Effects of Different Gluten Proteins on Starch’s Structural and Physicochemical Properties during Heating and Their Molecular Interactions

Abstract

:1. Introduction

2. Results

2.1. Pasting and Thermal Properties

2.2. Solubility and Swelling Power

2.3. Crystalline and Short-Range Ordered Structure

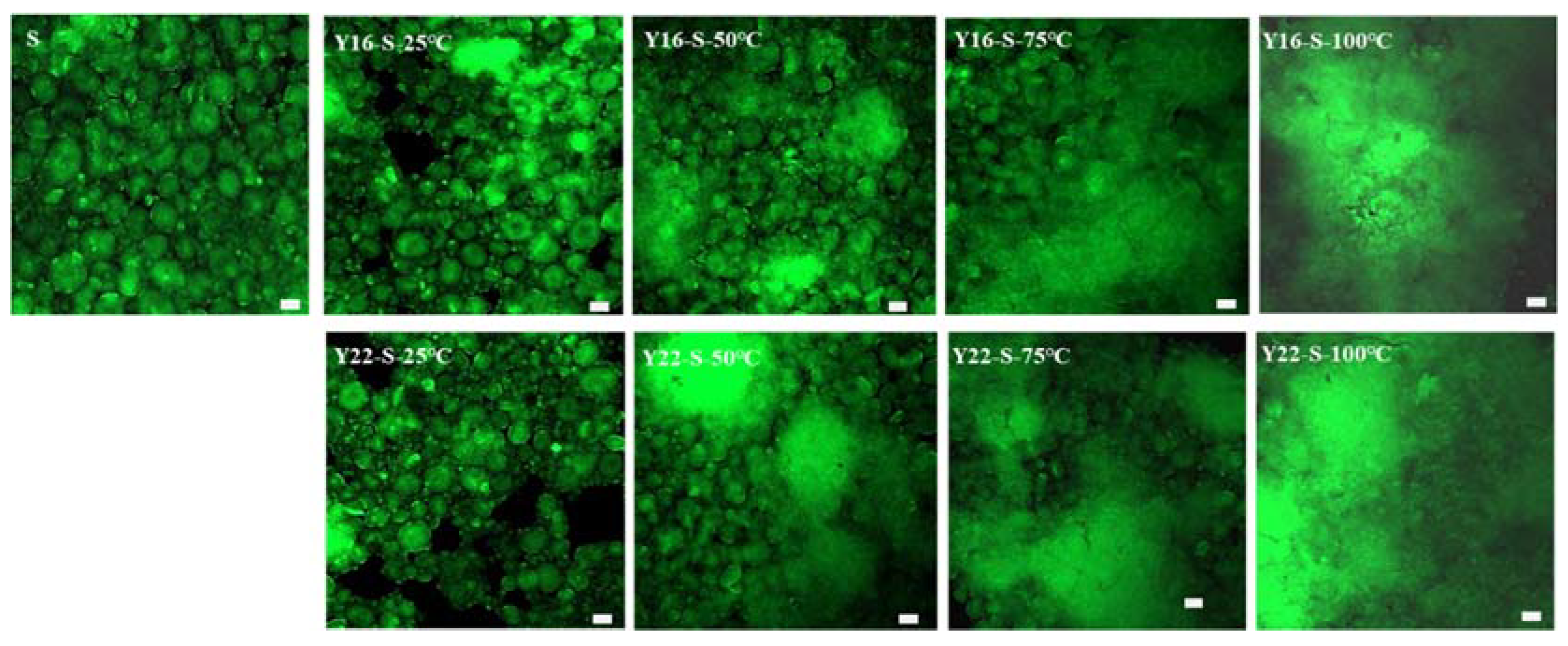

2.4. CLSM Characterization

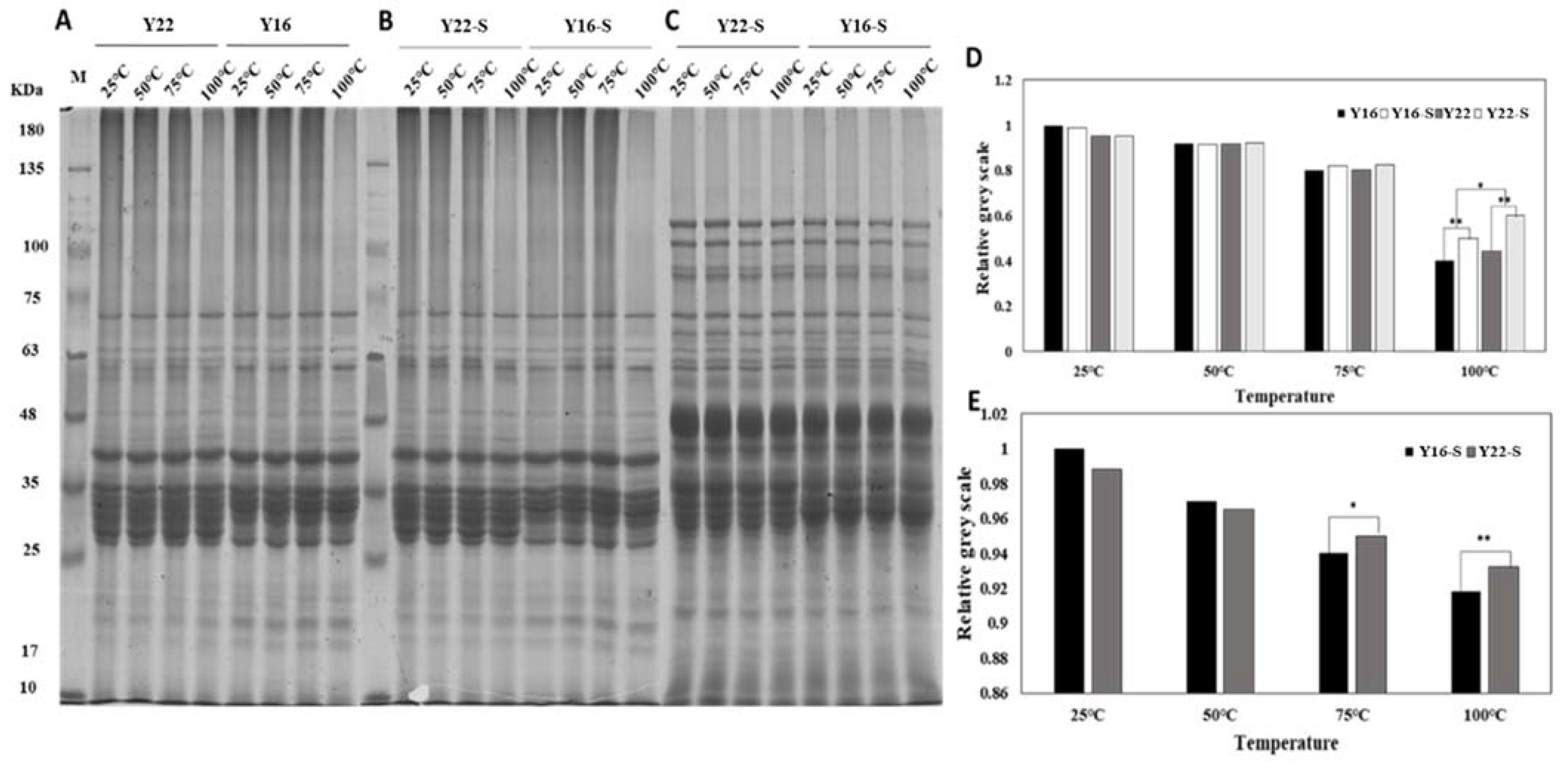

2.5. SDS-PAGE Analysis

2.6. Chemical Interactions

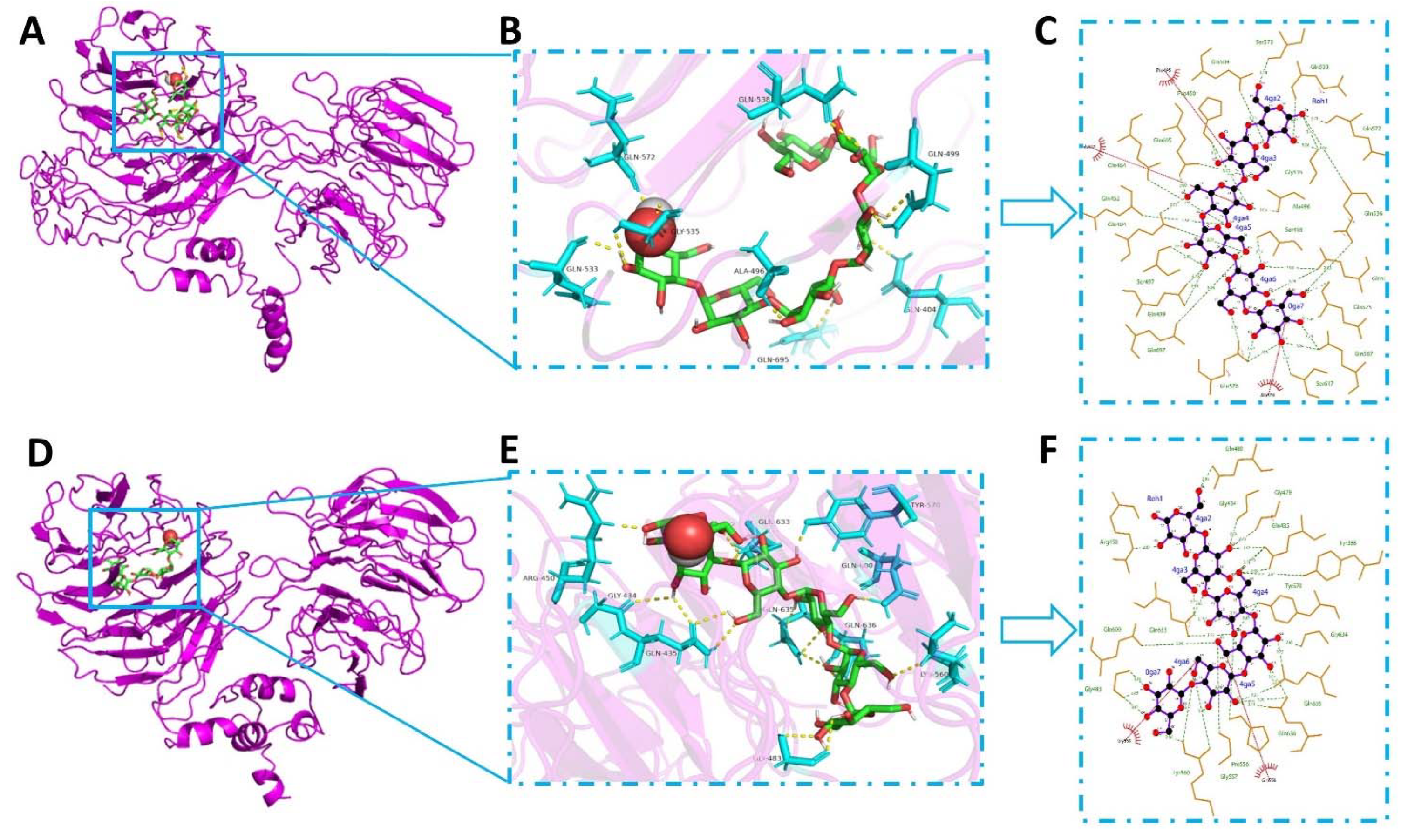

2.7. Molecular Docking

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Preparation of Starch–Gluten Mixture Samples with Hydrothermal Treatment

4.3. Pasting and Thermal Properties

4.4. Starch Swelling Power and Solubility

4.5. X-ray Diffraction (XRD)

4.6. Fourier Transform-Infrared (FT-IR) and Raman (FT-Raman) Spectroscopy

4.7. Confocal Laser Scanning Microscopy (CLSM)

4.8. Sodium Dodecyl Sulfate Polyacrylamide Gel Electrophoresis (SDS-PAGE)

4.9. Chemical Interactions

4.10. Molecular Docking

4.11. Statistics Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, D.; Mu, T.; Sun, H. Effects of starch from five different botanical sources on the rheological and structural properties of starch–gluten model doughs. Food Res. Int. 2018, 103, 156–162. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Guo, X.-N.; Zhu, K.-X. Polymerization of wheat gluten and the changes of glutenin macropolymer (GMP) during the production of Chinese steamed bread. Food Chem. 2016, 201, 275–283. [Google Scholar] [CrossRef]

- Jekle, M.; Mühlberger, K.; Becker, T. Starch–gluten interactions during gelatinization and its functionality in dough like model systems. Food Hydrocoll. 2015, 54, 196–201. [Google Scholar] [CrossRef]

