Fortification of Durum Wheat Pasta with Nut Oil Cake: Effects on Nutritional and Technological Properties

Abstract

1. Introduction

2. Results and Discussions

2.1. Chemical Composition of Raw Materials and Products

2.2. Antioxidant Potential and Total Phenolic Content

2.3. Cooking Properties of Pasta

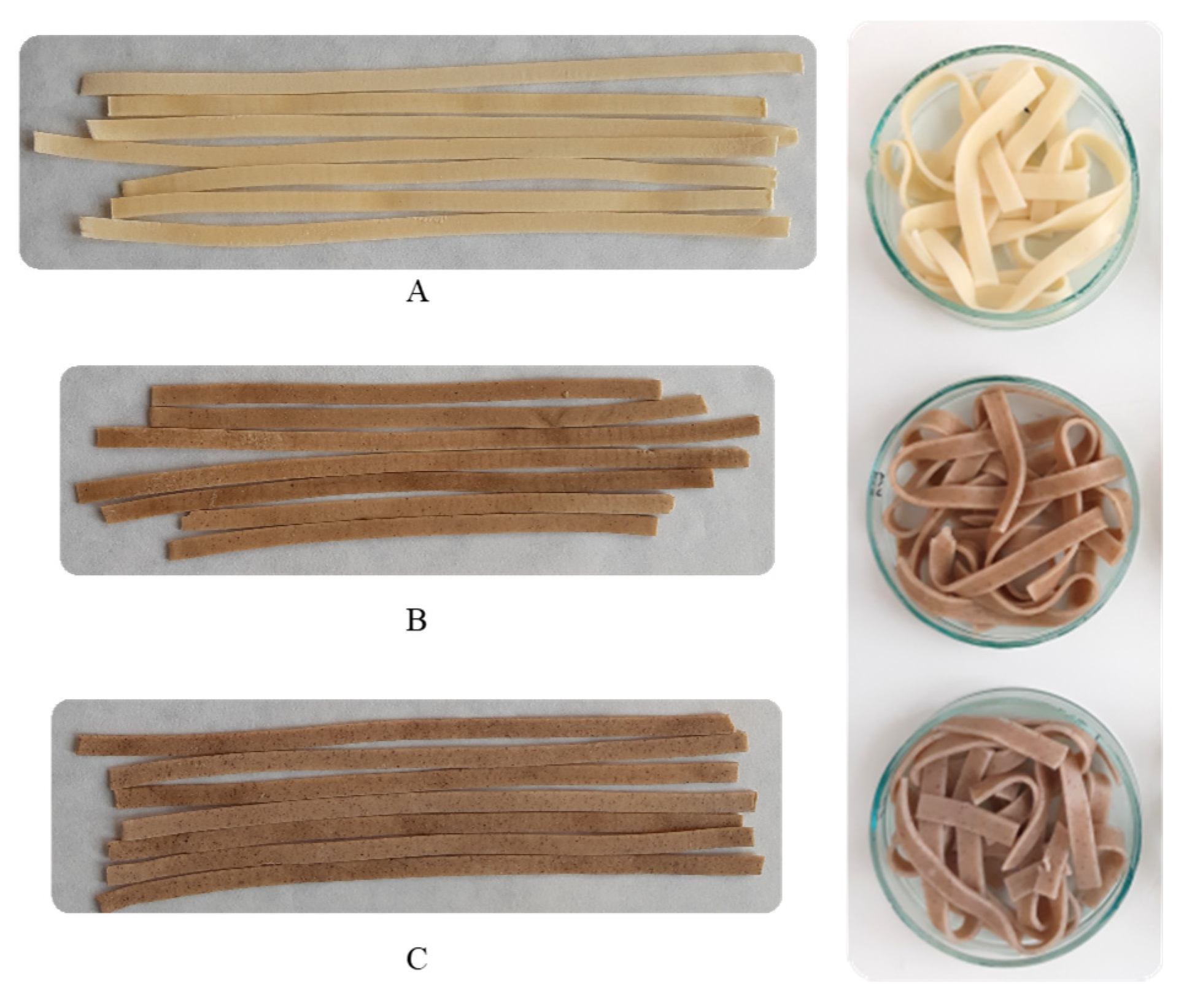

2.4. Color Parameters of Pasta

2.5. Texture Parameters of Pasta

2.6. RVA Parameters of Pasta Powder

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Pasta Preparation

3.2.2. Determination of Chemical Composition of Raw Materials and Products

3.2.3. Determination of Antioxidant Potential and Total Phenolic Content

Sample Preparation

Determination of Antioxidant Properties

Determination of Total Phenolic Content

3.2.4. Determination of Cooking Properties of Pasta

3.2.5. Determination of Color Parameters of Pasta

3.2.6. Determination of Texture Parameters of Pasta

3.2.7. Determination of RVA Parameters of Pasta Powder

3.2.8. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Conti, V.; Piccini, C.; Romi, M.; Salusti, P.; Cai, G.; Cantini, C. Pasta Enriched with Carrot and Olive Leaf Flour Retains High Levels of Accessible Bioactives after In Vitro Digestion. Foods 2023, 12, 3540. [Google Scholar] [CrossRef] [PubMed]

- Dziki, D. Current Trends in Enrichment of Wheat Pasta: Quality, Nutritional Value and Antioxidant Properties. Processes 2021, 91, 1280. [Google Scholar] [CrossRef]

- Romano, A.; Ferranti, P.; Gallo, V.; Masi, P. New Ingredients and Alternatives to Durum Wheat Semolina for a High Quality Dried Pasta. Curr. Opin. Food Sci. 2021, 41, 249–259. [Google Scholar] [CrossRef]

