Review on Aging Behavior and Durability Enhancement of Bamboo Fiber-Reinforced Polymer Composites

Abstract

1. Introduction

2. Bamboo Fiber Polymer Composites

2.1. Processing of Bamboo Fibers

2.2. Fabrication of Bamboo Fiber-Reinforced Polymer Composites

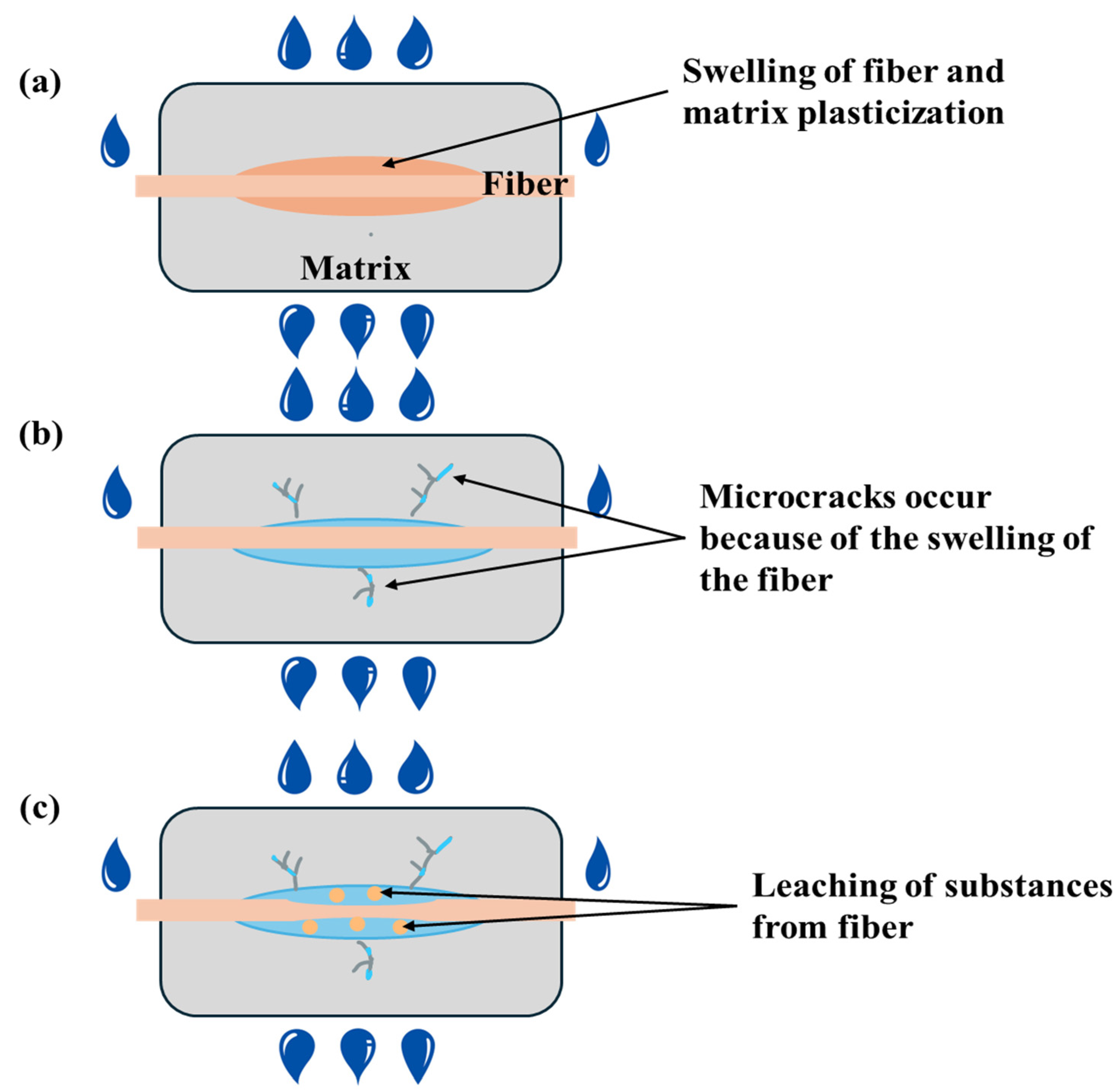

3. Water Absorption Behavior of Bamboo Fiber-Reinforced Polymer Composites

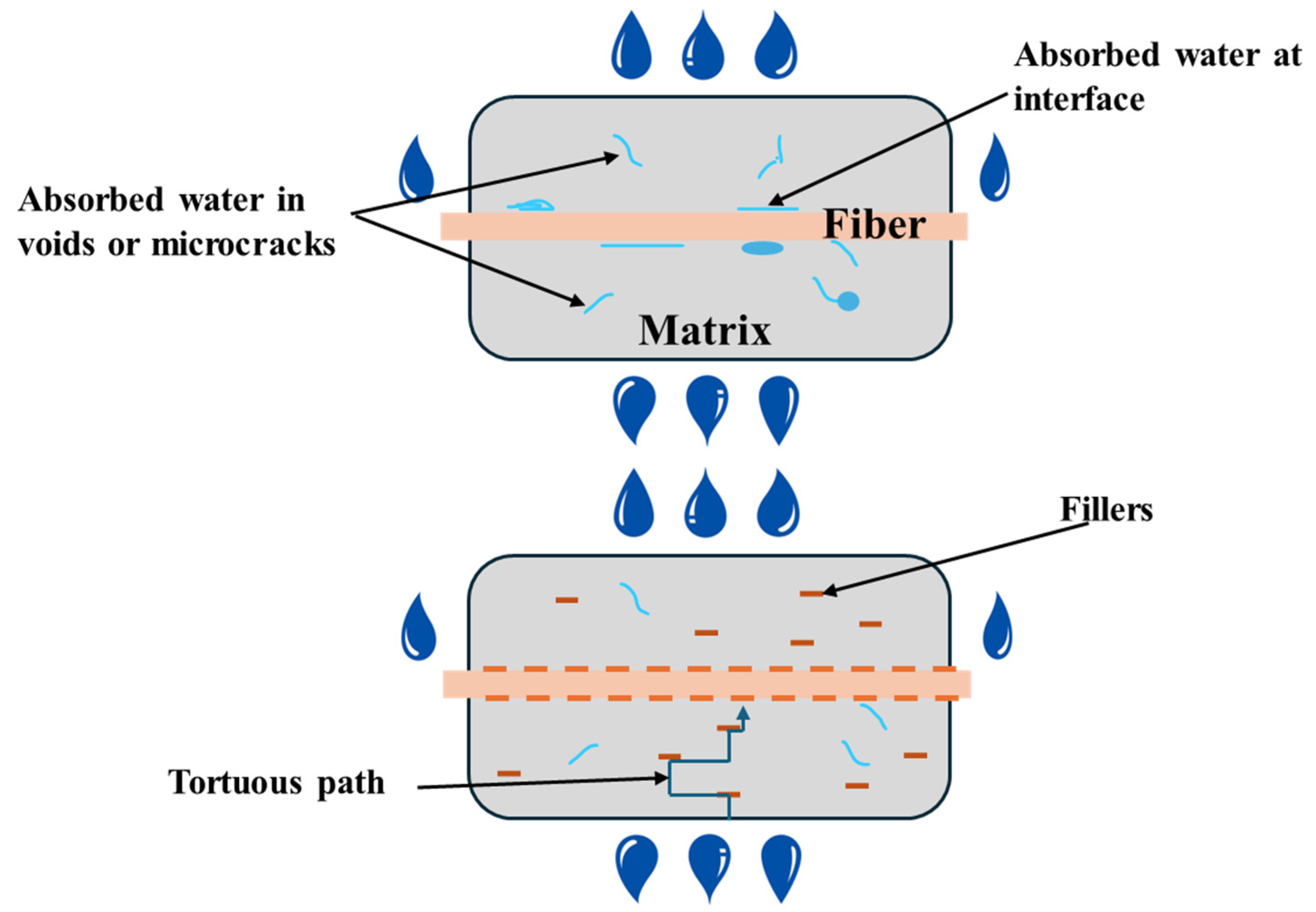