- Luo, Y.; Li, M.; Zhu, K.-X.; Guo, X.-N.; Peng, W.; Zhou, H.-M. Heat-induced interaction between egg white protein and wheat gluten. Food Chem. 2016, 197, 699–708. [Google Scholar] [CrossRef]

- Wang, S.; Copeland, L. Molecular disassembly of starch granules during gelatinization and its effect on starch digestibility: A review. Food Funct. 2013, 4, 1564–1580. [Google Scholar] [CrossRef]

- Li, J.-Y.; Yeh, A.-I. Effects of starch properties on rheological characteristics of starch/meat complexes. J. Food Eng. 2003, 57, 287–294. [Google Scholar] [CrossRef]

- Li, J.-Y.; Yeh, A.-I.; Fan, K.-L. Gelation characteristics and morphology of corn starch/soy protein concentrate composites during heating. J. Food Eng. 2007, 78, 1240–1247. [Google Scholar] [CrossRef]

- Zhu, Y.; Xiong, W.; Wang, L.; Ju, X. Insight into the effect of gluten-starch ratio on the properties of Chinese steamed bread (Mantou). Int. J. Biol. Macromol. 2020, 163, 1821–1827. [Google Scholar] [CrossRef]

- Brandner, S.; Becker, T.; Jekle, M. Classification of starch-gluten networks into a viscoelastic liquid or solid, based on rheological aspects—A review. Int. J. Biol. Macromol. 2019, 136, 1018–1025. [Google Scholar] [CrossRef]

- Homer, S.; Kelly, M.; Day, L. Determination of the thermo-mechanical properties in starch and starch/gluten systems at low moisture content—A comparison of DSC and TMA. Carbohydr. Polym. 2014, 108, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Appels, R.; Zhang, X.; Diepeveen, D.; Torok, K.; Tomoskozi, S.; Bekes, F.; Ma, W.; Sharp, P.; Islam, S. Protein interactions during flour mixing using wheat flour with altered starch. Food Chem. 2017, 231, 247–257. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, M.; Yue, Q.; Liu, C.; Zheng, X.; Hong, J.; Li, L.; Bian, K. Effect of gliadin/glutenin ratio on pasting, thermal, and structural properties of wheat starch. J. Cereal Sci. 2020, 93, 102973. [Google Scholar] [CrossRef]

- Li, C.; Chen, G.-J.; Ran, C.; Liu, L.; Wang, S.; Xu, Y.; Tan, Y.; Kan, J. Adlay starch-gluten composite gel: Effects of adlay starch on rheological and structural properties of gluten gel to molecular and physico-chemical characteristics. Food Chem. 2019, 289, 121–129. [Google Scholar] [CrossRef]

- Tamaki, Y.; Konishi, T.; Tako, M. Gelation and Retrogradation Mechanism of Wheat Amylose. Materials 2011, 4, 1763–1775. [Google Scholar] [CrossRef] [Green Version]

- Schurer, F.; Kieffer, R.; Wieser, H.; Koehler, P. Effect of hydrostatic pressure and temperature on the chemical and functional properties of wheat gluten II. Studies on the influence of additives. J. Cereal Sci. 2007, 46, 39–48. [Google Scholar] [CrossRef]

- Liao, L.; Zhang, F.-L.; Lin, W.-J.; Li, Z.-F.; Yang, J.-Y.; Park, K.H.; Ni, L.; Liu, P. Gluten-starch interactions in wheat gluten during carboxylic acid deamidation upon hydrothermal treatment. Food Chem. 2019, 283, 111–122. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Xu, L.; Nikoo, M.; Ocen, D.; Wu, F.; Yang, N.; Jin, Z.; Xu, X. Effect of frozen storage on the conformational, thermal and microscopic properties of gluten: Comparative studies on gluten-, glutenin- and gliadin-rich fractions. Food Hydrocoll. 2014, 35, 238–246. [Google Scholar] [CrossRef]

- Mittal, J.; Best, R.B. Thermodynamics and kinetics of protein folding under confinement. Proc. Natl. Acad. Sci. USA 2008, 105, 20233–20238. [Google Scholar] [CrossRef] [Green Version]

- BeMiller, J.N. Food Polysaccharides and Their Applications: Edited by A.M. Stephen, Marcel Dekker, 1995. $195.00 (xiii + 654 pages) ISBN 0 8247 9353 6. Trends Food Sci. Technol. 1996, 7, 207–208. [Google Scholar] [CrossRef]