- Cory, H.; Passarelli, S.; Szeto, J.; Tamez, M.; Mattei, J. The Role of Polyphenols in Human Health and Food Systems: A Mini-Review. Front. Nutr. 2018, 5, 87. [Google Scholar] [CrossRef]

- Gull, A.; Prasad, K.; Kumar, P. Nutritional, Antioxidant, Microstructural and Pasting Properties of Functional Pasta. J. Saudi Soc. Agric. Sci. 2018, 17, 147–153. [Google Scholar] [CrossRef]

- Peschel, W.; Sánchez-Rabaneda, F.; Diekmann, W.; Plescher, A.; Gartzía, I.; Jiménez, D.; Lamuela-Raventós, R.; Buxaderas, S.; Codina, C. An Industrial Approach in the Search of Natural Antioxidants from Vegetable and Fruit Wastes. Food Chem. 2006, 97, 137–150. [Google Scholar] [CrossRef]

- Majerska, J.; Michalska, A.; Figiel, A. A Review of New Directions in Managing Fruit and Vegetable Processing By-Products. Trends Food Sci. Technol. 2019, 88, 207–219. [Google Scholar] [CrossRef]

- Dey, D.; Richter, J.K.; Ek, P.; Gu, B.J.; Ganjyal, G.M. Utilization of Food Processing By-Products in Extrusion Processing: A Review. Front. Sustain. Food Syst. 2021, 4, 603751. [Google Scholar] [CrossRef]

- Rabrenović, B.; Natić, M.; Dabić Zagorac, D.; Meland, M.; Fotirić Akšić, M. Bioactive Phytochemicals from Walnut (Juglans spp.) Oil Processing By-Products. In Bioactive Phytochemicals from Vegetable Oil and Oilseed Processing By-Products; Reference Series in Phytochemistry; Springer: Cham, Switzerland, 2023; pp. 537–557. [Google Scholar] [CrossRef]

- Cao, S.; Xiang, F.; Li, S.; Ma, X.; Hu, H.; Guo, Q.; Jiao, B.; Agyei, D.; Wang, Q.; Shi, A. Characteristics of Walnut Oil and the Residual Cake Prepared Using Various Pretreatment and Extraction Methods. LWT 2024, 206, 116596. [Google Scholar] [CrossRef]