3.1. Remedies to Minimize the Water Absorption of Bamboo Fiber-Reinforced Polymer Composites

3.1.1. Surface Treatments of Fibers

3.1.2. Adding Filler Materials

3.1.3. Hybridization

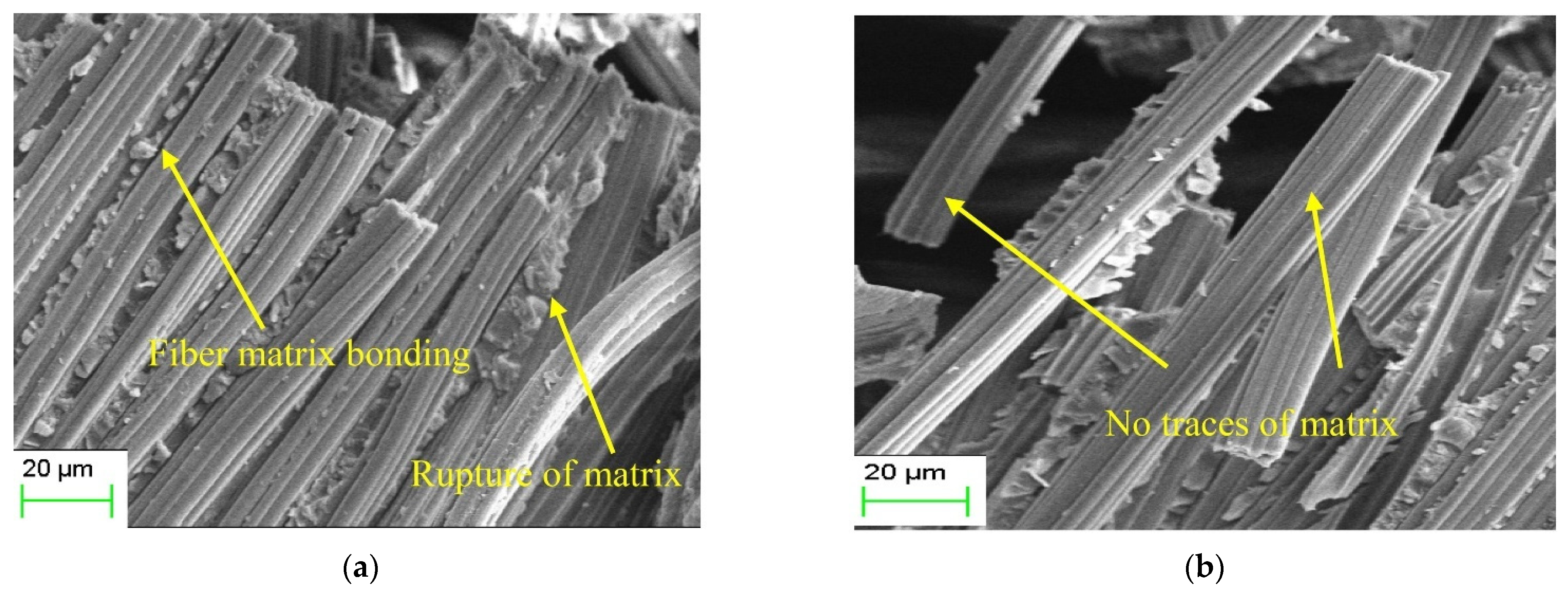

4. Effect of Water-Soaking Conditions on Mechanical Properties of Bamboo Fiber-Reinforced Polymer Composites

4.1. Mitigation Strategies for Reducing the Impact of Water-Soaking Conditions on the Mechanical Properties of Bamboo Fiber-Reinforced Polymer Composites

