Safety, Sensory Quality and Nutritional Value of Hybrid Meat Products Made from Turkey Meat and Red Beans Preserved with a Bioprotective Culture

Abstract

1. Introduction

2. Results

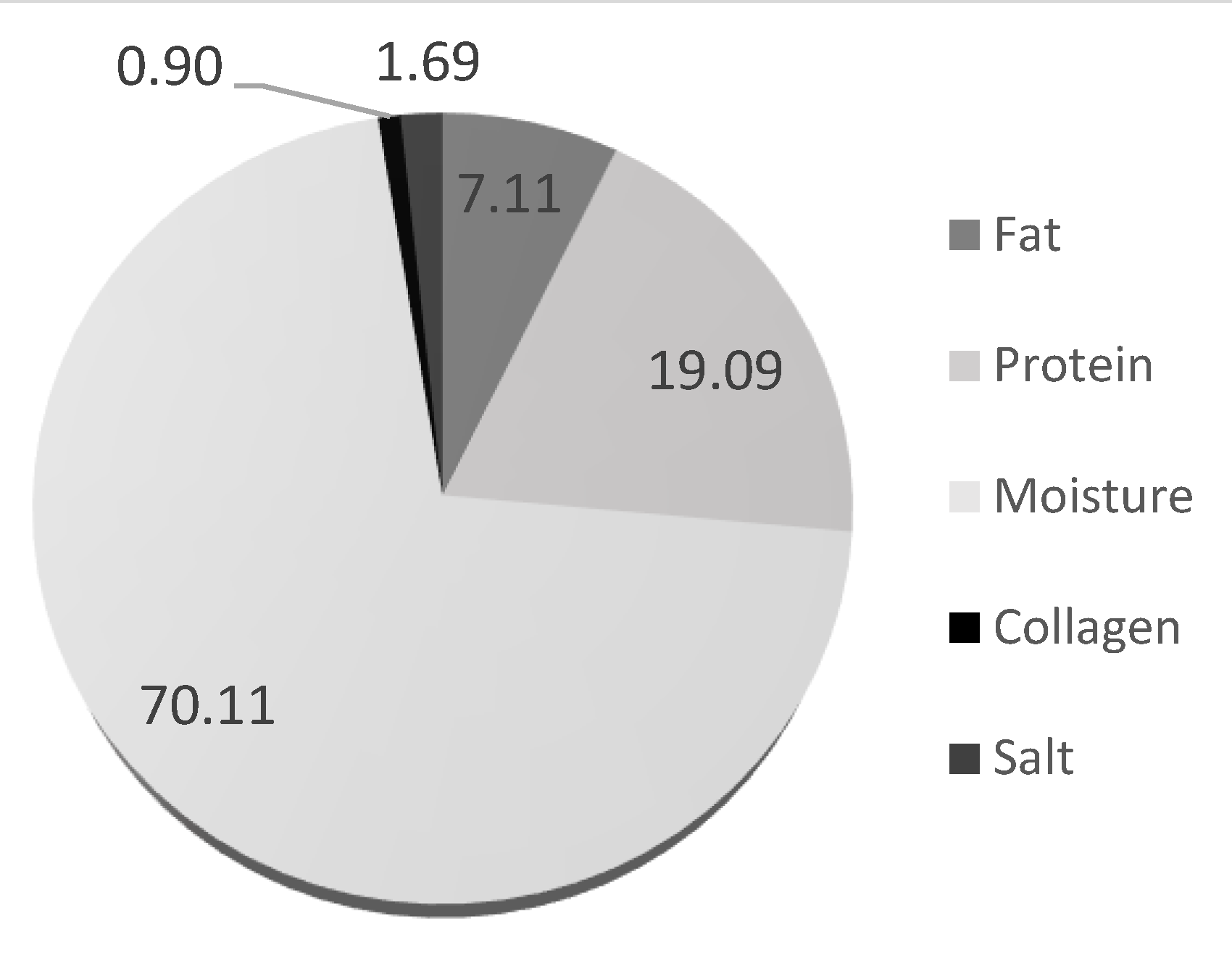

2.1. Chemical Composition (%)

2.2. Results of Microbiological Analyses

2.3. pH Level and Water Activity (aw)