- Pycia, K.; Juszczak, L. Influence of Hazelnut and Walnut Oil Cakes Powder on Thermal and Rheological Properties of Wheat Flour. Foods 2023, 12, 4060. [Google Scholar] [CrossRef]

- Savla, H.; Yardi, V. Development of Gluten-Free Pasta (Sevaiya) Using Grape Pomace and Assessing Its Quality And Acceptability. Int. Proc. Chem. Biol. Environ. Eng. 2016, 95, 44–49. [Google Scholar] [CrossRef]

- Tolve, R.; Pasini, G.; Vignale, F.; Favati, F.; Simonato, B. Effect of Grape Pomace Addition on the Technological, Sensory, and Nutritional Properties of Durum Wheat Pasta. Foods 2020, 9, 354. [Google Scholar] [CrossRef]

- Padalino, L.; Conte, A.; Lecce, L.; Likyova, D.; Sicari, V.; Pellicanò, T.M.; Poiana, M.; Del Nobile, M.A. Functional Pasta with Tomato By-Product as a Source of Antioxidant Compounds and Dietary Fibre. Czech J. Food Sci. 2017, 35, 48–56. [Google Scholar] [CrossRef]

- Gałkowska, D.; Witczak, T.; Pycia, K. Quality Characteristics of Novel Pasta Enriched with Non-Extruded and Extruded Blackcurrant Pomace. Molecules 2022, 27, 8616. [Google Scholar] [CrossRef]

- Zarzycki, P.; Sykut-Domańska, E.; Sobota, A.; Teterycz, D.; Krawęcka, A.; Blicharz-Kania, A.; Andrejko, D.; Zdybel, B. Flaxseed Enriched Pasta—Chemical Composition and Cooking Quality. Foods 2020, 9, 404. [Google Scholar] [CrossRef]

- Simonato, B.; Trevisan, S.; Tolve, R.; Favati, F.; Pasini, G. Pasta Fortification with Olive Pomace: Effects on the Technological Characteristics and Nutritional Properties. LWT 2019, 114, 108368. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A.; Dziki, D.; Gawlik-Dziki, U. The Influence of Cistus incanus L. Leaves on Wheat Pasta Quality. J. Food Sci. Technol. 2019, 56, 4311–4322. [Google Scholar] [CrossRef] [PubMed]

- Simonato, B.; Tolve, R.; Rainero, G.; Rizzi, C.; Sega, D.; Rocchetti, G.; Lucini, L.; Giuberti, G. Technological, Nutritional, and Sensory Properties of Durum Wheat Fresh Pasta Fortified with Moringa oleifera L. Leaf Powder. J. Sci. Food Agric. 2021, 101, 1920–1925. [Google Scholar] [CrossRef] [PubMed]

- Sȩczyk, Ł.; Świeca, M.; Gawlik-Dziki, U.; Luty, M.; Czyz, J. Effect of Fortification with Parsley (Petroselinum crispum Mill.) Leaves on the Nutraceutical and Nutritional Quality of Wheat Pasta. Food Chem. 2016, 190, 419–428. [Google Scholar] [CrossRef] [PubMed]

- Filipčev, B.; Kojić, J.; Miljanić, J.; Šimurina, O.; Stupar, A.; Škrobot, D.; Travićić, V.; Pojić, M. Wild Garlic (Allium ursinum) Preparations in the Design of Novel Functional Pasta. Foods 2023, 12, 4376. [Google Scholar] [CrossRef]

- Covaliov, E.; Capcanari, T.; Radu, O.; Boiștean, A. Oil Seed Meals and Pasta: A New Dimension in By-Product Valorization. Ann. Univ. Dunărea Galați Fascicle VI—Food Technol. 2024, 48, 9–26. [Google Scholar] [CrossRef]

- Samaan, J.; El-Khayat, G.H.; Manthey, F.A.; Fuller, M.P.; Brennan, C.S. Durum Wheat Quality: II. The Relationship of Kernel Physicochemical Composition to Semolina Quality and End Product Utilisation. Int. J. Food Sci. Technol. 2006, 41, 47–55. [Google Scholar] [CrossRef]

