Comparative Evaluation of the Repair Bond Strength of Dental Resin Composite after Sodium Bicarbonate or Aluminum Oxide Air-Abrasion

Abstract

1. Introduction

2. Results

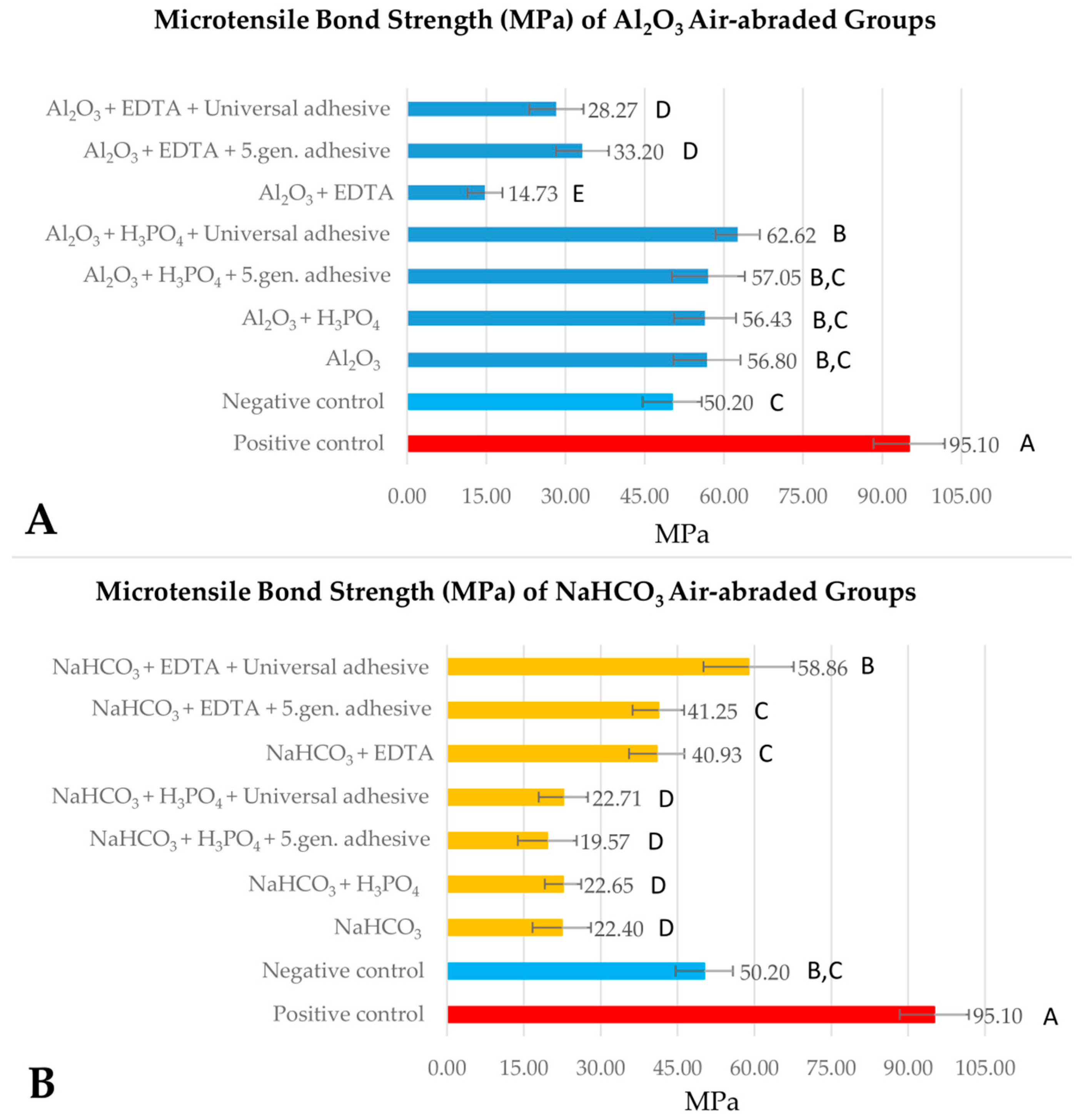

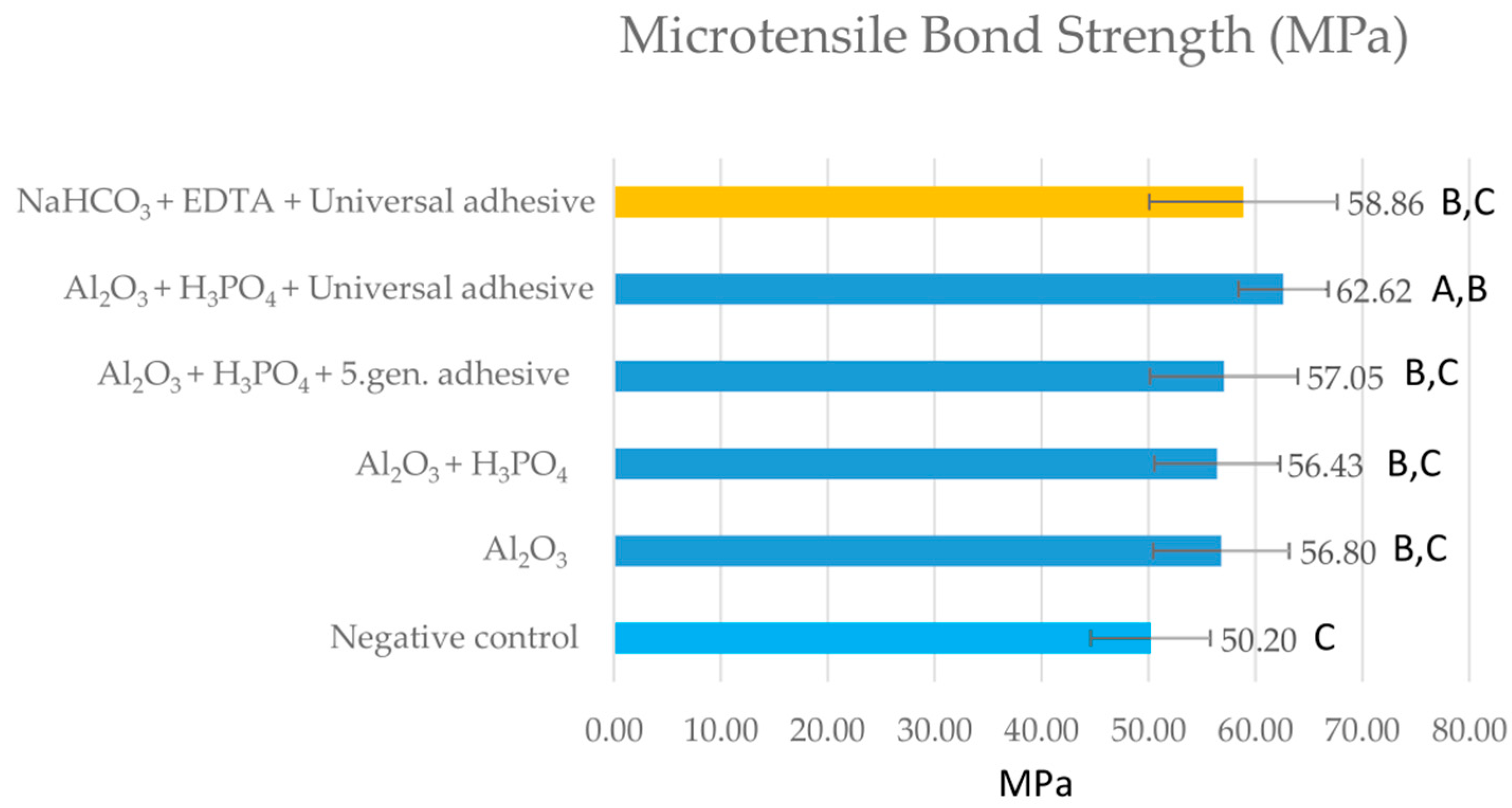

2.1. Microtensile Bond Strength Testing

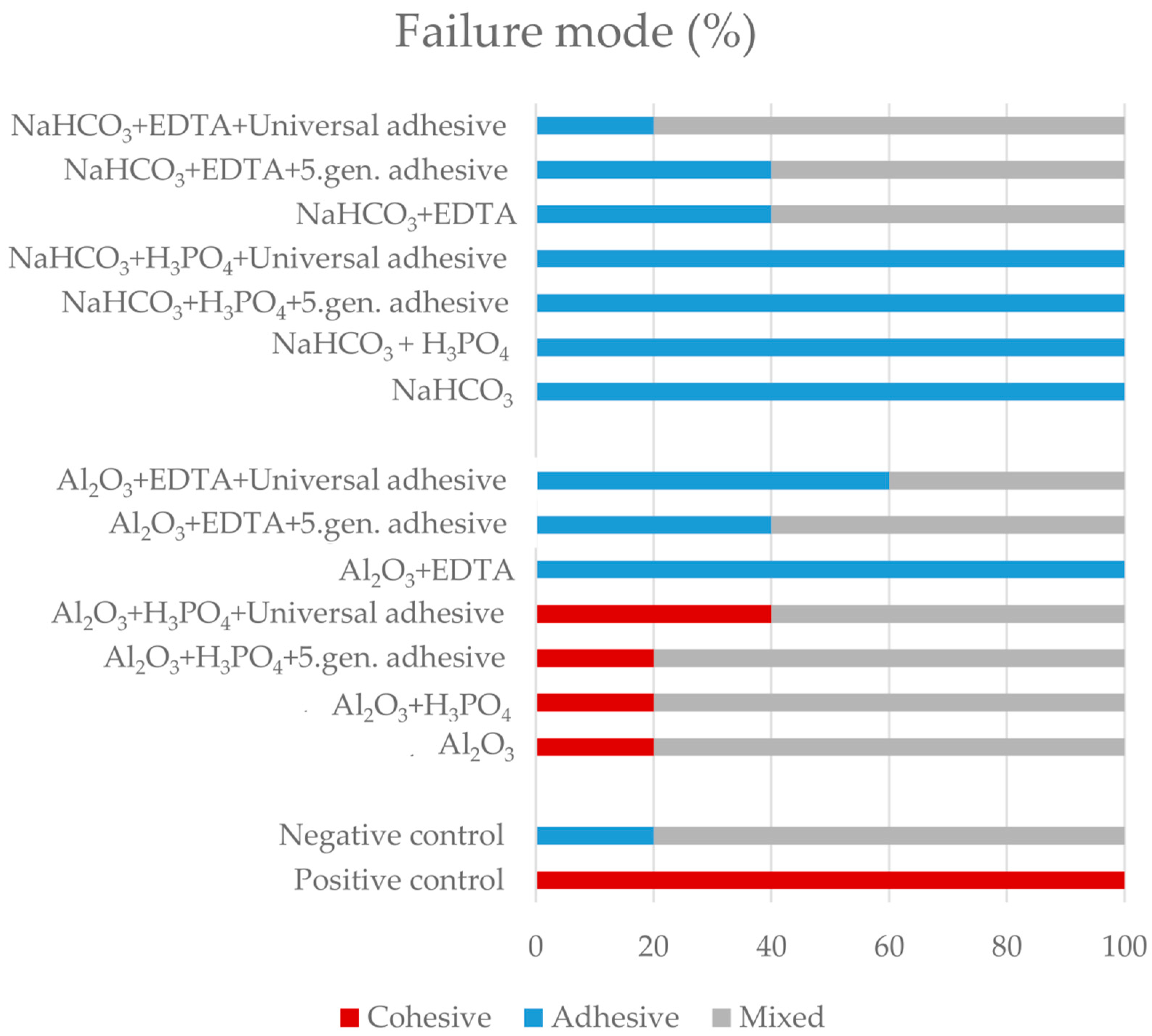