2.4. Antioxidant Activity

2.5. Lipid Quality Indicators

2.6. Sensory Parameters

3. Discussion

4. Materials and Methods

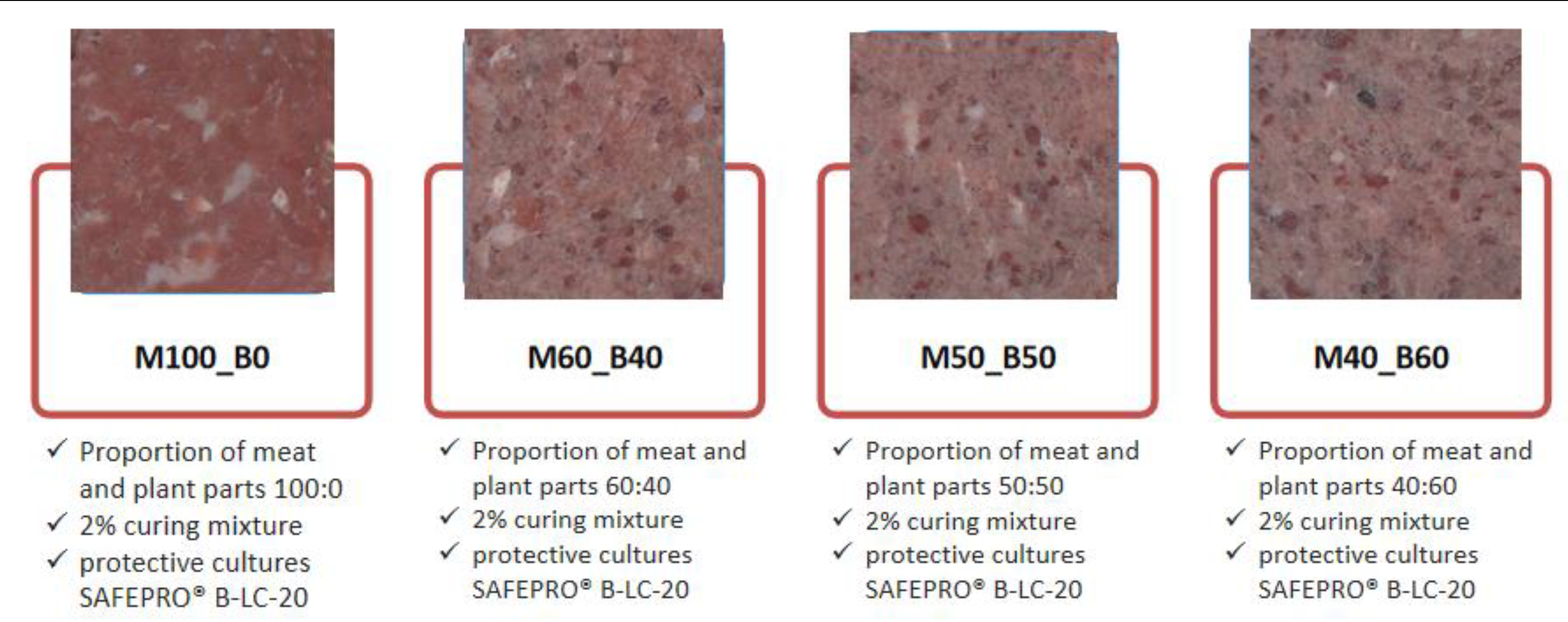

4.1. Preparation of the Experimental Material

4.2. Chemical Composition Analysis

4.3. Microbiological Analyses

4.4. Water Activity (aw) and pH Level

4.5. Determination of Antioxidant Capacity (DPPH and ABTS Methods) and TBARS Values

4.6. Fatty Acid Profile Measurements

4.7. Sensory Evaluation

4.8. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sheen, S.; Lim, A.J.Y.; Forde, C.G. Diversity among flexitarian consumers; stratifying meat reducers by their underlying motivations to move to a plant-based diet. Food Qual. Prefer. 2023, 112, 105022. [Google Scholar] [CrossRef]