- Pop, A.; Păucean, A.; Socaci, S.A.; Alexa, E.; Man, S.M.; Mureșan, V.; Chiş, M.S.; Salanță, L.; Popescu, I.; Berbecea, A.; et al. Quality Characteristics and Volatile Profile of Macarons Modified with Walnut Oilcake By-Product. Molecules 2020, 25, 2214. [Google Scholar] [CrossRef]

- Bakkalbasi, E.; Meral, R.; Dogan, I.S. Bioactive Compounds, Physical and Sensory Properties of Cake Made with Walnut Press-Cake. J. Food Qual. 2015, 38, 422–430. [Google Scholar] [CrossRef]

- Montrimaitė, K.; Moščenkova, E. Possibilities of Usage of Oilcakes from Non-Traditional Oil Plants for Development of Health-Friendly Functional Food Products. Food Sci. Appl. Biotechnol. 2018, 1, 154. [Google Scholar] [CrossRef]

- Lučan Čolić, M.; Jozinović, A.; Lukinac, J.; Jukić, M.; Antunović, M. Evaluation of Hazelnut Cake Flour for Use as a Milk Powder Replacer in Ice Cream. Appl. Sci. 2024, 14, 10303. [Google Scholar] [CrossRef]

- Gul, O.; Atalar, I.; Mortas, M.; Saricaoglu, F.T.; Besir, A.; Gul, L.B.; Yazici, F. Potential Use of High Pressure Homogenized Hazelnut Beverage for a Functional Yoghurt-Like Product. An. Acad. Bras. Cienc. 2022, 94, e20191172. [Google Scholar] [CrossRef]

- Burbano, J.J.; Correa, M.J. Composition and Physicochemical Characterization of Walnut Flour, a By-Product of Oil Extraction. Plant Foods Hum. Nutr. 2021, 76, 233–239. [Google Scholar] [CrossRef]

- Ozdemir, M.B.; Kılıçarslan, E.; Demir, H.; Koca, E.; Salum, P.; Berktaş, S.; Çam, M.; Erbay, Z.; Aydemir, L.Y. Upgrading the Bioactive Potential of Hazelnut Oil Cake by Aspergillus Oryzae under Solid-State Fermentation. Molecules 2024, 29, 4237. [Google Scholar] [CrossRef]

- Niyonshuti, E.; Kırkpınar, F. Comparison of Nutrient Composition and Potential Feed Value of Different Cakes Obtained by Cold Pressed Method. J. Hell. Vet. Med. Soc. 2024, 75, 8017–8026. [Google Scholar] [CrossRef]

- Zhu, K.; Ma, J.; Cong, J.; Zhang, T.; Lei, H.; Xu, H.; Luo, Z.; Li, M. The Road to Reuse of Walnut By-Products: A Comprehensive Review of Bioactive Compounds, Extraction and Identification Methods, Biomedical and Industrial Applications. Trends Food Sci. Technol. 2024, 143, 104264. [Google Scholar] [CrossRef]

- Panzanini, M.; Genesi, M.; Zeppa, G.; Dordoni, R. Unlocking Cold-Pressed Nut Potential: Focus on Tocopherol Content of Oils and Defatted Cakes. Ital. J. Food Sci. 2024, 36, 101–110. [Google Scholar] [CrossRef]

- Commission Regulation (EU) No 1047/2012 of 8 November 2012 Amending Regulation (EC) No 1924/2006 with Regard to the List of Nutrition Claims. Available online: https://eur-lex.europa.eu/eli/reg/2012/1047/oj/eng (accessed on 10 August 2025).