2.2. Failure Type Analysis

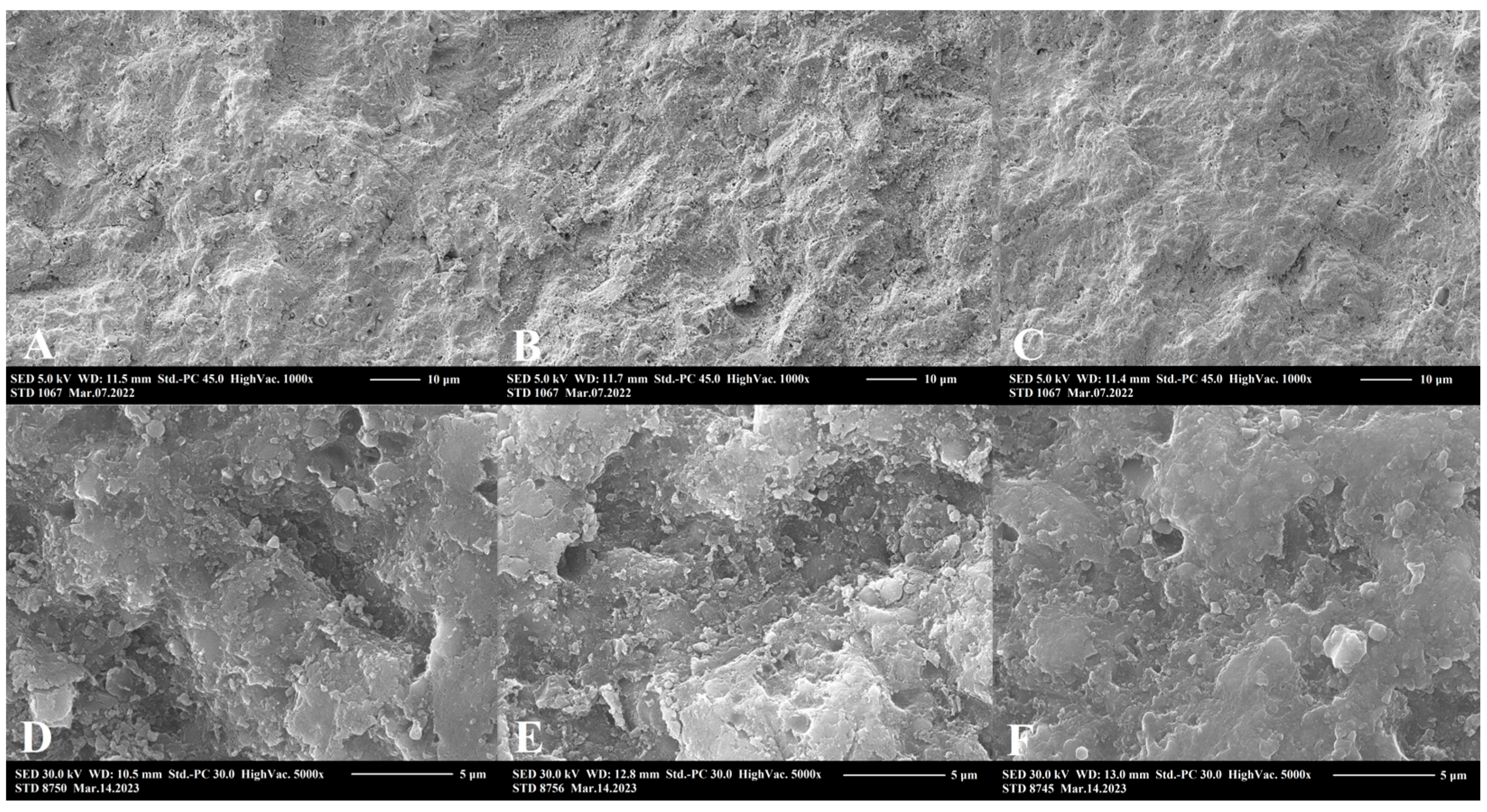

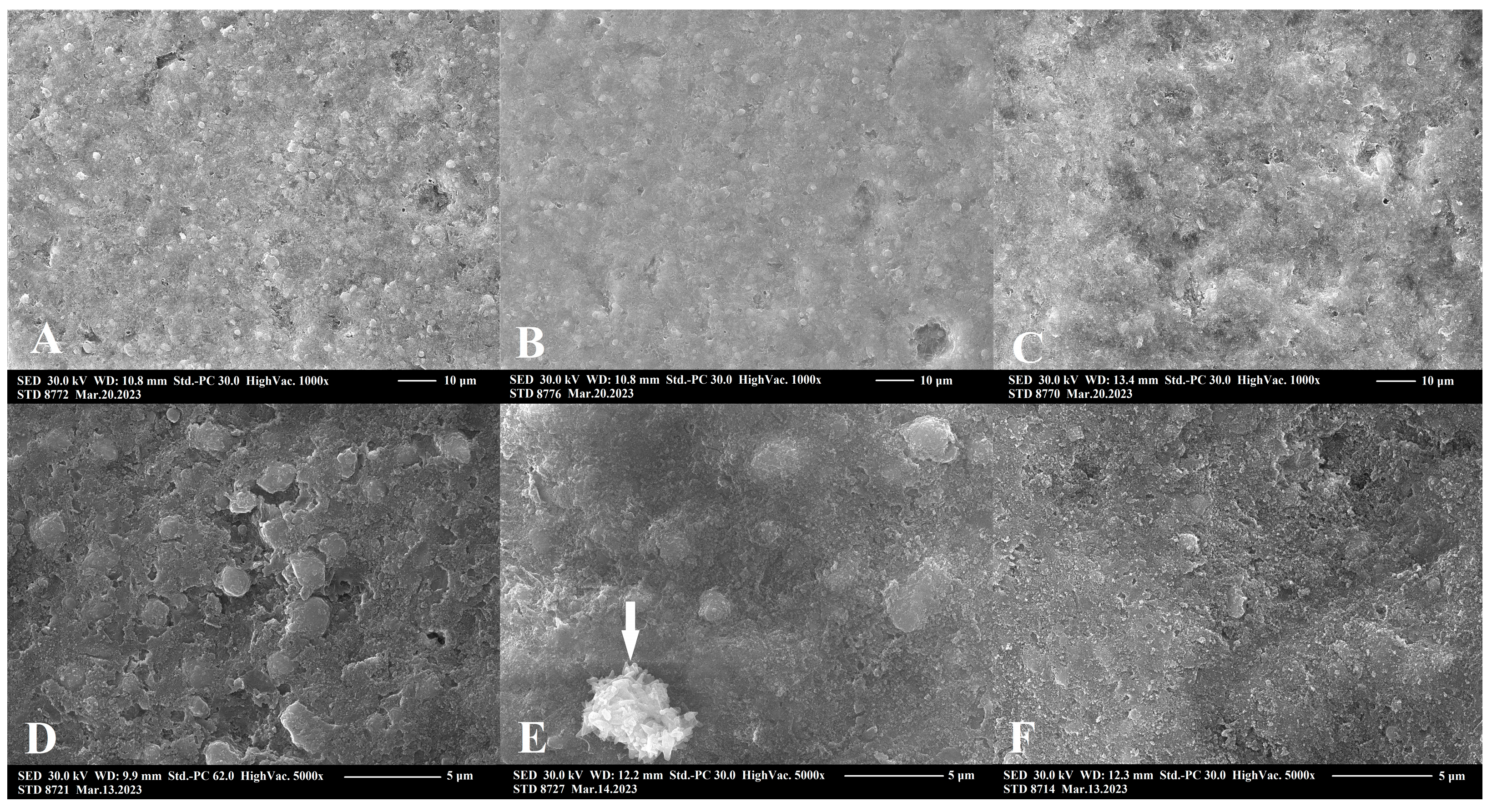

2.3. Scanning Electron Microscopic Analysis

3. Discussion

4. Materials and Method

4.1. Specimen Preparation

4.2. Surface Conditioning Methods

4.3. Repair Restoration

4.4. Microtensile Bond Strength (μTBS) Testing

4.5. Failure Type Analysis

4.6. Scanning Electron Microscopic Analysis

4.7. Statistical Analysis

5. Conclusions

- -

- A diverse combination of the applied surface preparation, cleaning method and intermediate adhesive layer significantly contributes to the repair bond strength achieved.

- -

- The widely available and routinely applied prophylactic cleaning method, namely sodium bicarbonate air-polishing followed by EDTA-cleaning and universal adhesive application, can provide a similar RBC repair bond strength to that of the commonly recommended aluminum oxide air-abrasion with or without phosphoric acid cleaning and/or adhesive application.

