In Vitro Corrosion and Cytocompatibility Properties of Nano-Whisker Hydroxyapatite Coating on Magnesium Alloy for Bone Tissue Engineering Applications

Abstract

:1. Introduction

2. Results and Discussion

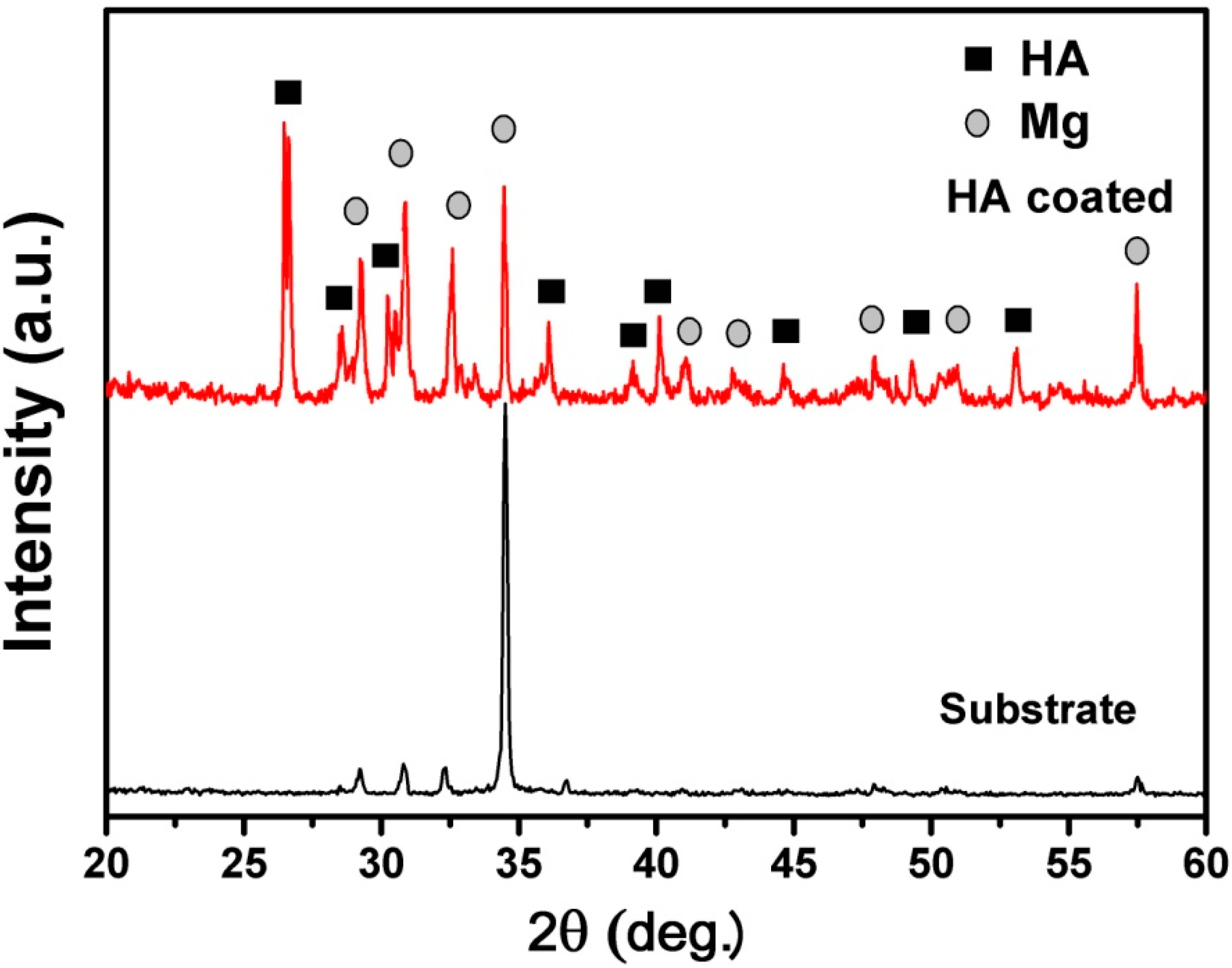

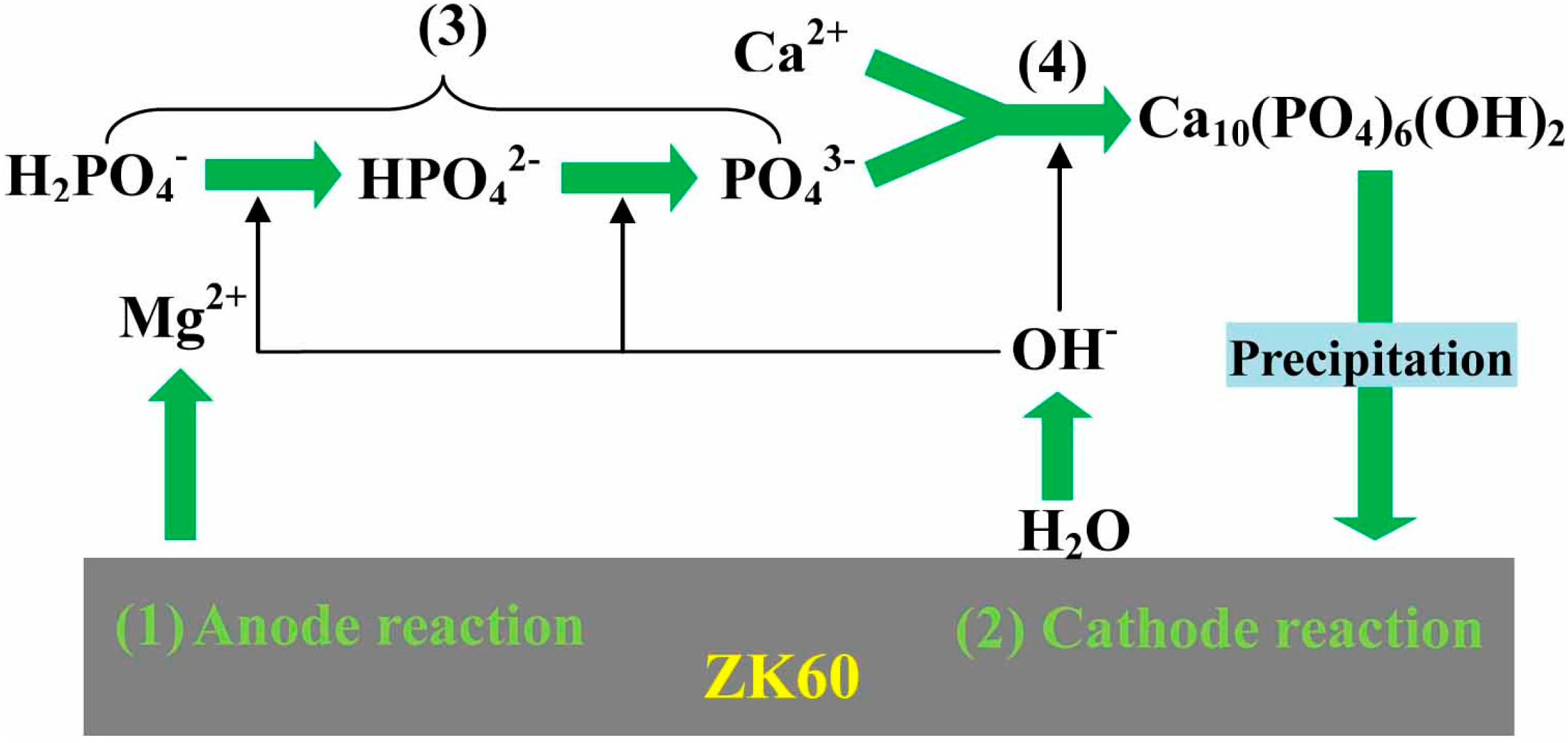

2.1. Formation of Hydroxyapatite (HA) on ZK60 Substrate

