.; Jia, L.; Liu, X.; Zhang, C. A Novel Silicon/Phosphorus Co-Flame Retardant Polymer Electrolyte for High-Safety All-Solid-State Lithium Ion Batteries. Polymers 2020, 12, 2937. [Google Scholar] [CrossRef]

- Yan, Q.; Li, C.; Yan, T.; Shen, Y.; Li, Z. Chemically Recyclable Thermoplastic Polyurethane Elastomers via a Cascade Ring-Opening and Step-Growth Polymerization Strategy from Bio-renewable δ-Caprolactone. Macromolecules 2022, 55, 3860–3868. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Yang, X.; Zhang, J.; Shang, B.; Lyu, P.; Zhang, C.; Liu, X.; Xia, L. Fabrication of Silane-Grafted Cellulose Nanocrystals and Their Effects on the Structural, Thermal, Mechanical, and Hysteretic Behavior of Thermoplastic Polyurethane. Int. J. Mol. Sci. 2023, 24, 5036. https://doi.org/10.3390/ijms24055036

Sun X, Yang X, Zhang J, Shang B, Lyu P, Zhang C, Liu X, Xia L. Fabrication of Silane-Grafted Cellulose Nanocrystals and Their Effects on the Structural, Thermal, Mechanical, and Hysteretic Behavior of Thermoplastic Polyurethane. International Journal of Molecular Sciences. 2023; 24(5):5036. https://doi.org/10.3390/ijms24055036

Chicago/Turabian StyleSun, Xuenan, Xinze Yang, Jiajing Zhang, Bin Shang, Pei Lyu, Chunhua Zhang, Xin Liu, and Liangjun Xia. 2023. "Fabrication of Silane-Grafted Cellulose Nanocrystals and Their Effects on the Structural, Thermal, Mechanical, and Hysteretic Behavior of Thermoplastic Polyurethane" International Journal of Molecular Sciences 24, no. 5: 5036. https://doi.org/10.3390/ijms24055036

APA StyleSun, X., Yang, X., Zhang, J., Shang, B., Lyu, P., Zhang, C., Liu, X., & Xia, L. (2023). Fabrication of Silane-Grafted Cellulose Nanocrystals and Their Effects on the Structural, Thermal, Mechanical, and Hysteretic Behavior of Thermoplastic Polyurethane. International Journal of Molecular Sciences, 24(5), 5036. https://doi.org/10.3390/ijms24055036