- -

- For clinical relevance, sodium bicarbonate air-polishing followed by EDTA cleaning and universal adhesive application could be a viable alternative in the RBC repair protocol.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Da Rosa Rodolpho, P.A.; Rodolfo, B.; Collares, K.; Correa, M.B.; Demarco, F.F.; Opdam, N.J.M.; Cenci, M.S.; Moraes, R.R. Clinical performance of posterior resin composite restorations after up to 33 years. Dent. Mater. 2022, 38, 680–688. [Google Scholar] [CrossRef] [PubMed]

- Opdam, N.J.; van de Sande, F.H.; Bronkhorst, E.; Cenci, M.S.; Bottenberg, P.; Pallesen, U.; Gaengler, P.; Lindberg, A.; Huysmans, M.C.; van Dijken, J.W. Longevity of posterior composite restorations: A systematic review and meta-analysis. J. Dent. Res. 2014, 93, 943–949. [Google Scholar] [CrossRef] [PubMed]

- Lempel, E.; Lovász, B.V.; Bihari, E.; Krajczár, K.; Jeges, S.; Tóth, Á.; Szalma, J. Long-term clinical evaluation of direct resin composite restorations in vital vs. endodontically treated posterior teeth—Retrospective study up to 13 years. Dent. Mater. 2019, 35, 1308–1318. [Google Scholar] [CrossRef] [PubMed]

- Blum, I.R.; Jagger, D.C.; Wilson, N.H.F. Defective dental restorations: To repair or not to repair? Part 1: Direct composite restorations. Dent. Update 2011, 38, 78–80, 82–84. [Google Scholar] [CrossRef] [PubMed]

- Hickel, R.; Peschke, A.; Tyas, M.; Mjör, I.; Bayne, S.; Peters, M.; Hiller, K.A.; Randall, R.; Vanherle, G.; Heintze, S.D. FDI World Dental Federation—Clinical criteria for the evaluation of direct and indirect restorations. Update and clinical examples. J. Adhes. Dent. 2010, 12, 259–272. [Google Scholar] [CrossRef]

- Blum, I.R.; Lynch, C.D.; Wilson, N.H. Factors influencing repair of dental restorations with resin composite. Clin. Cosmet. Investig. Dent. 2014, 6, 81–87. [Google Scholar] [CrossRef]

- Szczesio-Wlodarczyk, A.; Sokolowski, J.; Kleczewska, J.; Bociong, K. Ageing of dental composites based on methacrylate resins—A critical review of the causes and method of assessment. Polymers 2020, 12, 882. [Google Scholar] [CrossRef]

- Brendeke, J.; Ozcan, M. Effect of physicochemical aging conditions on the composite-composite repair bond strength. J. Adhes. Dent. 2007, 9, 399–406. [Google Scholar]

- Rathke, A.; Tymina, Y.; Haller, B. Effect of different surface treatments on the composite-composite repair bond strength. Clin. Oral Investig. 2009, 13, 317–323. [Google Scholar] [CrossRef]

- Yin, H.; Kwon, S.; Chung, S.H.; Kim, R.J.Y. Performance of universal adhesives in composite resin repair. Biomed. Res. Int. 2022, 2022, 7663490. [Google Scholar] [CrossRef]

- Wendler, M.; Belli, R.; Panzer, R.; Skibbe, D.; Petschelt, A.; Lohbauer, U. Repair bond strength of aged resin composite after different surface and bonding treatments. Materials 2016, 9, 547. [Google Scholar] [CrossRef]

- Rodrigues, S.A., Jr.; Ferracane, J.L.; Della Bona, A. Influence of surface treatments on the bond strength of repaired resin composite restorative materials. Dent. Mater. 2009, 25, 442–451. [Google Scholar]

- Costa, T.R.; Ferreira, S.Q.; Klein-Júnior, C.A.; Loguercio, A.D.; Reis, A. Durability of surface treatments and intermediate agents used for repair of a polished composite. Oper. Dent. 2010, 35, 231–237. [Google Scholar] [CrossRef]

- Baena, E.; Vignolo, V.; Fuentes, M.V.; Ceballos, L. Influence of repair procedure on composite-to-composite microtensile bond strength. Am. J. Dent. 2015, 28, 255–260. [Google Scholar]

- Gomes, I.A.; Mendes, H.G.; Filho, E.M.M.; de Castro Rizzi, C.M.; Nina, M.G.; Turssi, C.P.; Vasconcelos, A.J.; Bandeca, M.C.; de Jesus Tavarez, R.R. Effect of dental prophylaxis techniques on the surface roughness of resin composites. J. Contemp. Dent. Pract. 2018, 19, 37–41. [Google Scholar]

- Salerno, M.; Giacomelli, L.; Derchi, G.; Patra, N.; Diaspro, A. Atomic force microscopy in vitro study of surface roughness and fractal character of a dental restoration composite after air polishing. Biomed. Eng. Online 2010, 9, 59. [Google Scholar] [CrossRef]