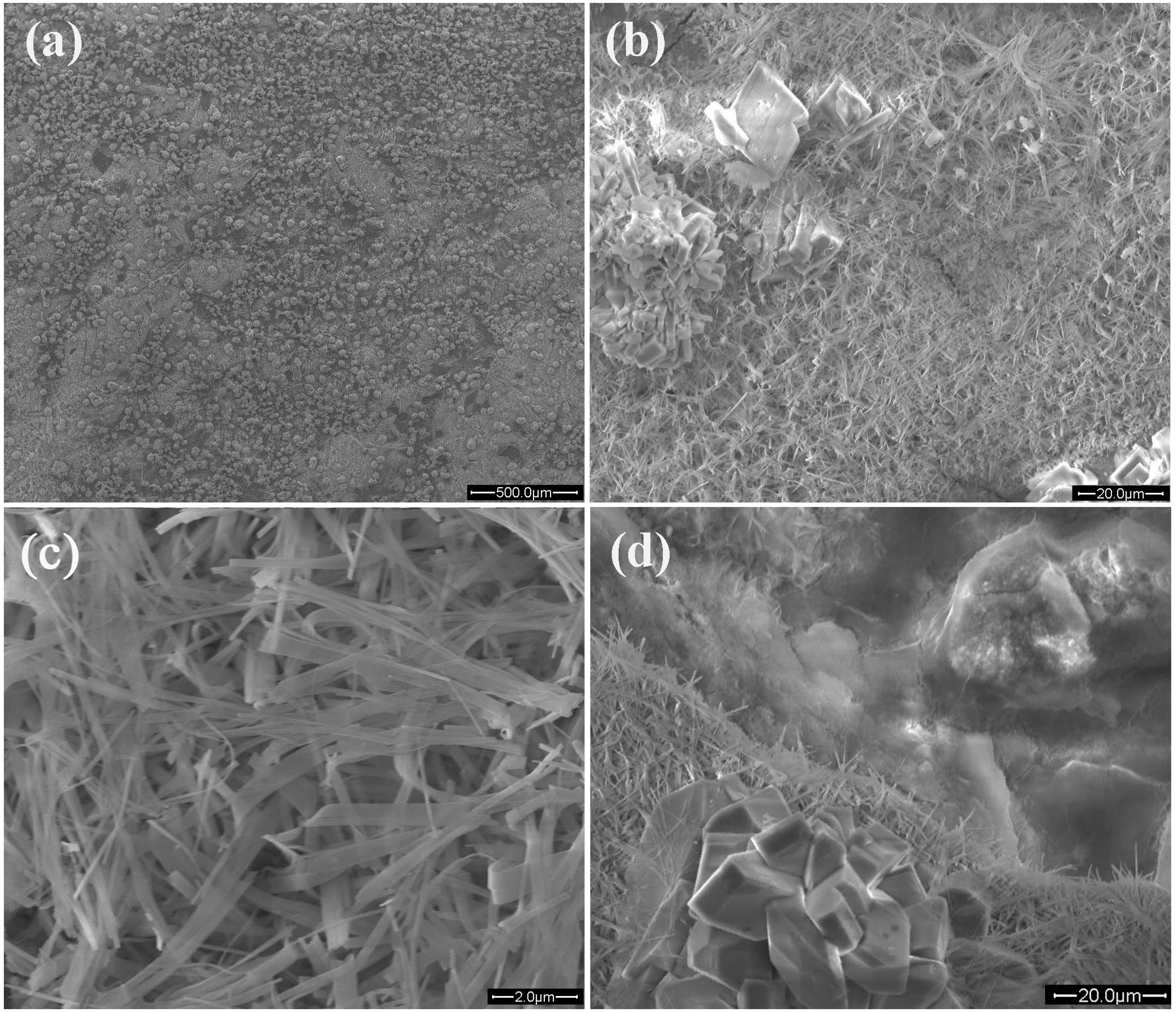

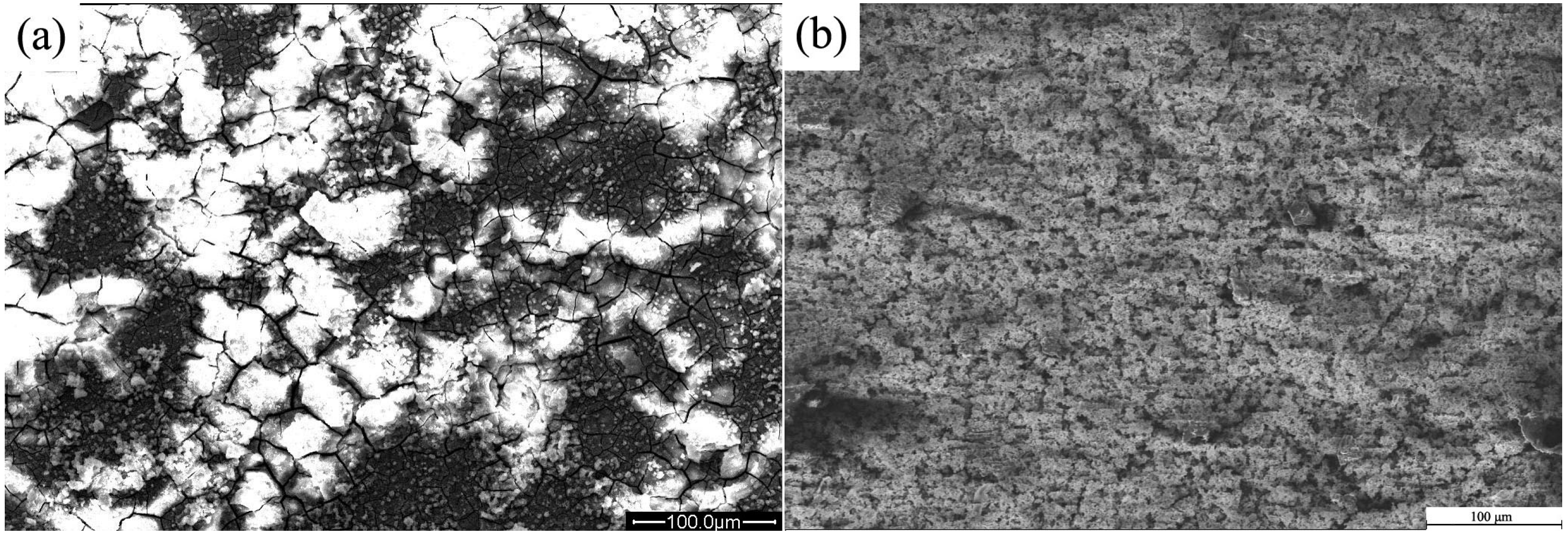

2.2. Microstructure of HA Coatings

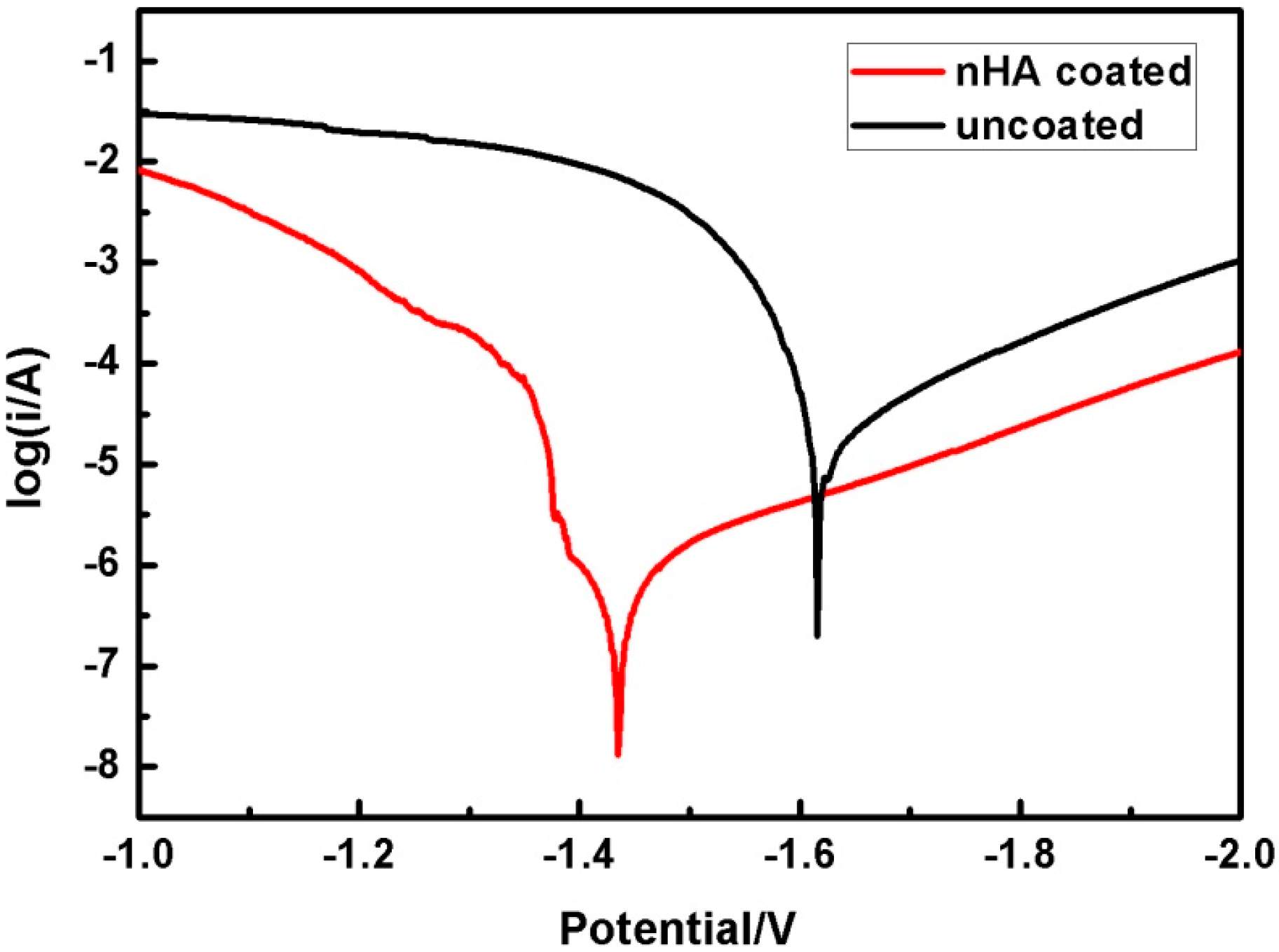

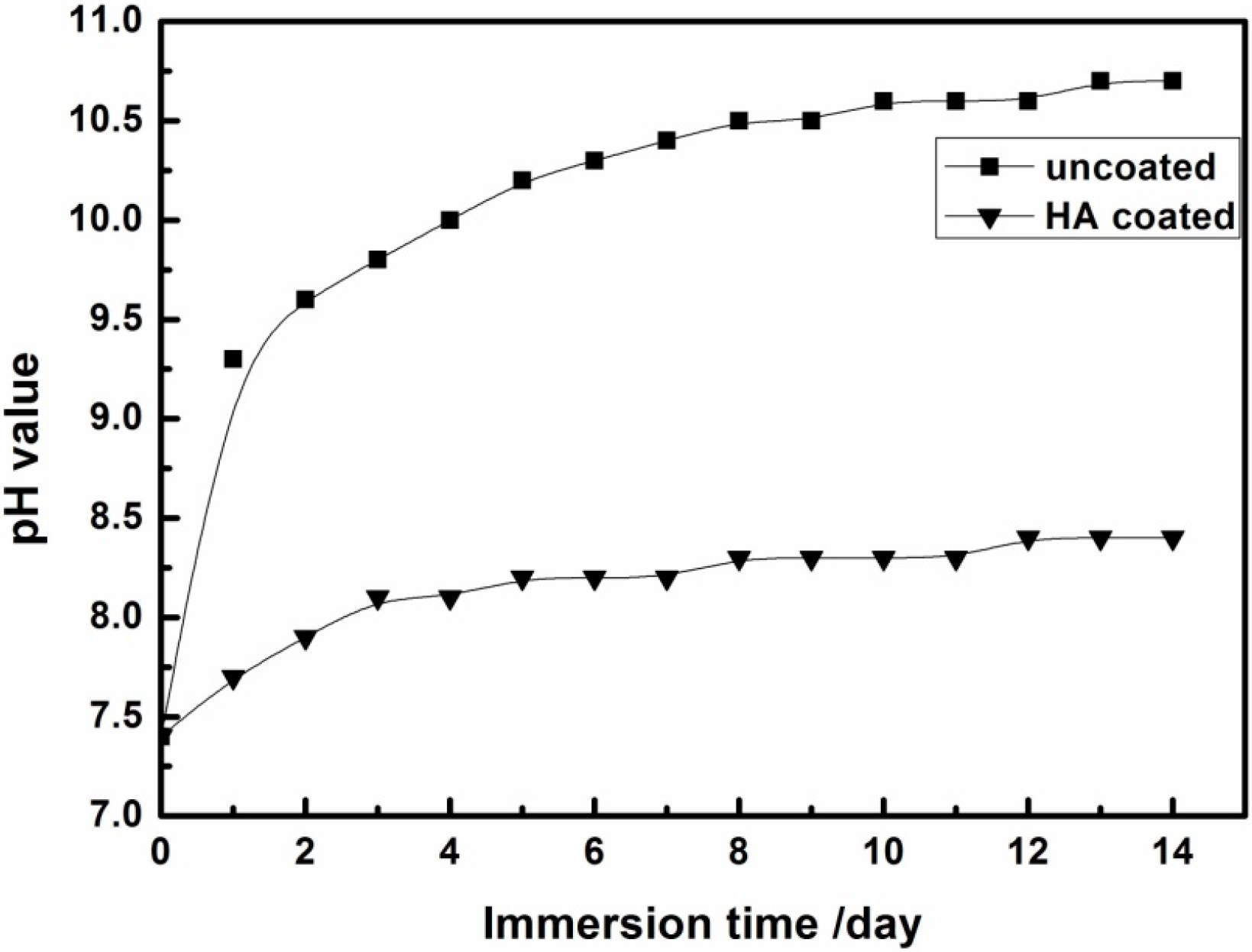

2.3. In Vitro Corrosion Property

| Sample | Ecorr (mV) | icorr (µA/cm2) |

|---|---|---|