- Wójcik, M.; Dziki, D.; Matwijczuk, A.; Gawlik-Dziki, U. Walnut Flour as an Ingredient for Producing Low-Carbohydrate Bread: Physicochemical, Sensory, and Spectroscopic Characteristics. Foods 2023, 12, 3320. [Google Scholar] [CrossRef]

- Bursa, K.; Toker, O.S.; Palabiyik, I.; Yaman, M.; Kian-Pour, N.; Konar, N.; Kilicli, M. Valorization of Hazelnut Cake in Compound Chocolate: The Effect of Formulation on Rheological and Physical Properties. LWT 2021, 139, 110609. [Google Scholar] [CrossRef]

- Pycia, K.; Kapusta, I.; Jaworska, G.; Jankowska, A. Antioxidant Properties, Profile of Polyphenolic Compounds and Tocopherol Content in Various Walnut (Juglans regia L.) Varieties. Eur. Food Res. Technol. 2019, 245, 607–616. [Google Scholar] [CrossRef]

- Pycia, K.; Kapusta, I.; Jaworska, G. Changes in Antioxidant Activity, Profile, and Content of Polyphenols and Tocopherols in Common Hazel Seed (Corylus avellana L.) Depending on Variety and Harvest Date. Molecules 2020, 25, 43. [Google Scholar] [CrossRef]

- Pycia, K.; Kapusta, I.; Jaworska, G. Walnut Oil and Oilcake Affect Selected the Physicochemical and Antioxidant Properties of Wheat Bread Enriched with Them. J. Food Process. Preserv. 2020, 44, e14573. [Google Scholar] [CrossRef]

- Martini, S.; Conte, A.; Cattivelli, A.; Tagliazucchi, D. Domestic Cooking Methods Affect the Stability and Bioaccessibility of Dark Purple Eggplant (Solanum melongena) Phenolic Compounds. Food Chem. 2021, 341, 2. [Google Scholar] [CrossRef] [PubMed]

- Sant’Anna, V.; Christiano, F.D.P.; Marczak, L.D.F.; Tessaro, I.C.; Thys, R.C.S. The Effect of the Incorporation of Grape Marc Powder in Fettuccini Pasta Properties. LWT 2014, 58, 497–501. [Google Scholar] [CrossRef]

- Hoffman, R.; Gerber, M. Food Processing and the Mediterranean Diet. Nutrients 2015, 7, 7925–7964. [Google Scholar] [CrossRef] [PubMed]

- de la Peña, E.; Manthey, F.A. Ingredient Composition and Pasta: Water Cooking Ratio Affect Cooking Properties of Nontraditional Spaghetti. Int. J. Food Sci. Technol. 2014, 49, 2323–2330. [Google Scholar] [CrossRef]

- Lončarić, A.; Kosović, I.; Jukić, M.; Ugarčić, Ž.; Piližota, V. Effect of Apple By-Product as a Supplement on Antioxidant Activity and Quality Parameters of Pasta. Croat. J. Food Sci. Technol. 2014, 6, 97–103. [Google Scholar] [CrossRef]

- Biernacka, B.; Dziki, D.; Miś, A.; Rudy, S.; Krzykowski, A.; Polak, R.; Różyło, R. Changes in Pasta Properties during Cooking and Short-Time Storage. Int. Agrophys. 2019, 33, 323–330. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, F.; Tolve, R.; Rainero, G.; Bordiga, M.; Brennan, C.S.; Simonato, B. Technological, Nutritional and Sensory Properties of Pasta Fortified with Agro-Industrial by-Products: A Review. Int. J. Food Sci. Technol. 2021, 56, 4356–4366. [Google Scholar] [CrossRef]

- Tudoriča, C.M.; Tudorică, T.; Kuri, V.; Brennan, C.S. Nutritional and Physicochemical Characteristics of Dietary Fiber Enriched Pasta. J. Agric. Food Chem. 2002, 50, 347–356. [Google Scholar] [CrossRef]

- Abdallah, I.B.; Tlili, N.; Martinez-Force, E.; Rubio, A.G.P.; Perez-Camino, M.C.; Albouchi, A.; Boukhchina, S. Content of Carotenoids, Tocopherols, Sterols, Triterpenic and Aliphatic Alcohols, and Volatile Compounds in Six Walnuts (Juglans regia L.) Varieties. Food Chem. 2015, 173, 972–978. [Google Scholar] [CrossRef]