- Németh, K.D.; Haluszka, D.; Seress, L.; Lovász, B.V.; Szalma, J.; Lempel, E. Effect of air-polishing and different post-polishing methods on surface roughness of nanofill and microhybrid resin composites. Polymers 2022, 14, 1643. [Google Scholar] [CrossRef]

- Valian, A.; Ansari, Z.J.; Rezaie, M.M.; Askian, R. Composite surface roughness and color change following airflow usage. BMC Oral Health. 2021, 21, 398. [Google Scholar] [CrossRef]

- Güler, A.U.; Duran, I.; Yücel, A.Ç.; Özkan, P. Effects of air polishing powders on the surface roughness of composite resins. J. Dent. Sci. 2010, 5, 136–143. [Google Scholar] [CrossRef]

- Janiszewska-Olszowska, J.; Drozdzik, A.; Tandecka, K.; Grocholewicz, K. Effect of air-polishing on surface roughness of composite dental restorative material—Comparison of three different air-polishing powders. BMC. Oral Health 2020, 20, 30. [Google Scholar] [CrossRef]

- Graumann, S.J.; Sensat, M.L.; Stoltenberg, J.L. Air polishing: A review of current literature. J. Dent. Hyg. 2013, 87, 173–180. [Google Scholar]

- Babina, K.; Polyakova, M.; Sokhova, I.; Doroshina, V.; Arakelyan, M.; Zaytsev, A.; Novozhilova, N. The effect of ultrasonic scaling and air-powder polishing on the roughness of the enamel, three different nanocomposites, and composite/enamel and composite/cementum interfaces. Nanomaterials 2021, 11, 3072. [Google Scholar] [CrossRef]

- Pashley, D.H.; Carvalho, R.M.; Sano, H.; Nakajima, M.; Yoshiyama, M.; Shono, Y.; Fernandes, C.A.; Tay, F. The microtensile bond test: A review. J. Adhes. Dent. 1999, 1, 299–309. [Google Scholar]

- Cavalcanti, A.N.; De Lima, A.F.; Peris, A.R.; Mitsui, F.H.; Marchi, G.M. Effect of surface treatments and bonding agents on the bond strength of repaired composites. J. Esthet. Restor. Dent. 2007, 19, 90–99. [Google Scholar] [CrossRef]

- Michelotti, G.; Niedzwiecki, M.; Bidjan, D.; Dieckmann, P.; Deari, S.; Attin, T.; Tauböck, T.T. Silane effect of universal adhesive on the composite-composite repair bond strength after different surface pretreatments. Polymers 2020, 12, 950. [Google Scholar] [CrossRef]

- Valente, L.L.; Sarkis-Onofre, R.; Gonçalves, A.P.; Fernández, E.; Loomans, B.; Moraes, R.R. Repair bond strength of dental composites: Systematic review and meta-analysis. Int. J. Adhes. Adhes. 2016, 69, 15–26. [Google Scholar] [CrossRef]

- Maneenut, C.; Sakoolnamarka, R.; Tyas, M.J. The repair potential of resin composite materials. Dent. Mater. 2011, 27, e20–e27. [Google Scholar] [CrossRef]

- Panchal, A.C.; Asthana, G. Oxygen inhibition layer: A dilemma to be solved. J. Conserv. Dent. 2020, 23, 254–258. [Google Scholar] [CrossRef]

- Li, J. Effects of surface properties on bond strength between layers of newly cured dental composites. J. Oral Rehabil. 1997, 24, 358–360. [Google Scholar] [CrossRef]

- Papacchini, F.; Toledano, M.; Monticelli, F.; Osorio, R.; Radovic, I.; Polimeni, A.; García-Godoy, F.; Ferrari, M. Hydrolytic stability of composite repair bond. Eur. J. Oral Sci. 2007, 115, 417–424. [Google Scholar] [CrossRef]

- Souza, M.O.; Leitune, V.C.; Rodrigues, S.B.; Samuel, S.M.; Collares, F.M. One-year aging effects on microtensile bond strengths of composite and repairs with different surface treatments. Braz. Oral Res. 2017, 31, 16–22. [Google Scholar] [CrossRef]

- Fawzy, A.S.; El-Askary, F.S.; Amer, M.A. Effect of surface treatments on the tensile bond strength of repaired water-aged anterior restorative micro-fine hybrid resin composite. J. Dent. 2008, 36, 969–976. [Google Scholar] [CrossRef]

- Brunharo, I.H.; Fernandes, D.J.; de Miranda, M.S.; Artese, F. Influence of surface treatment on shear bond strength of orthodontic brackets. Dental Press J. Orthod. 2013, 18, 54–62. [Google Scholar] [CrossRef]

- Bayram, M.; Yesilyurt, C.; Kusgöz, A.; Ulker, M.; Nur, M. Shear bond strength of orthodontic brackets to aged resin composite surfaces: Effect of surface conditioning. Eur. J. Orthod. 2011, 33, 174–179. [Google Scholar] [CrossRef]

- Park, J.; Park, H.; Lee, J. Effect of various surface treatment methods on shear bond strength of orthodontic brackets to aged composite resin. J. Korean Acad. Pediatr. Dent. 2014, 41, 125–133. [Google Scholar] [CrossRef]