| Uncoated ZK60 | −1666 | 35.39 |

| nHA coated ZK60 | −1485 | 0.25 |

| AZ91 * | −1713 | 65.7 |

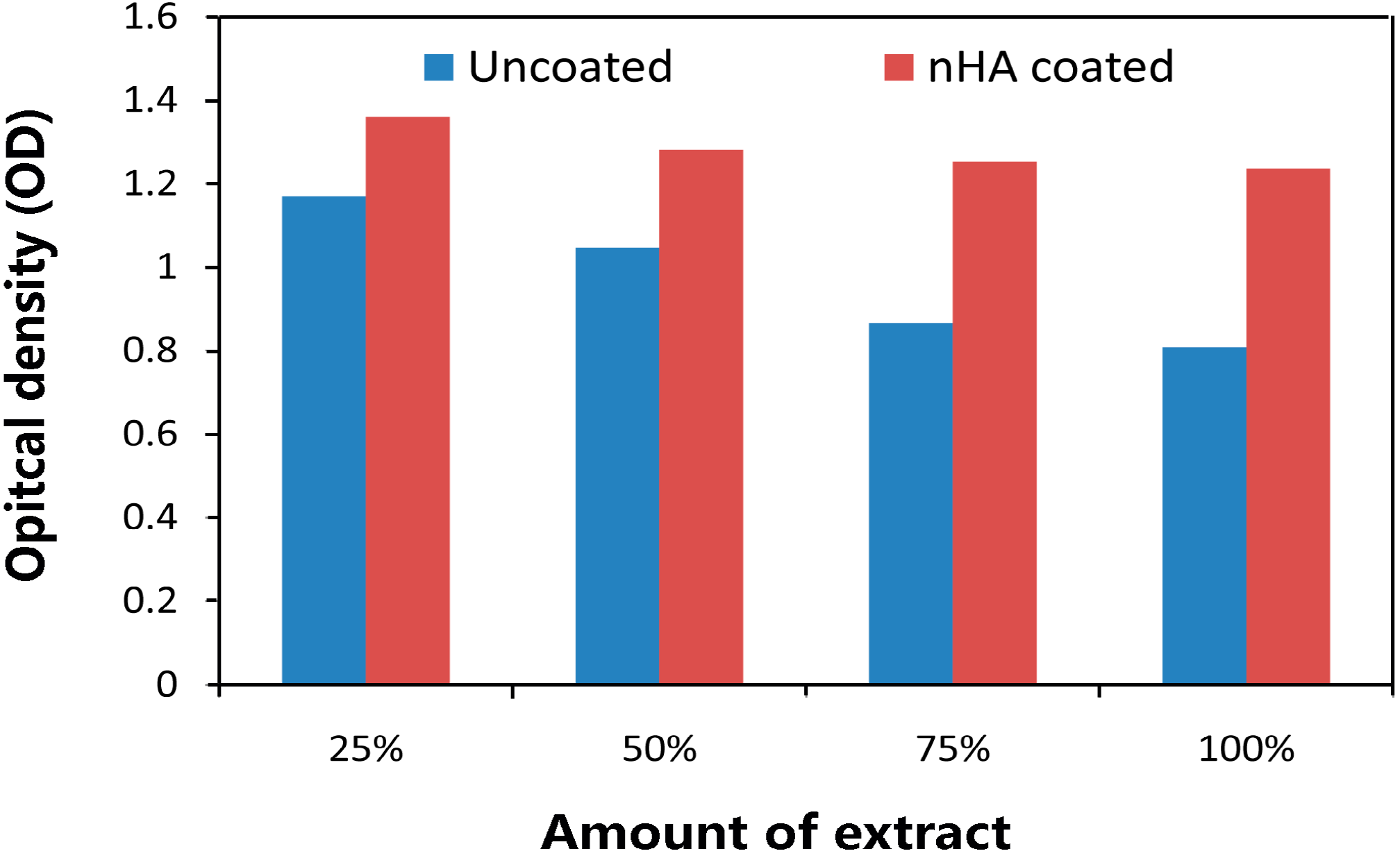

2.4. In Vitro Cytocompatibility

3. Experimentals

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dario, P.; Carlos, M.; Matteo, G.; Dinuccio, D.; Antonio, G.; Mairam, M.; Luigi, A.; Federica, C. Additive