- López-Barón, N.; Sagnelli, D.; Blennow, A.; Holse, M.; Gao, J.; Saaby, L.; Müllertz, A.; Jespersen, B.; Vasanthan, T. Hydrolysed pea proteins mitigate in vitro wheat starch digestibility. Food Hydrocoll. 2018, 79, 117–126. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, X.; Wang, S.; Copeland, L. Changes of multi-scale structure during mimicked DSC heating reveal the nature of starch gelatinization. Sci. Rep. 2016, 6, 28271. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, S.; Zheng, M.; Yu, J.; Wang, S.; Copeland, L. Insights into the Formation and Structures of Starch–Protein–Lipid Complexes. J. Agric. Food Chem. 2017, 65, 1960–1966. [Google Scholar] [CrossRef] [PubMed]

- Chao, C.; Cai, J.; Yu, J.; Copeland, L.; Wang, S.; Wang, S. Toward a Better Understanding of Starch–Monoglyceride–Protein Interactions. J. Agric. Food Chem. 2018, 66, 13253–13259. [Google Scholar] [CrossRef]

- Stănciuc, N.; Banu, I.; Bolea, C.; Patraşcu, L.; Aprodu, I. Structural and antigenic properties of thermally treated gluten proteins. Food Chem. 2018, 267, 43–51. [Google Scholar] [CrossRef]

- Bakar, J.; Saeed, M.; Abbas, K.; Rahman, R.A.; Hashim, R.K.D. Protein-starch interaction and their effect on thermal and rheological characteristics of a food system: A review. J. Food Agric. Environ. 2009, 7, 169–174. [Google Scholar]

- Chen, Q.; Zhang, J.; Zhang, Y.; Kaplan, D.L.; Wang, Q. Protein-amylose/amylopectin molecular interactions during high-moisture extruded texturization toward plant-based meat substitutes applications. Food Hydrocoll. 2022, 127, 107559. [Google Scholar] [CrossRef]

- Hirai, M.; Hirai, T.; Ueki, T. Effect of branching of amylopectin on complexation with iodine as steric hindrance. Polymer 1994, 35, 2222–2225. [Google Scholar] [CrossRef]

- Lu, Z.-H.; Donner, E.; Yada, R.Y.; Liu, Q. Physicochemical properties and in vitro starch digestibility of potato starch/protein blends. Carbohydr. Polym. 2016, 154, 214–222. [Google Scholar] [CrossRef]

- Chang, F.; He, X.; Huang, Q. The physicochemical properties of swelled maize starch granules complexed with lauric acid. Food Hydrocoll. 2013, 32, 365–372. [Google Scholar] [CrossRef]

- Yuan, T.Z.; Liu, S.; Reimer, M.; Isaak, C.; Ai, Y. Evaluation of pasting and gelling properties of commercial flours under high heating temperatures using Rapid Visco Analyzer 4800. Food Chem. 2020, 344, 128616. [Google Scholar] [CrossRef]

- Leach, H.W. Structure of starch granules I. Swelling and solubility patterns of various starches. Cereal Chem. 1959, 36, 534–544. [Google Scholar]

- Yang, T.; Wang, P.; Wang, F.; Zhou, Q.; Wang, X.; Cai, J.; Huang, M.; Jiang, D. Influence of starch physicochemical properties on biscuit-making quality of wheat lines with high-molecular-weight glutenin subunit (HMW-GS) absence. LWT 2022, 158, 113166. [Google Scholar] [CrossRef]

- Brandt, N.; Chikishev, A.; Golovin, A.; Kruzhilin, V.; Zalevsky, A. Raman spectroscopy of disulfide bridges in thrombin. Biomed. Spectrosc. Imaging 2014, 3, 287–292. [Google Scholar] [CrossRef]

- Gómez-Guillén, M.C.; Borderías, A.J.; Montero, P. Chemical Interactions of Nonmuscle Proteins in the Network of Sardine (Sardina pilchardus) Muscle Gels. LWT-Food Sci. Technol. 1997, 30, 602–608. [Google Scholar] [CrossRef]

- Zhang, Y. I-TASSER server for protein 3D structure prediction. BMC Bioinform. 2008, 9, 40. [Google Scholar] [CrossRef] [Green Version]