4.1.1. Surface Treatment of Bamboo Fibers

4.1.2. Matrix Modification by Adding Filler Materials

4.1.3. Hybridization of Fibers

5. Effect of Different Types of Aging Conditions on Mechanical Properties of Bamboo Fiber-Reinforced Polymer Composites

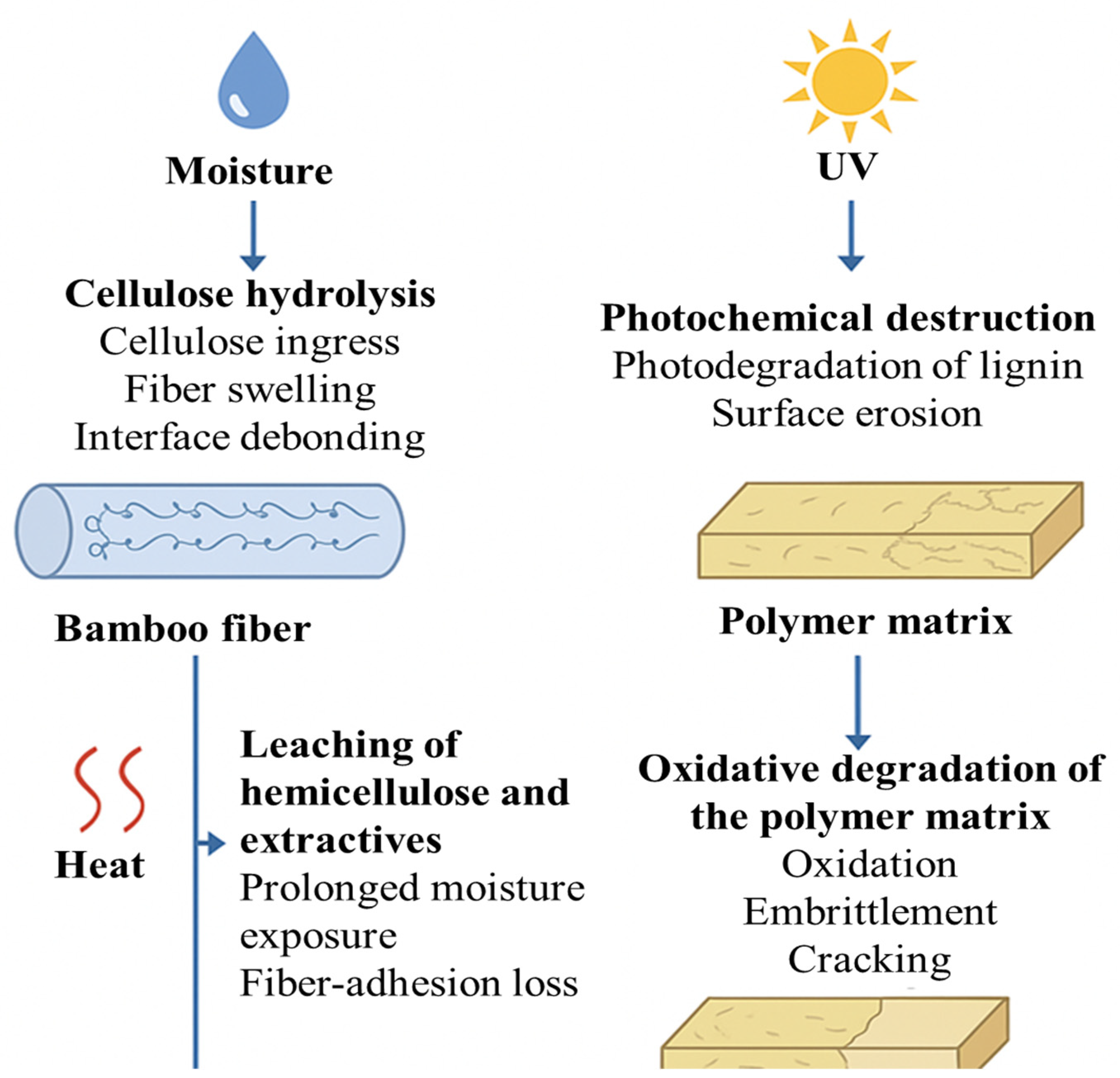

6. Molecular-Level Degradation Mechanisms in Bamboo Fiber-Reinforced Polymer Composites

7. Application of Bamboo Fiber-Reinforced Polymer Composites

- Outdoor construction panels and cladding: These applications face frequent exposure to moisture, UV radiation, and temperature variations. Bamboo fibers treated with NaOH or silane, combined with nanoclay- or TiO2-filled epoxy or HDPE matrices, offer improved resistance to environmental aging. Hybridization with glass fibers further enhances structural integrity and reduces water uptake, as shown in studies by Ahmad et al. [51] and Peng et al. [80].

- Automotive interiors: Interiors are exposed to humidity and thermal cycling. For such conditions, epoxy or polypropylene matrices reinforced with alkali-treated bamboo fibers and nanoclay or CaCO3 fillers demonstrate stable mechanical properties over time. Sugiman et al. [48] and Ahmad et al. [51] have shown that these formulations limit fiber swelling and matrix degradation under prolonged exposure.

- Marine and high-humidity environments: Composites incorporating bamboo–glass fiber hybrids within epoxy matrices are more suitable, as glass fibers reduce overall hydrophilicity and enhance dimensional stability. Mim [68] reports that such hybrids show significantly lower water absorption and degradation in saline immersion tests.

- Eco-friendly packaging and consumer goods: Composites made from enzyme- or untreated bamboo fibers and biodegradable polymer matrices such as PLA or PHBV are recommended for applications emphasizing end-of-life biodegradability. While these systems may offer reduced mechanical performance, they perform well in soil burial or refrigerated storage, as highlighted by Rao et al. [72].

- Building insulation panels: These face hygrothermal aging. Composites fabricated with alkali-treated bamboo fibers and hydrophobic fillers like silicon carbide or nanoclay help retain mechanical and thermal insulation properties. Work by Chakkour et al. [30] and Ahmad et al. [51] supports the effectiveness of such modifications.

8. Conclusions

- Surface treatments such as alkali and silane modification effectively reduce fiber hydrophilicity, improve fiber–matrix adhesion, and help retain mechanical performance under aging.

- Filler additions enhance the matrix’s barrier properties by reducing voids and increasing tortuosity for water diffusion. These improvements contribute to reduced moisture ingress and better retention of strength.