manufacturing of wet-spun polymeric scaffolds for bone tissue engineering. Biomed. Microdevices 2012, 14, 1115–1127. [Google Scholar] [CrossRef] [PubMed]

- Sandra, R.; Uwe, W.; Anita, I.; Hans-Joachim, W.; Antonio, G.; Jose, M.; Joana, S.; Joaquim, M.; Rui, L.; Hendrik, S. Hydrogels for nucleus replacement—Facing the biomechanical challenge. J. Mech. Behav. Biomed. Mater. 2012, 14, 67–77. [Google Scholar] [CrossRef] [PubMed]

- De Santis, R.; Gloria, A.; Russo, T.; D’Amora, U.; D’Anto, V.; Bollino, F.; Catauro, M. Advanced composites for hard-tissue engineering based on PCL/organic–inorganic hybrid fillers: From the design of 2D substrates to 3D rapid prototyped scaffolds. Polym. Compos. 2013, 34, 1413–1417. [Google Scholar]

- Witte, F.; Hort, N.; Vogt, C.; Cohen, S.; Kainer, K.U.; Willumeit, R.; Feyerabend, F. Degradable biomaterials based on magnesium corrosion. Curr. Opin. Solid State Mater. Sci. 2008, 12, 63–72. [Google Scholar] [CrossRef]