- Lang, L. Consumer acceptance of blending plant-based ingredients into traditional meat-based foods: Evidence from the meat-mushroom blend. Food Qual. Prefer. 2020, 79, 103758. [Google Scholar]

- Dagevos, H. Finding flexitarians: Current studies on meat eaters and meat reducers. Trends Food Sci. Technol. 2021, 114, 530–539. [Google Scholar]

- Kemper, J.A.; White, S.K. Young adults’ experiences with flexitarianism: The 4Cs. Appetite 2021, 160, 105073. [Google Scholar] [PubMed]

- Grasso, S.; Goksen, G. The best of both worlds? Challenges and opportunities in the development of hybrid meat products from the last 3 years. LWT Food Sci. Technol. 2023, 173, 114235. [Google Scholar] [CrossRef]

- Grasso, S.; Jaworska, S. Part meat and part plant: Are hybrid meat products fad or future? Foods 2020, 9, 1888. [Google Scholar] [CrossRef]

- Fernandez-Lopez, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M.; Sendra, E.; Sayas-Barberá, E. Meat products with plant-based ingredients: Nutritional and safety aspects. Food Funct. 2021, 12, 4538–4551. [Google Scholar]

- Multescu, M.; Culetu, A.; Susman, I.E. Screening of the Nutritional Properties, Bioactive Components, and Antioxidant Properties in Legumes. Foods 2024, 13, 3528. [Google Scholar] [CrossRef]

- Wu, D.; Wan, J.; Li, W.; Li, J.; Guo, W.; Zheng, X.; Gan, R.-Y.; Hu, Y.; Zou, L. Comparison of Soluble Dietary Fibers Extracted from Ten Traditional Legumes: Physicochemical Properties and Biological Functions. Foods 2023, 12, 2352. [Google Scholar] [CrossRef]

- Liu, H.; Xu, J.; Xu, X.; Yuan, Z.; Song, H.; Yang, L.; Zhu, D. Structure/function relationships of bean polysaccharides: A review. Crit. Rev. Food Sci. 2023, 63, 330–344. [Google Scholar]

- Wu, G.J.; Liu, D.; Wan, Y.J.; Huang, X.J.; Nie, S.P. Comparison of hypoglycemic effects of polysaccharides from four legume species. Food Hydrocoll. 2019, 90, 299–304. [Google Scholar] [CrossRef]

- Jayamanohar, J.; Devi, P.B.; Kavitake, D.; Priyadarisini, V.B.; Shetty, P.H. Prebiotic potential of water extractable polysaccharide from red kidney bean (Phaseolus vulgaris L.). LWT Food Sci. Technol. 2019, 101, 703–710. [Google Scholar] [CrossRef]

- Dasiewicz, K.; Szymanska, I.; Opat, D.; Hac-Szymanczuk, E. Development and characterization of hybrid burgers made from pork and multi-ingredient plant mixtures and protected with Lactic Acid Bacteria. Appl. Sci. 2024, 14, 6272. [Google Scholar] [CrossRef]

- Castellano, P.; Perez Ibarreche, P.; Blanco Massani, M.; Fontana, C.; Vignolo, G.M. Strategies for pathogen biocontrol using lactic acid bacteria and their metabolites: A focus on meat ecosystems and industrial environments. Microorganisms 2017, 5, 38. [Google Scholar] [CrossRef]

- Danielski, G.M.; Evangelista, A.G.; Luciano, F.B.; Freitas de Macedo, R.E. Non-conventional cultures and metabolism derived compounds for bioprotection of meat and meat products: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 1105–1118. [Google Scholar] [CrossRef]