- Stuetz, W.; Schlörmann, W.; Glei, M. B-Vitamins, Carotenoids and α-/γ-Tocopherol in Raw and Roasted Nuts. Food Chem. 2017, 221, 222–227. [Google Scholar] [CrossRef] [PubMed]

- Ali, G.; Zeb, A. Bioactive Composition and Medicinal Properties of Walnut Kernels. J. Agric. Food Res. 2024, 18, 101442. [Google Scholar] [CrossRef]

- Bruneel, C.; Pareyt, B.; Brijs, K.; Delcour, J.A. The Impact of the Protein Network on the Pasting and Cooking Properties of Dry Pasta Products. Food Chem. 2010, 120, 371–378. [Google Scholar] [CrossRef]

- Martín-Esparza, M.E.; Raigón, M.D.; Raga, A.; Albors, A. High Fibre Tiger Nut Pasta and Xanthan Gum: Cooking Quality, Microstructure, Physico-Chemical Properties and Consumer Acceptance. Food Sci. Biotechnol. 2018, 27, 1075–1084. [Google Scholar] [CrossRef]

- Long, D.Q.; Doan, T.B.N.; Ton, N.M.N.; Tran, T.T.T.; Le, V.V.M. Quality of Durum Wheat Pasta Fortified with Different Ratios of Turmeric Residue Powder. J. Agric. Food Res. 2024, 16, 101220. [Google Scholar] [CrossRef]

- Long, D.Q.; Trieu, T.M.; Tran, T.T.T.; Ton, N.M.N.; Le, V.V.M. Quality of High-Fibre Pasta Supplemented with Watermelon Rind Powder with Different Particle Sizes. Food Technol. Biotechnol. 2024, 62, 59–71. [Google Scholar] [CrossRef] [PubMed]

- Shiau, S.Y.; Li, G.H.; Pan, W.C.; Xiong, C. Effect of Pitaya Peel Powder Addition on the Phytochemical and Textural Properties and Sensory Acceptability of Dried and Cooked Noodles. J. Food Process. Preserv. 2020, 44, e14491. [Google Scholar] [CrossRef]

- Marti, A.; Seetharaman, K.; Pagani, M.A. Rheological Approaches Suitable for Investigating Starch and Protein Properties Related to Cooking Quality of Durum Wheat Pasta. J. Food Qual. 2013, 36, 133–138. [Google Scholar] [CrossRef]

- Balet, S.; Guelpa, A.; Fox, G.; Manley, M. Rapid Visco Analyser (RVA) as a Tool for Measuring Starch-Related Physiochemical Properties in Cereals: A Review. Food Anal. Methods 2019, 12, 2344–2360. [Google Scholar] [CrossRef]

- Tazrart, K.; Zaidi, F.; Salvador, A.; Haros, C.M. Effect of Broad Bean (Vicia faba) Addition on Starch Properties and Texture of Dry and Fresh Pasta. Food Chem. 2019, 278, 476–481. [Google Scholar] [CrossRef]

- Gałkowska, D.; Witczak, T.; Witczak, M. Ancient Wheat and Quinoa Flours as Ingredients for Pasta Dough—Evaluation of Thermal and Rheological Properties. Molecules 2021, 26, 7033. [Google Scholar] [CrossRef]

- Official Methods of Analysis of AOAC International, 19th ed.; Method 991.43; AOAC International: Rockville, MD, USA, 2012.