- Lu, W.; Ou, C.; Zhan, Z.; Huang, P.; Yan, B.; Chen, M. Microstructure and in vitro corrosion properties of ZK60 magnesium alloy coated with calcium phosphate by electrodeposition at different temperatures. Int. J. Electrochem. Sci. 2013, 8, 10746–10757. [Google Scholar]

- Iskandar, M.E.; Aslani, A.; Liu, H. The effects of nanostructured hydroxyapatite coating on the biodegradation and cytocompatibility of magnesium implants. J. Biomed. Mater. Res. Part A 2013, 101A, 2340–2354. [Google Scholar] [CrossRef]

- Liu, G.Y.; Tang, S.; Li, D.; Hu, J. Self-adjustment of calcium phosphate coating on micro-arc oxidized magnesium and its influence on the corrosion behaviour in simulated body fluids. Corros. Sci. 2014, 79, 206–214. [Google Scholar] [CrossRef]

- Kirkland, N.T.; Birbilis, N.; Staiger, M.P. Assessing the corrosion of biodegradable magnesium implants: A critical review of current methodologies and their limitations. Acta Biomater. 2012, 8, 925–936. [Google Scholar] [CrossRef] [PubMed]

- Peng, Q.; Huang, Y.; Zhou, L.; Hort, N.; Kainer, K.U. Preparation and properties of high purity Mg-Y biomaterials. Biomaterials 2010, 31, 398–403. [Google Scholar] [CrossRef] [PubMed]

- Kirkland, N.T.; Lespagnol, J.; Birbilis, N.; Staiger, M.P. A survey of bio-corrosion rates of magnesium alloys. Corros. Sci. 2010, 52, 287–291. [Google Scholar] [CrossRef]

- Wu, G.; Zhang, X.; Zhao, Y.; Ibrahim, J.M.; Yuan, G.; Chu, P.K. Plasma modified Mg-Nd-Zn-Zr alloy with enhanced surface corrosion resistance. Corros. Sci. 2014, 78, 121–129. [Google Scholar] [CrossRef]

- Li, K.; Wang, B.; Yan, B.; Lu, W. Microstructure, in vitro corrosion and cytotoxicity of Ca-P coatings on ZK60 magnesium alloy prepared by simple chemical conversion and heat treatment. J. Biomater. Appl. 2013, 28, 375–384. [Google Scholar] [CrossRef] [PubMed]

- Da Conceiçao, T.F.; Scharnagl, N.; Dietzel, W.; Kainer, K.U. Controlled degradation of a magnesium alloy in simulated body fluid using hydrofluoric acid treatment followed by polyacrylonitrile coating. Corros. Sci. 2012, 62, 83–89. [Google Scholar] [CrossRef]

- Li, K.; Wang, B.; Chai, J.; Yan, B.; Lu, W. Electrochemical behaviour and cytocompatibility of nano-fluoridated apatite coating on biodegradable magnesium alloy by simple chemical conversion. Sci. China Tech. Sci. 2013, 56, 80–83. [Google Scholar] [CrossRef]

- Lu, W.; Chen, Z.; Huang, P.; Yan, B. Microstructure, corrosion resistance and biocompatibility of biomimetic HA-based Ca-P coatings on ZK60 magnesium. Int. J. Electrochem. Sci. 2012, 7, 12668–12679. [Google Scholar]

- Ou, C.; Lu, W.; Zhan, Z.; Huang, P.; Yan, P.; Yan, B.; Chen, M. Effect of Ca and P ion concentrations on the structural and corrosion properties of biomimetic Ca-P coatings on ZK60 magnesium alloy. Int. J. Electrochem. Sci. 2013, 8, 9518–9530. [Google Scholar]

- Augat, P.; Schorlemmer, S. The role of cortical bone and its microstructure in bone strength. Age Ageing 2006, 35, 27–31. [Google Scholar] [CrossRef]

- Fadeev, I.V.; Shvorneva, L.I.; Barinov, S.M.; Orlovskii, V.P. Synthesis and structure of magnesium-substituted hydroxyapatite. Inorg. Mater. 2003, 39, 947–950. [Google Scholar] [CrossRef]

- Cao, X.; Harris, W. Carbonate and magnesium interactive effect on calcium phosphate precipitation. Environ. Sci. Technol. 2008, 42, 436–442. [Google Scholar] [CrossRef] [PubMed]

- Salimi, M.H.; Heughebaert, J.C.; Nancollas, G.H. Crystal growth of calcium phosphates in the presence of magnesium ions. Langmuir 1985, 1, 119–122. [Google Scholar] [CrossRef]