- Hybridization with synthetic fibers like glass reduces overall water absorption, improves dimensional stability, and provides better stress distribution. Hybrid composites exhibit notably higher durability and reduced property degradation under environmental stresses.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; van den Hurk, B.; Lugger, S.J.D.; Liu, T.; Blok, R.; Teuffel, P. Effect of environmental humidity on the creep behavior of flax fiber-reinforced polymer composites. Polym. Compos. 2023, 44, 6108–6121. [Google Scholar] [CrossRef]

- Iqbal, R.M.; Ahammad, R.; Arifuzzaman, M.; Islam, M.S.; Islam, M.M. Manufacturing and Properties of Jute Fiber-Reinforced Polymer Composites—A Comprehensive Review. Materials 2025, 18, 1016. [Google Scholar] [CrossRef] [PubMed]

- Islam, S.; Hasan, M.B.; Kodrić, M.; Motaleb, K.Z.M.A.; Karim, F.; Islam, M.R. Mechanical properties of hemp fiber-reinforced thermoset and thermoplastic polymer composites: A comprehensive review. SPE Polym. 2025, 6, e10173. [Google Scholar] [CrossRef]

- Santhosh, N.; Anand, P.B.; Gowda, A.; Munthala, D.; Pojprapai, S.; Naik, R.N.M. Synthesis and Mechanical Behaviour of Corn Husk and Sisal Fibre Reinforced Hybrid Polymer Composites. Mater. Res. Express 2025, 12, 055307. [Google Scholar] [CrossRef]

- Puttaswamygowda, P.H.; Sharma, S.; Ullal, A.K.; Shettar, M. Synergistic Enhancement of the Mechanical Properties of Epoxy-Based Coir Fiber Composites through Alkaline Treatment and Nanoclay Reinforcement. J. Compos. Sci. 2024, 8, 66. [Google Scholar] [CrossRef]

- Behera, D.; Pattnaik, S.S.; Nanda, D.; Mishra, P.P.; Manna, S.; Behera, A.K. A review on bamboo fiber reinforced composites and their potential applications. Emergent Mater. 2025, 8, 157–172. [Google Scholar] [CrossRef]

- Faheed, N.K. Advantages of natural fiber composites for biomedical applications: A review of recent advances. Emergent Mater. 2024, 7, 63–75. [Google Scholar] [CrossRef]

- Yu, H.; Wu, J.; Gao, Y.; Lu, Z.; Hu, W. Research progress on bamboo fiber reinforced polymeric composites: Processes, properties, and future directions. Polym. Compos. 2024, 45, 9629–9646. [Google Scholar] [CrossRef]

- Osmi, S.K.; Othman, M.; Daud, N.; Anuar, A.I.; Bahari, M.H.S. Tensile performance of bamboo fibre reinforced recycled polypropylene composites produced via injection moulding technique. IOP Conf. Ser. Earth Environ. Sci. 2025, 1444, 012024. [Google Scholar] [CrossRef]

- Rao, F.; Chen, Y.; Li, N.; Zhao, X.; Bao, Y.; Wu, Z.; Ren, D.; Xu, J.; Cai, H. Preparation and Characterization of Outdoor Bamboo-Fiber-Reinforced Composites with Different Densities. BioResources 2017, 12, 6789–6811. [Google Scholar] [CrossRef]

- Skosana, S.J.; Khoathane, C.; Malwela, T. Driving towards sustainability: A review of natural fiber reinforced polymer composites for eco-friendly automotive light-weighting. J. Thermoplast. Compos. Mater. 2025, 38, 754–780. [Google Scholar] [CrossRef]

- Popescu, C.; Dissanayake, H.; Mansi, E.; Stancu, A. Eco Breakthroughs: Sustainable Materials Transforming the Future of Our Planet. Sustainability 2024, 16, 10790. [Google Scholar] [CrossRef]

- Alemayehu, A.; Hido, A. Determinants and governance of bamboo production and marketing in Ethiopia: A critical review. Adv. Bamboo Sci. 2023, 5, 100047. [Google Scholar] [CrossRef]

- Li, Y.; Wang, N.; Latiff, A.R.A. Development of the bamboo forest economy: Reviewing China’s “bamboo as a substitute for plastic initiative” and its development. Adv. Bamboo Sci. 2025, 11, 100130. [Google Scholar] [CrossRef]

- Vedrtnam, A.; Gunwant, D.; Verma, H.; Kalauni, K. Effect of Aging and UV Exposure on Mechanical Properties of Natural Fiber Composites. In Aging Effects on Natural Fiber-Reinforced Polymer Composites; Muthukumar, C., Krishnasamy, S., Thiagamani, S.M.K., Siengchin, S., Eds.; Springer: Singapore, Singapore, 2022; pp. 189–217. [Google Scholar]

- Curto, M.; Le Gall, M.; Catarino, A.I.; Niu, Z.; Davies, P.; Everaert, G.; Dhakal, H.N. Long-term durability and ecotoxicity of biocomposites in marine environments: A review. RSC Adv. 2021, 11, 32917–32941. [Google Scholar] [CrossRef] [PubMed]

- Puttegowda, M. Eco-friendly composites: Exploring the potential of natural fiber reinforcement. Discov. Appl. Sci. 2025, 7, 401. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Zamani, M.H.; Estaji, S.; Tayouri, M.I.; Arjmand, M.; Jafari, S.H.; Nouranian, S.; Khonakdar, H.A. Mechanical properties of bamboo fiber-reinforced polymer composites: A review of recent case studies. J. Mater. Sci. 2022, 57, 3143–3167. [Google Scholar] [CrossRef]

- Mohammed, M.; Oleiwi, J.K.; Mohammed, A.M.; Jawad, A.J.M.; Osman, A.F.; Adam, T.; Betar, B.O.; Gopinath, S.C.B. A Review on the Advancement of Renewable Natural Fiber Hybrid Composites: Prospects, Challenges, and Industrial Applications. J. Renew. Mater. 2024, 12, 1237–1290. [Google Scholar] [CrossRef]

- Amjad, A.I. Bamboo fibre: A sustainable solution for textile manufacturing. Adv. Bamboo Sci. 2024, 7, 100088. [Google Scholar] [CrossRef]

- Rocky, B.P.; Thompson, A.J. Production and Modification of Natural Bamboo Fibers from Four Bamboo Species, and Their Prospects in Textile Manufacturing. Fibers Polym. 2020, 21, 2740–2752. [Google Scholar] [CrossRef]

- Rocky, B.P.; Thompson, A.J. Production of natural bamboo fibers-1: Experimental approaches to different processes and analyses. J. Text. Inst. 2018, 109, 1381–1391. [Google Scholar] [CrossRef]

- Asmare, F.W.; Liu, X.; Qiao, G.; Li, R.; Babu K., M.; Wu, D. Investigation and application of different extraction techniques for the production of finer bamboo fibres. Adv. Bamboo Sci. 2024, 7, 100070. [Google Scholar] [CrossRef]