- Pycia, K.; Pawłowska, A.M.; Posadzka, Z.; Kaszuba, J. Ground Ivy (Glechoma hederacea L.) as an Innovative Additive for Enriching Wheat Bread: Study on Flour Fermentation Properties, Dough Rheological Properties and Bread Quality. Appl. Sci. 2024, 14, 9392. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant Activity Applying an Improved ABTS Radical Cation Decolorization Assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Yen, G.C.; Chen, H.Y. Antioxidant Activity of Various Tea Extracts in Relation to Their Antimutagenicity. J. Agric. Food Chem. 1995, 43, 27–32. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. The Ferric Reducing Ability of Plasma (FRAP) as a Measure of “Antioxidant Power”: The FRAP Assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Ohlander, M.; Jeppsson, N.; Björk, L.; Trajkovski, V. Changes in Antioxidant Effects and Their Relationship to Phytonutrients in Fruits of Sea Buckthorn (Hippophae rhamnoides L.) during Maturation. J. Agric. Food Chem. 2000, 48, 1485–1490. [Google Scholar] [CrossRef] [PubMed]

- Method 66-50.01. Pasta and Noodle Cooking Quality—Firmness. In AACC Approved Methods of Analysis; Cereals & Grains Association: Saint Paul, MN, USA, 2010.

| Sample | Component (g/100 g d.w.) | ||||||

|---|---|---|---|---|---|---|---|

| Protein | Fat | Ash | SDF | IDF | TDF | Available Carbohydrates | |

| Raw Materials | |||||||

| Semolina | 13.0 a ± 0.1 | 1.32 a ± 0.05 | 0.80 a ± 0.02 | 1.91 a ± 0.15 | 2.57 a ± 0.28 | 4.48 a ± 0.13 | 80.4 b ± 0.2 |

| WOC | 37.3 c ± 0.3 | 20.8 c ± 0.1 | 5.01 b ± 0.09 | 3.89 c ± 0.06 | 13.78 b ± 0.07 | 17.67 b ± 0.01 | 19.2 a ± 0.3 |

| HOC | 32.8 b ± 0.7 | 19.8 b ± 0.3 | 5.88 c ± 0.04 | 2.50 b ± 0.17 | 21.13 c ± 0.01 | 23.63 c ± 0.16 | 17.9 a ± 0.8 |

| Products (Cooked and Dried) | |||||||

| SP | 12.9 a ± 0.1 | 1.19 a ± 0.07 | 0.40 a ± 0.02 | 2.34 c ± 0.09 | 2.22 a ± 0.22 | 4.56 a ± 0.13 | 81.0 b ± 0.3 |

| WOCP | 15.8 c ± 0.1 | 3.64 b ± 0.16 | 0.66 b ± 0.02 | 1.26 a ± 0.12 | 3.91 b ± 0.12 | 5.16 a ± 0.23 | 74.8 a ± 0.4 |

| HOCP | 15.0 b ± 0.3 | 3.47 b ± 0.20 | 0.66 b ± 0.00 | 1.81 b ± 0.09 | 4.95 c ± 0.28 | 6.75 b ± 0.19 | 74.1 a ± 0.5 |

| Sample | Antioxidant Activity | TPC (mg GAE/ 100 g d.w.) | ||

|---|---|---|---|---|

| ABTS Assay (mmol TE/ 100 g d.w.) | DPPH Assay (mmol TE/ 100 g d.w.) | FRAP Assay (mmol TE/ 100 g d.w.) | ||

| Uncooked | ||||

| SP | 0.73 a ± 0.02 | 0.04 a ± 0.01 | 0.01 a ± 0.00 | 80.95 b ± 3.65 |

| WOCP | 1.70 b ± 0.14 | 2.65 c ± 0.02 | 0.35 b ± 0.01 | 142.71 c ± 5.84 |

| HOCP | 0.64 a ± 0.03 | 0.31 b ± 0.04 | 0.03 a ± 0.00 | 65.79 a ± 2.89 |

| Cooked | ||||

| SP | 0.63 a ± 0.07 | 0.20 a ± 0.11 | 0.02 a ± 0.00 | 88.85 a ± 1.40 |

| WOCP | 1.58 b ± 0.06 | 2.50 c ± 0.02 | 0.36 b ± 0.03 | 145.48 b ± 5.90 |

| HOCP | 0.73 a ± 0.01 | 0.45 b ± 0.03 | 0.05 a ± 0.00 | 89.40 a ± 4.38 |

| Sample | Parameter | |||

|---|---|---|---|---|

| Optimal Cooking Time (min) | Water Absorption (g of water/100 g) | Swelling Index (g of water/g d.w.) | Cooking Loss (g d.w./100 g) | |