- Grasso, S. Opportunities and challenges of hybrid meat products: A viewpoint article. Int. J. Food Sci. Technol. 2024, 59, 8693–8696. [Google Scholar] [CrossRef]

- Sun, G.; Xiong, Y.; Feng, X.; Fang, Z. Effects of incorporation of hempseed meal on the quality attributes of chicken sausage. Future Foods 2022, 6, 100169. [Google Scholar] [CrossRef]

- Chandler, S.L.; McSweeney, M.B. Characterizing the properties of hybrid meat burgers made with pulses and chicken. Int. J. Gastr. Food Sci. 2022, 27, 100492. [Google Scholar] [CrossRef]

- Sogari, G.; Caputo, V.; Petterson, A.J.; Mora, C.; Boukid, F. A sensory study on consumer valuation for plant-based meat alternatives: What is liked and disliked the most? Food Res. Int. 2023, 169, 112813. [Google Scholar] [CrossRef]

- Asioli, D.; Aschemann-Witzel, J.; Caputo, V.; Vecchio, R.; Annunziata, A.; Næs, T.; Varela, P. Making sense of the “clean label” trends: A review of consumer food choice behavior and discussion of industry implications. Food Res. Int. 2017, 99, 58–71. [Google Scholar] [CrossRef]

- Commission Regulation (EU). No. 1129/2011 of 11 November 2011 amending Annex II to Regulation (EC) No. 1333/2008 of theEuropean Parliament and of the Council by establishing a Union list of food additives. J. Eur. Union 2011, 295, 1–177. [Google Scholar]

- Slima, S.B.; Ktari, N.; Triki, M.; Trabelsi, I.; Abdeslam, A.; Moussa, H.; Makni, I.; Herrero, A.M.; Jiménez-Colmenero, F.; Ruiz-Capillas, C.; et al. Effects of probiotic strains, Lactobacillus plantarum TN8 and Pediococcus acidilactici, on microbiological and physico-chemical characteristics of beef sausages. LWT Food Sci. Technol. 2018, 92, 195–203. [Google Scholar] [CrossRef]

- Yoon, J.W.; Kang, S.S. In vitro antibiofilm and anti-inflammatory properties of bacteriocins produced by Pediococcus acidilactici against Enterococcus faecalis. Foodborne Pathog. Dis. 2020, 17, 764–771. [Google Scholar] [PubMed]

- Martínez-Alonso, C.; Taroncher, M.; Castaldo, L.; Izzo, L.; Rodríguez-Carrasco, Y.; Ritieni, A.; Ruiz, M.J. Effect of Phenolic Extract from Red Beans (Phaseolus vulgaris L.) on T-2 Toxin-Induced Cytotoxicity in HepG2 Cells. Foods 2022, 11, 1033. [Google Scholar] [CrossRef]

- Yang, Q.; Gan, R.; Ge, Y.; Zhang, D.; Corke, H. Polyphenols in Common Beans (Phaseolus vulgaris L.): Chemistry, Analysis, and Factors Affecting Composition. Compr. Rev. Food Sci. Food Saf. 2018, 17, 1518–1539. [Google Scholar] [CrossRef]

- Madhujith, T.; Naczk, M.; Shahidi, F. Antioxidant activity of common beans (Phaseolus vulgaris L.). J. Food Lipids 2004, 11, 220–233. [Google Scholar] [CrossRef]

- Morales, M.; Munné-Bosch, S. Malondialdehyde: Facts and Artifacts. Plant Physiol. 2019, 180, 1246–1250. [Google Scholar] [CrossRef]

- Papastergiadis, A.; Mubiru, E.; Van Langenhove, H.; De Meulenaer, B. Malondialdehyde measurement in oxidized foods: Evaluation of the spectrophotometric thiobarbituric acid reactive substances (TBARS) test in various foods. J. Agric. Food Chem. 2012, 60, 9589–9594. [Google Scholar]