- Kirschner, K.N.; Yongye, A.B.; Tschampel, S.M.; González-Outeiriño, J.; Daniels, C.R.; Foley, B.L.; Woods, R.J. GLYCAM06: A generalizable biomolecular force field. Carbohydrates. J. Comput. Chem. 2008, 29, 622–655. [Google Scholar] [CrossRef] [Green Version]

| Sample | SP (g/g) | SI (%) | PV (cP) | TV (cP) | BV (cP) | FV (cP) | SV (cP) | PT (°C) | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S | 27.40 ± 0.02 a | 25.03 ± 0.03 a | 1903 ± 2 a | 1210 ± 13 b | 693 ± 6 a | 2227 ± 18 a | 1017 ± 5 a | 76.2 ± 0.03 f | 55.30 ± 0.37 g | 61.38 ± 0.22 g | 65.71 ± 0.34 g | 9.91 ± 0.16 a |

| Y22-S-25 °C | 17.64 ± 0.00 d | 18.18 ± 0.00 d | 1525 ± 3 d | 1244 ± 39 b | 282 ± 4 d | 1529 ± 16 e | 301 ± 1 d | 82.3 ± 0.17 d | 56.80 ± 0.23 f | 62.10 ± 0.53 f | 67.60 ± 0.32 f | 7.30 ± 0.12 b |

| Y22-S-50 °C | 18.22 ± 0.00 b | 22.73 ± 0.39 b | 1743 ± 12 b | 1377 ± 3 a | 367 ± 9 b | 1683 ± 10 b | 306 ± 6 d | 83.6 ± 0.95 c | 60.10 ± 0.53 d | 65.80 ± 0.33 d | 69.40 ± 0.32 d | 6.80 ± 0.32 c |

| Y22-S-75 °C | 13.22 ± 0.23 e | 17.05 ± 0.19 e | 992 ± 25 g | 886 ± 49 d | 76 ± 4 f | 1028 ± 45 h | 133 ± 9 e | 91.3 ± 0.00 b | 64.70 ± 0.65 b | 69.30 ± 0.55 b | 74.40 ± 0.22 b | 2.10 ± 0.22 e |

| Y22-S-100 °C | 12.3 ± 0.13 f | 14.72 ± 0.12 f | 1050 ± 28 f | 808 ± 24 d | 243 ± 3 e | 955 ± 6 i | 147 ± 18 e | 95.0 ± 0.03 a | - | - | - | - |

| Y16-S-25 °C | 17.92 ± 0.03 c | 18.18 ± 0.00 d | 1541 ± 2 cd | 1197 ± 8 b | 345 ± 2 c | 1595 ± 7 d | 405 ± 7 b | 78.4 ± 0.28 e | 57.90 ± 0.32 e | 64.30 ± 0.22 e | 68.50 ± 0.23 e | 6.80 ± 0.33 c |

| Y16-S-50 °C | 18.27 ± 0.04 b | 19.32 ± 0.19 c | 1587 ± 13 c | 1221 ± 17 b | 367 ± 16.26 b | 1638 ± 14.14 c | 417 ± 16.97 b | 78.6 ± 0.49 e | 61.60 ± 0.12 c | 68.70 ± 0.32 c | 70.10 ± 0.53 c | 5.30 ± 0.13 d |

| Y16-S-75 °C | 11.95 ± 0.00 g | 14.77 ± 0.19 f | 908 ± 12 h | 816 ± 16 d | 85 ± 8.48 f | 1113 ± 12.02 g | 297 ± 14.14 d | 91.7 ± 0.03 b | 66.40 ± 0.22 a | 72.90 ± 0.12 a | 74.70 ± 0.55 a | 1.70 ± 0.25 f |

| Y16-S-100 °C | 11.88 ± 0.01 g | 14.32 ± 0.26 f | 1188 ± 17 e | 1037 ± 75 c | 251 ± 5.65 e | 1451 ± 23.33 f | 365 ± 19.09 c | 74.0 ± 0.81 g | - | - | - | - |

| Sample | IR Ratio of 1047/1022 cm−1 | IR Ratio of 1022/995 cm−1 | FWHM at 480 cm−1 |