- Ahmad, S.M.; Gowrishankar, M.C.; Shettar, M. A review on properties of bamboo fiber polymer composites and bamboo/glass fiber/nanoclay hybrid composites. Mater. Res. Express 2025, 12, 012002. [Google Scholar] [CrossRef]

- Santhosh, N.; Praveena, B.A.; Srikanth, H.V.; Angadi, S.; Gunge, A.; Rudra Naik, M.; Shankar, G.; Ramesha, K.; Ravichandran, G. Experimental Investigations on Static, Dynamic, and Morphological Characteristics of Bamboo Fiber-Reinforced Polyester Composites. Int. J. Polym. Sci. 2022, 2022, 1916877. [Google Scholar] [CrossRef]

- dos Santos, A.J.; Ribeiro, M.M.; Corrêa, A.d.C.; Rodrigues, J.d.S.; Silva, D.S.; Junio, R.F.P.; Monteiro, S.N. Morphological, chemical and mechanical properties of hybrid polyester composites reinforced with bamboo fibers and kaolin waste. J. Mater. Res. Technol. 2024, 30, 1–15. [Google Scholar] [CrossRef]

- Chakkour, M.; Ould Moussa, M.; Khay, I.; Balli, M.; Ben Zineb, T. Effects of humidity conditions on the physical, morphological and mechanical properties of bamboo fibers composites. Ind. Crops Prod. 2023, 192, 116085. [Google Scholar] [CrossRef]

- Chakkour, M.; Moussa, M.O.; Khay, I.; Balli, M.; Ben Zineb, T. Hygroscopic aging cycles of bamboo fiber/epoxy composites: Comparative study between distilled water and sea water. Ind. Crops Prod. 2024, 209, 117957. [Google Scholar] [CrossRef]

- Chakkour, M.; Ould Moussa, M.; Khay, I.; Balli, M.; Ben Zineb, T. Effects of moist ageing on composites of bamboo fiber and montmorillonite/eggshell powder. Cellulose 2023, 30, 6349–6363. [Google Scholar] [CrossRef]

- Ahmad, S.M.; Gowrishankar, M.C.; Shettar, M. Experimental investigation of mechanical properties and morphology of bamboo-glass fiber- nanoclay reinforced epoxy hybrid composites properties and morphology of bamboo-glass. Cogent Eng. 2023, 10, 2279209. [Google Scholar] [CrossRef]

- Xia, L.; Wu, J.; Wang, H.; Huang, Z.; Yang, R.; Zhang, X.; Guo, F.; Li, J.; Yu, Y. Enhanced mechanical performance of bamboo fiber/polypropylene composites via micro-nano reinforcing strategy. Compos. Part B Eng. 2024, 280, 111488. [Google Scholar] [CrossRef]

- Mohanta, S.; Mahalik, P.; Hota, G.P.; Sahoo, B.B.; Pradhan, S.S.; Mohanty, S.P. Influence of surface-treatment of bamboo fiber on the physico-mechanical properties of bamboo fiber composites with virgin and recycled high-density polyethylene. Polym. Compos. 2024, 45, 914–923. [Google Scholar] [CrossRef]

- Takeuchi, T.; Luengrojanaku, P.; Ito, H.; Rimdusit, S.; Shibata, S. Effect of processing temperature and polymer types on mechanical properties of bamboo fiber composites. BioResources 2023, 19, 41–52. [Google Scholar] [CrossRef]

- Mohammed, K.; Zulkifli, R.; Faizal Mat Tahir, M.; Sumer Gaaz, T. A study of mechanical properties and performance of bamboo fiber/polymer composites. Results Eng. 2024, 23, 102396. [Google Scholar] [CrossRef]

- Li, L.; Liu, S.; Du, G.; Jiang, S.; Yang, J.; Zhang, J.; Li, T. Sustainable engineering polymer composites fabricated using delignified bamboo fiber as reinforcement and walnut shell powder as filler. Compos. Part B Eng. 2024, 287, 111857. [Google Scholar] [CrossRef]

- Jawaid, M.; Senthilkumar, K.; Chandrasekar, M.; Fouad, H.; Hashem, M.; Ismail, A.S.; Khiari, R.; Singh, B. Investigating the Effect of Varied Short Bamboo Fiber Content on the Thermal, Impact, and Flexural Properties of Green Epoxy Composites. J. Nat. Fibers 2024, 21, 2296915. [Google Scholar] [CrossRef]

- Yadav, J.; Ramkumar, P.L.; Pattani, S.; Rathod, N. Investigating the Processability of Linear Low-Density Polyethylene/Bamboo Fiber Polymer Composites for Rotational Molding. J. Mater. Eng. Perform. 2024, 34, 8350–8358. [Google Scholar] [CrossRef]

- Adil, M.M.; Hassan Parvez, M.M.; Rupom, S.M.N.; Tasnim, T.; Islam, M.S.; Gafur, M.A.; Mesbah, M.B.; Ahmed, I. Physical and thermal properties analysis of bamboo and rattan fiber reinforced polymer composite. Results Eng. 2024, 22, 102084. [Google Scholar] [CrossRef]

- Parvez, M.M.H.; Nur Rupom, S.M.; Adil, M.M.; Tasnim, T.; Rabbi, M.S.; Ahmed, I. Investigation of mechanical properties of rattan and bamboo fiber reinforced vinyl ester composite material for automotive application. Results Mater. 2023, 19, 100437. [Google Scholar] [CrossRef]

- Shi, J.; Wu, Y.; Zhang, M.; Zhang, J.; Zhang, W.; Chen, H.; Peng, Y.; Shi, S.Q.; Xia, C. Bamboo fiber-reinforced epoxy composites fabricated by vacuum-assisted resin transfer molding (VARTM): Effect of molding sequence and fiber content. Polym. Compos. 2024, 45, 256–266. [Google Scholar] [CrossRef]

- Martijanti, M.; Sutarno, S.; Juwono, A.L. Polymer Composite Fabrication Reinforced with Bamboo Fiber for Particle Board Product Raw Material Application. Polymers 2021, 13, 4377. [Google Scholar] [CrossRef] [PubMed]