- Goluch, Z.; Rybarczyk, A.; Poławska, E.; Haraf, G. Fatty acid profile and lipid quality indexes of the meat and backfat from porkers supplemented with EM Bokashi probiotic. Animals 2023, 13, 3298. [Google Scholar] [CrossRef]

- Baune, M.-C.; Jeske, A.-L.; Profeta, A.; Smetana, S.; Broucke, K.; Van Royen, G.; Gibis, M.; Weiss, J.; Terjung, N. Effect of plant protein extrudates on hybrid meatballs-changes in nutritional composition and sustainability. Future Foods 2021, 4, 100081. [Google Scholar] [CrossRef]

- Ulbricht, T.L.V.; Southgate, D.A.T. Coronary Heart Disease: Seven Dietary Factors. Lancet 1991, 338, 985–992. [Google Scholar] [CrossRef] [PubMed]

- Ouraji, H.; Shabanpour, B.; Kenari, A.A.; Shabani, A.; Nezami, S.; Sudagar, M.; Faghani, S. Total lipid, fatty acid composition and lipid oxidation of Indian white shrimp (Fenneropenaeus indicus) fed diets containing different lipid sources. J. Sci. Food Agric. 2009, 89, 993–997. [Google Scholar]

- Baune, M.-C.; Broucke, K.; Ebert, S.; Gibis, M.; Weiss, J.; Enneking, U.; Profeta, A.; Terjung, N.; Heinz, V. Meat hybrids–An assessment of sensorial aspects, consumer acceptance, and nutritional properties. Front. Nutr. 2023, 10, 1101479. [Google Scholar] [CrossRef] [PubMed]

- Aschemann-Witzel, J.; Ares, G.; Thøgersen, J.; Monteleone, E. A sense of sustainability?—How sensory consumer science can contribute to sustainable development of the food sector. Trends Food Sci. Technol. 2019, 90, 180–186. [Google Scholar]

- Verbeke, W. Functional foods: Consumer willingness to compromise on taste for health? Food Qual. Prefer. 2006, 17, 126–131. [Google Scholar]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Hwang, Y.-H.; Joo, S.-T. Characteristics of beef patties substituted by different levels of textured vegetable protein and taste traits assessed by an electronic tongue system. Foods 2021, 10, 2811. [Google Scholar] [CrossRef]

- ISO 11290-1:2017; Microbiology of The Food Chain—Horizontal Method for The Detection and Enumeration of Listeria monocytogenes and of Listeria spp. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 6579-1:2017-04; Microbiology of The Food Chain—Horizontal Method for Detection, Enumeration and Serotyping of Salmonella-Part 1: Detection of Salmonella spp. International Organization for Standardization: Geneva, Switzerland, 2017.

- Skwarek, P.; Karwowska, M. Fatty Acids Profile and Antioxidant Properties of Raw Fermented Sausages with the Addition of Tomato Pomace. Biomolecules 2022, 12, 1695. [Google Scholar] [CrossRef]

- Pikul, J.; Leszczynski, D.E.; Kummerow, F.A. Evaluation of three modified TBA methods for measuring lipid oxidation in chicken meat. J. Agric. Food Chem. 1989, 37, 1309–1313. [Google Scholar] [CrossRef]

- Barros, J.C.; Munekata, P.E.S.; de Carvalho, F.A.L.; Pateiro, M.; Barba, F.J.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Use of tiger nut (Cyperus esculentus L.) oil emulsion as animal fat replacement in beef burgers. Foods 2020, 9, 44. [Google Scholar] [CrossRef]

- ISO/DIS 13299.2; Sensory Analysis—Methodology—General Guidance for Establishing a Sensory Profile. Polish Committee for Standardization: Warsaw, Poland, 1998.