- Yang, Y.; Kim, K.H.; Ong, J.L. A review on calcium phosphate coatings produced using a sputtering process—An alternative to plasma spraying. Biomaterials 2005, 26, 327–337. [Google Scholar] [CrossRef] [PubMed]

- Xue, W.; Tao, S.; Liu, X.; Zheng, X.; Ding, C. In vivo evaluation of plasma sprayed hydroxyapatite coatings having different crystallinity. Biomaterials 2004, 25, 415–421. [Google Scholar] [CrossRef]

- Makar, G.L.; Kruger, J. Corrosion of magnesium. Int. Mater. Rev. 1993, 38, 138–153. [Google Scholar] [CrossRef]

- Ghali, E.; Dietzel, W.; Kainer, K.U. Testing of general and localized corrosion of magnesium alloys: A critical review. J. Mater. Eng. Perform. 2004, 13, 517–529. [Google Scholar] [CrossRef]

- Song, G. Recent progress in corrosion and protection of magnesium alloys. Adv. Eng. Mater. 2005, 7, 563–586. [Google Scholar] [CrossRef]

- Hiromoto, S.; Yamamoto, A.; Maruyama, N.; Somekawa, H.; Mukai, T. Influence of pH and flow on the polarisation behaviour of pure magnesium in borate buffer solutions. Corros. Sci. 2008, 50, 3561–3568. [Google Scholar] [CrossRef]

- Ban, S.; Maruno, S.; Arimoto, N.; Harada, A.; Hasegawa, J. Effect of electrochemically deposited apatite coating on bonding of bone to the HA-G-Ti composite and titanium. J. Biomed. Mater. Res. 1997, 36, 9–15. [Google Scholar] [CrossRef] [PubMed]

- Ou, C.; Lu, W.; Zhan, Z.; Huang, P.; Yan, B.; Chen, M. Effect of electrodepositing voltage on the structural and in vitro corrosion properties of CaP coatings on ZK60 magnesium alloy. Int. J. Electrochem. Sci. 2013, 8, 11151–11160. [Google Scholar]

- Kannan, M.B.; Raman, R.K.S. In vitro degradation and mechanical integrity of calcium-containing magnesium alloys in modified-simulated body fluid. Biomaterials 2008, 29, 2306–2314. [Google Scholar] [CrossRef] [PubMed]

- Guan, R.G.; Johnson, I.; Cui, T.; Zhao, T.; Zhao, Z.Y.; Li, X.; Liu, H. Electrodeposition of hydroxyapatite coating on Mg-4.0Zn-1.0Ca-0.6Zr alloy and in vitro evaluation of degradation, hemolysis, and cytotoxicity. J. Biomed. Mater. Res. Part A 2012, 100A, 999–1015. [Google Scholar] [CrossRef]

- Huan, Z.G.; Leeflang, M.A.; Zhou, J.; Fratila-Apachitei, L.E.; Duszczyk, J. In vitro degradation behavior and cytocompatibility of Mg-Zn-Zr alloys. J. Mater. Sci. Mater. Med. 2010, 21, 2623–2635. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Yan, X.; Ling, M.; Xiong, Z.; Ou, C.; Lu, W. In Vitro Corrosion and Cytocompatibility Properties of Nano-Whisker Hydroxyapatite Coating on Magnesium Alloy for Bone Tissue Engineering Applications. Int. J. Mol. Sci. 2015, 16, 6113-6123. https://doi.org/10.3390/ijms16036113

Yang H, Yan X, Ling M, Xiong Z, Ou C, Lu W. In Vitro Corrosion and Cytocompatibility Properties of Nano-Whisker Hydroxyapatite Coating on Magnesium Alloy for Bone Tissue Engineering Applications. International Journal of Molecular Sciences. 2015; 16(3):6113-6123. https://doi.org/10.3390/ijms16036113

Chicago/Turabian StyleYang, Huawei, Xueyu Yan, Min Ling, Zuquan Xiong, Caiwen Ou, and Wei Lu. 2015. "In Vitro Corrosion and Cytocompatibility Properties of Nano-Whisker Hydroxyapatite Coating on Magnesium Alloy for Bone Tissue Engineering Applications" International Journal of Molecular Sciences 16, no. 3: 6113-6123. https://doi.org/10.3390/ijms16036113

APA StyleYang, H., Yan, X., Ling, M., Xiong, Z., Ou, C., & Lu, W. (2015). In Vitro Corrosion and Cytocompatibility Properties of Nano-Whisker Hydroxyapatite Coating on Magnesium Alloy for Bone Tissue Engineering Applications. International Journal of Molecular Sciences, 16(3), 6113-6123. https://doi.org/10.3390/ijms16036113