- Kamble, Z.; Behera, B.K. Mechanical properties and water absorption characteristics of composites reinforced with cotton fibres recovered from textile waste. J. Eng. Fiber. Fabr. 2020, 15, 1558925020901530. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M. Water absorption behavior of cellulosic fibres polymer composites: A review on its effects and remedies. J. Ind. Text. 2022, 51, 7480S–7512S. [Google Scholar] [CrossRef]

- Widiastuti, I.; Pratiwi, Y.R.; Cahyo, D.N. A Study on Water Absorption and Mechanical Properties in Epoxy-Bamboo Laminate Composite with Varying Immersion Temperatures. Open Eng. 2020, 10, 814–819. [Google Scholar] [CrossRef]

- Gurmu, D.N.; Gebrelibanos, H.M.; Tefera, C.A.; Sirahbizu, B. Experimental investigation the effect of bamboo micro filler on performance of bamboo-sisal-E-glass fiber-reinforced epoxy matrix hybrid composites. Heliyon 2024, 10, e40176. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Lu, M.; Zhou, S.; Lu, Z.; Ran, S. Effect of Fiber Surface Modification on the Interfacial Adhesion and Thermo-Mechanical Performance of Unidirectional Epoxy-Based Composites Reinforced with Bamboo Fibers. Molecules 2019, 24, 2682. [Google Scholar] [CrossRef] [PubMed]

- Sugiman, S.; Setyawan, P.D.; Maryudi, M.; Madnasri, S. Water absorption, tensile, flexural and impact properties of aged bamboo fibre/nano CaCO3-modified unsaturated polyester composites. J. Appl. Sci. Eng. 2021, 24, 239–251. [Google Scholar] [CrossRef]

- Ratna Pratiwi, Y.; Widiastuti, I.; Harjanto, B. Studies on Water Sorption Behaviour of Laminated Bamboo Polymer Composite. E3S Web Conf. 2019, 130, 01040. [Google Scholar] [CrossRef]

- Tahir, D.; Abdul Karim, M.R.; Hu, H. Analysis of mechanical and water absorption properties of hybrid composites reinforced with micron-size bamboo fibers and ceramic particles. Int. Polym. Process. 2024, 39, 115–124. [Google Scholar] [CrossRef]

- Ahmad, S.M.; Gowrishankar, M.C.; Shettar, M. Water-soaking effect and influence of nanoclay on mechanical properties of bamboo/glass fiber reinforced epoxy hybrid composites. Cogent Eng. 2024, 11, 2338160. [Google Scholar] [CrossRef]

- Zhang, K.; Liang, W.; Wang, F.; Wang, Z. Effect of water absorption on the mechanical properties of bamboo/glass-reinforced polybenzoxazine hybrid composite. Polym. Polym. Compos. 2021, 29, 3–14. [Google Scholar] [CrossRef]

- Sathish, S.; Kumaresan, K.; Prabhu, L.; Vigneshkumar, N. Experimental Investigation on Volume Fraction of Mechanical and Physical Properties of Flax and Bamboo Fibers Reinforced Hybrid Epoxy Composites. Polym. Polym. Compos. 2017, 25, 229–236. [Google Scholar] [CrossRef]

- Ighalo, J.O.; Igwegbe, C.A.; Adeniyi, A.G.; Abdulkareem, S.A. Artificial Neural Network Modeling of the Water Absorption Behavior of Plantain Peel and Bamboo Fibers Reinforced Polystyrene Composites. J. Macromol. Sci. Part B 2021, 60, 472–484. [Google Scholar] [CrossRef]

- Zhuo, G.; Zhang, X.; Jin, X.; Wang, M.; Yang, X.; Li, S. Effect of Different Enzymatic Treatment on Mechanical, Water Absorption and Thermal Properties of Bamboo Fibers Reinforced Poly(Hydroxybutyrate-co-Valerate) Biocomposites. J. Polym. Environ. 2020, 28, 2377–2385. [Google Scholar] [CrossRef]

- Kudva, A.; Mahesha, G.T.; Pai, D. Influence of Chemical Treatment on the Physical and Mechanical Properties of Bamboo Fibers as Potential Reinforcement for Polymer Composites. J. Nat. Fibers 2024, 21, 2332698. [Google Scholar] [CrossRef]

- Barman, P.; Dutta, P.P.; Bardalai, M.; Dutta, P.P. Experimental investigation on bamboo fiber reinforced epoxy polymer composite materials developed through two different techniques. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 2185–2204. [Google Scholar] [CrossRef]

- Irvani, H.; Mahabadi, H.A.; Khavanin, A.; Variani, A.S. Improving the thermal and hydrophobic properties of bamboo biocomposite as sustainable acoustic absorbers. Sci. Rep. 2025, 15, 3148. [Google Scholar] [CrossRef] [PubMed]

- Nabinejad, O.; Debnath, S.; Kai Beh, J.; Yeakub Ali, M. Mechanical performance and moisture absorption of unidirectional bamboo fiber polyester composite. Mater. Sci. Forum 2018, 911, 88–94. [Google Scholar] [CrossRef]

- Al-Maharma, A.; Al-Huniti, N. Critical Review of the Parameters Affecting the Effectiveness of Moisture Absorption Treatments Used for Natural Composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, K.; Fang, Y.; Guo, Z.; Yang, X.; Sheng, K. Improvements in compatibility and properties of biocomposites modified through nanosilica attachment. Iran. Polym. J. 2022, 31, 1387–1398. [Google Scholar] [CrossRef]

- Wang, D.; Bai, T.; Cheng, W.; Xu, C.; Wang, G.; Cheng, H.; Han, G. Surface Modification of Bamboo Fibers to Enhance the Interfacial Adhesion of Epoxy Resin-Based Composites Prepared by Resin Transfer Molding. Polymers 2019, 11, 2107. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A. Improvement of Physiochemical Properties of Short Bamboo Fiber-Reinforced Composites Using Ceramic Fillers. J. Nat. Fibers 2020, 17, 1582–1593. [Google Scholar] [CrossRef]

- Abdelhamid, H.N. Natural and synthetic fiber-reinforced polymer composites and their impact on aging under environmental conditions. In Aging and Durability of FRP Composites and Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2024; pp. 171–188. [Google Scholar]