| M100_B0 | M60_B40 | M50_B50 | M40_B60 | ||

|---|---|---|---|---|---|

| Enterobacteriaceae [log CFU g−1] | Day 0 | 3.20 ± 0.11 aA | 3.13 ± 0.16 aA | 3.13 ± 0.18 aA | 3.09 ± 0.21 aA |

| Day 8 | 5.40 ± 0.33 aB | 5.36 ± 0.57 aB | 5.69 ± 0.30 aB | 4.99 ± 0.44 aB | |

| Day 15 | 7.59 ± 0.63 aC | 6.95 ± 0.28 aC | 6.88 ± 0.31 aC | 6.80 ± 0.24 aC | |

| Lactic acid bacteria [log CFU g−1] | Day 0 | 7.72 ± 0.25 aA | 8.18 ± 0.21 bA | 8.05 ± 0.20 bA | 8.42 ± 0.26 bA |

| Day 8 | 7.31 ± 0.54 aA | 8.09 ± 0.26 bA | 8.11 ± 0.29 bA | 8.17 ± 0.17 bA | |

| Day 15 | 8.06 ± 0.50 aA | 9.28 ± 0.05 bB | 9.41 ± 0.03 bB | 9.57 ± 0.31 bB | |

| E. coli [log CFU g−1] | Day 0 | 2.04 ± 0.12 aB | 2.04 ± 0.15 aA | 2.10 ± 0.10 aB | 1.90 ± 0.35 aA |

| Day 8 | 1.71 ± 0.27 aA | 1.97 ± 0.28 aA | 1.67 ± 0.28 aA | 1.77 ± 0.24 aA | |

| Day 15 | 1.40 ± 0.25 aA | 1.90 ± 0.19 bA | 1.78 ± 0.16 bA | 1.75 ± 0.15 bA | |

| L. monocytogenes [CFU g−1] | Day 0 | <10 | <10 | <10 | <10 |

| Day 15 | <10 | <10 | <10 | <10 | |

| Salmonella spp. [CFU g−1] | Day 0 | <10 | <10 | <10 | <10 |

| Day 15 | <10 | <10 | <10 | <10 | |

| M100_B0 | M60_B40 | M50_B50 | M40_B60 | ||

|---|---|---|---|---|---|

| pH | Day 0 | 5.95 ± 0.11 bA | 5.93 ± 0.01 bB | 5.91 ± 0.02 bB | 5.79 ± 0.03 aB |

| Day 8 | 5.94 ± 0.02 cA | 5.88 ± 0.01 bB | 5.88 ± 0.04 bB | 5.81 ± 0.02 aB | |

| Day 15 | 5.95 ± 0.06 bA | 5.39 ± 0.04 aA | 5.45 ± 0.09 aA | 5.55 ± 0.11 aA | |

| aw | Day 0 | 0.976 ± 0.002 aA | 0.975 ± 0.002 aA | 0.973 ± 0.003 aA | 0.977 ± 0.001 aA |

| Day 8 | 0.974 ± 0.006 aA | 0.974 ± 0.006 aA | 0.977 ± 0.005 aA | 0.976 ± 0.006 aA | |

| Day 15 | 0.975 ± 0.003 aA | 0.974 ± 0.004 aA | 0.976 ± 0.005 aA | 0.976 ± 0.004 aA | |

| M100_B0 | M60_B40 | M50_B50 | M40_B60 | ||

|---|---|---|---|---|---|

| ABTS [mg Trolox eqv. g−1] | Day 0 | 0.078 ± 0.007 aB | 0.091 ± 0.005 bB | 0.096 ± 0.005 bB | 0.099 ± 0.004 bB |

| Day 8 | 0.051 ± 0.005 aA | 0.072 ± 0.005 bA | 0.079 ± 0.003 bA | 0.087 ± 0.003 cA | |

| Day 15 | 0.101 ± 0.005 aC | 0.107 ± 0.001 bC | 0.114 ± 0.004 cC | 0.127 ± 0.002 dC | |

| DPPH [mg Trolox eqv. g−1] | Day 0 | 0.133 ± 0.005 aA | 0.150 ± 0.002 bA | 0.153 ± 0.003 bA | 0.155 ± 0.002 bA |