| SP | 11 | 124 a ± 8 | 1.37 a ± 0.01 | 4.52 a ± 0.27 |

| WOCP | 14 | 136 ab ± 2 | 1.47 b ± 0.03 | 5.79 b ± 0.14 |

| HOCP | 13 | 143 b ± 4 | 1.55 b ± 0.05 | 5.74 b ± 0.11 |

| Sample | Parameter | |||||

|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | |

| Uncooked | Cooked | |||||

| SP | 80.1 e ± 1.3 | 1.09 b ± 0.11 | 22.6 e ± 0.8 | 69.6 d ± 0.7 | −1.49 a ± 0.11 | 14.1 b ± 0.6 |

| WOCP | 61.8 c ± 1.1 | 6.55 f ± 0.24 | 25.5 f ± 0.5 | 54.2 a ± 0.4 | 3.83 c ± 0.13 | 15.3 c ± 0.4 |

| HOCP | 61.2 c ± 1.7 | 6.10 e ± 0.13 | 18.5 d ± 0.6 | 56.7 b ± 0.3 | 4.14 d ± 0.12 | 10.6 a ± 0.3 |

| Sample | Test | ||||

|---|---|---|---|---|---|

| 3-Point Bending Test of Uncooked Pasta | Tensile Test of Cooked Pasta | ||||

| Parameter | |||||

| Breaking Force (N) | Displacement at Fracture (mm) | Breaking Force (N) | Elongation at Break (%) | Tensile Strength (kPa) | |

| SP | 5.21 c ± 0.15 | 0.21 b ± 0.02 | 0.452 b ± 0.030 | 129 b ± 25 | 29.0 b ± 1.8 |

| WOCP | 3.11 b ± 0.37 | 0.18 a ± 0.02 | 0.491 b ± 0.054 | 81 a ± 12 | 31.5 b ± 3.7 |

| HOCP | 2.50 a ± 0.11 | 0.17 a ± 0.01 | 0.360 a ± 0.025 | 63 a ± 5 | 23.1 a ± 1.5 |

| Sample | Parameter | ||

|---|---|---|---|

| Pasting Temperature (°C) | Peak Viscosity (mPa∙s) | Final Viscosity (mPa∙s) | |

| SP | 86.1 a ± 0.3 | 705 b ± 48 | 2716 c ± 97 |

| WOCP | 88.0 b ± 0.5 | 531 a ± 21 | 1488 a ± 16 |

| HOCP | 89.1 c ± 0.6 | 506 a ± 18 | 1746 b ± 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gałkowska, D.; Pycia, K.; Krykhta, A. Fortification of Durum Wheat Pasta with Nut Oil Cake: Effects on Nutritional and Technological Properties. Molecules 2025, 30, 3411. https://doi.org/10.3390/molecules30163411

Gałkowska D, Pycia K, Krykhta A. Fortification of Durum Wheat Pasta with Nut Oil Cake: Effects on Nutritional and Technological Properties. Molecules. 2025; 30(16):3411. https://doi.org/10.3390/molecules30163411

Chicago/Turabian StyleGałkowska, Dorota, Karolina Pycia, and Anastasiia Krykhta. 2025. "Fortification of Durum Wheat Pasta with Nut Oil Cake: Effects on Nutritional and Technological Properties" Molecules 30, no. 16: 3411. https://doi.org/10.3390/molecules30163411

APA StyleGałkowska, D., Pycia, K., & Krykhta, A. (2025). Fortification of Durum Wheat Pasta with Nut Oil Cake: Effects on Nutritional and Technological Properties. Molecules, 30(16), 3411. https://doi.org/10.3390/molecules30163411