- Burrer, P.; Costermani, A.; Par, M.; Attin, T.; Tauböck, T.T. Effect of varying working distances between sandblasting device and composite substrate surface on the repair bond strength. Materials 2021, 14, 1621. [Google Scholar] [CrossRef]

- Huang, C.T.; Kim, J.; Arce, C.; Lawson, N.C. Intraoral air abrasion: A review of devices, materials, evidence, and clinical applications in restorative dentistry. Compend. Contin. Educ. Dent. 2019, 40, 508–513. [Google Scholar]

- Da Costa, T.R.; Serrano, A.M.; Atman, A.P.; Loguercio, A.D.; Reis, A. Durability of composite repair using different surface treatments. J. Dent. 2012, 40, 513–521. [Google Scholar] [CrossRef]

- Kouros, P.; Koliniotou-Koumpia, E.; Spyrou, M.; Koulaouzidou, E. Influence of material and surface treatment on composite repair shear bond strength. J. Conserv. Dent. 2018, 21, 251–256. [Google Scholar] [CrossRef]

- Lennemann, T. Air polishing: Overview. Can. J. Dent. Hyg. 2011, 45, 145–148. [Google Scholar]

- Bonstein, T.; Garlapo, D.; Donarummo, J., Jr.; Bush, P.J. Evaluation of varied repair protocols applied to aged composite resin. J. Adhes. Dent. 2005, 7, 41–49. [Google Scholar] [PubMed]

- Papacchini, F.; Dall’Oca, S.; Chieffi, N.; Goracci, C.; Sadek, F.T.; Suh, B.I.; Tay, F.R.; Ferrari, M. Composite-to-composite microtensile bond strength in the repair of a microfilled hybrid resin: Effect of surface treatment and oxygen inhibition. J. Adhes. Dent. 2007, 9, 25–31. [Google Scholar] [PubMed]

- Loomans, B.A.; Cardoso, M.V.; Roeters, F.J.; Opdam, N.J.; De Munck, J.; Huysmans, M.C.; Van Meerbeek, B. Is there one optimal repair technique for all composites? Dent. Mater. 2011, 27, 701–709. [Google Scholar] [CrossRef] [PubMed]

- Loomans, B.A.; Cardoso, M.V.; Opdam, N.J.; Roeters, F.J.; De Munck, J.; Huysmans, M.C.; Van Meerbeek, B. Surface roughness of etched composite resin in light of composite repair. J. Dent. 2011, 39, 499–505. [Google Scholar] [CrossRef] [PubMed]

- Lucena-Martín, C.; González-López, S.; Navajas-Rodríguez de Mondelo, J.M. The effect of various surface treatments and bonding agents on the repaired strength of heat-treated composites. J. Prosthet. Dent. 2001, 86, 481–488. [Google Scholar] [CrossRef]

- Nassoohi, N.; Kazemi, H.; Sadaghiani, M.; Mansouri, M.; Rakhshan, V. Effects of three surface conditioning techniques on repair bond strength of nanohybrid and nanofilled composites. Dent. Res. J. 2015, 12, 554–561. [Google Scholar]

- Chen, M.; Reid, R.S. Solution speciation in the aqueous Na(1)-EDTA and K(1)-EDTA systems. Can. J. Chem. 1993, 71, 763–768. [Google Scholar] [CrossRef]

- Martos, R.; Hegedűs, V.; Szalóki, M.; Blum, I.R.; Lynch, C.D.; Hegedűs, C. A randomised controlled study on the effects of different surface treatments and adhesive self-etch functional monomers on the immediate repair bond strength and integrity of the repaired resin composite interface. J. Dent. 2019, 85, 57–63. [Google Scholar] [CrossRef]

- Martos, R.; Szalóki, M.; Gáll, J.; Csík, A.; Hegedűs, C. Comparative analysis of bond strength durability of 10-methacryloyloxydecyl dihydrogen phosphate-containing adhesives on a low-viscosity bulk-fill composite surface. J. Adhes. Dent. 2022, 24, 427–434. [Google Scholar]

- Tezvergil, A.; Lassila, L.V.; Vallittu, P.K. Composite-composite repair bond strength: Effect of different adhesion primers. J. Dent. 2003, 31, 521–525. [Google Scholar] [CrossRef]

- Papacchini, F.; Magni, E.; Radovic, I.; Mazzitelli, C.; Monticellia, F.; Goracci, C.; Polimeni, A.; Ferrari, M. Effect of intermediate agents and pre-heating of repairing resin on composite-repair bonds. Oper. Dent. 2007, 32, 363–371. [Google Scholar] [CrossRef]

- Yoshihara, K.; Hayakawa, S.; Nagaoka, N.; Okihara, T.; Yoshida, Y.; Van Meerbeek, B. Etching efficacy of self-etching functional monomers. J. Dent. Res. 2018, 97, 1010–1016. [Google Scholar] [CrossRef]

- Nagaoka, N.; Yoshihara, K.; Feitosa, V.P.; Tamada, Y.; Irie, M.; Yoshida, Y.; Van Meerbeek, B.; Hayakawa, S. Chemical interaction mechanism of 10-MDP with zirconia. Sci. Rep. 2017, 7, 45563. [Google Scholar] [CrossRef]