- Oliveira, M.; Neves, V.; Banea, M.D. Mechanical and Thermal Characterization of Bamboo and Interlaminar Hybrid Bamboo/Synthetic Fibre-Reinforced Epoxy Composites. Materials 2024, 17, 1777. [Google Scholar] [CrossRef] [PubMed]

- Ahirwar, D.; Purohit, R.; Dixit, S. Eco-friendly recycled glass fiber and bamboo fiber reinforced epoxy-SiO2 polymer hybrid composite: Development and mechanical characterization. Polym. Compos. 2024, 45, 6093–6110. [Google Scholar] [CrossRef]

- Zuhairah Mahmud Zuhudi, N.; Jayaraman, K.; Lin, R.J.T. Water absorption behavior of the woven bamboo fabric polypropylene-based composites and their hybrids with glass. Mater. Today Proc. 2023, 74, 513–518. [Google Scholar] [CrossRef]

- Mim, F.A. Effect of moisture absorption on the mechanical behavior of banana-bamboo-glass fiber reinforced hybrid composites in NaCl solution. Hybrid Adv. 2025, 10, 100451. [Google Scholar] [CrossRef]

- Alfeki, M.A.; Feyissa, E.A. Water Absorption, Thermal, and Mechanical Properties of Bamboo Fiber with Chopped Glass Fiber Filler-Reinforced Polyester Composites. Adv. Mater. Sci. Eng. 2024, 2024, 6262251. [Google Scholar] [CrossRef]

- Hassanpour, B.; Karbhari, V.M. Characteristics and Models of Moisture Uptake in Fiber-Reinforced Composites: A Topical Review. Polymers 2024, 16, 2265. [Google Scholar] [CrossRef] [PubMed]

- Prabhu, R.; Mendonca, S.; D’Souza, R.; Bhat, T. Effect of Water Absorption on the Mechanical Properties of Alkaline Treated Bamboo and Flax Fiber Reinforced Epoxy Composites. Trends Sci. 2022, 19, 5779. [Google Scholar] [CrossRef]

- Rao, G.S.; Debnath, K.; Mahapatra, R.N. Recycling and degradation behaviour of the bamboo fibre reinforced green composite fabricated by injection moulding. Sustain. Mater. Technol. 2024, 39, e00865. [Google Scholar] [CrossRef]

- Haseebuddin, M.R.; Lobo, A.; Mohan Das, A.N.; Harsha, S.; Ganesh Acharya, K.; Balaji, G. Effect of Aging on Flexural Behavior of Disposed Glass Fiber Reinforced Bamboo Mat–Polyester Composites. J. Inst. Eng. Ser. D 2024, 106, 505–512. [Google Scholar] [CrossRef]

- Huang, J.-K.; Young, W.-B. The mechanical, hygral, and interfacial strength of continuous bamboo fiber reinforced epoxy composites. Compos. Part B Eng. 2019, 166, 272–283. [Google Scholar] [CrossRef]

- Ahmad, S.M.; Gowrishankar, M.C.; Shettar, M. Effect of boiling water soaking on the mechanical properties and durability of nanoclay-enhanced bamboo and glass fiber epoxy composites. Sci. Rep. 2025, 15, 3605. [Google Scholar] [CrossRef] [PubMed]

- Chunhong, W.; Shengkai, L.; Zhanglong, Y. Mechanical, hygrothermal ageing and moisture absorption properties of bamboo fibers reinforced with polypropylene composites. J. Reinf. Plast. Compos. 2016, 35, 1062–1074. [Google Scholar] [CrossRef]

- Fei, P.; Xiong, H.; Cai, J.; Liu, C.; Zia-ud-Din; Yu, Y. Enhanced the weatherability of bamboo fiber-based outdoor building decoration materials by rutile nano-TiO2. Constr. Build. Mater. 2016, 114, 307–316. [Google Scholar] [CrossRef]

- Fajardo Cabrera de Lima, L.d.P.; Santana, R.M.C.; Chamorro Rodríguez, C.D. Influence of Coupling Agent in Mechanical, Physical and Thermal Properties of Polypropylene/Bamboo Fiber Composites: Under Natural Outdoor Aging. Polymers 2020, 12, 929. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Lu, L.; Xue, K.; Yang, Y.; Fu, J. Analysis of the steam aging properties of boron nitride reinforced bamboo fiber/high density polyethylene composites. J. Thermoplast. Compos. Mater. 2025. [Google Scholar] [CrossRef]

- Peng, Z.; Yu, M.; Niu, Y.; Du, X.; Gao, S. Enhanced mechanical, thermal, water and UV aging resistance properties of bamboo fiber/HDPE composites through silane coupling agent modified nano-SiO2-TiO2. Ind. Crops Prod. 2024, 222, 119704. [Google Scholar] [CrossRef]

- Li, Z.; Li, X. Effect of freeze-thaw cycle aging on properties of bamboo fiber/ polypropylene composites. Fuhe Cailiao Xuebao/Acta Mater. Compos. Sin. 2024, 41, 6149–6156. [Google Scholar] [CrossRef]

| Method | Fiber Orientation | Polymer Type | Ref. |

|---|---|---|---|

| Hand lay-up | Chopped | Unsaturated polyester resin | [26] |

| Compression molding | Randomly oriented fibers | Polyester resin | [27] |

| Hand lay-up and compression molding | Unidirectional fibers | Epoxy resin | [28,29,30] |

| Bidirectional fibers | Epoxy resin | [31] | |

| Injection molding | Short fibers | Polypropylene pellets | [32] |

| Chopped fibers | HDPE | [33] | |

| Chopped fibers | PE, PP, PA12, ABS, PA6, and Durabio | [34] | |

| General casting | Fiber powder | Epoxy resin | [35] |

| Hot pressing | Cross-ply (0°/90°) orientations | MHU resin | [36] |

| Chopped fibers | Epoxy resin | [37] | |

| Dry blend rotational molding | Fiber powder | Linear low-density polyethylene powder | [38] |

| Vacuum bag molding | Bidirectional fiber mat | Vinyl ester resin | [39,40] |

| Vacuum-assisted resin transfer molding | Randomly oriented fibers | Epoxy resin | [41] |

| Extrusion method | Fiber powder | Polyester resin | [42] |

| Type of Water Soaking | Temperature | Duration | Bamboo Fiber (wt.%) | Polymer Type | Water Uptake (%) | Ref. |