|---|---|---|---|

| S | 0.61 ± 0.003 a | 1.00 ± 0.021 g | 16.54 ± 0.11 d |

| Y22-S-25 °C | 0.44 ± 0.004 f | 2.10 ± 0.089 d | 16.31 ± 0.27 e |

| Y22-S-50 °C | 0.44 ± 0.002 f | 2.23 ± 0.031 c | 17.06 ± 0.05 c |

| Y22-S-75 °C | 0.40 ± 0.008 g | 3.60 ± 0.080 b | 17.32 ± 0.08 b |

| Y22-S-100 °C | 0.36 ± 0.003 h | 4.86 ± 0.165 a | 17.74 ± 0.05 a |

| Y16-S-25 °C | 0.62 ± 0.003 a | 0.87 ± 0.018 h | 16.14 ± 0.13 ef |

| Y16-S-50 °C | 0.57 ± 0.002 b | 1.08 ± 0.015 g | 15.91 ± 0.12 f |

| Y16-S-75 °C | 0.52 ± 0.002 c | 1.54 ± 0.011 ef | 16.73 ± 0.07 d |

| Y16-S-100 °C | 0.49 ± 0.001 e | 1.45 ± 0.017 f | 17.54 ± 0.15 ab |

| Sample | Ionic Bonds (g/L) | Hydrogen Bonds (g/L) | Hydrophobic Bonds (g/L) | Disulfide Bonds (g/L) |

|---|---|---|---|---|

| Y22-S-25 °C | 0.52 ± 0.03 a | 3.46 ± 0.07 d | 26.24 ± 0.01 d | 25.33 ± 1.00 f |

| Y22-S-50 °C | 0.48 ± 0.01 a | 3.67 ± 0.01 c | 26.76 ± 0.46 c | 28.01 ± 0.03 e |

| Y22-S-75 °C | 0.46 ± 0.00 a | 3.42 ± 0.00 d | 23.76 ± 0.01 f | 31.56 ± 0.06 d |

| Y22-S-100 °C | 0.29 ± 0.03 b | 3.27 ± 0.03 e | 16.69 ± 0.07 h | 38.85 ± 0.04 b |

| Y16-S-25 °C | 0.48 ± 0.01 a | 4.34 ± 0.03 a | 28.83 ± 0.11 a | 31.25 ± 0.28 d |

| Y16-S-50 °C | 0.31 ± 0.03 b | 4.26 ± 0.01 a | 27.98 ± 0.37 b | 30.89 ± 0.89 d |

| Y16-S-75 °C | 0.21 ± 0.02 b | 3.86 ± 0.01 b | 25.27 ± 0.03 e | 36.45 ± 1.12 c |

| Y16-S-100 °C | 0.19 ± 0.07 c | 3.75 ± 0.06 c | 18.70 ± 0.00 g | 52.96 ± 0.32 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, T.; Wang, P.; Zhou, Q.; Zhong, Y.; Wang, X.; Cai, J.; Huang, M.; Jiang, D. Effects of Different Gluten Proteins on Starch’s Structural and Physicochemical Properties during Heating and Their Molecular Interactions. Int. J. Mol. Sci. 2022, 23, 8523. https://doi.org/10.3390/ijms23158523

Yang T, Wang P, Zhou Q, Zhong Y, Wang X, Cai J, Huang M, Jiang D. Effects of Different Gluten Proteins on Starch’s Structural and Physicochemical Properties during Heating and Their Molecular Interactions. International Journal of Molecular Sciences. 2022; 23(15):8523. https://doi.org/10.3390/ijms23158523

Chicago/Turabian StyleYang, Tao, Pei Wang, Qin Zhou, Yingxin Zhong, Xiao Wang, Jian Cai, Mei Huang, and Dong Jiang. 2022. "Effects of Different Gluten Proteins on Starch’s Structural and Physicochemical Properties during Heating and Their Molecular Interactions" International Journal of Molecular Sciences 23, no. 15: 8523. https://doi.org/10.3390/ijms23158523

APA StyleYang, T., Wang, P., Zhou, Q., Zhong, Y., Wang, X., Cai, J., Huang, M., & Jiang, D. (2022). Effects of Different Gluten Proteins on Starch’s Structural and Physicochemical Properties during Heating and Their Molecular Interactions. International Journal of Molecular Sciences, 23(15), 8523. https://doi.org/10.3390/ijms23158523