- Kanzow, P.; Wiegand, A.; Schwendicke, F.; Göstemeyer, G. Same, same, but different? A systematic review of protocols for restoration repair. J. Dent. 2019, 86, 1–16. [Google Scholar] [CrossRef]

- Arkoy, S.; Ulusoy, M. Effect of different surface treatments on repair bond strength of CAD/CAM resin-matrix ceramics. Materials 2022, 15, 6314. [Google Scholar] [CrossRef]

- Yoshihara, K.; Nagaoka, N.; Sonoda, A.; Maruo, Y.; Makita, Y.; Okihara, T.; Irie, M.; Yoshida, Y.; Van Meerbeek, B. Effectiveness and stability of silane coupling agent incorporated in ‘universal’ adhesives. Dent. Mater. 2016, 32, 1218–1225. [Google Scholar] [CrossRef]

- Neme, A.L.; Frazier, K.; Roeder, L.B.; Debner, T.L. Effect of prophylactic polishing protocols on the surface roughness of esthetic restorative materials. Oper. Dent. 2002, 27, 50–58. [Google Scholar]

- Barnes, C.M.; Covey, D.; Watanabe, H.; Simetich, B.; Schulte, J.R.; Chen, H. An in vitro comparison of the effects of various air polishing powders on enamel and selected esthetic restorative materials. J. Clin. Dent. 2014, 25, 76–87. [Google Scholar]

| Factor | p-Value | ƞ2 | Observed Power |

|---|---|---|---|

| Surface treatment (ST) | <0.001 | 0.516 | 1.000 |

| Cleaning method (CM) | 0.172 | 0.053 | 0.364 |

| Adhesive system (AS) | 0.034 | 0.099 | 0.641 |

| ST × CM | <0.001 | 0.641 | 1.000 |

| AS × CM | 0.161 | 0.055 | 0.377 |

| ST × AS | 0.264 | 0.040 | 0.283 |

| ST × AS × CM | 0.24 | 0.043 | 0.301 |

| Product | Composition | Lot Number | Manufacturer |

|---|---|---|---|

| Filtek Z250 | Bis-GMA, UDMA, Bis-EMA, TEGDMA, 0.6 µm zirconia-silica, 78 wt%, CQ, tertiary amine | 9438725 | 3M ESPE, St. Paul, MN, USA |

| Adper Single Bond 2 | BisGMA, HEMA, UDMA, glycerol 1,3 dimethacrylate, DPIHP, EDMAB, ethanol, water, copolymer of polyacrylic and polyitaconic acids, 5 nm filler | NE70992 | |

| Scotchbond Universal Plus Adhesive | BisGMA, HEMA, 1,10-decanediyl bismethacrylate, HEMA-phosphate, MDP, CQ, EDMAB, ethanol, water, copolymer of polyacrylic and polyitaconic acids, silane, filler | 7730432 | |

| Ultra-Etch | Phosphoric acid (<40 wt%), cobalt aluminate blue spinel (<1 wt%), siloxane (<1 wt%) | 311211 | Ultradent, South Jordan, UT, USA |

| Endo-Solution | EDTA-Na2 (15 wt%), sodium hydroxide (1 wt%) | 2401221 | Cerkamed, Stalowa Wola, Poland |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Németh, K.D.; Told, R.; Szabó, P.; Maróti, P.; Szénai, R.; Pintér, Z.B.; Lovász, B.V.; Szalma, J.; Lempel, E. Comparative Evaluation of the Repair Bond Strength of Dental Resin Composite after Sodium Bicarbonate or Aluminum Oxide Air-Abrasion. Int. J. Mol. Sci. 2023, 24, 11568. https://doi.org/10.3390/ijms241411568

Németh KD, Told R, Szabó P, Maróti P, Szénai R, Pintér ZB, Lovász BV, Szalma J, Lempel E. Comparative Evaluation of the Repair Bond Strength of Dental Resin Composite after Sodium Bicarbonate or Aluminum Oxide Air-Abrasion. International Journal of Molecular Sciences. 2023; 24(14):11568. https://doi.org/10.3390/ijms241411568

Chicago/Turabian StyleNémeth, Kinga Dorottya, Roland Told, Péter Szabó, Péter Maróti, Réka Szénai, Zsolt Balázs Pintér, Bálint Viktor Lovász, József Szalma, and Edina Lempel. 2023. "Comparative Evaluation of the Repair Bond Strength of Dental Resin Composite after Sodium Bicarbonate or Aluminum Oxide Air-Abrasion" International Journal of Molecular Sciences 24, no. 14: 11568. https://doi.org/10.3390/ijms241411568

APA StyleNémeth, K. D., Told, R., Szabó, P., Maróti, P., Szénai, R., Pintér, Z. B., Lovász, B. V., Szalma, J., & Lempel, E. (2023). Comparative Evaluation of the Repair Bond Strength of Dental Resin Composite after Sodium Bicarbonate or Aluminum Oxide Air-Abrasion. International Journal of Molecular Sciences, 24(14), 11568. https://doi.org/10.3390/ijms241411568