|---|---|---|---|---|---|---|

| Tap water | Ambient | 10 Days | 20 wt.% | Epoxy resin | 2.3% | [50] |

| Tap water | Ambient | 84 Days | 50 wt.% | Epoxy resin | 2.2% | [51] |

| Tap water | 25 °C | 20 Days | 20 wt.% | Benzoxazine resin | 4.24% | [52] |

| 80 °C | 6.32% | |||||

| Water | Ambient | 20 Days | 75 wt.% | Epoxy resin | 3.5% | [45] |

| 50 °C | 6.6% | |||||

| 80 °C | 7.8% | |||||

| Water | Ambient | 5 Days | 40 vf.% | Epoxy resin | 11% | [53] |

| Distilled water | Ambient | 11 Days | 20 wt.% | Polystyrene resin | 13.59% | [54] |

| Distilled water | Ambient | 10 Days | 20 wt.% | Poly(hydroxybutyrate-co-valerate) | 2.25% | [55] |

| Type of Water Soaking | Bamboo FIBER (wt.%) | Polymer Type | % of Reduction in Mechanical Properties | Ref. | |||

|---|---|---|---|---|---|---|---|

| Tensile Strength | Flexural Strength | Impact Strength | Hardness | ||||

| Tap water at room temperature | 50 wt.% | Epoxy resin | 13.86% | 12.9% | - | - | [51] |

| Tap water at 25 °C and 80 °C | 20 wt.% | Benzoxazine resin | 59% and 72.5% | 25.72% and 26.02% | - | - | [52] |

| Distilled water at room temperature | 50 wt.% | Epoxy resin | 18.12% | 20.08% | 10.11% | 21.42% | [71] |

| Distilled water at room temperature | 30 wt.% | Epoxy resin | 18.15% | - | - | - | [30] |

| Water | 20 wt.% | PLA | 73.5% | 45.15% | - | - | [72] |

| Water | 50 wt.% | Polyester resin | - | 33% | - | - | [73] |

| Distilled water | 25 vf.% | Polyester resin | 47% | 58% | - | - | [48] |

| NaCl water at 25 °C | 5 layers | Epoxy resin | 15.48% | 40.8% | - | - | [68] |

| Water at 100 °C | 42 wt.% | Epoxy resin | 57% | 62% | - | - | [74] |

| Boiling water | 50 wt.% | Epoxy resin | 27% | 20% | - | - | [75] |

| Types of Aging Conditions | Parameters | Bamboo Fiber (wt.%) | Polymer Type | % of Reduction in Mechanical Properties | Ref. | |||

|---|---|---|---|---|---|---|---|---|

| Tensile Strength | Flexural Strength | Impact Strength | Hardness | |||||

| Hygrothermal chamber aging | 40 °C and 93% RH | 60 wt.% | Polypropylene | 18.42% | 19.23% | - | - | [76] |

| Accelerated weathering | Xenon-arc radiation at 65 °C and 18 min water spray. | 36 wt.% | High-density polyethylene | - | 24% | - | - | [77] |

| Natural outdoor aging | Temp: 11 to 36 °C Average rainfall: 6.6 mm UV Index: 4 to 14 | 30 wt.% | Polypropylene | 37% | - | 29% | - | [78] |

| Steam aging | Steam is generated by heated distilled water, | 44 wt.% | High-density polyethylene | 39.7% | 39.6% | - | - | [79] |

| Ultraviolet aging | UV energy density: 0.76 W/m2, Temp: 0 °C ± 3 °C | 50 wt.% | High-density polyethylene | - | 15.6% | - | - | [80] |

| Soil burial | Garden soil with some moisture content, 28 days | 20 wt.% | Polylactic acid | 67.64% | 49.88% | - | - | [72] |

| Refrigerator aging | Temp: below 4 °C, 28 days | 47.05% | 21.70% | - | - | |||

| Freeze–thaw cycle aging | 10 freeze–thaw cycles (each cycle: 24 h soaking, 24 h freezing at −27 °C, 24 h thawing) | 30 wt.% | Polypropylene | 23.1% | 13.11% | 28.17% | - | [81] |

| Application Area | Common Aging Conditions | Effect on Product Performance | Mitigation Strategies |

|---|---|---|---|

| Automotive interior components | UV radiation, elevated temperatures, humidity fluctuations | Discoloration, cracking, delamination, and mechanical degradation | Use of UV stabilizing fillers, hybrid reinforcements |

| Automotive exterior panels | UV exposure, thermal cycling, rain/moisture, | Surface cracking and mechanical degradation | Use of UV stabilizing fillers, hybrid reinforcements |

| Construction panels | Moisture ingress, UV radiation, freeze–thaw cycles | Swelling, delamination | Surface treatment of fibers, use of UV stabilizing fillers, and hybrid reinforcements |

| Furniture and home decor | Direct sunlight (UV), ambient moisture | Microcracking and mechanical degradation | Use of fillers and hybrid reinforcements |

| Sporting goods | Moisture absorption and temperature variation | Moisture-induced delamination | Use of fillers and hybrid reinforcements |

| Building insulation panels | Hygrothermal aging | Physical and mechanical degradation | Surface treatment of fibers, use of fillers, and hybrid reinforcements |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shettigar, S.; Gowrishankar, M.C.; Shettar, M. Review on Aging Behavior and Durability Enhancement of Bamboo Fiber-Reinforced Polymer Composites. Molecules 2025, 30, 3062. https://doi.org/10.3390/molecules30153062

Shettigar S, Gowrishankar MC, Shettar M. Review on Aging Behavior and Durability Enhancement of Bamboo Fiber-Reinforced Polymer Composites. Molecules. 2025; 30(15):3062. https://doi.org/10.3390/molecules30153062

Chicago/Turabian StyleShettigar, Sameeksha, Mandya Channegowda Gowrishankar, and Manjunath Shettar. 2025. "Review on Aging Behavior and Durability Enhancement of Bamboo Fiber-Reinforced Polymer Composites" Molecules 30, no. 15: 3062. https://doi.org/10.3390/molecules30153062

APA StyleShettigar, S., Gowrishankar, M. C., & Shettar, M. (2025). Review on Aging Behavior and Durability Enhancement of Bamboo Fiber-Reinforced Polymer Composites. Molecules, 30(15), 3062. https://doi.org/10.3390/molecules30153062