| Day 8 | 0.138 ± 0.003 aA | 0.147 ± 0.004 bA | 0.152 ± 0.002 bA | 0.155 ± 0.004 bA | |

| Day 15 | 0.137 ± 0.004 aA | 0.146 ± 0.002 bA | 0.149 ± 0.003 bA | 0.152 ± 0.005 bA | |

| TBARS [mg MDA kg−1] | Day 0 | 0.547 ± 0.025 aA | 0.968 ± 0.092 bA | 1.178 ± 0.102 cA | 1.182 ± 0.091 cA |

| Day 8 | 0.659 ± 0.026 aB | 1.262 ± 0.231 bB | 1.352 ± 0.193 bB | 1.351 ± 0.127 bB | |

| Day 15 | 0.542 ± 0.029 aA | 1.123 ± 0.113 bB | 1.436 ± 0.208 cB | 1.640 ± 0.134 cC | |

| M100_B0 | M60_B40 | M50_B50 | M40_B60 | |

|---|---|---|---|---|

| Σ SFA | 36.63 ± 0.92 a | 37.72 ± 0.54 a | 40.39 ± 0.04 b | 41.33 ± 4.92 b |

| Σ MUFA | 37.36 ± 0.24 a | 38.02 ± 0.36 a | 38.65 ± 0.17 a | 37.26 ± 2.33 a |

| Σ PUFA | 18.59 ±1.87 b | 15.67 ± 1.69 b | 10.71 ± 0.31 a | 12.49 ± 2.49 a |

| Σ n-3 | 1.21 ± 0.11 b | 1.15 ± 0.12 b | 0.84 ± 0.11 a | 0.81 ±0.12 a |

| Σ n-6 | 17.38 ± 1.76 c | 14.52 ± 1.57 b | 9.87 ± 0.30 a | 11.68 ± 2.11 a |

| n-6/n-3 | 14.39 ± 0.22 b | 12.62 ± 0.07 a | 11.75 ± 0.24 a | 12.51 ± 2.64 a |

| UFA/SFA | 1.53 ± 0.09 c | 1.42 ± 0.06 c | 1.22 ± 0.01 a | 1.36 ± 0.03 b |

| PUFA/SFA | 0.51 ± 0.06 c | 0.42 ± 0.05 c | 0.27 ± 0.01 a | 0.36 ±0.02 b |

| AI | 0.69 ± 0.04 a | 0.74 ± 0.03 ab | 0.86 ± 0.01 c | 0.77 ± 0.02 b |

| TI | 1.12 ± 0.07 a | 1.20 ± 0.06 ab | 1.43 ± 0.01 c | 1.26 ± 0.01 b |

| M100_B0 | M60_B40 | M50_B50 | M40_B60 | |

|---|---|---|---|---|

| Color in cross-section | 8.43 ± 1.36 a | 7.64 ± 1.90 a | 7.50 ± 1.66 a | 6.25 ± 2.25 a |

| Juiciness | 5.43 ± 1.04 b | 5.22 ± 1.37 b | 2.38 ± 1.44 a | 1.83 ± 1.31 a |

| Hardness | 6.00 ± 2.06 b | 5.58 ± 0.49 b | 3.07 ± 1.24 a | 1.58 ± 0.86 a |

| Intensity of meat aroma | 7.97 ± 1.19 c | 7.36 ± 1.17 c | 5.56 ± 1.04 b | 2.50 ± 1.54 a |

| Intensity of bean aroma | 0.14 ± 0.21 a | 1.47 ± 1.35 b | 5.50 ± 1.73 c | 7.10 ± 1.43 d |

| Intensity of meat taste | 8.46 ± 1.8 b | 6.98 ± 1.16 b | 3.93 ± 1.34 a | 3.48 ± 1.83 a |

| Intensity of bean taste | 0.11 ± 0.15 a | 3.00 ± 1.53 b | 6.79 ± 1.75 c | 7.75 ± 1.41 c |

| Overall quality | 8.11 ± 1.75 b | 7.14 ± 1.34 b | 3.10 ± 1.75 a | 2.66 ± 0.59 a |

| Fatty Acid Group/Lipid Quality Indicators | Calculation Formula |

|---|---|

| ΣSFA (Saturated fatty acids) | Sum from C4:0 to C24:0 |

| ΣMUFA (Monounsaturated fatty acids) | Sum from C14:1 to C24:1 |

| ΣPUFA (Polyunsaturated fatty acids) | Σ n-3 PUFA + Σ n-6 PUFA |

| ΣPUFA n-3 (Polyunsaturated fatty acids n-3) | C18:3 n-3 + C18:4 n-3 + C20:3 n-3 + C20:5 n-3 + C22:5 n-3 + C22:6 n-3 |

| ΣPUFA n-6 (Polyunsaturated fatty acids n-6) | C18:2 n-6 + C18:3 n-6 + C20:3 n-6 + C20:4 n-6 + C22:2 n-6 + C22:4 n-6 |

| ΣPUFA n-3/ΣPUFA n-6 | C18:3 n-3 + C18:4 n-3 + C20:3 n-3 + C20:5 n-3 + C22:5 n-3 + C22:6 n-3/C18:2 n-6 + C18:3 n-6 + C20:3 n-6 + C20:4 n-6 + C22:2 n-6 + C22:4 n-6 |

| ΣUFA/ΣSFA Unsaturated/Saturated fatty acids | ΣMUFA + ΣPUFA//ΣSFA |

| ΣPUFA/ΣSFA Polyunsaturated/Saturated fatty acids | Σ n-3 PUFA + Σ n-6 PUFA/ΣSFA |

| AI Atherogenicity index | [C12:0 + (4 × C14:0) + C16:0 + C18:0]/[Σ MUFA + Σ PUFA n-6 + Σ PUFA n-3 |

| TI Thrombogenicity index | (C14:0 + C16:0 + C18:0)/[(0.5 × Σ MUFA) + (0.5 × Σ PUFA n-6) + (3 × Σ PUFA n-3) + (Σ PUFA n-3/ΣPUFA n-6)] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karwowska, M.; Skwarek, P.; Solska, E.; Nowaczyk, A.; Goławski, A.; Wojtaś, P.; Stasiak, D.M. Safety, Sensory Quality and Nutritional Value of Hybrid Meat Products Made from Turkey Meat and Red Beans Preserved with a Bioprotective Culture. Molecules 2025, 30, 691. https://doi.org/10.3390/molecules30030691

Karwowska M, Skwarek P, Solska E, Nowaczyk A, Goławski A, Wojtaś P, Stasiak DM. Safety, Sensory Quality and Nutritional Value of Hybrid Meat Products Made from Turkey Meat and Red Beans Preserved with a Bioprotective Culture. Molecules. 2025; 30(3):691. https://doi.org/10.3390/molecules30030691

Chicago/Turabian StyleKarwowska, Małgorzata, Patrycja Skwarek, Elżbieta Solska, Agata Nowaczyk, Andrzej Goławski, Przemysław Wojtaś, and Dariusz M. Stasiak. 2025. "Safety, Sensory Quality and Nutritional Value of Hybrid Meat Products Made from Turkey Meat and Red Beans Preserved with a Bioprotective Culture" Molecules 30, no. 3: 691. https://doi.org/10.3390/molecules30030691

APA StyleKarwowska, M., Skwarek, P., Solska, E., Nowaczyk, A., Goławski, A., Wojtaś, P., & Stasiak, D. M. (2025). Safety, Sensory Quality and Nutritional Value of Hybrid Meat Products Made from Turkey Meat and Red Beans Preserved with a Bioprotective Culture. Molecules, 30(3), 691. https://doi.org/10.3390/molecules30030691